Burning characteristics of high density foamed GAP/CL-20 propellants

Mn-mn Li ,Rui Hu ,Ming-hui Xu ,Qiong-lin Wng ,Wei-to Yng ,b,*

a Xi'an Modern Chemistry Research Institute,Xi'an,710065,PR China

b School of Physics,Xi'an Jiaotong University,Xi'an,710049,PR China

Keywords:Monolithic foamed propellants Two-step foaming process Casting process GAP/CL-20

ABSTRACT The monolithic foamed propellants with high densities were prepared by casting and two-step foaming processes.Glycidyl azide polymer(GAP)and isocyanate were used as the binder system and 2,4,6,8,10,12-hexanitro-2,4,6,8,10,12-hexaazaisowurtzitane(HNIW,CL-20)was employed as the energetic component.The newly designed formulation containing 60 % CL-20 produced a force constant of 1077 J/g and low flame temperature of 2817 K.Two foamed propellants with densities of 1.32 g/cm3 and 1.53 g/cm3 were fabricated by a confined foaming process and examined by closed bomb tests.The results revealed that porosity significantly affects burning performance.A size effect on combustion behaviors was observed for the foamed propellant with 5.56 % porosity,and a double-hump progressive dynamic vivacity curve was obtained.At last,the 30 mm gun test was carried out to demonstrate the interior ballistic performance,and the muzzle velocity increased by 120 m/s at the same maximum chamber pressure when monolithic propellant was added in the charge.

1.Introduction

State-of-the-art gun propellants maingrains produce loading densities of roughly 1.1 g/cm.This energy density does not deliver the desired energy for future indirect fire support [1].Similar shortfalls occur in the tomorrow's gun or artillery systems.Monolithic gun propellants provide an alternative to meet the requirement of high energy density and very high burn rate.The foamed propellants show high burning rates and high loading density due to their bulk configuration and specific inner porous structure.In addition,previous studies have proven that foamed propellants burn by in-depth or volumetric combustion mechanism,and the combustion behaviour can be adjusted by changing the porous structure (pore size or pore density) [2-5].

Researchers in ICT (Fraunhofer Institute for Chemical Technology)initiated the one-step chemical foaming and reaction injection moulding(RIM)processes to fabricate foamed propellants based on polymer bonded nitramines[6-8].Polyurethane formation and gas generation simultaneously occurred by admixing an isocyanate,a hydroxyl-terminated GAP,and water.The foaming technology and performances of RDX/GAP/polyurethane foam cubes were expounded in previous references,showing good dimensional stability,combustion consistency and low sensitivity[9,10].For RIM technology,the fluidity of slurry is a key parameter and slurries containing up to 70%RDX are very viscous to process.The limited solid content has a negative effect on energy content and oxygen balance of the polymer bonded propellant.Meanwhile,the highest density of the reported foamed propellants was 1.2 g/cm,which need to be improved to cover the shortfall of energy density.

With the development of high energy compounds,an attractive approach to realize high energy and high energy density is the use of energetic binders and high energy density compounds(HEDC).A typical high energy density compound is 2,4,6,8,10,12-hexanitro-2,4,6,8,10,12-hexaazaisowurtzitane (HNIW,CL-20),which has a greater density (2.04 g/cm),energy and oxygen balance (-11 %)than HMX and RDX [11,12].According to the advantages of CL-20,addition of CL-20 to foamed propellants is expected to increase the force constant,burn rate and oxygen balance without increasing the solid content[13].

In this paper,a newly designed foamed propellant formulation is composed of the GAP polymer and CL-20.The two-step process is adopted to avoid the instantaneously exothermic reaction that occurred in the one-step foaming process used before.The foamed propellants are fabricated in a monolithic configuration,and their combustion behaviors are studied.At last,the firing of a 30 mm gun setup with monolithic foamed gun propellant is demonstrated.

2.Experimental

2.1.Materials

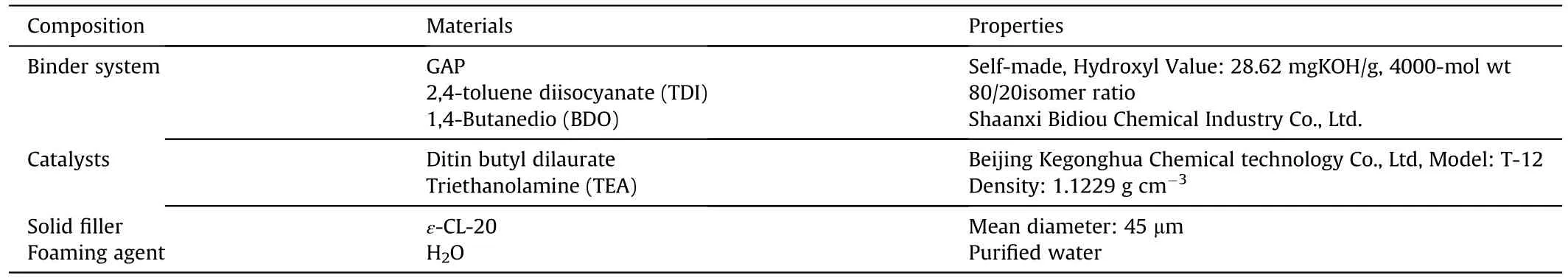

Table 1 lists the materials used in this study.The foamed propellants were prepared from glycidyl azide polymer (GAP),2,4-toluene diisocyanate (TDI),1,4-butanedio (BDO),mixed catalysts,foaming agent HO and 2,4,6,8,10,12-hexanitro-2,4,6,8,10,12-hexaazaisowurtzitane (HNIW,CL-20).Triethanolamine (TEA) is a gel catalyst and cross-linking agent.Ditin butyl dilaurate (T-12) is used as the catalyst to accelerate the generation of gas.The porous structure of foams can be adjusted via changing the ratio between the two catalysts.Finally,the chosen catalyst ratio of TEA to T-12 is 1/0.7 according to our previous study [14].

