Artificial solid electrolyte interphase based on polyacrylonitrile for homogenous and dendrite-free deposition of lithium metal?

Hang-Yu Xu(徐航宇), Quan Li(李泉), Hong-Yi Pan(潘弘毅), Ji-Liang Qiu(邱紀(jì)亮),Wen-Zhuo Cao(曹文卓), Xi-Qian Yu(禹習(xí)謙),?, and Hong Li(李泓),?

1Beijing National Laboratory for Condensed Matter Physics,Institute of Physics,Chinese Academy of Sciences,Beijing 100190,China

2University of Chinese Academy of Sciences,Beijing 100049,China

Keywords: lithium deposition,polymer coating,artificial solid electrolyte interphase,polyacrylonitrile

1. Introductio n

Lithium metal anode has become particularly attractive as an ultimate anode for next-generation high-energy batteries due to the high theoretical specific capacity(3860 mAh/g)and the most negative equilibrium potential(-3.04 V vs.standard hydrogen electrode).[1,2]Tremendous research efforts have been devoted to lithium metal anode since the 1970s, however,the commercialization of lithium metal batteries(LMBs)is still hindered by poor cycling life and the severe safety hazard.[3,4]Major challenges for LMBs come from the problems of lithium metal anode including high chemical reactivity, large volume changes, and uncontrollable lithium dendrite growth.[5-7]The former two issues likely result in inhomogeneous lithium deposition which is the direct incentive of the latter one. In order to overcome these problems,some prominent strategies have been proposed such as mechanically blocking with solid electrolyte,[8-11]using superconcentrated electrolyte,[12,13]controlling solid electrolyte interface (SEI) forming with electrolyte additives,[14,15]modifying interface,[16-18]designing three-dimensional(3D)structured anode,[19-21]etc.

In addition, building an artificial SEI on lithium metal by polymer coating has shown promising results.[22-25]First,the polymer layer can avoid direct contact between lithium metal and electrolyte, and therefore decrease the continuous consumption of active lithium. Then, the flexible polymer layer can improve the coherency of interfacial stress distribution and accommodate the interface fluctuation during lithium plating and stripping. Finally, a homogeneous polymer layer can make the lithium ion flux uniform,reduce the uncontrolled lithium nucleation and growth,and thus suppress the dendrite growth.[26]Cui et al.[27]investigated the effects of different kinds of polymer coatings on electrodeposited lithium. Their results showed that high dielectric constant polymers can provide higher exchange currents and promote larger lithium deposits. Polyacrylonitrile(PAN)with polar nitrile groups in the side chain has a relative high dielectric constant and,therefore,could be an ideal coating material for lithium metal. PANbased polymer electrolyte has been intensively investigated owing to its high ionic conductivity, great homogeneity, and good mechanical properties.[28-30]

Herein, we investigate the effects of PAN-based polymer coating as an artificial solid electrolyte interphase on electrodeposited lithium. We find that the polymer coating composed of polyacrylonitrile and lithium bis(trifluoromethylsulphonyl)imide (LiTFSI) is able to suppress the lithium dendrites and improve the coulombic efficiency in Li-Cu cells with carbonate based electrolyte. In addition, heat treatment can further promote the coating effects on regulating lithium deposition and reducing side reactions,leading to improved cycling performance over the pristine ones. This can be attributed to the fact that heat treatment improves the homogeneity, compaction, and mechanical properties through changing the chemical structure of the PAN polymer matrix which could be indicated by the attenuated total reflection Fourier transformed infrared(ATR-FTIR)spectrum.

2. Experimental

2.1. Preparation of PAN coated Cu electrode

Prior to sample preparation,PAN(Mw=150,000,Sigma Aldrich) was dried at 50°C in vacuum oven for 12 hours.12μm thick copper current collector was wiped with alcohol until the surfaces were clean,and dried at 70°C.To coat PANbased thin layer on Cu current collector, PAN and LiTFSI were firstly added into N,N-dimethylformamide(DMF)with a PAN/LiTFSI mole ratio of 10:1 and the concentration of PAN in DMF was 3.6 g/100 mL. The mixture was stirred at 50°C for 8 hours in order to obtain well dispersed slurry. Then,the slurry was coated onto the copper foil using a spin coater with programed speed and time.The solvent was removed by evaporation in a vacuum chamber for 8 h. The Cu electrodes with heat-treated PAN coating layer were prepared by heating the as-obtained electrodes at 120°C for 5 min. The thickness of the pristine PAN coating film was 3.17μm while heat-treated PAN coating film was 2.24 μm. All the procedures sensitive to moisture or oxygen during sample preparation were carried out in Ar-filled gloveboxes.

