Dynamic Simulation and Analysis of Industrial Purified TerephthalicAcid Solvent Dehydration Process*

LI Chengfei (李澄非)

?

Dynamic Simulation and Analysis of Industrial Purified TerephthalicAcid Solvent Dehydration Process*

LI Chengfei (李澄非)**

Wuyi University, Jiangmen 529020, China

Dynamic model for dehydration process of industrial purified terephthalic acid solvent is investigated to understand and characterize the process. A temperature differential expression is presented, which ensures the equation to convergence and short computation time. The model is used to study the dynamic behavior of an azeotropic distillation column separating acetic acid and water using-butyl acetate as the entrainer. Responses of the column to feed flow and aqueous reflux flow are simulated. The movement of temperature front is also simulated. The comparison between simulation and industrial values shows that the model and algorithm are effective. On the basis of simulation and analysis, control strategy, online optimization and so on can be implemented effectively in dehydration process of purified terephthalic acid solvent.

dynamic simulation, purified terephthalic acid, solvent dehydration, azeotropy

1 Introduction

Purified terephthalic acid (PTA) is an important raw material for polyester production widely used in textile and packaging industries. It is produced by catalytic oxidization of PX (paraxylene) fo1lowed by subsequent purification of the crude terephthalic acid by selective hydrogenation.

Acetic acid is the solvent in the PTA production process and its concentration is an important quality criterion. The content of acetic acid at the bottom of solvent dehydration column directly influences the product quality of upstream oxidation unit. Less acetic acid lost at the top of solvent dehydration column results in more energy consumption. Thus it is necessary to investigate the separation of acetic acid and water in the recovery unit for saving energy and ensuring the purity of PTA in the oxidation unit.

PTA production process is a typical heterogeneous azeotropic distillation system. The simulation for steady state PTA production process has been carried out [1, 2]. However, heterogeneous azeotropic distillation is very unstable and it is difficult to be controlled [3-8]. Because the azeotropic distillation shows extremely complex dynamic behavior and is sensitive to slight disturbances, it is difficult to operate it and to design its controller, and a dynamic simulation is needed to understand the nonlinear characteristics of the system. Acetic acid dehydration is an important operation in the azeotropic distillation, so its dynamic simulation and analysis is important to control and optimization of industrial PTA process. Design for acetic acid dehydration system using an entrainer, which is used to reduce the organic reflux and heat duty in the dehydrating column, were reported in several publications [9]. Pham and Doherty took ethyl acetate as entrainer [10], and Tanaka and Yamada used-butyl acetate [11]. Siirola used acetic ethyl acetate as entrainer to design a complete acetic acid dehydration process with multiple effect azeotropic distillation [12]. Wasylkiewicz. used geometric method for optimum process design of an acetic acid dehydration column with-butyl acetate as entrainer [13]. Luyben and Tyreus used vinyl acetate monomer as an example for simulation, design, and control studies [14]. Kurooka. proposed a nonlinear control system for the acetic acid dehydration column with-butyl acetate as entrainer [15, 16]. Gaubert. studied the industrial dehydration operation of an unnamed organic acid using an immiscible entrainer [17], in which multiple steady states were confirmed for the heterogeneous column by simulation and experimental data. Chien. designed an acetic acid dehydration systemheterogeneous azeotropic distillation [18], with iso-butyl acetate as the entrainer. The optimum process design and operating condition were determined for high acetic acid concentration at the bottom and small loss of acetic acid through the top aqueous flow. Chien and Kuo added a pre-concentrator column in the upstream of the heterogeneous azeotropic distillation column [19] and investigated the necessity of the pre-concentrator column from aspect of design and control. For a typical waste isopropyl alcohol stream with equal moles of isopropyl alcohol and water, the design and control of the overall isopropyl alcohol dehydration process were investigated [20] and a novel side-stream operating strategy was proposed to maintain the impurity concentration inside the column for an energy-efficient operation[21]. The optimum process design and operating condition were determined by intelligence method [22].

