Design and simulation of an accelerometer based on NV center spin–strain coupling

Lu-Min Ji(季魯敏), Li-Ye Zhao(趙立業(yè)), and Yu-Hai Wang(王裕海)

Key Laboratory of Micro-Inertial Instrument and Advanced Navigation Technology,Ministry of Education,Department of Instrument Science and Engineering,Southeast University,Nanjing 210096,China

Keywords: nitrogen-vacancy(NV)accelerometer,spin–strain,diamond

1.Introduction

From fundamental physics to quantum metrology and quantum information processing, quantum systems have attracted a surge of interest recently.[1–3]Meanwhile, the development of nanofabrication technology has facilitated the fabrication of high-quality mechanical oscillators.[4–6]Benefiting from the diversity of interactions between oscillator motion and quantum systems,[5]quantum hybrid systems(QHSs) with different materials, structures, and principles combining their advantages have been widely explored, including conducting devices, ultracold atoms, and solid-state qubits.[7–12]They have stood out as strong candidates to replace conventional quantum and micro-electromechanical systems (MEMSs) for realizing high-precision magnetic field, acceleration, displacement, and other physical quantity sensing.[13–18]

After studying the influence of strain, electric and magnetic fields on the ground state and excited state of the negatively charged nitrogen-vacancy (NV) center (hereafter referred to as NV center),[19,20]the verification of the NV spin oscillator systems paves the way for its intensive research in the field of precision measurement.[21–24]These QHSs based on NV realize the coupling of spin and mechanical oscillator through magnetic field gradient or the electric field introduced by strain.[22]The mechanical motion provides a coherent control method of the quantum system which in turn can be sensed as a signal source through spin state readout.[5]Owing to the atomic size of the center and the well-established quantum manipulation technology,they have been proven to be a powerful tool to achieve high-resolution measurement of the spin state phase.[25,26]In addition, the high Young’s modulus and low internal dissipation of diamond entail the possibility of production of the NV spin-oscillators with high frequency and strength.[5,13,27–29]

However,the field fluctuations induced by the indispensable component including the magnetic tip or the cavity in the NV QHS using magnetic coupling or optical radiation force coupling respectively cannot be ignored.[5,10,27]To obtain systems that are less susceptible to ambient thermal noise and produce fewer stray fields,[23,30,31]researchers have shown a grown emphasis on the NV strain based QHS in which the coupling is intrinsic in the crystal and the simple monolithic structure does not require precise alignment of additional components.[13]University of California Santa Barbara demonstrated that the strain sensitivity of 3×10?6strain/and the displacement resolution of 7 nm could be achieved utilizing the designed diamond membrane.[30]University of Basel quantified the NV strain coupling constants and estimated the sensitivity of 76 MHz/μm using their cantilever beam.[32]Australian National University presented a diamond nanopillar structure and optimized the static force sensitivity to 100

So far, previous studies have been conducted to consistently show that the NV strain based QHSs are capable of being burgeoning and leading platforms in the field of metrology,such as vibrometry and pressure sensing.However,what is not yet understood is the feasibility of applying NV spinstrain systems to the measurement of acceleration.In this paper, a MEMS accelerometer based on NV strain QHS is proposed.Compared with traditional piezoelectric or capacitive accelerometers,it does not need additional circuit connection and has the advantages of low power consumption,small size,high bandwidth, and satisfactory sensitivity.This research offers a new way of acceleration sensing in biomedicine, vibrometry,and inertial navigation fields.

2.Principle

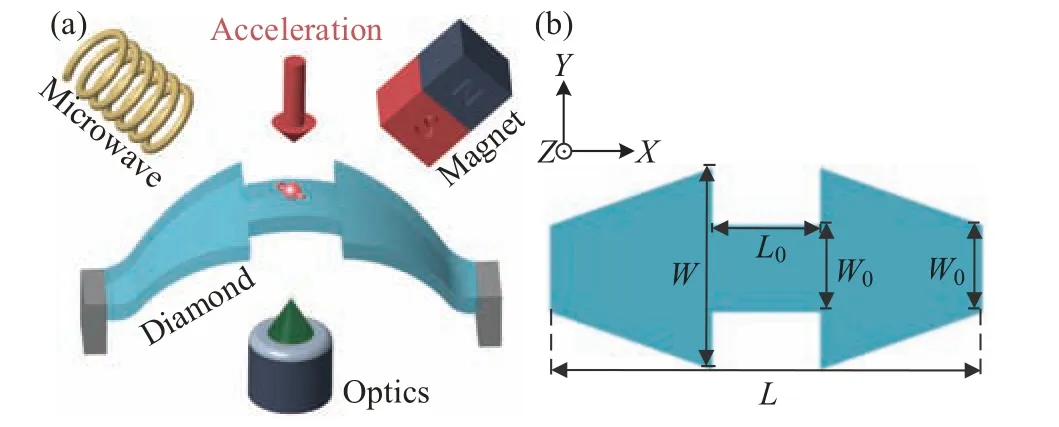

The acceleration measurement device based on the NV spin-oscillator is shown in Fig.1(a).The mechanical oscillator fixed at both ends is a diamond membrane containing NV centers.The structural coordinate system(CS)is defined asXYZ, and the view along theZaxis of the structural CS is shown in Fig.1(b).The total lengthL, total widthWand heightDare along the directions ofX,YandZaxes, respectively.The effective sensitive unit is a cuboid in the middle of the whole structure with lengthL0and widthW0.When acceleration as shown is applied along theZaxis direction, the diamond structure generates strain under the action of inertial force.

