Study of the tungsten sputtering source suppression by wall conditionings in the EAST tokamak

Junru WANG (王俊儒), Yaowei YU (余耀偉), Houyin WANG (王厚銀),Bin CAO (曹斌), Jiansheng HU (胡建生),3,?and Wei XU (徐偉)

1 Institute of Plasma Physics, Hefei Institutes of Physical Science, Chinese Academy of Sciences, Hefei 230031, People’s Republic of China

2 University of Science and Technology of China, Hefei 230026, People’s Republic of China

3 Key Laboratory of Photovoltaic and Energy Conservation Materials,Chinese Academy of Sciences,Hefei 230031, People’s Republic of China

Abstract The steady fusion plasma operation is constrained by tungsten (W) material sputtering issue in the EAST tokamak.In this work, the suppression of W sputtering source has been studied by advanced wall conditionings.It is also concluded that the W sputtering yield becomes more with increasing carbon(C)content in the main deuterium(D)plasma.In EAST,the integrated use of discharge cleanings and lithium (Li) coating has positive effects on the suppression of W sputtering source.In the plasma recovery experiments, it is suggested that the W intensity is reduced by approximately 60% with the help of ~35 h Ion Cyclotron Radio Frequency Discharge Cleaning (ICRF-DC) and ~40 g Li coating after vacuum failure.The first wall covered by Li film could be relieved from the bombardment of energetic particles, and the impurity in the vessel would be removed through the particle induced desorption and isotope exchange during the discharge cleanings.In general, the sputtering yield of W would decrease from the source,on the bias of the improvement of wall condition and the mitigation of plasmawall interaction process.It lays important base of the achievement of high-parameter and longpulse plasma operation in EAST.The experiences also would be constructive for us to promote the understanding of relevant physics and basis towards the ITER-like condition.

Keywords: tungsten sputtering source, carbon impurity, wall conditioning, PWI, EAST

1.Introduction

In the tokamak research,the high-Zmaterial W is a promising candidate of the plasma facing materials (PFMs) to be exposed to the harsh divertor working conditions, as a result of its high melting point, low tritium retention, and low sputtering yield [1–3].However, the strong W particle flux could be produced via surface erosion process and transported into the core plasma.The W erosion would affect the lifetime of PFMs as the long-term damage accumulation.Moreover,the radiation power of the plasma would also be enhanced by eroded W particles flux, which inevitably cools down the plasma and degrades the plasma performance [4].Thus, the relevant research about the control of W sputtering yield has been carried out and investigated for ITER in existing tokamak devices, such as JET [4], ASDEX-Upgrade [5, 6], and WEST[7,8]and EAST[9,10].It is concluded that the low-Zimpurities,such as carbon,in the incident plasma flow,are the main reasons for the sputtering of W target plate [11, 12].In this paper, the impact of C content is be studied and the suppression effect of the W source is also evaluated by wall conditionings.

