Effect of carrier mobility on performance of perovskite solar cells?

Yi-Fan Gu(顧一帆),Hui-Jing Du(杜會(huì)靜),Nan-Nan Li(李楠楠),Lei Yang(楊蕾),and Chun-Yu Zhou(周春宇)

Key Laboratory for Microstructural Material Physics of Hebei Province,School of Science,Yanshan University,Qinhuangdao 066004,China

1.Introduction

Perovskite solar cells(PSCs)have attracted considerable attention in the past few years due to their rapid photovoltaic efficiency improvement,from 10%in 2012[1,2]to 23.2%in 2018.[3]The excellent photovoltaic performance of PSCs is ascribed to its excellent optoelectrical characteristics,such as high light absorption coefficient,[4,5]long carrier diffusion length,[6,7]high carrier mobility,[8,9]and long recombination lifetime.[9]The transportation of carriers from the absorber to charge transport layer and the collection of them by electrodes are key processes to determine the cell efficiency,hence carrier mobility is one of the significant factors affecting cell performance.The carrier mobility and diffusion length of perovskite crystal have reached to hundreds of cm2/V·s and hundreds ofμm respectively.However,can the higher mobility and the longer diffusion length lead to better PSCs’performance?Research has drawn different conclusions about the influence of carrier mobility[10–12]and diffusion length[10,13–15]on PSCs performance.Simulation studies based on one-dimensional simulation software SCAPS show that the diffusion length longer than 1μm and higher mobility of the carriers have no positive effect on the cell performance promotion,[13,15]and high mobility of the charge transport layer is also necessary for the high efficiency.[16,17]The influence of carrier mobility on the cell performance is restricted by other cell parameters,such as doping concentration,layer thickness,etc.In these papers,these factors were not considered as a whole.Carrier transportation can be enhanced if the parameters of the cell are well matched,and thus improve cell performance.Many experimental and theoretical studies of the mobility influence on the organic solar cells’performance demonstrated that there exists an optimal value of mobility for obtaining high efficiency organic cells.[18–21]While the systematic study of carrier mobility in PSCs is very rare,this would affect the best utilization of the excellent carriers’transportation characters of perovskite material to improve cell performance.To clarify these questions,we construct the device model and simulate the carrier transportation to understand the mechanism of carrier mobility influencing the cell performance.Our simulation study shows that the optimal mobility also exists in perovskite solar cells,and by matching the carrier mobility of the transportation layer and the absorption layer,the efficiency of perovskite solar cells can be enhanced.The optimized cells’structure with a diffusion length of nearly 1.9μm and the photovoltaic efficiency of 27.39%is obtained ultimately.

2.Device model and simulation parameters

In our previous research on lead-free perovskite solar cells,[22]we obtained an efficiency of 23.36%by optimizing the doping concentration,defect density and electron affinity of the buffer.To elucidate the mechanism of high carrier mobility and long diffusion length of the perovskite materials influencing the cell performance,our simulation is based on that previous optimized structure(glass substrate/TCO/buffer layer TiO2(ETM)/absorption layer CH3NH3SnI3/hole transport material(HTM)spiro-OMeTAD/metal back contact)to avoid the influence of other cell parameters.The parameters of that previous structure,serving as our initial simulation parameters,are listed in the following Table 1.The simulation principle,the cell architecture,and other simulation parameters selected for each layer can also be found from our previous studies.[22]

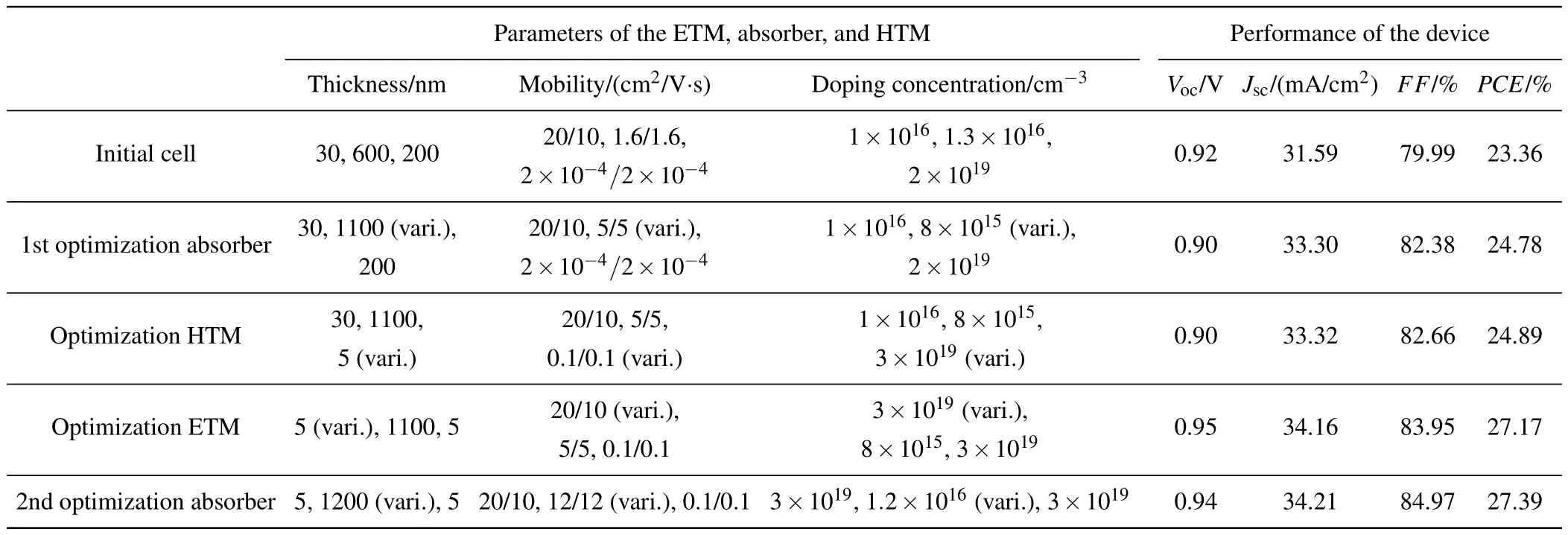

Table 1.Simulation parameters and performances of device during optimization.The parameters in bold text are the optimal value during the optimization.

The current density–voltage( J–V)characteristic curve of the cell with initial parameters is shown in Fig.1(curve 1).Short-circuit current density( Jsc)of 31.59 mA/cm2,opencircuit voltage(Voc)of 0.92 V, fill factor(FF)of 79.99%,and power conversion efficiency(PCE)of 23.36%are obtained.

Fig.1. J–V curves of PSCs during optimization.

