Unique Outcomes of Internal Heat Generation and Thermal Deposition on Viscous Dissipative Transport of Viscoplastic Fluid over a Riga-Plate

Z.Iqbal,Ehtsham Azhar,Zaffar Mehmood,and E.N.Maraj

Department of Mathematics,Faculty of Sciences,HITEC University Taxila,Pakistan

1 Introduction

Radiation effects on flow and heat transfer is very important in the scaffold of space technology and processes involving high temperature.Visible light and infrared light emitted by an incandescent light bulb,the infrared radiation emitted by animals that is detectable with an infrared camera,and the cosmic microwave background radiation are some examples of thermal radiation.In manufacturing industries radiative heat transfer flow is very signi ficant for depiction of reliable equipment,nuclear power plants,gas turbines and different propulsion devices for satellites,missiles,aircraft and space vehicles.Viscous and non-Newtonian fluids through various aspects and thermal radiation have been examined by many researchers.Pramanik[1]discussed numerical solutions for steady boundary layer flow and heat transfer for a Casson fluid over an exponentially permeable stretching surface in the presence of thermal radiation.He concluded that temperature as well as thermal boundary layer enhances due to thermal radiation.Hydromagnetic mixed convection heat and mass transfer flow of an incompressible Boussinesq fluid past a vertical porous plate with constant heat flux and thermal radiation is analyzed by Makinde.[2]The effects of thermal radiation over a stretching sheet under different flow geometries have been reported by several researchers.[3?5]

Impact of viscous dissipation is usually neglected but its presence become noteworthy when liquid viscosity is high.It changes the temperature distributions by playing a role like an energy source,which leads to affect heat transfer rates.Viscous dissipation is of interest for several applications such as notable temperature rises are witnessed in polymer processing,injection molding or extrusion at high rates.The effect of viscous dissipation was initially considered by Brickman.[6]According to him temperature distribution of Newtonian fluid in straight circular tube and interprets result that the effects were produced in the close region.Chandet al.[7]studied effects of viscous dissipation and radiation on unsteady flow of electrically conducting fluid through a porous stretching surface.He examined that Eckert number boost temperature pro file.Hayatet al.[8]presented MHD stagnation point flow of Jeffrey fluid by a radially stretching surface with viscous dissipation and Joule heating.Hayatet al.,[9]Barik and Dash[10]also studied the flow of Newtonian fluid under the combined effects of thermal radiation and viscous dissipation.Some notable recent articles are cited in Refs.[11–19]and many therein.In nature,some non-Newtonian fluids behave like elastic solid that is,no flow occurs with small shear stress.Casson fluid is one of such fluids.The examples of Casson fluid are of the type as follows:jelly,tomato sauce,honey,soup and concentrated fruit juices.Human blood can also be treated as Casson fluid.In 1959,Casson introduced this fluid model for the prediction of flow behavior of pigment-oil suspensions.[20]Animasaun[21]has studied MHD dissipative Casson fluid flow with suction andn-th order of chemical reaction.He depicts that temperature and concentration are decreasing function of Casson fluid parameter.Nadeemet al.[22]put his contribution on Casson fluid past a linearly stretching sheet with convective boundary condition.Casson fluid model under different circumstances like thermal radiation,slip condition etc.is studied by many researchers(see Refs.[23–25]).

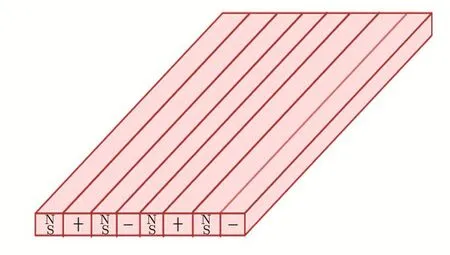

All of the above studies on Casson fluid had reported the boundary layer flow over stretching sheet in the absence of electrically conducting fluids over a Riga plate.This plate is used to produce magnetic field due to which Lorentz force is generated which controls the fluid flow.Riga plate is electromagnetic plate consisting of periodic pairs of electrodes proposed by Gailitis and Lielausis.[17]After identifying Lorentz force theoretically[26]and experimentally[27]as a resourceful mediator to reduce the skin friction;few recent studies of laminar fluid flow over a Riga plate has been reported.Pantokratoras and Magyari[28]explained EMHD free-convection boundary-layer flow from a Riga-plate.Later on,aiding and opposing mixed convection flows over the Rigaplate was investigated by Magyari and Pantokratoras.[29]Pantokratoras[30]considered Sakiadis and Blasius flow for Riga-plate by using finite difference method.

After reviewing above literature,it predicts that effect of viscous dissipation and thermal radiation for Casson lf uid over an electrically conducted Riga plate incorporating with stagnation point has not been considered.Keeping this in mind,in present article we have studied the in fluences of viscous dissipation on boundary layer flow of a Casson fluid over a Riga plate in presence of activation energy near a stagnation point.Governing nonlinear ordinary differential equations are then solved by using finite difference approach named as Keller-Box scheme.To validate proposed scheme results comparison is provided with well establish,stable numerical procedure.

2 Problem Formulation and Governing Equations

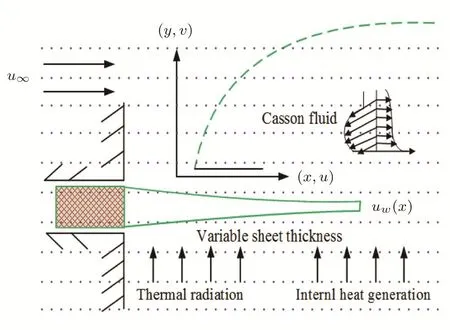

Present article focuses on study steady state,incompressible,two-dimensional flow of an electrically conducting Casson fluid over a stretchable Riga-plate.The plate is considered to have variable thicknessδ,such that thickness is small relative to plate length.It is worth mentioning here that an alternate arry of electrodes and permanent magnets fixed on a plane surface constructs a Riga-plate(see Fig.1).In addition,heat transfer phenomenon is examined under the in fluence of viscous dissipation and thermal radiation.Temperature at the wallTwand ambient temperatureT∞are taken to be constant. Moreover,free stream velocity is taken to beUe(x)=U∞(x+b)nand sheet is assumed to be stretched with velocityUw(x)=U0(x+b)n,whereU∞,U0>0 are dimensional constants.Schematic diagram for both stretching and boundary-layer flows is presented in Fig.2.