2.2. Cell assembly and electrochemical characterizations

Electrochemical measurements were performed using CR2023 coin-type cells. The working electrodes, including Cu electrodes with no polymer coating,pristine PAN coating,and heat-treated PAN coating, were punched into 14 mm diameter discs, and paired with 15 mm diameter lithium electrodes using polypropylene separators. 120 μL electrolyte was composed of 1 M LiPF6in ethylene carbonate (EC) and dimethyl carbonate (DMC) with the volume ratio of 1:1. All the cells were rested for 8 hours before testing.

Cycling tests were carried out galvanostatically at a current density of 0.5 mA·cm-2. Lithium was deposited onto the working electrode at the capacity loading of 1 mAh·cm-2,and subsequently stripped away until the voltage reached 1.0 V.Electrochemical impedance spectra were collected on electrochemical workstation(Zhanner IM6)at open circuit potential with a frequency range from 5 mHz to 8 MHz.

2.3. Characterizations

Hitachi S-4800 scanning electron microscopy(SEM)was employed to determine the surface morphology of the working electrodes at 10.0 kV. The electrodes after the 1st halfcycle of lithium deposition were washed with DMC and dried in a vacuum chamber before SEM analysis. The samples were prepared in an Ar-filled glovebox and transferred to the SEM chamber by a sealed transfer box.

The ATR-FTIR spectroscopy was performed at Vertex 70 Brucker to characterize the structure change of heat-treated PAN thin film with LiTFSI. The roughness and mechanical properties of the PAN coating layer were measured with peak force quantitative nanomechanical(PFQNM)mode by a scanning probe microscope(SPM,Bruker Multimode 8)equipped in an Ar-filled glove box (H2O and O2<0.5 ppm). The exclusive PFQNM probe is employed in this experiment.