For this NV spin-strain coupling QHS, the NV electron spin states are initialized by laser pumping at 532 nm with non-radiative transition process and controlled by microwave sequences.The optical readout is realized by the dependence of photoluminescence on spin states.The strain generated by the diamond mechanical oscillator under acceleration changes the intensity and contrast of photoluminescence, thus providing a way to measure the external physical quantity.

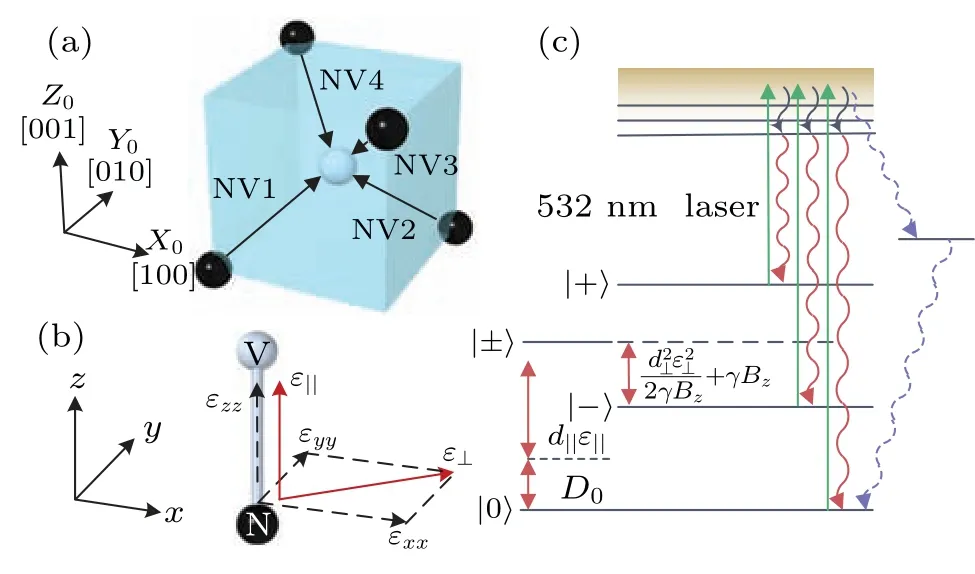

The crystal CS is defined asX0Y0Z0, and the four NV CSs in the crystal are defined asxyzm,m ∈{NV1,NV2,NV3,NV4}.The four internuclear NV axes corresponding to NV1, NV2, NV3, NV4 are along the direction ofin the crystal,which are thezaxes of the four NV CSs,respectively.The relationship between the crystal CS and the four internal NV CSs is shown in Fig.2(a).The strain that contributes to atomic displacement and electron density change in the diamond crystal can be regarded as an additional local electric field action on the NV centers.The Hamiltonian can be described by[20,34]

whereD0= 2.87 GHz is the zero field splitting constant.γ=geμB/h=2.8 MHz/Gs is the electron gyromagnetic ratio.μBis the Bohr magnet.ge=2.0023 is the electrongfactor.Bis the applied magnetic field.Sx,SyandSzare the Pauli matrixes of spin 1.The normal strain components in the NV CS are represented byεxx,εyyandεzz.The ground state strain coupling constants parallel to and perpendicular to the NV axis are respectivelyd‖andd⊥.[32]

Fig.1.Diamond-spin-oscillator acceleration sensor: (a) schematic diagram of the overall setup; (b) structure diagram of the diamond mechanical oscillator in structure CS.

Considering that the diamond structure explored here is still a beam with a high aspect ratio, the shear strain components of the structure can be approximately ignored.The optimal lattice cutting direction is selected to minimize the coupling degree between the lateral components of the normal strain and the NV spin.In the NV CS (shown in Fig.2(b)),the strainε‖=εzzparallel to the NV axis causes the contraction and elongation of the nitrogen bond without changing theC3Vsymmetry of the NV center,which can be seen as a linear correction to the zero field splittingD0.[23]The strainperpendicular to the NV axis causes deformation of the carbon bond,destroying the rotational symmetry and breaking the degeneracy of the statems=±1,resulting in a spin mixing state.[30]The energy level of the NV spin state is presented in Fig.2(c).