Fig.1 Riga plate.

Fig.2 Physical flow diagram.

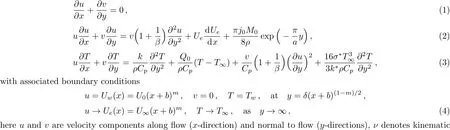

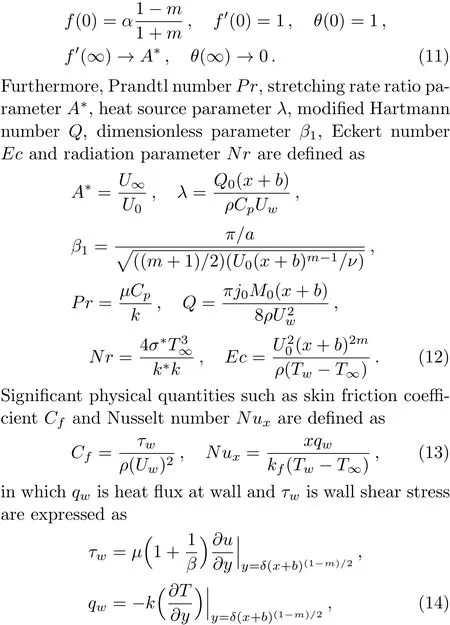

Now,governing boundary layer equations(see Refs.[23],[30],and[31])of stagnation-point flow and heat transfer with internal heat generation of Casson fluid over Riga-plate are:

whereas corresponding boundary conditions become

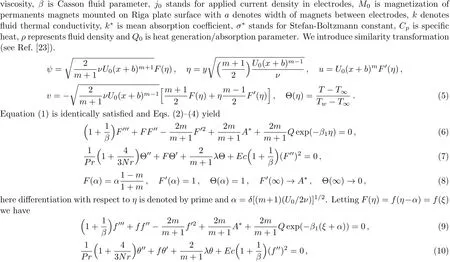

after applying similarity variables above expressions take the form:

3 Computational Scheme and Accuracy

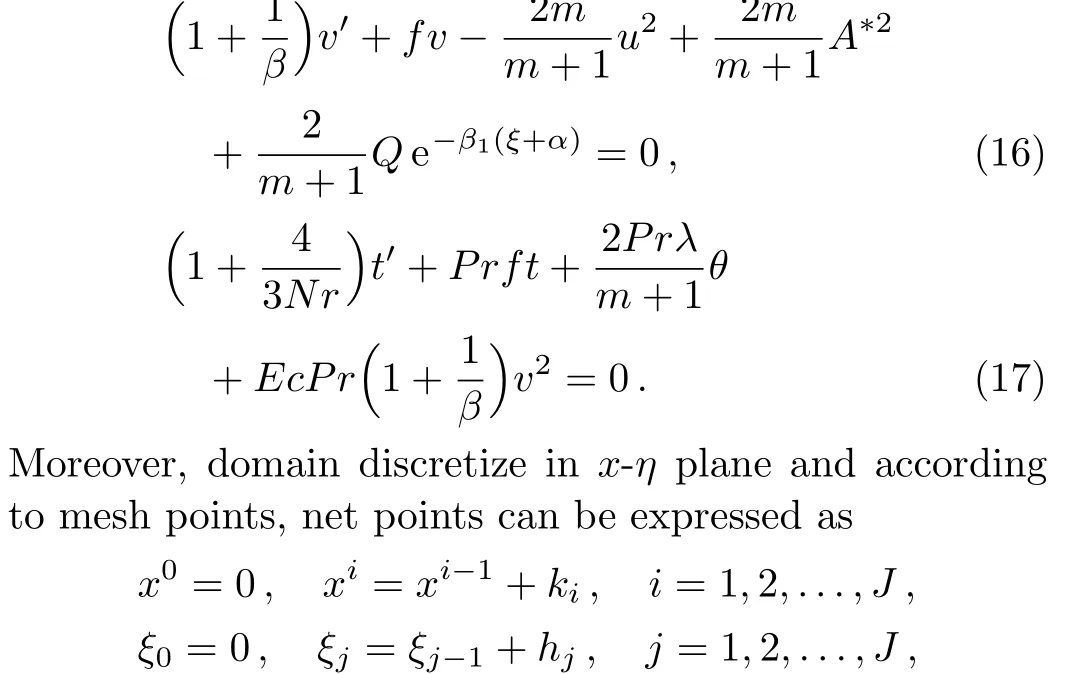

In order to solve nonlinear system(9)and(10)subject to boundary conditions(11),Keller box technique has been applied by incorporating new independent variablesu(x,ξ),v(x,ξ)andt(x,ξ)such thatf′=u,u′=vandθ′=t,so that Eqs.(9)–(10)simplify to first order ODE i.e.

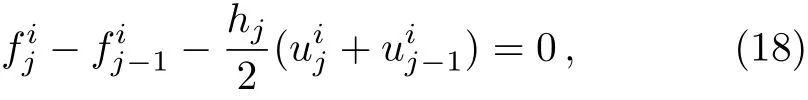

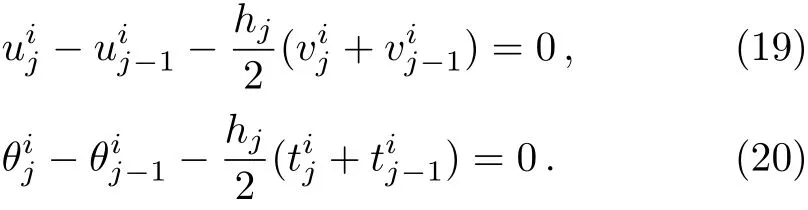

wherekiandhjare the?xand?ξ-spacing.Hereiandjare just sequences of numbers that indicate the coordinate location.Using central difference formulation at midpoint(xi,ξj?1/2)we arrived at

Block tri-diagonal matrix is solved by means ofLUfactorization.The value ofδis calculated repeatedly until

is attained where?1=10?6is small prescribed value.

