Effects of Inflow and Outflow of Floodwater on the Parametric Roll of a Damaged Ship

-,,,

(China Ship Scientific Research Center,Wuxi 214082,China)

Abstract:A damaged ship flooded with water does not necessarily end up with capsizing.Motions of a damaged ship during and after flooding are also worth studying.This work studied the effects of floodwater on the parametric roll of a damaged ship using a combined CFD and potential theory method.Water flooding process of a damaged compartment was simulated by the unsteady RANS equations combined with the VOF method. The accuracy of the method was verified by one available model test on flooding process.The parametric roll of the damaged ship was calculated based on the three dimensional time domain potential theory.Influence of flooding water was studied by coupling the forces obtained from flooding process simulation as external loads. The results show that the effects of floodwater on parametric roll are similar to passive anti-roll tank and are dependent on the position of damaged compartment.

Key words:floodwater dynamics;damaged opening;parametric roll;ship stability

0 Introduction

Evaluating the motion of a damaged ship is believed to be a difficult task.The motions of a damaged ship in waves are influenced not only by the external excitations of waves, but also by the internal loads of the fluid flow and sloshing. Water flowing into the compartment has a significant effect on the ship stability and safety.Under severe situations,e.g.large amplitude motions, capsizing normally might occur. Several works have been devoted to the study of capsizing and its prediction. Jasionowski et al (2001)[1-2]simulated the motion responses of one damaged Ro-Ro ship by a time domain numerical simulation method. Umeda et al (2004)[3]developed a theoretical model of a damaged ship by multiple time scale expansion, in which the interaction between slow and fast motion can be taken into account.They found that the static assumption (the ship is considered to sink gradually in keeping an upright condition) fails to predict the survivability of a damaged ship even in calm water. Spanos and Papanikolaou (2007)[4]analyzed the capsizing time of one damaged Ro-Pax ship in waves by nonlinear hydrodynamic method. The statistical simulation method was used to consider the change and the uncertainty of viscous parameters.The ship motions were solved by the linear potential flow theory and nonlinear FK forces,and the flow problem was solved by the quasi-static method based on the Bernoulli equation.The same method was also used by Van Walree et al (2007)[5]who analyzed the capsizing of one towed fishing boat.

Under certain conditions,however,it is possible that a flooded damaged ship does not capsize, but rather encounter other stability problems, e.g. parametric roll. To the author’s best knowledge,only a few works can be found dealing with this aspect.Particularly,despite a number of studies that focused on the relationship between the flooding water and the motion response of a damaged ship[6-7], the effects of flooding dynamics on the parametric roll of a damaged ship is not yet clearly understood.

Same with the research of parametric roll, the assessment of damaged ship motion is normally based on potential theory.However,the potential theory cannot characterize the influence of flooding process well. The hydrodynamic loads caused by external waves are calculated in a similar way to the intact ship, which is obviously not the case for a damaged ship; the internal sloshing caused by floodwater inside the compartment is usually ignored;the internal surface is assumed to be horizontal or a free-moving plane; the inflow and outflow of water through the damaged opening are calculated by the modified empirical Bernoulli’s equation. Furthermore,the roll damping is usually calculated by empirical formulae considering the effects of floodwater.Some researchers also use shallow water equation to simulate the physical characteristics of the internal flow inside the compartment.Chang et al(1998)[8]used this method to calculate the dynamic characteristics of the internal flow. Santos et al (2006, 2008)[9-10]studied the motion of one damaged Ro-Pax in random waves and compared with the model tests. Although the improved model can display the nonlinear characteristics of the flow inside the compartment, yet the method still fails to characterize the inflow and outflow of water through damaged opening and the internal flooding of water.

CFD method is deemed to be a better choice that can offer a detailed description of the dynamic characteristics of flow.Indeed,it has been used by several researchers to study the flooding process of damaged ships. Cho et al (2006)[11]analyzed the influence of the compartment opening geometry, the internal layout and the air compressibility on the flow process. Nabavi et al(2006)[12]investigated the influence of damaged geometric parameters on the discharge rate of water flow on deck. Gao and Vassalos (2011)[13]analyzed the hydrostatic characteristics of the section of one damaged barge on the condition of forced and free motions.Strasser(2010)[14]and Gao (2011)[15]simulated the transient and progressive flooding of a damaged barge ship in calm water.All the work mentioned above prove that CFD is able to describe the flow and its characteristics pretty well. However, it should be pointed out that it is hard for CFD method to simulate the whole damaged ship motion due to limitations of the computation resources and costs.

The above discussions inspire us to establish a method that combines CFD and potential theory to investigate the hydrodynamics of floodwater and its effects on the damaged ship motion.Firstly,flooding process of six different damaged openings are studied through a CFD simulation model. The unsteady RANS equations combined with the VOF method are used. The simulation method was then validated with a standard experimental test. Forces and moments imposed by flooding water on the damaged compartment are then obtained. The parametric roll of the damaged ship is calculated based on the three dimensional time domain potential theory.Forces obtained from flooding process simulation are coupled as external loads in the parametric roll calculation. The time history records of heave, roll and pitch motions of the damaged ship at different damage locations are compared and analyzed. In parallel, the influence of different damaged openings is also investigated.

