Preparation of Tungsten Film and Its Tribological Properties under Boundary Lubrication Conditions

Li Xingliang; Yue Wen; Wang Song,3; Li Guolong; Zhao Shiqian

(1. Aviation Key Laboratory of Science and Technology on Precision Manufacturing Technology, Beijing Precision Engineering Institute for Aircraft Industry, Beijing 100076; 2. School of Engineering and Technology, China University of Geosciences (Beijing), Beijing 100083; 3. Xi’an Research Institute of China Coal Technology & Engineering Group Corp., Xi’an 710054)

Preparation of Tungsten Film and Its Tribological Properties under Boundary Lubrication Conditions

Li Xingliang1,2; Yue Wen2; Wang Song2,3; Li Guolong1; Zhao Shiqian1

(1. Aviation Key Laboratory of Science and Technology on Precision Manufacturing Technology, Beijing Precision Engineering Institute for Aircraft Industry, Beijing 100076; 2. School of Engineering and Technology, China University of Geosciences (Beijing), Beijing 100083; 3. Xi’an Research Institute of China Coal Technology & Engineering Group Corp., Xi’an 710054)

Tungsten film (W film) is deposited by using the ion beam assisted deposition (IBAD) on the 316L substrate surface in this experiment. The micro structure and nano-hardness of the film are investigated by scanning electron microscopy (SEM) and nano-indentation tester. The tribological behavior of W film under lubrication by oil with ZDDP and MoDTC is evaluated by a SRV test machine. The tribo-film formed on the worn surfaces is investigated by X-ray photoelectron spectroscopy (XPS) to find out the tribological mechanisms between the W film and the two additional additives. The result shows that the W film lubricated by ZDDP and MoDTC-blended base oil has synergistic effects on the friction reduction property, while the anti-wear property is mainly caused by the hard surface of W film.

IBAD, W film, lubricant additive, tribological properties.

1 Introduction

Most sliding counterparts operate inefficiently under boundary lubrication condition, because aggressive wear and consequent seizure of mating parts would occur in these lubricant deficient environments, and contribute to a high friction and wear loss which is undesirable for the lubricant system[1]. The friction and wear behavior under boundary lubrication is mainly determined by the property of the surfaces and the lubricants[2]. Investigation about the tribological properties and mechanisms of different surfaces and various lubricants has been conducted. They are mainly related with the Fe-based surface and different additives such as ZDDP and MoDTC[3]. However, with the rapid development of vacuum technology, many new surface treatment methods are introduced[4-7]. Coatings such as Al, W, DLC and some alloy films were produced which improved the corrosion resistance and mechanical properties of the materials[8-9]. But the tribological behavior and mechanisms of these films in the boundary lubrication environment were found to be different from that on the Fe-based surfaces. Yang Dehua, et al. have investigated the tribochemical behavior of A1 ion-implanted pure iron material lubricated with ZDDP-containing base oil which showed that the wear resistance of A1 ion-implanted pure iron specimens was lower than that of the un-implanted specimen because the existence of Al element retarded the formation of tribofilm[10]. Anne Neville has made a comparison of boundary lubrication behavior between steel and Co/Cr/Mo thermal spray coating under lubrication with ZDDP-containing base oil, which have found out that the wear film on the Co/Cr/Mo coating comprised an adherent hydrocarbon layer over a thin base layer of species derived from the additive. It effectively reduced friction at all temperatures and reduced wear at the highest temperature (100 ℃)[11]. M. I. de Barros’Bouchet has investigated the boundary lubrication mechanisms of carbon coatings in the presence of a lube oil containing MoDTC and ZDDP additives, and it was interesting to notice that tribochemical reactions can occur without the presence of iron catalyst element in the tribo-system[12]. Different films and different additives can give rise to different tribochemical reactions, which can result in different tribological behavior. Tungsten has the highest melting point, high strength andhardness and good chemical stability. It can effectively improve the anti-wear and anti-corrosive properties of the rubbing surfaces. So tungsten and tungsten-base alloys are widely used in cutting tools, engine components, printing rollers, metal-ceramic materials and resistance heating elements. Meanwhile, ZDDP and MoDTC are two kinds of widely used lubricant additives[13-14]. But information about the boundary lubrication mechanisms of W films in the presence of MoDTC and ZDDP additives is quite scarce in the literature.

So, the purpose of this work is to investigate the boundary lubrication mechanism of tungsten film prepared via IBAD and lubricated by MoDTC and ZDDP-containing base oil. In this study, the W film was prepared on the surface of 18Cr-12Ni-2.5Mo austenitic (316L) stainless steel. The structure and mechanical behavior of the tungsten film was studied, and the tribological behavior of the W film under oil lubrication at high temperature (100 ℃) was investigated. The tribological mechanism was approached and discussed through a series of microanalyses. The results are expected to propose a high-temperature lubricant system that combine the W film with traditional lubricant additives.

2 Experimental

2.1 Experimental materials and method of preparation

The substrate material was the 316L stainless steel with a hardness of HV 153 and an elasticity modulus of 200 GPa. The chemical composition and physical property of the 316L stainless steel is shown in Table 1. The specimens were 3 mm in thickness and 60 mm×30 mm in dimension. The average surface roughness Ra of each specimen was 4 nm.