4 Theoretical Results Description

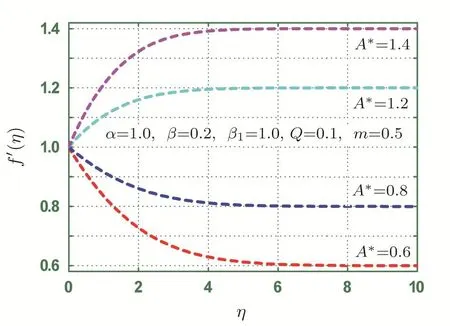

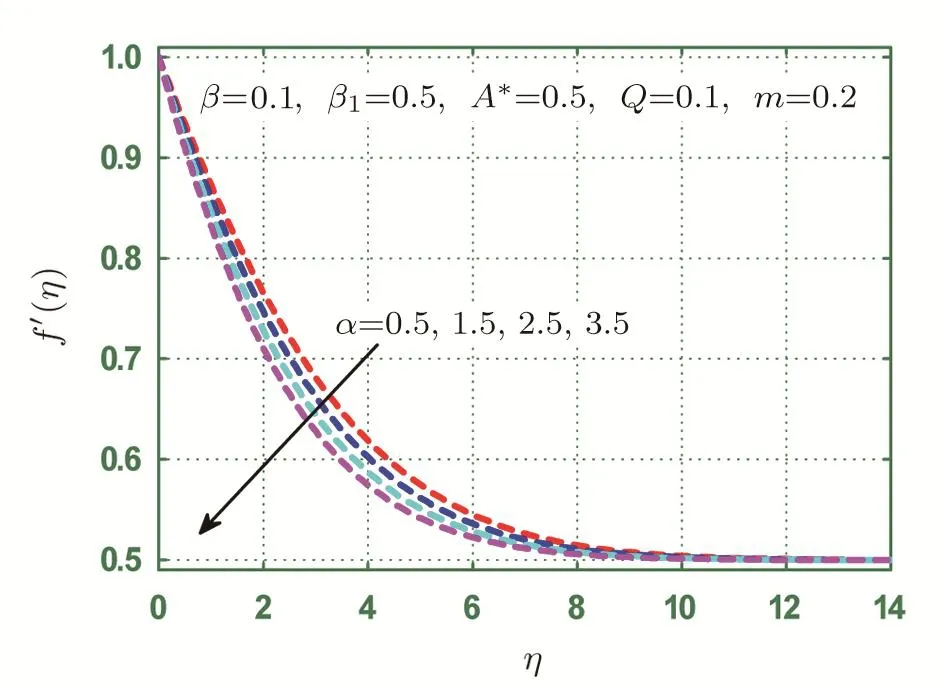

This section provides detailed study on graphical aspects of velocityf′(η)and temperatureθ(η)pro files for noteworthy parameters.Figure 3 demonstrates behavior of Casson fluid velocity for stretching parameterA?.It is revealed that an inverted boundary layer appeared forA?<1 andA?>1.Moreover,thickness of boundary layer decreases with increase inA?<1.Internal forces like adhesive forces contribute in lowering velocity of fluid.Wall thickness maximizes these forces acting on fluid and hence velocity decreases.The effect of wall thickness parameterαon velocity pro file is displayed in Fig.4.From this diagram it is depicted that velocity falls as wall thickness parameterαincreases.Moreover,viscous boundary layer thickness has no remarkable affects with an increas-ing value ofαhowever,thickness decays for higher values ofα.

Fig.3 Variation of A? on

Fig.4 Variation of α on

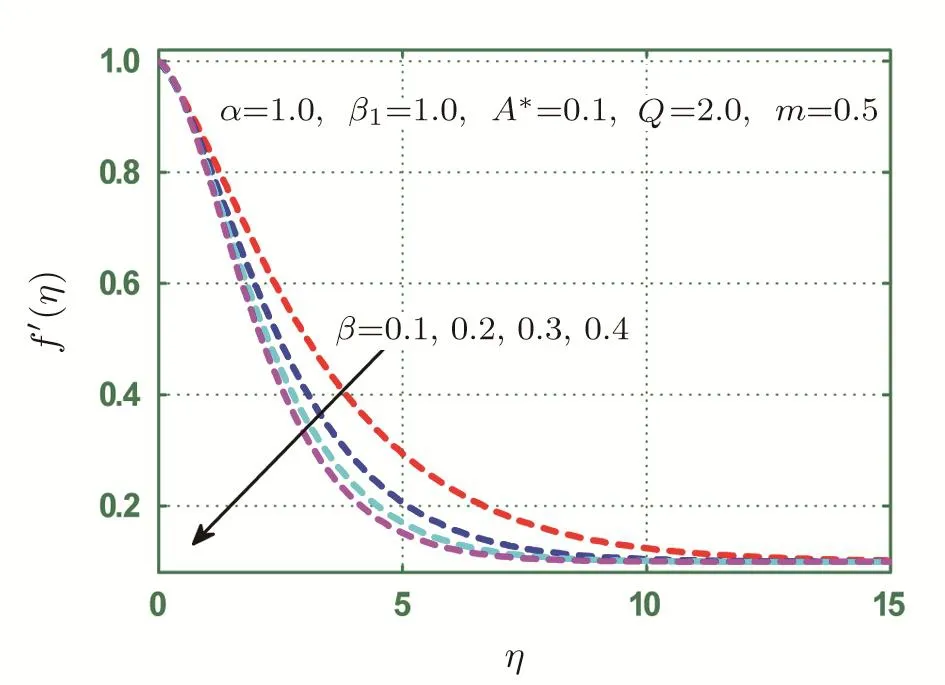

Fig.5 Variation of β on

Figure 5 demonstrates variation of velocityfor various values of fluid parameterβ.Flow velocity depends directly on yield stress.Fluid parameter adds in reducing yield stress for its greater values.Due to this fact velocityand associated momentum boundary layer thickness diminishes signi ficantly with rise of fluid parameterβ.