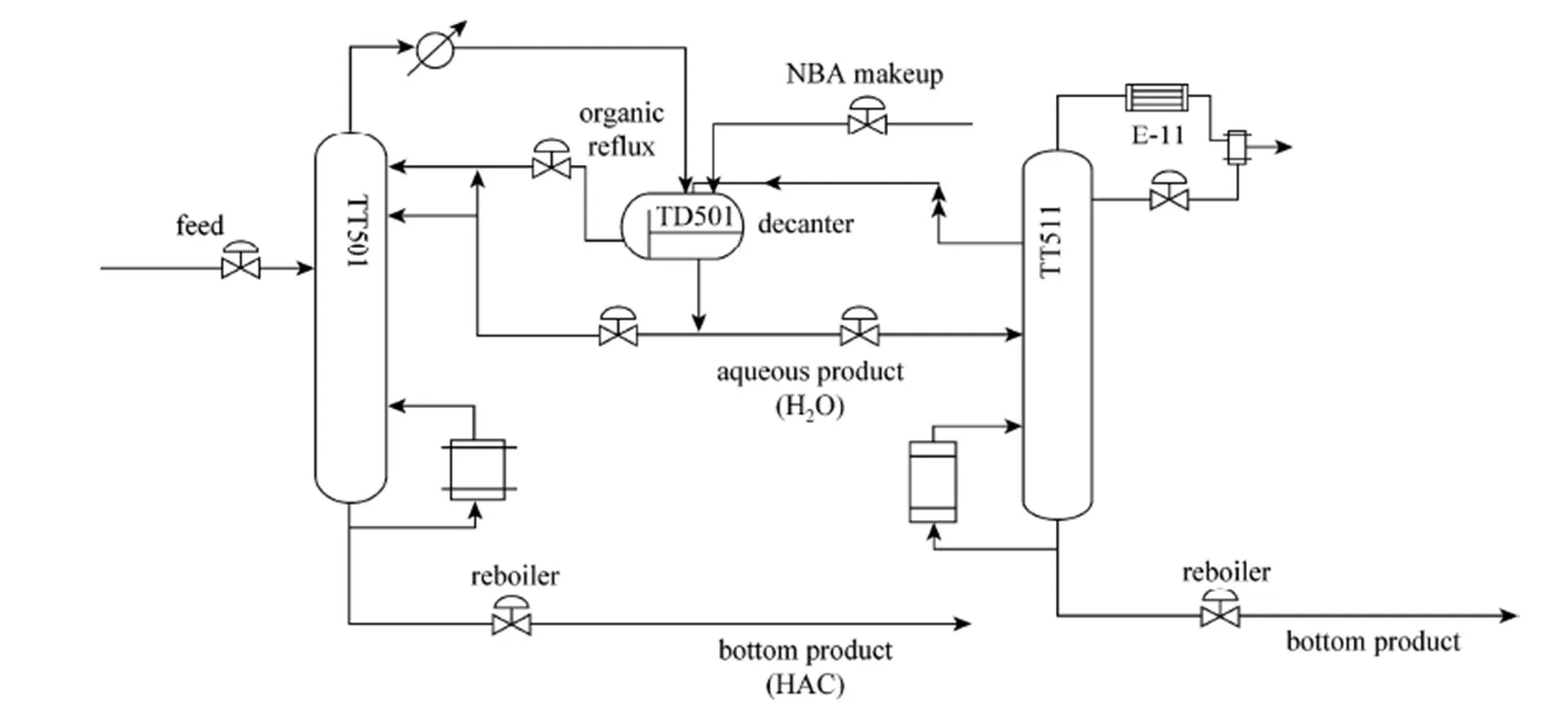

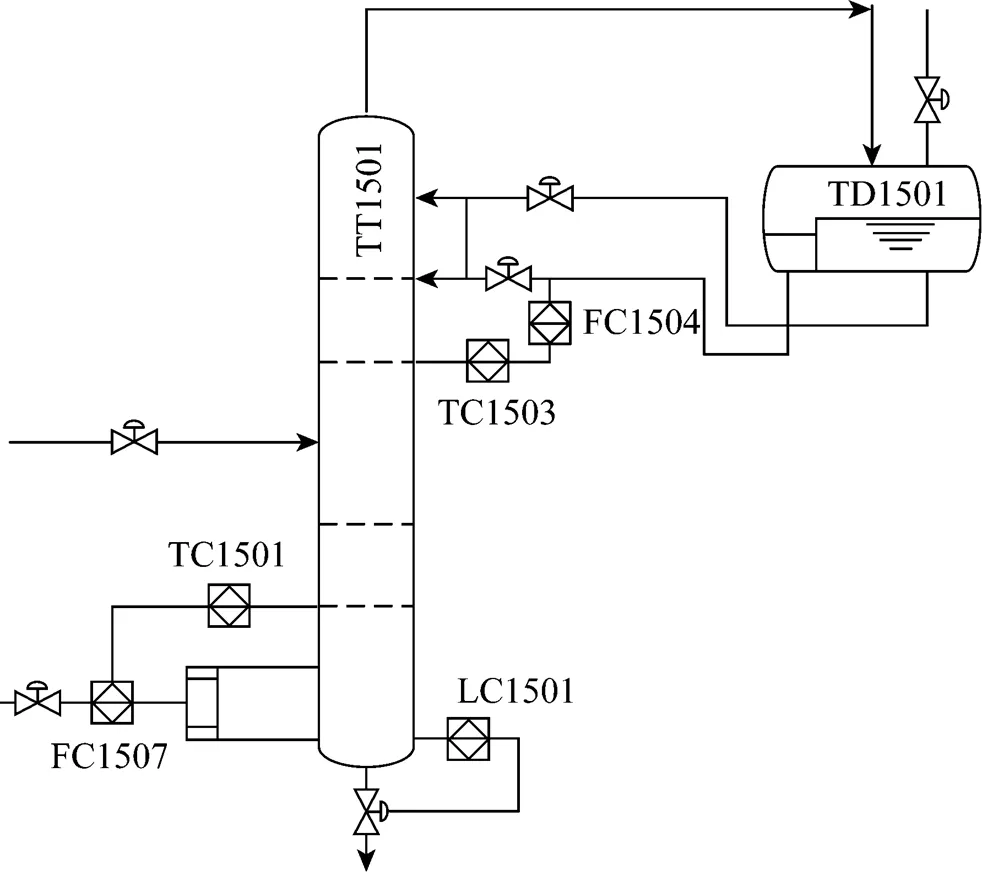

Figure 1 Industrial purified terephthalic acid solvent dehydration system

The flowsheet of this study is similar to the column system in literature, with components of acetic acid and water. The dynamic simulation and analysis on industrial PTA solvent dehydration with-butyl acetate as entrainer are investigated in this work to understand and characterize the process, which have been little discussed in literature.

2 Industrial Purified Terephthalic Acid solvent dehydration system

Figure 1 shows the industrial purified terephthalic acid solvent dehydration system. The solvent recovery section recovers and purifies the acetic acid solvent with an azeotropic distillation system, before it is recycled to other section. The condensate from the reflux drum containing water and small amount of organics formed in the reaction step and that from oxidation unit are collected in drum acetic acid. This dilute acetic acid solution is fed to 15th tray of distillation column TT501 through pumps with flow control. This azeotropic distillation system utilizes another solvent,-butyl acetate (NBA) called the entrainer, which is relatively immiscible with water. The entrainer forms azeotrope with water and increases the relative volatility of water to acetic acid, which leads to less reflux ratio and fewer distillation stages. The water containing 0.1% (by mass) acetic acid is removed as distillate. The tower is operated at an external reflux ratio of approximate 0.6. The overhead azeotropic vapor at 90°C is condensed, cooled to 40°C in the condenser and flows into the reflux drum. TD501 is internally divided by weir into the phase separating zone, in which the condensate is separated into entrainer phase and aqueous phase by decantation, and the entrainer overflows the weir into the entrainer collecting zone. The entrainer is refluxed to the top of TT501 with flow control. A portion of aqueous phase containing some dissolved entrainer is refluxed from the bottom of the phase separating zone to the top of TT501 with flow control through water reflux pumps. The remainder is fed to the NBA recovery tower TT511 with interface level controller of the phase separating zone. Purified acetic acid as bottom product of TT501 flows into the bottom acetic acid drum with level control.