Table 1 Details of essential raw materials.

2.2.Formulation design

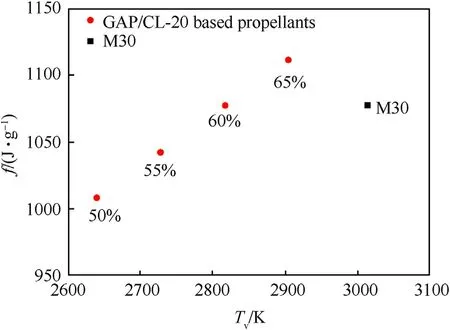

One objective of this study is to develop a propellant formulation with similar or better thermochemistry performance compared with traditional nitrocellulose-based propellants.For internal ballistics,thermochemistry is used to calculate the force constant () and adiabatic flame temperature ().After several casting trials of slurries,the solid content should stay below 70%for good self-leveling performance.Then,the force constant and flame temperature of formulations containing 50 %-65 % CL-20 were calculated by the EMATRIX calculating software and compared with the M30 propellant(a conventional triple base gun propellant)[15].The calculating results are shown in Fig.1.As shown in the figure,the force constant of the GAP/CL-20 based foamed propellant varies from 1008 J/g to 1111 J/g.It can be perceived that the calculated results have reached the expected outcome.The basic formulation containing 60%CL-20 is adopted in this study,and the force constant and flame temperature of the selected formulation are 1077 J/g and 2817 K,respectively.It is noticed that the selected formulation produced a reduction of adiabatic flame temperature by about 200 K compared with M30 (3013 K).Evidences have proven that the wear of gun barrel increases exponentially with temperature and becomes very sensitive to small changes in bore temperature[16,17].According previous studies,the reduced flame temperature in this study may reduce the thermal erosion of gun barrel on the premise of not considering the effects of chemical erosion caused by combustion products.

Fig.1.Force constant and flame temperature of foamed propellants.

2.3.Two-step foaming process and sample preparation

The one-step process is composed of simultaneous reactions of polyurethane formation and gas generation by admixing an organic TDI,a hydroxyl-terminated polyester,and water.This process is highly exothermic and the reaction is too quick to control.Therefore,this study adopts the two-step process [18] as shown in Eqs.(1) and (2).The two-step foaming process moderates the violence of reactions,and thus the slurry can be cast in the mould like composite rocket propellants.

where R is the GAP chain and Ris the isocyanate residue.

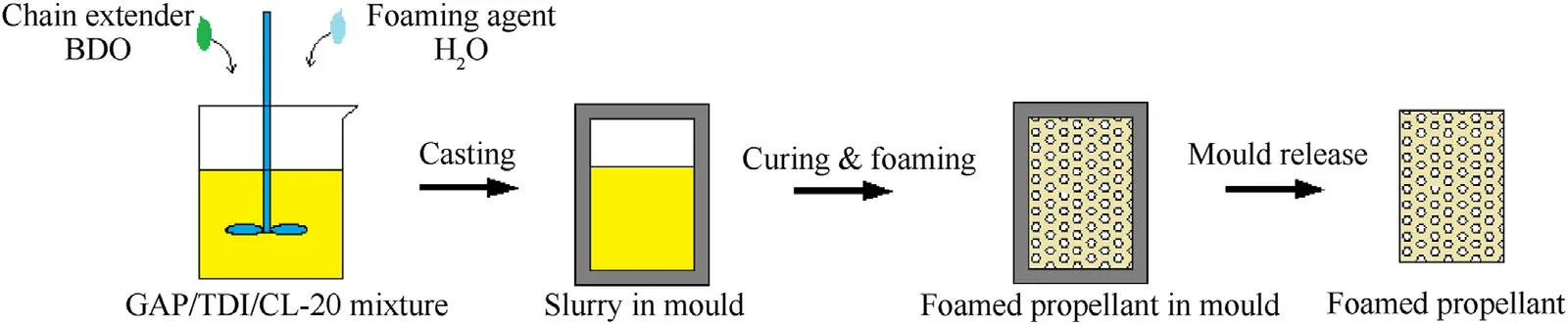

Based on the above reactions,a confined foaming process was designed and the schematic diagram is presented in Fig.2.Firstly,GAP/TDI prepolymer was prepared according to Formulation 1 and blended with CL-20.Secondly,the 0.1 % foaming agent (HO) and chain extender(BDO)were added in the mixture and stirred.Then,the slurries were cast in the mould and cured for 12 h.At last,the mould was released and the final samples were obtained.

Fig.2.Confined foaming process of monolithic propellant.

