Influence of carbide ceramic reinforcements in improving tribological properties of A333 graded hybrid composites

Manu Sam, N. Radhika

Department of Mechanical Engineering, Amrita School of Engineering, Coimbatore, 641112, Amrita Vishwa Vidyapeetham, India

Keywords:Composites Functional Wear Carbide ceramics

ABSTRACT Aluminium hybrid functionally graded metal matrix composites (FGMMCs), meet growing demands for supreme tribo-mechanical performance in automotive and aviation industry. This research experimentally compares the influence of carbide ceramics (B4C, SiC, TiC) as reinforcements, in improving reciprocating tribology performance and mechanical strength of A333 hybrid composites against alloy.Hollow cylindrical samples of A333/6 wt%B4C/4 wt%TiC and A333/6 wt%B4C/4 wt%SiC hybrid FGMMCs were developed using horizontal centrifugal casting. Metallography analysis on both composites revealed increasing ceramic gradient distribution towards outer composite wall.Particle rich zone of A333/B4C/SiC hybrid FGMMC showed maximum micro-hardness (198.9 HV) and tensile strength (267.9 MPa).Elemental mapping confirmed effective distribution of ceramics and detected elemental composition of both composites. Particle rich layer of A333/B4C/SiC hybrid FGMMC exhibited improved wear resistance in comparison with all three layers of A333/B4C/TiC hybrid FGMMC and alloy. Third-body abrasion and tribo-chemical wear were the predominant mechanisms revealed for both composites during worn surface analysis.

1. Introduction

Changing industrial demands and optimization of production techniques have promoted the development of advanced materials that replace the conventional materials. Concept of Functionally Graded Composites(FGC)have driven this transformation to a great extend meeting expectations of manufacturers and consumers on a same scale. The global acceptance for this advanced material has gained the attention of many researchers, attempting to replace existing metals and alloys used for diverse applications [1-3].Functional grading helps to integrate diverse functional properties within a single component through various popular production techniques like casting techniques, powder metallurgy, coating technique, additive manufacturing etc. Selection of appropriate manufacturing technique based on compositional elements that include matrix and reinforcements, along with the production parameters are the key strategies that enable desired localized properties within the same component[4].Poor tensile properties(ductility and elongation)of existing piston materials like EN steel(48,000) reported fatigue failure during reciprocal sliding under dry conditions [5]. Functional grading along the piston skirt overcomes this limitation,improving mechanical strength and thermal resistance of piston crown [6]. Light-weightiness of aluminium makes it versatile among commonly utilized matrix materials(aluminium, brass, bronze, magnesium and titanium) for functionally graded material (FGM) fabrication [7]. Machinability and cast-ability of aluminium improved extensively when alloyed with silicon[8].Meagre fraction of copper improves the wettability and tensile properties of Al-Si alloys [8]. These properties make them employable for automotive engine components like piston or cylinder heads,crankcases,engine gearbox and industrial compressor housings [9]. Metallography analysis of aluminium composite reinforced with Titanium Carbide reported degradation of tribomechanical properties with extensive phase formation of AlTi[10]. Effective control of such phase formations plays a key role in retaining uniform superior strength throughout the matrix irrespective of gradation. Approach of producing hybrid FGMs, transformed themselves as an advanced sub-class of composites, as it possesses the potential to meet diverse functional requirements of industrial applications [11]. Limited researchers have focused the possibilities of integrating ceramic-ceramic reinforcing technique with centrifugal casting.Moreover,various possibilities of utilizing secondary ceramic particles and analyzing the influence of carbidecarbide ceramic combinations as primary and secondary particles are unexplored yet. On contrast, excessive ceramic presence as primary and secondary reinforcements in hybrid composites,raise a challenge of improper miscibility and wetting. Those were overruled through the addition of magnesium traces, which hardly get expressed in the overall alloy composition [12]. Secondary ceramic particles embedded over the matrix, provided adequate structural strength, high temperature stability, chemical corrosion resistance, superior wear response etc. Pre-dominantly used ceramic family variants were oxides,carbides,borides,nitrides and silicides[13].Secondary reinforcements are preferably utilized in a minimal ratio to impart zonal properties whereas primary reinforcements are chosen with a privilege to serve desired properties throughout the matrix. Hence, ratio fixation of primarysecondary ceramic particles are largely dependent on applications and desired properties [14]. Centrifugal casting technique is inferred as an optimal technique for facilitating effective matrix gradation as the centrifugal force involved helps to limit cast defects occurred during gravity casting. Horizontal centrifugal casting technique modifies the dendritic columnar grain structure of α-Si present in Al-Si-Cu alloys to form finer grains towards peripheral composite wall. Grain refinement improves mechanical strength[15]. Functional grading through centrifugal casting eliminates sharp changes across the composite wall layers by introducing gradient-smooth effective transition across the matrix. This improves the tribo-mechanical properties of graded composites reducing tears or peel-off [16]. Process parameters like applied normal load, sliding frequency, sliding distance etc., significantly influenced the tribology behaviour of Al-Si alloy[17].Worn surface analysis on Al6061 reinforced with 10 wt%TiBsamples revealed adhesive wear and ploughing phenomenon at lower loads of 40 N.These features were transformed as deep ridges and surface layer delamination at higher load of 120 N [18].

In order to match the performance of developed aluminium hybrid FGMs with presently existing materials,tribology tests were performed against counter plates of various EN 31 steel grade,chosen for reciprocating application [19]. Alloys reported severe wear mechanisms (delamination wear, surface seizure and peeloffs) compared to their composites. This reveals the role of ceramic reinforcement in wear reduction [20].