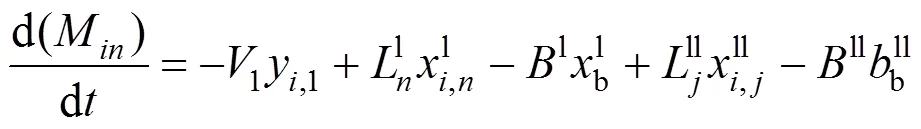

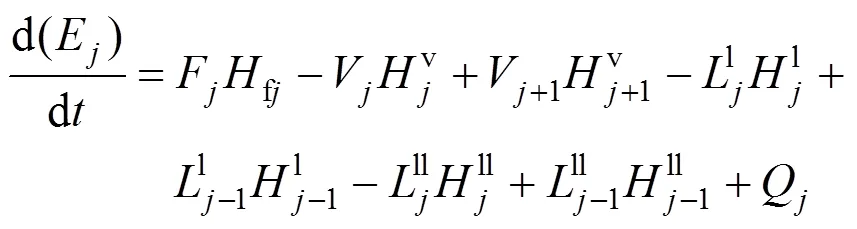

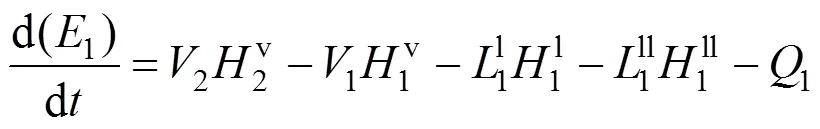

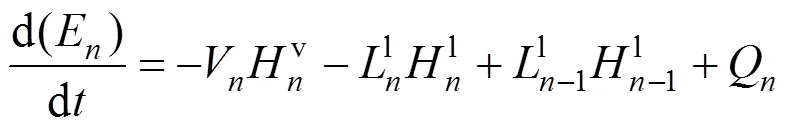

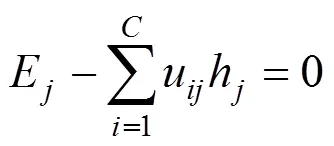

3 formation OF AN Improved Dynamic Model

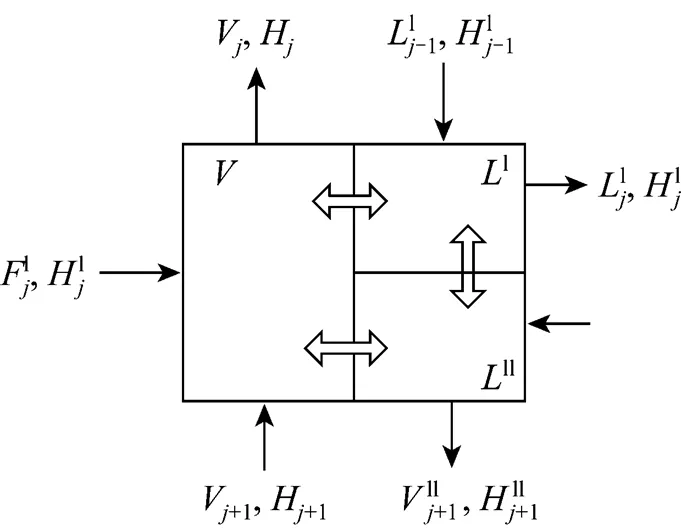

Figure 2 shows the three phase equilibrium model used in this study. Because the industrial PTA solvent dehydration system shows extremely complex dynamic and nonlinear characteristics, the model is developed with following assumptions: perfect mixing in vapor and liquid phases, equilibrium vapor-liquid-liquid phases, ideal stage, negligible vapor holdup, and steam condensation at saturated temperature in reboiler.

Figure 2 Sketch of three phase equilibrium model

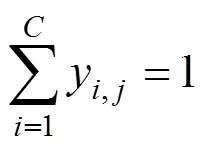

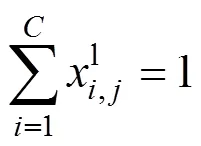

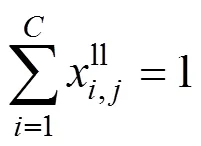

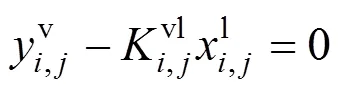

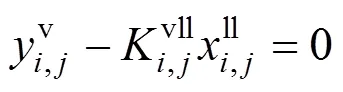

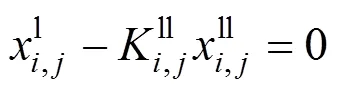

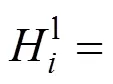

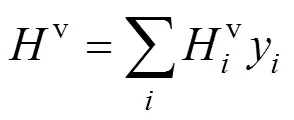

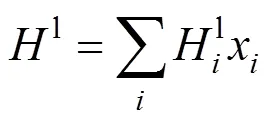

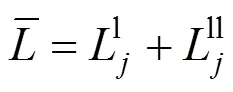

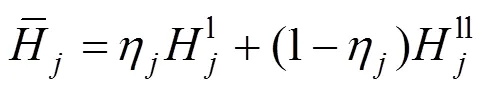

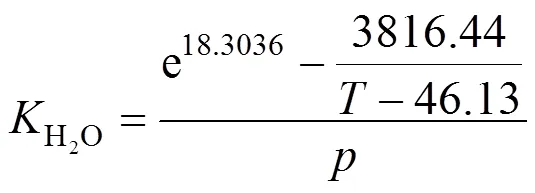

Vapor-liquid-liquid equilibrium (VLLE) is represented with the non-random two liquids (NSTL) equation. The model equations are described as follows:

Phase equilibrium equations are

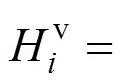

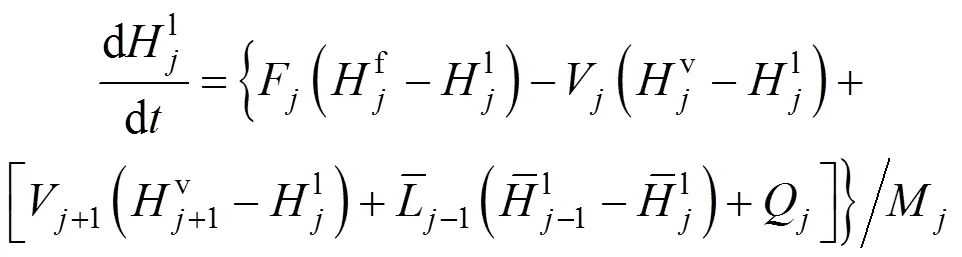

The values of enthalpy are as follows:

HAC vapor:

water vapor:

NBA vapor:

HAC vapor:

NBA liquid:

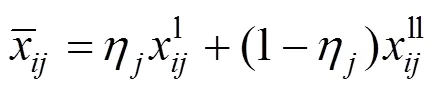

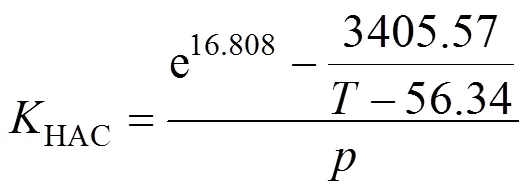

On the basis of the above assumptions, the equilibrium constants are obtained as follows:

HAC equilibrium constant:

H2O equilibrium constant:

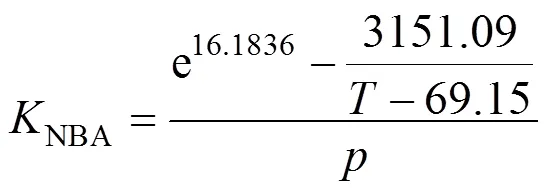

NBA equilibrium constant:

whereis the system pressure, andis the temperature.

