Total Reflux Operation of Multivessel Batch Distillation for Separation of Binary Mixtures

TANG Ke (唐克)*, BAI Peng (白鵬) and LI Guangzhong (李廣忠)School of Chemical Engineering and Technology, Tianjin University, Tianjin 300072, China

Total Reflux Operation of Multivessel Batch Distillation for Separation of Binary Mixtures

TANG Ke (唐克)*, BAI Peng (白鵬) and LI Guangzhong (李廣忠)

School of Chemical Engineering and Technology, Tianjin University, Tianjin 300072, China

Multivessel batch distillation (MVBD) is mainly used to separate mixtures with more than two components. In this article, a new operation mode with MVBD is proposed for separation of binary mixtures under total reflux. A mathematic model is setup for the simulation. The proposed operation policy and the regular operation with constant reflux are compared theoretically and experimentally. The results show that the new operation mode has great advantages in time saving and operation flexibility. MVBD presents great potential for separation with high efficiency.

multivessel batch distillation, total reflux, binary system

1 INTRODUCTION

Batch distillation is widely used in fine and specialty chemical and pharmaceutical industries for purification or recovery of high-value liquid components because of its advantages such as flexibility and several products with a single column. With an increasing demand for high quality products and flexible plants, the optimal operation of columns is of great economic importance. The optimization of batch distillation has been widely studied in the past decades [1-4]. Some new operating modes in batch distillation process have been proposed and studied, which present higher efficiency or flexibility, such as cyclic total reflux operation, inverted operation, middle vessel operation [5-7]. However, the most common operation modes of a batch column are (1) constant reflux and variable product composition and (2) variable reflux and constant product composition of a key component and the optimal operation depends strongly on the reflux policy and the use of off-cuts to achieve the desired product composition.

The total reflux operation is one of the promising modes of batch distillation. The most common cycling control proposed by Perry is that the column is operated at infinite reflux ratio and the light component is enriched in the reflux drum as the process proceeds [8]. When the concentration in the reflux drum reaches the specified value, the top product is drained away in a short period of time, and then returns to the total reflux operation. This mode has several main advantages over the conventional partial reflux modes such as the maximum fractionating capacity, easier operation control and fewer disturbances to product quality and yield. Sorensen investigated the cyclic distillation of binary mixtures with constant relative volatility through theory and practice [9] and recommended this policy for difficult separations with small amounts of product recovered. However, the simplest operation strategy is with only one cycle, that is, the column is operated under total reflux and the final products are collected in the condenser drum and reboiler.

Multivessel batch distillation (MVBD) is a superstructure among all batch distillation configurations. The scheme is operated under total reflux. The term is often used for processes with at least four product vessels including reboiler and distillate receiver. A generalization of the closed operation of conventional batch distillation in the case with several vessels along the column (multivessel column) was proposed by Hasebe et al [10]. With n vessels along the column including reboiler, condenser, and intermediate vessels, it is possible to obtain n+1 pure products in a single batch. The main reason for using a multivessel column is that it is usually more energy efficient (or shorter batch time for a given heat input) than a regular batch distillation column [11, 12]. However, the MVBD was merely used for separation of more than two components in previous studies.

In this article, a new operation strategy using MVBD is proposed to separate binary systems with cyclic total reflux operation and a mathematical model for simulation is set up. The simulation results are compared with those under regular constant reflux ratio (CR) and non-cyclic total reflux operation. The new operation strategy is applied for the separation of mixtures with different relative volatilities and initial feed concentrations in a laboratory-scale distillation column.

2 NEW STRATEGY

MVBD is one of the most promising new operation modes, which can be used to separate binary mixtures with constant total reflux. The column configuration of the new operation mode is shown in Fig. 1. n vessels with the same shape and capacity are distributed evenly along the column. The one at the top (reflux drum) is connected to the condenser as the product receiver. At the beginning of the operation, all thevessels are filled with a specified amount of feed. The total reflux operation proceeds until the holdup in the top drum reaches its on-specification composition. At the same moment the filled reflux drum is isolated from the system and the other n?1 vessels are moved upwards in turn through switching the pumps and valves in the pipelines. The liquid in vessel 1 is the top product. The whole operation is carried out with infinite reflux ratio until all the vessels are filled with on-specification product. As well known, if the column is operated at total reflux, the charge in each vessel will be purified with the highest degree as the distillation proceeds. Therefore, the new operation mode with multivessel has higher efficiency than the finite reflux ratio mode.

