Flow Pattern and Pressure Fluctuation of Severe Slugging inPipeline-riser System*

LUO Xiaoming (羅小明), HE Limin (何利民) and MA Huawei (馬華偉)

?

Flow Pattern and Pressure Fluctuation of Severe Slugging inPipeline-riser System*

LUO Xiaoming (羅小明)**, HE Limin (何利民) and MA Huawei (馬華偉)

Department of Storage & Transportation Engineering, China University of Petroleum, Qingdao 266555, China

During the exploitation of offshore oil and gas, it is easy to form severe slugging which can cause great harm in the riser connecting wellheads and offshore platform preprocessing system. The flow pattern and pressure fluctuation of severe slugging were studied in an experimental simulation system with inner diameter of 0.051 m. It is found that severe slugging can be divided into three severe slugging regimes: regime I at low gas and liquid flow rates with large pressure fluctuation, intermittent flow of liquid and gas in the riser, and apparent cutoff of liquid phase, regime II at high gas flow rate with non-periodic fluctuation and discontinuous liquid outflow and no gas cutoff, regime III at high liquid flow rate with degenerative pressure fluctuation in form of relatively stable bubbly or plug flow. The results indicate that severe slugging still occurs when the declination angle of pipeline is 0?, and there are mainly two kinds of regimes: regime I and regime II. As the angle increases, the formation ranges of regime I and regime III increase slightly while that of regime II is not affected. With the increase of gas superficial velocity and liquid superficial velocity, the pressure fluctuation at the bottom of riser increases initially and then decreases. The maximum value of pressure fluctuation occurs at the transition boundary of regimes I and II.

multiphase flow, severe slugging, pipeline-riser system, flow regime, pressure fluctuation

1 INTRODUCTION

During the exploitation of offshore oil and gas, a long riser is needed to transport oil (with water) and associated gas from submarine wellheads to an offshore platform preprocessing system. Due to the flow rate variation and the rugged subsea terrain, it is easy to form severe slugging in the riser, which is characterized by considerable gas-liquid flow rate variation and pressure fluctuation. Severe slugging can result in rapid changes of pressure drop in pipeline, and lead to overflow or interruption of the terminal gas-liquid separator. Also it can cause the formation of hydrate to block the pipeline. Besides, it can increase the wellhead back pressure and reduce well production.

In recent years, the research of severe slugging attracts more attention with the development of offshore oil exploitation in deep-water area. Some researchers focused on formation mechanism, flow characteristics and elimination methods of severe slugging by theoretical and experimental research. The formation mechanism of severe slugging is different from that of hydrodynamic slug flow. Hydrodynamic slug flow is formed because the interface fluctuation aroused by Kelvin-Helmholtz instability causes the pipeline blocked by liquid slug [1-7]. However, the mechanism of severe slugging is that the liquid accumulating at the bottom of riser blocks the gas in the pipe and then long liquid slug is formed [8]. B?e [9] believed that the ratio of the increasing rate of the accumulated liquid pressure to that of the gas compressing pressure in the riser is the criterion of severe slugging formation. He. [10-12] proposed a method which utilized pressure signals to measure characteristic parameters of severe slugging. Tin. [13, 14] indicated that the accumulated gas in the declined pipe before the last ascending pipe in S-pipe had great influence on the characteristics of severe slugging. Montgomery and Yeung [15] found that the formation range of unstable flow was little affected by the increase of system back pressure. Corteville [16] studied the severe slugging in U-pipe and believed that flow instability in U-pipe was lower than that in the riser. Liu. [17] built a simplified quasi-equilibrium state mathematical model of severe slugging based on one-dimensional hydrodynamic equation. Yu. [18] performed the numerical simulation of transient flow characteristics and sensibility in the riser by OLGA 2000. Wang and Guo [19] developed a simplified theoretical model based on the drift flux model which can help accurately predict the expansion process of gas flow and the system variables such as period, liquid slug length and maximum liquid length in inclined pipe. Mokhatab [20] built a dynamic model which can exactly simulate severe slugging in floating riser. Hernandez. [21] analyzed the process of bubbles moving from the bottom to the top of riser and revised the deviation of gas density. The modified transient model was more accurate than the former ones.

Regimes I and II are always the focus of researches, while regime III gets little attention which is an important part of severe slugging as well. In this paper, the flow regimes and pressure fluctuation of severe slugging in pipeline-riser system were studied in order to obtain a more impeccable relationship.