Fig.2.Schematic diagram of NV spin-strain coupling mechanism.(a) Schematic diagram of the relationship between 4 NV CSs and the crystal CS.(b)Normal strain components in parallel and vertical directions.(c)Energy levels of NV ground state in the presence of strain and magnetic field.

Ramsey sequence can be utilized for acceleration measurement in this scheme.Applying a microwave field with an effective intensity ofB1and a frequency ofD0?γBz, the Hamiltonian of the ground spin state under rotating wave approximation is

The axial magnetic fieldBzis assumed to be large enough to ignore the effect of the lateral strain coupling termThe subspace of state?1 and state 0 is used as two energy levels approximation.After the evolution processπ/2–τ–π/2, the two-level system will accumulate phaseΦ(τ)=d‖ε‖τbetween the two states.Considering the attenuation caused by the dephasing effect, the probability of the electronic spin state remaining in the state can be expressed as, thus the phase information could be obtained through the radiation fluorescence measurement.

Mechanical oscillators can be classified by the geometry of the structure shape and the number of fixed ends.Typical oscillators include singly-clamped structures (e.g.,‘U’-shaped and cantilever) and doubly-clamped structures(e.g.,bridge).[35]For the general strip diamond structure with double-clamped ends,the vibration of the bridge with a length larger than the cross-section scale can be described by Euler–Bernoulli’s theory according to the elastic theory.[29,30]The eigenfrequency can be expressed as

whereEis Young’s modulus of the material,ρis the density,Ais the cross-section area,landdare the length and height,respectively.Iis the moment of inertia,ωdnis thenth order eigenfrequency,andκnis the constant depending on the fixed way and order.[36]As the vibration frequency of the longitudinal mode is much higher than that of the transverse mode,the longitudinal mode is ignored here and only the fundamental mode is analyzed.

3.Simulation results and analysis

3.1.Sensitivity analysis

Assuming that the NV axial strain of the diamond mechanical oscillator caused by the external accelerationaisε‖,the scale factor determined by the diamond structure and cutting orientation can be expressed asε‖/a.Considering that the interrogation time determined by the quantum manipulation sequence isτ, for the Ramsey and spin echo sequences,τcan be taken as the dephasing time and coherence time,i.e.,τ ≤T?2andτ ≤T2.A general sensitivity expression for the acceleration measurement can be obtained,In addition, the sensitivity of an NV spin-strain QHS is related to spin projection noise, photon shot noise, and overhead time.[37]Therefore, for the system here using Ramsey sequences,the noise determined acceleration sensing sensitivity can be expressed as follows:

whereCis the fluorescence collection efficiencyC=0.3.[38]pcan be 1, 2, 3, andp=2 is taken here.tpolandtroare the initialization time and readout time, respectively, which can be ignored.Therefore,τis taken asτ=T?2/2 to obtain the optimal sensitivity.The number of effective spins is taken as a quarter of the total number of centersN=nV/4.The nitrogen density is about 1018cm?3,thus the NV center density isn=1017cm?3with NV center conversion ratio 0.1.[38]T?2is taken as 10μs,Vis the effective sensing volume,d‖is taken as 13.3 GHz.[33]Therefore, the sensitivity of acceleration measurement is expressed as