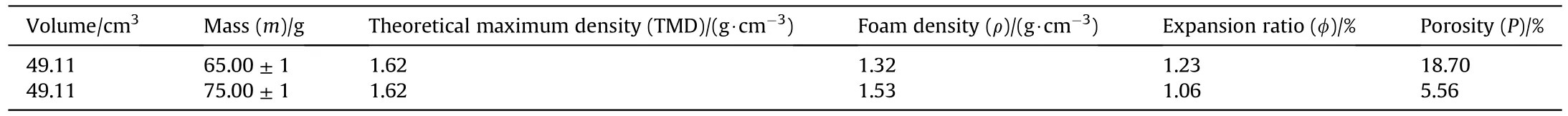

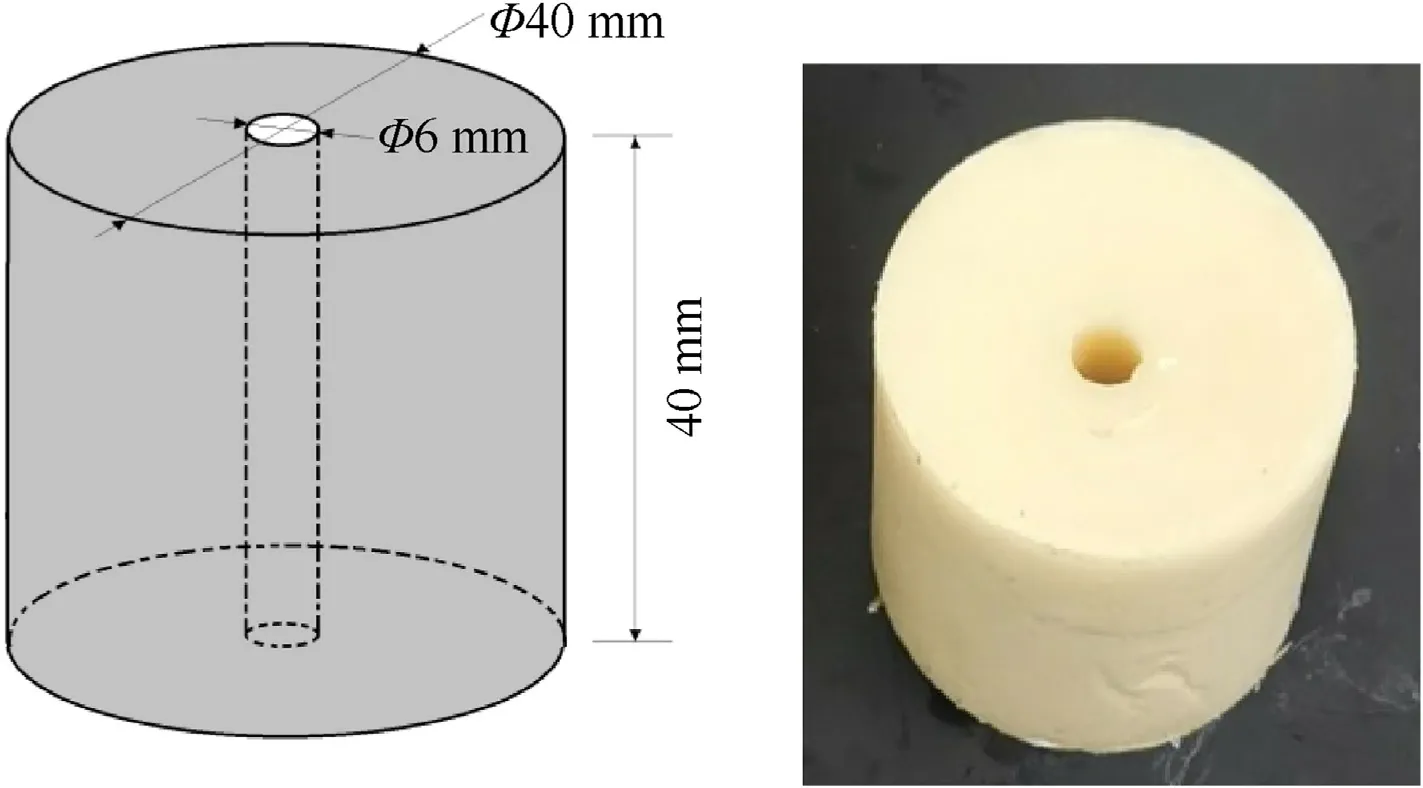

In the confined foaming process,the slurries were cured and foamed with the constraint of the mould.For the volume in the mould is definite,the density of foams can be controlled by controlling the mass of cast slurries ().According to the chamber structure of a 30 mm laboratory test gun,a monolithic propellant was designed and fabricated (shown in Fig.3).The outer diameter of the monolithic propellant is 44 mm,and an ignition hole with diameter of 6 mm is also designed for better flame propagation.Then,propellants with densities (ρ) of 1.32 g/cmand 1.53 g/cmwere prepared by the confined foaming process.As the theoretical maximum density(TMD)of the propellant composed of 60%CL-20 and 40 % GAP binder is 1.62 g/cm,the expansion ratio (φ) and porosity () can be estimated (shown in Table 2).For the foamed propellants,the porosity is 18.7 % and 5.56 %,respectively.The picture of the prepared monolithic foamed propellant is presented in Fig.3,and a Micro-Computed Tomography(-CT)of YXLON FF20 CT was used to study the inner porous structure.

Table 2 Density,expansion ratio and porosity of foamed propellants.

