Separation of Oil Phase from Dilute Oil/Water Emulsion in Confined Space Apparatus*

WANG Shuo (王碩), QIN Wei (秦?zé)?** and DAI Youyuan (戴猷元)

State Key Laboratory of Chemical Engineering, Department of Chemical Engineering, Tsinghua University, Beijing 100084, China

Separation of Oil Phase from Dilute Oil/Water Emulsion in Confined Space Apparatus*

WANG Shuo (王碩), QIN Wei (秦?zé)?** and DAI Youyuan (戴猷元)

State Key Laboratory of Chemical Engineering, Department of Chemical Engineering, Tsinghua University, Beijing 100084, China

A miniature process for separating the oil phase from dilute oil/water emulsion is developed. This process applies a confined space apparatus, which is a thin flow channel made of two parallel plastic plates. The space between the two plates is rather narrow to improve the collisions between oil droplets and the plate surface. Oil droplets have an affinity for the plate surface and thus are captured, and then coalesce onto the surface. The droplet size distribution of the residual emulsion resulted from the separation process is remarkably changed. The oil layer on the plate weakens the further separation of oil droplets from the emulsion. Three types of plate materials, polypropylene (PP), polytetrafluoroethylene (PTFE) and nylon 66, were used. It is found that PP is the best in terms of the oil separation efficiency and nylon 66 is the poorest. The interaction between droplets in the emulsion and plate surface is indicated by the spreading coefficient of oil droplet on the plate in aqueous environment, and the influences of formed oil layer and plate material on the separation efficiency are discussed.

oil/water emulsion, confined space apparatus, oil separation efficiency, spreading coefficient

1 INTRODUCTION

Wastewaters containing emulsified oil are produced from many industrial processes that involve multiphase systems where one fluid phase is dispersed in another immiscible liquid phase, such as liquid-liquid extraction [1], metal-working [2, 3], and oil production[4]. Surfactants in these processes stabilize the wastewater as the dilute oil/water emulsion. The wastewater must be demulsified in order to reduce the process cost and meet the strict environmental requirements.

Conventional separation techniques for oil/water emulsion involve gravity settlers [5, 6], chemical methods [7-9], physical fields (electric field [10, 11],acoustical [12], centrifugal [13], etc), air flotation [14, 15],porous medium filtration and coalescence (porous beds [16-19], membranes [20-24]), etc. Gravity settlers are often ineffective for the emulsion with small droplets. Chemical methods involve the use of additives, which must be removed in subsequent processes.Physical fields with the energy input increase the cost and there are difficulties in the scale-up of these processes. In the filtration process, medium fouling occurs when pores of the media are blocked by the intercepted oil phase.

Coalescence of oil droplets in fibrous beds and membranes is efficient and easy to design. When emulsions flow through the media, the plate surface captures the droplet because of its wetting property. More and more droplets are aggregated on the surface with time,and finally coalesce to form larger droplets, which can be separated by gravity settlers. The separation capacity can be intensified by reducing the pore size and improving the surface property of the material. However, the pressure drop of the process rapidly increases as the pore size is lessened, and the accumulated oil in the media also causes a rise of the pressure drop.

In this work, a device with thin flow channel made up of two parallel plates of polymer material is developed. This confined space apparatus has been proved to be an efficient method for the separation of dilute oil/water emulsion and the factors influencing the process efficiency are discussed.

2 EXPERIMENTAL

2.1 Chemicals and materials

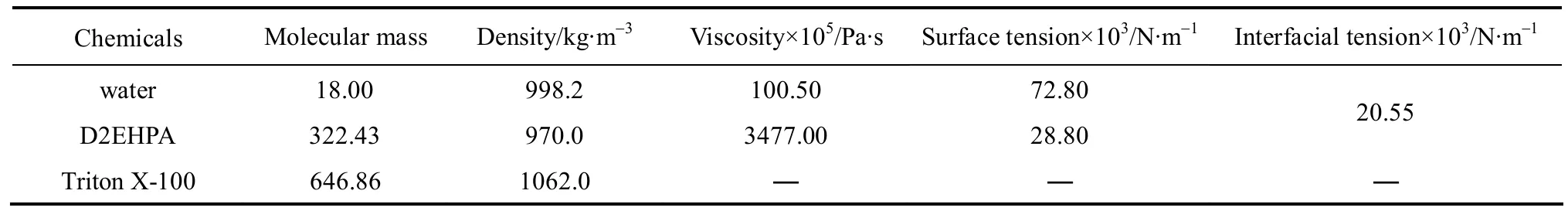

A commonly used extractant, bis-(2-ethylhexyl)phosphoric acid (briefly known as D2EHPA), was chosen as the oil phase, and the non-ionic surfactant,octylphenolpoly (ethyleneglycolether)x, known as Triton X-100, was also added in the emulsion. D2EHPA and Triton X-100 were supplied by Sinopharm Chemical Reagent Co. (China). All reagents were chemically pure and used without further purification. Deionized water was used as the continuous phase. The properties of chemicals used in this work are listed in Table 1.