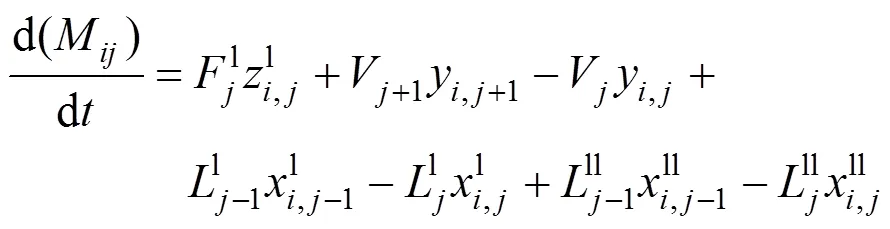

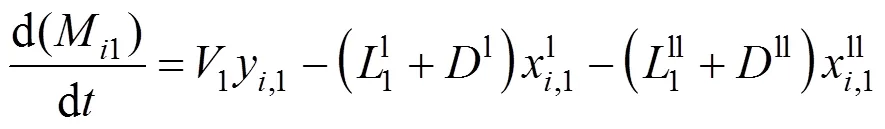

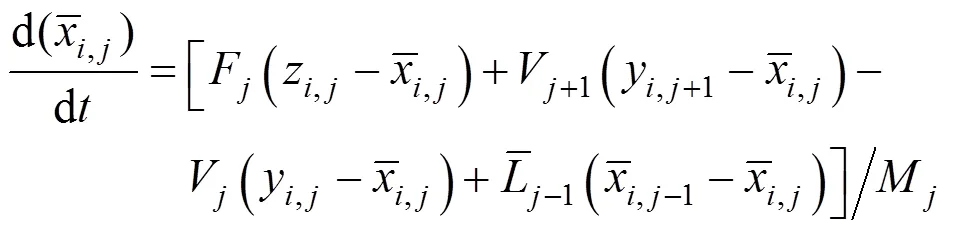

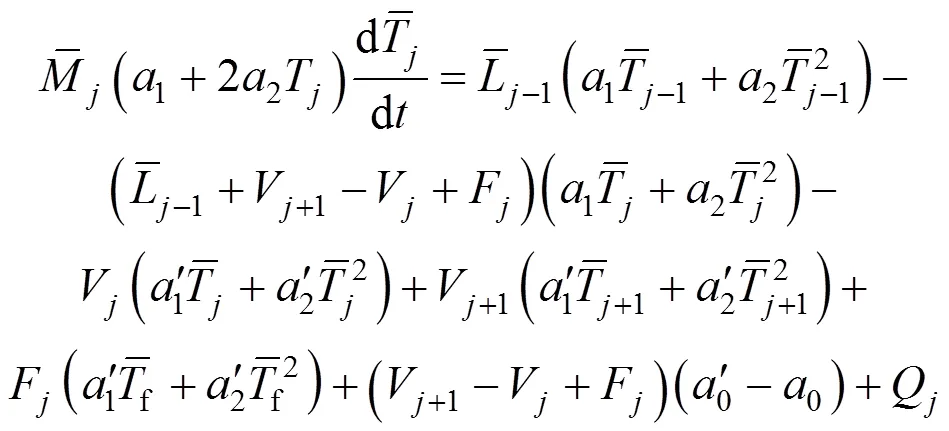

This differential equation of liquid composition and flux represents well the dynamic characteristic of distillation column. Vapor flow changes sharply, so it has little effect on the equation, while temperature is an important process variable that represents the characteristic of distillation process. In steady state simulations, temperature is obtained using bubble-point method based on phase equilibrium. In dynamic simulations, the bubble-point equation is nonlinear with complicated iterative process and it is difficulty to convergence and even leads to calculation failure. In order to improve the convergence and reduce computation time, the differential equation for temperature is obtained.

Equations (21)-(24), and (29) are changed to

The algorithm for solving the problem is as follows.

Step 1 Calculate initial value.

Step 5 Repeat Step 2 to Step 4 until the convergence within a tolerance level is achieved.

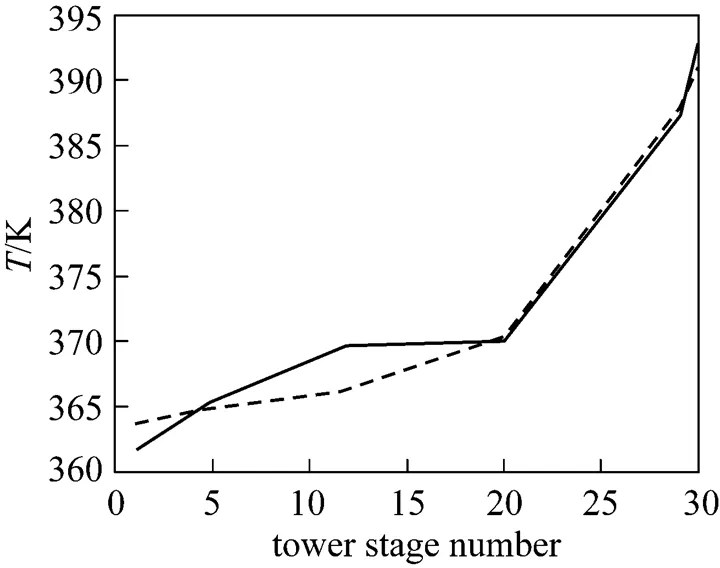

The differential equation is solved with the ODE (ordinary differential equation) algorithm in Matlab, which is for solving nonlinear problem so convergence is ensured. The calculation results are shown in Table 1 and Fig. 3. The simulation is satisfactory, indicating that the model is appropriate.

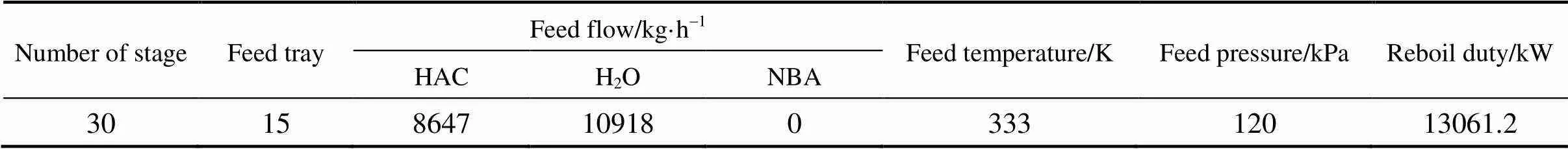

Table 1 Comparison of the simulation and industrialvalues (feed flow rate 19565 kg·h-1)

Figure 3 Comparison of simulation with industrial data

4 Dynamic simulation and analysis

The optimum operating condition is determined for high concentration of bottom acetic acid and small acetic acid loss through the top aqueous stream. The nonrandom two-liquids (NRTL) activity coefficient model is used for vapour-liquid-liquid equilibrium for the ternary system.

Since the relative volatility between water and acetic acid is very small,-butyl acetate is used as the entrainer for efficient separation. In the heterogeneous azeotropic distillation column, water is obtained from the heavy phase in the decanter and acetic acid is withdrawn from the bottom of the column. With this three-component mixture, the liquid phase is heterogeneous not only in the decanter but also in the upper part of the column. The column has two reflux flows,.., the entrainer reflux and water reflux. The top vapor stream forms two liquid phases. The organic phase is refluxed to the column to provide enough entrainer, and the aqueous phase containing mostly water is drawn out from the system for further treatment. Some of the aqueous phase is refluxed to the column if the organic reflux is too small to fulfill the column specifications. Therefore, there are three manipulated variables,.., entrainer reflux flow, water reflux flow, and vapor flow.