Based on previous optimized structure,we further investigate the relation between the carrier mobility and the cell performance.Taking into account the influence of each layer on the performance of perovskite solar cells,the optimization process consists of four steps.The parameters of thickness,carrier mobility,and doping concentration are optimized in the absorber layer,HTM,and ETM layers in sequence at the first three steps.At the fourth step,the parameters of the absorber layer are re-optimized to realize the matching optimization of all the parameters.Experimental research has shown that the mobilityμis independent of charge carrier concentration of the perovskite absorber layer at lower concentrations(1016cm?3–1018cm?3).[23,24]

3.Results and discussion

3.1.Optimization of the absorption layer

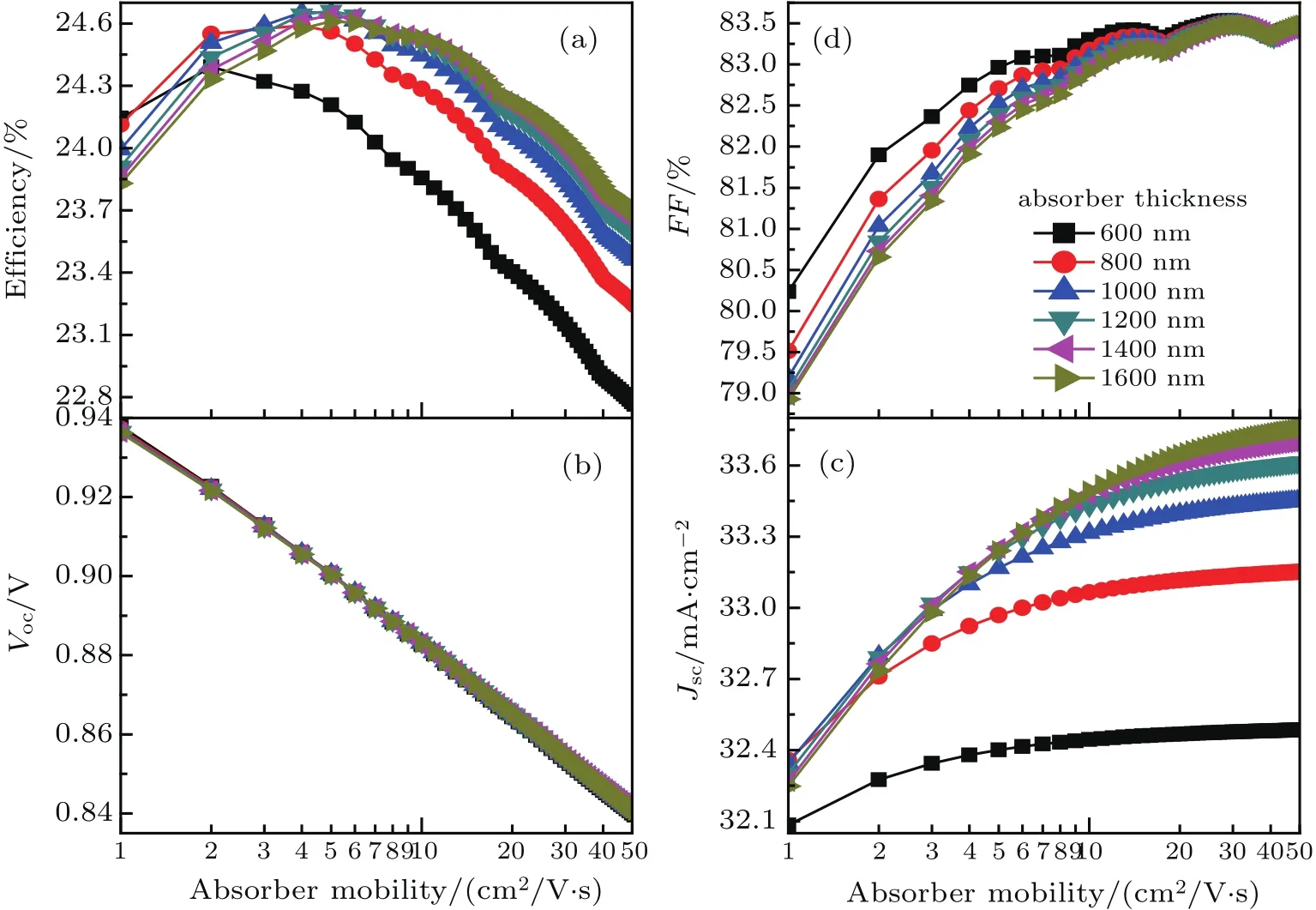

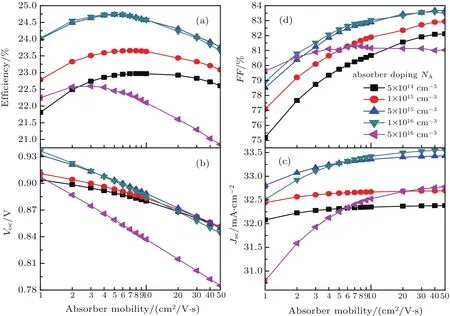

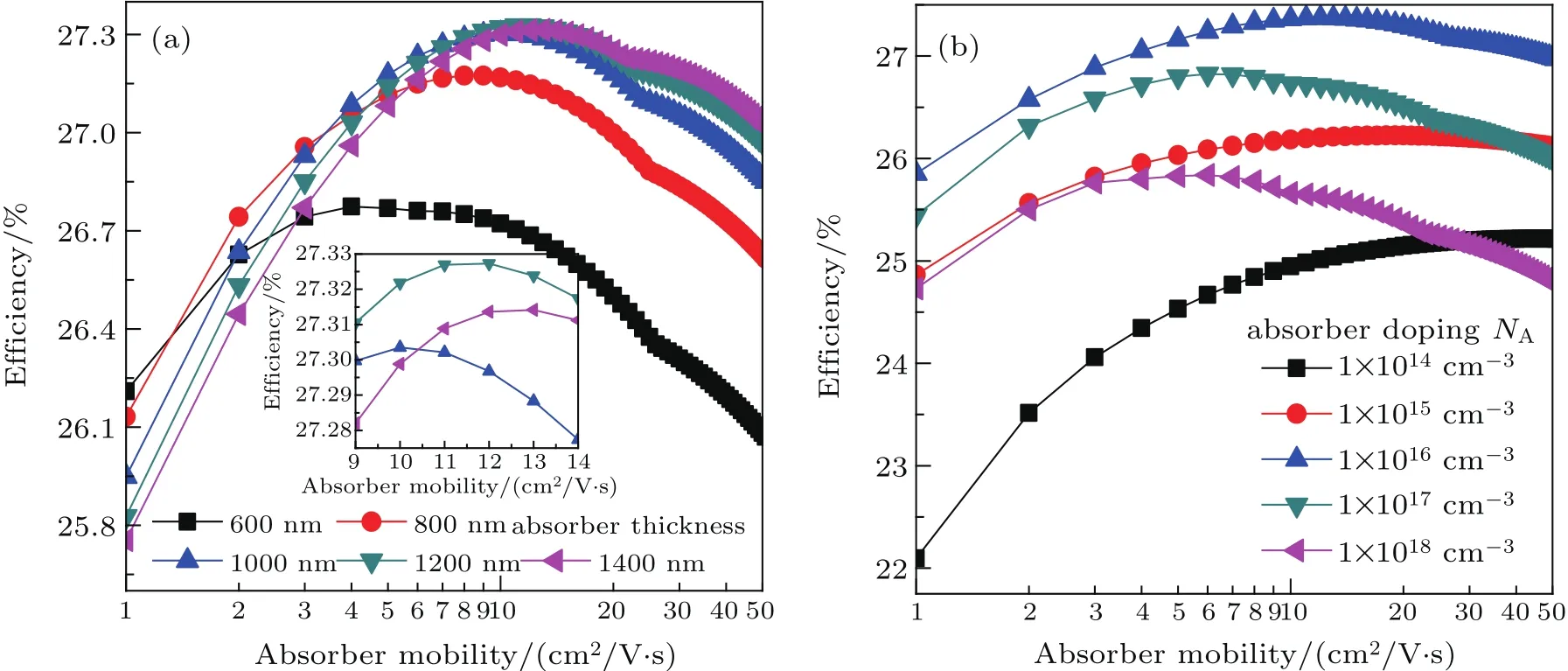

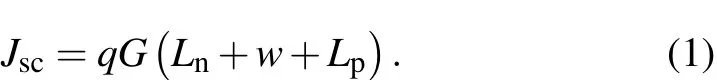

In this step,the relation of the mobility with the thickness and doping concentration of the absorber is investigated first based on the parameters of the initial cell in Table 1.Figures 2 and 3 illustrate the effects of mobility on the device performance under various absorber thickness values and doping concentrations.It can be seen that the optimal value of mobility(Figs.2(a)and 3(a))changes with the absorber thickness and doping concentration.At an optimal value of 5 cm2/V·s(1100 nm),the cell efficiency increases slightly from the initial 23.36%to 24.66%.With the enhancement of the mobility,the FF and the Jscincrease significantly,which is consistent with the experimental research in the literature.[19,25]When the carrier mobilityμ is smaller than 10 cm2/V·s,efficiency and Jscof the device first rise and then decreases with thickness increasing,and a moderate thickness of 800 nm is conducible to the improvement of efficiency, so we adopted an optimal thickness 600 nm of the absorption layer when μ was 2 cm2/V·s in our previous paper.[22]This is consistent with the experimental research that the absorber thickness is always about 700 nm,because the mobility of the polycrystalline perovskite film is always lower than 10 cm2/V·s.[3,26,27]When μ is higher than 10 cm2/V·s,the absorber thicker than 800 nm is more suitable to the obtaining of a higher efficiency,which is embodied with the significant increment of Jsc.The higher the thickness absorber layer,the more the generated photo-carriers is,and especially more longwaves can be absorbed.[28,29]This can be seen in the external quantum efficiency(QE)curve(Fig.4),where the QE at the longwave increases with the augmentation of the absorber thickness.

Fig.2.Variations of(a)efficiency,(b)Voc,(c) Jsc,and(d)FF of PSCs with thickness and mobility of the first optimization of absorber.

Fig.3.Variations of(a)efficiency,(b)Voc,(c) Jsc,and(d)FF of PSCs with doping concentration and mobility of the first optimization of absorber.

Figure 3 illustrates the effects of mobility on the cell performance at various doping concentrations of the absorber layer based on the optimized absorber thickness of 800 nm obtained from Fig.2.The Jscand FF both increase with mobility increasing at different doping concentrations,especially the Jsccan be significantly augmented(Fig.3(c)).The obvious influence of mobility on Jsccan be observed when NAis higher than 1×1016cm?3.With a certain mobility,say,μ =6 cm2/V·s, Jscfirst increases with the augment of doping concentration and then decreases significantly with NAfurther increasing to 5×1016cm?3.This is because both Jscand recombination rate increase with the augment of doping concentration.Mobility can surmount the contradiction between high Jscand high recombination rate caused by the high doping concentration.Recombination can be weakened through good transportation performance of perovskite material with high mobility,which would be explained in the paper in the last simulation step(see Fig.11).The optimal value of mobility gradually decreases with NAincreasing,thus lowering the negative effect of the doping concentration increment(see Fig.3(a)).Moderate doping concentration(5×1015cm?3≤NA<1×1016cm?3)is beneficial to the improvement of efficiency forμ >10 cm2/V·s.