3.2.Optimization of diamond crystal cutting orientation

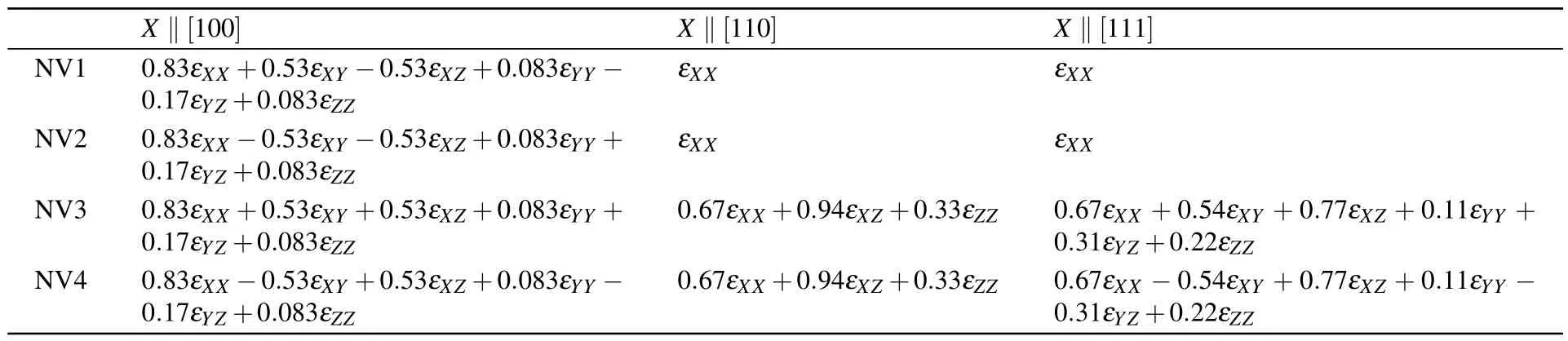

The structural strain tensor needs to be converted into the NV CSs to calculate the effective strain.Therefore, the cutting direction of the diamond crystal is optimized to reduce the coupling of transverse strain with the NV axis.TheXaxis in the structure CS can be chosen to be along[100],[110]or[111]direction with a great degree of symmetry in the crystal,[39]which is denoted asXYZk k∈{1,2,3}corresponding to the above three cases.Without loss of generality,the orientations of the three structure CSsXYZkand the four NV CSsxyzmin the crystal CS are assumed in Table 1.According to the rotation matrixLmkof thekth structure CS to themth NV CS,the strain tensorεxyzm=LεXYZLTin the NV CS can be obtained.The strain tensor forms in the structure CS and the NV CS are respectively shown below:

The strain components in the corresponding CS satisfyεij=εji,i,j∈{X,Y,Z},i/=jandεpq=εqp,pq∈{x,y,z},p/=q.

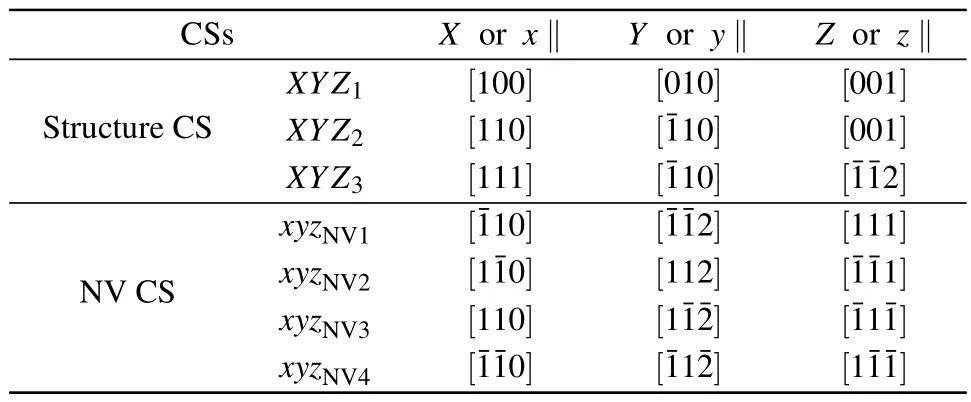

Table 1.Representation of 3 structure CSs and 4 NV CSs in the crystal CS.

A finite element analysis software is used to obtain the strain distribution of the diamond structure under the action of acceleration along the?Zaxis.Poisson ratio, Young’s modulus, and density of diamond are 0.069, 1220 GPa, and 3.515 g/cm3, respectively.[33,36]In Figs.3(a)–3(c), the strain is concentrated at the sensitive unit and the fixed ends of the overall structure.In the length direction of the oscillator (Xaxis in the structure CS),the strain at the sensitive unit is relatively high.In the height direction(Zaxis), the strain at the sensitive element gradually decreases from the surface to the middle.It is apparent from Fig.3(d)that in the sensitive unit,εXZandεYZare significantly smaller among the shear components of the strain tensor,and about one order of magnitude lower thanεXY.Similarly,εXXis the maximum among the normal strain, one order of magnitude higher thanεXXandεYY.This result can be explained by the fact that the structure is overall beam-shaped and the acceleration is input along theZdirection.Meanwhile,the shear strain components,which can be ignored,are more than two orders of magnitude lower than the normal strain components.

Fig.3.Mechanical simulation of the spin–strain coupling oscillator.(a)The log-normalized effective strain distribution of the diamond structure on the surface parallel to the XOY plane under acceleration.The effective strain distribution along the length(b)and height(c)directions of the structure is shown in(a).(d)Schematic diagram of the components of the log-normalized strain on the surface of the structure parallel to the plane XOY.

The influence of different diamond cutting orientations on the sensing performance can be analyzed according to the above simulation results.The effective strain transformation results are calculated for three different diamond cut orientations in four NV CSs shown in Table 1.The effective strain componentsε‖are present in Table 2.Considering that the influence of the normal strain components perpendicular to the NV axis on the energy splitting between 0 and 1 states can be approximated asd2⊥((εxxm)2+(εyym)2)/(2γB)according to Eq.(6), we can ignore the normal strain componentε⊥and shear strain in the NV CS,and takeε‖as the effective strain.For the normalization of the normal strain tensor of the structure,εXX,εYYandεZZcan be expressed as 1,0.1,0.1.It can be concluded that theXaxis along[110]or[111]could achieve a 19.3%improvement of the effective strain than being along[100] direction.In addition, the effective strain of NV1 and NV2 is equal,which increases the number of the effective NV centers twice and optimizes the sensitivity of the ensemble NV measurement scheme of acceleratitimes.The results of this investigation show that the[110]direction is better because there is no energy level difference in this direction NV3 and NV4,so the energy level splitting can be easier to identify.