2.4.Mechanical strength analysis

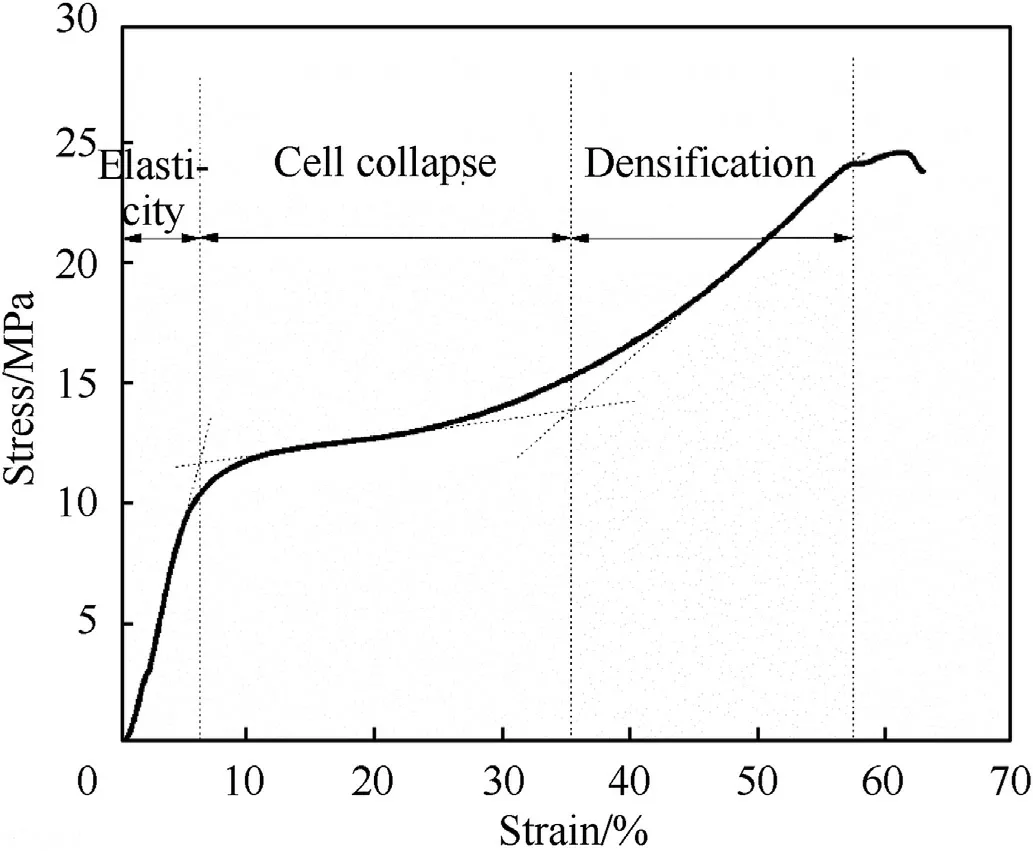

Compression tests were performed on the foamed propellants using a universal tensile testing machine(REGER RGM-50)at 20C and 10 mm/min.A cylindrical foamed propellant with a diameter of 20 mm and height of 50 mm (shown in Fig.6) was used in the compression test.The stress-strain curve was obtained and discussed.

Fig.3.Picture of foamed propellant by confined foaming process.

2.5.Burning characteristics analysis

Firstly,the monolithic propellants were cut into 8 × 8 × 8 mm cubes,and the cubes were fired in a 100 mL closed bomb to evaluate the apparent burn rate of the propellants.The apparent linear burn rate of propellant formulations was derived using the geometry function and constant volume combustion equation.The loading density for these tests is 0.20 g/cm.

Secondly,the combustion performance of the monolithic propellants was also tested in a 300 mL closed vessel.The loading densities are 0.22 g/cm(one module,65 g) and 0.25 g/cm(one module,75 g),respectively.Dynamic vivacity () is defined as the derivative of the pressure d/ddivided by the product of the pressuretimes the maximum pressureachieved in the experiment,as illustrated by the following formulation (3).

All the propellants were ignited using 1.1 g 2# nitrocellulose whose nitrogen content was 12.4%.The pressure history(-curve)was obtained by a pressure gauge and the data acquisition system.Dynamic vivacity () curves were obtained,where=/.

2.6.30 mm gun test

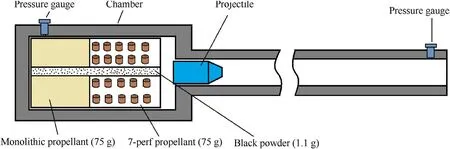

To demonstrate the ballistic performance of the monolithic propellants,a 30 mm laboratory test gun was used to fire a 200 g projectile.The chamber volume is 330 cm,and the projectile travel is 2 m.The propellants were fired by 1.1 g black powder filled in a plastic tube,and the black powder was ignited by the electrical match.In this test,the 7-perforated single propellants (containing 93.6-89.4 % nitrocellulose,0.5-1.2 % diphenylamine,1.0-1.5 %centralite II,4.5-6.5 % camphor,0.1-0.4 % graphite and 0.3-1.0 %kalium sulfate) [19] were also used to promote the combustion of the monolithic propellants.For interior pressure recording,gas pressure gauges were located at the muzzle and the breech of the chamber.The skyscreen target was used to measure the muzzle velocity(actually the velocity at 10 m away from the muzzle).