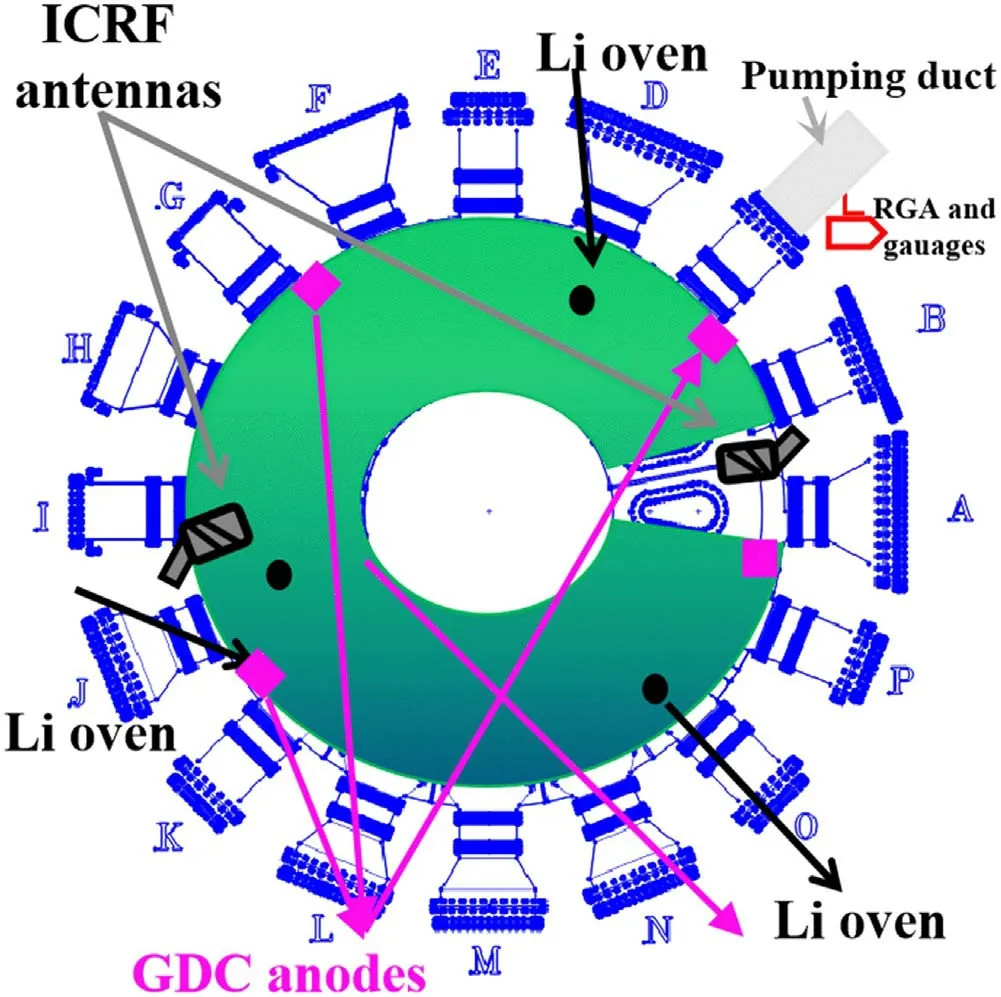

Figure 1.The schematic of vacuum and wall conditioning system in the EAST tokamak.

In the tokamak,various wall conditioning techniques are effective to remove C impurity and weaken the tungsten sputtering behavior.As for EAST, Glow Discharge Cleaning(GDC) and ICRF-DC are widely used to remove the low-Zimpurities, such as C, oxygen (O) and hydrogen (H).It is believed that the above discharge cleaning methods are effective to improve the first wall conditions and suppress the process of plasma-wall interaction (PWI) [13–15].In addition,Li coating which has been routinely employed in EAST,would cover the divertor and adsorb water,hydrocarbons and hydrogen.It could reduce the bombardment of tungsten by fuel or C particles [16], and it also helps the suppression of PWI process.The influence of C impurity on the W sputtering is evaluated through the data analysis of the C injection experiments and long-term monitoring.The above wall conditionings are confined to control W sputtering yield actively from the source.Through the study of lithium, we can understand the control mechanism of low-Zcoatings on fuel recycling and W sputtering suppression,which would provide an important step forward the development of new coating wall conditioning methods.It is believed that the experiences and lessons are beneficial to the exploration of high-power plasma operation mode for EAST.

2.Experiment setup

EAST is the first fully superconducting tokamak with D-shaped poloidal cross-section and advanced divertor configuration.The main parameters of the device are the major radiusR=1.85 m,minor radiusa=0.45 m,plasma currentIp~1 MA and toroidal fieldBt=3.5 T[17],and the layout of vacuum and wall conditioning system is presented in figure 1.Wall conditioning system is an important role to achieve ultra-high clean vacuum, which is composed of hot N2baking,GDC(pink squares),ICRF-DC(gray antennas)and three sets of Li evaporation coating ovens (black dots) [18], in the EAST tokamak.The Li coatings could effectively cover~95%surface area of the plasma discharge vessel,as shown with the green region [19].

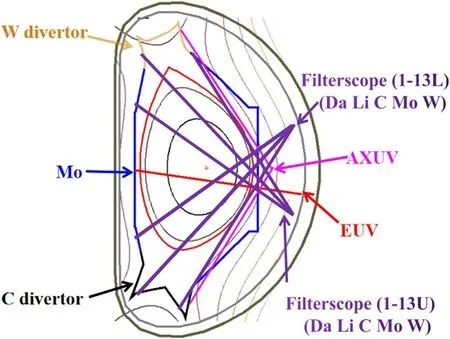

Figure 2.The cross section and observation string of main spectrometer diagnosis in EAST.