Three types of plate materials, polypropylene(PP), polytetrafluoroethylene (PTFE) and nylon 66,were used in this work. The surface and interfacial tension of liquid and materials, as well as the contact angle were measured using a video optical analyzer for contact angle and surface tension (OCAH200,Dataphysics, German), and are presented in Table 2.

2.2 Emulsion preparation

A given amount of Triton X-100 was dissolved in

Table 1 Properties of the chemicals (20 °C)

Table 2 Properties of the materials used in this work

water; then the aqueous solution and a known volume of D2EHPA were mixed and the mixture was stirred vigorously for 5 min using a homogenizer at 10000 r·min?1. This procedure typically produced an emulsion with droplet sizes ranging from 0.1 to 10 μm. The emulsion could be stable for dozens of hours without treatment.

2.3 Flow channel and experimental setup

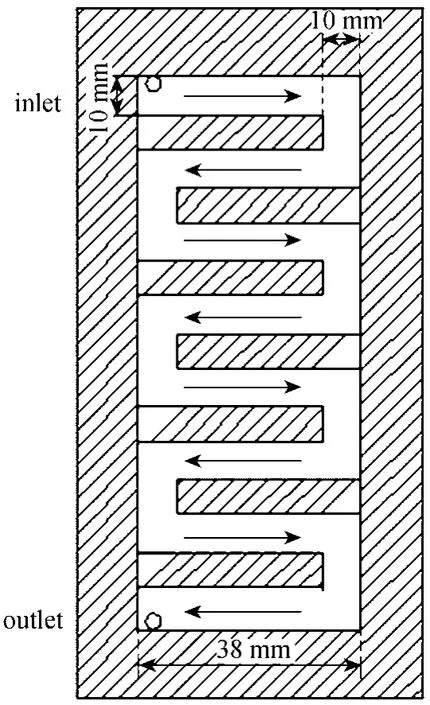

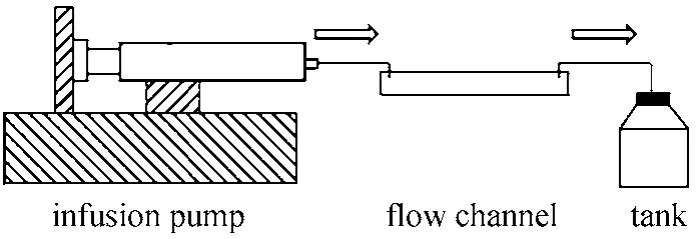

The experiments were carried out in a thin flow channel made of two parallel plates. The cross section of the flow channel is 10 mm×0.5 mm. The shape of flow channel is shown in Fig. 1. As shown in Fig. 2, the experimental setup includes the flow channel, the entrance and export glass tube. The glass tube was testified to ensure its incapability of influencing the experiment results. The emulsion was supplied by a syringe pump.

Figure 1 Shape of the flow channel

Figure 2 Schematic view of experimental setup

In the experiment, the outflow was collected in a tank and pumped back to the inlet to flow through the channel for another time. This process was repeated several times and the oil phase concentration of the emulsion in the tank (Cn, where n indicates the number of passes) was analyzed after each pass. The separation efficiency (E 1 Cn/Ci) was calculated, where Ciis the initial oil phase concentration in the emulsion.