2 EXPERIMENTAL

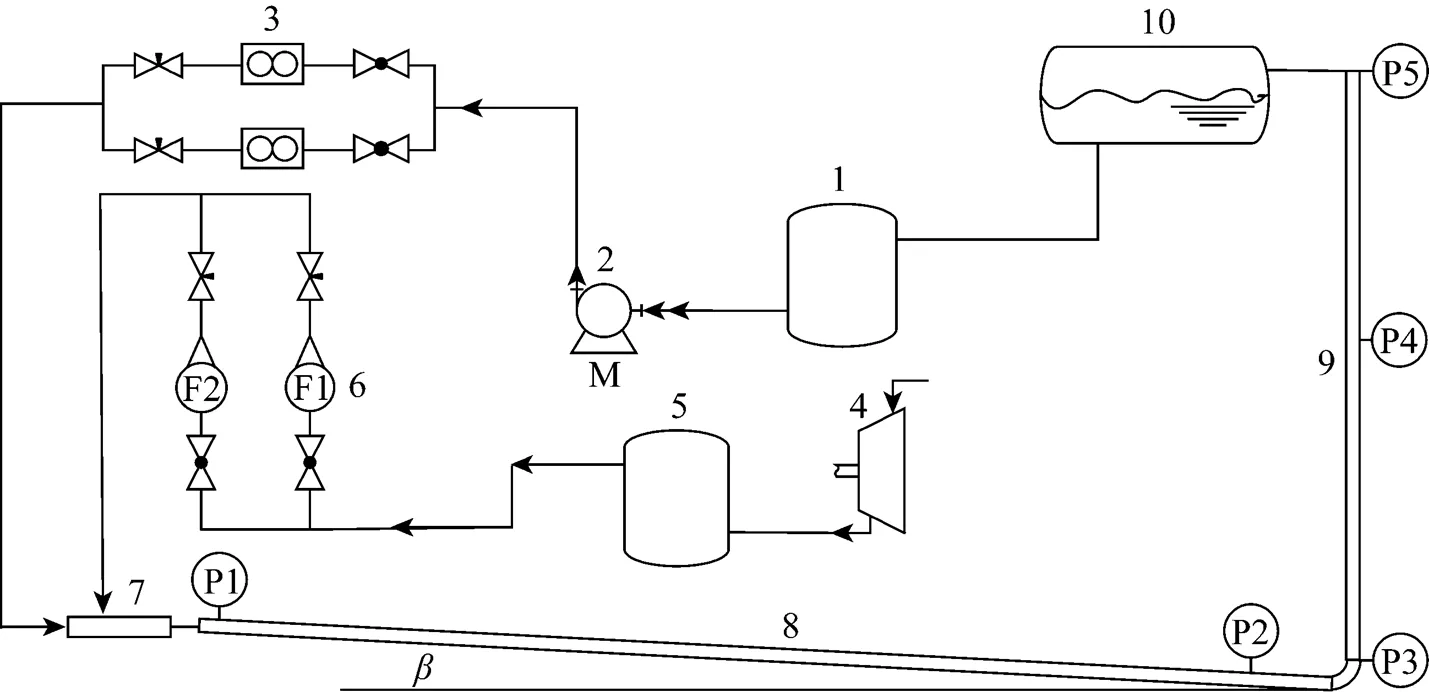

The experimental system consists of liquid tank, centrifugal pump, screw compressor, gas buffer tank, metallic gas float flow meter, liquid elliptical gear flow meter, precise regulation valve, baffle-type gas-liquid mixer, test pipe, gas-liquid separator and so on. The ID of the test pipe is 0.051 m, and the pipe is made of transparent (poly methylmethacrylate) PMMA for visual observation. Along the flow direction, it can be divided into three parts: a declined pipe with a length of 10.6 m, and the inclination is(0--4°); a vertical pipe with a length of 4.1 m; and a 0.6 m long horizontal pipe which connects the gas-liquid separator. The declined pipe and the ascending pipe are connected by a 0.4 m long hose to adjust the inclination easily. The detailed diagram of experimental system is shown in Fig. 1.

Figure 1 Schematic diagram of experimental system

1—liquid tank; 2—pump; 3—elliptic gear flow meter; 4—compressor; 5—gas tank; 6—float flow meter; 7—mixer; 8—declined pipe; 9—riser; 10—separator

In order to study pressure fluctuation characteristics of severe slugging, 5 Keller PA23 pressure transducers (P1-P5) with the frequency of 5 kHz are installed. The accuracy, repeatability and temperature stability can meet the requirements of present experiment. The liquid holdup is tested with two groups of self-made annular conductance probes. Each one is made up of two parallel stainless steel wires with diameter of 0.6 mm. The two electrodes 5 mm apart are implanted into PMMA tube and are both parallel with the wall. The input signal of conductance probe is sine-wave signal with amplitude of 10 V and frequency of 100 kHz. The output signal enters the self-made processing circuit which consists four parts: voltage- current switching circuit, full-wave rectifier circuit, range adjustment, and second-order low-pass active filter. NI PCI-6071E high-speed acquisition panel is used for data acquisition, and the sampling frequency is 1 kHz. The wavelet self-adaptive filtering method is chosen to filter pressure signal. The range of experimental parameters is as follows: gas superficial velocity ranges from 0.02 m·s-1to 1.0 m·s-1(standard state), liquid superficial velocity ranges from 0.02 m·s-1to 1.0 m·s-1, and the declination angle of declined pipe ranges from 0° to-4°. The maximum relative uncertainty of superficial gas velocity, superficial liquid velocity, pressure and liquid holdup are 2.01%, 1.46%, 1.75% and 2.70%, respectively.

3 FLOW PATTERN

3.1 Classification of severe slugging

Severe slugging is a kind of periodic flow phenomenon that occurs at low gas and liquid flow rates. Due to the influence of pipeline layout, liquid tends to accumulate at the lower part of pipeline and form liquid slugs. The gas blocked by the liquid slug in limited space accumulates continuously and finally blows out. The characteristics of severe slugging are listed as follows: (1) occurs at low gas and liquid flow rates; (2) great static pressure posed by the liquid accumulated in the riser leads to great pressure fluctuation when gas blows out; (3) great changes of gas and liquid flow rates at the pipeline outlet; (4) periodicity of characteristic parameters such as pressure fluctuation and flow rate variation.

According to above definition and characteristics, severe slugging caused by the changes of gas and liquid flow rates can be classified into three types.

Figure 2&for SS I (-2°)

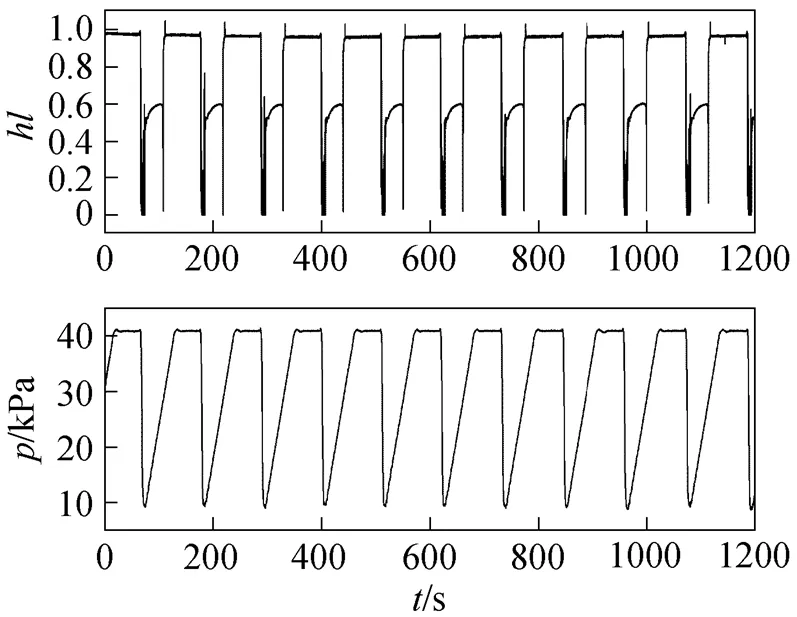

Severe slugging regime I (SS I) [9] occurs at low gas and liquid flow rates, and the length of liquid slug reaches as long as one or several heights of the riser. Fig. 2 shows the fluctuation curves of pressure and liquid holdup which indicate the characteristics of regime I: large pressure fluctuation, intermittent flow of liquid and gas phase in the riser, and apparent cutoff of liquid phase.