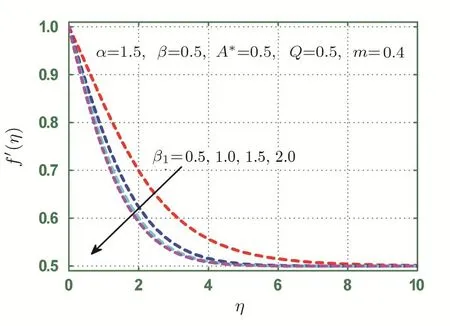

Fig.6 Variation of β1on

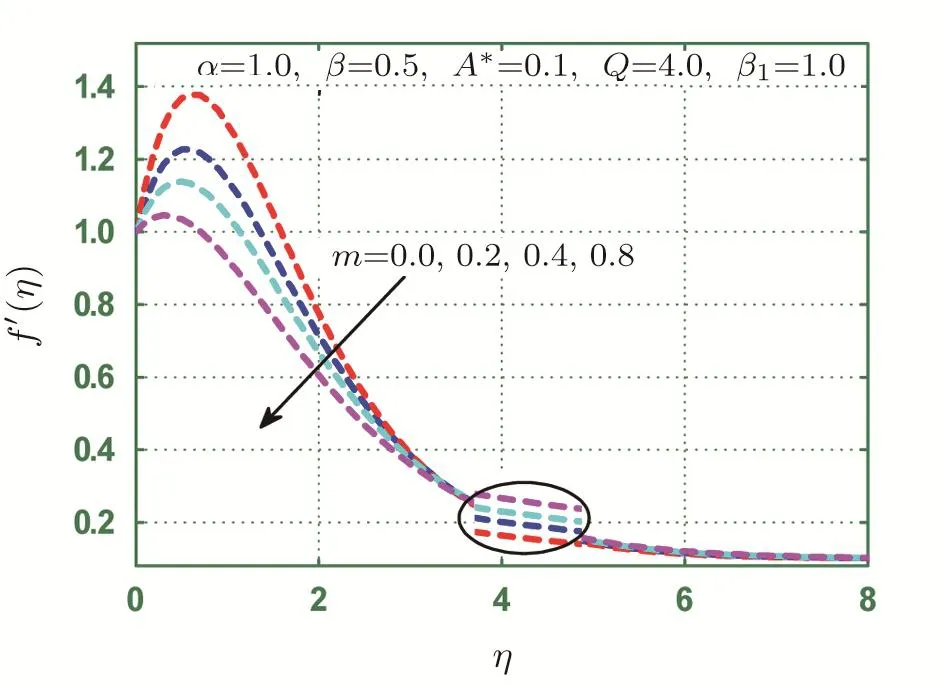

Fig.7 Variation of m on

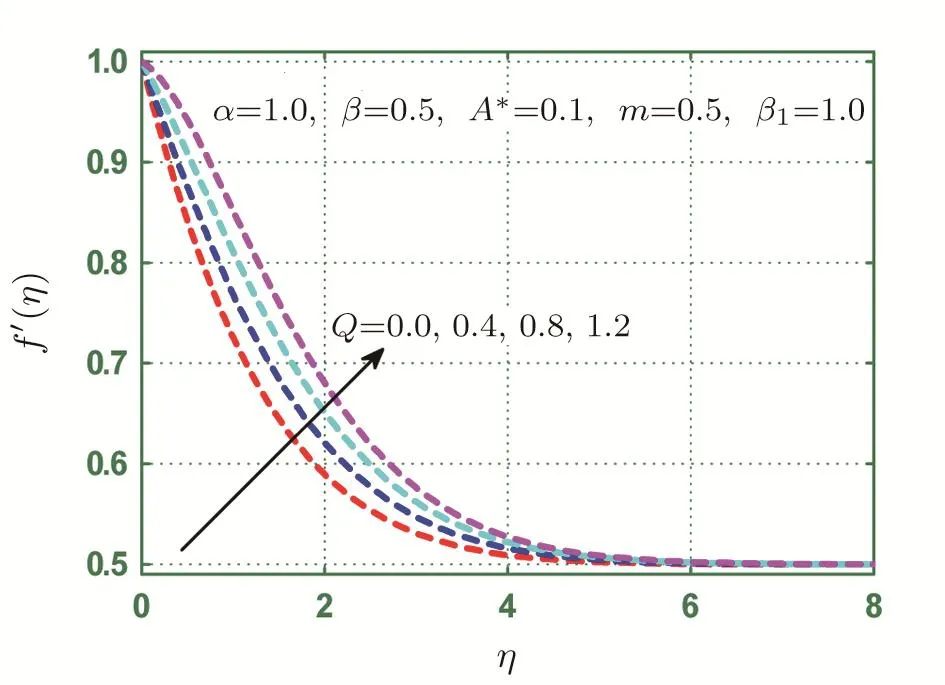

Fig.8 Variation of Q on f′(η).

Physical analysis of velocitypro file for dimensionless parameterβ1is given in Fig.6.It is obvious that fluid velocity declines with mount in value ofβ1.It is also viewed that viscous boundary layer descends with ascending values ofβ1.Figure 7 exhibits behavior of power indexmon velocitydistribution.This analysis reveals that with an increase in value ofm,drops near sheet and opposite trend is observed far from sheet.The fact is that power indexmcontributes in varying stretching velocity positively and hence fluid behavior is ultimately changed,so for growing values ofm,flow velocity at and near sheet boosts.Electric field strength contributes in varying magnetic behavior in flow field.This results in modifying flow pattern.On increasing external electric force field,Hartmann/magnetic numberQlessens which results in enhancing velocity distribution.Impact of modi fied Hartmann numberQon velocityis shown in Fig.8.Heat transfer depends on thickness of wall.The thicker wall results in less heat transfer in it.

Fig.9 Variation of α on θ(η).

Fig.10 Variation of β on θ(η).