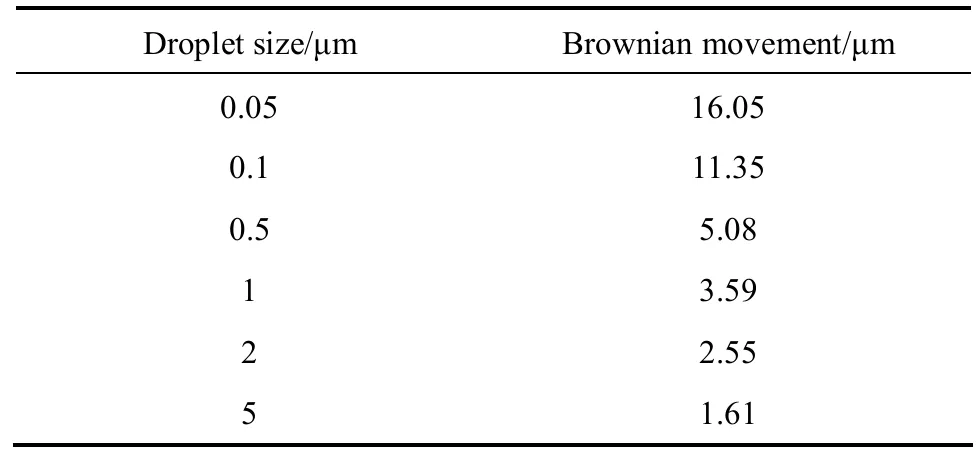

2.4 Brownian movement of droplets in the flow channel

The flow pattern of the emulsion in the channel is laminar (Reynold number ~10), so the droplets collide with the surface via Brownian motion. The retention time of emulsion in the channel for each pass is about 15 s. The average distance of a droplet traveling along any axis in this period by Brownian motion can be calculated from the Einstein equation [25]. The results are displayed in Table 3.

Table 3 Brownian movement of droplets

As the space between the two plates is 0.5 mm(500 μm), there may be not enough contact between droplets and surface. However, the pressure drop of the process will be greatly increased if decreasing the flow space further. This dilemma was resolved by the recycle of emulsion through the flow channel for several times.

2.5 Analysis

Droplet size distribution of the emulsion was measured using Malvern Mastersizer 2000 (Britain).As D2EHPA contains phosphor element, its concentration could be obtained via measuring the amount of phosphorus in the emulsion by the Ammonium Molybdate Spectrophotometric Method (GB 11893-89,China), which involves the absorbance measurement with spectrophotometer (UV-2450, Shimadzu, Japan).

3 RESULTS AND DISCUSSION

3.1 Effects of surfactant concentration

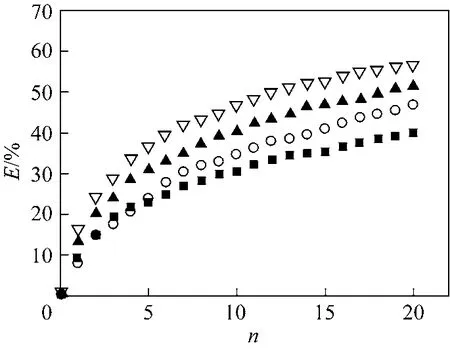

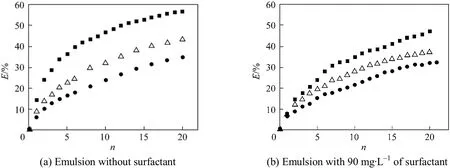

Figure 3 shows the oil separation efficiency against the number of passes of the emulsion through the channel made of PP material at a constant flow velocity (v) of 0.0333 m·s?1, with the initial volume concentration of oil at 0.2% and the total volume of emulsion (V) of 30 ml. The results indicate that the separation efficiency increases after each pass, but the amount of oil separated for each pass decreases with time and after a certain number of passes, there may be no increase. It should be noted that the density of D2EHPA is similar to that of water, and there is little gravity separation within the channel. For the emulsion without surfactant, about 56% of oil is separated at the end of the 20th pass. As the concentration of surfactant (Ctx) increases, less oil is removed because the interfacial tension between oil and water decreases,resulting in a more stable emulsion.

Figure 3 Effect of Triton X-100 concentration on the separation efficiency of oil (v=0.0333 m·s?1, Ci=0.2%, V 30 ml)Ctx/mg·L?1: ▽ 0; ▲ 30; ○ 90; ■ 150

In order to indicate the adsorption of oil on the plate surface, a small amount of red dye (waxoline red MP), which only dissolves in oil, was added to the oil phase. At the end of experiment, the flow channel was found to be red colored, as shown in Fig. 4.

