Research Progress on Moisture and Heat Transfer Model for Ventilation Drying of Grain under Bulk Storage

CHEN Pengxiao, LIU Ye, WU Jianzhang, JIANG Mengmeng, LU Xuezhong, ZHANG Debang,ZHU Wenxue*

(1.School of Food and Strategic Reserves, Henan University of Technology, Zhengzhou 450001, China)

(2.Zhengzhou Wangu Machinery Co. Ltd., Zhengzhou 450041, China)

Abstract: Food security has been at the forefront of state governance throughout history. The safety of grain storage is particularly important, which is related to the national security of a country. A large amount of grain is lost after harvest every year owing to reasons such as the primitive grain drying and storage methods and the backward drying technology. The uneven distribution of moisture and heat in stored grain will not only lower the quality of grain, but also seriously affect the food safety of grain caused by mildew, insect pests and other problems.Therefore, how to reduce quickly and uniformly the moisture content or temperature of bulk grain piles with low energy consumption to ensure grain quality while saving energy is an important direction for grain drying and storage research, which has profound theoretical and practical significance. Ventilation drying is an important measure to ensure the uniform distribution of moisture and heat in stored grain, and constructing a drying model to predict the moisture and heat distribution of grain pile is an important means to study the moisture and heat transfer during the drying process of grain piles. This paper reviewed three models of moisture and heat transfer in bulk grain piles, the empirical model, continuum model and discrete model. The empirical model is easy to obtain but rarely used. The continuum model is widely used, but it cannot reflect the pore characteristics of grain piles. The discrete model reflects well the pore structure of grain piles, though it relies on large amounts of calculations and is difficult to understand and construct. Finally, it is pointed out in this paper that corresponding models can be established in combination with advanced calculation methods and processing techniques according to different moisture and heat transfer processes to meet different simulation requirements. In addition, the future research direction of moisture and heat transfer models for ventilation drying of grain pile under storage is also prospected in this paper.

Key words: grain pile; empirical model; continuum model; discrete model

1 Introduction

As we all know, food security is an essential part of a country’s security, which is a fundamental issue related to human survival. Therefore, it is one of our top vital strategic choice to ensure food security and reduce food losses based on China’s realities, and our national and worldwide food situation[1]. There are three big safety issues in the current world, grain safety, energy safety and financial safety, respectively[2,3]. When it comes to the grain safety, it is not merely about the security of production, storage, circulation or trade, but a sophisticated grain safety system integrated all sections.Grain storage is one of the key sections in retaining grain safety. The concern of grain storage safety in different countries depends on their national situation and changes over time. Most developing countries take more efforts to control the loss of the storage of grain, while most developed countries emphasis more on advanced technologies to ensure the grain quality during storage.However, the global grain losses are still high, with about 30% of global food loss and waste in cereal food per year according to the data of FAO, and about 67% of the post-harvest loss in all cereal losses. In China, the number of grain post-harvest losses are even over 25 billion kilos,in which the storage loss is nearly 40%[4,5]. The drying of grain is seen as of great significance as its important link with ensuring food security after harvest. The main ways of drying grain in China are natural drying, hot air drying,infrared drying and so on. The drying rate of natural drying is slow and natural drying is affected by the weather and site. Hot air drying mainly uses hot air as a drying medium to dry materials, suitable for solid materials, such as rice, vegetables, fruits and other materials. There are several advantages of this method,less investment in drying equipment, low drying cost,simple operations in the drying process and so on.However, the product quality is poor with great color change, great loss of flavor and nutrition, and hard epidermal tissue structure afterwards[6,7]. Far infrared grain drying is achieved by the emitted radiation elements such as graphene. It has the characteristics of high drying efficiency, good drying effect, energy-saving and low cost, but it cannot be utilized in large-scale drying[8].

The reasons of storage losses are various, such as poor facilities and technologies, improper temperature,humidity conditions, insects and mildew. Among these factors, temperature and the humidity play a major role in controlling grain quality and losses. Multiple sensors are used to monitor the grain temperature, air temperature and air humidity in the warehouse to reflect the real-time conditions of grain. But it is not able to predict the future tendency in those parameters of the grain. By contrast,modelling and simulation methods can forecast the distribution fields of temperature, moisture content or humidity, air velocity or pressure and then preventive measure can be taken to maintain the grain quality and its reliability of mathematical models can be verified by grain storage experiments. This method tends to be more prevailing in grain storage research recently as it is time-saving and cost-effective.

The drying process of stored grain pile is a complex research area, involving with many topics such as biology,chemistry, thermodynamics and hydrodynamics. It includes moisture and heat transfer in grain, gas flow between pores and moisture and heat transfer between pores and grain[9,10]. During the process, the physical parameters in grain pile, the moisture and heat transfer mechanism are all hard to be determined directly.Therefore, drying modelling is viewed as the main way to anticipate the process of grain pile ventilation and drying and then deduce related mechanism of the drying process.