Fig.4.Curves of external quantum efficiency versus wavelength of PSCs during optimization.

This analysis presents that monotonically increasing the mobility of the absorber layer is not beneficial to the performance of the PSCs.Taking into account the influence of the thickness and doping concentration,an optimal value of mobility exists.The corresponding J–V characteristic curve(curve 2)is shown in Fig.1,and Jscrises significantly from the initial 31.59 mA/cm2to 33.30 mA/cm2.TheVocof 0.90 V,FF of 82.38%,and PCE of 24.78%are obtained at this preliminary optimization of the absorption layer.

The transportation parameter’s matching between the absorber and the charge transport layer is important to avoid the excessive accumulation of the carriers at their interface during the photon-generated carriers transporting to the corresponding electrodes.Hence,after the absorber layer optimization,the carrier mobility and other parameters,such as doping concentration and thickness,of HTM and ETM should also be optimized.

3.2.Optimization of the charge transport layer

3.2.1.Optimization of the hole transport layer(HTM)

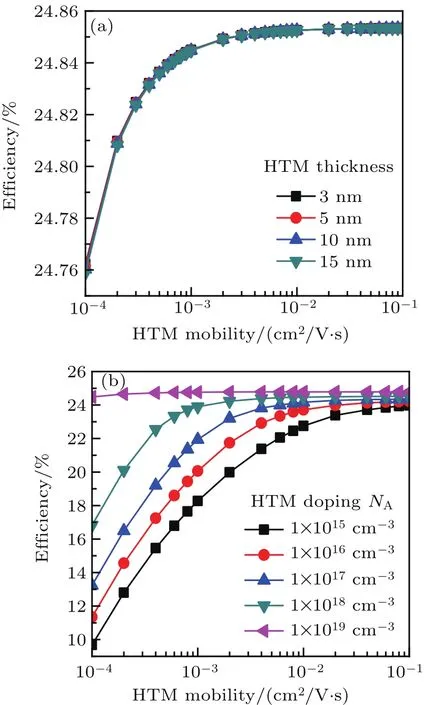

The HTM layer is optimized based on the preliminarily optimized absorber layer.The effects of mobility on the performance of perovskite solar cells under various HTM thickness values(Fig.5(a))and doping concentrations(Fig.5(b))are given.In a 3-nm–15-nm range of HTM thickness,when the mobility of HTM increases from 10?4cm2/V·s to 5 ×10?2cm2/V·s,the efficiency of perovskite solar cells increases gradually.Little change of the efficiency can be seen forμ >1×10?2cm2/V·s because the carriers’diffusion length is longer than the thickness of the HTM.When doping concentration is smaller than 1×1019cm?3,PSCs’efficiency augments gradually with mobility increasing and reaches a saturation level at an HTM mobility of 0.1 cm2/V·s.When the doping concentration is 1×1019cm?3,the effect of the mobility is very weak on the cell’s efficiency.

Fig.5.Plots of efficiency versus mobility of PSCs for various(a)thickness values and(b)doping concentrations of HTM.

Figure6 shows the variation trends of device performance affected by thickness,doping concentration,and mobility of HTM,respectively.During simulation,other two parameters are kept unchanged when the optimized parameters are extracted from Fig.5 with an HTM thickness of 5 nm,a doping concentration of 1×1019cm?3and mobility of 0.1 cm2/V·s.The efficiency, Jscand FF rise with the mobility of HTM increasing,and the open-circuit voltage Vocis almost constant,which is in accordance with the work of Alnuaimi.[30]Doping concentration enhancement of HTM can increase its conductivity,hole mobility and charge density,and this will significantly improve the device performance.[31,32]The improvement of device performance with doping concentration growing is consistent with the scenario in the literature,[33]and we set 3×1019cm?3and 0.1 cm2/V·s as the optimal doping concentration and mobility of HTM,respectively.The optimal mobility value of 0.1 cm2/V·s is in agreement with that in the literature.[30]Although thinner thickness is more beneficial to the cell performance promoting,considering the difficulty of preparation,the optimal thickness value of HTM is taken to be 5 nm.After the optimization of the HTM,a PCE of 24.89%is obtained with Jscof 33.32 mA/cm2,Vocof 0.904 V,FF of 82.66%,and its J–V curve is depicted with curve 3 in Fig.1.In comparison with the preliminary optimization of the absorber layer(curve 2 Fig.1),an obvious augment of Vocis obtained.