In addition, various diagnostic systems are widely employed to provide the information of plasma impurity emission, and the vertical section of the EAST tokamak is shown in figure 2.It presents the main diagnostics used in this paper, including Filterscope [20], Absolute Extreme Ultra-Violet (AXUV) [21] and a flat-field Extreme Ultra-Violet(EUV) [22].The W sputtering is quantified by means of emission spectroscopy, which is used to monitor the WI (at

λ=400.9 nm) at the vertical target in the outer divertor.Based on the Filterscope measurement,we investigate the line emission of Dα (at λ=656.1 nm), Li II (at λ=548.6 nm)and C III(at λ=464.7 nm),and the particle flux is evaluated from an absolutely measured atomic line intensity through the so-calledS/XBmethod[23].As shown in the formula(1),the impurity intensity of a spectral line Φ is characterized by an excitation rateXto the upper level of the corresponding transition and the branching ratioBof the transition[24,25],and the number of atoms is determined by the ionization rateSand the atom influx Γ.Thus, the impurity influx could be calculated as a function of the line intensity:

The line-integrated radiated power is measured by AXUV to evaluate plasma radiation, and the impurity information of core plasma is monitored by EUV spectrometer.The divertor Langmuir probe measurements [26] are used to determine the information of the temperature at the outer strike line as well as the plasma flux.Moreover,the materials of the first wall, upper divertor and lower divertor are molybdenum (Mo), W and C, respectively [27].

3.Results and discussion

3.1.Impact of carbon impurity on tungsten sputtering

According to the Yamamura semi-empirical formula[28],the sputtering thresholds of deuterium ion-induced and C ioninduced to W are ~210 eV and ~54 eV, respectively.The sputtered C atoms would bombard the W divertor and aggravate the sputtering behavior of W.It is concluded that the low-Zimpurities in the D main plasma, such as carbon and beryllium,would cause the sputtering of W divertor plate in the divertor region,rather than pure D incident flow.In the plasma discharge vessel of EAST, the internal parts of carbon-based materials would be bombarded by the edge plasma and generated hydrocarbons, which would influence the W sputtering behavior[29].It should be noted that the chemical sputtering yield of C usually accounts for only 1% [30], and physical sputtering is mainly considered and discussed, here.

As hown in figure 3, the phenomenon is also verified in the CD4gas seeding experiments conducted in EAST 2019 autumn campaign.The selected two typical shots have the total auxiliary heating power of ~7.5 MW (shown in figure 3(a)) and upper single null (USN) discharge configuration.In figures 3(b) and (c), theand ГWbegin to increase with the injection of CD4in 4.5–6.5 s, andand ГWin shot #91643 are higher than those in shot #91645,because shot #91645 has less CD4injection volume than shot #91643.