Metal-metal interfacial wear was significantly limited through tribo-oxide films formed during tribo-chemical wear. Reinforcement craters along with material transfer from counter surface promoted this tribolayer growth [21].

Based on literatures,it is concluded that limited research works have explored the reciprocal tribo-mechanical performance of Al-9Si-3Cu(A333)composites under dry sliding conditions.Even though amble researchers have focused on ceramic reinforced aluminium composites, studies focused on hybrid ceramic functional grading concept using centrifugal casting technique is not explored sufficiently.Moreover,the scope of reinforcing A333 with same family of hard ceramics(carbide-carbide)are left untouched.Therefore, this research conducts a comparative analysis on influence of carbide-ceramics - as a combination of primary (BC) and secondary ceramics (SiC or TiC) in hybrid composites. Effect of reciprocating wear parameters (applied normal load and sliding distance) are studied against wear response of A333/BC/TiC and A333/BC/SiC hybrid FGMMCs. Detailed characterization of wear features and tribology by-products are analyzed and compared between both the hybrid composites to study the influence of secondary ceramics.

2. Selection of alloy, reinforcements and fabrication process

A superior tribo-resistant variant of hypo-eutectic Al-9Si-3Cu alloy also named as A333, was preferred due to its excellent castability and applicability for engine systems and components. This alloy exhibited a superior affinity with diverse ceramics. Materials for reinforcement and base alloy were supplied from Commercial Metal Vendors-Coimbatore,India.BC(6 wt%)of average density-2.523 g/cmwas selected as the primary ceramic for both the hybrid composites. This closeness of density of BC with that of matrix (2.84 g/cm) facilitated effective distribution and ensured superior mechanical properties across the composite wall.TiC(4 wt%) of average density - 4.93 g/cmwas the secondary reinforcement material for A333/BC/TiC hybrid FGMMC and SiC (4 wt%)of average density - 3.21 g/cmwas the secondary reinforcement material for A333/BC/SiC hybrid FGMMC. However, the threshold of overall ceramic presence was limited up to 10 wt% as it caused clustering effect [22-24]. Weight percentage of primary and secondary particles in hybrid composites are significantly dependent over the zonal required properties of the composite.

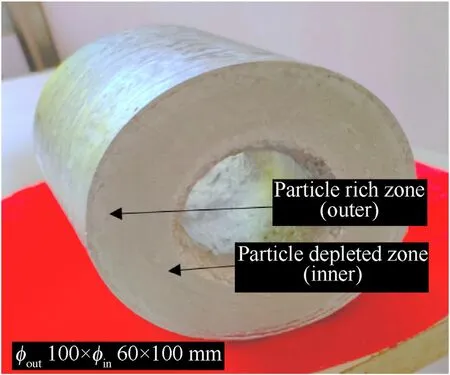

Fig.1. Hollow cylindrical functionally graded composite.

The functionally graded hybrid ceramic composites were prepared through centrifugal casting. Alloy ingots were placed in a 12 kg capacity graphite crucible and was melt using an electric resistance furnace. The preheated ceramics were added through a hopper and mechanically stirred at a temperature lower to liquidus temperature along with magnesium ribbons. Addition of magnesium aided in forming a reaction barrier, which controlled triggering of undesirable chemical reactions. Centrifugal die was rotated at a constant rotational speed of 1000 rpm to result in a hollow cylindrical composite (Fig.1) of dimension - φ100 × φ60×100 mm.The primary reason for preferring hollow cylindrical shape is the application for which the composite is developed.This composite is suggested mainly for high performance piston rings that are significantly useful for diverse industries like defense,aerospace and automotive industries. The natural clustering tendency of BC [25] was limited through combining horizontal centrifuge casting technique with hybrid reinforcement. Centrifugal force drove the heavier secondary ceramic particles towards the outer zone of composite.This phenomenon led to disintegration of agglomerated BC lumps and increasing ceramic gradient distribution towards the outer zone. Rise in ceramic concentration improves the mechanical characteristics of the composite[26].Higher particle presence reduces the inter-particulate distance, and increases the dislocation strength of the composite. The presence of denser secondary reinforcement in addition to primary reinforcement, has led to particle abundance at the outer region of the composite wall.The thickness of particle rich zone which improved the tribological properties along with mechanical strength, was directly influenced by die rotational speed, solidification rate and density variance of material composition. The optic spectroscopy results of as-received A333 alloy is shown in Table 1.