Figure 4 Photo of the plate surface colored by dyed oil droplets

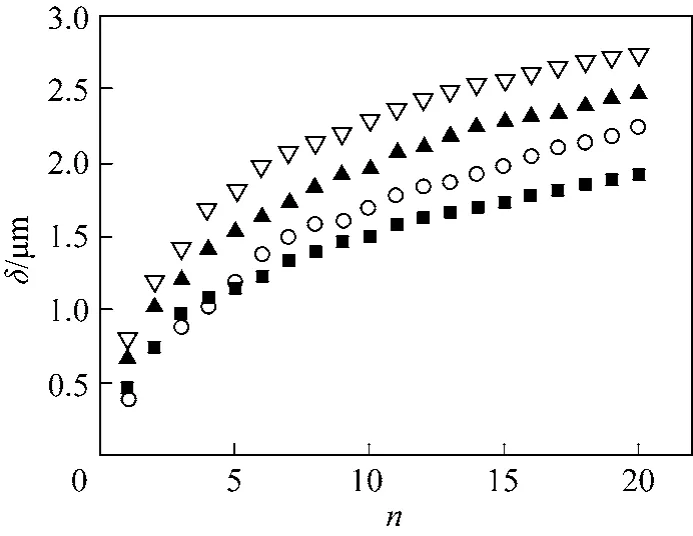

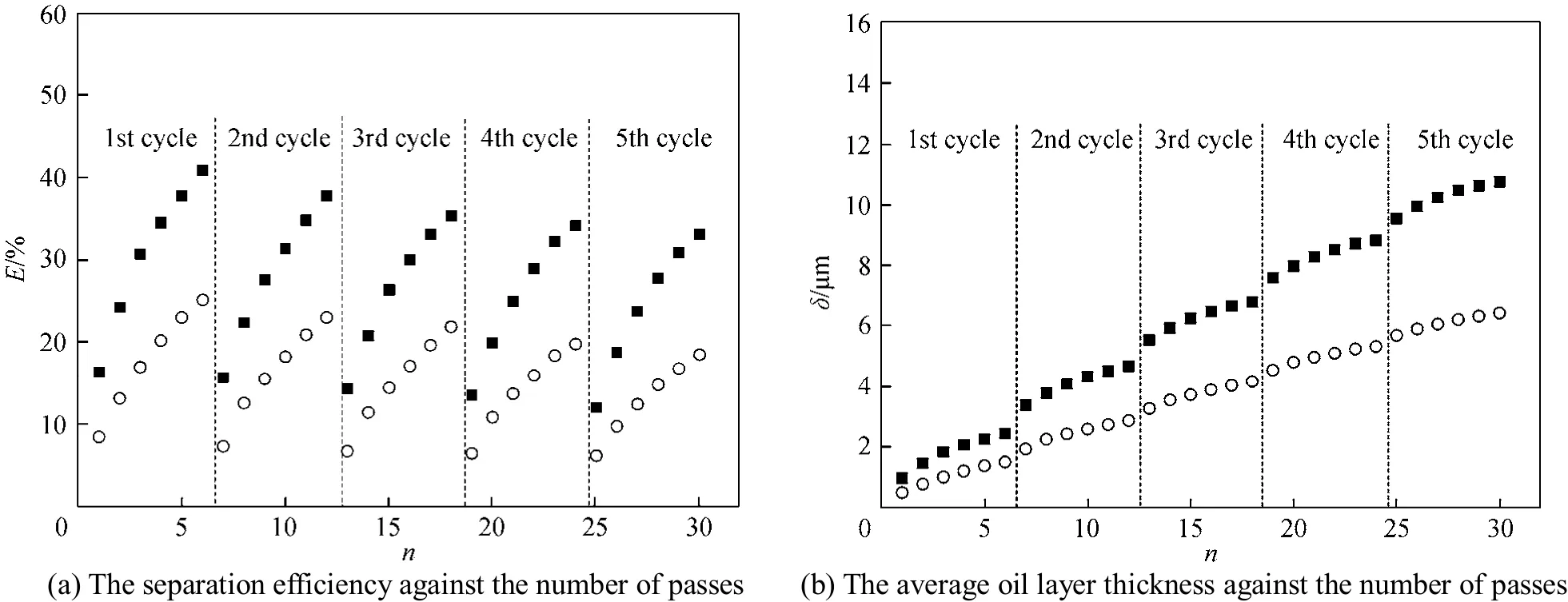

The average oil layer thickness (δ) adsorbed on the plate can be calculated on the basis of the mass balance of oil phase between the emulsion and the plate. The results are indicated in Fig. 5, and there may be a variation of oil layer thickness for different position of the plate. The curves follow an approximately power law relationship, with the index being less than one, so the saturation adsorption of oil exists.On the one hand, as oil droplets accumulate on the surface, the surface property is changed; on the other hand, there is a diversity of oil droplet sizes in the emulsion, which indicates that some droplets are easier to be separated so that the residual emulsion is more difficult to be separated.

Figure 5 Effect of Triton X-100 concentration on the average oil layer thickness (v 0.0333 m·s?1, Ci=0.2%, V 30 ml)Ctx/mg·L?1: ▽ 0; ▲ 30; ○ 90; ■ 150

3.2 Effect on droplet size distribution

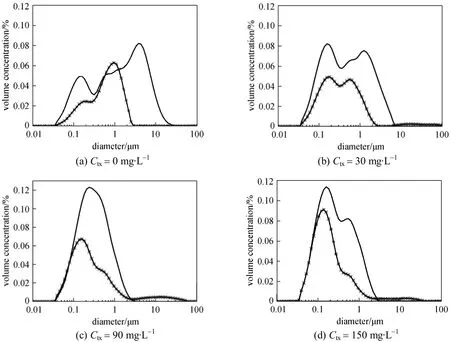

Figure 6 Change of droplet size distribution (v=0.0333 m·s?1, Ci0.2%, V 30 ml)initial emulsion;residual emulsion