Severe slugging regime II (SS II) [8]: In the severe slugging regime I, as the gas flow rate increases, the gas in the declined pipe gets into the riser before the slug head formed at the end of blowout reaches the top of the riser. Meanwhile, the length of outflow liquid slug is shorter than that of the riser. As the gas flow rate increases further, the gas gets into the riser continuously, and then slugs containing many bubbles are formed. Meanwhile, the regime in the riser is bubble flow or plug flow, and no gas cutoff occurs at the pipe outlet, but the blowout of gas and liquid still happens. Fig. 3 demonstrates that regime II displays periodic fluctuation. As the gas flow rate increases, the cycle length changes more intensely until the periodicity disappears gradually. Liquid outflows of the pipe outlet discontinuously with no gas cutoff.

Figure 3for SS II (-2°)

Severe slugging regime III (SS III): In the severe slugging regime I, as the liquid flow rate increases, the liquid column formed at the end of blowout in the riser becomes higher, and the rising velocity of liquid level becomes larger. When liquid flow rate rises to a certain value, the whole riser is filled with liquid phase at the end of blowout, and no liquid cutoff occurs at the pipe outlet. Fig. 4 indicates that the periodicity of regime III is basically corresponded to that of regime I. However, as liquid flow rate increases, the pressure fluctuation becomes smaller gradually, and severe slugging disappears, and then relatively stable bubble flow or plug flow is formed. Gas outflows of the pipe outlet discontinuously with no liquid cutoff.

At certain gas and liquid flow rates, there will be a long period of steady flow, but severe slugging may happen occasionally which results in fluctuations of pressure and outlet flow rate. This regime is known as irregular severe slugging. Wang and Guo [19] also discovered this kind of regime. Irregular severe slugging appears in the region of SS II or SS III where the gas and liquid flow rates are very close to those of steady flow. Hence this phenomenon still belongs to SS II or SS III. When the declination angle is 0° and the gas-liquid flow rate is low, the liquid hold-up of horizontal pipe is high. The liquid and gas flow rates in the riser and the pressure fluctuation will cause the gas-liquid interface fluctuation in the horizontal pipe, thus the regime will change from stratified flow to bubble flow or plug flow. When the bubble flow or plug flow enters into the riser, certain pressure fluctuation will maintain. No severe slugging occurs.

Figure 4for SS III (-2°)

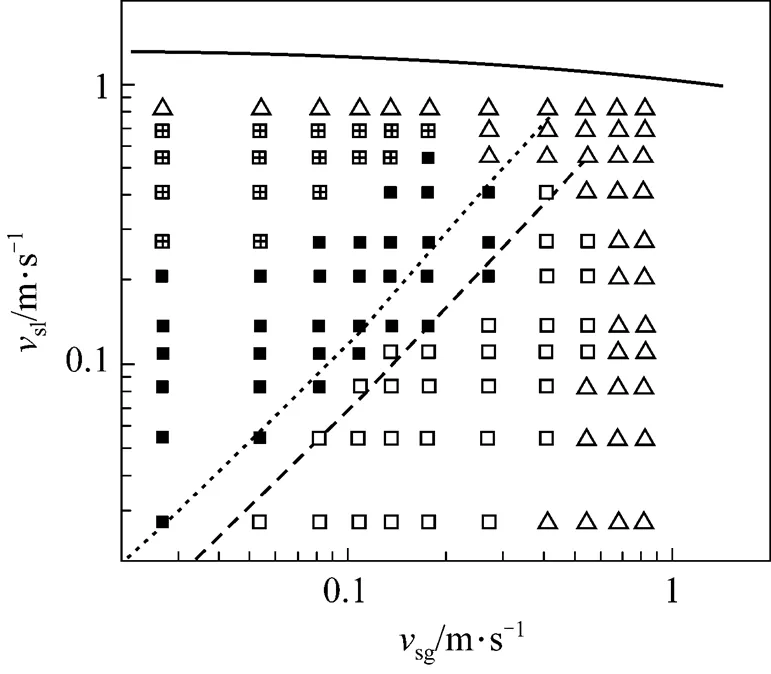

Figure 5 Flow pattern map (0°)

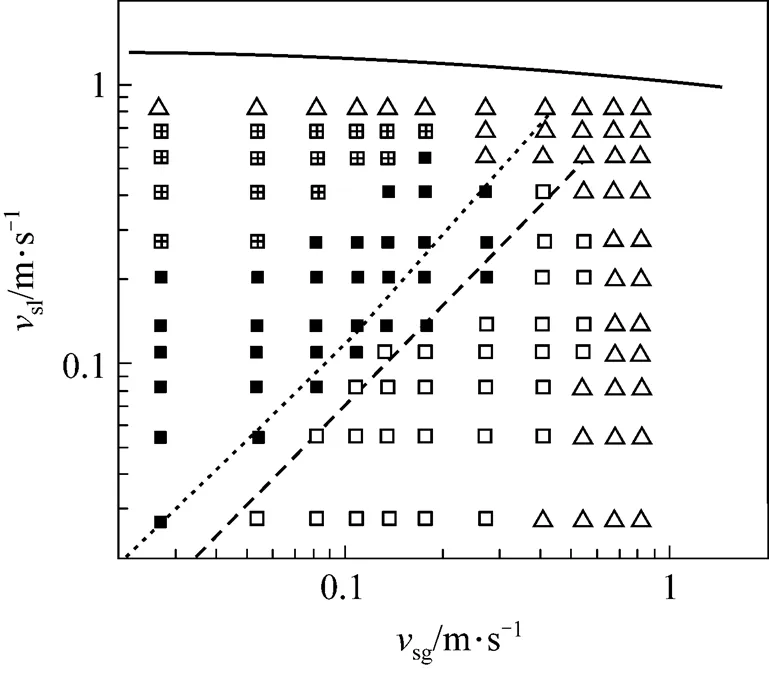

Figure 6 Flow pattern map (-1°)