3. Experimental results and discussion

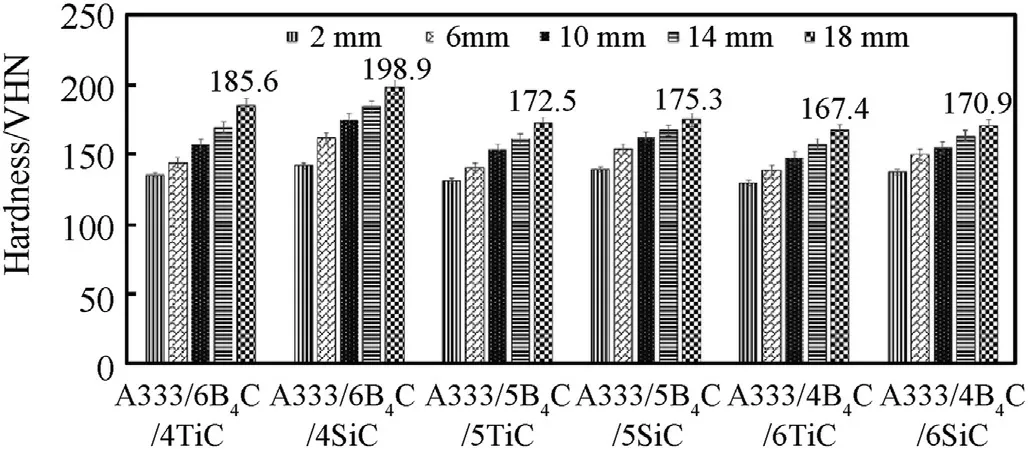

Experimental trials were performed as a preliminary research to determine the best proportion of ceramic composition. As the material is developed for automotive piston rings, hardness and tribology properties were of primary importance. Among which,preferred design was to exhibit superior hardness throughout the component and excellent tribology resistance at the outer zone.Hence, micro-hardness anchored as a primary essential property was compared among FGCs of hybrid reinforcement ratios 4:6,5:5 and 6:4 respectively.This property of each composite is compared using a plot(Fig.2),where superior micro hardness is exhibited at an optimal ratio of 6:4 for both BC/TiC and BC/SiC reinforced composites.Hence,this combination was followed for further study and characterization. Incorporation of higher proportion of hard ceramic BC into the ductile aluminum matrix obstructed the growing α-phase during the solidification process [27]. This attributed to the increase in the overall hardness of composites as it enhanced the resistance to plastic deformations,acting as a barrier for the dislocation movement.Similar inferences were reported in a study on AA6061/(BC+h-BN)hybrid composite where the overall ceramic content above 10 wt% led to agglomeration and increased interfacial debonding, decreasing the mechanical properties of composite [28]. This range for primary and secondary ceramic proportions were preferred based on the observations from similar studies on hybrid composites,which reported that overall ceramic proportion greater than 2.5 wt% exhibited effective particle distribution and segregation compared to 1-1.75 wt%[29].The optimum overall ceramic presence needs to be limited up to 10-12 wt% for hybrid composites,because particles less than 5 wt%often result in lack in homogeneity [30] and increased porosity. Whereas, overall particle presence greater than 12 wt% results in clustering effect and precipitation during casting [31].

Fig. 2. Comparison of micro-hardness for A333/B4C/TiC and A333/B4C/SiC hybrid FGMMCs at varied proportion of ceramics.

Fig. 3. Micro-hardness for A333 alloy, A333/B4C/TiC and A333/B4C/SiC hybrid FGMMCs.

Mechanical and reciprocating tribology performance of A333/6 wt%BC/4 wt%TiC and A333/6 wt%BC/4 wt%SiC hybrid FGMMCs are experimentally compared with alloy in the below sub-sections.

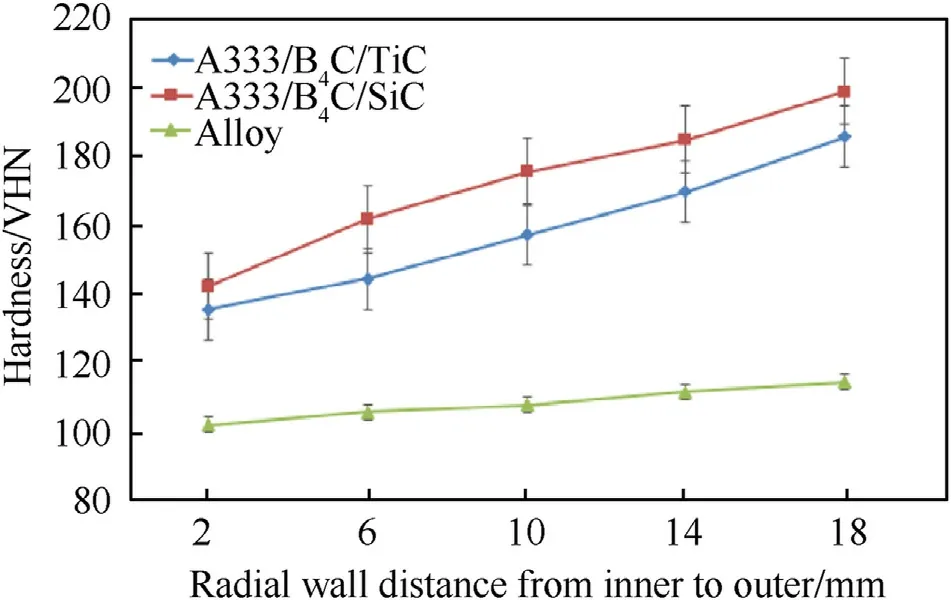

3.1. Hardness property

Improvement and zonal variation of hardness due to functional grading were analyzed and compared using Vickers micro hardness, radially measured across the alloy and composite walls.Pyramid-diamond indenter affixed Mitutoyo make Vickers hardness tester was utilized for measurement. Average of five measurements made across each radial wall distances (2, 6,10,14 and 18 mm from outer layer) for alloy and composites, are shown in Fig. 3.

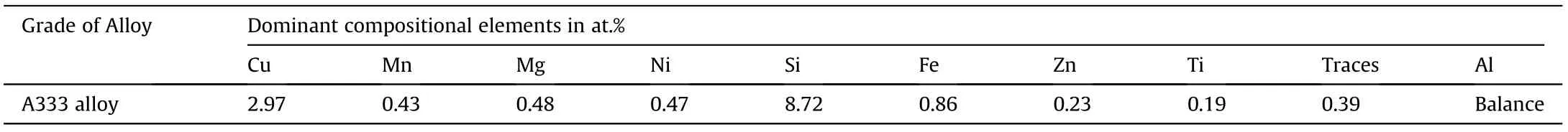

Table 1 Optical Emission Spectroscopy Results of A333 alloy.