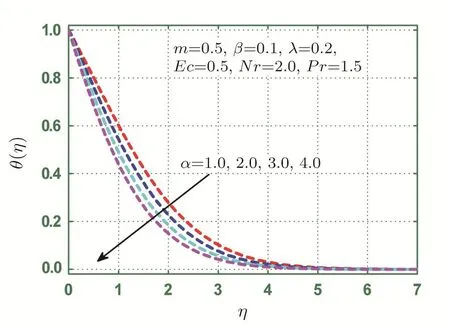

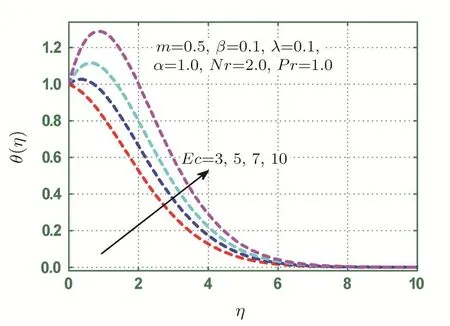

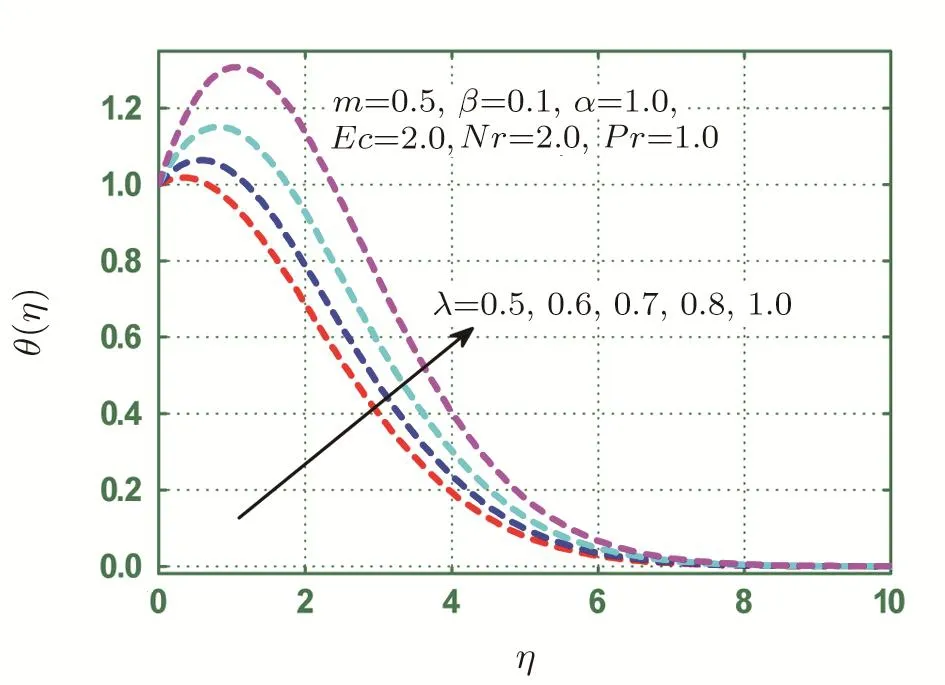

Figure 9 portraits temperatureθ(η)with variation of wall thickness parameterα.Temperature distribution is almost self-governing of Casson parameter in several cases.For higher values ofβ,it results in raise temperature of fluid.Plot of temperature distributionθ(η)for fluid parameterβis displayed in Fig.10.Eckert number is an illustration of heat dissipation in flow. Kinetic energy of flow is increased for increasing values of Eckert number and therefore,temperature rises.The impact of Eckert number Ec on temperature pro fileθ(η)is sketched in Fig.11.Temperatureθ(η)is an increasing function of heat source parameterλ.By de finition,λis a source to provide heat to the system.

Fig.11 Variation of Ec on θ(η).

Fig.12 Variation of λ on θ(η).

Fig.13 Variation of m on θ(η).

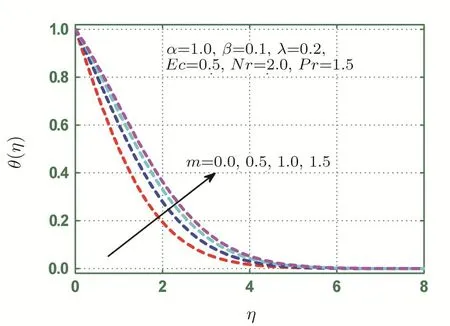

It results in increasing thermal energy of fluid,so temperature enhances with greater values of heat source parameterλ.This fact is analyzed through Fig.12.Influence of power indexmon temperature pro fileθ(η)is discussed in Fig.13.On increasing stretching velocity,kinetic energy of fluid grows signi ficantly which enhances heat transfer rate.Because of this,temperature and associated thermal boundary layer grows up for higher values ofm.

Fig.14 Variation of Nr on θ(η).

Fig.15 Variation of Pr on θ(η).