3.Results and discussion

3.1.Inner porous structure

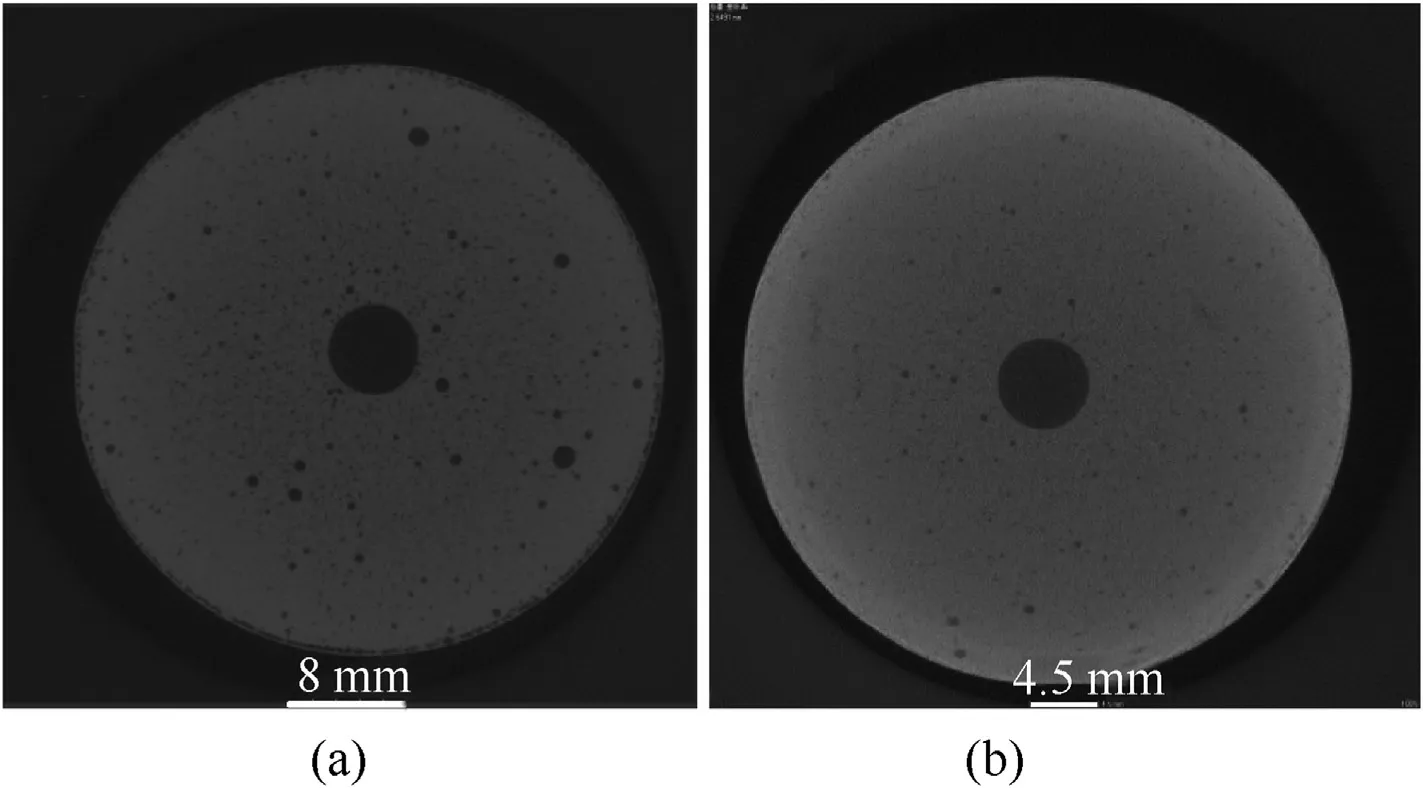

In our previous study,the morphology of pores is mainly affected by the ratio between catalysts.After optimizing the ratio of TEA/T-12 (1/0.7),the foamed propellant exhibits spherical and closed porous structure [14].In this paper,the Micro-Computed Tomography (μ-CT) of YXLON FF20 CT was used to study the porous structure in the monolithic blocks before the study of combustion performance.As shown in Fig.4,the size of pores was also determined by the expansion ratio.When the expansion ratio was 1.23,the propellant expanded sufficiently within the free volume in the mould,resulting in large pores (mean pore size~0.3 mm).When the expansion ratio was 1.06,only confined space was left for the growth of pores,resulting in smaller pores (mean pore size~0.1 mm).

Fig.4.CT images of monolithic foamed propellant with densities of 1.32 g/cm3 (a) and 1.53 g/cm3 (b).

Fig.5.Compression curve of foamed cylinder.

Fig.6.Samples before and after compression test.

3.2.Compression strength of foamed propellants

The compression test of the foamed propellants was conducted as poor mechanical strength may affect the combustion behavior of propellants [20].The compression curve of the foamed propellant with a density of 1.53 g/cmis shown in Fig.5.As illustrated,three distinct regimes of compressive behavior can be observed.The first regime is a linear elastic region with stress of 10.26 MPa and strain of 6.14 %.The second regime is the cell collapse region where the stress is about 12.5 MPa with a shallow slope.The third regime is the densification region with a steep slope.The final tested compression strength and the compressibility are 24 MPa and 50%,respectively.In previous studies [21,22],the compression strength and compressibility of LOVA propellant (75%RDX,10 % nitrocellulose,9%cellulose acetate,6%triacetin),triple base propellant(30%nitrocellulose,25%nitroglycerin,40%picrite,2% KSO,1% N,Ndiethyl diphenyl urea,and 2%dibutyl phthalate)were 435 kg/cm(~42.63 MPa),257 kg/cm(~25.19 MPa) and 9.0 %,10.3 %,respectively.Compared with traditional gun propellants,the mechanical strength of the foamed propellants is similar and the compressibility is better.The photos of the foamed propellants before and after compression are shown in Fig.6.As indicated,the cylinder does not crush when the strain is~60 %.

3.3.Burning characteristics of foamed propellants

Evidences has proven that the foamed propellants do not burn by the normal surface combustion mechanism,but rather by some complex in-depth combustion mechanism for which no form function exists[23].Instead,apparent burn rates are determined by assuming and applying a traditional form function to the combustion event.Although the mechanism and behavior of convective burning are very complicated and poorly known in some aspects,the apparent burn rate is still used for representing the burn rate of foamed propellants [24].