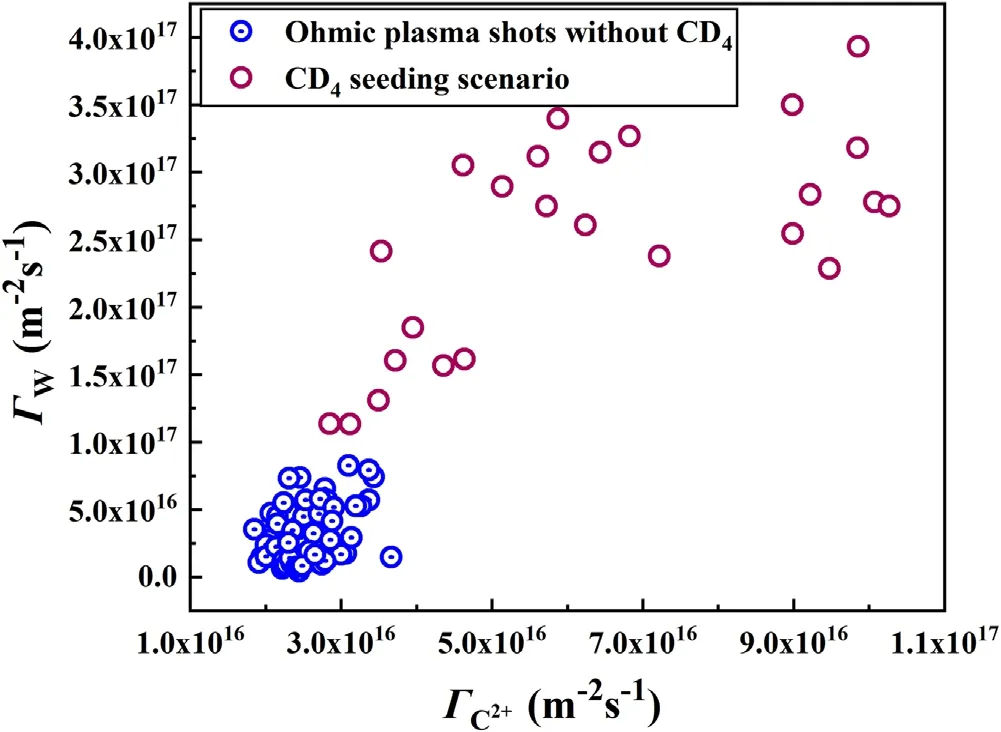

Figure 4.The evolution of ГW versus during 2019 autumn campaign.

As mentioned,C is a key factor to the sputtering yield of W, especially for EAST.On this basis, we have analyzed more data to further illustrate the relationship betweenand ГW.Figure 4 shows the evolution of ГWversusduring 2019 autumn campaign.The data in blue cycles are obtained from the flat-top phase of ohmic shots without CD4seeding, and the data in purple are calculated from the shots with CD4seeding.The impurities signal is obtained by Filterscope diagnostics and calculated from its average value in the flat-top phase of each shot.It is suggested that ГWrises asincreases.In addition, ГWin ohmic shots are higher than those of the shots with CD4seeding.It mainly results from that the increase of C content enhances the sputtering behavior of W.Therefore,the W production caused by C impurity ions must be taken into account [31].

3.2.Discharge cleanings on the suppression of tungsten sputtering source

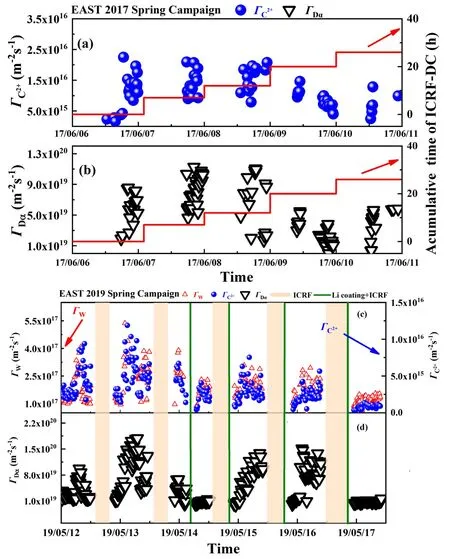

Since the core plasma has a very low tolerability to the W concentration, the heavy impurity burst, such as W, is the critical challenge which influences the set-up of plasma and the recovery of plasma performance after vacuum failure.Thus,the control of the C impact on W production is the key issue for long-pulse high performance operation in EAST[32].Figure 5 shows the process and the evolution of impurity in the vacuum and plasma recovery process of 2017 campaign and 2019 campaign.Before the plasma recovery process, the baking and GDC are usually operated to remove the residual impurities introduced due to vacuum failure.However, the impurity flux is still at a high level from the figure.And we conduct ICRF-DC after daily plasma experiments.It is observed thatand ГDαdecrease as the total duration of ICRF-DC accumulates in the figures 5(a)and(b),and it is the same as the situation of the recovery process in the EAST 2019 campaign, presented in figures 5(c) and (d).The baseline of ГWis reduced by approximately 60% form the first experiment day after vacuum failure (May 12th,2019), with the help of ~35 h ICRF-DC and ~40 g Li coating.

Figure 5.The evolution of ГW, ГC2+ and ГDα during the plasma recovery process after vacuum failure.The and ГDα versus the accumulative time of ICRF-DC during the recovery process in EAST 2017 spring campaign are shown in(a)and(b).The ,ГW and ГDα during the recovery process in EAST 2019 spring campaign are shown in (c) and (d).