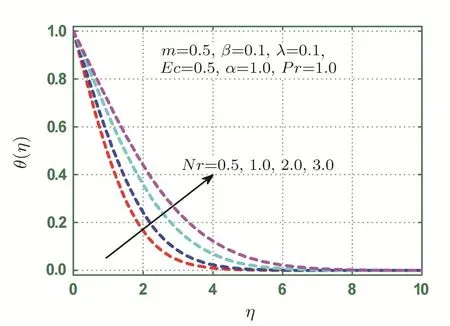

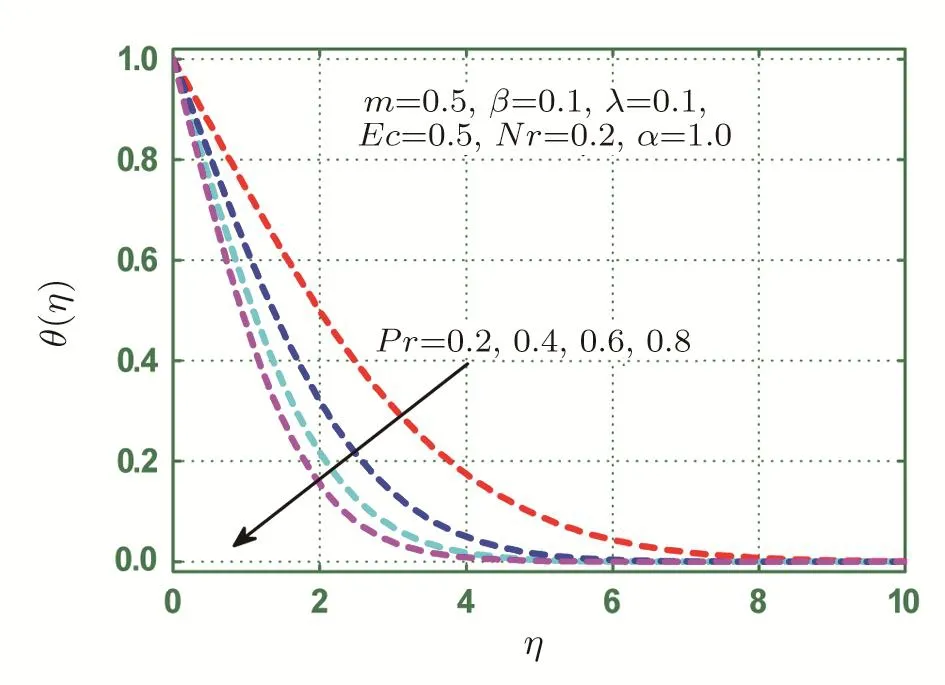

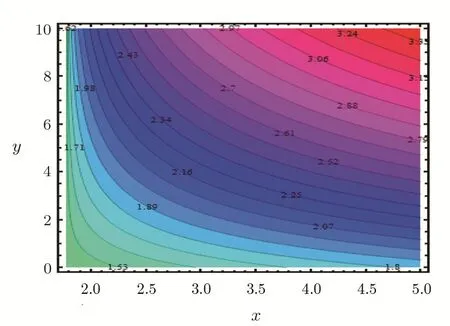

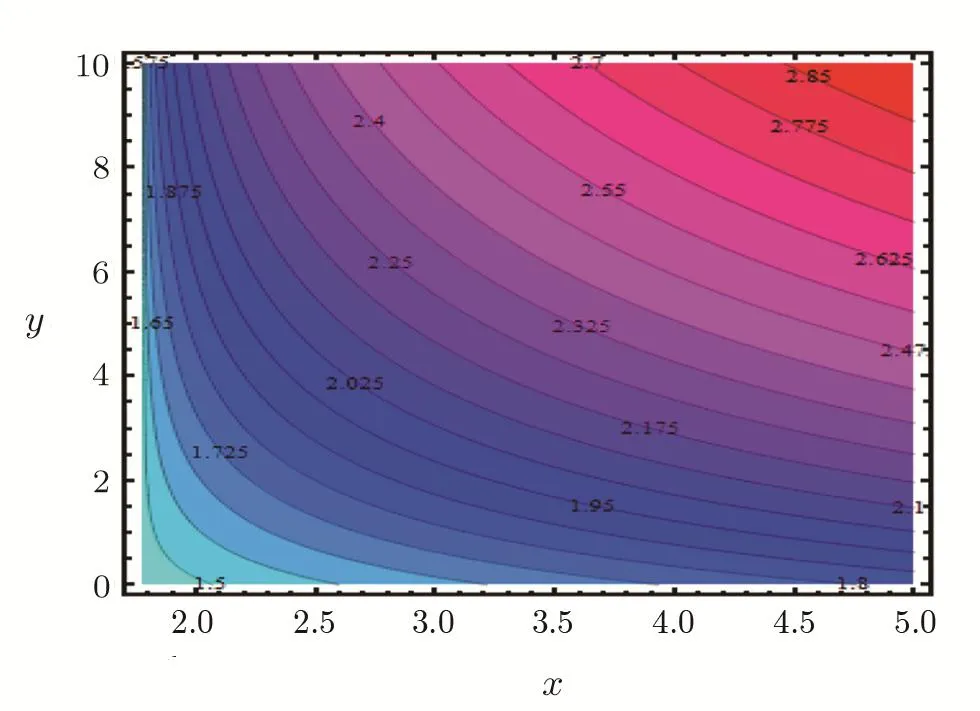

Radiation parameter ampli fies fluid thermal capability.Hence temperature rises with thermal radiation parameter Nr as shown in Fig.14.Prandtl numberPris inversely associated to thermal diffusivity of fluid and accordingly fall downs temperature distribution.Prcontributes in lowering temperatureθ(η)of fluid.Figure 15 is a graphical representation of this fact.Figures 16 and 17 represent the streamlines for various values ofβ1and show the Casson fluid flow pattern.

Fig.16 Stream pattern when β1=0.0.

Fig.17 Stream pattern when β1=0.2.