Fig.6.Variations of performance parameters of PSCs with(a)thickness,(b)doping concentration,and(c)mobility of HTM.

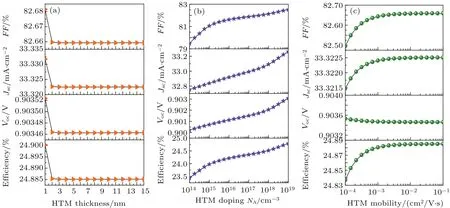

Fig.7.Plots of efficiency of PSC versus mobility for(a)various thickness values and(b)various doping concentrations of ETM.

3.2.2.Optimization of the electron transport layer(ETM)

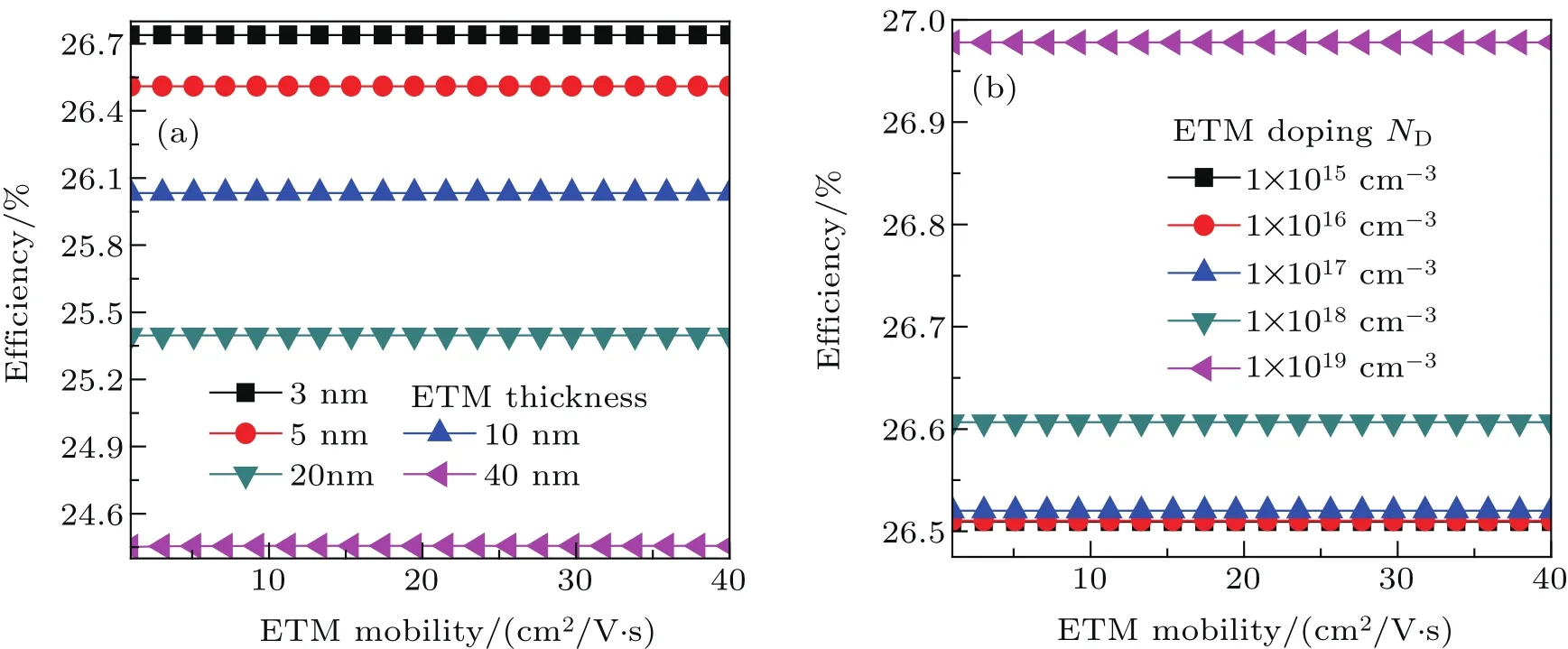

The parameters of the ETM layer are optimized in sequence.Figure 7 reveals the influences of ETM mobility on device efficiency with various thickness values and doping concentrations.The efficiency decreases with the thickness of ETM increasing from 3 nm to 20 nm but does not vary with the mobility of ETM.Figure 8 exhibits the variations in thickness,doping concentration,and mobility of ETM versus device performance parameters,respectively.When the ETM thickness increases from 1 nm to 15 nm,all the performance parameters,such as Jsc,Voc,FF,and PCE of the device first rise and then decrease,and there exists an optimal thickness value of 5 nm for the ETM layer.For polycrystalline perovskite,CH3NH3PbI3,whose diffusion length is short,a thick mesoporous ETM layer is generally required.[34]But for the single crystal perovskite with L on the order of micros,the ETM layer is not necessary for the high efficiency cell.The TiO2ETM of the planner structured PSC can be prepared fast by spraying pyrolysis with good crystallinity.[35]

The device performance parameters continuously increase as the doping concentration of ETM increases because of the enhancement of the carrier concentration and conductivity,[36,37]while they do not vary with the mobility of optimization of electron transport layer.We take 3×1019cm?3as the optimum doping concentration for ETM,which is compatible to that in Refs.[38]and[39]and highly efficient semiconducting TiO2can also be obtained by aerosol pyrolysis.[40]The importance of the high doping of the TiO2ETM to match the HTM with high mobility was also investigated systematically in Ref.[17].The J–V curve of the device after the optimization of ETM is illustrated in curve 4 of Fig.1,and Jscof 34.16 mA/cm2,Vocof 0.947 V,FF of 83.95%,and PCE of 27.17%are obtained.

Because the diffusion length L of micrometer magnitude caused by the high mobility(1 cm2/V·s–40 cm2/V·s)of ETM is far beyond the ETM thickness(5 nm–40 nm),the influence of the ETM mobility on device performance is weaker than that of the HTM.

Fig.8.Variations of performance parameters of PSCs with(a)thickness,(b)doping concentration,and(c)mobility of ETM.