For wet and unsaturated porous medium, researchers build models to study the heat, mass and momentum transfer process in pores inside or between materials. The bulk grain in the bin, as a porous medium, is treated as continuum medium or discrete medium in different research.Due to the various assumed material conditions, different appropriate modeling methods would be chosen in grain storage, among which empirical method, continuum method,and the discrete method are wildly used.

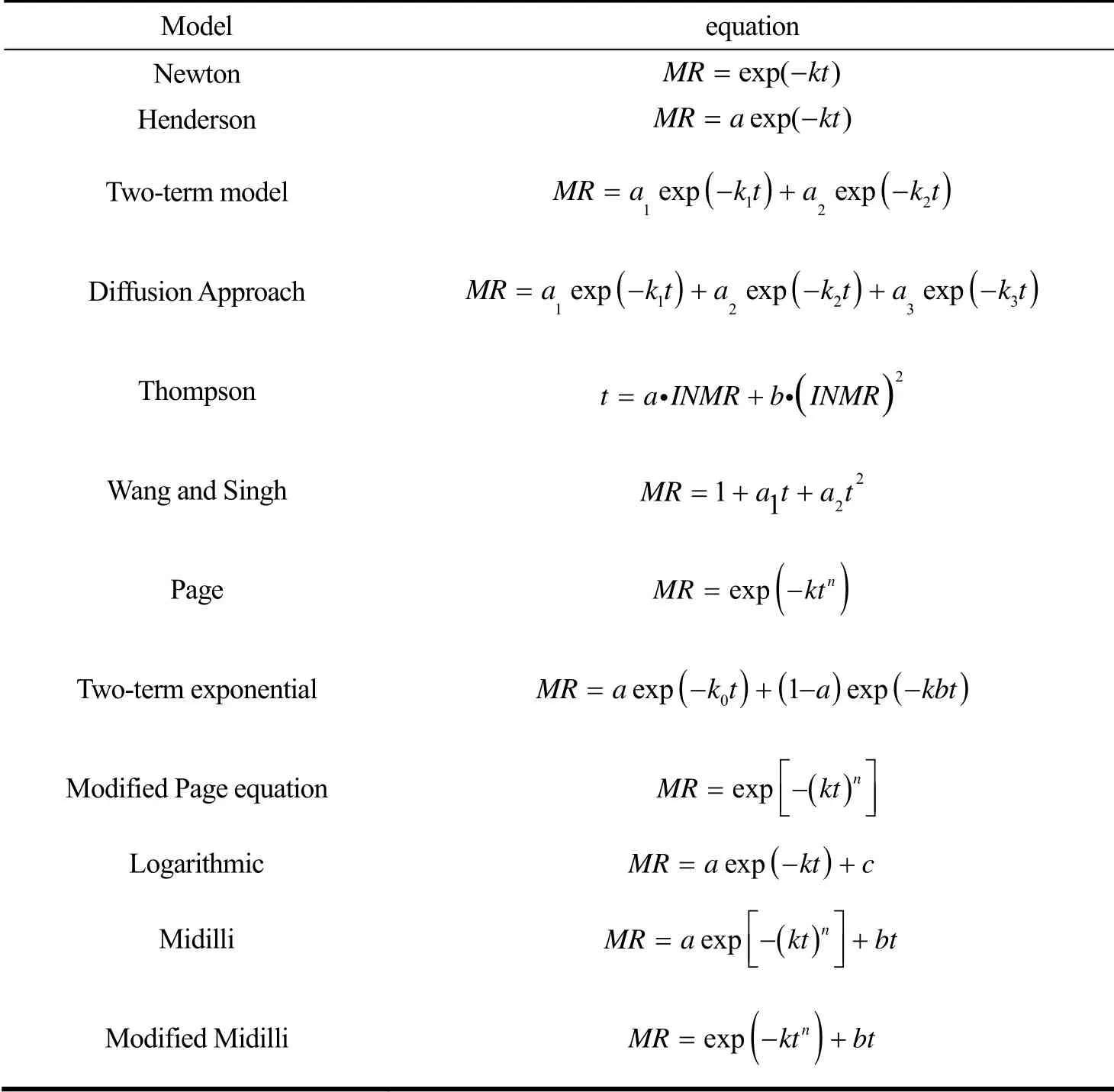

Table 1 Thin layer drying equation

2 Empirical Method

At the beginning of the research, the drying empirical equation is often obtained through the actual warehouse experiment method, and on this basis, the moisture and heat transfer mechanism of the grain drying process is studied. The thin-layer drying equation is the basis of deep-bed drying simulation of grain, and it is developed on the basis of deep-bed drying research. In the simulation analysis of deep-bed drying (the actual drying system), the deep-bed grain is usually regarded as composed of many thin layers of grain, calculated layer by layer, and finally get the result. Therefore, the thin-layer drying equation has become a key model for grain drying simulation. Hukill[11]obtained the drying experience equation through a large number of experiments. Using the drying experience equation and a series of dimensionless curves, it calculated the grain moisture at any depth of the grain bed during a certain drying time. The research found that there is drying frontier phenomenon during the drying process. In 1967,T. L. Thompson[12]proposed a series of semi-empirical formulas to simulate the moisture distribution of grains in the cross-flow, counter-current and downstream drying processes, which is with good results. In the early 1970s,Bakker-Arkema[13]derived a theoretical model of grain drying based on the basic principles of heat and mass transfer, which consists of four partial differential equations. According to the initial conditions, the moisture and temperature of the thin-layer grains and the temperature and humidity of the hot air can be solved after a certain period of time. Cao[11]studied the effects of grain drying process, grain size and shape density on the shape of the drying front through a self-made device, and found that the air ducts on both sides of the square have better drying effects through comparison experiments.Li[14]established a mathematical model to predict the temperature of the measurement points in the next three days through multiple regression of the temperature changes at each measurement point in the granary within a week. This mathematical model is an empirical model,which is with limited application scope. Wu[15]explored the drying characteristics under the orthogonal combination of different hot air temperature, wind speed,relative humidity and initial grain moisture based on the multi-parameter controllable thin layer drying experiment of corn. Tian[16]used the independently developed rotating ventilated drying barn to study the precipitation process of high-moisture corn. The results showed that the temperature and humidity of each monitoring point in the grain pile changed with the environment, and the temperature and humidity of the monitoring points in the same layer or the same column were basically the same.Wang[17]used response surface analysis to simulate the change of resistance pressure drop of ventilation in rice stack, and the study showed that resistance pressure drop increased with the increase of water content of rice, wind speed and bed depth, among which the interaction of wind speed and bed depth had the most significant influence on pressure drop. A Ostrikov[18]studied the drying dynamic characteristics of grain under variable temperature drying by empirical mathematical modeling method, and the mathematical model proposed can calculate the temperature distribution in the grain layer.