1 Simulation of the flooding process

1.1 Simulation model

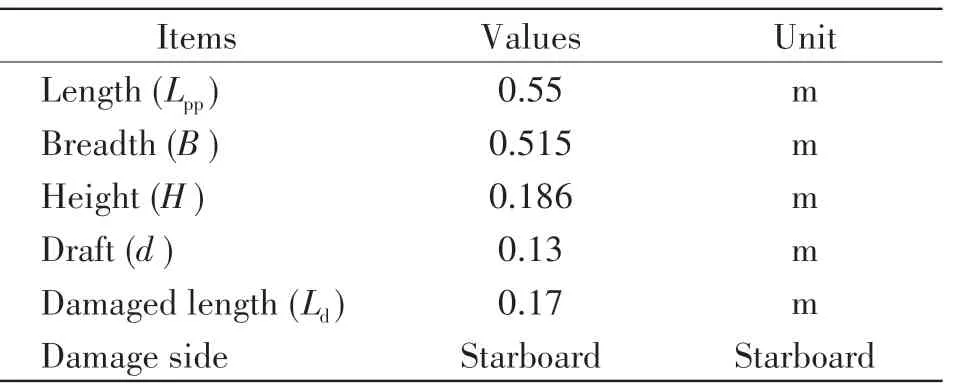

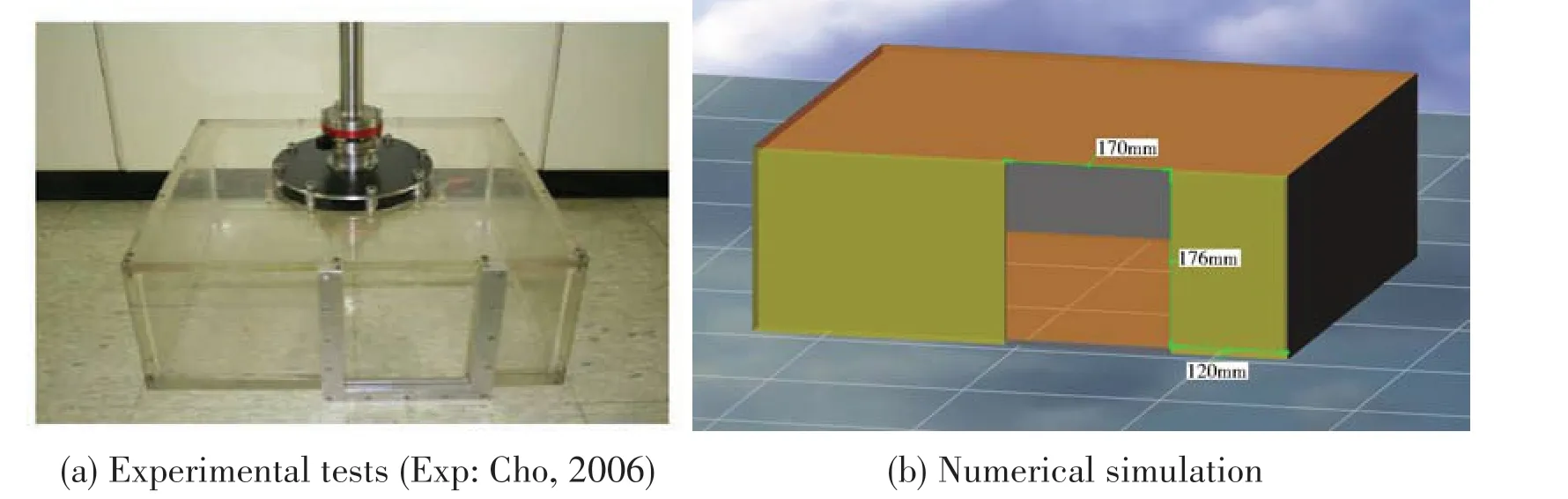

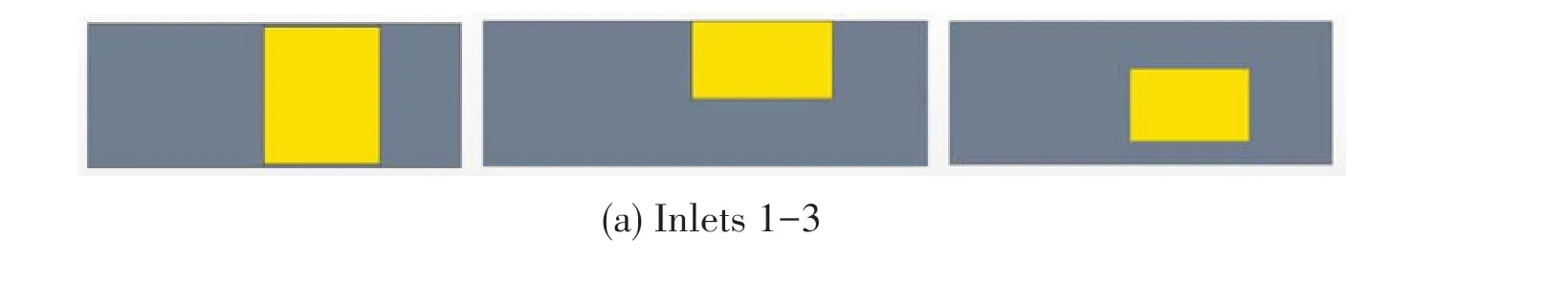

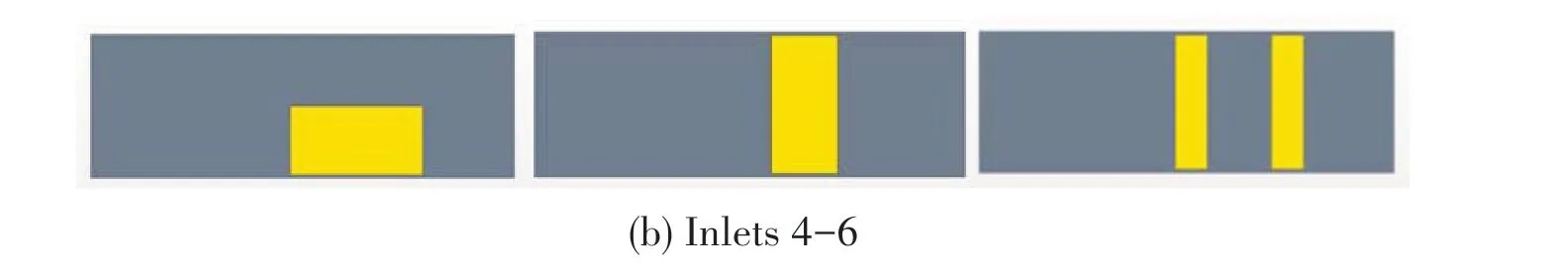

To verify the simulation method, the simulation model was built in accordance with the model tests performed by Cho (2006)[11]. He conducted a systematically experimental research on the damaged flow of six different opening shapes, which are now one of the commonly used data for the study of damaged flow. The main particulars of this model are summarized in Tab.1.The geometry is depicted in Fig.1.Six different damaged openings are shown in Figs.2-3.

Tab.1 Main particulars of the compartment

Fig.1 Geometry of damaged compartment

Fig.2 Different types of damaged opening in experimental tests(Exp:Cho(2006))

Fig.3 Damaged opening dimensions in numerical simulations

1.2 Simulation method

The commercial CFD software was used in the numerical simulation of the hydrodynamics of floodwater.Inlet 1 was chosen to verify the numerical simulation strategy.

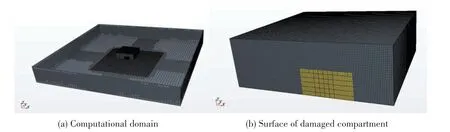

The computational domain is divided into two regions, as shown in Fig.4. The boundaries of the fluid domain are comprised of the following parts: the front boundary which is about 3.0Lppfrom the bow of the model;the back boundary which is about 3.0Lppfrom the stern of the model; the side boundaries which are about 3.0Bfrom the sides of the model; the top boundary which is about 1.0dabove the waterline;the bottom boundary which is about 2.0dbelow the waterline; the model outer surface of the compartment; the opening of the compartment. The boundaries of the second computational domain consist of two parts:the surface of the compartment and the opening of the compartment.

The growth rate of mesh sizes in the computation domain is 1.3.The meshes of the second computation domain are shown in Fig.4, and the density is kept constant in this domain. The meshes around waterline and compartment are refined.