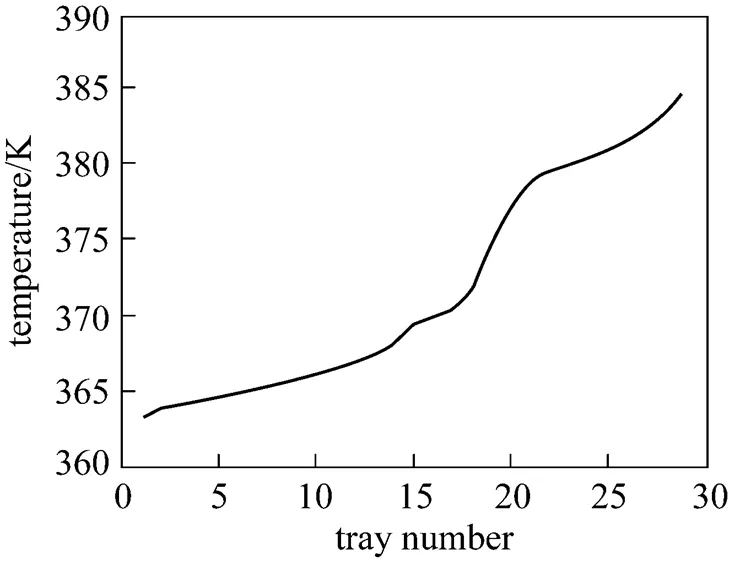

Figure 4 shows three parts of the temperature profile. The temperature in the trays above the feed tray, 15#, changes slowly, where vapor and two liquids are in equilibrium. The main compositions are water and NBA and the concentration of acetic acid is very low. At stage 20#, three phases become two phases, so that the temperature and composition change sharply. The sharp decrease in concentration of NBA is accompanied by a steep increase of acetic acid, as shown in Fig. 5. In those trays beneath the feed tray, NBA is very little and does not function in the distillation. Thus no azeotropic phenomenon happens in these stages and it is a binary acetic-water distillation.

Figure 4 Temperature. the number of tower stage

Figure 5 Liquid composition. the number of tower stage

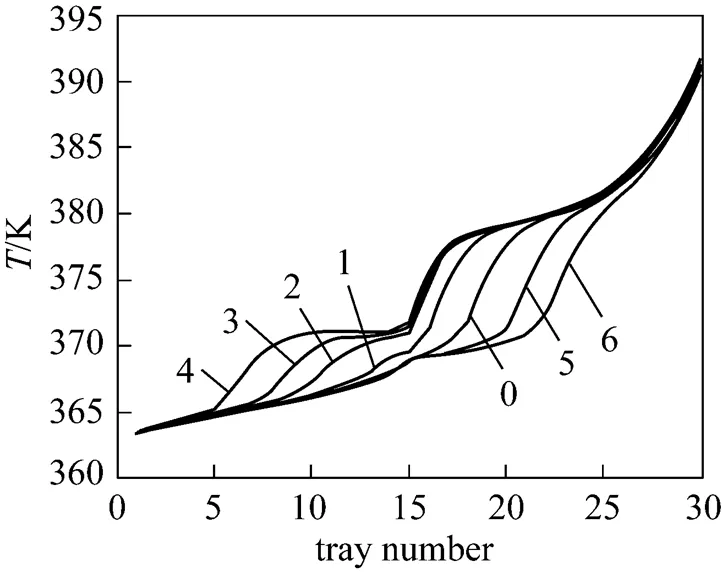

Figure 6 Temperature profile at different reflux flow

1—reflux flow in crease 2%; 2—reflux flow constant;3—reflux flow decrease 2%; 4—reflux flow decrease 4%

The NBA concentration at trays toward tower bottom lower than tray 15#decreases rapidly. The temperature at the tray at which the temperature changes sharply (sensitive point) must be controlled to ensure the HAC concentrations at the bottom and the top. The temperature of sensitive point is manipulated by controlling the reflux flow. Fig. 6 shows that temperature profile changes with reflux flow. If the temperature is increased (temperature front shifting toward the tower top), the HAC concentration in the vapor increases, losing more HAC. The strategy is implemented by increasing the reflux flow. However, the NBA reflux flow can not be excessive. It is seen from Figs. 5 and 6 that as the NBA reflux flow increases, the NBA concentration in the liquid near the bottom of tower increases. The NBA at the bottom is sent to the oxidation unit of PTA to be dissolved, so the cost increases. Moreover, HAC concentration at the bottom will decrease.

Figure 7 shows that the heat flow of reboiler affects the tray temperature obviously. The temperature increases with the heat flow.

Figure 7 Temperature profile at different reboil duties

reboil duty/kW: 0—13061.2; 1—13067.2; 2—13074.5;3—13087.3; 4—13113.4; 5—13057.3; 6—13035.1

The dynamic analysis is as follows.

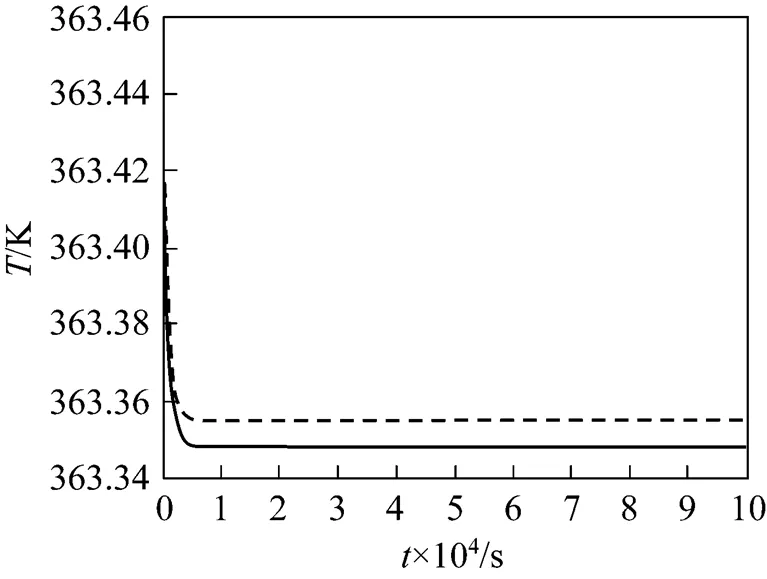

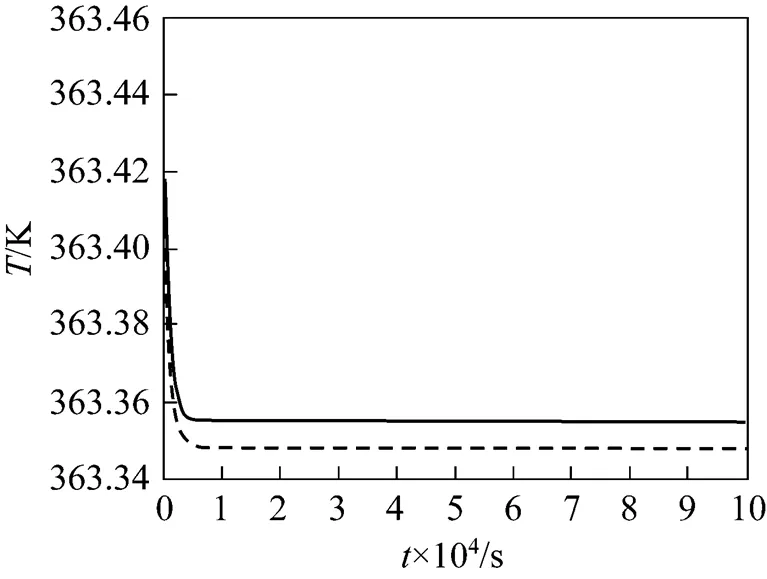

(1) Response of temperature to the change of reflux flow

Figures 8 and 9 indicate that the tray temperature decreases as reflux flow increases, and increases as reflux flow decreases.