Figure 7 Flow pattern map (-2°)

Figure 8 Flow pattern map (-4°)

3.2 Flow regime map

Schmidt. [8] believed that when inclination angle was 0°, severe slugging would not occur. However, Wang and Guo [19] thought that severe slugging might occur when inclination angle was 0° because of the influence of liquid viscosity. In this study, severe slugging is observed when inclination angle is 0°. As shown in Fig. 6, there are mainly two kinds of regimes: regime I and regime II. When inclination angle is 0°, the gas and liquid superficial velocity corresponding to the formation region of severe slugging are very low.

Comparing the figures when the inclination angle-1°,-2°,-4°, it is found that as the inclination angle increases the region of severe slugging increases slightly. Meanwhile, the region of regime II is hardly affected by the change of inclination angle.

4 PRESSURE FLUCTUATIONS

4.1 Analysis of pressure fluctuation

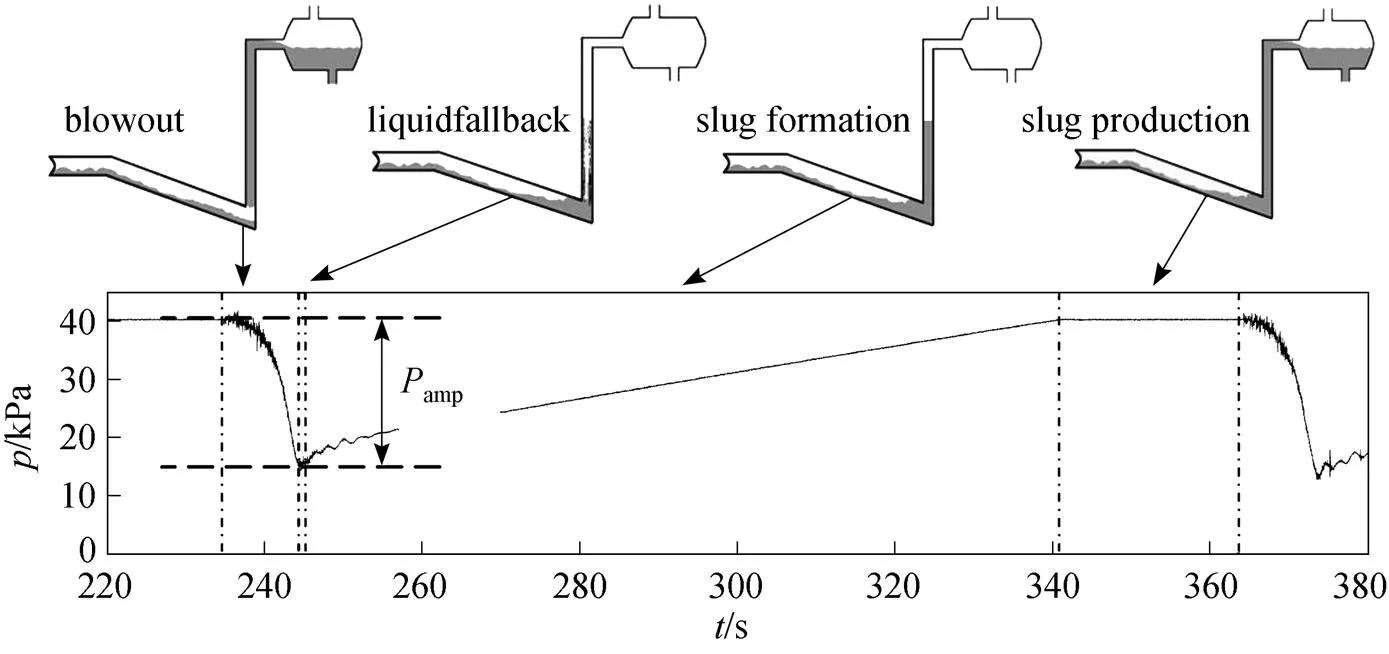

The characteristic parameters of severe slugging vary periodically over time. Generally, one severe slugging cycle can be divided into 4 stages: blowout, liquid fallback, slug formation and slug production as shown in Fig. 9. In the lower part of Fig. 9, the amplitude of pressure fluctuation,ampis defined.

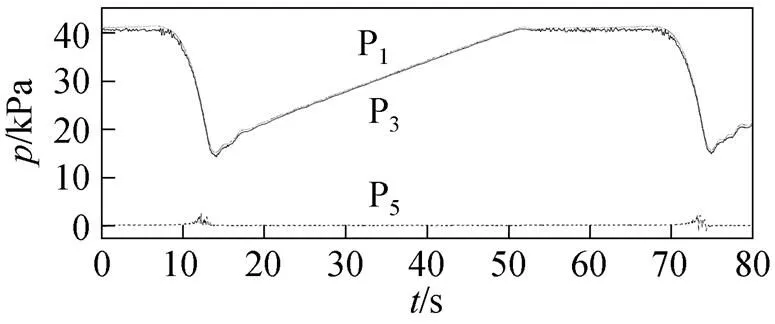

Figure 10 shows the pressure fluctuation time series of P1, P3and P5, and the pressure signals of P1and P3are almost the same. This indicates that when severe slugging occurs, the pressure drop is very small due to the stratified flow or bubble flow in declined pipe. The pressure of P3at the bottom of the riser is the most representative pressure parameter for it can represent both the gas pressure in declined pipe and the pressure of liquid flowing in the riser. The pressure and fluctuation amplitude of P5are both smaller compared with those of P1and P3. It is because that P5locates at the top of the riser. Therefore, the pressure signal of P3at the bottom of the riser is used to analyze the pressure fluctuation characteristics of severe slugging.