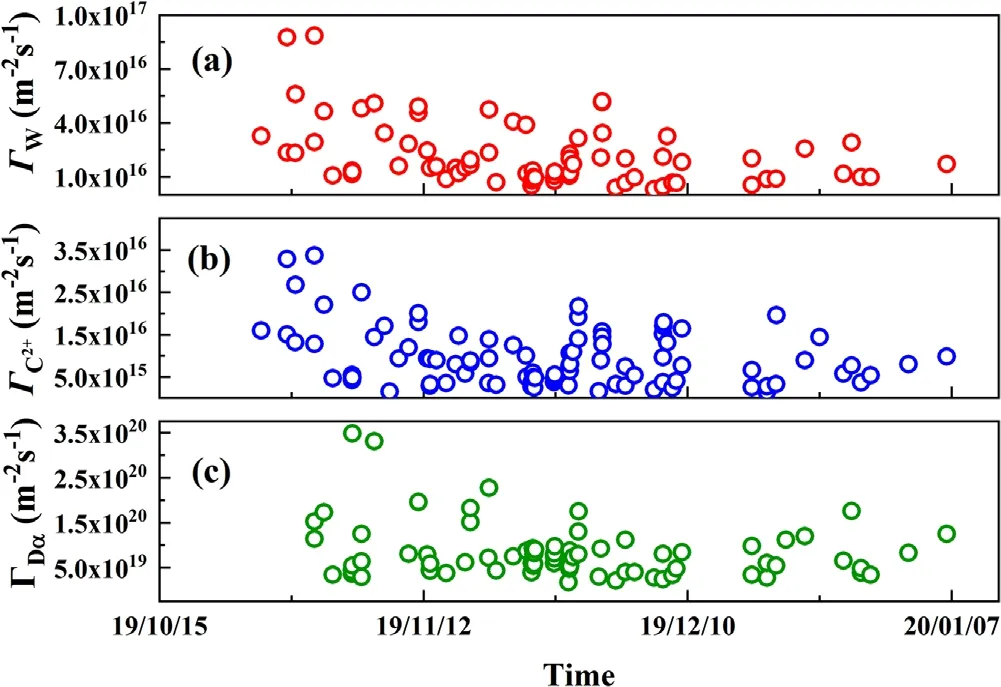

As shown in figure 6, the evolution characteristics of impurity levels are monitored during the whole autumn campaign in 2019.The data points are taken from the flat-top phase of the ohmic shots in the campaign.It reflects the evolution of impurity in the long-term plasma discharge of the device.It is clearly observed from the figures 6(b)and(c)thatand ГDαdecrease significantly as the discharge time and shot numbers accumulation day by day.The ГWin the plasma also shows the slight decrease and stable trend in figure 6(a).It is a positive signal of the wall condition improvement and the mitigation of PWI which effectively influences the W atom flux from divertor.Not only does ICRF-DC have the effect on removing impurities,but the plasma discharges also could improve the wall condition.Compared to the ICRF-DC,the higher energy particles could be produced during plasma shots which bombard impurity particles adsorbed on the first wall surface, leading to the desorption of impurity particles from the first wall surface via particle-induced desorption and isotope exchange [34].With the help of discharge cleanings,the erosion of the W first wall would be controlled due to the decrease of C impurity.

Figure 6.The evolution of ГW, and ГDα versus accumulated discharge duration in long-term monitoring.(a) ГW, (b) and(c) ГDα.

3.3.Suppression of W source by Li coating

In the tokamak operation,the first wall is exposed to the high heat flux and particles flux, and the C target plate is easily bombarded by the energetic particles,especially for the strike line region.It would cause serious W sputtering.Thus,lithium and boron are routinely employed in several tokamaks, through evaporation coating and powder injection.These procedures improve plasma performance by providing a low-ZPFM, and they also lower the neutral gas pressure at the first wall by reducing the fuel recycling[17,35].In EAST,the Li evaporation coating has obvious effect on controlling W sputtering,especially for the poor wall condition.The first Li coating is used in 14 May 2019, as shown in figures 5(c)and(d).It is clearly observed that the interaction between the edge plasma and divertor would be decreased with the help of Li film.