Among hybrid FGMMCs, A333/BC/SiC shows a dominating trend compared to A333/BC/TiC, and alloy reveals the lowest average hardness (101.2 ± 2.4 HV). However, it is apparent that there is a negligible change in alloy hardness across the wall,unlike in hybrid composites. Outer layer of A333/BC/SiC hybrid FGMMC reveals a gradually rising trend from inner(142.2±0.8 HV)towards outer, where it shows the peak hardness (198.9 ± 2.7 HV) at outermost layer. Peak hardness at outer layer of A333/BC/SiC hybrid FGMMC is 84% higher to that exhibited by the base alloy.This is due to the higher tendency of SiC particles, which forms carbide lumps with the BC particles at the outer layer. This phenomenon increases the surface area of hard ceramics in the matrix,bearing more load and reducing the plastic deformation.Whereas,for A333/BC/TiC hybrid FGMMC the rising gradient distribution of TiC improved the hardness from inner (135.4 ± 3.4 HV) towards outer periphery(185.6±3.7 HV).This was due to higher dislocation density at the particle-matrix interface, facilitated by the ductile nature of matrix that accommodates reinforcements up to precipitation threshold. Incorporating higher resistance to plastic deformation improves the overall hardness of the composite.Centrifugal force, density variance and hybrid ceramic reinforcing techniques were the key factors that facilitates functional grading [32,33].Functional gradation phenomenon exhibited zonal variance in mechanical properties for both hybrid FGMMCs.

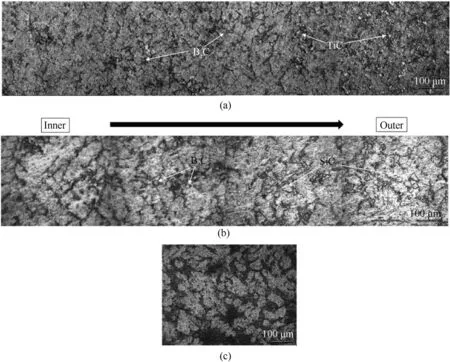

3.2. Metallographic analysis

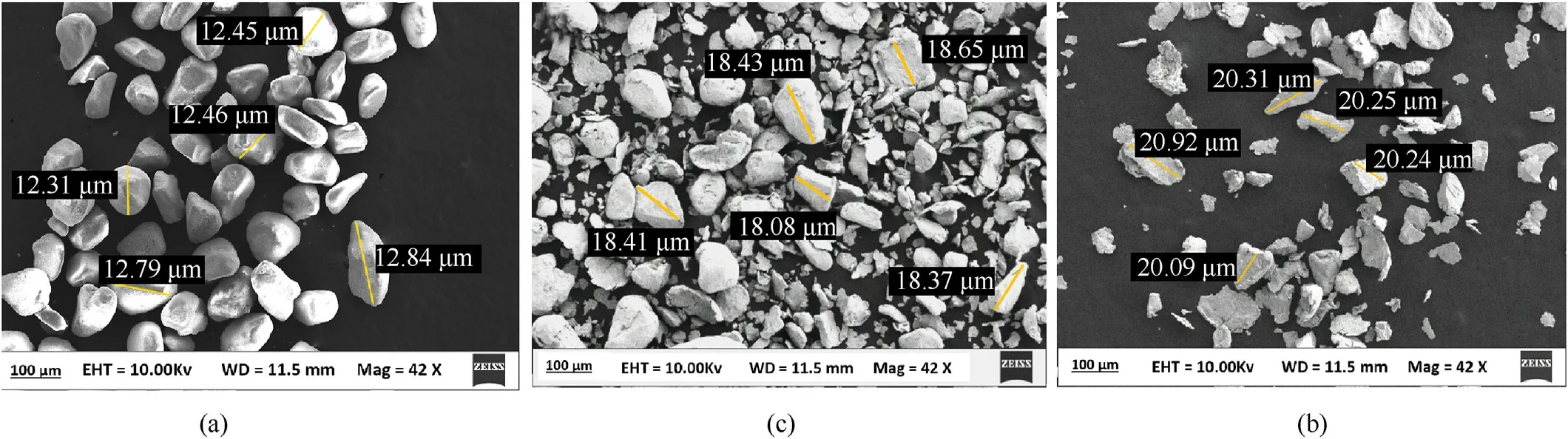

Metallographic analysis was conducted as per ASTM E03-11 standards to compare the ceramic distribution of A333/BC/TiC and A333/BC/SiC hybrid FGMMCs.Comparison was made across inner(1-7 mm),middle(8-14 mm)and outer(15-20 mm)layers along radial direction of hollow cylindrical composite using Zeiss make inverted metallurgy microscope. SEM analysis (Fig. 4) of primary(BC) and secondary (TiC and SiC) ceramic particles confirm the average particle size as 12.58 μm,18.64 μm and 20.59 μm respectively. Strength enhancing effective ceramic distribution was achieved under the influence of centrifugal action. In addition,closeness of density of BC(2.523 g/cm)with respect to A333 alloy matrix (2.84 g/cm) also facilitated smooth and uniform flow of particles across the composite wall. Whereas, secondary ceramics having higher density compared to BC and alloy; were pushed towards the outer composite wall zone under centrifugal force.For both hybrid composites, majority of matrix zone comprised aluminium grains surrounded with non-homogenous and accumulated eutectic Si. These dendritic eutectic structures were broken to form equi-axed structure with the vicinity of secondary ceramics. For A333/BC/TiC hybrid FGMMC (Fig. 5a), lower rate of rising gradient distribution of primary ceramic is observed towards outer. Rising fraction of TiC is revealed from middle towards outer zone. Gas holes and porosity are more visible at the ceramic depleted inner zone compared to outer layer. Similar mode of ceramic distribution and refined grain boundaries are observed(Fig.5b)for A333/BC/SiC hybrid FGMMC,from inner towards outer layer. Microstructure of base alloy (Fig. 5c) helps to compare the structural modifications undergone in hybrid composites,with the influence of primary and secondary reinforcements. Unlike TiC,meagre cohesion of SiC particles are observed along the increasing ceramic gradient from middle towards outer layer. Better refinement of grains significantly enhances the mechanical properties[34]. Minor fraction of Mg ribbons catalyzed the ceramic-matrix interfacial interactions, and this aid improved the wettability forming a reaction layer without expressing in the overall composition.Bright thin layer of magnesium formed around BC particles have enhanced the wettability and fluidity during casting.