Although the empirical model can describe the heat and mass transfer process of grain stack drying, it can only accurately describe the drying process under specific drying conditions. Its application scope is limited, and it cannot reveal the heat and mass transfer mechanism among the internal structures of grain stack. The commonly used thin layer drying equation is shown in Table 1.

3 Continuum Method

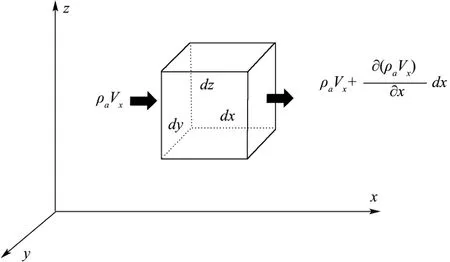

The basic ideas of computational fluid dynamics(CFD) are to substitute a set of variable values from a series of finite discrete points for the field that physical quantities is characteristic of continuous distribution in original time and space, such as velocity field,temperature field and pressure field, then to establish the algebraic equations between the discrete points and field variables by some principles and methods, finally to get the approximate field variable values by solving the algebraic equations. Nowadays, researchers take the bulk grain as the continuum medium in some CFD software,and discretize it to get the meshes. Then the governing equations combined with the meshes are solved by different solvers. The usually used CFD software is as follows: fluent, comsol multiphysics, phoenics, ANSYS,etc. The applications of CFD method in grain storage focus on predicting the temperature field and moisture field of grain and air, optimizing the ventilating duct structure and operating parameters under mechanical ventilation and quasi-steady state storage[19,20]. Figure 1 shows the structure of the calculated cell in the continuum hypothesis.

Fig.1 Computational micro-element in the continuum hypothesis

In the process of mechanical ventilation, researchers chose the operating conditions by simulating and optimization under environmental conditions. Wang[21]established novel models in which Wang dealt with temperature and moisture content changes by cooling grain with refrigerated air other than ambient air on summer. Lopes[22]compared two equilibrium models and with the simulation results people could lower the aeration costs and shorten the operation times in ventilation process. Lawrence[23]used the 2D PHAST-FEM model to study 15 aeration strategies under the subtropical weather conditions, and the results showed the best aeration strategies for grain storage safety.

Other researchers verified the validity of models based on the simulation results, most of which were from experiments. Bartzanas[24]used a CFD model to evaluate numerically the temporal and spatial distribution of air temperature and oxygen concentration within silage stacks, and the results showed the simulated quality parameters fitted well with the experimental results, and it has great potential for making possible preventive measures in storage biomasses. Lawrence[25]used a 3D finite element stored grain ecosystem model describing and comparing heat and momentum transfer for the peaked, leveled, and inverted cone grain mass configurations, and the fan run time, electricity consumption, and the potential for grain spoilage in the results were discussed. Zhang[26]based on CFD numerical simulation technology, numerical simulation of the change of temperature distribution and velocity distribution in the grain stack under the pressure ventilation and suction ventilation. The study found that the ventilation effect of the grain stack area in the shallow silo under the four ventilation modes was similar, and the ventilation uniformity was good. However, the cooling rate is higher and the grain temperature uniformity is better in the suction ventilation (closed at the top of the central air collector).