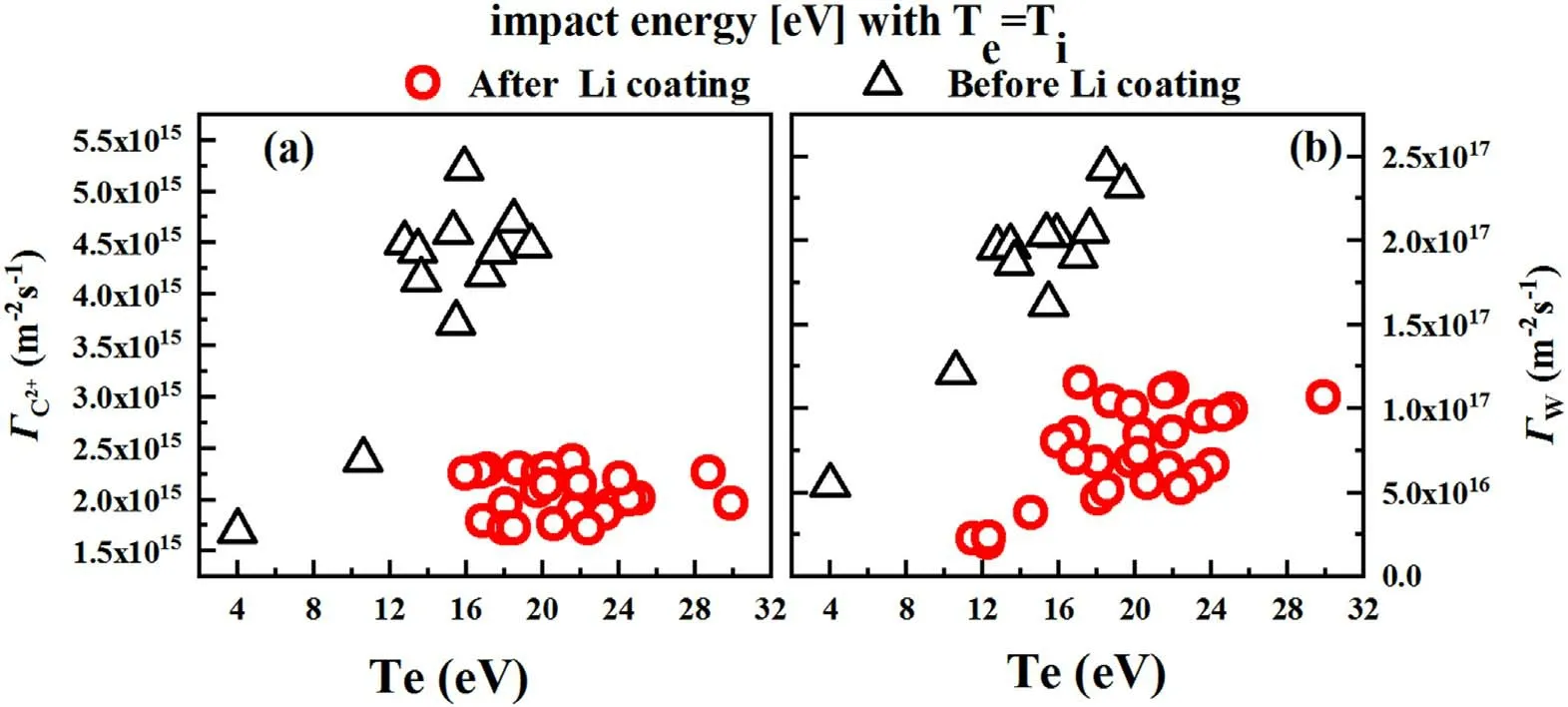

Furthermore, we research the evolution of plasma edge temperature and ГWandThe sputtering yield has the positive correlation with the energy of incident particle, and the impact energy (~3Te+2Ti) at the outer strike line is a function of the plasma edge temperature [28, 36, 37].In figure 7, ГWrises as the plasma edge temperature increases,which is the same for both before and after lithiation,and ГWis approximately linear with the plasma edge temperature.It is also presented that there is a relationship between the plasma edge temperature and impurities particle flux.The black triangles and red cycles represent the impurity intensities before and after lithiation in the same experiment day, respectively,and ГWafter lithiation is significantly lower than that before lithiation.