3.3.Ultimate optimization of absorption layer

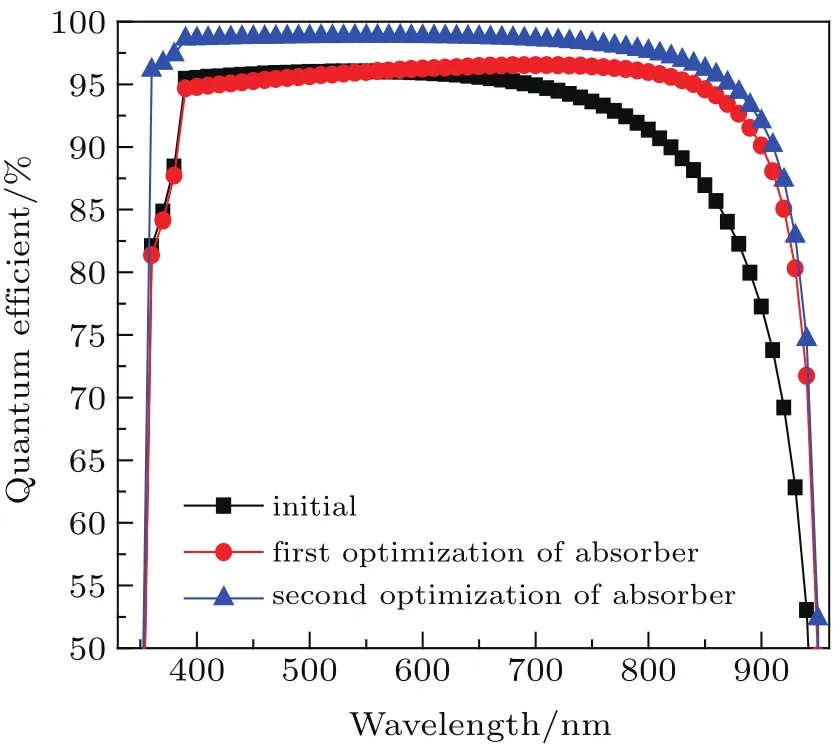

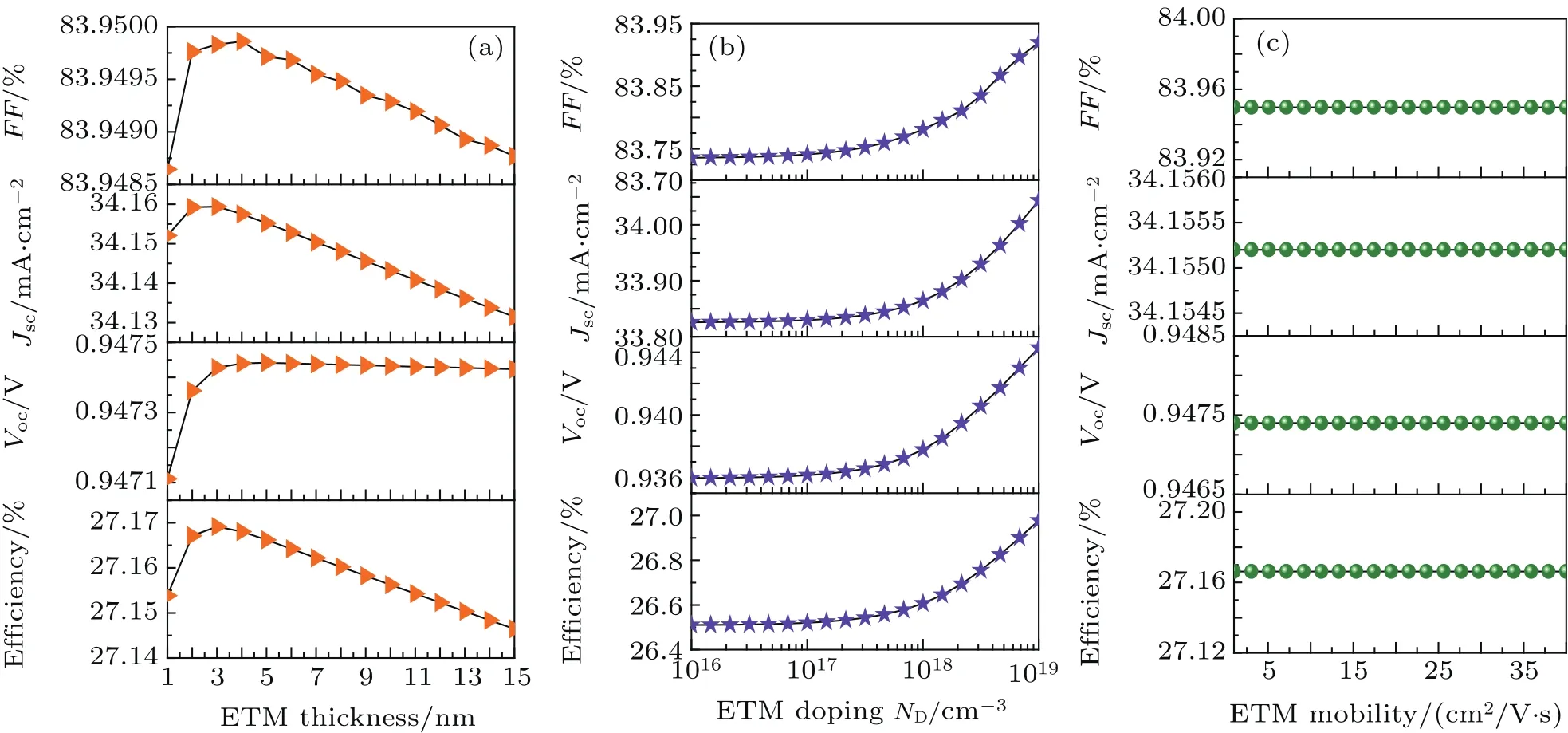

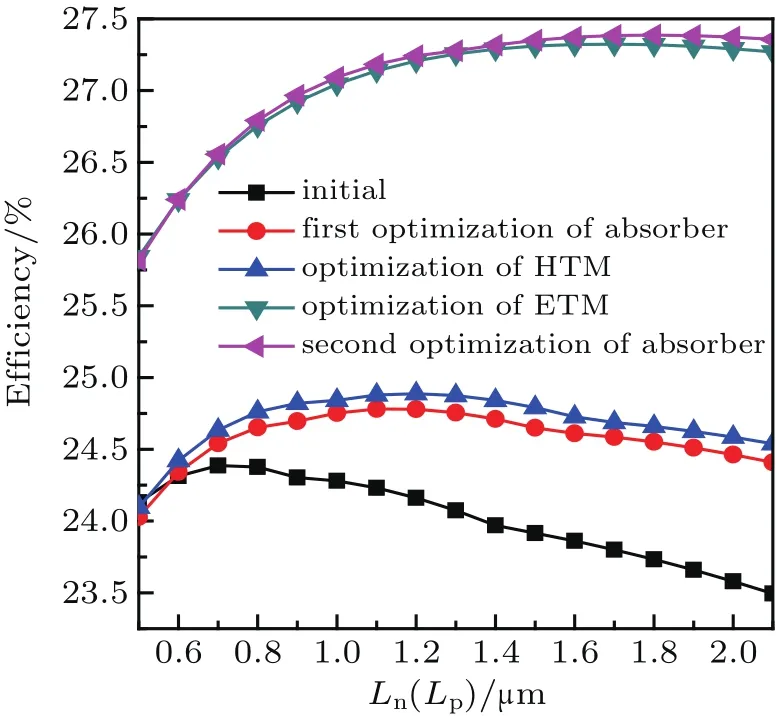

After the preliminary optimization of the absorber and charge transport layer,ultimate optimization of the absorption layer is carried out to access a good match between layers.Figure 9 depicts the relationships between mobility and efficiency of PSCs at diverse thickness values and doping concentrations of the absorber layer.The optimal absorber thickness increases from about 800 nm to 1200 nm whenμrises from 3 cm2/V·s to 12 cm2/V·s,which can be seen from the partially detailed map inset in Fig.9(a)clearly.A similar parabola relation between the absorber mobility and the cell efficiency is exhibited in an organic cell.[18,19]The optimal mobility is small for the thin absorber,and when the mobility of the absorber is higher than 10 cm2/V·s,a thicker absorber is more beneficial to the cell efficiency improvement.This enhancement of the optimal thickness of the absorber is induced by increasing the absorber mobility and the NA,Dof the charge transportation layer,the same change trend is observed in Ref.[41].