Table 1.Normal strain component parallel to the NV axis in the NV CS.

3.3.Structural parameters influence on sensing performance

To characterize the sensing performance of the spin-strain coupling system,simulations are conducted from the perspectives of sensitivity, power, and size.Based on the analysis above,the diamond cutting orientationX‖[110]and effective NV axis of NV1 and NV2 are applied in the simulation,with the corresponding effective strainε‖=εXX.

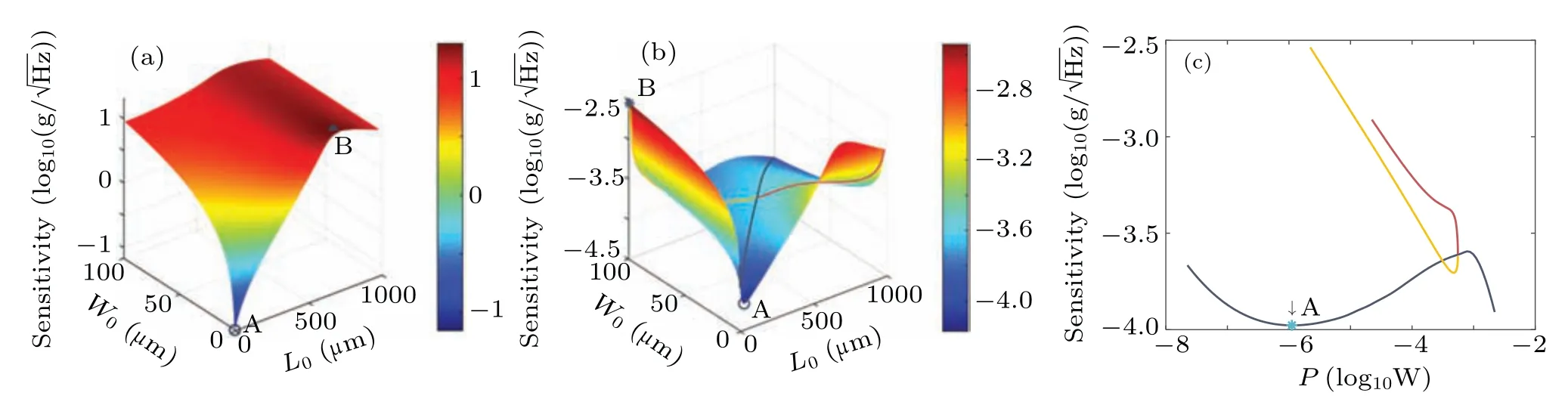

First of all, the influence of the sensitive unit size on the sensitivity is simulated when the overall size of the structure is determined.We chooseL=1000 μm,W=100 μm,D=1 μm, and length-height ratio to be 1000.[40]The single NV center is in the center of the sensitive unit surface to avoid strain upheaval points for a single NV scheme.For the ensemble NV scheme,the effective center is taken as the whole sensitive unit containing centers.The lengthL0and widthW0are adjusted with the optimization principle:D ≤L0≤L,D ≤W0≤W.So the variation ranges ofL0andW0are respectively[1μm, 1000μm]and[1μm, 100μm].