Figure 8 Response of temperature at the top to increase in the reflux flow

Figure 9 Response of temperature at the top to decrease in the reflux flow

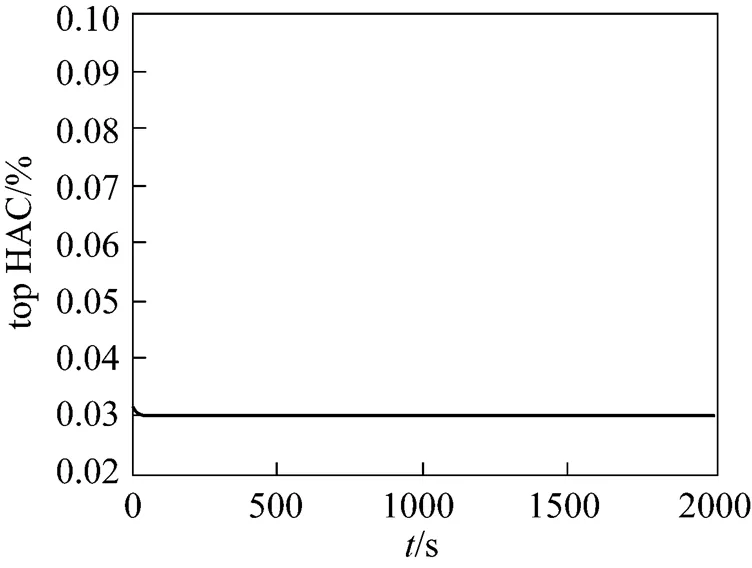

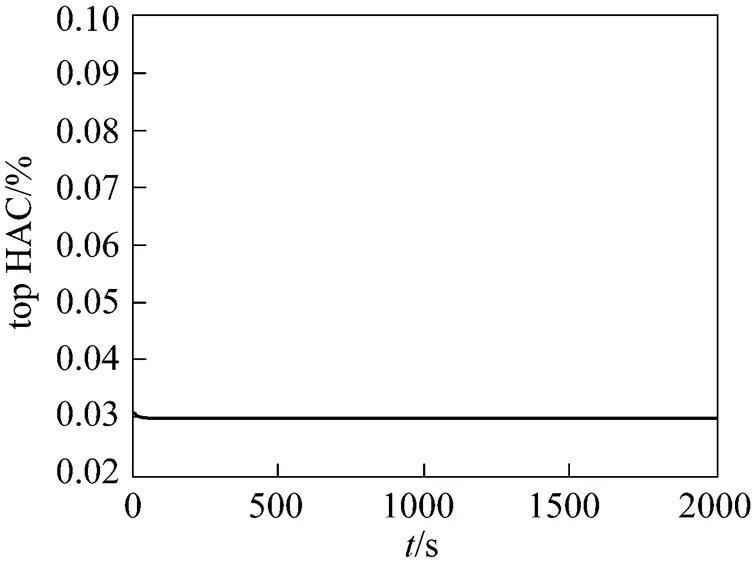

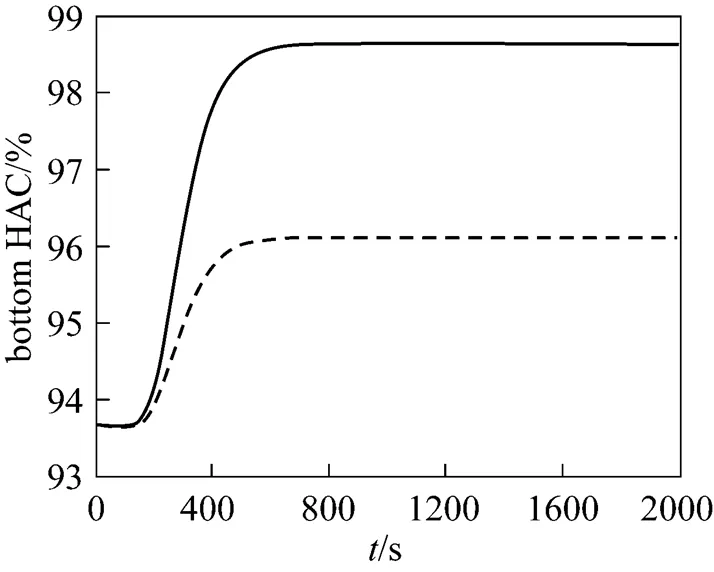

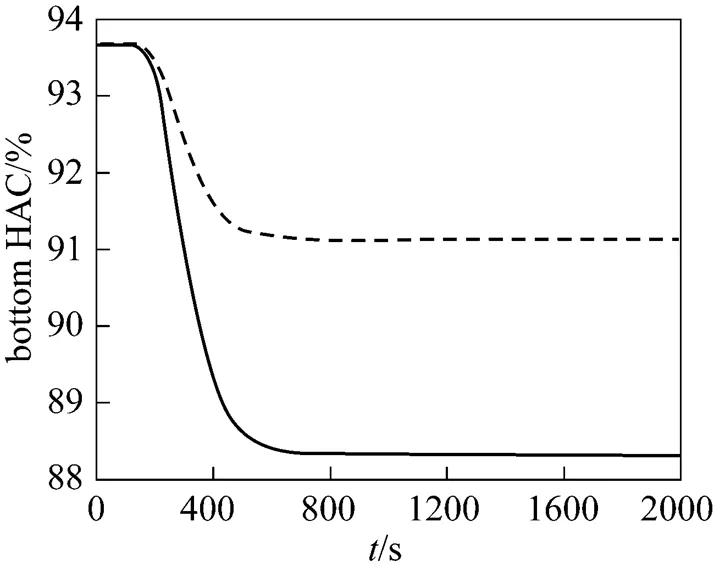

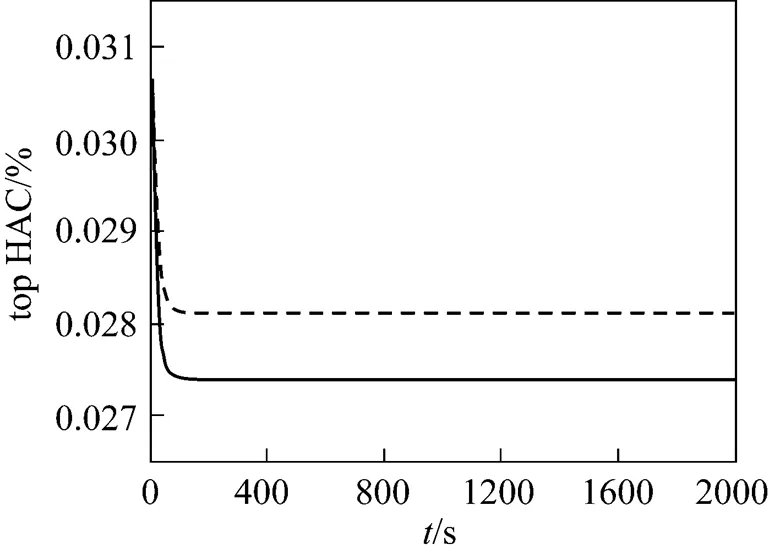

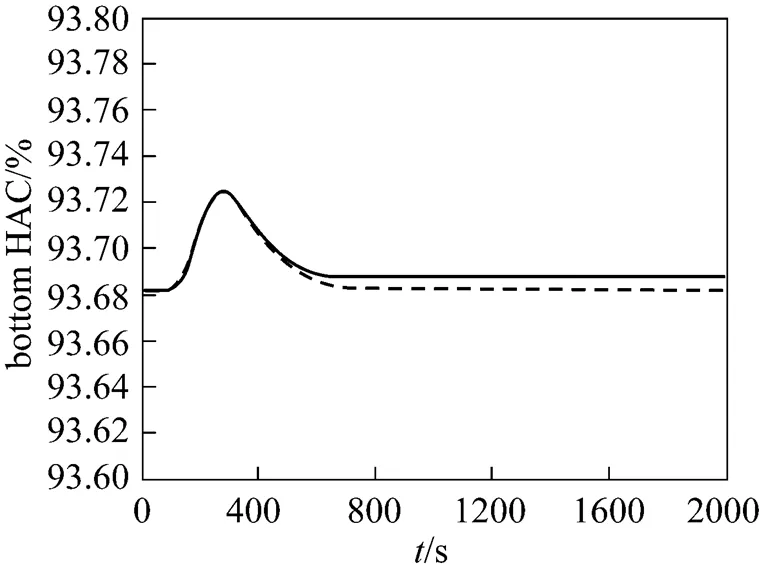

(2) Response of concentration to the change of feed flow

Figures 10 and 11 show that the change of feed flow does not affect the concentration of top product. Figs. 12 and 13 indicate that HAC concentration at the bottom increases with feed flow increasing and decreases as the feed flow decreases.

Figure 10 Response of top HAC concentration to increase in the feed flow

Figure 11 Response of top HAC concentration to decrease in the feed flow

Figure 12 Response of bottom HAC concentration to increase in the feed flow

Figure 13 Response of bottom HAC concentration to decrease in the feed flow

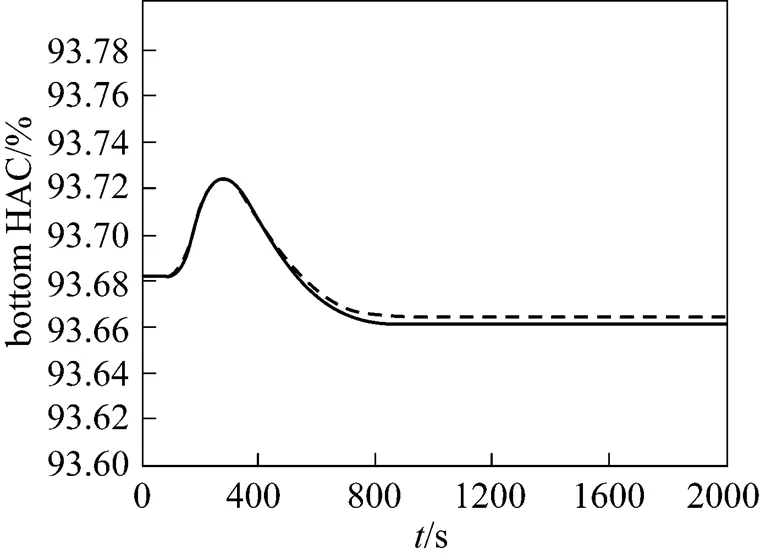

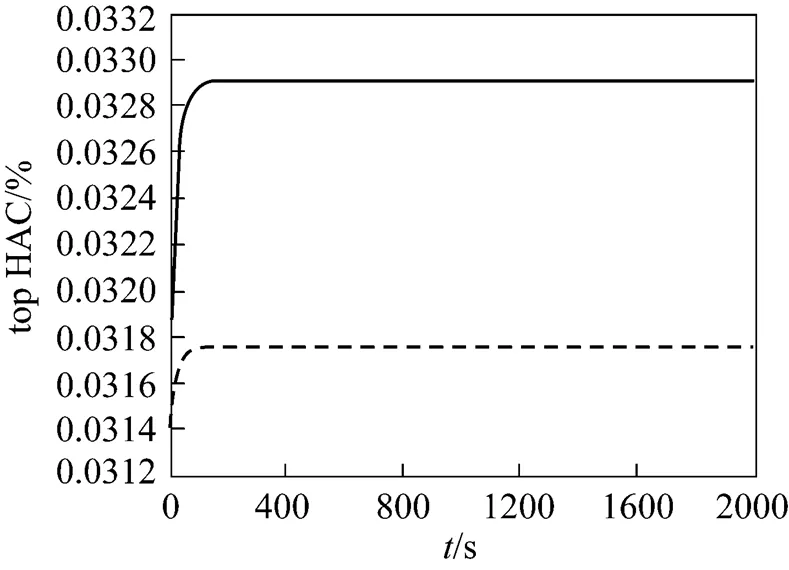

(3) Response of concentration to the change in reflux flow

Figures 14 and 15 show that top and bottom HAC concentrations increase as reflux flow decreases. The increase of top HAC concentration should be prevented, but the increase in bottom HAC concentration is desired, so it must be careful to decrease the reflux flow. In PTA industry, the decision-maker usually ensures that the top HAC concentration is in the range of preset values. Figs. 16 and 17 show that top and bottom HAC concentrations decrease as reflux flow increases. The decrease in top HAC concentration is desired, so it must be careful to manipulate the reflux flow.

