Structural evolution in deformation-induced rejuvenation in metallic glasses:A cavity perspective?

Shaoqin Jiang(江少欽),Yong Huang(黃勇),and Maozhi Li(李茂枝)

Department of Physics,Beijing Key Laboratory of Opto-electronic Functional Materials&Micro-nano Devices,Renmin University of China,Beijing 100872,China

1.Introduction

Recently,the rejuvenation of metallic glasses has attracted much interest,since it is a promising approach for improving the plasticity of metallic glasses and thereby enhancing their potential applicability as structural materials.[1–10]Experimentally,various approaches have been developed for achieving the rejuvenation of metallic glasses.It was found that rejuvenation of bulk metallic glasses can be achieved through elastostatic compression for high strength and large plasticity.[1–3]The mechanism was attributed to the irreversible structural changes based on the generation of free volume.Similarly,shot-peening of pre-annealed metallic glasses can also realize the mechanically induced rejuvenation.[4]It was argued that shot-peening may induce the part of the free volume distribution associated with flow defects.It was also found that plastic deformation by the high-pressure torsion technique can also effectively rejuvenate the structure of metallic glasses.[5]Further study revealed a transition of the deformation mode from heterogeneous, localized deformation to homogeneous deformation in Zr50Cu40Al10bulk metallic glass and attributed the transition to a change in the local atomic environment in the rejuvenated volume.[6]Moreover,ion irradiation was also found to rejuvenate metallic glasses,leading to significant tensile ductility and plastic deformation,while electron diffraction indicated subtle signatures of structural changes of metallic glasses.[7]Very recently,thermal cycling induced rejuvenation of metallic glasses was also achieved in experiments.[8]It was explained that thermal cycling induced rejuvenation results from the intrinsic nonuniformity of the glass structure,and thermal cycling introduces heterogeneities which effectively induces flow and improves plasticity.In addition,a method was proposed via molecular dynamics simulations to control the level rejuvenation through systematic thermal processing,and crucial conditions for rejuvenation were clarified.[9]

Although plenty of studies have been devoted to rejuvenation of amorphous materials,the evolution of atomic structures in rejuvenation is still elusive.Using Monte Carlo simulation for a binary Lennard–Jones mixture,rejuvenation in glasses was observed via mechanical loading and the pair correlation functions were analyzed for understanding the structure evolution in rejuvenation.[10]However,no details of the atomic structure information related to rejuvenation were provided.As indicated above,the increase of the free volume and its distribution in metallic glasses plays important roles in rejuvenation.[1–4,6,8,11–13]However,the characteristic of free volume in rejuvenation or how free volume influences rejuvenation of metallic glasses is not clear,either.On the other hand,the free volume was defined as the Voronoi-cell volume minus the volume of atom.[14]This free volume is a thermodynamic quantity,and cannot reflect the topological information of atoms packing for the structural evolution.[15]It has been revealed that there exist cavities in metallic glasses,[16]which is often regarded as a topology-based defect due to packing deficiencies in metallic liquids and glasses.[15–21]The formation of large cavities in metallic glasses is the result of mechanical instability.[18–20]Moreover,cavities in metallic glasses can be measured by positron annihilation life time measurements.[22–24]Therefore,characterization of cavities in metallic glasses may provide new insight into the structure property relationship.

In this work,we performed classical molecular dynamics simulations to investigate the structural evolution in deformation-induced rejuvenation in Cu80Zr20metallic glasses by characterizing cavities.The creation and annihilation of cavities in deformation process is found to be responsible for the underlying structural basis of rejuvenation in metallic glasses.In deformation process,cavities prefer to form in the relatively densely packed regions,leading to the irreversible rearrangements in metallic glasses.The characteristic of cavities provides a universal structural description for both aging and rejuvenation mechanism in metallic glasses.

2.Model and simulation method

In our studies,classic molecular dynamic(MD)simulations were performed for Cu80Zr20metallic alloy and a realistic embedded atom method potential was employed to describe the interatomic interactions.[25]All of the simulations were performed using the large-scale atomic/molecular massively parallel simulator(LAMMPS)package.[26]The structure contains 4×104atoms in a cubic box with periodic boundary conditions applied in three dimensions.The initial configuration was melted and equilibrated at T=2000 K for 0.2 ns in isothermal–isobaric(NPT)ensemble,and then cooled down to 300 K with four different cooling rates of 0.1 K/ps,1 K/ps,10 K/ps,and 100 K/ps,respectively.In these processes,the box size was adjusted to give a zero pressure.The samples were further relaxed at300K in canonical(NVT)ensemble for 0.4 ns.In our MD simulations,temperature and pressure were controlled with Nose–Hoover thermostat and barostat,respectively.To examine the deformation-induced rejuvenation in four metallic glass samples,uniaxial compression along the Z direction with constant strain rate was applied to the samples at 300 K.Periodic boundary conditions were applied in the X and Y directions.