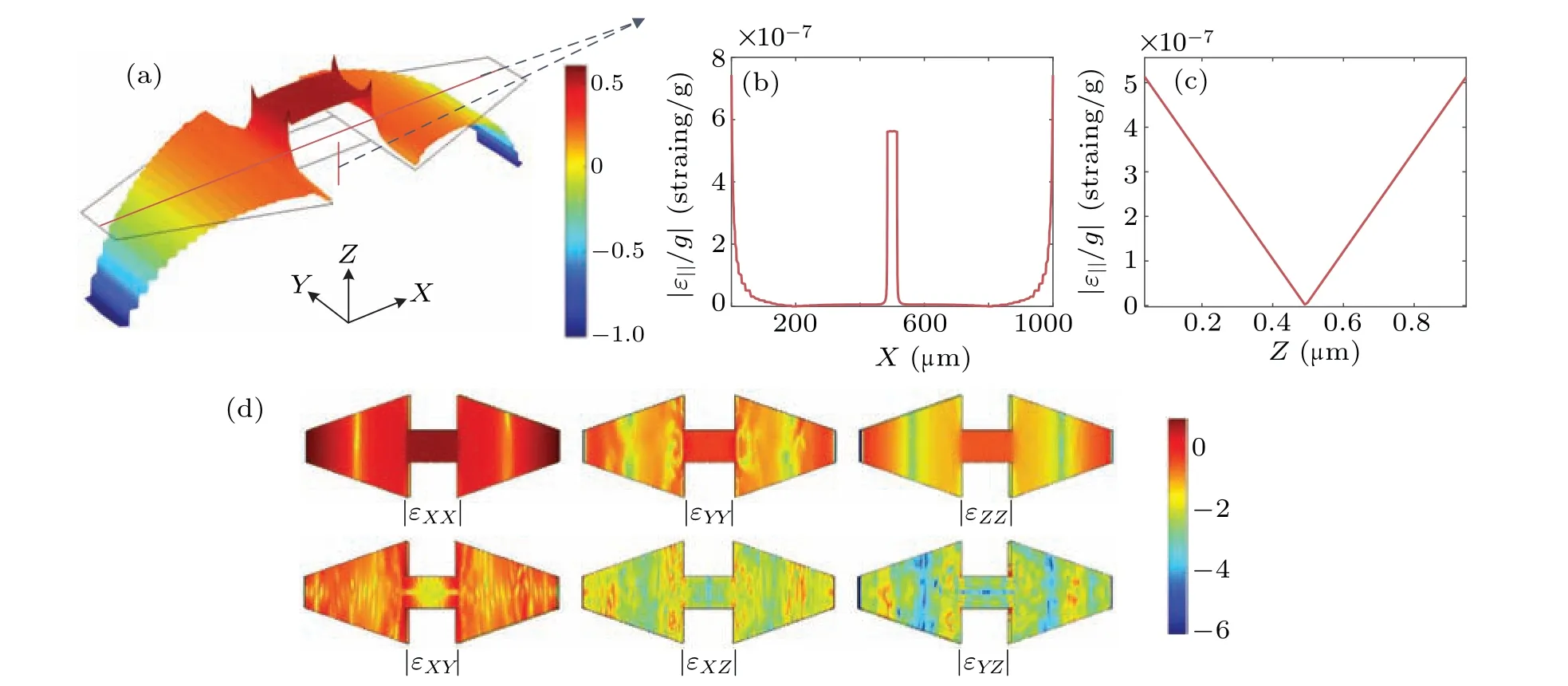

The results of sensitivity change with the size of the sensitive unit are shown in Figs.4(a)and 4(b).Points A,marked with circles,and points B,marked with asterisks,indicate the best and worst sensitivity simulation results,respectively.Evidently, the sensitivity of the ensemble NV center-based system is considerably better than that of the single NV centerbased system.Optimal sensitivities are 6.7×10?5(L0=30 μm,W0=1 μm) and 0.068(L0=1 μm,W0=1μm),respectively.If the length and width of the sensitive unit are equal to the length and width of the overall structure, respectively, the structure is a simple Euler–Bernoulli beam.The corresponding sensitivity and power consumption are not optimal, which verifies the effectiveness of the proposed structure in this work.In addition, the obvious difference between the two measurement methods is that for the multi-spin scheme, the structural parameters leading to relatively good performance correspond to the length and width of the sensitive element being synchronous large and small.While for the single-spin scheme,they only correspond to the length and width being small at the same time.Reducing the overall size of the sensitive unit can increase the effective mass and decrease the system’s stiffness for both single and ensemble center based schemes.When the length and width are increasing simultaneously, the sensitivity is excellent for the muti-spin scheme,which benefits from the increase in the number of effective NV centers.Through this structure optimization,the sensitivity of the single spin and multi-spin measurement schemes can be respectively improved by 2.4 and 1.6 orders of magnitude.

Fig.4.The comprehensive effect of the length and width of the sensitive unit in(a)single NV and(b)ensemble NV center based schemes on the sensitivity of acceleration measurement.Points A and B represent the best and worst simulation results in both figures.(c)The influence of excited light power on the sensitivity of the ensemble NV center based sensor.Point A represents the best simulation result.

Considering that the sensitivity optimization procedures for a multi-spin system have different requirements on the excitation light power, we analyze the effect of laser power on the sensitivity of acceleration measurements later.The black line through(L0min,W0min)and(L0max,W0max),the red line through(L0max,W0min)and(L0max/2,W0max/2), the yellow line through (L0min,W0max) and (L0max/2,W0max/2) in Fig.4(a)are chosen to calculate the power consumption.Assume that each NV center requires three excited photons of 532 nm to achieve optical polarization, then the laser power expression is

wherehis Planck’s constant,cis the speed of light, and the 532 nm light wavelengthλis taken.As can be seen from the black curve in Fig.4(c),with the increase of the available power,the curve shows a trend of decreasing,increasing,and then decreasing.This phenomenon can be attributed to the counterbalance between the system response and the effective color number.When the length and width of the sensitive unit vary by the same multiple, the system performance is optimized at a certain intermediate value,as indicated by point A marked with a circle.The corresponding moderate power is only 1.1μW,which is three orders of magnitude less than the maximum power,and better sensitivity can be obtained.It can be concluded from the red and yellow lines in Fig.4(c) that the sensitivity nearly shows a monotonically improving trend with the increase of provided power.Starting from that point,the sensitivity of increasing the length is slightly better than that of increasing the width with a fixed power consumption.Moreover,for the optimal sensitivity of the multi-spin scheme aforementioned, the power required is only 0.69 μW, on the sub-μW scale.