Sometimes mechanical ventilation in grain storage is similar with the drying process in reducing the moisture content of bulk grain. Hemis[27]developed a mathematical model to simulate the deep-bed convective drying of Algerian wheat and barley, and the simulation results were in good agreement with experimental results.Wang simulated the transfer process in bulk grain by COMSOL Multiphysics software, where six parameters were taken into account in the model, including the temperature and moisture content of grain, the temperature, humidity, velocity, pressure of air. Although it was the drying process, it can provide some implications for storage[28]. From above all, we can predict that the mechanical ventilation models can describe the transfer process in bin with the six parameters under various storage conditions. Moreover,more complicated models have been in use from one dimensional space to three dimensional spaces. Most of the models are various based on different environmental conditions. So they can provide us the implications on simulation and optimization of grain storage.

Environmental condition is different from everywhere in the world, so the boundary conditions are various for quasi-steady state storage. And different factors need to be considered based on the local environment and researchers’ special purposes. As in the mechanical ventilation, to optimize the bins’ structure and operation parameters, verify the validity of CFD simulations were the main purposes.

Chen[29]established CFD mathematical models on quasi-static temperature field for underground warehouse structure, which provided references and basis for its design. Zhang[30]studied the temperature and moisture in grain bin by local heat and mass balance principle and volume average method, which ignored the temperature change in vertical direction. The results provided scientific basis for preventing mildew and moisture condensation. Yin[31]got the distribution of grain temperature by temperature sensor array, obtained the regression function of temperature field by fitting algorithm and MATLAB software, and predicted the condensation to avoid grain mildew by analyzing cloud pictures. Qi[32]modeled the heat and moisture source in grain bin caused by grain respiration, and got the results to guide engineering practice. Based on the mathematical model of heat and moisture transfer, Liu[33]carried out numerical simulation of the static storage process of corn grain stacks in bungalows. Taking the variation of daily average temperature and humidity as the boundary condition, the coupling law of heat and humidity in grain stack was obtained, and the accuracy of numerical simulation was verified by the measured data.

Arias Barreto[34,35]applied a 2D finite element momentum, heat and mass transfer model to predict natural convection flows, temperature distribution and moisture migration in bulk corn and wheat respectively stored in cylindrical bins, and the model was applied in bulk soybean while taking the solar radiation into consideration in different season. The results showed that the permeability had the strongest effect on natural convection, and the moisture migration was different for soybean, corn and wheat. Arias Barreto[36]analyzed the effect of climatic conditions on the gas concentration in silo-bags holding wheat as well as grain storage condition by a validated mathematical model describing the energy and mass balances for the grain and air phases in a control volume, and the results showed that reference levels of O2and CO2strongly depend on initial moisture content and bagging grain temperature. Bochtis[37]used a prediction tool based on a validated CFD model from Fluent about temperature and the oxygen content, during the biomass storage process in a diagnostic system. And the system will provide managers with a solid basis for necessary preventive measures. Gaston[38]established a 2D finite element model to predict temperature distribution and moisture migration of wheat stored in silo-bags, and many factors such as grain respiration,carbon dioxide and oxygen concentrations were took into consideration for predicting grain storability with good prediction of CO2concentration during storage and poor prediction of O2concentration for wet grain.

Many papers showed us the quasi-steady state storage models considering different factors and environmental conditions. And much more complicated models are taking various factors into account. We could know which factor need to be considered under certain storage conditions and the effects of different factors on the simulation results. The convection is not taken into consideration in some equilibrium models during the quasi-steady state storage. In fact, it will need long time to be balance. Duckworth[39]showed that at least 14 days might be recommended in real food materials measured with the proposed method equilibration. Compared with the assumption, so long equilibration time could make simulation results inaccurate. If the convection is considered in the model with more real assumption, the simulation results are more accurate and the model could be used for mechanical ventilation. Then it can be applied more widely in different conditions.

Wang[40]based on the continuous medium method and taking wheat as the research object, conducted a numerical simulation study on experimental conditions of double-side suction out oblique flow cooling and water-retaining ventilation in tall bungalows, and analyzed the change rules of grain pile temperature and moisture in the process of double-side suction out oblique flow air. Liu[41]applied CFD to simulate the air flow field in the mechanical ventilation process of wheat with high moisture content, and analyzed the spatial distribution rules of static pressure, dynamic pressure and flow rate in grain stacks. Wang[42]took wheat as the research object and established a mathematical model of heat and moisture transfer and flow inside grain stacks in shallow silos, as well as an empirical model of pests and fumigation. The study found that ventilation had a significant impact on temperature and moisture inside grain stacks as well as the growth of pests. Jin[43]constructed a heat and mass transfer model of hot air drying of corn, and conducted numerical simulation study on water diffusion process and mass transfer resistance in hot air drying of corn, and found that corn seed coat had a great influence on mass transfer in drying process, and the higher the air temperature in a certain range, the lower the mass transfer resistance of seed coat.