Fig.9.Efficiency of PSCs as a function of mobility with(a)thickness and(b)doping concentration of the second optimization of absorber.

However,the excessive thickness and mobility do not achieve higher efficiency(Figs.10(a)and 10(c)),and the efficiency reaches a saturation level at a thickness of 1200 nm.An optimal value of 12 cm2/V·s for the mobility exists with an absorber thickness of 1200 nm.[42]When the doping concentration changes from 1014cm?3to 1016cm?3,the maximum efficiency of the cell appears at NAof 1.2×1016cm?3.The enhancement of the mobility results in the increase of FF and Jsc,while the Vocreduces.The Vocaugments obviously with NAfurther increasing from 8×1015cm?3(preliminary optimization)to 1.2×1016cm?3(ultimate optimization),which is reflected in the J–V curves 2 and 4 in Fig.1,respectively.The change of the optimal value of NAis caused by increasing the optimal value of the thickness and mobility of the absorber.

Fig.10.Plots of PSCs’performance with(a)thickness,(b)doping concentration,and(c)mobility of the second optimization of absorber.

Finally,after the four optimizing steps,the device PCE reaches 27.39%with Jscof 34.21 mA/cm2,Vocof 0.942 V,FF of 84.97%.The efficiency increases by 4.03%compared with the initial one,and this efficiency is highest,to our knowledge,for the single junction PSCs obtained by simulation.The optimal match between the mobility and other parameters of the absorber and the charge transport layer induces the value of Jscand Vocto obviously augment,which can be seen in the J–V characteristic curve(curve 5)of the ultimate optimized cell in Fig.1.

4.Detailed analysis of the influence mechanism of carrier mobility on cell influence

4.1.Effect of mobility on JJsc

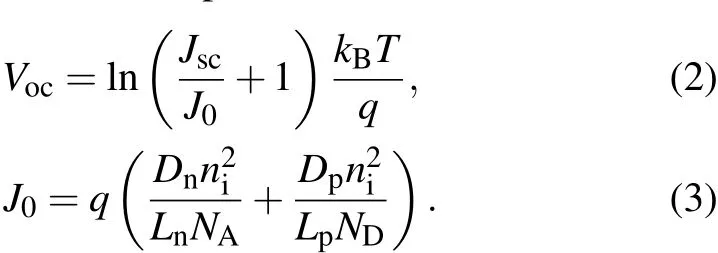

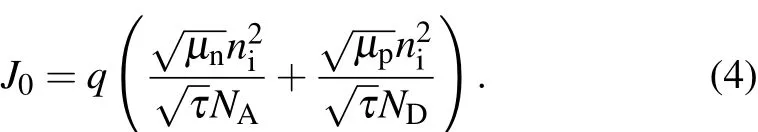

Jsccan be approximated as

The photo-generation rate G can be considered as a constant under certain lighting conditions AM1.5.Depletion width w of the p-n junction depends on carrier concentration. The value of Jscwould ascend with the increase of diffusion length L,because the value of w is unchangeable in the NA,Dinvariable situation(Fig.3(c)).The significant increase of Jscas NA,Dincreases can be seen in Figs.3(c),6,and 8.This happens because the depletion width decreases due to the increase of NA,D,and this can lower the contact resistance of the interface,which is favorable to the transportation of the carriers.

4.2.Effect of mobility on open-circuit voltage VVoooccc

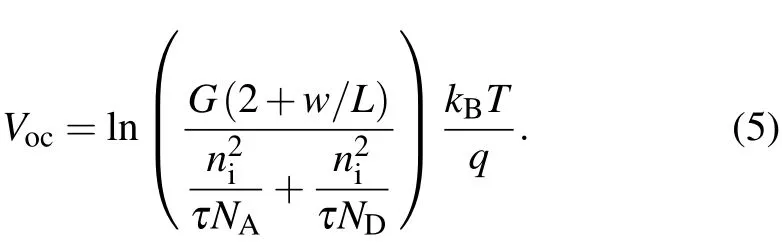

Obvious improvement of Vocis obtained for the optimized cell,and this is the combined influence of doping concentration and the carrier mobility.The formula of Vocand reverse saturation current J0can be expressed as

According to the Einstein relationship and the diffusion length(Ln)formula, Jcan be described as

In our simulation,the lifetime τ can be considered as a constant in the case of invariable defect concentration.The value of J0decreases with the increase of NA,Dof the charge transport layer.Owing to the influence of the strong increase of Jscwith the increase of NA,D,the Vocwill increase based on formula(2).Because of the considerable difference in magnitude between NA,Dandμn,p,the influence of mobility on J0is negligible.

According to formulas(1)–(4),Voccan be expressed as

Keeping the NA,Dconstant,Vocdecreases with the enhancement of diffusion length,that is,Vocdecreases with the enhancement of mobility under the NA,Dinvariable condition(see Fig.3(b)).

4.3.Effect of mobility on other cell parameters

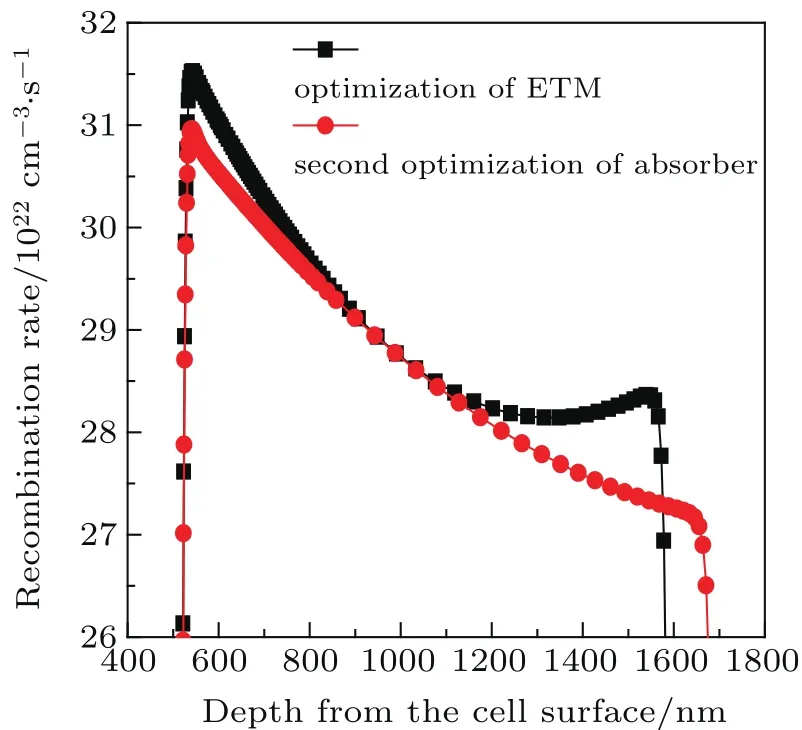

The final part of this article is dedicated to investigating the contribution of mobility to recombination rate R,carrier density distribution,and band structure in planar heterojunction PSCs.The recombination rate of the process of optimization of ETM layer and the second optimization of the absorber layer is depicted in Fig.11.The increasing of doping concentration of the absorber layer from 8×1015cm?3to 1.2×1016cm?3in the last optimization step should cause the recombination rate to increase,while a weakened recombination rate can be seen in Fig.11.

Fig.11.Recombination distributions of different optimizations.