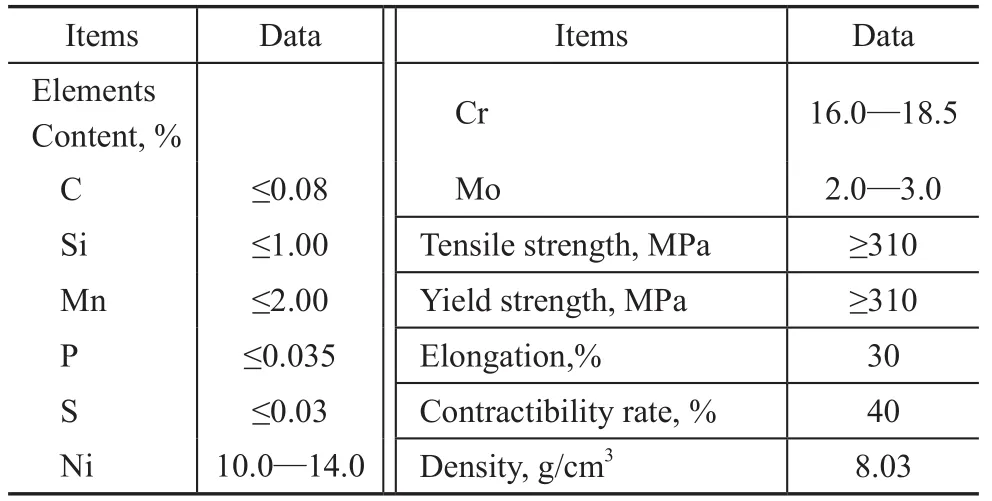

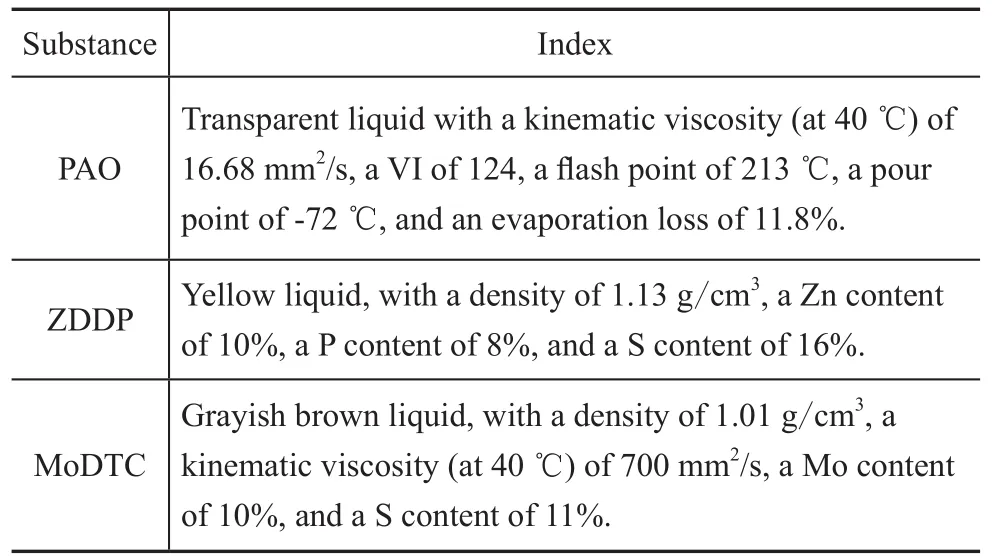

Table 1 Chemical composition and physical properties of the 316L stainless steel

The tungsten film was deposited by means of an ISB-700 multi-functional ion beam sputtering machine. The W target had a purity of 99.95%, with a dimension of 120 mm×100 mm×7 mm. The 316L stainless steel was placed on the sample holder. The temperature of the substrate during the deposition was about 20—85 ℃. The system base pressure prior to deposition was 2×10-4Pa, with a high-purity Ar gas (99.999%) being used as a sputtering gas and assisting gas. Two symmetrical sputtering sources corresponding to two symmetrical targets and one assisting source were adopted in the preparation of film deposition. The ion energy and beam current applied to the targets were 2 700 eV and 100 mA, respectively. The total time for each deposition was 3 h. Prior to deposition, a thick Cr interlayer was deposited to enhance the adhesion between the thin tungsten film and the stainless steel substrate.

The lubricating oil used was a synthetic base oil—poly-αolefin (PAO), with a kinematic viscosity of 16.68 mm2/s at 40 ℃ and a VI of 124. And the additives selected were two typical additives (ZDDP and MoDTC). The chemical composition and physical properties of base oil and additives are listed in Table 2.

Table 2 Chemical composition and physical properties of base oil and additives

2.2 Friction and wear test

The wear testing equipment is a sliding, reciprocating and vibrating test machine (Optimol SRV, Germany). An ISI52100 steel ball (with a diameter of 10 mm, a Ra of 25 nm and a hardness of 770 HV) was mounted in the clamper and was oscillated against the stationary plate of modified films. The tests were conducted under a load of 20 N, at an oscillating frequency of 10 Hz and an amplitude of 1 mm over a period of 30 min. The lambda ratio, known as the ratio of film thickness to the surface rough-ness, can be used as a criterion for de fining the lubricating condition. For this test the lambda ratio was calculated to be 0.167 and 0.291 for the 316L and W surfaces, respectively. Although the lambda ratios of two surfaces were not equal, they were all less than 1. So the lubrication of the two films was in the boundary regime. The lubricating oil was preheated to 100 ℃ and was kept at this fixed temperature in the process of testing. The friction coefficients were recorded directly by the SRV tester. By using a pro filometer, the cross-sectional area of worn track on the three modified samples was obtained afterwards, which was used to calculate the worn volume. The testing of every sample was repeated three times.

2.3 Film characterization

A JSM-7001F field emission scanning electron microscope (FE-SEM) with an energy dispersive spectroscope (EDS) was utilized to observe the surface and cross-sectional morphologies of the films. The nano-hardness and elastic modulus were measured by a XP nano-indentation tester equipped with a three-sided pyramid diamond indenter tip (Berkovich type). The maximum depth at which the indenter tip drove into the sample surface was less than 100 nm. The ESCALAB 250Xi X-ray photoelectron spectroscopy (XPS) was utilized to identify the chemical state of the compounds formed on the worn surface. The surfaces were coated with a thickness of 5 nm via Ar+ ion sputtering before the data collection in order to reduce the in fluence of the surface pollutants on the results. And the peaks of C1s occurring at a binding energy of 284.5 eV was considered as the reference for charge correction.