In our work,the cavities in metallic glasses were characterized in terms of the numerical algorithm developed by Sastry et al.[17]In this algorithm,Voronoi and Delaunay tessellations were constructed with the atomic radii of Cu (1.28 A° ) and Zr (1.59 A° ) taken into account, and an exclusion radius was applied to determine the void regions and the volumes of cavities.According to previous studies,[17]1.4 times of the atomic radii of Cu and Zr were chosen as the exclusion radii for Cu and Zr atoms,respectively,which are comparable to the distances that pair correlation functions start to be nonzero.[28]More details about the algorithm can be found in Ref.[17].The connectivity of nearest neighboring cavities was also considered,[27]so that a rigorous and precise cavity in metallic glasses can be quantitatively defined and characterized.

3.Results and discussions

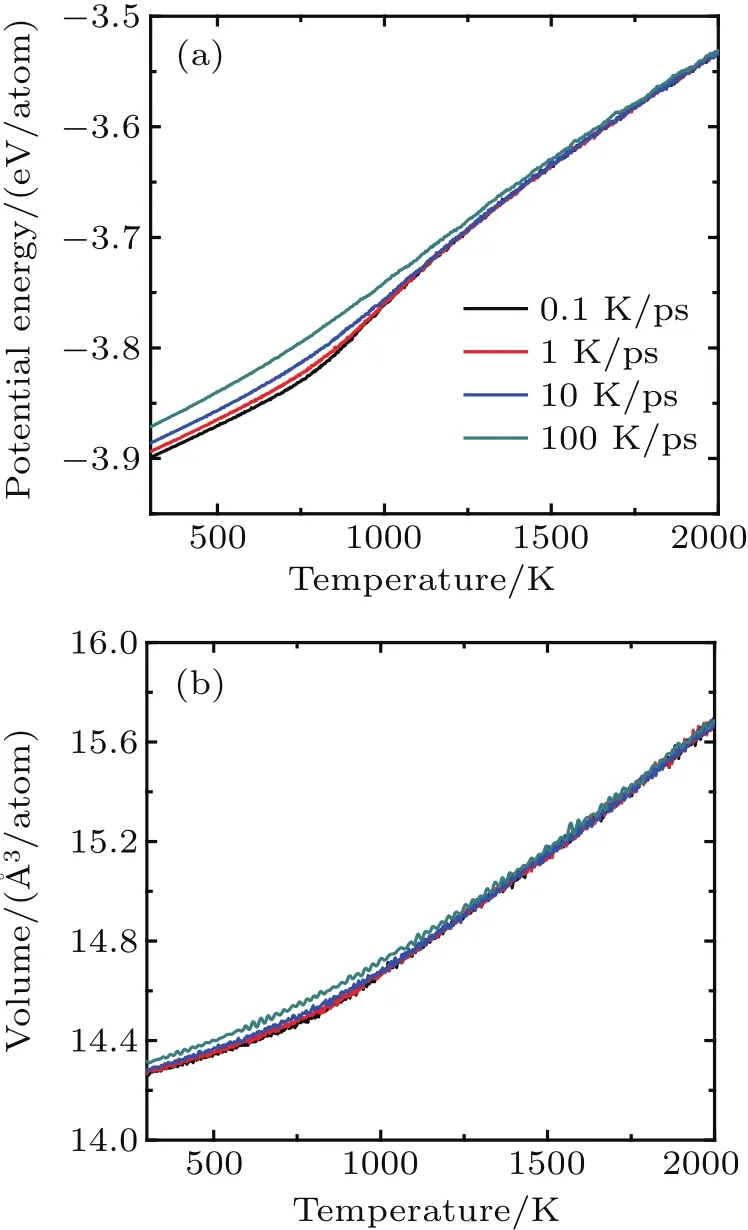

Figure 1 shows the potential energy and volume per atom in four samples with different cooling rates as a function of temperature in the cooling process.Both the potential energy and the volume decrease as the temperature decreases,exhibiting a kink below a certain temperature, and indicating the glass transition in four samples.It can be seen that the slower the cooling rate,the lower the potential energy,and the smaller the volume per atom,indicating that four metallic glassy samples with different states are obtained.

Fig.1.The evolution of(a)potential energy per atom and(b)volume per atom as the samples are cooled from 2000 K to 300 K with four different cooling rates.