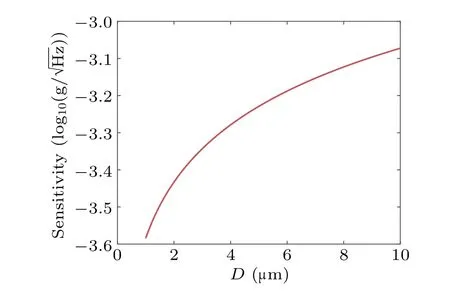

Then we explore the influence of the structure heightDon sensitivity,and setW=1000μm,L=100μm,L0=W0=10μm,1μm<D <10μm.As shown in Fig.5,the sensitivity improvement is less than one order magnitude(about 3 times)when the height changes by 10 times,indicating that the thickness has a limited effect on the performance under the current parameters.

Fig.5.The influence of the overall structure height on the sensitivity.

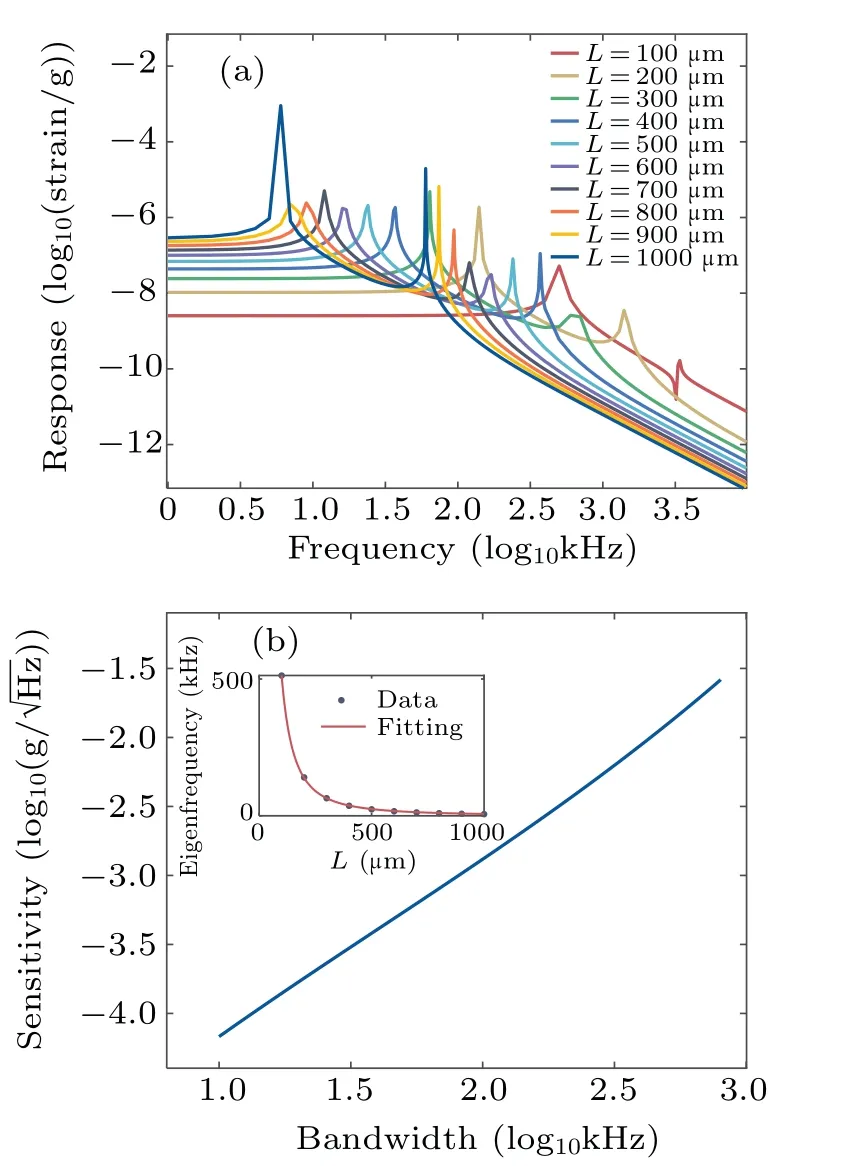

Finally, the frequency response caused by the change in the overall length of the structure with other parameters being constant (W= 100 μm,L0= 30 μm,W0= 1 μm, andD= 1 μm) is investigated.As shown in Fig.6(a), if the lengthLincreases from 100μm to 1000μm,the corresponding resonant frequency will decrease from the order of 1 MHz to the order of 10 kHz.It can be inferred from the inset of Fig.6(b) that the eigenfrequency of the system and the total lengthLare negatively correlated, and can be fitted byy= 5.03×106/x1.97.This relationship, which is approximatelyw1∝1/L2,is similar to that of the Eulbernoulli beam.