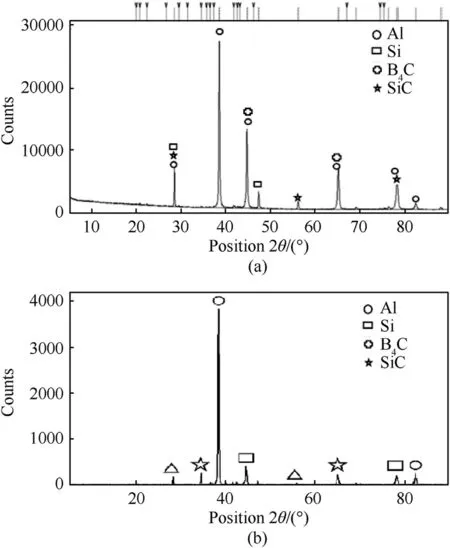

X-ray Diffraction(XRD)analysis of A333/BC/TiC and A333/BC/SiC hybrid FGMMCs were performed at their respective outer layers with a scanning rate preset to 5/min and at an increment of 0.03.XRD intensity peaks were detected at 2θ=38.5090 for aluminium and 2θ = 28.4813 for silicon. Intensity peak for primary ceramic(BC) was detected at 2θ = 56.8323 for both hybrid composites.Secondary ceramic particles like TiC(Fig.6a)and SiC(Fig.6b)were detected at 2θ = 66.3742 and 2θ = 38.2843 respectively at a superior intensity than BC.This ensures the dominance of secondary ceramic over primary ceramic at the outer zone for both hybrid composites.

Fig. 4. SEM analysis of as-obtained (a) B4C (b) TiC and (c) SiC.

Fig.5. Micrographs showing the rising gradient distribution of ceramics from inner towards outer layers of(a)A333/B4C/TiC and(b)A333/B4C/SiC hybrid FGMMCs,against the base structure of (c) A333 alloy.

Fig. 6. XRD pattern of (a) A333/B4C/TiC and (b) A333/B4C/SiC hybrid FGMMCs.

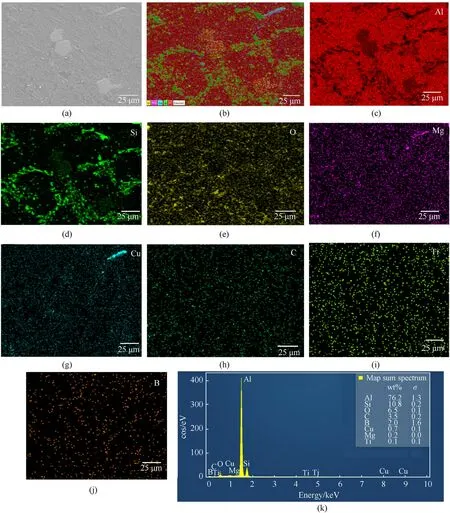

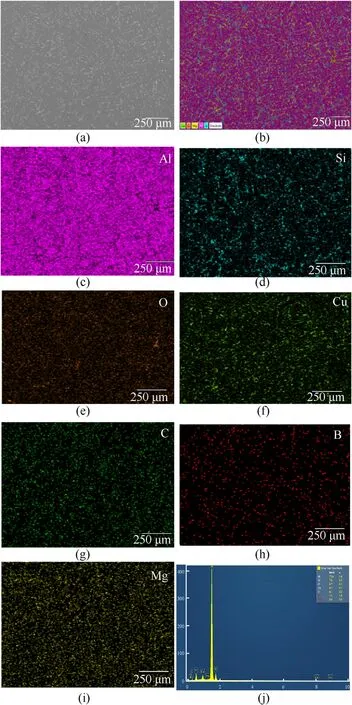

The mapping analysis of samples from outer zones of both A333/BC/TiC and A333/BC/SiC hybrid FGMMCs are shown in Figs.7 and 8 respectively. This analysis chromatically differentiates the distribution of primary(BC)and secondary(TiC and SiC)ceramics with the Al-9Si-3Cu matrix. Each constituent element is individually represented using unique colour. Boron of primary ceramic BC is distributed non-clustered within the matrix, with interface forming carbide layer. Carbon contributed from primary and secondary ceramic particles showed superior reaction affinity with α-Al,aided by meagre traces of O.Miscibility challenge at the molten phase during casting with excessive ceramics,were overruled using minor fraction of Mg ribbons[35] that triggered the reaction layer formations.Ti and Si contributed from secondary reinforcements of both hybrid composites, are detected with effective distribution and higher fraction. Energy Dispersive X-Ray Spectroscopy (EDS)analysis on the colour mapped zone of Field Emission Scanning Electron Microscopy (FESEM) depicted the weight percentages of their individual compositional elements.