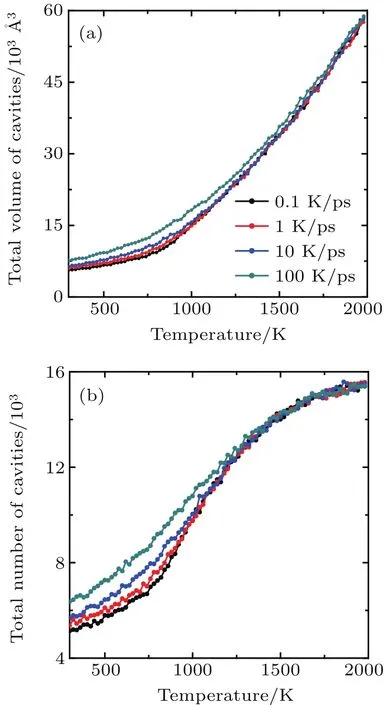

First,we investigate the temperature evolution of cavities in four samples in the cooling process.As shown in Fig.2,both the total volume and the number of cavities decrease significantly as the temperature decreases,indicating that there exist numerous cavities in high temperature liquids,and the cavities are rapidly annihilated in the cooling process.It can be seen that in high temperature liquids, both volume and number of cavities are almost the same in four samples, independent of the cooling rate. As temperature decreases below about 1400 K, both volume and number of cavities change with cooling rate.Slower cooling rate accelerates the annihilation of cavities in both volume and number as shown in Fig.2,leading to the least cavities in the sample of 0.1 K/ps.This indicates that the sample of 0.1 K/ps can be relaxed much more adequately,so that more cavities are annihilated in the cooling process.In addition,the aging effect in the cooling process with different cooling rates can be well characterized by the annihilation of cavities,so that cavities can be used to characterize the metallic glasses at different glassy states.

Fig.2.The evolution of(a)total volume and(b)total number of cavities of four different specimens as a function of temperature from 2000 K to 300 K.