3 MATHEMATICAL MODEL

For the simulation of MVBD, a rigorous nonlinear model is presented based on the following assumptions. (1) The relative volatility is constant. (2) Molar liquid holdups on the stages are constant (with liquid flow dynamics neglected). (3) Molar vapor flows are constant. (4) The vapor holdup is negligible. (5) The mixing on all trays and in all vessels is perfect.

Figure 2 shows the flows of liquid and vapor in the equipment. The numbering is from the top to the bottom, with index i denoting theoretical stages and j denoting components.

The overall material balance and component balances are as follows. The material balance for the top vessel (i=0) is

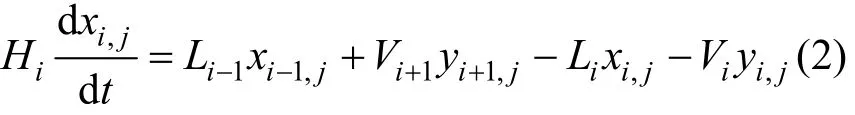

The material balance for component j on stage i away from vessels is

With vessel i (ith stage) connected to the column, the material balance for component j on stage i?1 above the vessel is

For intermediate vessel i,

And the material balance for component j on stage i+1 under the vessel is

With vessel i (ith stage) isolated from the column, the material balance for component j on stage i?1 above the vessel isThe material balance for component j on stage i+1 under the vessel is

Figure 2 Vapor and liquid flows in column and vessels

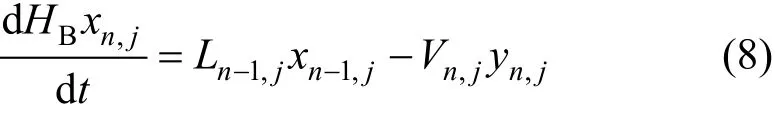

The material balance for the reboiler is

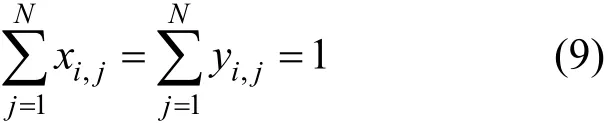

The material balances should satisfy the summation equations:

The vapor-liquid equilibrium can be expressed as

4 SIMULATION RESULTS AND DISCUSSION

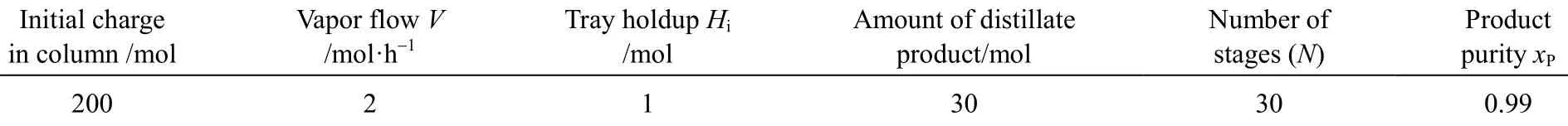

The process of MVBD with constant total reflux is simulated with the proposed mathematical model for separation of binary mixtures, which is performed on Matlab software with Runge-Kutta integral method. Specifications for the computation are shown in Table 1 and the initial value of purity in the column is the same as the feed concentration.