Fig.4 Meshes of computation domain and compartment surface

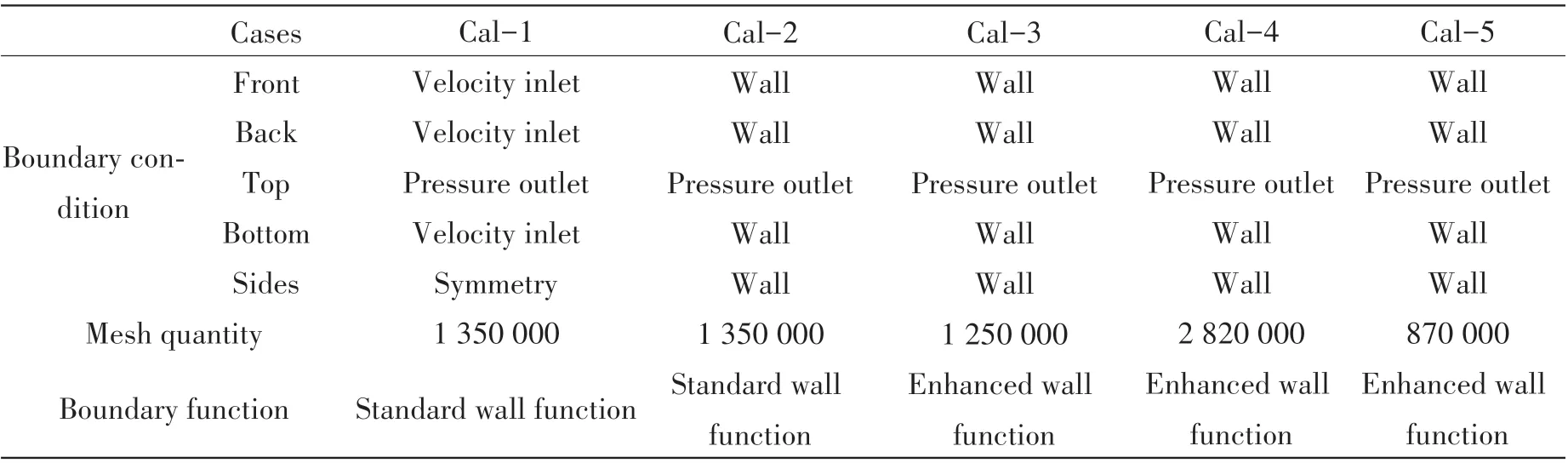

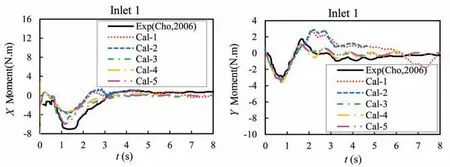

A single factor rotation method was used to study the calculation strategy for the inflow of fluid into the damaged compartment. Five different computation cases were investigated. Firstly, the boundary condition of the computational domain is studied by comparing the results of two calculation cases. In Case 1 (Cal-1), the front, back and bottom boundaries are all velocity inlet conditions. In Case 2 (Cal-2), the front, back and bottom boundaries are all wall conditions.Secondly,the wall function is studied by comparing the results of Case 2 and Case 3 with experimental results. The standard wall function is used in the‘Cal-2’and the enhanced wall function is used in the‘Cal-3’.Thirdly,the mesh quantity is studied by comparing the calculation results of Case 3, Case 4 and Case 5. The detailed information of each strategy is listed in Tab.2.

Tab.2 Comparison of computation cases

In the calculation,the damaged opening is located on one side.Thex-axis is along the longitudinal direction, and the positivey-axis points portside. The heave motion is along thezaxis. The force in thezdirection represents the compartment vertical load induced by floodwater,and this value can indirectly reflect the mass of floodwater inside the compartment.xmoment represents the roll moment imposed on the compartment,andymoment represents the pitch moment on compartment.

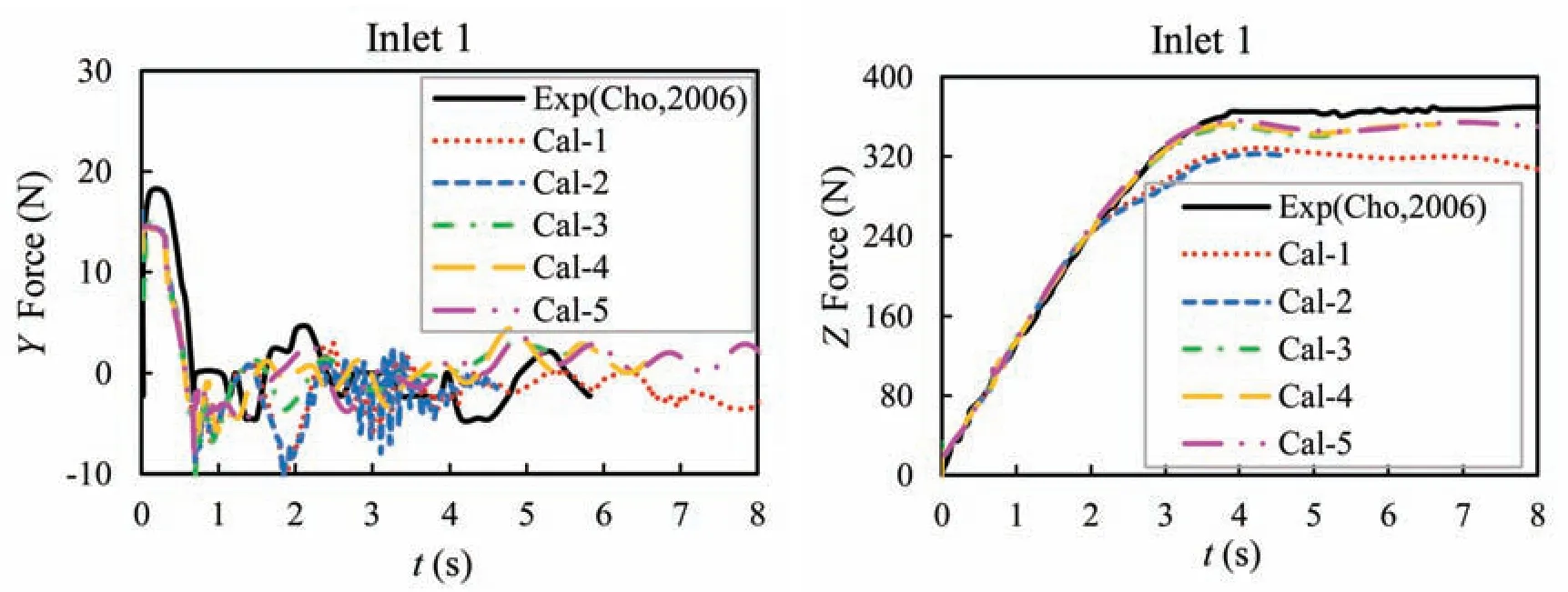

Fig.5 Comparison of forces calculated by different computation cases

Fig.6 Comparison of moments calculated by different computation cases

The comparison of calculated results and model test results in different cases is shown in Figs.5-6. The results show that the calculated results by Cal-3, Cal-4 and Cal-5 are in good agreements with the results from model tests. Considering the mesh quantity in Cal-5 is less than the mesh quantity in Cal-3 and Cal-4, the calculation strategy used in‘Cal-5’is used for the following simulations and analysis.