What’s more,the relationship between the sensitivity and the bandwidth is simulated in Fig.6(b).When the length is increased by one order of magnitude,the corresponding bandwidth, from 790 kHz to 10 kHz, is decreased by nearly two orders of magnitude,and the sensitivity is improved by nearly three orders of magnitude.The simulation result represents a trade-off between bandwidth and sensitivity.For the frequency of acceleration lower than 3 kHz, a better sensitivity can be obtained whenLis chosen to be sufficiently large,e.g.,1000μm.For a high-frequency signal(hundreds of kHz)sensing,a smallerLis preferred to obtain a larger working range.

Fig.6.Influence of different overall lengths L on sensor performance.(a) Different frequency responses of effective strain.(b) The relationship between bandwidth and sensitivity.The inset shows the impact of L on the eigenfrequency.

4.Discussion

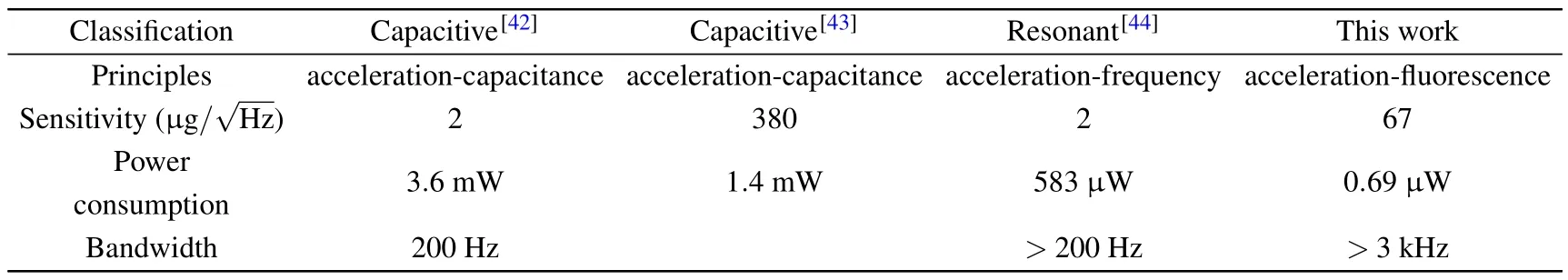

The performance compared with other types of MEMS accelerometers is shown in Table 3.Compared with traditional accelerometers, the superiority of the MEMS accelerometer proposed in this paper is reflected in its flexibility,versatility,and integrated potential.With its fine sensitivity, wide bandwidth, and non-contact measurement properties, this sensor has broad prospects in inertial navigation,[41]seismology,and bioscience in the future.

Table 3.Main performance comparisons of this work and other MEMS accelerometers.

In general,although the NV strain based system does not require the precise alignment of spin and oscillator,the precise positioning of the NV center in the single NV center scheme is necessary, which is still challenging.This problem can be weakened by using the ensemble NV system.However, the noise calculation method described here,which does not fully consider the impact of impurities in ensemble samples,cannot be ignored in practical application.[5]To further improve sensor performance, optimization could be conducted from the following perspectives in the future.The Ramsey sequence could be replaced with spin echo with longer interrogation time to improve the sensitivity by abouttimes.Similarly,a more complex dynamic decoupling sequence can further increase the interrogation time at the cost of bandwidth loss.[38,45]Considering the sensitivity of the ensemble NV based system related to the number of effective NV centers,a scheme with an array of small-volume diamond oscillators could be investigated with the development of nanoelectromechanical systems(NEMS)fabrication technology.The method of coupling the oscillator with the NV spin excited state to improve the coupling strength is also worth further exploring.[36]

5.Conclusion

In summary, this work proposes a diamond based spinstrain coupling scheme for acceleration measurement and characterizes its performance.The effective strain under acceleration applied along three symmetrical crystal directions is analyzed through the transformation between the structure,crystal, and NV CSs.The measurement bandwidth ranges from 3 kHz to hundreds of kHz with structure optimization.The sensitivity can reach 6.7×10?5withμm level effective size and sub-μW power consumption.

Acknowledgements

Project supported by the National Natural Science Foundation of China (Grant No.62071118) and the Primary Research & Development Plan of Jiangsu Province (Grant No.BE2021004-3).

- Chinese Physics B的其它文章

- High responsivity photodetectors based on graphene/WSe2 heterostructure by photogating effect

- Progress and realization platforms of dynamic topological photonics

- Shape and diffusion instabilities of two non-spherical gas bubbles under ultrasonic conditions

- Stacking-dependent exchange bias in two-dimensional ferromagnetic/antiferromagnetic bilayers

- Controllable high Curie temperature through 5d transition metal atom doping in CrI3

- Tunable dispersion relations manipulated by strain in skyrmion-based magnonic crystals