As the fresh Li film covers the first wall of the device, it becomes the ‘first’ wall material which directly faces the plasma instead of C, Mo and W, and the sputtering of deuterium plasma on Li has become the main part instead of the sputtering of deuterium plasma on C and W.Bedsides, the distribution of Li film is uneven along the poloidal field, and the coating in the lower C divertor is usually thinner than other areas.The W and C sputtering would be triggered as the lifetime of the coating decreases.Thus, the integrated use of Li coating and ICRF-DC is the appropriate way to control the W sputtering source.It is noticed that the induced form of lithium or boron needs to be further explored and optimized for the steady-state operation mode in the future fusion reactors.

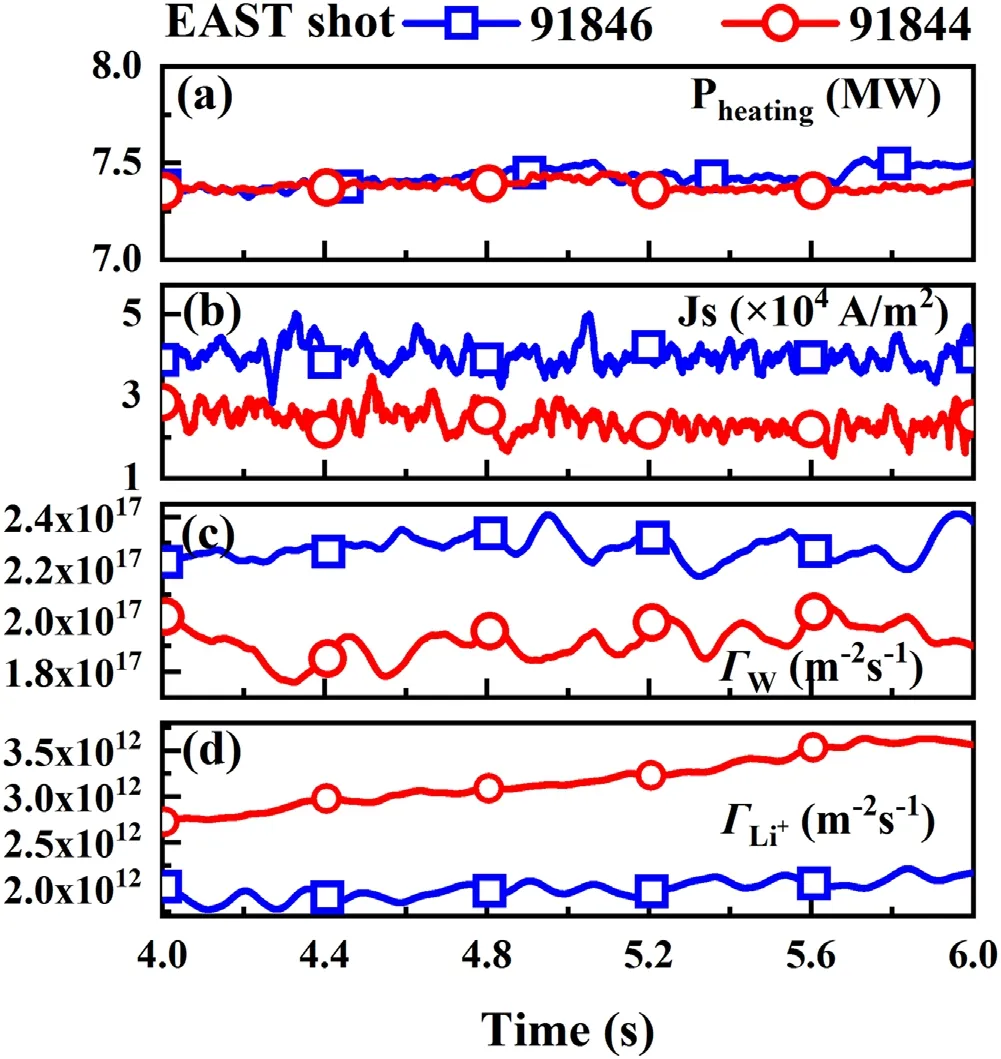

In addition, figure 8 shows the comparison of ГWin two typical shots (#91844 and #91846).It is noted that the W impurity intensity is quite different among the shots with various Li intensity levels.The two typical shots (#91844 and #91846)are shown in red line and blue line respectively,both of them have the total auxiliary heating power of~7.5 MW (shown in figure 8(a)) and USN discharge configuration, and the reason of W source suppression is discussed and evaluated through the plasma parameters and the impurities behaviors.