1.3 Influence of different damaged openings

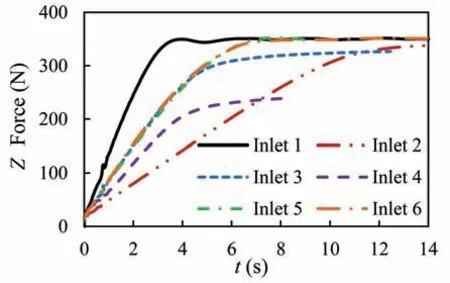

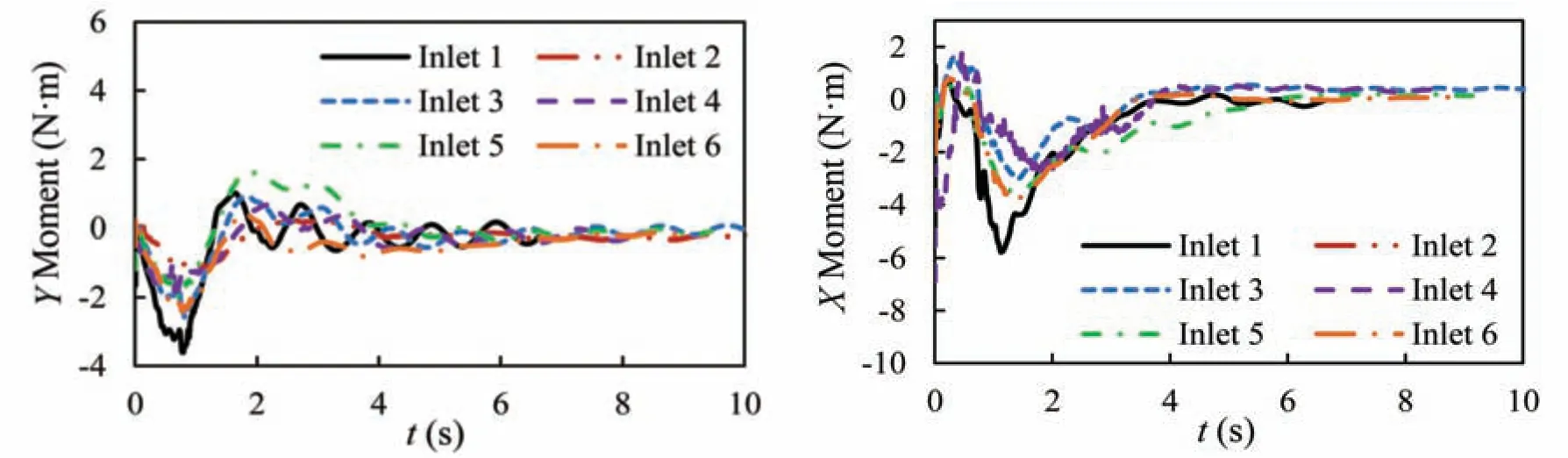

The other inlets are also calculated sequentially based on the calculation method used for Inlet 1,as shown in Figs.7-8.From the comparison curves,it can be seen that the flooding process of Inlet 1 which has the largest opening area is the fastest. The speed of Inlet 2 is the slowest, because this opening is above the waterline. For the roll moment, it starts with positive values and then becomes negative, followed by an equilibrium at the end. These characteristics are basically consistent with the dynamic characteristics of the flow process. In the initial stage of the flow process,the water accumulates at the entrance side, then rushes to the opposite direction of the entrance,and finally reaches an equilibrium.For the pitch motion,the amplitude is relatively small compared with the roll moment, as it is mainly caused by the rotation of floodwater.

Fig.7 Comparison of forces in vertical direction with different types of inlets

Fig.8 Comparison of moments in pitch motion and roll motion with different types of inlets

2 Calculation of parametric roll

2.1 Computation model

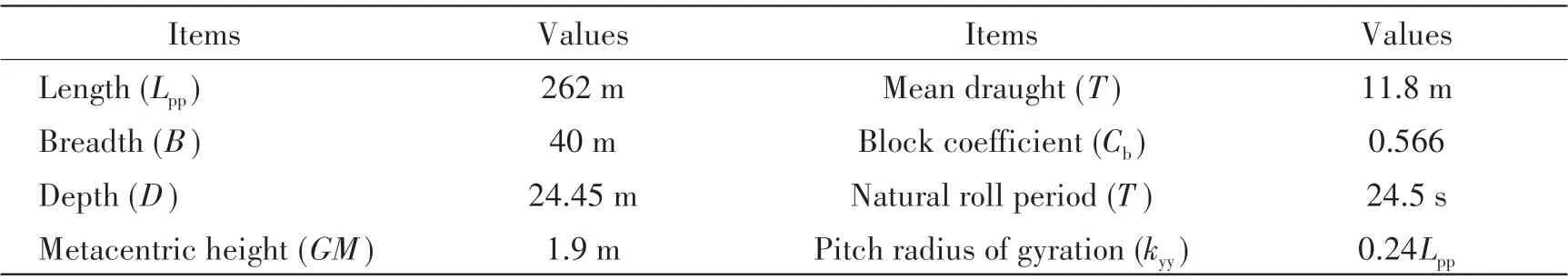

The international standard study model C11 containership was used as the calculation model for the research of the effects of floodwater on parametric roll. The main particulars of the ship are listed in Tab.3.The hull gemoetry is shown in Fig.9(a).The parametric roll in inact state was conducted in our seakeeping basin (Fig.9(b)). The experimental results were used to verify the calculation method described in the following section.