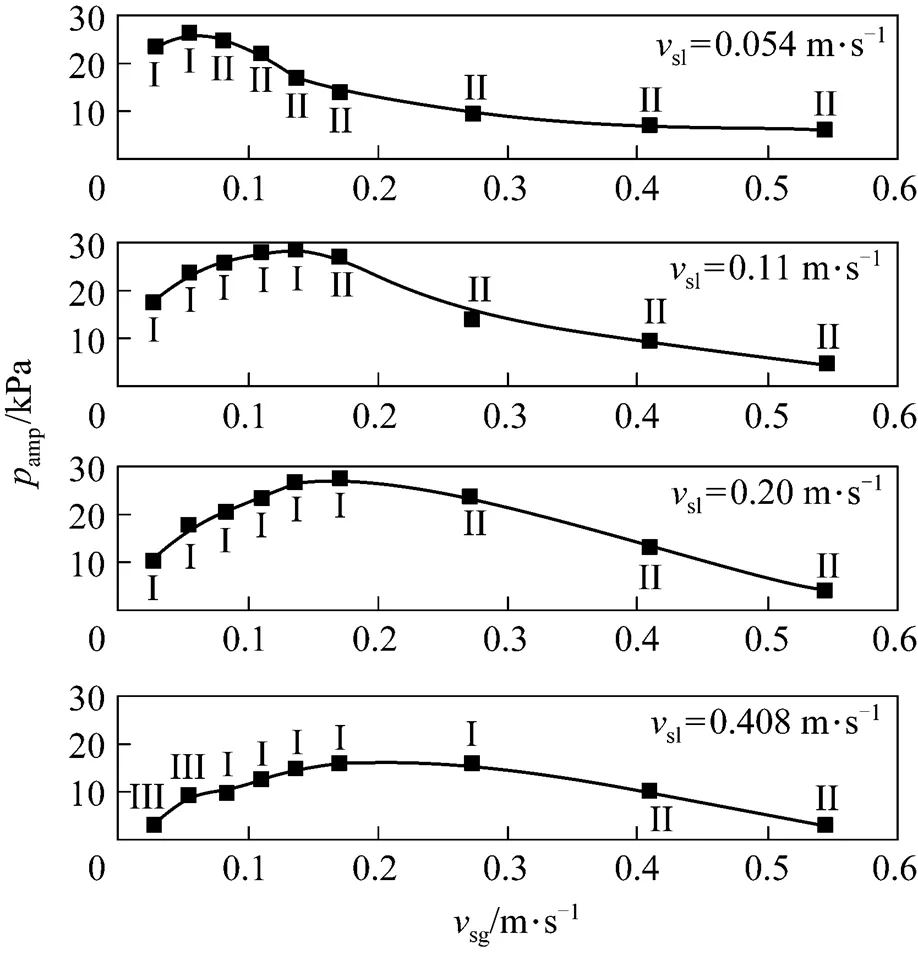

4.2 Relationship of pressure fluctuation and gas velocity

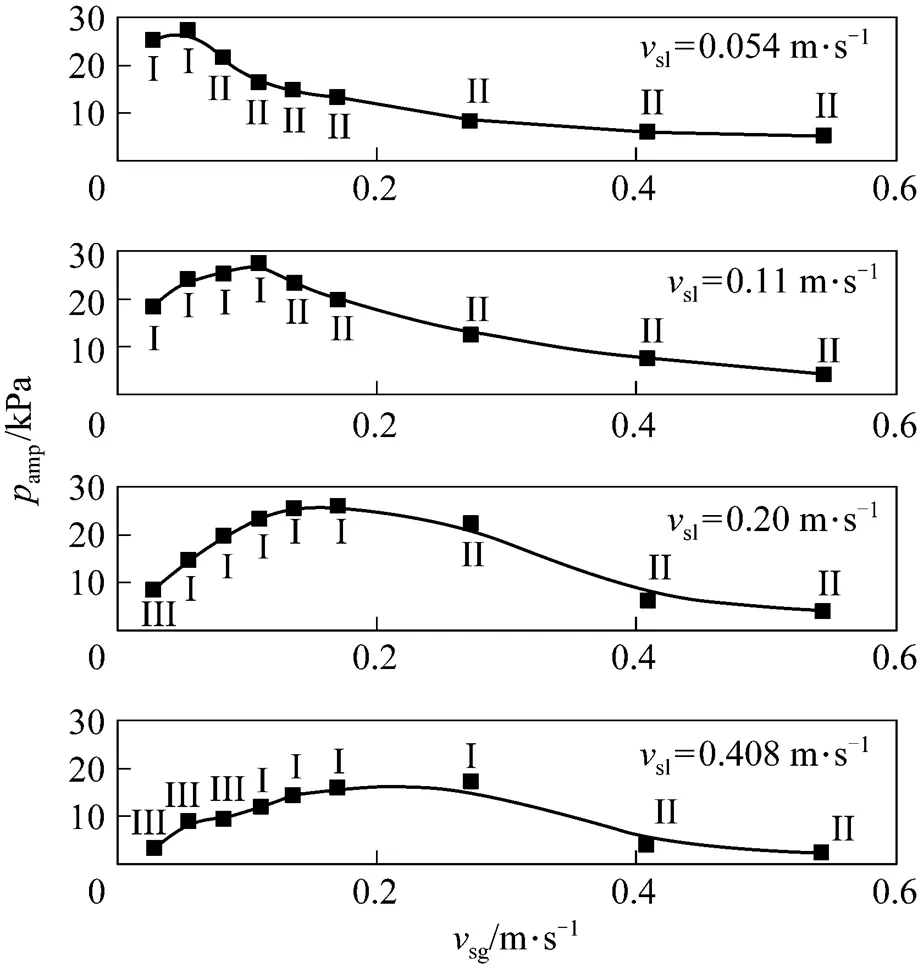

Figures 11, 12 and 13 show the relation curves of pressure fluctuation amplitude (amp) of P3with superficial gas velocity (sg) when inclination angles are-1°,-2° and-4° respectively. It demonstrates that with the increase of gas superficial velocity, the flow pattern of severe slugging changes from SS III to SS I, and then to SS II. In this process, the maximum amplitude of pressure fluctuation occurs at SS I.