We ascribe the weakening of recombination to the increasing of mobility of the absorber from 5 cm2/V·s to 12cm2/V·s,which improves the transportation performance of the cell.The influence of carrier mobility on the carrier transportation is studied based on the last optimized cell structure through the observation of carrier concentration distribution in the absorber layer with the mobility increasing from 2 cm2/V·s to 40 cm2/V·s(see Fig.12).The empty and the solid symbols represent holes and electrons,respectively.The simulation is conducted based on the final optimization step,with keeping all the parameters constant,except for the enhanced mobility of the absorber.The carriers’concentration of the absorber does not rise consistently with the mobility increase,and the maximum concentration of carriers appears at a mobility of 12 cm2/V·s,which is the optimal value of the mobility in the absorber.The enhanced drift velocity v(v=μE)of the carriers,caused by the improved mobility,can augment the concentration of carriers crossing the cell section,which benefits the cell performance improvement.While the enhanced carrier concentration also increases the recombination rate,and there is a competing mechanism between the improvement of the carrier transportation and the enhanced recombination brought by the enhanced mobility,only an optimal mobility value can improve the cell performance.[43]

Fig.12.Carrier’s density distribution with different mobility values of absorber layer.

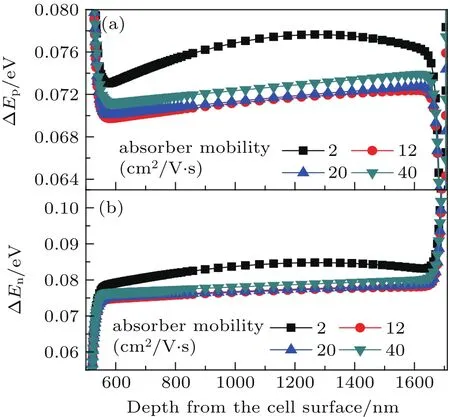

Fig.13.Difference in quasi-Fermi energy(a)?Epand(b)?Enversus depth from cell surface for different mobility values of absorber layer.

The distribution of carriers in a nonequilibrium state is related to quasi-Femi energy.The energy bands of the simulated structure with different absorber mobility values are studied based on the last optimized cell structure,and we obtain the energy difference between the Ev(Ec)and EFp(EFn)(Fig.13).When the energy difference ?Ep(?En)is smaller,the carrier concentration is higher.It can be seen that the electrons(holes)transport from the absorber layer to the ETM(HTM)layer,because of the rapid reduction of the?En(?Ep)at their interface.The fastest decline in?E,namely the fastest growing of the carrier concentration,appears at the architecture with a mobility of 12 cm2/V·s,which means the fastest transportation of the carriers.So the mobility of 12 cm2/V·s is an optimal value of our simulated structure with the highest efficiency of 27.39%.

Fig.14.Plots of efficiency of PSC versus carrier diffusion length L during optimization.

4.4.How long carrier diffusion length is enough to achieve high cell efficiency?

Getting a long diffusion length by improving perovskite process can enhance cell efficiency.[16]Diffusion length L of single CH3NH3PbI3crystal has reached 175μm.[44]Now,a question arises:can the longer L achieve the better performance of the PSCs?In this paper,L is adjusted by changing the mobility,with the defect concentration of the absorber unchanged.The efficiency of the cell with the changing of L at the different optimization steps in the paper is shown in Fig.14.The length L of 0.7μm is enough to construct the initial cell with a small absorber thickness(600 nm),and this thickness value is consistent with those for most of the PSCs with high efficiency in the experimental research.The appropriate L rises with the increase of thickness and mobility of the absorber.[38]Finally,the highest efficiency appears at L of 1.9μm,which is larger than the absorber thickness of 1200 nm.Many researchers have pointed out that L of 1μm is enough to construct the cell device,but this conclusion is obtained under specified circumstances,such as the thickness of the absorber is about hundreds of nanometers.In Ref.[6],L(1.2 μm)is twice the CH3NH3PbI3?xClxabsorber thickness(500 nm).The L higher than the absorber thickness in the perovskite is needed for efficient carriers’extraction before significant recombination occurs.The Jscis limited by the material’s long wavelength response,and the higher absorber thickness benefits the strong red spectral absorption.[28,43]In Fig.2,the trends of Jsc,and Vocvarying with absorber thickness are opposite,which can be seen asμ >10 cm2/V·s.Improving L(namely,mobility)of the perovskite material can avoid the joint reduction of Jscand Vocwhen the absorber layer thickness increases.

Many researchers have indicated that the PCE of the PSCs is insensitive to the absorber thickness beyond 600 nm,this lies in the fact that the recombination rate of the thicker perovskite layer is higher than that of the thinner layer.In the research by Jeon et al.,[3]the PSC reached a high efficiency of 23.2%.The absorber thickness is selected to be 600 nm to avoid the carriers crossing the grain boundaries during transporting to the electrodes.We expect that if the crystal size presented in Joen et al.’s research[3]can be improved to 1 μm and an absorber thicker than 600 nm can be obtained,the cell efficiency can be further improved based on our simulation.Now the single perovskite crystal with a size of 300μm has been achieved in experiment.[44]High-performance PSC with absorber layer thickness of 1150 nm has been realized by the hot casting method.[42]And more importantly,the thick- film PSC has good stability.This research bodes well for the great potential of thick- film PSCs in mass-produce of PSCs.

The relatively undoped(Sn4+-free)and pinhole-free CH3NH3SnI3perovskite films and the near-single-crystalline FASnI3film have been fabricated.[22,45–47]If the background doping of CH3NH3SnI3can decrease to 1015cm?3,then L can reach to micrometers.With the advance in preparation technology,lead-free perovskite materials with low defect and longer diffusion can be achieved.

5.Conclusions

The effects of the carrier mobility and diffusion length on the PSC’s performance are studied systematically with the device simulation.A similar parabolic relationship between the mobility of absorber and the efficiency for PSC to that for the organic solar cell is observed and there also exists an optimal mobility of the absorber.Diffusion length longer than 1 μm is also beneficial to the PSCs’performance when the absorber is thick and has high crystalline quality.The improved carrier mobility of the absorber and the HTM appropriately is favorable to the reduction of the recombination rate and the improvement of the carrier transportation,which can avoid the joint reduction of Jsc,and Vocwhen the absorber layer thickness increases,and these can improve the cell’s efficiency.The doping of the carrier transport layer has a significant role in improving the cell performance.Finally,we obtain the Jscof 34.21 mA/cm2,Vocof 0.942 V,FF of 84.97%,and PCE of 27.39%in our cell structure with an absorber thickness of 1200 nm,a high mobility of 12 cm2/V·s,and long diffusion length of 2μm.Using the hot casting method to realize high quality perovskite films may be a promising method to realize the high efficiency PSCs with thick absorber and high stability.