4.1 Simulation of multivessel batch distillation

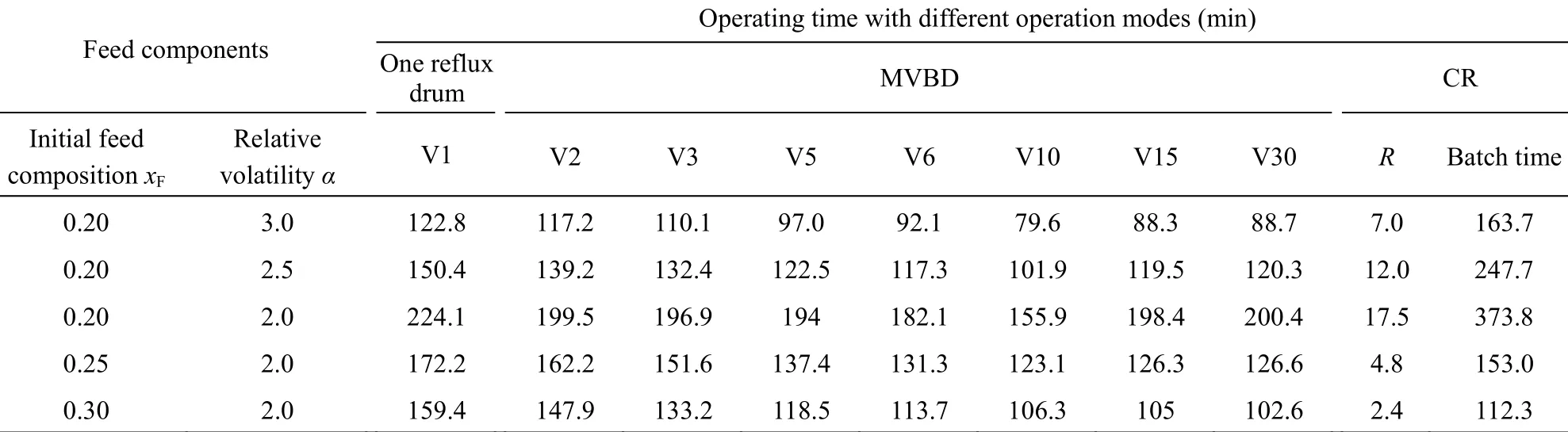

The simulation results of MVBD are shown in Figs. 3 and 4. The operating time with different operation modes is included in Table 2. Fig. 3 shows that, for certain number of vessels, the operation time required to purify the holdup in the top vessel increases except the first one, and then decreases for the last ones. The explanation is that the concentrations of light component in the vessels moving upward decrease as the process proceeds so that more time is required to purify the liquid to the specification. During the last period, the whole holdup in the vessels is just a small part and it is easy to obtain the eligible product in the top vessel. It means that the operation time for each cycle varies with the whole holdup in the vessels. As the number of vessels increases, the time required for purifying the liquid in the top vessel decreases, because the holdup (H0) in each vessel is less for the same amount of distillate product. According to the mathematical model, H0is proportional inversely to integration variable of concentration. Therefore, to some extent more vessels are advantageous for MVBD mode. However, once the top vessel is isolated from the column and the other ones move upwards, the concentration gradient in the column is disturbed, which is adverse to the following purifying step (Fig. 3). As shown in Table 2 and Fig. 4, when the number of vessels is beyond the specific value, more operation time is required due to more disturbances. It is concluded that there is an optimal number of vessels for MVBD, especially for the system difficult to separate. For example, when the feed molar composition is 0.2 and the relative volatility of binary mixture is 2.0, MVBD with ten vessels requires less time than that with other numbers of vessels. For feed molar concentration of 0.3 and α=2.0, MVBD with 30 vessels needs the minimum operation time.

Table 1 Specification for the simulation

Table 2 The operating time under different operation conditions

4.2 Comparison with CR and one reflux drum

The parameters for CR operation are optimized and the simulation results are shown in Table 2 and Fig. 5. Compared to the regular CR operation depending on the reflux policy and the total reflux withone reflux drum mode, the MVBD operation mode needs less operation time with higher separation efficiency. For χFof 0.20 and α of 2.0, MVBD with ten vessels saves the operation time by more than 35.2% and 51.7%, respectively, compared with the CR operation and one reflux drum mode, while the purity ofdistillate product using CR reaches the specification (0.99) with a very high reflux ratio (17.5). However, the MVBD with fewer vessels needs more operation time than CR operation when χFis over 0.25, which means that MVBD is not always advantageous. The new operation mode is more suitable for separation of mixtures with low concentration of light component.