Figure 9 Time series of P3

Figure 10 Time series of P1, P3, P5

Figure 11amp.sg(-1°)

I—SS I; II—SS II; III—SS III

Figure 12amp.sg(-2°)

I—SS I; II—SS II; III—SS III

Figure 13amp.sg(-4°)

I—SS I; II—SS II; III—SS III

When SS III and SS I occur, the maximum pressure (max) at the riser base almost does not change with the changes of gas superficial velocity, liquid superficial velocity or inclination angle. However, the increase of gas flow rate leads to more intense blowout of gas, and more liquid is carried out of pipeline in the process of blowout. Therefore, the gas pressure of declined pipe is much lower at the end of the liquid fallback stage and the initial length of newly formed liquid slug decreases. The pressure fluctuation of P3shows that the minimum pressure (min) decreases indicates that the pressure fluctuation amplitude (amp) in the riser increases.

In the transition regime of SS II,maxat the bottom of riser is lower than those when SS III and SS I occur. The increase of gas flow rate can heighten the void fraction of liquid slug in riser and reducemaxfurther at the bottom of riser. Meanwhile, the pressure at the bottom of riser decreases, so does the intensity of blowout, and less liquid is carried out of the pipeline. Therefore the initial length of liquid slug formed after liquid fallback increases. Theminincreases andampdecreases in riser.