3 Results and Discussion

3.1 Microstructure and hardness

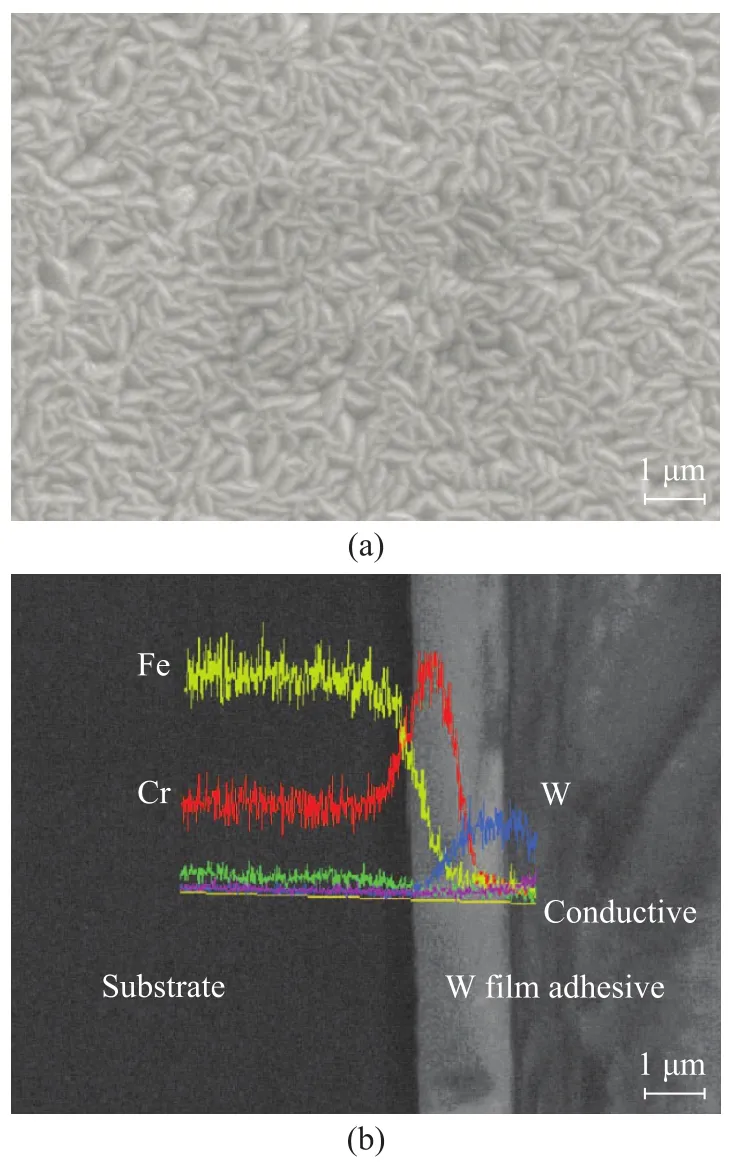

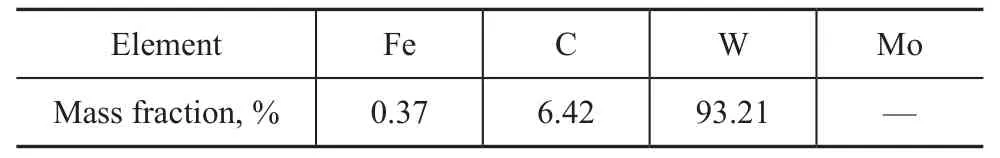

Figure 1 shows the surface and cross-sectional morphology of the W film. It can be seen from Figure 1(a) that the surface of the W film is quite smooth with an average surface roughness (Ra) of 55 nm. The surface element contents analyzed by EDS are shown in Table 3 which shows that the deposited film has a high purity. Figure 1(b) shows the cross-sectional morphology and the EDS line scans of W film. The bright ribbon stands for the deposited film which is about 1.5 μm in thickness[15-16].

Figure 1 SEM images of W film∶ (a) surface; (b) cross section

Table 3 EDS results on W film

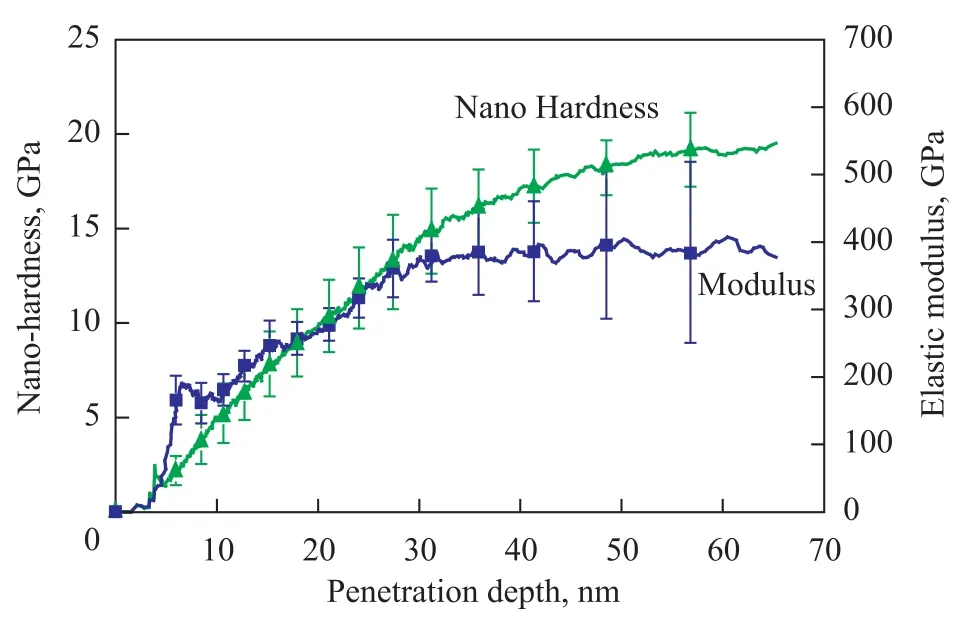

Figure 2 shows the variation of hardness and elastic modulus with the penetration depth obtained from the nano-indentation tests performed on the W film. The data of hardness and elastic modulus are the average value of three repeated indentation tests. The average hardness and elastic modulus of the W film are equal to 19.0±5.0 GPa and 400±100 GPa, respectively.