Figure 3 The concentration as a function of time in different vessels (α=2.0, χF=0.20)

Figure 4 The top concentration as a function of time

Figure 5 Comparison of operation time with different operation modes

5 EXPERIMENTAL

5.1 Apparatus and procedure

The laboratory batch distillation column used in this study is shown schematically in Fig. 6. It consists of a 1 L reboiler, a condenser, three packed column sections with 8 theoretical trays and inner diameter of 30 mm, a product receiver, three liquid traps, and three vessels with a maximum holdup of 60 ml. The column is packed with double-deck Dixon Rings of 5 mm in diameter and 5 mm in length. The height of each packed layer is 0.5 m. The flow rate of rising vapor in the column and the temperature of reflux liquid are controlled by changing electric power. The initial liquid is fed along the column and vessels into the reboiler in order to make the concentration uniform, which approximately satisfies the assumption that the initial concentration in the system is the same everywhere. As the total reflux operation proceeds, the concentration of holdup in top vessel reaches specified value and the vessel is isolated from the system as the product receiver. At the same time, the vessels below are moved up in turn. In the experiment, the column is always at constant total reflux, so the new operation mode is easy to be operated. The experiment with CR is conducted in the same column with vessels isolated from the system. The operation time to obtain the same amount of product with specified purity is used for comparison. Before the experiments, the CR process was simulated on Aspen plus software to optimize the reflux ratio.

Figure 6 The experimental setup 1—thermocouple; 2—liquid trap; 3—condensor; 4—electromagnet; 5—product receiver; 6—vessel; 7—packed column section; 8—pressure meter; 9—reboiler; 10—heater

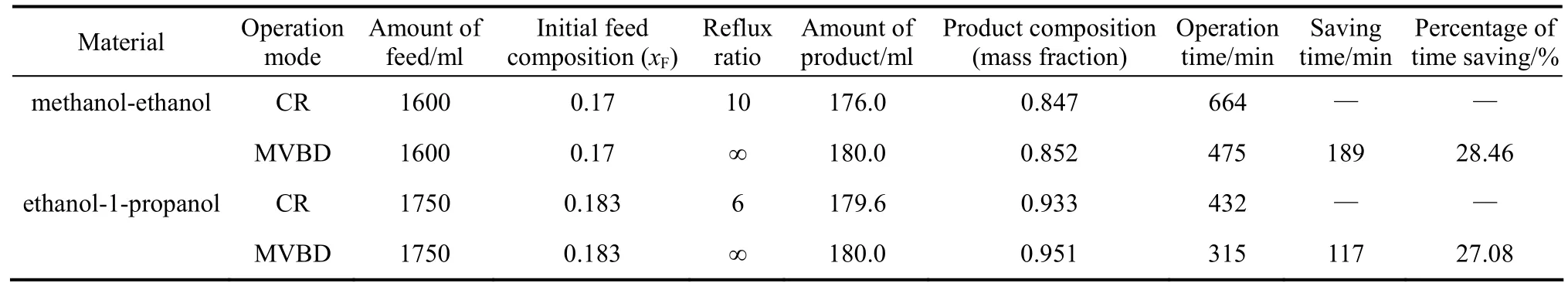

Table 3 Experimental conditions and results

5.2 Experimental results and discussion

Two binary mixtures, methanol-ethanol and ethanol-1-propannol, are used in the experiment. The condition of initial feed and the results are shown in Table 3. The MVBD mode shows obvious advantage in saving time. Compared to the regular CR operation, the reduction of operation time for the separation of methanol-ethanol and ethanol-1-propanol is approximately 28.46% and 27.08%, respectively. Fig. 7 shows the top concentration as a function of time for separation of two mixtures with different operation modes.The total reflux operation for the first vessel is longer than that with the constant finite reflux operation, which is the negative effect of the liquid holdup in three vessels. With larger amount of total holdup in the column and vessels, the product concentration in the top vessel increases more slowly and requires more time to reach the specification value.