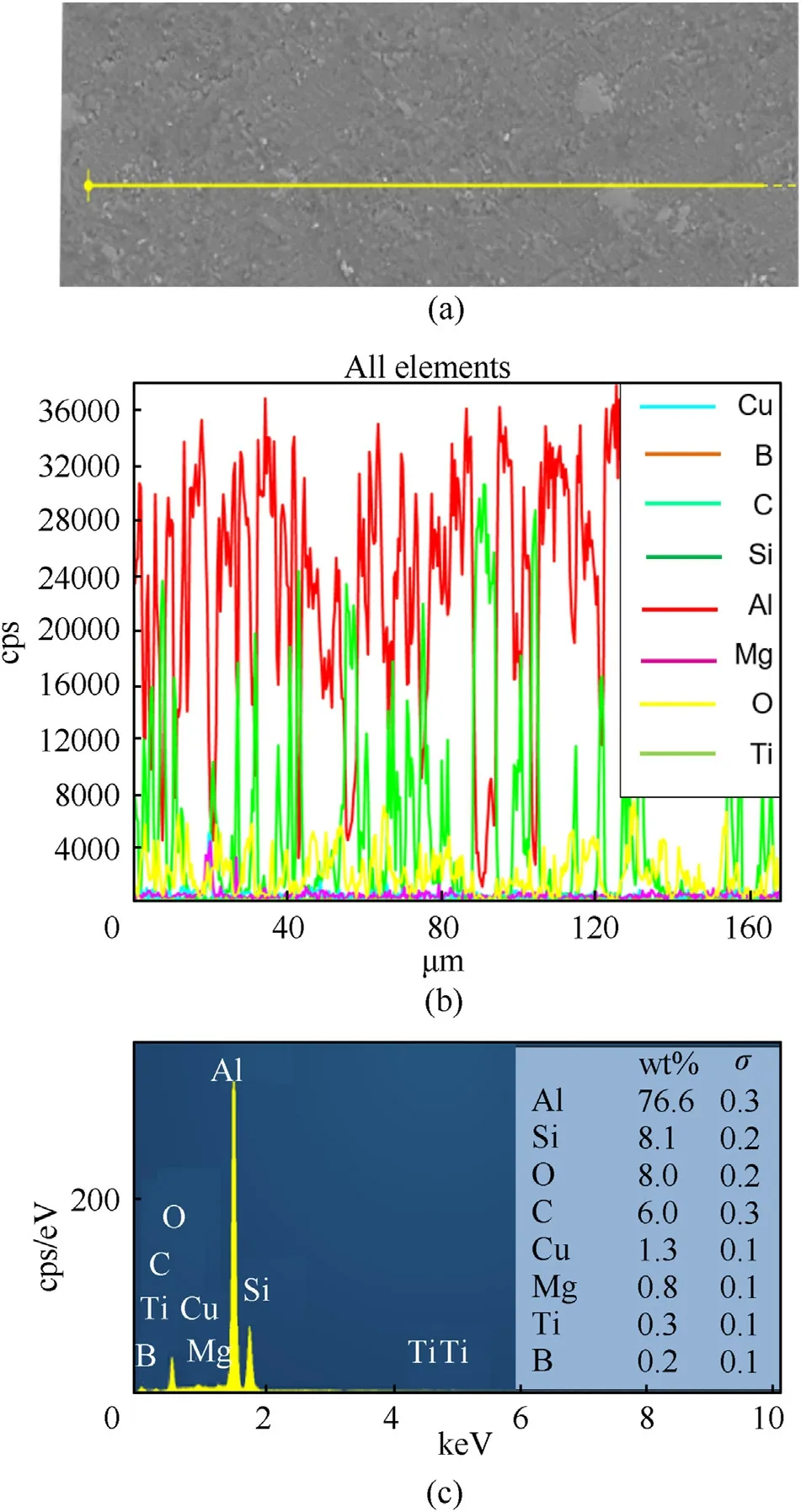

SEM image of a sample from outer zone of A333/BC/TiC hybrid FGMMC with mapped line is shown in Fig.9a.EDX line scan profile(Fig.9b)of A333/BC/TiC hybrid FGMMC is analyzed at the matrixparticle interfaces to confirm the distribution, interaction and wettability.Profile interactions of Al,Si and O intensity peaks depict the inevitable oxidation phenomenon. Ti, B and C peaks of line spectrum(Fig.9c)quantifies the intensity of secondary ceramics at the scan zone.

Fig. 7. Mapping analysis of A333/B4C/TiC hybrid FGMMC.