Figure 14 Response of top HAC concentration to increase in the reflux flow rate

Figure 15 Response of bottom HAC concentration to increase in the reflux flow

Figure 16 Response of top HAC concentration to decrease in the reflux flow

Figure 17 Response of bottom HAC concentration to decrease in the reflux flow

Table 2 Specification for the azeotropic distillation column

When the feed flow increases, tray temperature front will move to the top. Increase in tray temperature will lead to an increase in the HAC concentration at the top after a while. The measure is taken to decrease the top HAC concentration by increasing the reflux flow. On the other hand, less feed flow will lead to a decrease in the bottom HAC concentration. The measure is taken to increase the bottom HAC concentration by decreasing the reflux flow.

In conclusion, reflux flow is an important manipulating variable in industrial operation and temperature is also important to the HAC concentration. Increase of reflux flow decreases top HAC concentration to prevent the loss of HAC at the top, with bottom HAC concentration decreased. Feed flow does not affect top HAC concentration, but changing bottom HAC concentration. In practical operation, reflux flow is adjusted when tray temperature changes. According to the above simulation result and analysis, some control scheme is implemented. Table 2 is the specification for the azeotropic distillation column. Fig. 18 givesthe control strategy as follows: using reflux flow FC1504 to control temperature TC1503 and using the heat flow of reboiler FC1507 to control temperature TC1501. The above control strategy is consistent with the industrial control strategy, verifying our analysis results.