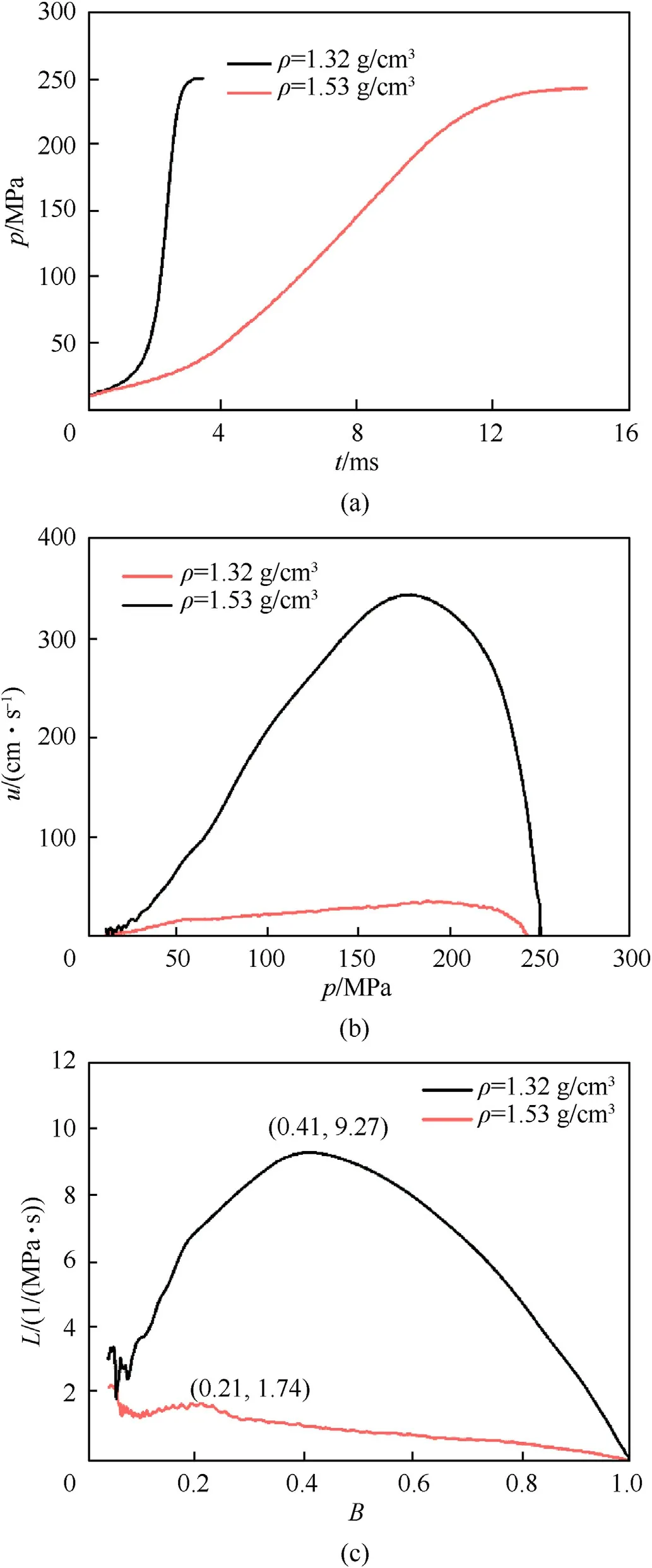

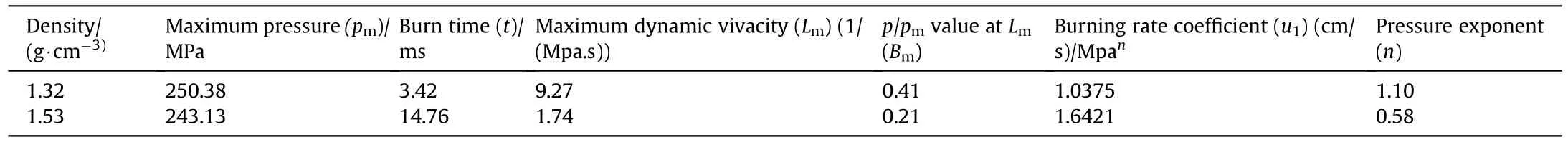

Fig.7 and Table 3 present the combustion performances and parameters of the foamed propellants with different densities.Here,the propellant blocks with 8 × 8 × 8 mm cubic geometry were prepared using the slicer and tested by a 100 mL closed vessel.As Fig.7 (a) shows,the burn time increases from 3.42 ms to 14.76 ms as propellant density is increased from 1.32 g/cmto 1.53 g/cm.Meanwhile,the maximum pressure slightly decreases due to heat loss caused by longer burning time.

Fig.7. p-t (a), u-p (b) and L-B (c) curves of foamed propellants with various densities.

Table 3 Combustion characteristic points of monolithic propellants with different densities.

The combustion products could infiltrate through the pores and led to an in-depth combustion or volumetric combustion.Thus,the porosity is a key parameter which determines the penetration depth of combustion gases.As shown in Fig.7 (b),the foamed propellant with 18.70 % porosity possesses a very high apparent burn rate(315 m/s at 150 MPa)and a high pressure exponent of 1.1.Unlike the propellant with high porosity,the foamed propellant with 5.56 % porosity shows a relative low burn rate (30 cm/s at 150 MPa)and moderate change.Meanwhile,the pressure exponent is only 0.58,indicating a weak dependence of burn rate on pressure.

Consistent with the results shown inandcurves,thecurve also presents different dynamic vivacity changing trends between the two samples.Although both samples has the same geometry and web size,the dynamic vivacity curves presents different characteristics.Propellant with high porosity and pressure exponent presents a progressive combustion behavior,and the propellant with lower porosity and pressure exponent shows degressive combustion.

3.4.Size effect on convective combustion of foamed propellants

The monolithic propellants shown in Fig.3 were tested by a large closed vessel.The loading densities for one propellant module were 0.22 g/cmand 0.25 g/cm,respectively.During the examination of combustion behaviors,the size effect on the combustion of the foamed propellants was noticed.