Based on the continuum assumption of storage grain bulk thermal mass transfer model to heat and mass transfer process of grain heap structure characteristics related to the influence of all included in the "effective transmission coefficient", so that in the description of grain pile in gas-solid two-phase and heat mass transfer between pore situations too general, unable to reveal the grain heap internal gas-solid two phase and gas phase thermal mass migration mechanism for heat and mass transfer.

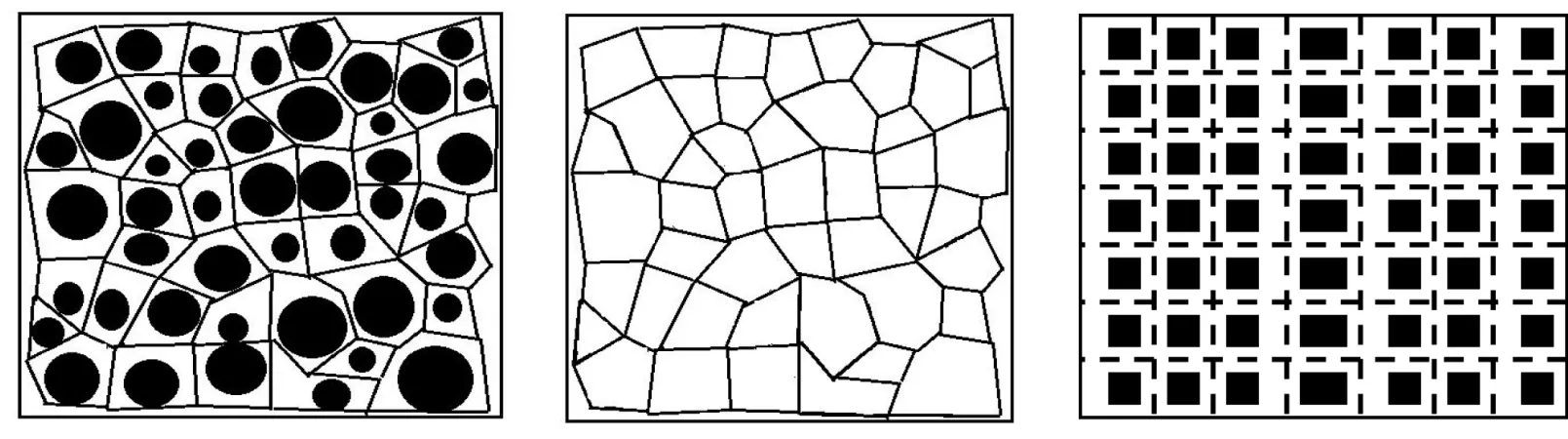

Fig.2 The construction process of two dimensional discrete model

4 Discrete Method

According to the continuous methods, the bulk grain is taken as fictitious homogeneous continuous media, and the differences of geometric packing structure, heat and mass transfer properties in pores and bones, and other physical properties are ignored. All skeleton, pores and the related physical parameters can distribute continuously in porous medi. Its physical model is shown in Figure 2. For bulk grain, the pore size is similar with the grain size in mm scale. The complicated packing structure of bulk grain cannot be treated as continuous medium but only as discrete medium, where the moisture could transfer in the arbitrary direction but in the pore space. The modeling methods include direct methods and indirect methods.

Modeling and simulation based on real or approximately real pore structure is called direct method.There are two main direct methods to obtain the pore network inside porous media. The first method is taking a porous medium as aggregates of particles, which the packing structure is homogeneous or inhomogeneous,regular or random. Discrete element method (DEM) can be used to solve this problem. The other method is to obtain the pore network by imaging techniques[44]. The direct methods are usually not used in large scale, which is the main difference from the indirect methods. Prat[45]considered that the direct methods are mainly used to study the microscopic phenomena at the scale of a few pores or less. In fact, some problems can also be tackled with the direct methods in middle scale.

As early as in 1994, DEM has been used by Rong[46]in agriculture and food industry. DEM can simulate the packing process and structure of discrete particles by tracking the motion of individual particles[47]. Qi[48]simulated the mixing process of non-cohesive particles,cohesive fine and wet particles, non-spherical particles in rotary and fixed mixers by DEM. The non-spherical particle can be described by direct shape description method and multi-sphere method. So the pore network of bulk grain could be obtained.

Although its application in grain post-harvest operations is becoming popular, DEM is mainly focus on the forces and motions of granular materials. There are little literatures about the heat and mass transfer in grain storage by DEM, especially for the mass transfer. In different research fields, the direct methods mean different methods to tackle with the porous medium.