Figure 2 Average nano-hardness and modulus versus the penetration depth of the W film

3.2 Tribological behavior

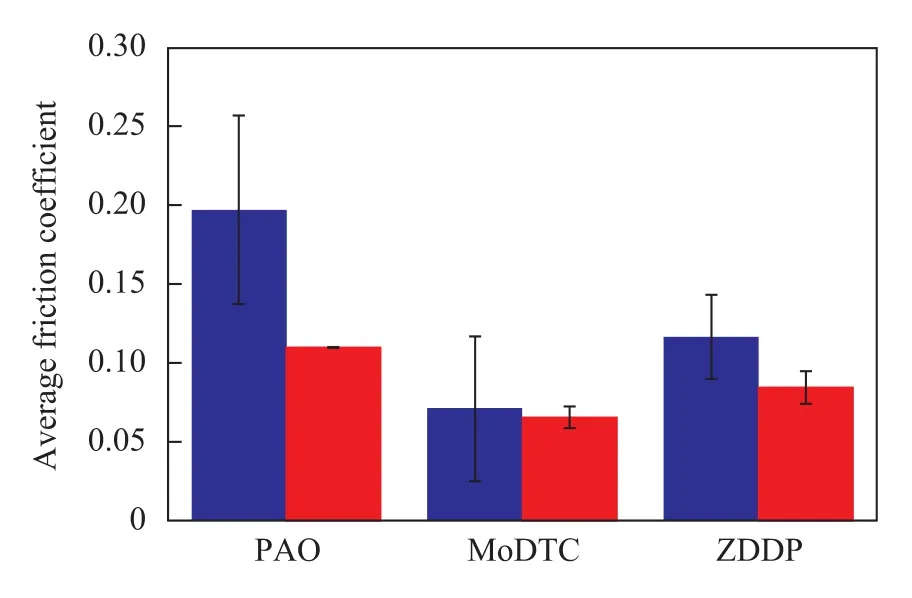

Figure 3 shows the average friction coef ficient of two materials under the lubrication of PAO, PAO+1% MoDTC, and PAO+1% ZDDP, respectively. It can be seen from Figure 3 that the average friction coef ficients of two material surfaces are greater than 0.1 under the lubrication of the PAO base oil. With addition of the additives, all the friction coef ficients decreased as compared with that lubricated by the base oil. Especially under the lubrication of PAO+1% MoDTC, the average friction coefficients of the two surfaces are less than 0.07. Moreover, under the same lubrication condition, the average friction coefficient of the W film is smaller than that of the 316L substrate surface.

Figure 3 Average friction coefficient of the substrate and W film under different lubrication conditions

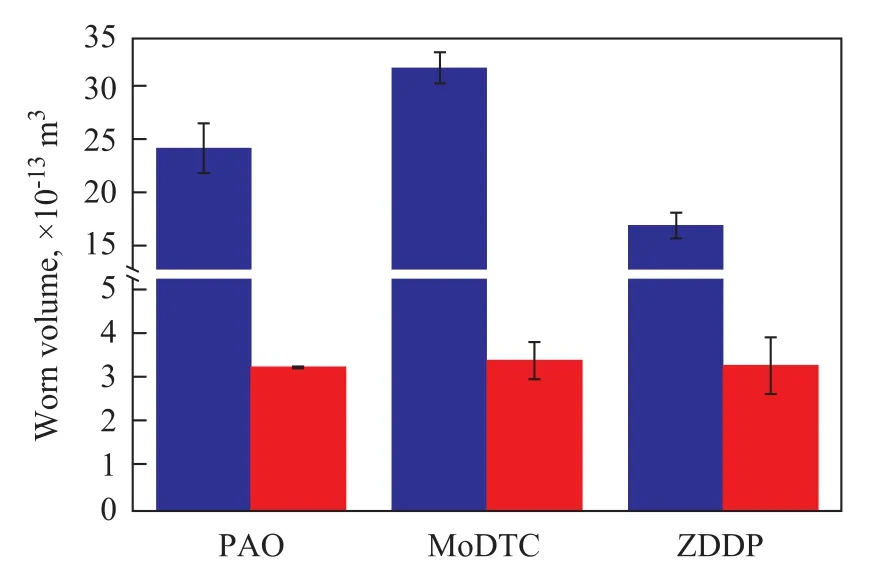

Figure 4 shows the worn volume of the surfaces under different lubrication conditions. It can be seen that the worn volume on the 316L surface increases under lubrication by PAO+MoDTC in comparison with that under lubrication by PAO, while the lowest wear is identified under the lubrication by the base oil with ZDDP. The worn volume on the W film surface is smaller than that on the substrate surface under the same lubrication condition. However, the worn volumes on the W film surface are basically the same under the three lubrication conditions.