Tab.3 Principal particulars of C11 containership(Scale 1/65.5)

Fig.9 Hull geometry of C11 containership and ship model in the free running experiment

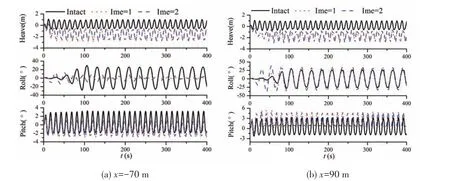

2.2 Computation method

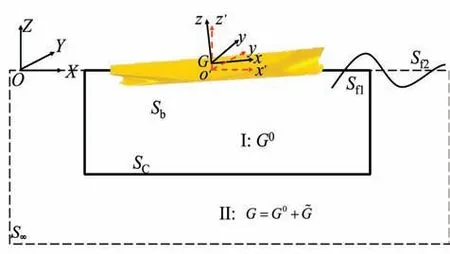

A mixed source method using both transient Green functions and Rankine sources was developed for the calculation of large amplitude roll motion. In this method, the fluid domain is split into two domains as shown in Fig.10. The inner fluid field (I) is solved by Rankine sources within the domain enclosed by the wetted body surfacesSb, one part of the free surfaceSfnear the body(Sf1), and an arbitrarily shaped control surfaceSCaway from the body. The transient Green functions was used to solve the problem in the outer fluid field (II) distributed over control surface,whereS∞is the imaginary surface at infinity.

The advantage of this method is that Rankine sources are much better than transient Green functions near the body and free surface, and that the control surface can be selected to guarantee good numerical behaviors of the transient Green functions.The transient Green functions satisfy both the linearized free surface boundary condition and the radiation condition, allowing the control surface to be placed fairly close to the body.

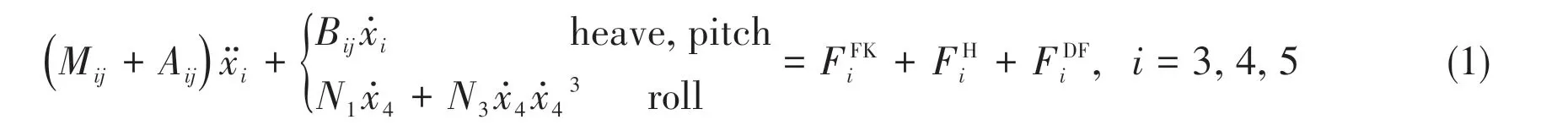

The coupled heave-roll-pitch mathematical model expressed in Eq.(1) was used to calculate ship motions in regular head seas.

Fig.10 Mixed source formulation of panel method

whereMi jis the mass or moment inertia;Ai jis the added mass or added inertia;Bi jis the roll damping;xiis the displacement inidirection;N1,N3are the linear and cubic roll damping coefficients, respectively, which can be obtained from model tests or experience formula;FFK+Hare the FK forces and hydrostatic forces, and can be calculated by integrating the incident wave pressure around the instantaneous wetted hull surface;FDFare diffraction forces calculated in the same way as radiation forces.

2.3 Results and validations

In order to study the effects of water inflow on the large amplitude roll motion,the parametric roll of intact ship under different wave conditions was firstly simulated.The three dimensional time domain panel method was used to calculate the parametric roll in regular waves.The results were compared with the model tests we have conducted. Fig.11 displays the roll amplitudes along with the Froude number under different wave slopes.We can see that the maximum roll amplitude measured in the experimental tests reaches almost 35°. The roll amplitudes calculated by three dimensional hybrid time domain panel method are in good agreement with experimental results. Fig.12 displays the time history records of roll and pitch motions under one wave condition. The comparisons between numerical simulations and experimental tests prove the reliability of the three-dimensional time domain method for the calculation of parametric roll.

Fig.12 Time history records of roll and pitch motions(Fn=0.1,H/λ=0.03)

3 Influence of floodwater on the parametric roll

3.1 Mathematical model

Two approaches were used to investigate the influence of floodwater on damaged roll motion.In the first method,the floodwater is treated as one part of the hull.The mathematical model can be written as Eq.(2). In the second method, the floodwater is treated as one independent part.The mathematical model is written as Eq.(3).

Method-1(Ime-1):

whereMw(t)is the mass of floodwater;M?w(t)is the velocity of floodwater mass;is the restoring moment caused by floodwater inside the compartment;is the liquid load due to the motion of floodwater inside the compartment.

In this paper,the effects of floodwater on parametric roll were analyzed by these two methods separately. In the simulation, the loads induced by the floodwater and the change of water amount are calculated by CFD method with the scale of 77.7. The ship motions are calculated by the three dimensional time domain panel method. The initial draft of the damaged compartment is the same with the draft of the ship.