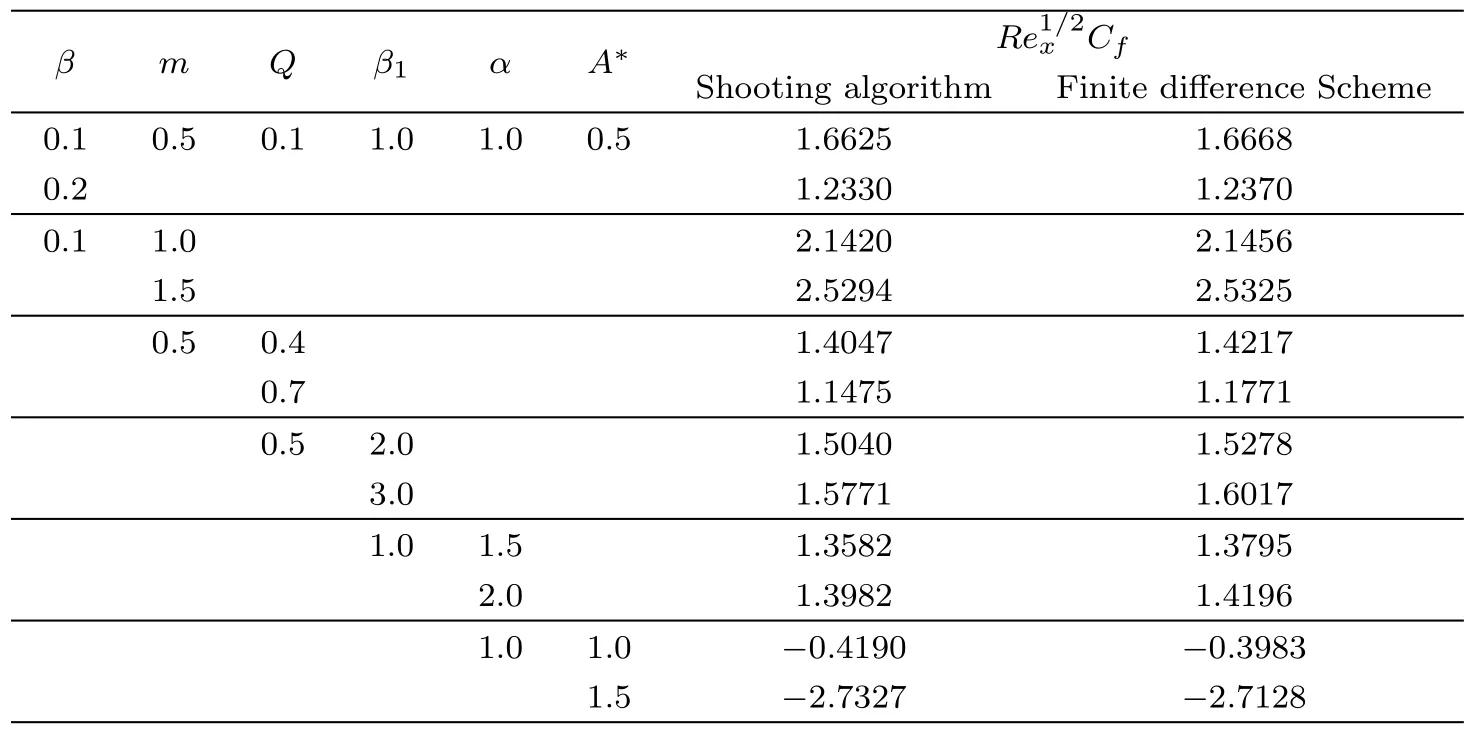

Table 1 Tabulated skin friction values for distinct values of several parameters.

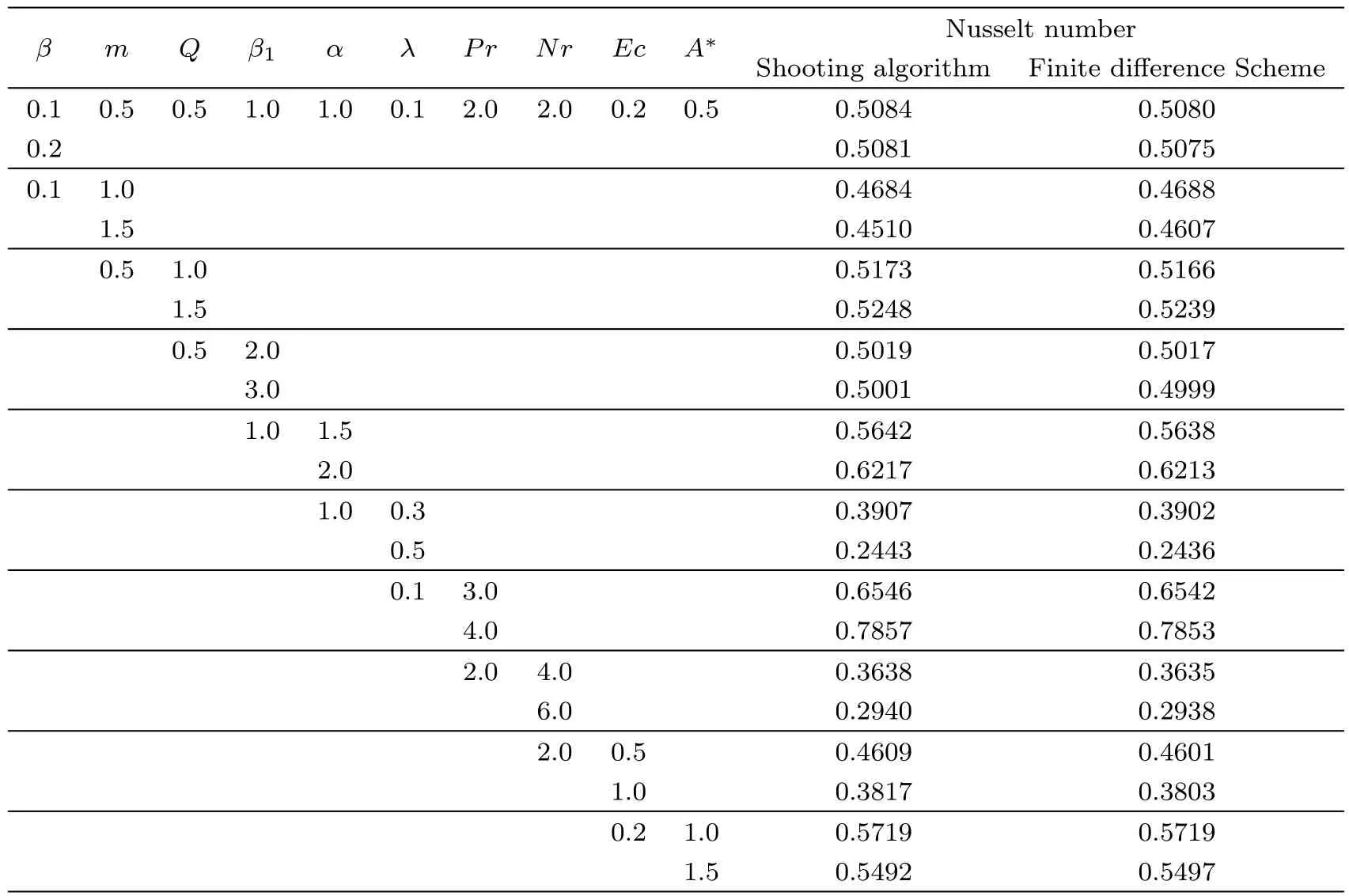

Further Table 1 presents numerical results of rate of shear stress at surface for several in fluential parameters.We suggest from this tabulated outcomes that magnitude of skin friction coefficient increases with an increase inm,β1,andα.It can be observed that fluid parameter and Hartmann numbers result in lessening stress rate at surface.Table 2 shows heat transfer rate with respect to pertinent parameters.It is obvious from this table thatPr,αandQrelated directly with Nusselt numberNuxand inversely related to indexm,fluid parameterβ,stretching parameterA?radiation parameter Nr and Eckert number Ec.