Figure 4 Worn volumes of the surfaces under different lubricant conditions

3.3 SEM analysis

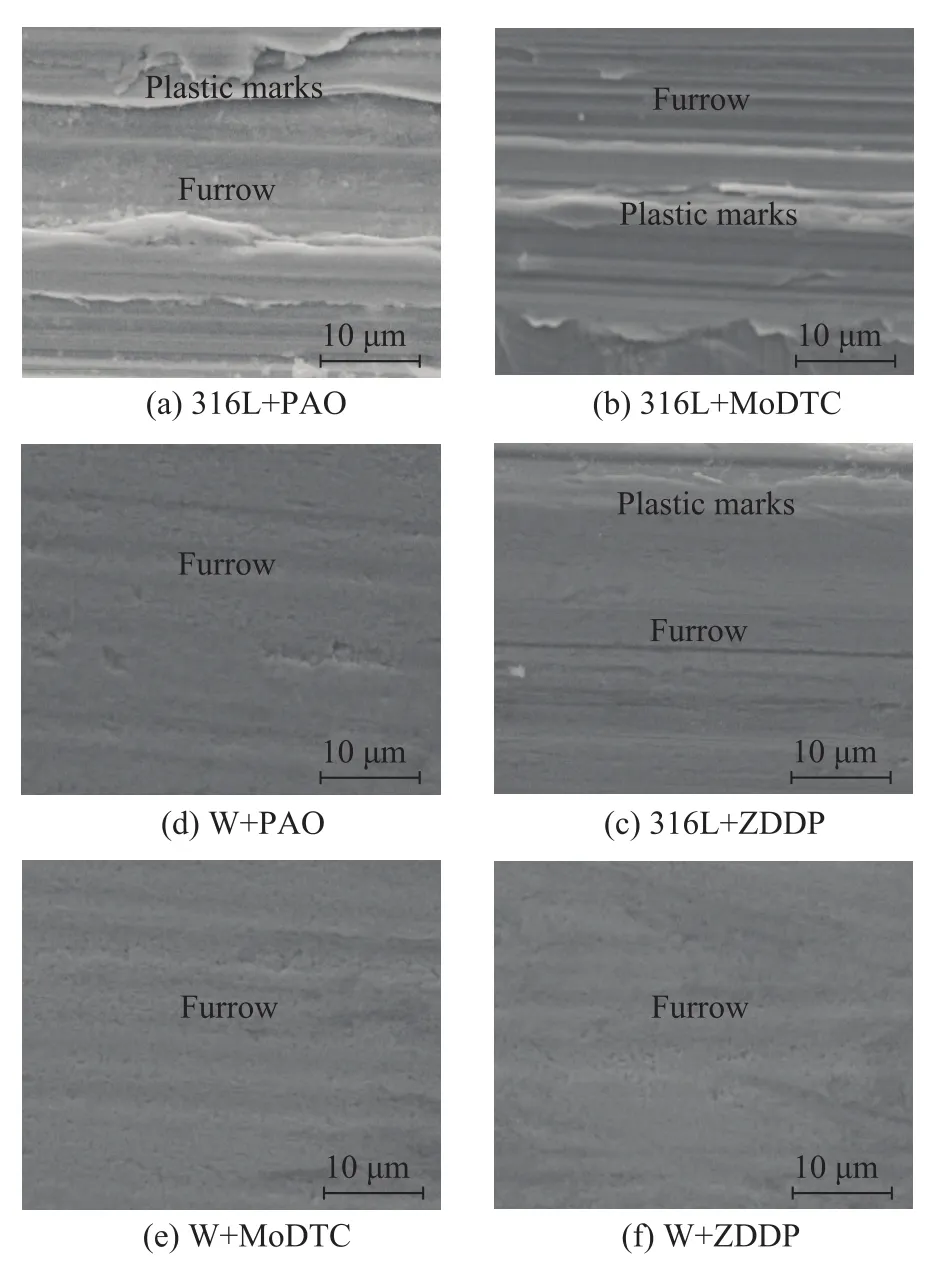

Figure 5 shows the SEM analyses of the worn surfaces on the 316L stainless steel and W film under the lubrication by base oil with addition of MoDTC and ZDDP. The worn surfaces on the 316L steel have two typical morphologies. One is the plastic marks which are caused by plastic deformation, another is the furrows which might be caused by the wear grains. The tungsten worn surfaces just have furrows which are slighter than those on the worn surfaces of 316L steel. These morphologies correspond quite well with the wear volumes.