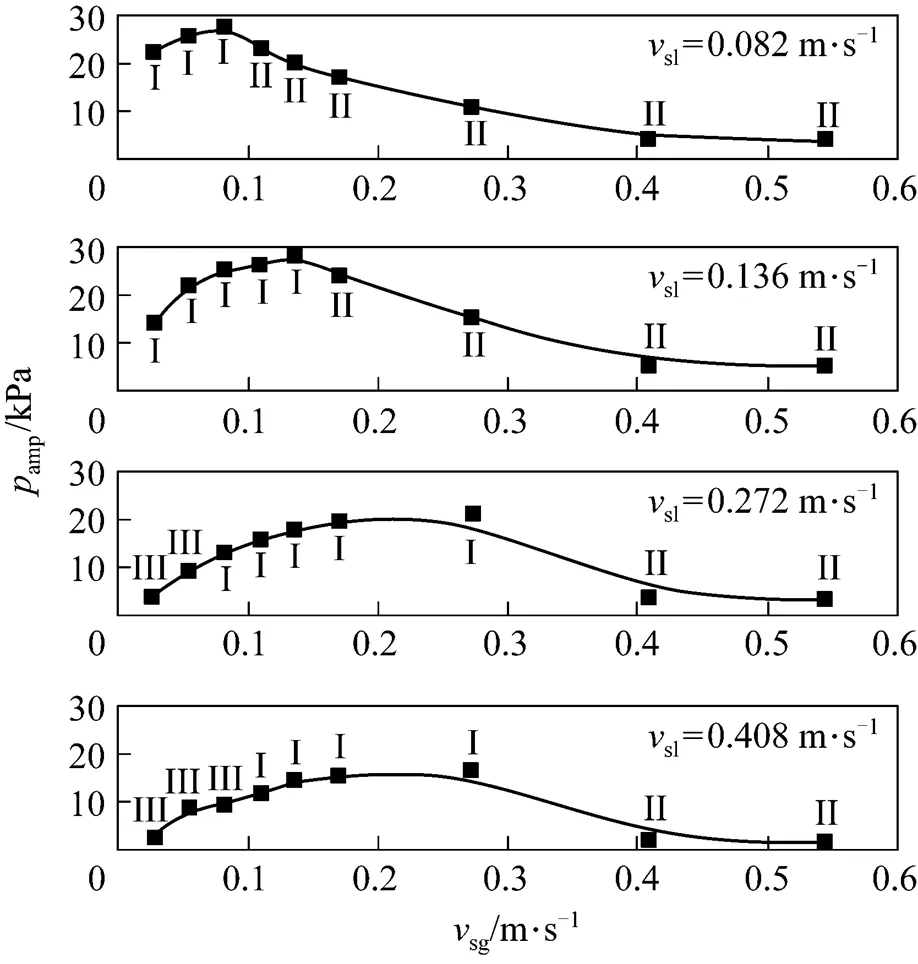

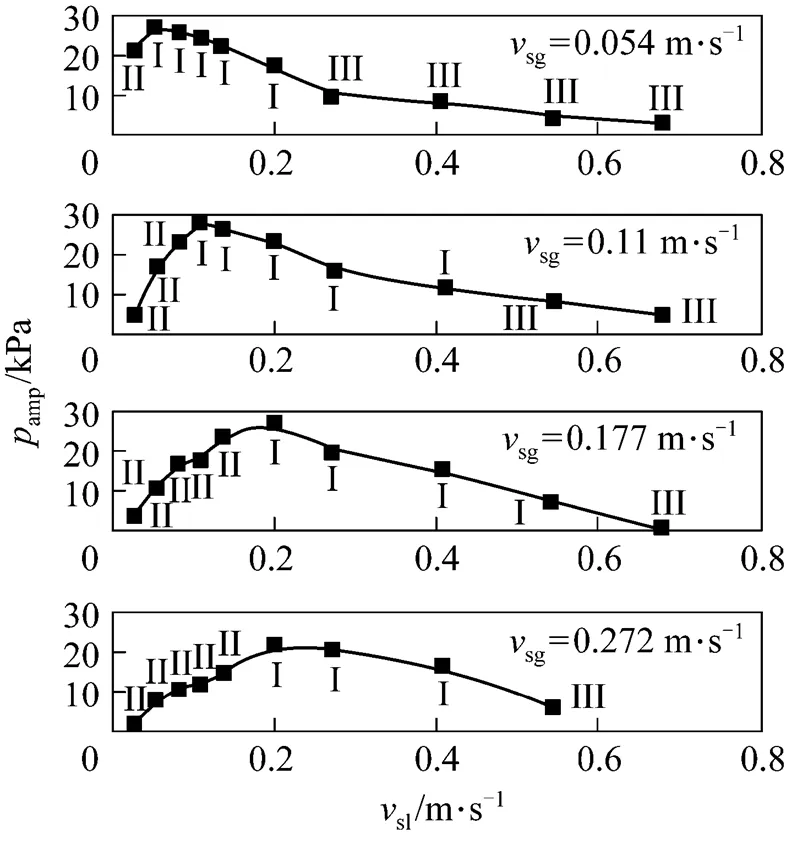

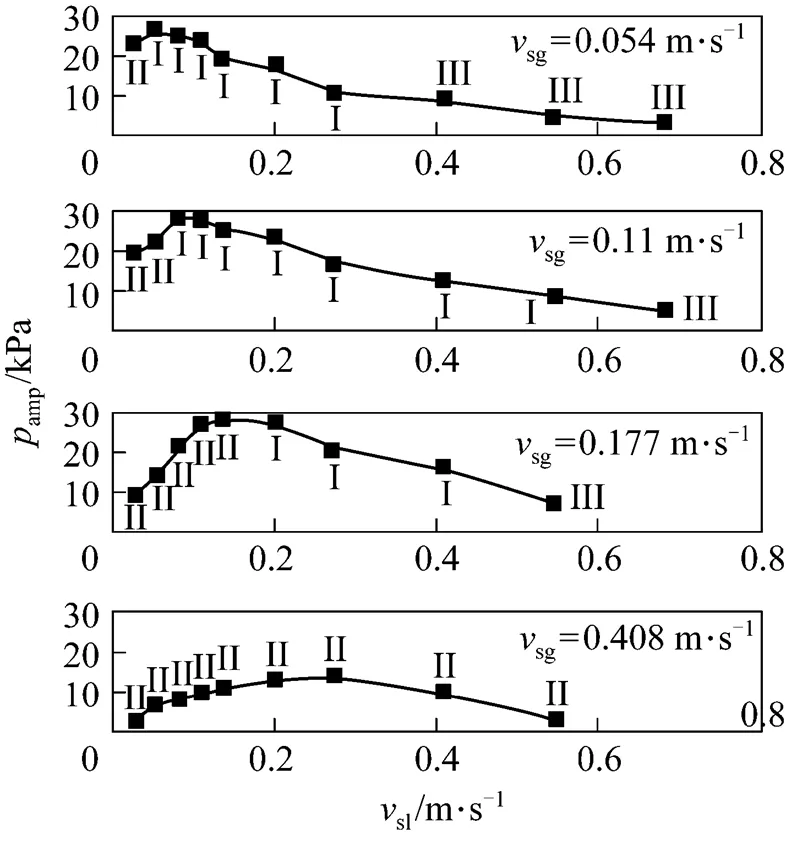

4.3 Relationship of pressure and liquid velocity

Figures 14, 15 and 16 show the relation curves of pressure fluctuation amplitude (amp) of P3at the bottom of riser with liquid superficial velocity (sl) when inclination angles are-1°,-2° and-4° respectively. It demonstrates that with the increase of liquid superficial velocity (sl),.. liquid flow rate, severe slugging changes from SS II to SS I, and then to SS III. In this process,ampincreases when SS II occurs, and decreases when SS III and SS I appear.

Figure 14amp.sl(-1°)

I—SS I; II—SS II; III—SS III

Figure 15amp.sl(-2°)

I—SS I; II—SS II; III—SS III

Figure 16amp.sl(-4°)

I—SS I; II—SS II; III—SS III

When SS II occurs, the increase of liquid flow rate leads to the decrease of void fraction of liquid slug in the riser and the increase ofmaxat the bottom of riser. Meanwhile, the pressure at the bottom of the riser increases, leading to the more intense blowout of gas, and more liquid is carried out. Theminat the bottomof riser decreases, and theampin the riser increases.

When SS III and SS I occur, themaxat the bottom of riser generally keeps constant. The increase of liquid flow rate can enhance more liquid entering into riser during the blowout. The liquid film adhering to the pipe wall becomes thicker and the initial length of slug formed after liquid fallback increases. In the riser, theminincreases andampdecreases.

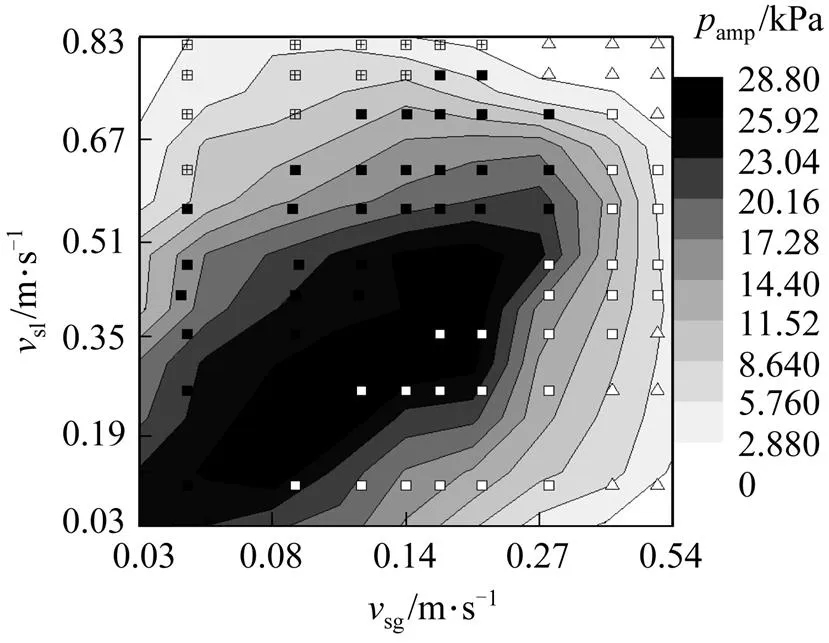

4.4 Relationship of pressure and flow pattern

In the regions of SS I, SS II and SS III, the regular pattern that pressure fluctuation amplitude (amp) varies with the changes of gas and liquid superficial velocity is different from each other. The contour lines of pressure fluctuation amplitude at different liquid and gas superficial velocities are drawn in the flow regime maps when inclination angles are-1°,-2° and-4° respectively, as shown in Figs. 17, 18 and 19.