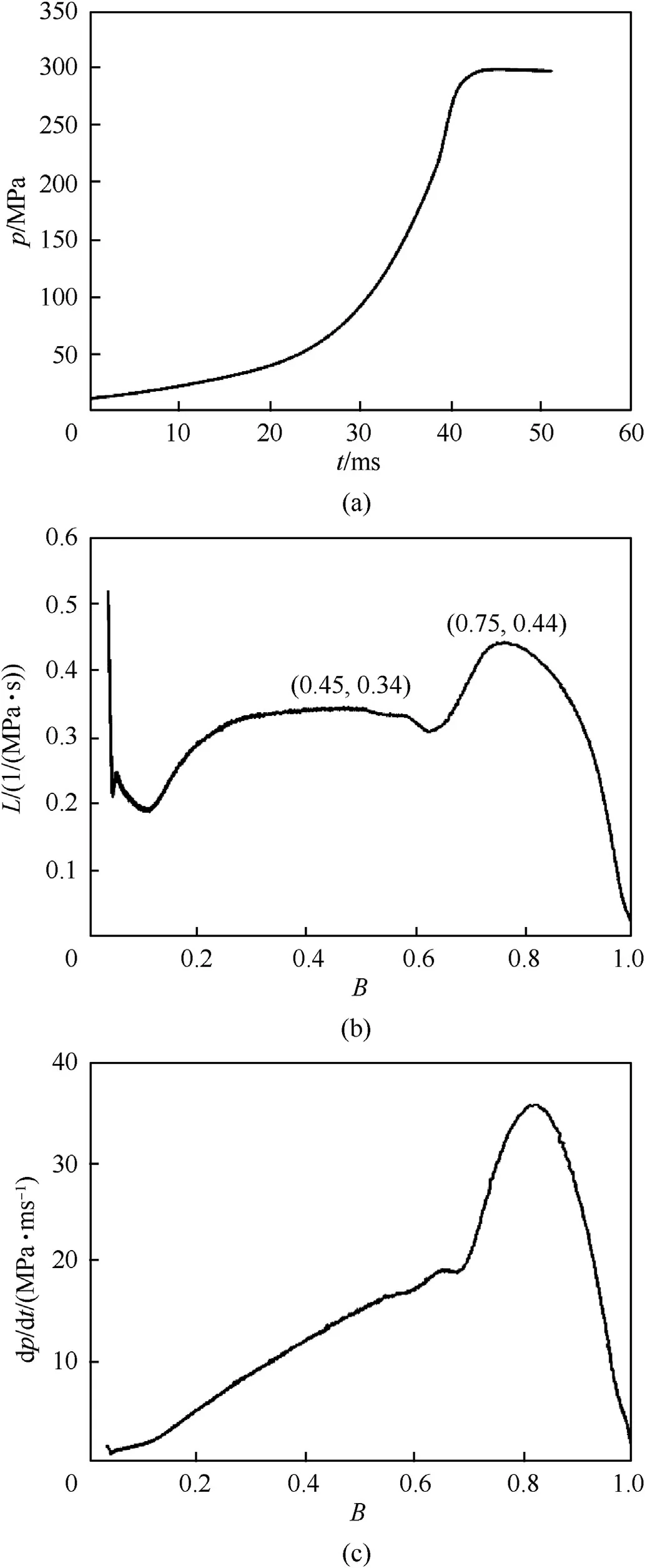

Fig.8(a)shows the burn time increases from 3.42 ms to 4.27 ms as the web size increases for the foamed propellant with 18.7 %porosity.Nonetheless,the dynamic vivacity curve is very similar to each other.This phenomenon indicates an independence of combustion on the geometry and web size of this foamed propellant.The suggested reason is the combustion gas easily penetrates in the whole foamed propellants with large porosity regardless of web size,forming a volumetric burning where combustion occurs within the whole propellants rather than at the surface or in some depth.Fig.8(b) also exhibites an iconic “semicircular” dynamic vivacity curve of the foamed propellants,which has been repeatedly presented in previous studies [4,6,25].The d/d-curve(shown in Fig.8(c))exhibits a linear increase of d/dwith,which is in accord withcurve.

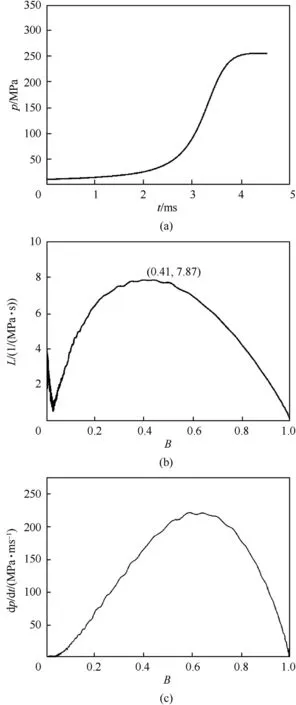

Fig.9(a)presents an obvious increase of combustion time from 14.76 ms to 44.86 ms for propellants with 5.56 % porosity.Meanwhile,Fig.9(b) demonstrates a noticeable change in the dynamic vivacity curves.The dynamic vivacity curve of the monolithic propellant shows double humps: a flat hump between 0.1-0.6 and a bulging hump between 0.6-1.0.It reveals that the propellants burns as a 1-perforated propellant does at the initial combustion stage,and then burns as the foamed propellant does during the following step.The d/dt-curve(shown in Fig.9(c))also presents a jump at=0.68,coinciding withvalue incurve.This inflection point reveals a pressure jump at=0.68.It is suspected that the there is a transition from the linear burning mode to the convective burning mode at high pressures (~200 MPa) for the foamed propellant with high density and large size.

3.5.30 mm gun test

To demonstrate the ballistic behavior of the foamed propellant with double humps,a 30 mm gun test was carried out.As the burn time of the dense monolithic propellant is too long and it is hard to burn out in the barrel,propellant grains are added in the charge to decrease the burn time[26].As shown in Fig.10,the mixed charge is composed of one monolithic propellant (ρ = 1.53 g/cm,mass =75 g)and one paper bag containing 75 g 7-perforated single base propellants grains with web size is 0.5 mm.In the chamber,the black powder filled in a plastic tube is ignited by the electrical match,and then the black powder ignites the propellant charge.