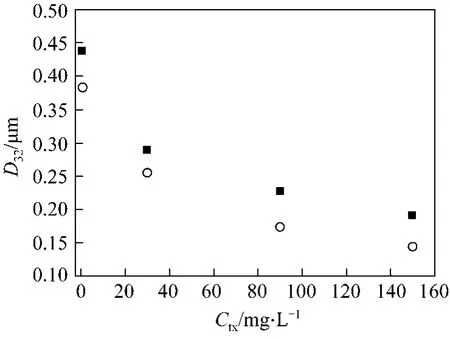

Figure 7 Change of the specific surface area size (v 0.0333 m·s?1, Ci=0.2%, V=30 ml)■ initial emulsion; ○ residual emulsion

The droplet size distribution of the emulsion after 20 passes through the channel is shown in Fig. 6,where the ordinate value is the volume concentration of oil droplets for each size, and the change of specific surface area size (D32) of droplets is shown in Fig. 7.Remarkable change can be seen from the results. For the emulsion without surfactant, the process results in a narrower droplet size distribution with the removal of larger and the smaller droplets. Larger droplets are easier to be separated for emulsions with surfactant.Also, after passing through the channel, the drop size distribution shows a small peak between 10 and 100 μm,resulted from the coalescence of droplets. As shown in Table 3, the Brownian motion is more violent for smaller droplets, so the collision frequency against plate surface is higher. As the droplet becomes smaller,it behaves as rigid spheres because of a smaller Weber number (ρv2d/σ), which indicates a greater difficulty to be coalesced on the surface.

3.3 Effect of adhered oil layer on the separation efficiency

In this experiment, 30 ml of emulsion was delivered through the flow channel made of PP material for 6 passes; then another 30 ml of fresh emulsion was introduced to the same channel, which was reused without any treatment (e.g. cleaning of the surface), to make another cycle of 6 passes. This process was repeated several times to investigate the influence of the adhesive oil layer on the properties of plate surface,while maintaining the character of the emulsion for each cycle approximately constant. The oil separation efficiency and oil layer thickness against the number of passes for each cycle are shown in Fig. 8. The results indicate that the separation efficiencies of each cycle are lower compared with the previous cycle,since the plate surface property is gradually changed due to the oil layer. The oil layer maintains the oil separation capacity, but not as effective as the fresh plate surface.

Figure 8 Effect of adsorbed oil layer on the process (v 0.0333 m·s?1, Ci0.2%, V 30 ml)Ctx/mg·L?1: ■ 0; ○ 90

Figure 9 The reduction proportion of oil concentration for each pass (v 0.0333 m·s?1, Ci0.2%, V=30 ml)■ 1 cycle for 20 passes; ○ 5 cycles, each for 6 passes