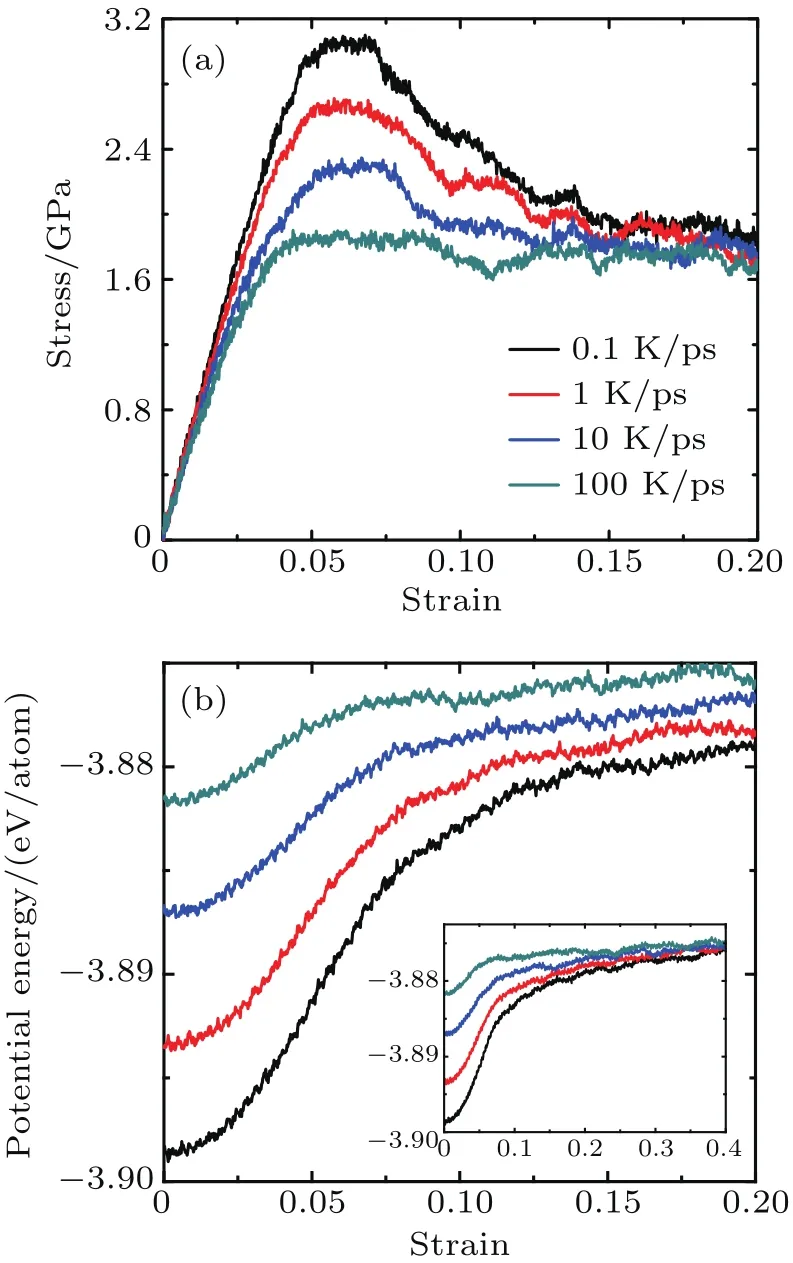

Next,we analyze the evolution of the cavities in deformation process.Figure 3(a)shows the strain–stress curves in four samples as the compressive deformation is applied.The yield stress increases as the cooling rate is decreased.There is almost no overshoot in the strain–stress curve in the sample of 100 K/ps.As the cooling rate decreases,the overshoot becomes more significant.As the strain goes beyond the yield point,the stress in the samples with slower cooling rates decreases,and the strain–stress curves almost collapse together as the strain is over 15%.Figure 3(b)shows the evolution of potential energy with the strain.Before compression,the potential energies in four samples are different.As the external stress is applied,the potential energy in all samples increases as the strain increases.The increase in potential energy is much more drastic in the sample of 0.1 K/ps.As the strain increases,the difference in potential energy in the four samples becomes smaller and almost the same as the strain reaches about 40%.This indicates that these glassy samples are rejuvenated to higher energy states,and the aging effect produced in the cooling process in four samples can be completely erased by applying mechanical deformation.This is consistent with previous studies.[10]It can be seen that rejuvenation of metallic glasses can be achieved by applying mechanical deformation.

Fig.3.(a)Strain–stress curves of four metallic glassy samples in compressive deformation;(b)evolution of potential energies in four samples in deformation process.The inset in panel(b)shows the evolution of the potential energy in four samples up to 40%strain.