Table 2 Numerical values of local heat flux for notable parameters.

5 Summary and Novelty of Article

Boundary layer stagnation point Casson flow problem in fluenced by thermal radiation and viscous dissipation is investigated over a Riga plate of variable thickness.Governing physical problem is tackled numerically using Keller Box Method.Moreover,a comparative numerical analysis is drawn with shooting method.This analysis will help in developing more understanding to boundary layer flow over an electromagnetic plate for viscoelastic fluids.Such type of problems are encounter in electronic and electric devices manufacturing.Graphical and numerical results are shown for various pertinent parameters on velocity and temperature distribution.It is concluded that velocityskin frictionCfand rate of heat fluxNuxis a decreasing function of Casson rheological parameterβand distribution of temperatureθ(η)grows up withβ.Further,Eckert number contributes in enhancing temperature of fluid.Modi fied Hartmann numberQresults in increasing fluid velocity.Radiation parameter Nr and index numbersmenhance temperature.Rise in Eckert number leads to raise temperature and reduce Nusselt number at the sheet.Finally,comparative analysis reveals that Keller Box Method converges more rapid as compare to shooting method.Hence proposed method is reliable and efficient to solve nonlinear differential equations.

[1]S.Pramanik,Ain Shams Engg.J.5(2014)205.

[2]O.D.Makinde,Chem.Engg.Commun.198(2011)590.

[3]A.Y.Bakier,Int.Commun.Heat Mass Transf.28(2001)119.

[4]I.Zahmatkesh,Emir.J.Engg.Res.12(2007)47.

[5]S.Nadeem,S.Zaheer,and T.Fang,Num.Algo.57(2011)187.

[6]H.C.Brinkman,Appl.Sci.Res.A 2(1951)120.

[7]G.Chand and R.N.Jat,Therm.Energy Power Engg.3(2014)266.

[8]T.Hayat,M.Waqas,S.A.Shehzad,and A.Alsaedi,J.Hydrol.Hydromech.63(2015)311.

[9]T.Hayat,S.Asad,and A.Alsaedi,Appl.Math.Mech.35(2014)717.

[10]R.N.Barik and G.C.Dash,Appl.Math.Comp.226(2014)423.

[11]K.Maqbool,A.Sohail,N.Manzoor,and R.Ellahi,Commun.Theor.Phys.66(2016)547.

[12]M.Nawaz,A.Zeeshan,R.Ellahi,et al.,Int.J.Numer.Meth.Heat Fluid Flow 25(2015)665.

[13]A.Zeeshan,A.Majeed,and R.Ellahi,J.Mol.Liq.215(2016)549.

[14]A.Majeed,A.Zeeshan,and R.Ellahi,J.Mol.Liq.223(2016)528.

[15]T.Hayat,R.Sajjad,T.Muhammad,et al.,Results Phys.7(2017)535.

[16]T.Hayat,R.Sajjad,R.Ellahi,et al.,J.Mol.Liq.240(2017)209.

[17]R.Ellahi,M.Hassan,and A.Zeeshan,J.Mech.Adv.Mat.Struct.24(2017)1231.

[18]T.Hayat,R.S.Saif,R.Ellahi,et al.,Results Phys.7(2017)2601.

[19]R.S.Saif,T.Hayat,R.Ellahi,et al.,Results Phys.7(2017)2821.

[20]N.Casson,A Flow Equation for the Pigment Oil Suspensions of the Printing Ink Type,inRheology of Disperse Systems,Pergamon,New York(1959)84–102.

[21]I.Animasaun,J.Nigerian Math.Soc.34(2015)11.

[22]S.Nadeem,R.Mehmood,and N.Akbar,Int.J.Therm.Sci.78(2014)90.

[23]N.Akbar and Z.Khan,J.Magn.Magn.Mater.378(2015)320.

[24]K.Ramesh and M.Devakar,Ain Shams Engg.J.6(2015)967.

[25]S.Pramanik,Ain Shams Engg.J.5(2014)205.

[26]A.Gailitis and O.Lielausis,Appl.Magnetohydrodyn.12(1961)143.

[27]T.W.Berger,J.Kim,C.Lee,and J.Lim,Phys.Fluids 12(2000)631.

[28]J.Pang and K.S.Choi,Phys.Fluids 16(2004)35.

[29]A.Pantokratoras and E.Magyari,J.Engg.Math.64(2009)303.

[30]E.Magyari and A.Pantokratoras,Commun.Nonlinear Sci.Numer.Simul.16(2011)3158.

[31]A.Pantokratoras,Prog.Comp.Fluid Dyn.11(2011)329.

[32]T.Hayat,M.I.Khan,M.Farooq,et al.,Int.J.Heat Mass Transf.99(2016)702.

Communications in Theoretical Physics2018年1期

Communications in Theoretical Physics2018年1期

- Communications in Theoretical Physics的其它文章

- Solitary Potential in a Space Plasma Containing Dynamical Heavy Ions and Bi-Kappa Distributed Electrons of Two Distinct Temperatures

- Ti Impurity Effect on the Optical Coefficients in 2D Cu2Si:A DFT Study?

- Simultaneous Effects of Impurity and Electric Field on Entropy Behavior in Double Cone-Like Quantum Dot

- Electron Acceleration by Beating of Two Intense Cross-Focused Hollow Gaussian Laser Beams in Plasma?

- Discrete Boltzmann Method with Maxwell-Type Boundary Condition for Slip Flow?

- Spatial Dependent Spontaneous Emission of an Atom in a Semi-In finite Waveguide of Rectangular Cross Section?