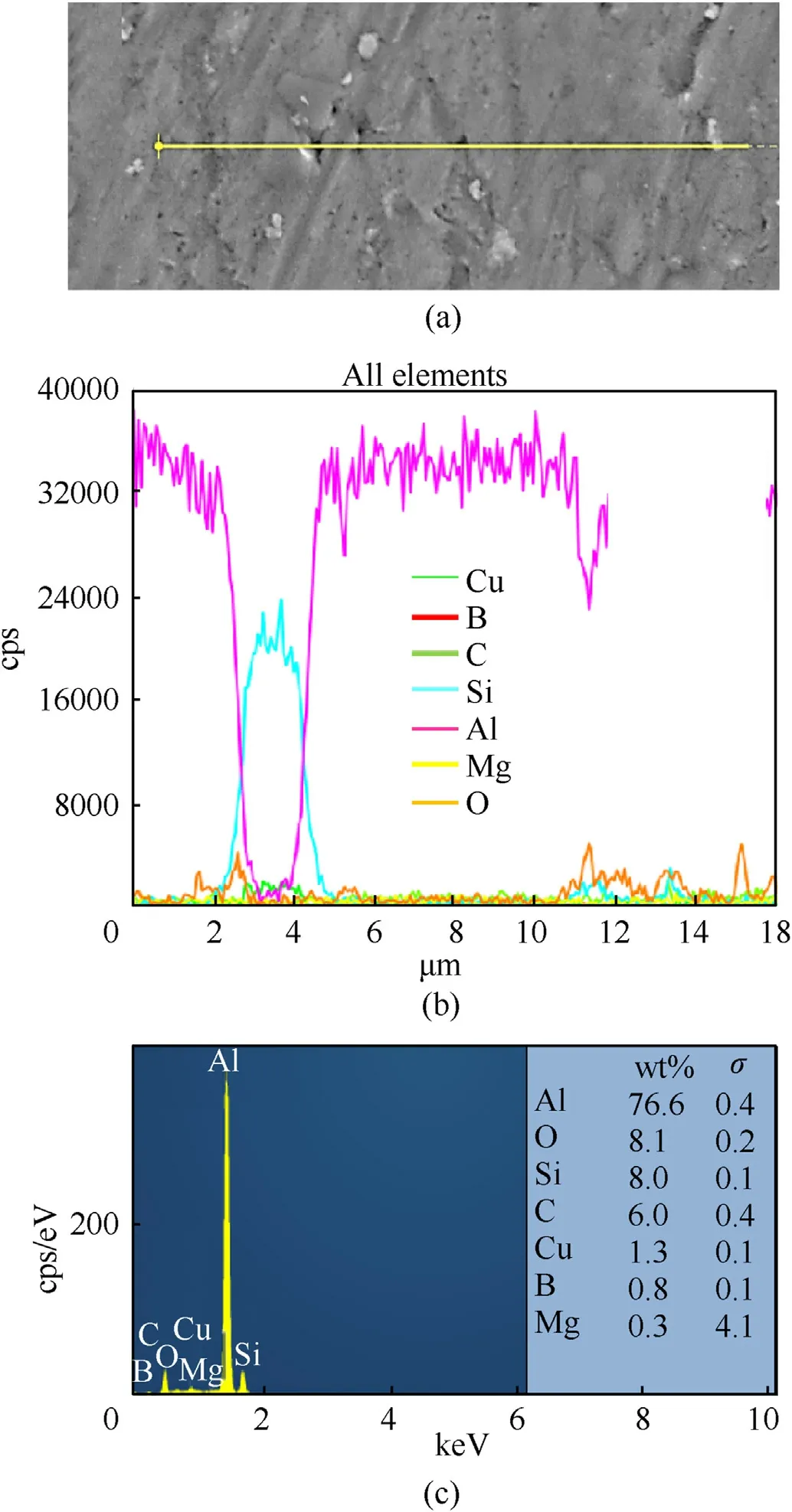

Whereas,SEM image of a sample from outer zone of A333/BC/SiC hybrid FGMMC with mapped line is shown in Fig.10a. Corresponding EDX line scan profile reveals (Fig. 10b) a single point interface between Al,Si and O.Beyond this,profile continued in the same pattern with same intensity as it was before. Line spectrum(Fig.10c) depict higher intensity peak of Si compared to that of B.This act as an evidence for the presence of secondary ceramic particle - SiC, which increased the fraction of Si in addition to its dominant presence as an alloy component.