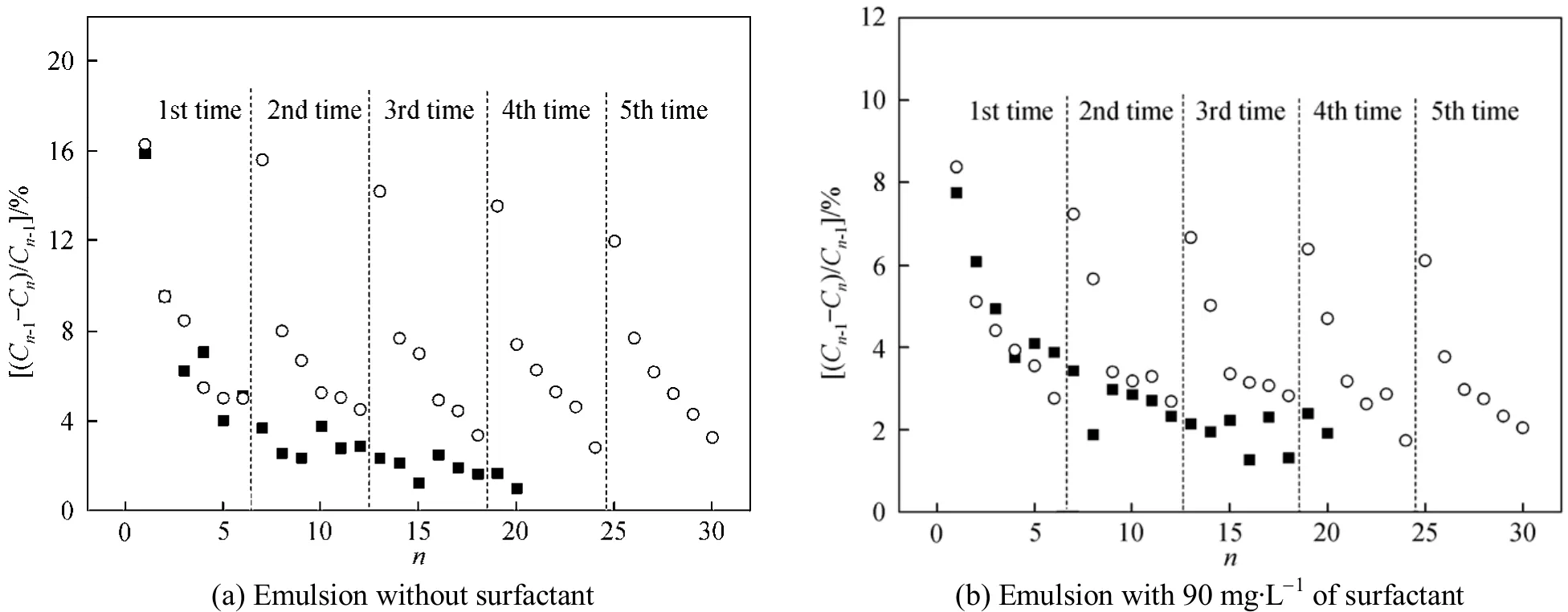

The reduction proportion of oil concentration for each pass [(Cn-1Cn)/Cn-1], which indicates the separation capacity of each pass, was also calculated and compared with the results obtained when the emulsion was cycled for 20 passes in Fig. 9. As discussed above,after some oil is separated from the emulsion, the residual emulsion is more stable. When fresh emulsion is introduced after a cycle of 6 passes, the separation capacity is only slightly lower than the previous cycle because of the adhesion of oil on the surface; while the continuous cycle of 20 passes results in a consecutive drop of separation capacity with time, mainly because of the better stability of the residual emulsion.

Because the separation capacity declines as oil droplets accumulate on the surface, the oil must be got rid of when the separation capacity drops below a critical value. The adhesive oil could be easily washed with a small volume of organic solvent and then the mixture can separated through the distillation process.

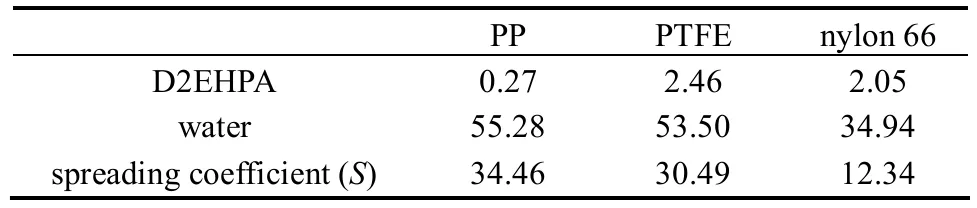

3.4 Effect of plate materials

Three types of plate material were examined, as shown in Fig. 10. PP is the best in terms of oil separation efficiency and nylon 66 is the poorest. The surface properties of the three materials are different, as shown in Table 2. PTFE is the most hydrophobic, and nylon 66 is the least. PP and nylon 66 can be totally wetted by the oil phase D2EHPA, while the PTFE is not wetted. The surface tension data are in such a rank:nylon 66 > PP > PTFE. The effect of plate materials on separation efficiency could not be explained by the sole physical properties and a more comprehensive and accurate criterion is needed.

3.5 The interaction of oil droplet and plate surface in aqueous circumstance

The interaction of oil droplet in the emulsion and the plate surface is described by the spreading coefficient of oil on the surface when surrounded by water, S,which is calculated as:

Figure 10 The separation efficiency of various plate materials (v 0.0333 m·s?1, Ci0.2%, V 30 ml)■ PP; △ PTFE; ● nylon 66

where γsois the interfacial tension between plate surface and oil phase, γswis the interfacial tension between plate surface and water phase, and γowis the interfacial tension between oil and water phase. A larger spreading coefficient indicates stronger adherence of oil droplet and the surface.

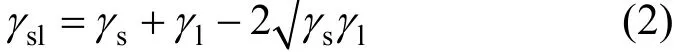

The contact angles (θ), which are given in Table 2,can be obtained by the Young equation [26] from the surface tension and interfacial tension data of the liquid and plate surface. Thus the interfacial tension between liquid and plate surface may be calculated from the contact angle and surface tension. However,Young’s equation is no longer suitable for D2EHPA on the PP and nylon 66 surfaces because these two materials are totally wetted. In this case, the interfacial tension is estimated from an empirical equation recommended by Fowkes [27]:

The obtained interfacial tensions between liquid and plate surface, as well as the spreading coefficients,are shown in Table 4. The spreading coefficients are in such a rank: PP > PTFE > nylon 66, which qualitatively explains the effects of plate materials on the separation efficiency. Also, when the plate surface is totally covered by the oil phase, the spreading coefficient of oil droplet on the adhered oil layer is 0; while the spreading coefficients for all three materials are larger than 0,which indicates the stronger interactions between the droplets and the plate surface than the adhesive oil layer. Thus the separation efficiency declines as the plate is gradually covered by the adhesive oil droplets.