3. Results and discussions

3.1. Electrochemical characterizations

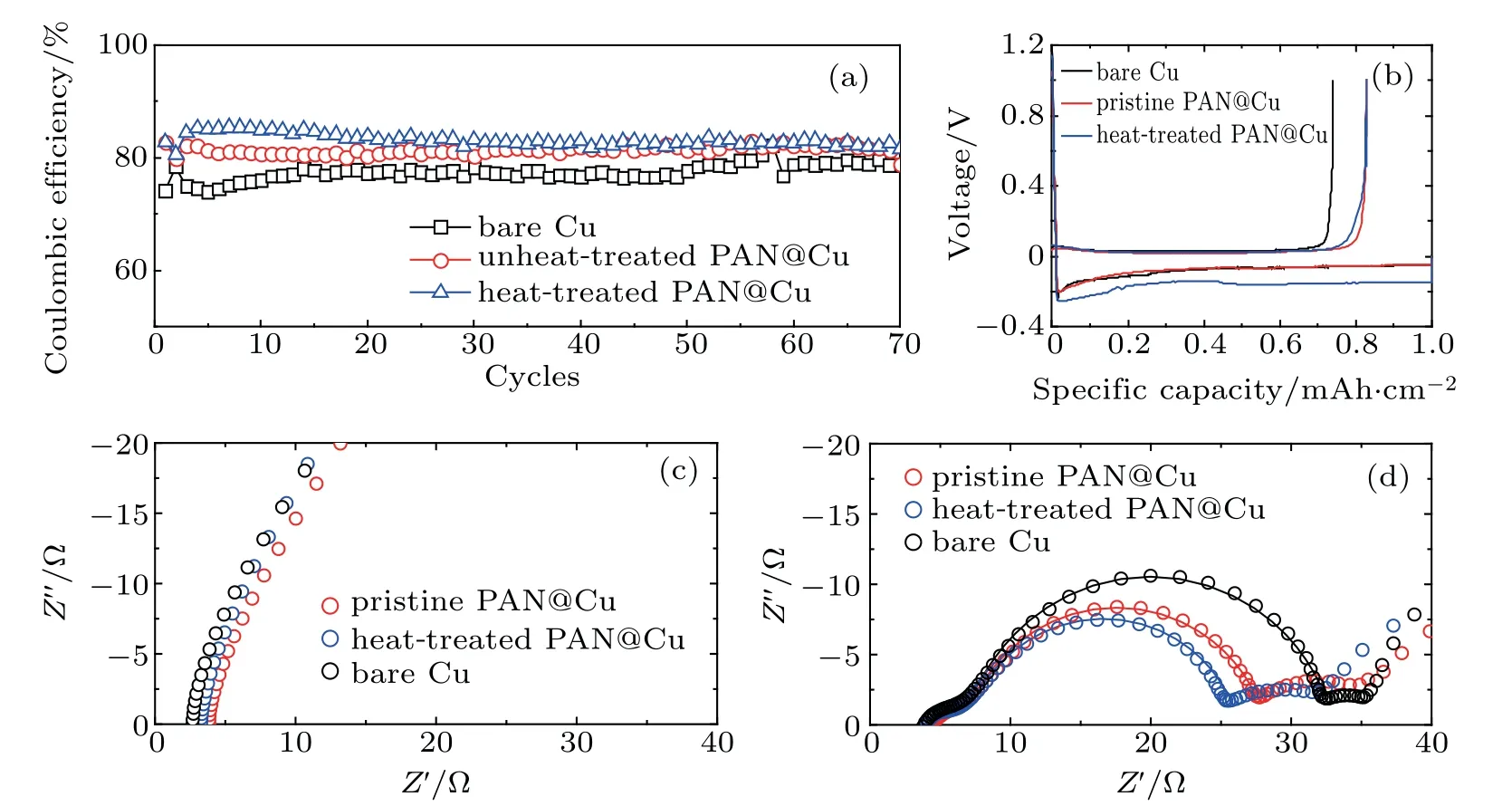

Li-Cu Cells are adopted to demonstrate the effects of PAN-based polymer coating on cycling performance. Figure 1(a) shows the galvanostatic cycling performance at a current density of 0.5 mA·cm-2with a loading capacity of 1.0 mAh·cm-2. The cells with bare Cu foil as working electrode exhibit a low coulombic efficiency of less than 80%.It is generally accepted that carbonates with relatively low lowest unoccupied molecular orbital(LUMO)energies are less stable to lithium reduction than ethers.[31]Thus, without any additives, the natural SEI formed on electrodeposited lithium in contact with carbonate electrolyte is more inorganic and fragile. During lithium plating and stripping,the recurrent breakdown and repair of SEI will cause continuous consumption of active lithium, leading to poor cycling performance of Li-Cu cells. A higher coulombic efficiency of 81%is retained in the cell of Cu electrode coated with pristine PAN layer. For the Cu electrode coated with heat-treated PAN layer,the coulombic efficiency is improved to 85%at the early stages of cycling.Figure 1(b)shows the discharging/charging voltage profiles of different Cu electrode at the first cycle,among which the heattreated PAN set appears to have the largest stripping capacity of lithium in the first charge. These phenomena mainly stem from the fact that PAN coating functions as passivation layers, which avoids the direct contact between electrodeposited lithium and electrolyte, since the reduction of side reactions can be very helpful to increase the electrode efficiency.

The electrochemical impedance spectra of Li-Cu cells before(Fig.1(c))and after(Fig.1(d))the 70th cycle are measured at open circuit potential. In the cycled cells, the resistances contributed from SEI are small,as can be seen from the first semicircles at high frequencies. Furthermore, the electrodes with PAN coating display lower charge-transfer resistances than bare Cu over cycles, which can be seen from the second semicircles at medium frequencies.

Fig. 1. Electrochemical characterizations of Cu electrodes with no coating, pristine PAN coating, and heat-treated PAN coating in Li|Cu cells. (a)Coulombic efficiency at a constant current density of 0.5 mA·cm-2of the Cu electrode(loading capacity 1.0 mAh·cm-2). (b)The corresponding galvanostatic discharge/charge profiles of the 1st cycle. Impedance spectra of pristine(c)Li|Cu cells and(d)cycled cells at open circuit potential after the 70th discharge. The scattered dots in panel(d)represent impedance data while the solid lines are fitting curves.

3.2. Morphologies of electrodeposited lithium

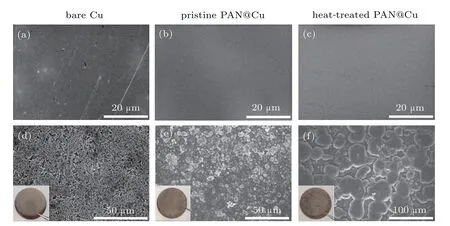

To evaluate the dendrite suppression ability of PAN-based polymer coating,the morphologies of electrodeposited lithium on the working Cu electrodes are investigated by SEM. For the bare Cu electrode,with some tiny scratches on the pristine surface(Fig.2(a)),a large number of needle-like dendrites are observed after the 1st deposition of lithium at a current density of 0.5 mA·cm-2and a capacity of 1.0 mAh·cm-2(Fig.2(d)).When stripped away during cell charging, the needle-like deposits are easy to lose electrical contact with the current collector and cause “dead lithium” generation. This is another contributing factor of the low coulombic efficiency of bare Cu electrode.