[1]Kim H S,Lee C R,Im J H,Lee K B,Moehl T,Marchioro A,Moon S J,Humphry-Baker R,Yum J H,Moser J E,Gratzel M and Park N G 2012 Sci.Rep.2 591

[2]Lee M M,Teuscher J,Miyasaka T,Murakami T N and Snaith H J 2012 Science 338 643

[3]Jeon N J,Na H,Jung E H,Yang T Y,Lee Y G,Kim G,Shin H W,Seok S I,Lee J and Seo J 2018 Nat.Energy 3 682

[4]Baikie T,Fang Y,Kadro J M,Schreyer M,Wei F,Mhaisalkar S G,Graetzel M and White T J 2013 J.Mater.Chem.A 1 5628

[5]Phillips L J,Rashed A M,Treharne R E,Kay J,Yates P,Mitrovic I Z,Weerakkody A,Hall S and Durose K 2016 Sol.Energy Mater.Sol.Cells 147 327

[6]Stranks S D,Eperon G E,Grancini G,Menelaou C,Alcocer M J,Leijtens T,Herz L M,Petrozza A and Snaith H J 2013 Science 342 341

[7]Zhao Y,Nardes A M and Zhu K 2014 J.Phys.Chem.Lett.5 490

[8]Takahashi Y,Hasegawa H,Takahashi Y and Inabe T 2013 J.Solid State Chem.205 39

[9]Ponseca C S,Jr.,Savenije T J,Abdellah M,Zheng K,Yartsev A,Pascher T,Harlang T,Chabera P,Pullerits T,Stepanov A,Wolf J P and Sundstrom V 2014 J.Am.Chem.Soc.136 5189

[10]Huang L,Sun X,Li C,Xu R,Xu J,Du Y,Wu Y,Ni J,Cai H,Li J,Hu Z and Zhang J 2016 Sol.Energy Mater.Sol.Cells 157 1038

[11]Fu K,Zhou Q,Chen Y,Lu J and Yang S E 2015 J.Opt.17 105904

[12]Zhou Y and Gray-Weale A 2016 Phys.Chem.Chem.Phys.18 4476

[13]Da Y,Xuan Y and Li Q 2018 Sol.Energy Mater.Sol.Cells 174 206

[14]Sheikh A D,Bera A,Haque M A,Rakhi R B,Gobbo S D,Alshareef H N and Wu T 2015 Sol.Energy Mater.Sol.Cells 137 6

[15]Minemoto T and Murata M 2014 J.Appl.Phys.116 054505

[16]Kour N,Mehra R and Chandni 2018 Chin.Phys.B 27 018801

[17]Adhikari K R,Gurung S,Bhattarai B K and Soucase B M 2016 Phys.Status Solidi C 13 13

[18]Mandoc M M,Koster L J A and Blom P W M 2007 Appl.Phys.Lett.90 133504

[19]Deibel C,Wagenpfahl A and Dyakonov V 2008 Phys.Status Solidi-Rapid Res.Lett.2 175

[20]Ram′?rez O,Cabrera V and Res′endiz L M 2014 Opt.Quantum Electron.46 1291

[21]Shieh J T,Liu C H,Meng H F,Tseng S R,Chao Y C and Horng S F 2010 J.Appl.Phys.107 084503

[22]Du H J,Wang W C and Zhu J Z 2016 Chin.Phys.B 25 108802

[23]Manser J S,Christians J A and Kamat P V 2016 Chem.Rev.116 12956[24]He Y and Galli G 2017 Chem.Mater.29 682

[25]Jiang C S,Yang M,Zhou Y,To B,Nanayakkara S U,Luther J M,Zhou W,Berry J J,Lagemaat J,Padture N P,Zhu K and Al-Jassim M M 2015 Nat.Commun.6 8397

[26]Yang G,Ding B,Li Y,Huang S,Chu Q,Li C and Li C 2017 J.Mater.Chem.A 5 6840

[27]Tan H,Jain A,Voznyy O,Lan X,Arquer F P G,Fan J Z,Bermudez R Q,Yuan M,Zhang B,Zhao Y,Fan F,Li P,Quan L N,Zhao Y,Lu Z H,Yang Z,Hoogl,S and Sargent E H 2017 Science 355 722

[28]Shirayama M,Kadowaki H,Miyadera T,Sugita T,Tamakoshi M,Kato M,Fujiseki T,Murata D,Hara S,Murakami T N,Fujimoto S,Chikamatsu M and Fujiwara H 2016 Phys.Rev.Appl.5 014012

[29]Albrecht S,Saliba M,Correa-Baena J P,J¨ager K,Korte L,Hagfeldt A,Gr¨atzel M and Rech B 2016 J.Opt.18 064012

[30]Alnuaimi A,Almansouri I and Nayfeh A 2016 J.Comput.Electron.15 1110

[31]Abate A,Leijtens T,Pathak S,Teuscher J,Avolio R,Errico M E,Kirkpatrik J,Ball J M,Docampo P,McPherson I and Snaith H J 2013 Phys.Chem.Chem.Phys.15 2572

[32]Leijtens T,Lim J,Teuscher J,Park T and Snaith H J 2013 Adv.Mater.25 3227

[33]Toshniwal A,Jariwala A,Kheraj V,Opanasyuk A S and Panchal C J 2017 J.Nano-Electron.Phys.9 03038

[34]Edri E,Kirmayer S,Henning A,Mukhopadhyay S,Gartsman K,Rosenwaks Y,Hodes G and Cahen D 2014 Nano Lett.14 1000

[35]Liu X,Bu T,Li J,He J,Li T,Zhang J,Li W,Ku Z,Peng Y,Huang F,Cheng Y B and Zhong J 2018 Nano Energy 44 34

[36]Zhang H,Shi J,Xu X,Zhu L,Luo Y,Li D and Meng Q 2016 J.Mater.Chem.A 4 15383

[37]Liu D,Li S,Zhang P,Wang Y,Zhang R,Sarvari H,Wang F,Wu J,Wang Z and Chen Z D 2017 Nano Energy 31 462

[38]Zhou Q,Jiao D,Fu K,Wu X,Chen Y,Lu J and Yang S E 2016 Sol.Energy 123 51

[39]Iftiquar S M and Yi J 2018 Mater.Sci.Semicond.Process 79 46

[40]Kavan L and Gr¨atzel M 1995 Electrochim.Acta 40 643

[41]Momblona C,Malinkiewicz O,Rold′an-Carmona C,Soriano A,Gil-Escrig L,Bandiello E,Scheepers M,Edri E and Bolink H J 2014 APL Mater.2 081504

[42]Chen J,Zuo L,Zhang Y,Lian X,Fu W,Yan J,Li J,Wu G,Li C Z and Chen H 2018 Adv.Energy Mater.8 1800438

[43]Chiang C H and Wu C G 2016 Nat.Photon.10 196

[44]Dong Q,Fang Y,Shao Y,Mulligan P,Qiu J,Cao L and Huang J 2015 Science 347 967

[45]Koh T M,Krishnamoorthy T,Yantara N,Shi C,Leong W L,Boix P P,Grimsdale A C,Mhaisalkar S G and Mathews N 2015 J.Mater.Chem.A 3 14996

[46]Bansode U,Naphade R,Game O,Agarkar S and Ogale S 2015 J.Phys.Chem.C 119 9177

[47]Shao S,Liu J,Portale G,Fang H H,Blake G R,ten Brink G H,Koster L J A and Loi M A 2018 Adv.Energy Mater.8 1702019

- Chinese Physics B的其它文章

- Plasma electrolytic liquefaction of sawdust?

- Insight into band alignment of Zn(O,S)/CZTSe solar cell by simulation?

- Effect of terahertz pulse on gene expression in human eye cells?

- Ultraviolet photodetectors based on wide bandgap oxide semiconductor films?

- A primary model of decoherence in neuronal microtubules based on the interaction Hamiltonian between microtubules and plasmon in the neurons

- Effect of temperature on photoresponse properties of solar-blind Schottky barrier diode photodetector based on single crystal Ga2O3?