Table 4 Interfacial tensions and spreading coefficients (×103/N·m?1)

4 CONCLUSIONS

A confined space apparatus made of two parallel plates was devised to separate oil phase from dilute oil/water emulsions. This flow channel was proved to be an effective separation method for the dilute emulsion in the experiment. The separation effect of each pass decreases with time because of the accumulation of oil phase on the plate surface and better stability of residual emulsion. The formed oil layer causes a slight decrease in the separation effect when the channel is reused without cleaning. Three kinds of plate materials were tested, and the effects of plate materials and the formed oil layer on the separation efficiency are discussed in terms of the spreading coefficient, which indicates the interaction between oil droplets and plate surface in aqueous environment. This work displays the phase separation phenomena of dilute emulsion in the narrow space and also provides a demulsification method.

NOMENCLATURE

Ciinitial oil phase volume concentration of emulsion, %

Cnoil phase volume concentration of emulsion after n passes through the channel, %

Ctxconcentration of surfactant (Triton X-100) in the emulsion, mg·L?1

D32specific surface area size, μm

E oil separation efficiency, %

n number of passes through the channel

S spreading coefficient of oil on the surface (×103), N·m?1

V total volume of emulsion, ml

v flow velocity of emulsion through the channel, m·s?1

γlsurface tension of liquid phase (×103), N·m?1

γssurface tension of plate surface (×103), N·m?1

γowinterfacial tension between oil and water phase (×103), N·m?1

γslinterfacial tension between liquid and plate surface (×103), N·m?1

γsointerfacial tension between plate surface and oil phase (×103), N·m?1

γswinterfacial tension between plate surface and water phase (×103), N·m?1

δ average oil layer thickness, μm

θ contact angle of liquid on solid surface, (°)

Subscripts

l liquid phase

n number of passes of emulsion through the channel

ow oil and water phase

s plate surface

sl plate surface and liquid

so plate surface and oil phase

sw plate surface and water phase

tx Triton X-100

1 Spasic, A.M., Djokovic, N.N., Babic, M.D., Marinko, M.M.,Jovanovic, G.N., “Performance of demulsions: entrainment problems in solvent extraction”, Chem. Eng. Sci., 52, 657-675 (1997).

2 Patterson, J.W., Industrial Wastewater Treatment Technology, 2nd ed., Butterworths, Stoneham, MA (1985).

3 Hlavacek, M., “Break-up of oil-in-water emulsions induced by permeation through a microfiltration membrane”, J. Membr. Sci., 102,1-7 (1995).

4 Yang, C.L., “Electrochemical coagulation for oily water demulsification”, Sep. Purif. Technol., 54, 388-395 (2007).

5 Sadeghi, R., Mohebbi, A., Sarrafi, A., Soltani, A., Salmanzadeh, M.,Daneshpojooh, S., “CFD simulation and optimization of the settler of an industrial copper solvent extraction plant: A case study”, Hydrometallurgy, 106, 148-158 (2011).

6 Berman, Y., Tamir, A., “Kinetics of droplets’ sedimentation in a continuous gravity settler”, Chem. Eng. Sci., 58, 2089-2102 (2003).

7 Yuan, S.H., Tong, M., Wu, G.M., “Destabilization of emulsions by natural minerals”, J. Hazard. Mater., 192, 1882-1885 (2011).

8 Liu, J., Lu, L.J., Huang, X.F., Shang J.J., Li, M. X., Xu, J.C., Deng,H.P., “Relationship between surface physicochemical properties and its demulsifying ability of an alkaliphilic strain of Alcaligenes sp.S-XJ-1”, Process Biochem., 46, 1456-1461 (2011).

9 Bratskaya, S., Avramenko, V., Schwarz, S., Philippova, I., “Enhanced flocculation of oil-in-water emulsions by hydrophobically modified chitosan derivatives”, Colloid Surf. A-Physicochem. Eng.Asp., 275, 168-176 (2006).

10 Ichikawa, T., Itoh, K., Yamamoto, S., Sumita, M., “Rapid demulsification of dense oil-in-water emulsion by low external electric field I.Experimental evidence”, Colloid Surf. A-Physicochem. Eng. Asp.,242, 21-26 (2004).