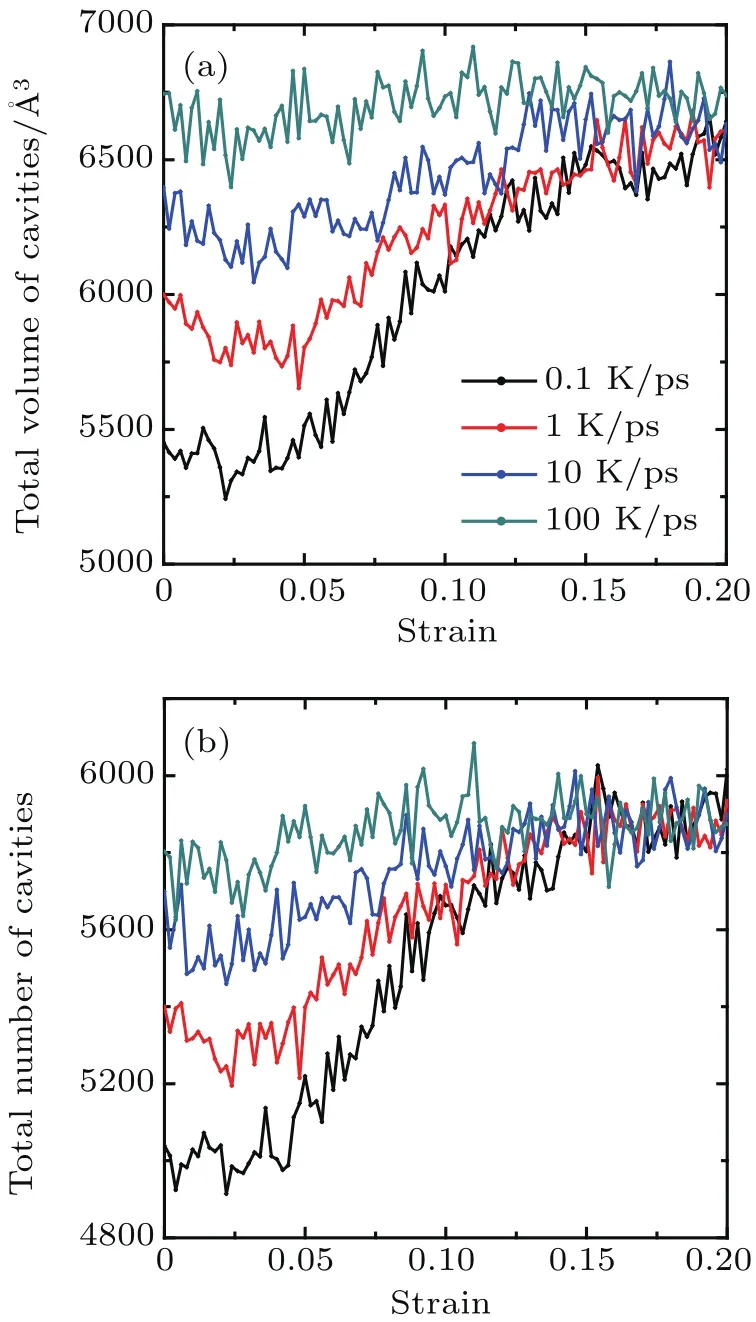

To understand the underlying structural basis of the deformation induced rejuvenation of metallic glasses,the evolution of the cavities in four samples in deformation process is analyzed.Figure 4 shows the change of volume and number of cavities with strain.Both the total volume and number of cavities in these samples decrease a little as the strain increases to before 5%.This indicates that some cavities are shrunk or annihilated under the deformation in the apparent elastic regime.In the sample of 0.1 K/ps,the volume and number of cavities do not change much with strain smaller than 5%.This implies that the sample is adequately relaxed in the cooling process with a cooling rate of 0.1 K/ps,so that the compressive deformation does not induce further decrease in the volume or number of cavities.However,in the samples of 1 K/ps and 10 K/ps,the deformation induces significant decrease in the volume and number of cavities before 5%.In the sample of 100 K/ps,the volume and number of cavities do not change much,either.This is because this sample is yielded quickly as the strain exceeds 2%.As the strain is larger than 5%,the total volume and number of cavities in all samples increase as the samples are further deformed.The increase is more drastic in the sample of 0.1 K/ps,indicating that the local atomic rearrangement is more significant and more cavities are generated in this sample under deformation.As the strain is larger than 15%,the volume and number of cavities become similar in four samples.This behavior is quite similar to the potential energy in the deformation process.Thus,four metallic glassy samples at different states obtained in cooling processes are rejuvenated into a higher energy state with similar potential energy and atomic structure feature.It can be seen that the aging history in four samples is finally erased by the deformation induced rejuvenation.Moreover,the generation and annihilation of cavities in metallic glassy samples play a key role in both aging and rejuvenation processes.As shown above,while the annihilation of cavities dominates in the aging process,the generation of cavities essentially controls the rejuvenation process.Therefore,the characteristics of cavities provide a generic description for both aging and rejuvenation in metallic glasses.

Fig.4.The evolution of(a)volume and(b)number of cavities in four metallic glassy samples in compressive deformation process.

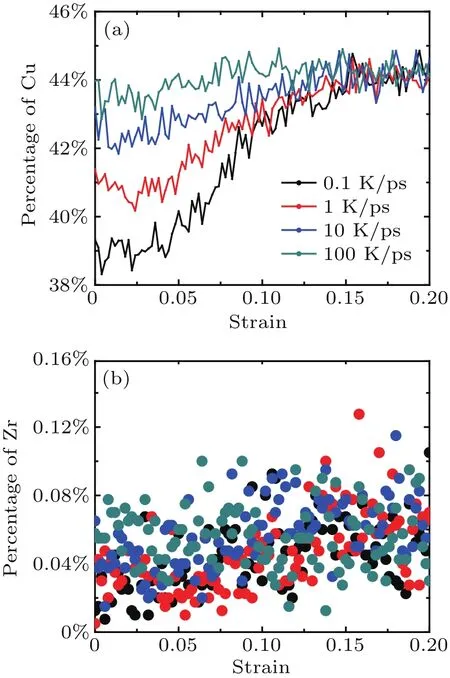

To get further insight into the relationship between cavities and rejuvenation in metallic glasses,we investigate the role of each element in the creation of cavities in the deformation process.Figure 5 shows the variation of the percentage of Cu and Zr around cavities with strain in the sample of 0.1 K/ps,respectively.It can be seen that while the percentage of Cu around cavities increases with strain,the percentage of Zr is fluctuating,and does not change much in the deformation process.This indicates that new cavities are essentially created around Cu atoms,leading to the increase of Cu atoms around cavities.This also implies that most atomic irreversible rearrangements take place around Cu atoms,which is consistent with the characterization of atomic rearrangements in metallic glasses.[29]

Fig.5.Variation of the percentage of(a)Cu and(b)Zr atoms around cavities compared to the total number of atoms in the metallic glassy sample of 0.1 K/ps with strain.