There are few literatures about mechanical ventilation in grain storage with discrete methods, but more on drying. Wang[49]extracted pore network geometry from a real solid particle packing by 3D X-ray images[50], simulated the liquid transfer and drying process based on a 3D irregular pore network model. The simulation results matched the experimental results well.It showed that the 3D irregular pore network generated by Voronoi tessellation could be a substitution for the pore space.

During the mechanical ventilation, the convective motion of gas plays an important role in heat transfer in porous media, which mainly happens in pores based on the assumption that the particles do not take part in the mass transfer as discussed above. In reality, the moisture in grain particle will be desorbed during ventilation or lose by respiration. In other areas, such as rock,petroleum and soil, the fluid multi-phase flow is studied by Lattice Boltzmann method (LBM) and maximal ball method (MBM). LBM is one of particle-based methods,where particles represent packets of fluid. The maximal ball method provides us a numerical description of the pore space from digital images, where we can locate every pore and throat of the real porous medium[51]. Then we can study the fluid flow in the pore and throat accurately. But we will miss the solid particles information by LBM and MBM.

There are only a few literatures about quasi-steady state storage in grain storage with discrete methods.Rusinek[52]used the DEM model to predict the temperature distribution, avoiding the self-heating phenomenon during the storage of rapeseed. Rusinek and other researchers[53,54]claimed that the effect of conduction by seed-to-seed contact dominates in small grain cereals such as wheat, rice, and rapeseed, while the effect of convection in pores is more important for larger particles such as apples and potatoes. Both the size of corn and potato are bigger than rice and wheat, and the convection during the storage should not be neglected.However, there are few literatures about this method.What’s more, the ambient temperatures, bin structure or loose packing of grain particles could influence the quasi-steady state storage, and the convection might have more effect than assumptions. If the bulk grain is in a complicated environmental condition, more factors need to be taken into consideration.

Moreover, some researches are close to it. Kohout et al[55]made direct simulations of the drying process in a random packing of less than 400 particles by using X-ray microtomography scanner. Some drying phenomena were investigated; neither the heat nor the mass transfer simulations were studied.

There are only a few literatures related to grain storage. Huang[56]got pore network parameters of bulk grain based on maximal ball algorithm, and reconstructed a 3D stochastic pore network. This model could be used for mechanical ventilation and quasi-steady state storage when the position of grain particle is relatively fixed.However, the information of particle skeleton was lacked in the reconstructed 3D stochastic pore network. So the convection, conduction and seed respiration could not be considered unless the missed parameters were added into the model.

From all above, there are not many literatures about discrete approaches in grain storage even though the description of bulk grain is close to the true porous medium. As we can see, either the particles or the pore space could be taken into consideration in the discrete methods. But there are only a few models based on the particles and the pore space simultaneously, while the model was complicated. Its application maybe affected by some reasons. Firstly, the latest description of the skeleton and pore space in porous medium is more accurate, but it is so complicated that it is time-consuming for simulation and the sample modeled is too small to expand its applications. So some simple fundamental studies still need to be done. Secondly, the limited computer power is a challenge for personal computers to deal with the huge calculation. For example,there are more than 25 million of grain particles in a cylindrical bin with the height of 1.45m and the diameter of 1.1m, the requirements to computer power is far more than the performance of personal computer. So, in some papers, aggregates of only hundreds of particles are calculated even without heat and mass transfer in the pore space. Thirdly, the main interesting concerned in DEM is about particles’ motions and stress, while the cereals in grain storage are static in most of the storage time. So there are only a few papers studying the heat and mass transfer by the DEM method.

With the development of technology, researchers combined refined mesh of the pore network for momentum transfer in the pore space, and normal mesh for the pore network and the granular skeleton for heat transfer. The above two meshes are completed by the continuum methods, such as CFD; granular packing by the discrete methods, such as DEM. Although there are few literatures about grain storage by this method, many valuable implications are provided.