In contrast, the Cu electrode with PAN coating shows a smooth surface (Figs. 2(b) and 2(c)). With the PAN coating layers,the electrodeposited lithium exhibits a particle-like morphology with no observable dendrites on the PAN coated Cu electrode(Figs.2(e)and 2(f)). The deposited lithium particles on heat-treated PAN coated Cu are more homogenous and the size grows even one order of magnitude larger than the unheated one.

The quality of the SEI layer is critical for the performance of electrodeposited lithium. When lithium deposits on bare Cu,the uncontrollable SEI forming process leads to an uneven and fragile interface. In addition, the large volume change during lithium deposition will cause the formation of cracks on the SEI. Both of these factors contribute to the local enhancement of the Li-ion flux, which will result in the formation of lithium dendrites. However, the well-distributed PAN coating layers can make the Li-ion flux and lithium deposition uniform,and thus suppress the lithium dendrites.

Fig.2.Pristine morphology of Cu electrodes with(a)no coating,(b)pristine PAN coating,and(c)heat-treated PAN coating.Lithium deposition morphology on Cu electrodes with(d)no coating,(e)pristine PAN coating and(f)heat-treated PAN coating. The depositing current density is 0.5 mA·cm-2 with a loading capacity of 1.0 mAh·cm-2.

3.3. Mechanical properties of PAN coating

In order to investigate the intrinsic reason,the roughness and mechanical properties of the PAN coating are studied by scanning probe microscopy. As can be seen from Figs. 3(a)and 3(b), the heat-treated PAN coating layer has more uniform and compact morphology with less and smaller holes than the pristine PAN coating. The well distributed polymer layer could partly contribute to the homogenous lithium deposition as well. Significant mechanical property change can be seen from Figs.3(c)and 3(d)that heat treatment dramatically reinforces the PAN coating’s Young modulus from 175 MPa to more than 450 times higher(82.7 GPa). The reinforced Young modulus may be caused by structure changes of PAN molecular chains during heat treatment as will be discussed below.

It is supposed that modulus on the order of 1 GPa would be sufficient to suppress lithium dendrites,[32]so that the heattreated PAN coating should be a strong physical barrier to prevent the dendrite growth. The homogeneity of mechanical strength of heat-treated PAN is also improved compared to the pristine PAN,which may be helpful for unifying the interface stress distribution of electrodeposited lithium.

Fig. 3. Morphology of (a) pristine PAN coating and (b) heat-treated PAN coating on Cu electrode. Young modulus mapping of (c)pristine PAN coating and(d)heat-treated PAN coating on Cu electrode.