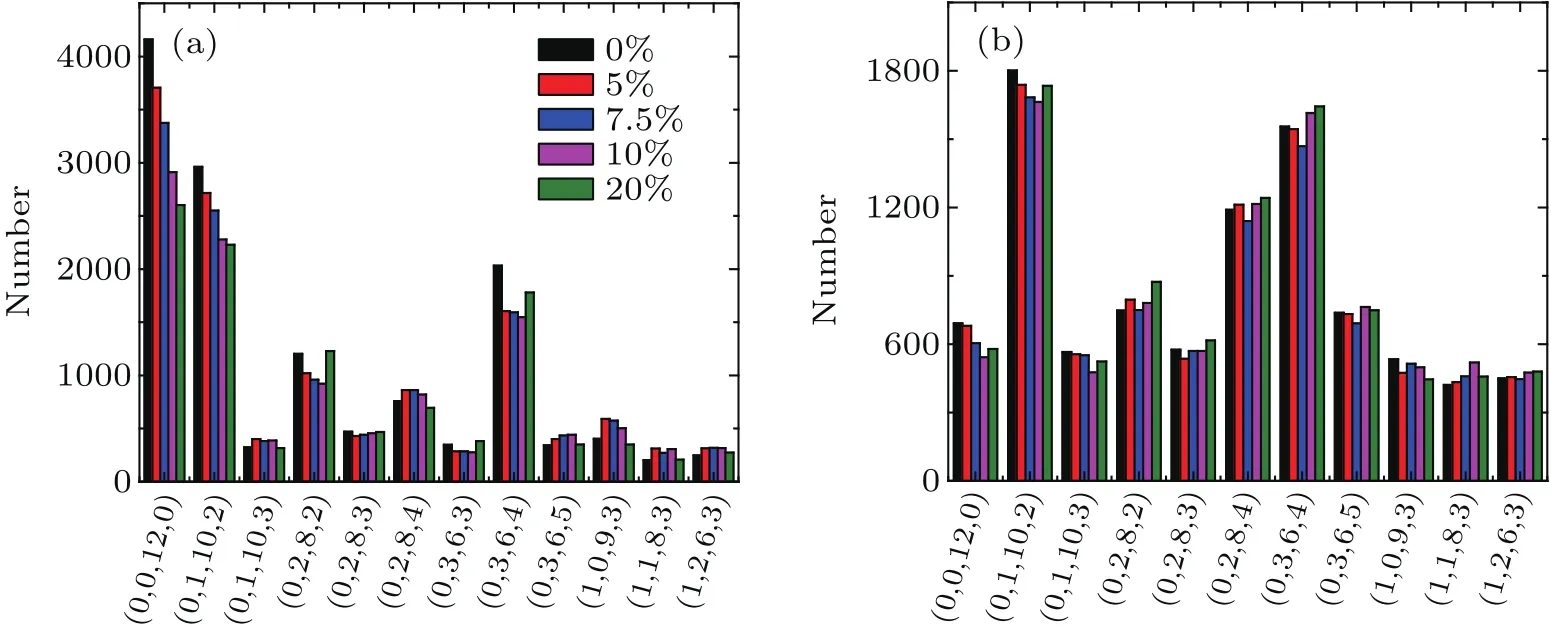

We also investigate the relationship between the creation of cavities and atomic clusters in the deformation process. Figure 6 shows the major populated clusters with and without cavities surrounded at different strains.It can be seen that while much more icosahedral clusters are populated in the regions without cavities,only a small fraction of icosahedral clusters are located around cavities,indicating the dense packing feature of icosahedral clusters.In contrast,while the fraction of icosahedral clusters decreases monotonically with the increase of the strain,the fraction of icosahedral clusters located around cavities does not change much with the strain.This implies that the decrease of icosahedral clusters in the regions without cavities is accompanied with the creation of cavities,and icosahedral clusters are mainly transformed to some lowpopulated clusters in the deformation process.[30]On the other hand,the population of the major clusters around cavities does not vary much with the strain.This indicates that the plastic deformation mainly changes the atomic environments in the regions without cavities,although the fraction of atomic clusters changes with strain.[31,32]This also indicates that if only atomic clusters and their evolution are characterized in the rejuvenation process,one cannot obtain the generic structure feature for better understanding of the rejuvenation mechanism in metallic glasses.