Figure 17 Contour plot ofamp(-1°)

Figure 18 Contour plot ofamp(-2°)

Figure 19 Contour plot ofamp(-4°)

The above figures show that with the increase of gas superficial velocity (sg), severe slugging changes from SS III to SS I, and then to SS II. In this process, theampincreases while SS III and SS I occur, and decreases when SS II appears. As the liquid superficial velocity (sl) increases, the flow pattern of severe slugging undergoes reversed order, andampat the bottom of the riser increases when SS II occurs, then decreases when SS I and SS III happen. Therefore the maximum value ofampappears at the transition boundary of SS I and SS II.

5 CONCLUSIONS

(1) Severe slugging still occurs when inclination angle is 0°. As the inclination angle increases from-1° to-4°, the formation range of severe slugging increases slightly. When the inclination angle changes, the formation range of regime II is almost invariant, and those of regime I and regime III vary slightly.

(2) With the increase of gas superficial velocity and liquid superficial velocity, the pressure fluctuation amplitude at the bottom of the riser increases initially and then decreases, and the maximum value occurs at the transition boundary of SS I and SS II.

1 Kordyban, E., “Horizontal slug flow: A comparison of existing theories”,., 112 (1), 74-83 (1990).

2 Fabre, J., Line, A., “Modeling of two-phase slug flow”,..., 24, 21-46 (1992).

3 Wallis, G.B., Dobson, J.E., “The onset of slugging in horizontal stratified air-water flow”,.., 1 (1), 173-193 (1973).

4 Taitel, Y., Dukler, A.E., “A model for predicting flow regime transition in horizontal and near horizontal gas-liquid flow”,., 22 (1), 47-54 (1976).

5 Taitel, Y., Dukler, A.E., “A model for slug frequency during gas-liquid flow in horizontal and near horizontal pipes”,.., 3 (5), 585-596 (1977).

6 Mishima, K., Ishii, M., “Theoretical prediction of onset of horizontal slug flow”,.., 102 (4), 441-445 (1980).

7 Barnea, D., Taitel, Y., “Kelvin-Helmholtz stability criteria for stratified flow, viscousnon-viscous (inviscid) approaches”,.., 19 (4), 639-649 (1993).

8 Schmidt, Z., Brill, J.P., Beggs, H.D., “Choking can eliminate severe pipeline slugging”,., 12 (3), 230-238 (1979).

9 B?e, A., “Severe slugging characteristics: (1) Flow regime for severe slugging (2) Point model simulation study”, Presented at Selected Topics in Two-Phase Flow, NTH, Trondheim, Norway (1981).

10 He, L.M., Zhao, Y.C., Luo, X.M., “The measurement methods on characteristic parameters of air-water severe slugging in pipe-riser systems”,..., 26 (4), 621-624 (2005). (in Chinese)

11 Luo, X.M., He, L.M., Ma, H.W., “Experimental study of characteristic parameters of severe slugging in riser-pipe systems”,.., 29 (6), 74-77 (2005). (in Chinese)

12 Ma, H.W., He, L.M., Luo, X.M., “Experiment on pressure fluctuation characteristic of severe slugging”,.., 32 (1), 95-99 (2008). (in Chinese)

13 Tin, V., Sarshar, M.M., “An investigation of severe slugging characteristics in flexible risers”, In: Proc. 6th Int. Conf. on Multiphase Production, BHRG, France, 205-228 (1993).

14 Tin, V., “Severe slugging in flexible risers”, In: Proc. 5th BHRG Int. Conf. Multiphase Production, France, 507-525 (1991).

15 Montgomery, J.A., Yeung, H.C., “The stability of fluid production from a flexible riser”,.., 124 (2), 83-88 (2002).

16 Corteville, T., “An experimental study of severe slugging in multiphase production lines”, In: Proc. of the 7th Int. BHRG Conf. on Multiphase Production, France, 105-121 (1995).

17 Liu, M.E., Li, Q.P., An, W.J., “One-dimension unsteady model of severe slugging in a riser system”,, 19 (2), 125-130 (2007). (in Chinese)

18 Yu, X.C., Ren, Y.B., Wu, Y.L., “The analysis of transient flow characteristics and sensitivity in the riser of subsea multiphase pipeline”,, 19 (1), 60-64 (2007). (in Chinese)

19 Wang, X., Guo, L.J., “Experimental investigation and simulation of severe slugging in pipeline-riser system”,.., 27 (4), 611-614 (2006). (in Chinese)

20 Mokhatab, S., “Severe slugging in a catenary-shaped riser: Experimental and simulation studies”,, 25 (6), 719-740 (2007).

21 Hernandez, G., Asuaje, M., Kenyery, F., Tremante, A., Aguillón, O., Vidal, A., “Two-phase flow transient simulation of severe slugging in pipeline-risers systems”,.., 56 (4), 39-50 (2007).

22 Mandhane, J.M., Gregory, G.A., Aziz, K., “A flow pattern map for gas liquid flow in horizontal pipes”,.., 1, 537-551 (1974).

** To whom correspondence should be addressed. E-mail: luo-xiaoming@163.com

2010-04-07,

2010-12-12.

the National High Technology Research and Development Program of China (2006AA09Z302).

——戎利民教授

Chinese Journal of Chemical Engineering2011年1期

Chinese Journal of Chemical Engineering2011年1期

- Chinese Journal of Chemical Engineering的其它文章

- Dynamic Simulation and Analysis of Industrial Purified TerephthalicAcid Solvent Dehydration Process*

- Preparation of p-Hydroxybenzaldehyde by Hydrolysis of DiazoniumSalts Using Rotating Packed Bed*

- Liquid-solid Equilibria in Quinary System Na+, K+, Mg2+//Cl-,?at 25 °C*

- Pervaporation Separation of Butanol-Water Mixtures UsingPolydimethylsiloxane/Ceramic Composite Membrane*

- Reaction Kinetics of Biodiesel Synthesis from Waste Oil Using a Carbon-based Solid Acid Catalyst

- Enzyme-catalyzed Synthesis of Vitamin E Succinate Using aChemically Modified Novozym-435*