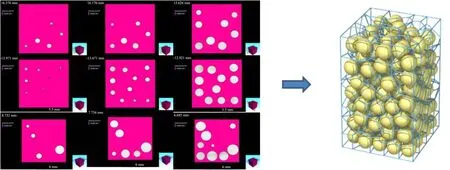

Yuan[57]built a 2D pore network model for drying corn, where the location of particles, pores and throats were in regular distribution. And every particle was considered as a continuum based on the homogenization assumption. In this model, the hot air flowed in pore spaces and heat transferred mainly by convection. The experimental results showed good agreement with the simulation results. Narsilio[58]used 3D synthetic grain packing technique by discrete element method to characterize conduction parameters in geomaterials at the particle scale. And the finite element methods were used for solving the governing equations of conduction parameters and thermal conduction. The results showed that the velocity field of fluid in the pore network and the temperature field in the pore network and skeletal structure of particles, which does us a favor to know the fluid flow and heat transfer in porous media. Similarly,Yun[59]developed a 3D random thermal network model for simulation of heat transfer in porous media in the dry and water-saturated conditions. And the model integrated the coordination number, packing density and the inter-particle contact condition. Rickelt[60]simulated convective heat transfer in moving granular material by coupled DEM/CFD simulations, which showed a good agreement between simulations and experiments. And Rickelt pointed out the implications for complex particle shapes represented by polyhedrons, and for multi-dimensional inner-particle heat transfer. Tsory[61]developed the particle-particle and particle-wall heat transfer models integrated into the in-house unsteady three-dimensional discrete element method (DEM)software. The 3D channel network model construction process is shown in Figure 3. Tsory pointed out that DEM-only and two-way-coupling schemes had different results, and advised the roughness as a parameter to be considered. Haddad et al[62]simulated heat transfer in 2D continuous medium using cylindrical discrete elements and the coupled DEM-FEM (discrete element method-finite element method) method. And the numerical results by DEM, FEM and coupled DEM-FEM method were compared to validate the DEM-FEM coupling method. CFD-DEM models and numerical simulation software have been developed to describe the transfer of momentum and heat between fluid and solid particles.

Fig.3 3D channel network model construction process

Chen et al[63,64]constructed two irregular pore network physical model to simulate the heat and mass transfer processes of corn piles. In his paper, the 2D irregular pore network model was constructed based on the image of monolayer material, and the distribution of extracted particle sizes is similar to that of the real particles. The pore space parameters of the reconstructed irregular pore network model are similar to the extracted parameters from a 2D image. The reconstruction method can be used for reconstruction of an irregular pore network model with a random size. In his three-dimensional multiscale irregular pore network model, the stacking process of a small corn pile in a regular container was simulated by DEM software, the location information of pores and throats was obtained with Voro++software, and an algorithm was proposed to determine the relationships among pores, throats, and particles, as well as their respective dimensions. The experimental and simulation results showed that the two irregular pore network models can effectively simulate the heat and mass transfer processes of corn piles.Moreover, the LIGGGHTS, an emerging software, is dedicated to open source high performance scientific computing in fluid mechanics and particle science. It will be much more appropriate for simulating the real grain storage process. Huang[65]improved the existing two-dimensional multi-scale regular channel network model to describe the drying process, and constructed a three-dimensional multi-scale irregular channel network mathematical model. A new pore network model is proposed to solve the problem that the previous pore network model only reflects the pore structure information but lacks the skeleton information. Chen[66]constructed the three-dimensional pore network model can describe the internal pore structure of stored grain stacks, and the constructed structural parameters are more comprehensive, which can more accurately describe the relationship among particles, pores and throat in stored grain stacks.

A Kraiem[67]took corn as the research object and constructed the two-dimensional regular stacking structure of stored grain pile. Combined with the shrinkage model, they studied the heat and mass transfer of hot air drying of grain pile and found that the shrinkage model could make the drying model more accurate.

In the pore network model based on the assumption of discrete medium, the "controlled volume balance method" is adopted to calculate the moisture and heat amount in the pore of grain stack. The continuous flow field between the pore and grain stack is ignored, and the heat and mass exchange between grain and surrounding pore does not consider the gas flow direction, so the flow characteristics of the flow field between the pore and grain stack cannot be revealed.