3.2 Results and discussions

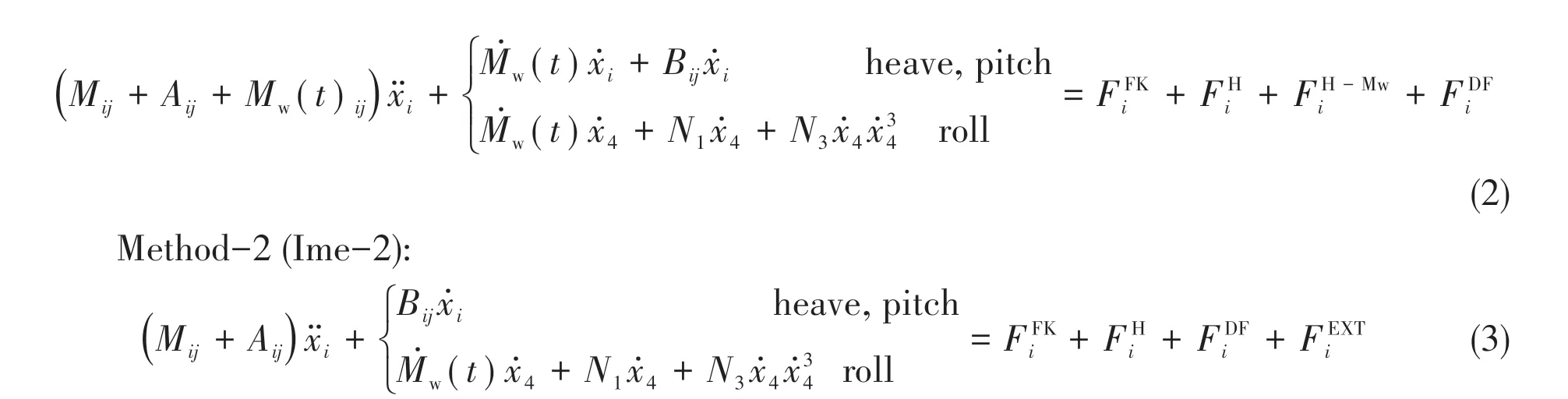

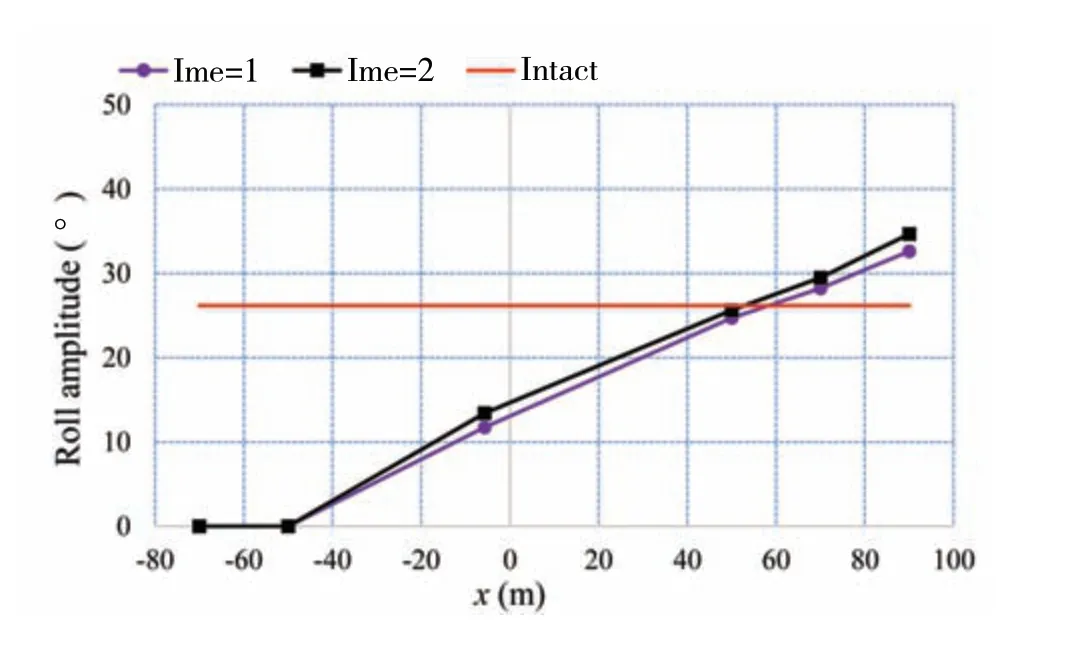

The ship is assumed to be sailing in head seas with forward speedFn=0.1 under the wave slopeH/λ=0.03.Fig.13 displays the time history records of heave,roll and pitch motions of the damaged ship,assuming that the damaged compartment is located at thex=-70 m andx=90 m,respectively.The results show that the time history calculated by Method 2(Ime-2)is more violent than the results calculated by Method 1 (Ime-1) in the initial stage. This is because Method 1 considers the influence of floodwater through the change of water amount, while Method 2 considers the force and moment directly. The forces and moments are very violent (shown in Fig.7 and Fig.8) due to the high hydrostatic pressure across the opening in the initial several minutes. The parametric roll disappears after 50 s in the case that the damaged compartment locates atx=-70 m, while the roll amplitudes increase from the beginning in the case that damaged compartment locates atx=90 m. This distinct motion response indicates that the longitudinal location of the damaged compartment has a significant influence on the parametric roll of a damaged ship.

Fig.13 Comparison of time history when damaged opening located at x=-70 m,x=90 m(The‘intact’in the curves stands for the intact state.The‘Ime=1’and‘Ime=2’in the curves stand for the motions calculated by mathematical model 1 and model 2,respectively.)