Figure 5 SEM images of the worn surfaces

3.4 XPS analysis

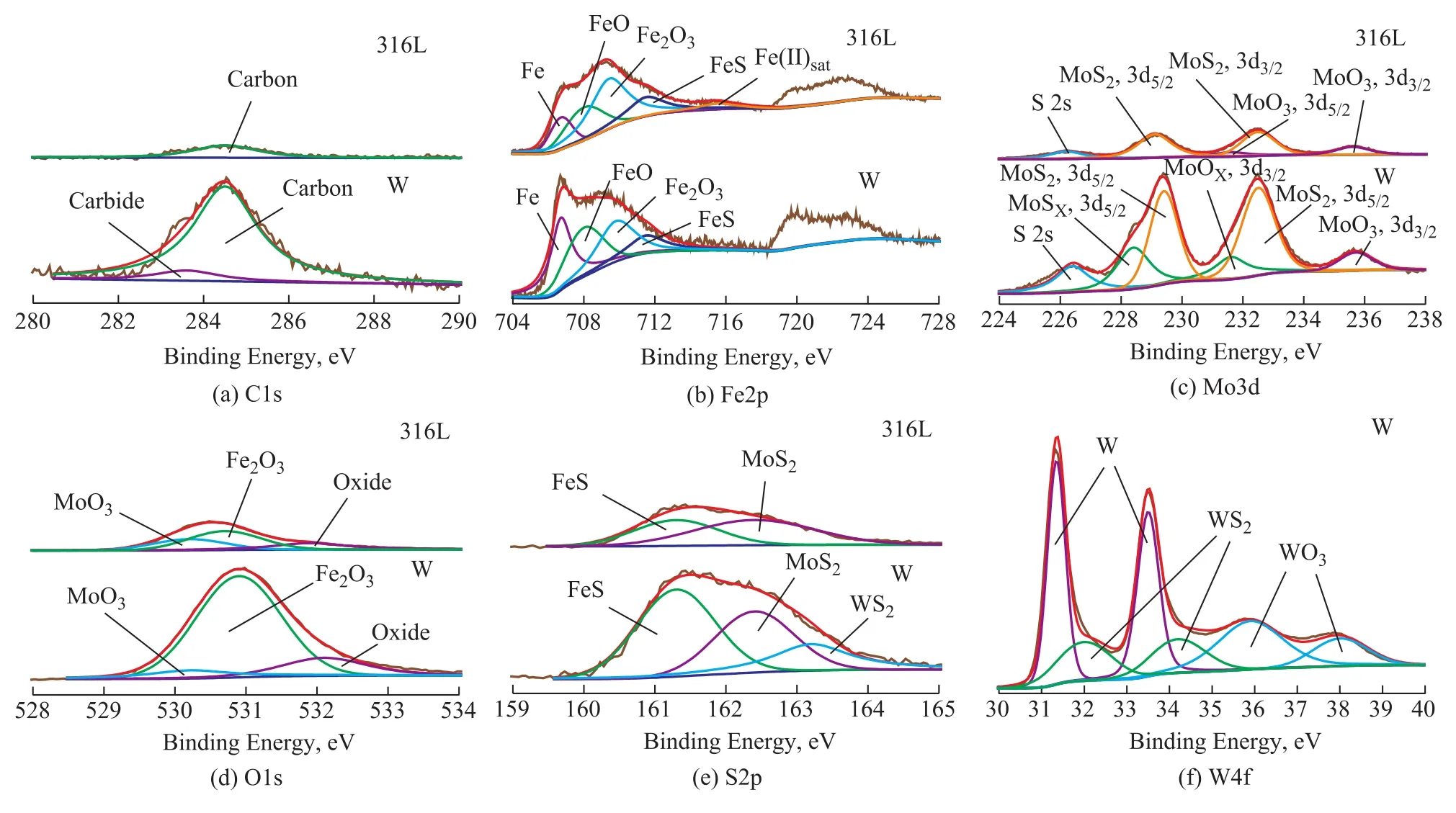

In order to further understand the tribological mecha-nism between the different surfaces under lubrication of MoDTC and ZDDP, the XPS analyses were conducted on the worn surfaces. Figure 6 shows the XPS spectra of elements on the worn 316L substrate and W surfaces under lubrication by PAO+1% MoDTC. It can be seen from Figure 6(a) that the peak of C1s occurring at 284.5 eV is ascribed to adsorptive C, and the peak at a binding energy of 283.7eV is assigned to the carbide. Figure 6(b) shows that the chemical state of Fe in both reaction films is the same, and is mainly associated with Fe (at 706.7 eV), FeO (at 708 eV), Fe2O3(at 709.8 eV) and FeS (at 711.5 eV)[17]. We can find out from Figure 6(c) that the element Mo on the two worn surfaces has two chemical states. One is MoOx, the other is MoSx. The chemical states of element O on the two worn surfaces shown in Figure 6(d) are also the same. They are MoO3(at 529.7 eV), Fe2O3(at 530.1 eV) and oxide (at 531.6 eV), which are in agreement with the chemical state of other elements. As regards the chemical states of element S on the two surfaces, we can see from Figure 6(e) that the peaks of S2p occurring at 161.3 eV and 162.4 eV are FeS and MoS2on the worn 316L substrate surface, while on the worn W surface, there are not only FeS and MoS2but also WS2at a binding energy of 163.3 eV. The element W on the worn W surface is also detected in the Figure 6(f), the peaks of W4f occurring at 31.4 eV, 32 eV and 36 eV are identified as W, WS2and WO3, respectively.

Figure 6 XPS spectra of elements on the worn substrate and W surfaces under lubrication of PAO+1% MoDTC

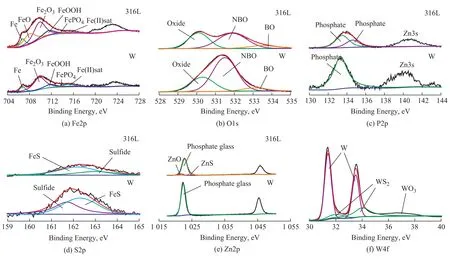

Figure 7 shows the XPS spectra of elements on the worn 316L substrate and W surfaces under lubrication of PAO+1% ZDDP. It can be seen from Figure 7(a) that the peaks of Fe2p3/2occurring at 706.7 eV, 708 eV, 709.8 eV, 711.8 eV, 713.5 eV and 715.5 eV are ascribed to Fe, FeO, Fe2O3, FeOOH, FePO4and Fe(II)sat, respectively, on the worn 316 L substrate surface, while the binding energies of 706.7 eV, 709.8 eV, 711.8 eV, 713.5 eV and 715.5 eV are ascribed to Fe, Fe2O3, FeOOH, FePO4and Fe(II)sat, respectively, on the worn W surface. In Figure 7(b), the Ols peak is composed of oxide, BO and NBO. They are the same on the two surfaces analyzed thereby. The P2p peaks in Figure 7(c) are mainly composed of phosphates. It can be seen from Figure 7(d), that WS2and sulfide are formed on both worn surfaces. The Zn2p peaks in the Fig-ure 7(e) are composed of ZnO, phosphate and ZnS at the binding energies of 1 021.7 eV, 1 022.8 eV and 1 024.7 eV, respectively, while the W4f peaks on the worn W surface in Figure 7(f) indicate to W, WS2and WO3with the binding energies of 31.4 eV, 32 eV and 36 eV, respectively[18-21].