Figure 18 Schematic diagram of control structure

5 ConclusionS

This work introduces an improved model and algorithm for the dynamic simulation of industrial PTA solvent dehydration tower. A new model for temperature is derived. Dynamic analysis is presented. The comparison between the simulation and industrial values shows that the model and algorithm are particularly effective for the separation of HAC and water with NBA. Based on this model, advanced process control, online optimization, performance monitoring, and production evaluation can be implemented.

ACKNOWLEDGEMENTS

.

NOMENCLATURE

amount of product in tower bottom

the number of components

amount of product in tower top

energy hold up on tray j, J

feed flow, kmol·h-1

enthalpy, kJ·kmol-1

equilibrium constant

holdup, kmol

the number of tower tray

pressure, kPa

heat duty, kJ·h-1

temperature, K

time, s

liquid holdup, kmol

,flow of vapor and liquid phases, kmol·h-1

,mole fraction of liquid and vapor phases

phase separation parameter

Superscripts

l the first liquid phase

ll the second liquid phase

v vapor phase

Subscripts

f feed

index of component

index of tray

1 Wang, L.J., Li, X., Zhang, H.J., “Thermodynamic analysis and azeotropic distillation simulation for aceticacid-water-butylacetate system”,, 56 (7), 1260-1266 (2005).(in Chinese)

2 Geng, J., Wu, Y., T., Liu, Q.L., Zhang, Z.B., “The vapor-liquid equilibrium of acetic acid-water system and its simulation of the distillation process”,, 36 (4), 491-496 (2000). (in Chinese)

3 Kannan, A., Joshi, M.R., Reddy, G.R., Shah, D.M., “Multiple-steady states identification in homogeneous azeotropic distillation using a process simulator”,, 44, 4386-4399 (2005).

4 Rovaglio, M.R., Doherty, M.F., “Dynamics of heterogeneous azeotropic distillation columns”,, 36 (1), 39-52(1990).

5 Widagdo, S., Seider, W.D., Sebastian, D.H., “Dynamic analysis of heterogeneous azeotropic distillation”,, 38 (8), 1229-1242 (1992).

6 Chien, I.L., Wang, C.J., Wong, D.S.H., “Dynamics and control of a heterogeneous azeotropic distillation column: Conventional control approzch”,, 38 (2), 468-478 (1999).

7 Chien, I.L., Wang, C.J., Wong, K.S.H., Lee, C.H., Cheng, S.H., Shih, R.F., Liu, W.T., “Experimental investigation of conventional control strategies for a heterogeneous azeotropic distillation column”,, 10 (4), 333-340 (2000).

8 Chien, I.L., Zeng, K.L., Chao, H.Y., Liu, J.H., “Design and control of actic acid hydration systemheterogeneous azeotropic distillation”,, 59 (21), 4547-4567 (2004).

9 Rovaglio, M., Faravelli, T., Biardi, G., Gaffuri, P., Soccol, S., “The key role of entrainer inventory for operation and control of heterogeneous azeotropic distillation column towers”,, 17 (5), 535-547 (1993).

10 Pham, H.N., Doherty, M.F., “Design and synthesis of heterogeneous azeotropic distillations (III) Column sequences”,, 45 (7), 1845-1854 (1990).

11 Tanaka, S., Yamada, J., “Graphical calculation method for minimum reflux ratio in azeotropic distillation”,, 5, 20-26 (1972).

12 Siirola, J.J., “An industrial perspective on process synthesis”,., 91 (304), 222-233 (1995).

13 Wasylkiewicz, S.K., Kobylka, L.C., Castillo, F.J.L., “Optimal design of complex azeotropic distillation columns”,, 79 (3), 219-227 (2000).

14 Luyben, M.L., Tyreus, B.D., “An industrial design/control study for the vinyl acetate monomer process”,, 22 (7), 867-877 (1998).

15 Kurooka, T., Yamashita, Y., Nishitani, H., “Multivariable control of a distillation column by exact input-output linearization”,, 26 (3), 406-416(2000). (in Japanese)

16 Kurooka, T., Yamashita, Y., Nishitani, H., Hashimoto, Y., Yoshida, M., Numata, M., “Dynamic simulation and nonlinear control system design of a heterogeneous azeotropic distillation column”,, 24 (2), 887-892 (2000).

17 Gaubert, M.A., Gerbaud, V., Joulia, X., Peyrigain, P.S., Pons, M., “Analysis and multiple steady states of an industrial heterogeneous azeotropic distillation”,, 40 (13), 2914-2924 (2001).

18 Chien, I.L., Chen, W.H., Chang, T.S., “Operation and decoupling control of a heterogeneous azeotropic distillation column”,, 24, 893-899 (2004).

19 Chien, I.L., Kuo, C.L., “Investigating the need of a pre-concentrator column for acetic acid dehydration systemheterogeneous azeotropic distillation”,, 61, 569-585 (2006).

20 Arifin, S., Chen, I.L., “Combined preconcentrator/recovery column design for isopropyl alcohol dehydration process”,, 46 (8), 2535-2543 (2007).

21 Lee, H.Y., Huang, H.P., Chien, I.L., “Design and control of an acetic acid dehydration column with-xylene or-xylene feed impurity (2) Bifurcation analysis and control”,, 47 (9), 3046-3059 (2008).

22 Xu, Y., Zhu, Q.X., “Research and implementation of decreasing the acetic acid consumption in purified terephthalic acid solvent system”,, 16 (4), 650-655 (2008).

23 Fu, J.Q., Phase Equilibrium and Simulation Calculation of Distillation for Special System,, Beijing, 106 (2001). (in Chinese)

** To whom correspondence should be addressed. E-mail: chengfeili@sina.com.cn

2009-12-11,

2010-07-12.

the National Natural Science Foundation of China (61072127) and the Outstanding Young Innovative Personnel Project of Guangdong Colleges (LYM08098).

Chinese Journal of Chemical Engineering2011年1期

Chinese Journal of Chemical Engineering2011年1期

- Chinese Journal of Chemical Engineering的其它文章

- Preparation of p-Hydroxybenzaldehyde by Hydrolysis of DiazoniumSalts Using Rotating Packed Bed*

- Liquid-solid Equilibria in Quinary System Na+, K+, Mg2+//Cl-,?at 25 °C*

- Pervaporation Separation of Butanol-Water Mixtures UsingPolydimethylsiloxane/Ceramic Composite Membrane*

- Reaction Kinetics of Biodiesel Synthesis from Waste Oil Using a Carbon-based Solid Acid Catalyst

- Enzyme-catalyzed Synthesis of Vitamin E Succinate Using aChemically Modified Novozym-435*

- Alkylation of p-Cresol with tert-Butanol Catalyzed by NovelMultiple-SO3H Functioned Ionic Liquid*