5 Conclusions

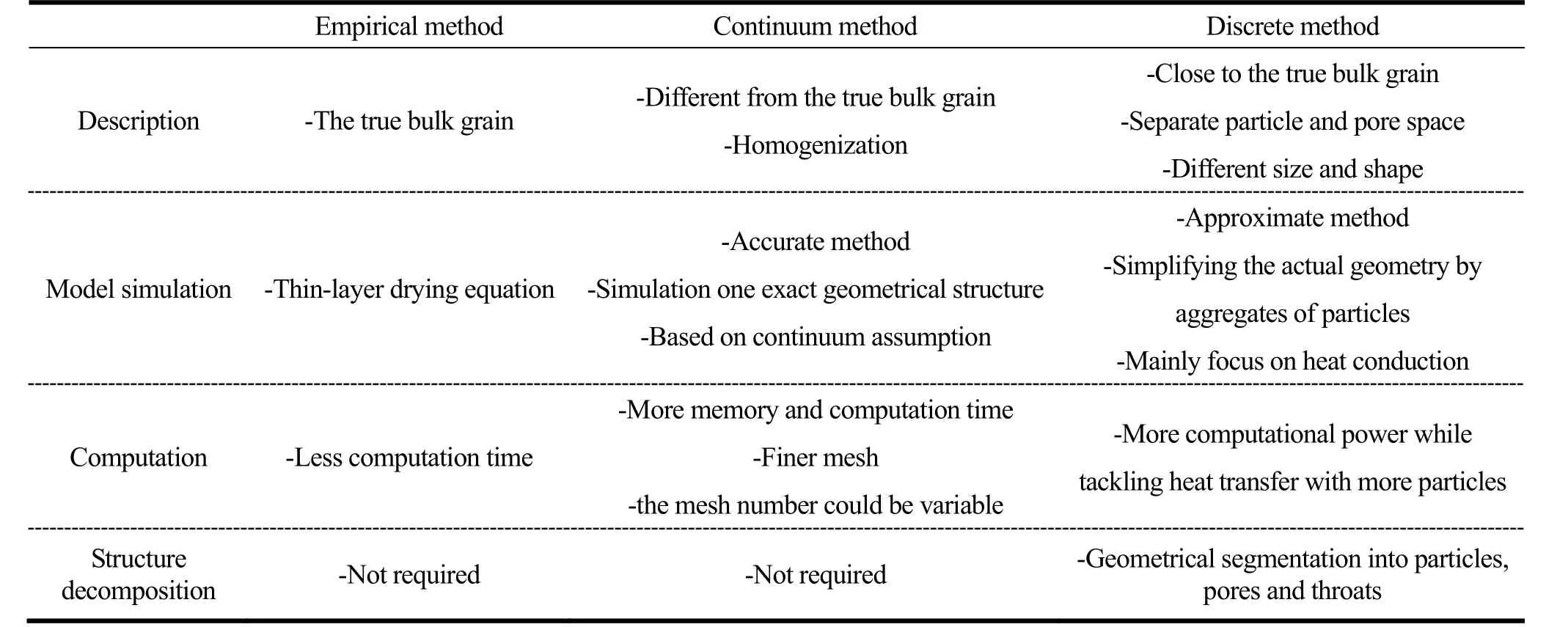

The empirical method, the Continuum method and the discrete method can be used under different conditions and assumptions. The main features of the three methods are shown in Table 2.

Through the research on the heat and mass transfer of the ventilating and drying of grain piles, it is found that both the continuous medium and the pore network can deduce the ventilating and drying process of grain piles,but their accuracy needs to be improved.

The heat mass transfer model of the grain pile based on the continuum medium assumption includes all the effects related to the internal structural characteristics of the grain pile into the “effective transmission coefficient”,so that the heat and moisture exchange between grains and pores and among pores are general. The pore network model based on the hypothesis of discrete media ignores the existence of a continuous flow field between pores in the grain pile and the flow characteristics of the flow field in pores, and does not consider the gas flow direction during the simulation process of the moisture and heat exchange in grain pores. So, it cannot truly reflect the damp and heat exchange situation. In dealing with the practical problem, we can choose the suitable method according to the features of different methods.

Table 2 The main features of the empirical method, the continuum method and the discrete method

It can be seen from the project progress, there are still some practical problems and technical bottleneck that need to be addressed in the storage of grain heap ventilated dry wet and heat transfer mechanism research,including: (1) the storage of grain heap of porosity is an important place for ventilation and heat mass transfer in the drying process. Porosity and internal mass migration situation are still unable to obtain owing to limited experimental equipment; the three-dimensional ventilation and drying heat and mass transfer model can reflect the heat and mass transfer in a grain stack structure.It is also one of the key factors to study the heat and mass transfer mechanism in grain stack, but has not been obtained yet. (2) Grain parameters (geometric parameters and physical parameters) can affect the ventilation and drying process of grain piles, but generally, grain has specific geometric parameters and physical parameters. It is impossible to compare and analyze the effect of grain parameters on the ventilation and drying process by orthogonal experiment; Ventilation drying process parameters (drying medium parameters and grain silo structure parameters) can show the heat and mass transfer process of grain stack ventilation drying, but due to the limited experimental conditions and grain storage safety problems, it is impractical to explore the limit conditions of the ventilation drying process and drying effect of different grain silo structure.

With the development of relevant technique, the simulations in grain storage will be more complicated,more accurate, closer to the practical problem. All of them will lead to high requirements for solver of simulation software and computer performances.Interdisciplinary knowledge is required in research on grain storage, so related theories and application achievements in other areas also need to be introduced.With the rise of parallel computing or GPUs (graphical processing units), most computations of heat, mass,momentum transfer will be used for a more accurate

description of grain storage and guidance of operations.To sum up, many researcher study in storage grain bulk thermal mass transfer accumulation for a long time under the practical requirements of grain storage ventilation drying process optimization, and that is helpful in improving the construction of mechanism and process. The authors believe that we should combine the continuum method and the discrete method and regard the grain in piles as discrete accumulation solid phase and the pores in piles as continuous gas phase. In this case, it is capable to establish the storage grain heap ventilated dry thermal mass transfer model to decipher the heat and mass migration inside the pores in piles. Furtherly, it can simulate and explore the influence of grain parameters and ventilation and drying process parameters on the heat and mass transfer of grain piles, expose and improve the mechanism. Also, this is a better way to describe the grain heap internal heating ventilation, dry heat mass transfer model of mass transfer, clear food grain physical parameters and geometric parameters and drying process parameters and granary structure parameters on the grain bulk thermal mass transfer, the influence of ventilation drying grain bulk thermal mass transfer mechanisms, for grain storage ventilation drying process of the theoretical basis for optimization and innovation.