Figure 7 XPS spectra of elements on the worn substrate and W surfaces under lubrication of PAO+1% ZDDP

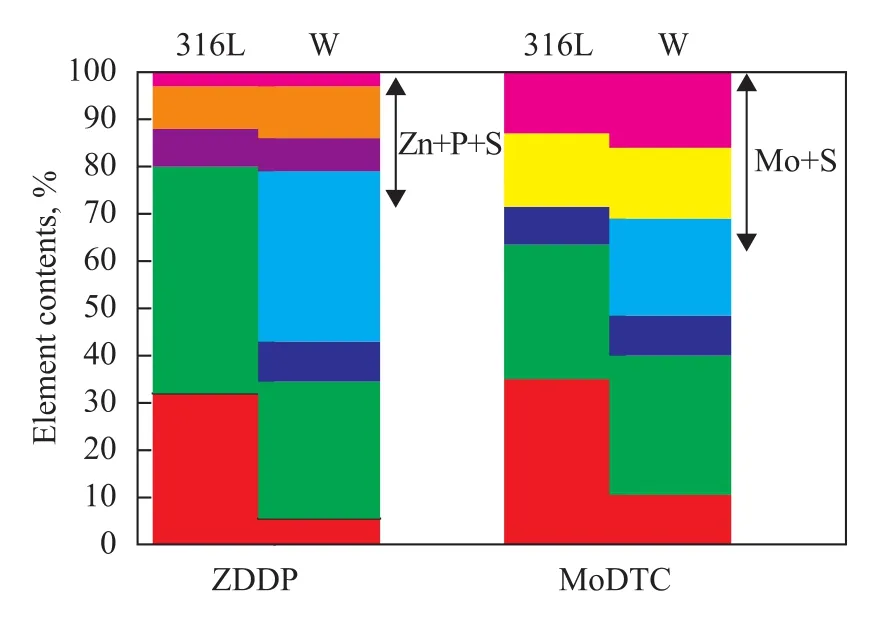

The element contents on the worn surfaces under lubrication by ZDDP and MoDTC added to the base oil are shown in Figure 8. The elements P, S and Zn are the typical ones originated from ZDDP[22]that reflect the degree of ZDDP decomposition, while the elements Mo and S reflect the degree of MoDTC decomposition. It can be seen from Figure 8 that the percentage of Zn+P+S on the W surface is just the same as those identified on the 316 L surface. While the percentage of Mo+S on the two surfaces is equal to around 30 %, the total contents of Mo and S do not have much difference. This phenomenon implies the existence of lubricant additives on the W surfaces.

Figure 8 Element contents on the worn surfaces

3.5 Discussion

The friction coefficients and worn volumes on W surface are lower than that on the 316L substrate under the same lubrication condition. But the friction coefficients and worn volumes on the W surface do not have significant difference under different lubrication conditions, especially in terms of the worn volumes identified under different lubrication conditions, showing that they are basically the same. It is interesting to recognize that hardness is not the only factor that determines the wear resistance. Coating elasticity and toughness can also have an important influence on the wear. Plastic deformation (which is mostly determined by material elasticity) leads to large transplant of the materials on the rubbing surfaces and causes serious wear. So there are some merits to use H/E ratio for describing the coating properties without using hardness alone as the only measurement criterion[23]. During this experiment, the W film formed via ion beam assisted deposition(IBAD) method has the advantage to produce dense structural film thanks to the beam-enhanced migration. And the W film has a harder surface than the untreated surface. In addition, the hardness of W film is 19 GPa and its modulus of elasticity is 400 GPa, and the H/E ratio for W film is about 0.047 5. The hardness of the 316L stainless steel is about 153 HV which is converted to be 1.53 GPa and its modulus of elasticity is 200 GPa, with its H/E equating to about 0.007 65, which is much smaller than that of the W film. So the W film has a superior property to resist plastic deformation and wear. And the W film has better tribological behavior than the 316L substrate under the same lubrication condition.

When the additives are added to PAO, it could not be denied that there are some benefits for the formation of a sliding layer on the surface. The friction coefficients on the 316L and W surfaces are reduced consequently. But the formed compounds do not have significant effect on the wear behavior for the W film. Since the wear behavior is mainly defined by the surface hardness in this experiment, the hard W film has a superior tribological behavior compared to that of 316L surface under the same lubrication condition. However, tungsten has little advantage in promoting the decomposition of the additives. It was reported that W content in the film could lead to the formation of a more stable and protective transfer film on the surface[24-27].

4 Conclusions

(1) The tungsten film was successfully prepared on the 316 L stainless steel surface via IBAD with an average hardness of 19.0±5.0 GPa, an elastic modulus of 400±100 GPa, and a film thickness of about 1.5 μm.

(2) Upon being lubricated by the base oil (PAO), the W film with a dense and hard surface showed smaller friction coefficient and worn volume as compared with those of the stainless steel substrate.

(3) When additives were added to the base oil, more easyto-slide products were generated on the hard surface, and the friction coefficient on the W film decreased significantly as compared with the case lubricated by PAO. However, the worn volumes on the W film surface were basically the same under three lubrication conditions.

Acknowledgements:The authors would like to thank the Beijing Natural Science Foundation (3132023), the National Natural Science Foundation of China (51275494 and 51005218), the Fundamental Research Funds for the Central Universities (2652012115 and 2652013081) and the Tribology Science Fund of State Key Laboratory of Tribology (SKLTKF13B10) for their financial support to this research.