It is observed from figure 8(d)thatin shot #91844 is higher than that of shot #91846 in the flat-top phases.As the plasma experiments continue, the Li coating is consumed gradually.Its effect on the decreasing the neutral gas pressure and the fuel recycling at the first wall continues to be weakened.Therefore, the particle flux in shot #91846 is higher than that of shot #91846, as shown in figure 8(b).The energetic particle bombardment of the first wall would be serious,because the buffering effect of Li film becomes weak with the consumption of Li film.The ГWin shot #91846 increases by ~13% due to the less, compared to shot #91844, which is observed in figures 8(c) and (d).

4.Discussion

The first wall material is composed of C, W and Mo, in EAST.The low-Zcoating material,such as Li would enhance the target plate erosion resistance.It also has effect on the controlling C and fuel recycling, and the W sputtering could be suppressed due to the decrease of incident particle flux.In addition, the in-between shots lithium evaporation coating system, lithium powder injection system and the flowing liquid Li limiters are developed in EAST to meet the requirements of quasi-steady-plasma operation mode[38,39].It was confirmed that the introduction of low-Zmaterial can effectively improve plasma performance.Although there are gaps or limitations in using Li coating for steady state plasma operation in ITER.The research of W sputtering is a continuously work for fusion reactors.It is necessary for researchers to verify the compatibility between high performance discharges and low-Zmaterial (not just Li), and understand the suppression mechanism of the W sputtering under the low-Zmaterial wall.In addition, some key technologies also provide the working basis for developing the use form of the suitable low-Zmaterial.

Figure 7.The plasma edge temperature versus ГW and intensity after and before Li coating in the same experimental day.(a) The evolution of Г and (b) the evolution of ГW.

Figure 8.The comparison of ГW with different intensities in two typical shots.(a) The total auxiliary heating power, (b) the particle flux, Js, (c) ГW, (d)

5.Summary

The control of W sputtering source issue is a key scientific goal for EAST,during the exploration of high-power plasma operation mode.It is noticed that the C lower divertor would suffer the extreme particle and heat flux, and the sputtered and remained impurities in the plasma discharge vessel,especially C impurity, would aggravate the W sputtering behavior.According to the results in the plasma recovery process after vacuum failure, the evolution of W intensity decreases by ~60% with the accumulation duration of ~35 h ICRF-DC and ~40 g Li coating.The comparison in the shots with similar plasma parameters shows that the particle flux and ГWare decreased by ~35% and ~13% with the help of ~50% more, separately.The Li film could not only suppress the fuel recycling and PWI process, but also improve the state of the wall conditions.The Li coating has a strong adsorption effect with C and H in the plasma discharge vessel.It is also conducive to controlling W sputtering from the source owing to the reduction of C content.Furthermore, the discharge cleanings are needed in cooperation with Li coating.The integrated use of wall conditionings could remove impurities remained in the vessel and actively control W sputtering source.The experiences and lessons about wall conditionings on the suppression of W sputtering source in EAST also would be constructive for us to promote the understanding of relevant physics and basis towards the ITER-like condition.

Acknowledgments

This work is supported by the National Key Research and Development Program of China(Nos.2017YFE0301100 and 2017YFA0402500), National Natural Science Foundation of China (No.11605237), and the Users with Excellence Program of Hefei Science Center CAS (2020HSC-UE010).

Plasma Science and Technology2021年5期

Plasma Science and Technology2021年5期

- Plasma Science and Technology的其它文章

- UV and soft x-ray emission from gaseous and solid targets employing SiC detectors

- The acceleration mechanism of shock wave induced by millisecond-nanosecond combined-pulse laser on silicon

- Investigation of non-thermal atmospheric plasma for the degradation of avermectin solution

- Laser-induced breakdown spectroscopy for the classification of wood materials using machine learning methods combined with feature selection

- Colorimetric quantification of aqueous hydrogen peroxide in the DC plasma-liquid system

- Plasma-assisted Co/Zr-metal organic framework catalysis of CO2 hydrogenation:influence of Co precursors