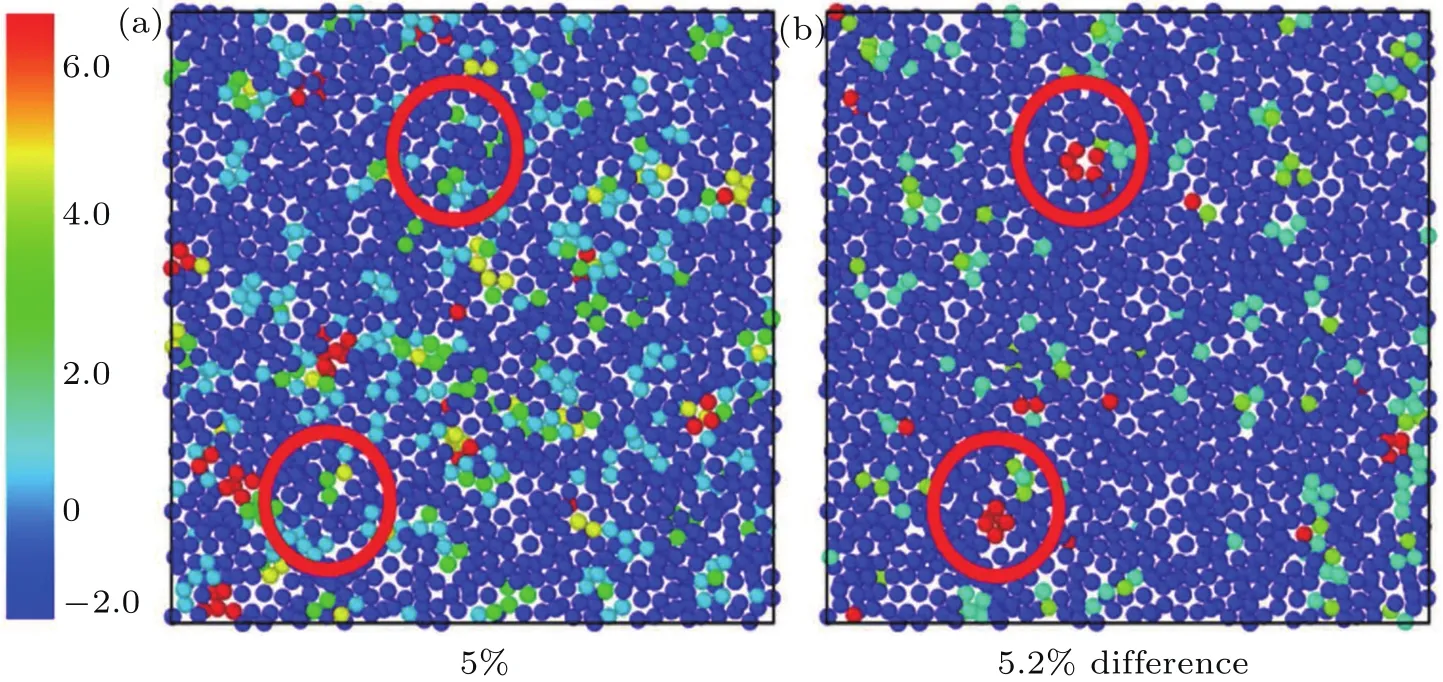

Figure7further confirms this point.Figure7(a)shows the cavity distribution in the sample of 0.1 K/ps at a strain of 5%,and figure 7(b)shows the volume difference of cavities between the strain of 5.2%and 5%,which indicates the creation and annihilation of cavities in the deformation process.The red circles mark the region without cavities in Fig.7(a),and the corresponding volume difference in cavities in Fig.7(b),respectively.It can be seen that the big cavities are mainly created in the densely packed region,not in the so-called loosely packed region.[33,34]Moreover,there are some small cavities populated around such regions,and the length scale is far beyond the nearest neighbor distance.This clearly demonstrates that new cavities are mainly created in the densely packing regions.

Fig.6.Population of the major atomic clusters(a)without and(b)with cavities surrounded in the metallic glassy sample of 0.1 K/ps.

Fig.7.(a)Snapshot of cavity distribution in the sample of 0.1 K/ps at a strain of 5%;(b)the volume difference of cavities between the strain of 5.2%and 5%.The cross-section in the middle of the sample along the X direction is taken for the illustration.The color bar represents the cavity volume in panel(a)and volume difference in panel(b),respectively.The circles mark the regions without cavity in panel(a)and the corresponding volume difference in panel(b).

4.Conclusion

The rejuvenation of metallic glasses has been realized by applying compressive deformation.Metallic glasses in different energy states have been rejuvenated into a higher energy state with similar potential energy.Numerous cavities are created in this process,which is the main underlying structural basis of rejuvenation of metallic glasses.Moreover,cavities tend to be formed in the densely packed regions.The creation of cavities essentially facilitates the irreversible rearrangements in plastic deformation.