Reference

[1] Hsu S M, Gates R S. Boundary lubricating films: Formation and lubrication mechanism[J]. Tribology International, 2005, 38(3): 305-312

[2] Neville A, Morina A, Haque T, et al. Compatibility between tribological surfaces and lubricant additives—How friction and wear reduction can be controlled by surface/lube synergies[J]. Tribology International, 2007, 40(10/12): 1680-1695

[3] Onodera T, Morita Y, Suzuki A, et al. A theoretical investigation on the abrasive wear prevention mechanism of ZDDP and ZP tribofilms[J]. Applied Surface Science, 2008, 254 (23): 7976-7979

[4] Donnet C, Erdemir A. Historical developments and new trends in tribological and solid lubricant coatings[J]. Surface and Coatings Technology, 2004, 180-181: 76-84

[5] Holmberg K, Mathews A. Coatings tribology: A concept, critical aspects and future directions[J]. Thin Solid Films, 1994, 253(1/2): 173-178

[6] Pradip K S. Thermodynamics and tribology in aluminum extrusion[J]. Wear, 1998, 218(2): 179-190

[7] Tang J G, Liu D X, Tang C B, et al. Tribology behavior of double-glow discharge Mo layers on titanium alloy in aviation kerosene environment[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(8): 1967-1974

[8] Vanhulsel A, Velasco F, Jacobs R, et al. DLC solid lubricant coatings on ball bearings for space applications[J]. Tribology International, 2007, 40(7): 1186-1194

[9] Carr G E, Conde R H. Tribology of hard coating alloys deposited by thermal methods: Applications to industrial components[J]. Surface and Coatings Technology, 2008, 203(5/7): 685-690

[10] Yang D H, Zhou J R, Xue Q J. Study of the tribochemical behavior of A1 ion-implanted pure iron lubricated with ZDDP[J]. Surface and Coatings Technology, 1998, 102 (3): 223-232

[11] Neville A, Kollia-Rafailidi V. A comparison of boundary wear film formation on steel and a thermal sprayed Co/Cr/ Mo coating under sliding conditions[J]. Wear, 2002, 252 (3): 227-239

[12] de Barros’Bouchet M I, Martin J M, Le-Mogne T, et al. Boundary lubrication mechanisms of carbon coatings by MoDTC and ZDDP additives[J]. Tribology International, 2005, 38(3): 257-264

[13] Spikes H. The history and mechanisms of ZDDP[J]. Tribology Letters, 2004, 17(3): 469-489

[14] Yamamoto Y, Gondo S. Friction and wear characteristics of molybdenum dithiocarbamate and molybdenum dithiophosphate[J]. Tribology Transactions, 1989, 32(2): 251-257

[15] Li G Y, Xu J H, Zhang L Q, et al. Growth, microstructure, and microhardness of W/Mo nanostructured multilayers[J]. Journal of Vacuum Science & Technology B: Microelectronics and Nanometer Structures, 2001, 19(1): 94-97

[16] Li G Y, Han Z H, Tian J W, et al. A study on the interface microstructure and superhardness effect of W/Mo multilayer[J]. Raremetal Materials and Engineering, 2003, 42(6): 2-5

[17] Wagner C D, Riggs W M, Davis L E, et al. Handbook of XRay Photoelectron Spectroscopy[M]. Perkin Elmer, 1979

[18] Martin J M. Antiwear mechanisms of zinc dithiophosphate: A chemical hardness approach[J]. Tribology Letters, 1999, 6(1): 1-8

[19] Willermet P A, Dailey D P, Carter III R O, et al. Mechanism of formation of antiwear films from zinc dialkyldithiophosphates[J]. Tribology International, 1995, 28(3): 177-187

[20] Yue W, Gao X C, Wang C B, et al. Synergistic effects between plasma-nitrided AISI 52100 steel and zinc dialkyldithiophosphate additive under boundary lubrication[J]. Tribology Transactions, 2012, 55 (3): 278-287

[21] Onodera T, Kuriaki T, Morita Y, et al. Influence of nanometer scale film structure of ZDDP tribofilm on Its mechanical properties: A computational chemistry study[J]. Applied Surface Science, 2009, 256 (4): 976-979

[22] Grossiord C, Martin J M, Mogne T L, et al. In situ MoS2formation and selective transfer from MoDPT films[J]. Surface and Coatings Technology, 1998, 109 (1/3): 352-359

[23] Leyland A, Matthews A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour[J]. Wear, 2000, 246 (1): 1-11

[24] Haseeb A S M.A, Albers U, Bade K. Friction and wear characteristics of electrodeposited nanocrystalline nickel–tungsten alloy films[J]. Wear, 2008, 264 (1/2): 106-112

[25] An V, Bozheyev F, Richecoeur F, et al. Synthesis and characterization of nanolamellar tungsten and molybdenum disulfides[J]. Materials Letters, 2011, 65 (15/16): 2381-2383

[26] Zhu L N, Wang C B, Wang H D, et al. Microstructure and tribological properties of WS2/MoS2multilayer films[J]. Applied Surface Science, 2012, 258 (6): 1944-1948

[27] Greenwood O D, Moulzolf S C, Blau P J. The influence of microstructure on tribological properties of WO3thin films[J]. Wear, 1999, 232 (1): 84-90

Received date: 2014-03-25; Accepted date: 2014-08-05.

Dr. Li Xingliang, Telephone: +86-10-68380521; E-mail: lixing3758@126.com.

- 中國煉油與石油化工的其它文章

- Solvothermal Synthesis of V2O3Catalysts for Oxidative Desulfurization of Dibenzothiophene

- Identification and Characterization of Sulfur Compounds in Straight-Run Diesel Using Comprehensive Two-Dimensional GC Coupled with TOF MS

- Effects of Promoters on the Ignition Process over NiO/Al2O3Catalyst for Autothermal Reforming of Methane to Hydrogen

- Oligomerization of 1-Decene: Catalyzation by Immobilized AlCl3/γ-Al2O3Catalyst in Fixed-bed Reactor

- Study on Tribological Properties of CVT Fluid Containing Inert and Active Functional Elements

- Application of Modified Attapulgite Clay as the Adsorbent in Gasoline Desulfurization