11 Ichikawa, T., Nakajima, Y., “Rapid demulsification of dense oil-in-water emulsion by low external electric field. II. Theory”,Colloid Surf. A-Physicochem. Eng. Asp., 242, 27-37 (2004).

12 Pangu, G.D., Feke, D.L., “Acoustically aided separation of oil droplets from aqueous emulsions”, Chem. Eng. Sci., 59, 3183-3193 (2004).

13 Cambiella, A., Benito, J.M., Pazos, C., Coca, J., “Centrifugal separation efficiency in the treatment of waste emulsified oils”, Chem. Eng.Res. Des., 84, 69-76 (2006).

14 Al-Shamrani, A.A., James, A., Xiao, H., “Separation of oil from water by dissolved air flotation”, Colloid Surf. A-Physicochem. Eng.Asp., 209, 15-26 (2002).

15 Zouboulis, A.I., Avranas, A., “Treatment of oil-in-water emulsions by coagulation and dissolved-air flotation”, Colloid Surf.A-Physicochem. Eng. Asp., 172, 153-161 (2000).

16 Briscoe, B.J., Luckham, P.F., Jayarajah, J.N., Akeju, T., “Separation of emulsions using fibrous fabric”, Colloid Surf. A-Physicochem.Eng. Asp., 163, 151-164 (2000).

17 Multon, L.M., Viraraghavan, T., “Removal of oil from produced water by coalescence/filtration in a granular bed”, Environ. Technol., 27,529-544 (2006).

18 Ito, H., Hayashi, H., Sasaki, H., “Rapid separation of oil particles from low-concentrated O/W emulsions in the presence of anionic surfactants using fibrous slag”, J. Colloid Interface Sci., 252,214-221 (2002).

19 Huang, X.F., Lim, T.T., “Performance and mechanism of a hydrophobic-oleophilic kapok filter for oil/water separation”, Desalination,190, 295-307 (2006).

20 Chakrabarty, B., Ghoshal, A.K., Purkait, M.K., “Cross-flow ultrafiltration of stable oil-in-water emulsion using polysulfone membranes ”, Chem. Eng. J., 165, 447-456 (2010).

21 Shu, L., Xing, W.H., Xu, N.P., “Effect of ultrasound on the treatment of emulsification wastewater by ceramic membranes”, Chin. J.Chem. Eng., 15, 855-860 (2007).

22 Hong, A.C., Fane, A.G., Burford, R.P., “The effects of intermittent permeate flow and crossflow on membrane coalescence of oil-in-water emulsions”, Desalination, 144, 185-191 (2002).

23 Hong, A.C., Fane, A.G., Burford, R.P., “Factors affecting membrane coalescence of stable oil-in-water emulsions”, J. Membr. Sci., 222,19-39 (2003).

24 Wang, S., Chu, L.Y., Chen, W.M., “Fouling-resistant composite membranes for separation of oil-in-water microemulsions”, Chin. J.Chem. Eng., 14, 37-45 (2006).

25 Lissant, K.J., Demulsification: Industrial Applications, Marcel Dekker, New York and Basel (1983).

26 Huang, Z.Q., Ding, E.J., Surface Infiltration and Wetting Transition,Shanghai Scientific and Technical Press, Shanghai (1994). (in Chinese)

27 Fowkes, M., Treatise on Adhesion and Adhesivesx, Marcel Dekker,New York (1967).

2011-07-24, accepted 2011-12-07.

* Supported by the Eleventh Five-Year Plan of national support (2007BAI26B03-04).** To whom correspondence should be addressed. E-mail: qinwei@tsinghua.edu.cn

——例談尊重與正確歸因在建立和諧師生關(guān)系中的重要價值

Chinese Journal of Chemical Engineering2012年2期

Chinese Journal of Chemical Engineering2012年2期

- Chinese Journal of Chemical Engineering的其它文章

- Optimization for Production of Intracellular Polysaccharide from Cordyceps ophioglossoides L2 in Submerged Culture and Its Antioxidant Activities in vitro*

- A Pilot-scale Demonstration of Reverse Osmosis Unit for Treatment of Coal-bed Methane Co-produced Water and Its Modeling*

- ECT Image Analysis Methods for Shear Zone Measurements during Silo Discharging Process*

- Temperature-triggered Protein Adsorption and Desorption on Temperature-responsive PNIPAAm-grafted-silica: Molecular Dynamics Simulation and Experimental Validation*

- Adsorptive Thermodynamic Properties and Kinetics of trans-1,2-Cyclohexandiol onto AB-8 Resin

- Tracking Submicron Particles in Microchannel Flow by Microscopic Holography*