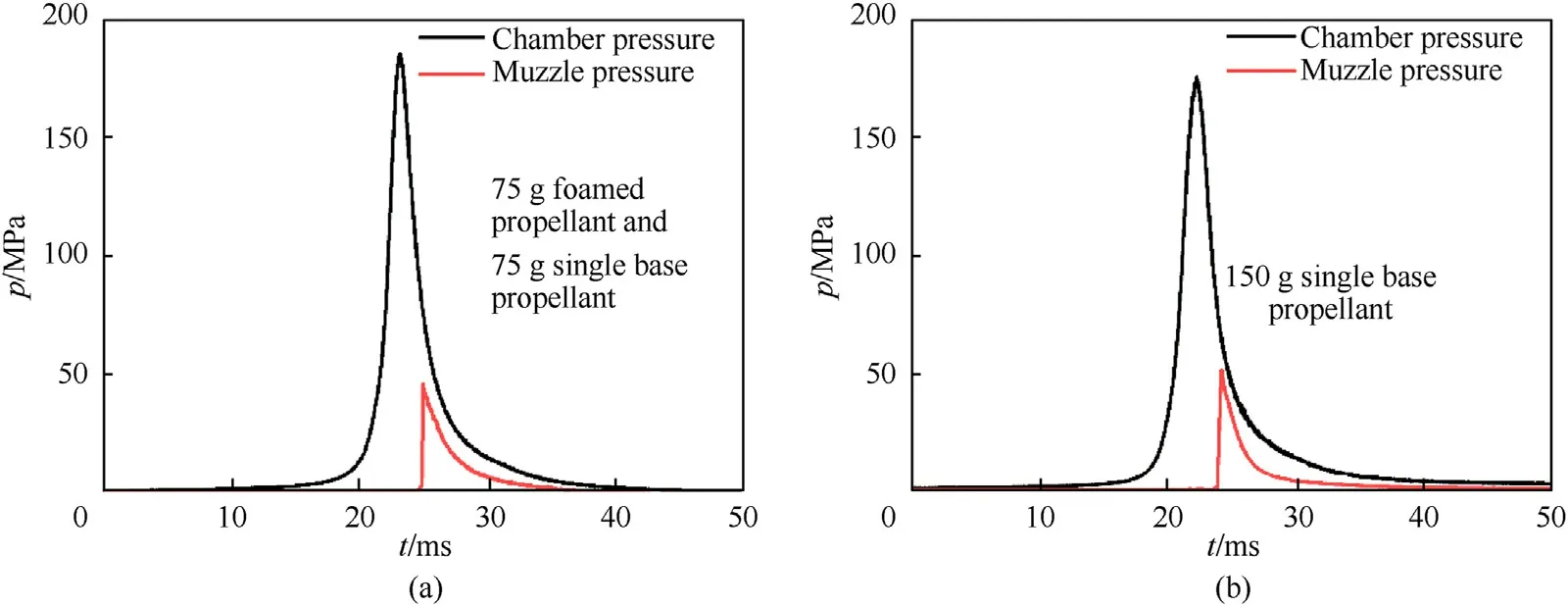

Fig.11 shows the pressure-time curves of the interior ballistic cycle.The left line represents the pressure in the chamber,and the right one is the pressure at the muzzle.In Fig.11(a),the velocity of the projectile is about 1163 m/s,and the maximum pressure in the chamber is 185 MPa.A charge containing 150 g 7-perforated single base propellant grains is also fired and presented in Fig.11(b).The muzzle velocity is 1043 m/s and the maximum pressure is 180 MPa[27].The muzzle velocity increases by 120 m/s at the same maximum chamber pressure by replacing 75 g single base propellant grains with the monolithic block.It is supposed that the convective burning of the foamed propellant at high pressures contributes to the increased muzzle velocity.However,more research needs to be done to determine the mechanisms of interior ballistic performance.

4.Conclusions

Newly designed GAP/CL-20 propellants were prepared by the two-step foaming process and casting method.The new formulation composed of GAP base polyurethane and CL-20 produced a high force constant and relatively low flame temperature.The reduced flame temperature (~200 K) is beneficial to reduce the thermal erosion of gun barrel.The foamed propellant presented three distinct regimes of compressive behavior,which are different from traditional propellants.Meanwhile,unlike conventional gun propellants,combustion performances of foamed propellants presented an in-depth combustion mode.Foamed propellants with lower porosity gave a double-hump progressive curve.A 30 mm test gun demonstrated a promising interior ballistic behavior.

Fig.8. p-t (a), L-B (b) and dp/dt-t (c) curves of monolithic propellant with density of 1.32 g/cm3 (loading density is 0.22 g/cm3).

Fig.9. p-t (a), L-B (b) and dp/dt-B (c) curves of monolithic propellant with density of 1.53 g/cm3 (loading density is 0.25 g/cm3).

Fig.10.Diagram of 30 mm gun test.

Fig.11.Pressure-time diagrams in barrel.(a) 150 g single base propellant,(b) 75 g foamed propellant and 75 g single base propellant.

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

- Defence Technology的其它文章

- Establishment,simulation and verification of firepower safety control model

- Cell-type continuous electromagnetic radiation system generating millimeter waves for active denial system applications

- Sandwich structure for enhancing the interface reaction of hexanitrohexaazaisowurtzitane and nanoporous carbon scaffolds film to improve the thermal decomposition performance

- Ablation characteristics of insulator under high-temperature gas dualpulse erosion

- Influence of shaped charge structure parameters on the formation of linear explosively formed projectiles

- Novel aluminum-based fuel: Facile preparation to improve thermal reactions