3.4. Structure change of heat-treated PAN

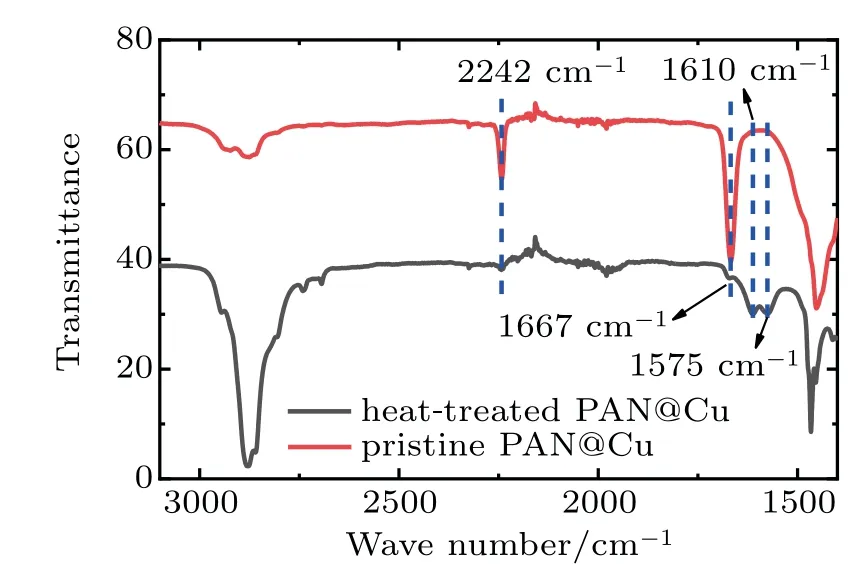

Figure 4 shows the changes of infrared absorbance spectrum of a PAN-LiTFSI thin film which is heated at 120°C for 5 mins in Ar atmosphere. The absorption at 1667 cm-1is from the residual DMF which is the solvent used for PAN film preparation. The nitrile absorption at 2242 cm-1decreases after heat-treatment, which indicates that the nitrile groups have been transformed through some reactions with PAN degraded. Based on former research, cyclization, dehydrogenation,aromatization,oxidation,and crosslinking would result in the formation of conjugated ladder structure in PAN during heat treatment at 180-300°C, which will lead to a series of complex color changes.[33,34]Similar color changes are observed at a lower temperature at 120°C when PAN with LiTFSI is heated.Doublet bands at 1575 cm-1and 1610 cm-1are observed. Heterocyclic structure with conjugated double bonds resulted from linear polymerization of nitrile groups is responsible for such observations.[35]It can be deduced that the nucleophilic attack of bis(trifluoromethylsulphonyl)imide anion (TFSI-) at the nitrile groups in PAN generates such kinds of structure in the main chain of PAN during heat treatment. The flexibility of polymers originates from the internal rotation of the main chains. Since heterocyclic structure with conjugate double bond cannot rotate freely, the Young modulus of heat-treated PAN with such kinds of structure can be increased. Since the amount of nitrile groups in PAN will be reduced during heat treatment, heat-treated PAN may be less reactive with lithium,which will improve the chemical stability of the interface.

Fig.4.FTIR spectra of pristine PAN-LiTFSI film and heat-treated PANLiTFSI film(120 °C for 5 min)from 1400-3100 cm-1.

3.5. Discussion on the PAN coating effects

On the basis of the above results, the effects of PAN coating layer on the electrodeposited lithium are illustrated in Fig. 4. For the bare Cu, the unstable SEI layer causes the continuous consume of electrodeposited lithium and the unevenness of Li-ion flux which give rise to the non-uniform and dendritic morphology(Fig.5(a)). Whereas on Cu coated with PAN,the smooth coating layer leads to uniform and dendritefree lithium deposition (Fig. 5(b)) through regulating the Liion flux. A step further, the heat-treated PAN layer shows the improved homogeneity of its morphology and mechanical properties which could provide stronger effects on homogenizing the lithium deposition. Thus,there would be more homogenous nucleation sites and larger deposit particles during lithium deposition(Fig.5(c)).

A higher coulombic efficiency is also observed on the Cu electrode with heat-treated PAN coating. There are three factors that may contribute to this. First,the polymer coating can improve the coulombic efficiency through avoiding the direct contact between electrolyte and active lithium,and heat treatment improves the compaction and mechanical strength which provides better protection. Second,the heat-treated PAN may be less reactive to lithium because of the chemical change during heat treatment. Third, it promotes larger deposits with smaller surface areas and minimizes the exposure of the fresh lithium at the interface.

Fig. 5. Schematic illustration of the lithium behavior on the Cu electrodes with(a)no coating,(b)pristine PAN coating,and(c)heat-treated PAN coating. The brown parts stand for Cu,blue parts stand for PANbased coatings,and the grey parts stand for electrodeposited lithium.

4. Conclusion and perspectives

In summary,we propose a PAN-based polymer coating as an artificial solid electrolyte interphase over electrodeposited lithium. Cu electrodes with no coating,pristine PAN coating,and heat-treated PAN coating are prepared to examine the effects of PAN coatings on lithium deposition morphology and cycling performance. It is demonstrated that the PAN coating leads to uniform and dendrite-free lithium deposition as well as relatively high coulombic efficiency through homogenizing lithium deposition and reducing the side reactions of active lithium. Notably, heat treatment is proved to be an effective modification of PAN coating. PAN molecular structure change will take place during heat treatment with obvious color change. The heat-treated PAN coating shows better compaction,higher mechanical strength,and improved homogeneity of morphology,which contribute to larger lithium deposits with a higher coulombic efficiency. This work provides strategies for the design and modification of polymer coating to achieve a lithium metal anode with good stability and high coulombic efficiency. Thus, constructing artificial SEI with good chemical composition, compaction, homogeneity, and mechanics is an effective method for building better lithium metal batteries.

- Chinese Physics B的其它文章

- Topological magnon insulator with Dzyaloshinskii-Moriya interaction under the irradiation of light?

- Wavelength dependence of intrinsic detection efficiency of NbN superconducting nanowire single-photon detector?

- Effects of CeO2 and nano-ZrO2 agents on the crystallization behavior and mechanism of CaO-Al2O3-MgO-SiO2-based glass ceramics?

- Modulation of magnetic and electrical properties of bilayer graphene quantum dots using rotational stacking faults?

- Thermal conductivity characterization of ultra-thin silicon film using the ultra-fast transient hot strip method?

- Thickness-dependent magnetic anisotropy in obliquely deposited Fe(001)/Pd thin film bilayers probed by VNA-FMR?