[1]Concustell A,Mear F O,Surinach S,Baro M D and Greer A L 2009 Phil.Mag.Lett.89 831

[2]Ke H B,Wen P,Peng H L,Wang W H and Greer A L 2011 Scr.Mater.64 966

[3]Zhang M,Wang Y M,Li F X,Jiang S Q,Li M Z and Liu L 2017 Sci.Rep.7 625

[4]Zhang Y,Wang W H and Greer A L 2006 Nat.Mater.5 857

[5]Dmowski W,Yokoyama Y,Chuang A,Ren Y,Umemoto M,Tsuchiya K,Inoue A and Egami T 2010 Acta Mater.58 429

[6]Meng F Q,Tsuchiya K,Seiichiro I I and Yokoyama Y 2012 Appl.Phys.Lett.101 121914

[7]Magagnosc D J,Kumar G,Schroers J,Felfer P,Cairney J M and Gianola D S 2014 Acta Mater.74 165

[8]Ketov S V,Sun Y H,Nachum S,Lu Z,Checchi A,Beraldin A R,Bai H Y,Wang W H,Louzguine-Luzgin D V,Carpenter M A and Greer A L 2015 Nature 524 200

[9]Wakeda M,Saida J,Li J and Ogata S 2015 Sci.Rep.5 10545

[10]Utz M,Debenedetti P G and Stillinger F H 2000 Phys.Rev.Lett.84 1471

[11]Ding J,Cheng Y Q and Ma E 2014 Acta Mater.69 343

[12]Heggen M,Spaepen F and Feuerbacher M 2005 J.Appl.Phys.97 033506

[13]Struik L C E 1997 Polymer 38 4053

[14]Spaepen F 2006 Scr.Mater.54 363

[15]Cohen M H and Turnbull D 1959 J.Chem.Phys.31 1164

[16]Sheng H W,Ma E and Kramer M J 2012 JOM 64 856

[17]Sastry S,Corti D S,Debenedetti P G and Stillinger F H 1997 Phys.Rev.E 56 5524

[18]WangXD,AryalS,ZhongC,ChingWY,ShengHW,ZhangH,Zhang D X,Cao Q P and Jiang J Z 2015 Sci.Rep.5 9184

[19]Guan P,Lu S,Spector M J B,Valavala P K and Falk M L 2013 Phys.Rev.Lett.110 185502

[20]Pan S P,Feng S D,Qiao J W,Wang W M and Qin J Y 2016 J.Alloys Compd.664 65

[21]Sastry S,Corti D S,Debenedetti P G and Stillinger F H 1997 Phys.Rev.E 56 5533

[22]Nagel C,Ratzke K,Schmidtke E,Wolff J,Geyer U and Faupel F 1998 Phys.Rev.B 57 10224

[23]Flores K M,Suh D and Dauskardt R H 2002 J.Mater.Res.17 5

[24]Kanungo B P,Glade S C,Asoka-Kumar P and Flores K M 2004 Intermetallics 12 1073

[25]Mendelev MI,Kramer MJ,Ott RT,Sordelet D J,Yagodin D and Popel P 2009 Phil.Mag.89 967

[26]Plimpton S 1995 J.Comput.Phys.117 1

[27]Sietasma J and Thijsse B J 1995 Phys.Rev.B 52 3248

[28]Bernal J D 1964 Proc.R.Soc.Lond.A 280 299

[29]Shang B S,Li M Z,Yao Y G,Lu Y J and Wang W H 2014 Phys.Rev.E 90 042303

[30]Cheng Y Q and Ma E 2011 Prog.Mater.Sci.56 379

[31]Hu Q,Zeng X R and Fu M W 2012 J.Appl.Phys.111 083523

[32]Peng H L,Li M Z and Wang W H 2011 Phys.Rev.Lett.106 135503

[33]Falk M L and Langer J S 1998 Phys.Rev.E 57 7192

[34]Spaepen F 1977 Acta Metall.25 407

- Chinese Physics B的其它文章

- Effect of carrier mobility on performance of perovskite solar cells?

- Plasma electrolytic liquefaction of sawdust?

- Insight into band alignment of Zn(O,S)/CZTSe solar cell by simulation?

- Effect of terahertz pulse on gene expression in human eye cells?

- Ultraviolet photodetectors based on wide bandgap oxide semiconductor films?

- A primary model of decoherence in neuronal microtubules based on the interaction Hamiltonian between microtubules and plasmon in the neurons