In order to further understand the effects of the damaged compartment position on the ship motion, we calculated the roll amplitudes under conditions of different longitudinal positions of the damaged compartment.From the calculation results (shown in Fig.14),it can be seen that the roll amplitudes are considerably affected by the longitudinal location of the damaged compartment.The amplitudes increase with the damaged locations in thex-axis,which is similar to the passive anti-roll tank.

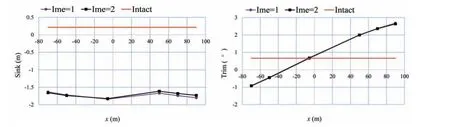

It is known that the increase of water amount will cause the sinkage and trim of the damaged ship. Fig.15 shows the sinkage and trim compared with the intact ship due to water accumulation inside the hull.Obviously,the change of sinkage and trim cannot be ignored.Trim angle is more susceptible to thex-axis locations of damaged compartment comparing with the sinkage, in which the latter shows to be independent ofx-axis locations. From the comparison results, we can also see that the results calculated by Method 1 and Method 2 are almost the same.This is because the final volumes of floodwater inside the compartment calculated by these two methods are almost the same, and the final states of the ship are basically the same.

Fig.14 Comparison of roll amplitudes calculated by different methods

Fig.15 Comparison of ship sinkage and trim calculated by different methods

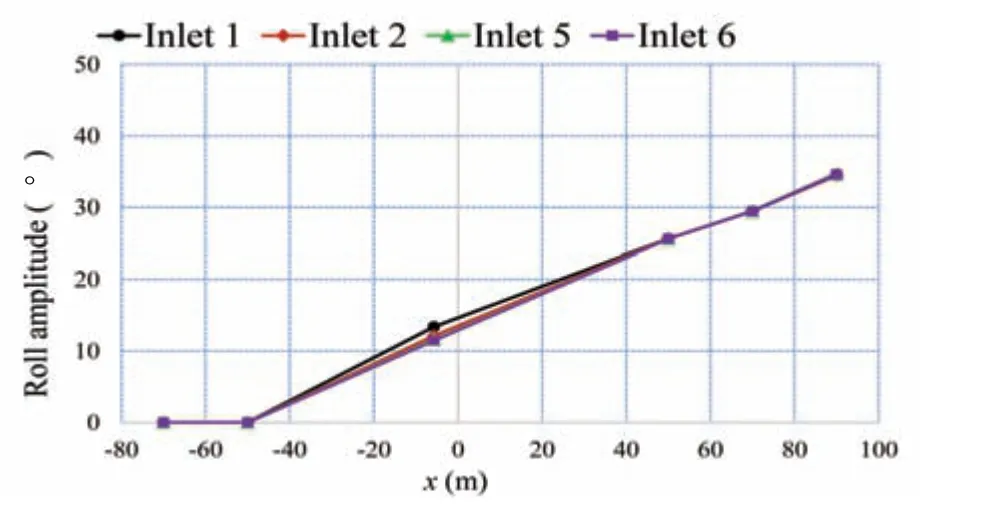

Method 2 is used to further compare the effects of different openings on the roll amplitude.The calculation results are shown in Fig.16.It is seen that the influence of different opening forms on the stability of the ship is basically the same. This can be explained that the loads imposed on the compartment are basically the same when it reaches the steady state, despite that different opening forms have different effects on the initial stage of the ship.

Fig.16 Comparison of roll amplitude with different types of inlets

4 Conclusions

In this paper, the flooding process of dynamical characteristics of floodwater was studied by CFD method,and the influence of different openings on the parametric roll of C11 containership was analyzed.The following remarks can be obtained:

(1)The forces/moments induced by the floodwater differ considerably with different shapes of the damaged openings in the initial stage of flooding process.The changes of forces/moments during flowing process are basically consistent with the dynamic characteristics of the flow process.

(2) The parametric roll of damaged ship is significantly influenced by longitudinal locations of the damaged compartment. The effects of floodwater are similar to passive anti-roll tank.

(3)Sinkage and trim of the ship caused by flood water are noticeable.Trim angle is susceptible to thex-axis locations of damaged compartment,while sinkage tends to be independent of thex-axis locations of damaged compartment.

It should be noted that only the influence of damaged compartment influx on the ship motion is considered in this work.Future work will take into account the time domain coupling between the damaged compartment influx and the ship large amplitude motion.

Acknowledgements

This work was supported by Ministry of Industry and Information Technology of China([2017]614).Preliminary results were firstly presented on the 13th International Conference on the Stability of Ships and Ocean Vehicles (STAB 2018), and many researchers gave their valuable comments with regard to the work. The C11 containership used in this paper is provided by IMO correspondence group for the study of second generation intact stability. The authors sincerely thank the above organization and individuals.

- 船舶力學(xué)的其它文章

- Effective Elastic Modulus Characteristics of Buoyancy Materials of Full-ocean-depth Manned Submersible

- Fatigue Strength Assessment of Welded Joints Using Strain Energy Density Method Based on NSIF

- Hydrodynamic Analysis of a Spar Platform under Asymmetrical Mooring System

- Analysis of Drilling Riser in Re-entry Operation Under Complex Currents

- Nonlinear Numerical Simulation for Flexible Pipes Carcass Wet Collapse

- Numerical and Experimental Study for SCR with Cable3D