As well known, the total reflux operation has the highest separation efficiency for the column with the same number of theoretical trays, and regular batch distillation at constant reflux ratio does not make full use of the separation ability of the column. As a result, MVBD shows great advantages under the same operating specifications such as feed concentration, product concentration and relative volatility. Thus MVBD operation policy in separation of binary mixtures is more flexible and provides new potential for improvement of batch distillation.

Figure 7 The top concentration vs. time with different operation modes

6 CONCLUSIONS

The MVBD at constant total reflux for separation of binary mixture is studied theoretically and experimentally. The process is simulated with a mathematical model consisting of material balance equations and the computational results show that its separation efficiency is increased greatly compared with the conventional operation modes. The new mode saves much operation time compared with regular CR in batch distillation. In the experiment, the new mode reduces the operation time by more than 28.46% and 27.08% for two binary systems. MVBD does not adjust the reflux ratio, as in a regular CR operation, but collects the product by shifting the vessels or switching the valves in the pipelines under total reflux. Thus the new mode is easier to operate without expensive instrumentation. However, much work has to do in the research of mass transfer and control policy in order to make the process a practical technology.

NOMENCLATURE

REFERENCES

1 Balchen, J.G., Dynamics and Control of Chemical Reactors, Distillation Columns and Batch Processes, Pergamon Press, Amsterdam, 303-308 (1993).

2 Mujtaba, I.M., Macchietto, S., “Optimal operation of multicomponent batch distillation”, Computers and Chemical Engineering, 17 (12), 1191-1207 (1993).

3 Barolo, M., Cengio, P.D., “Closed-loop optimal operation of batch distillation columns”, Computers and Chemical Engineering, 25 (4), 561-569 (2001).

4 Weerachaipichasgul, W., Kittisupakorn, P., Saengchan, A., “Batch distillation control improvement by novel model predictive control”, Journal of Industrial and Engineering Chemistry, 16 (2), 305-313 (2010).

5 Peng, B., Chao, H., “Cyclic total reflux batch distillation with two reflux drums”, Chemical Engineering Science, 60 (21), 5845-5851 (2005).

6 S?rensen, E., Skogestad, S., “Comparison of regular and inverted batch distillation”, Chemical Engineering Science, 51 (22), 4949-4962 (1996).

7 Chad, A.F., Urmila, D., “Dual composition control in a novel batch distillation column”, Ind. Eng. Chem. Res., 37 (1), 89-96 (1998).

8 Perry, R.H., Chemical Engineers Handbook, 6th edition, McGraw-Hill, New York, USA., 1382-1390 (1984).

9 S?rensen, E., “A cyclic operating policy for batch distillation—Theory and practice”, Computers and Chemical Engineering, 23 (4), 533-542 (1999).

10 Hasebe, S., Kurooka, T., Hashimoto, I., “Comparison of the separation performances of a multi-effect batch distillation system and a continuous distillation system”, In: Proc. IFAC Symp. DY-CORD ’95, Elsinore, Denmark, 249-254 (1995).

11 Wittgens, B., Litto, R., S?rensen, E., “Total reflux operation of multivessel batch distillation”, Computers and Chemical Engineering, 20 (2), 1041-1046 (1996).

12 Low, K.H., S?rensen, E., “Simultaneous optimal design and operation of multivessel batch distillation”, AIChE J., 49 (10), 2564-2576 (2003).

2013-04-26, accepted 2013-12-13.

* To whom correspondence should be addressed. E-mail: tangke1984@126.com

Chinese Journal of Chemical Engineering2014年6期

Chinese Journal of Chemical Engineering2014年6期

- Chinese Journal of Chemical Engineering的其它文章

- Unified Model of Purification Units in Hydrogen Networks*

- Photochemical Process Modeling and Analysis of Ozone Generation

- Removal of Thiophenic Sulfur Compounds from Oil Using Chlorinated Polymers and Lewis Acid Mixture via Adsorption and Friedel-Crafts Alkylation Reaction*

- Roles of Biomolecules in the Biosynthesis of Silver Nanoparticles: Case of Gardenia jasminoides Extract*

- Phase Behavior of Sodium Dodecyl Sulfate-n-Butanol-Kerosene-Water Microemulsion System*

- Symbiosis Analysis on Industrial Ecological System*