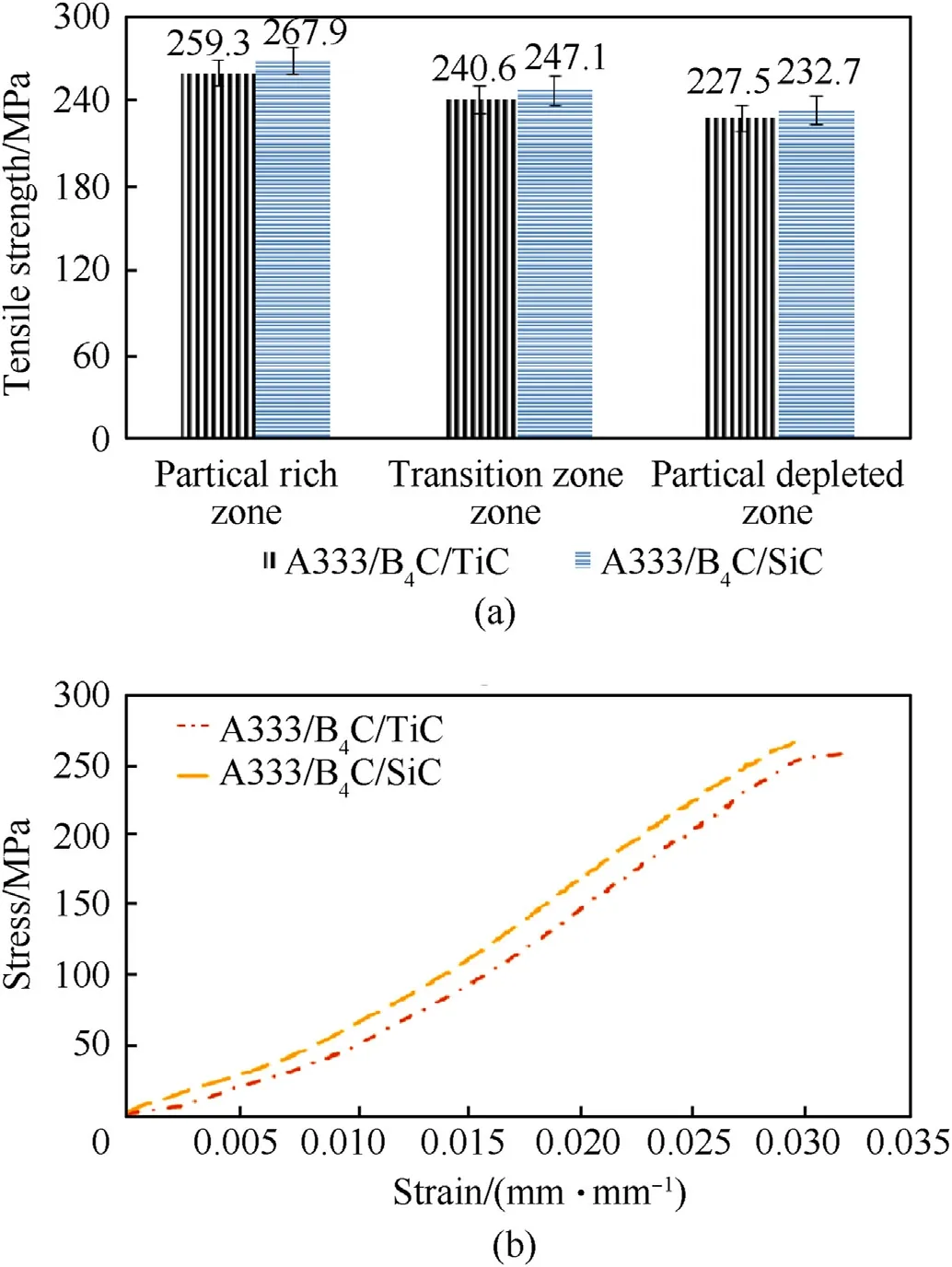

3.3. Tensile property

Transition of ceramic distribution and its hybrid nature has influenced the tensile properties across the composite wall. The improvement in properties of all three zones (Particle rich, Transition, Particle depleted) were compared among both composites.Tensile strength was analyzed as per ASTM B557M using Tinius make Universal Tensile Testing Machine.

Fig. 8. Mapping analysis of A333/B4C/SiC hybrid FGMMC.

Fig. 9. a) SEM image of outer A333/B4C/TiC hybrid FGMMC with mapped line, b) EDX line scan profile and c) Line sum spectrum.

Fig.10. a) SEM image of A333/B4C/SiC hybrid FGMMC with mapped line, b) EDX line scan profile and c) Line sum spectrum.

Result analysis (Fig.11a) compares the tensile strength of particle rich zones of hybrid FGMMCs against the particle-depleted zones. For both composites, zone enriched with the presence of ceramics showed higher tensile strength compared to particledepleted zones. Among this, particle rich zone of A333/BC/SiC hybrid FGMMC composite showed the highest tensile strength(267.9±1.3 MPa),which is 17.5%and 15%higher than the particledepleted zones of A333/BC/TiC and A333/BC/SiC hybrid FGMMCs respectively. This is due to higher concentration of heavier secondary particles (TiC or SiC) at this zone, along with higher presence of primary ceramic - BC. It was accomplished with the support of centrifugal force that pushed the large particles of heavier secondary ceramics towards outer layer (particle rich)during centrifugal casting. Smaller particles of primary ceramic occupied the granular voids created by secondary ceramics and boosted the mechanical strength at this zone. Tensile strength of particle rich zone of the A333/BC/SiC hybrid FGMMC was also 3.2%higher than the particle rich zone of the A333/BC/TiC hybrid FGMMC.Particle rich zone of the A333/BC/SiC hybrid FGMMC also showed an improvement of 30.3% in tensile strength when compared to its base alloy which showed an average tensile strength of 205.7 ± 1.3 MPa. The average tensile strength was determined from the values obtained through three repetitive tests conducted as per ASTM B557M standards.

Fig.11. (a) Tensile result analysis and (b) Stress-strain plot of A333/B4C/TiC and A333/B4C/SiC hybrid FGMMCs.

As agglomerates increases the ceramic surface area for effective load transfer, dominant agglomerating tendency of secondary particle SiC compared to TiC was considered as a significant reason for this superiority in strength. A significant decline in tensile strength is observed at the transition zone of both hybrid composites. This is due to the increasing gradient distribution of primary ceramic - BC and meagre presence of secondary ceramic -TiC or SiC at the transition zone. Hard ceramic enrichment at particle rich zone ensured effective load transfer, improving tensile strength. Close bondage between primary and secondary ceramic particles, along with their superior embedment on aluminium matrix at a lower aspect ratio facilitated proper strengthening[36].Thermal expansion mismatch at aluminium-ceramic interface imparted dislocation punch while quenching. This indirectly improved the overall tensile behaviour of both hybrid composites[37]. Ceramic doping limits the primitive ductile nature of Al-Si alloy modifying its stiffness, imparting brittle nature and improving tensile strength[38,39].As an inference from this stressstrain plot(Fig.11b),a similar phenomenon of declining ductility is predominant for both hybrid composites under the influence of factors like silicon fraction, ceramic concentration and dislocation density. A333/BC/SiC hybrid composite showed superior tensile strength and brittle nature when compared to A333/BC/TiC hybrid composite.

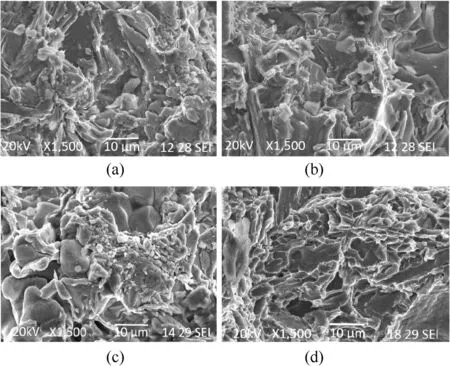

3.4. Fractography

Broken tensile specimens of both hybrid composites were subjected to fracture analysis using SEM(Fig.12),in order to detail the mode of fracture at both - ceramic depleted and enriched zones.Rising ceramic presence naturally induces brittleness, inhibiting the ductile nature of hybrid composite. Primary and secondary αaluminum in association with inferior fraction of eutectic silicon provided ductile nature to the matrix. Control on ductility was majorly influenced by eutectic silicon than α-aluminum. This was accomplished through significantly inhibiting the ductile nature by point edge-rod shape of eutectic silicon. This combined nature of ductile-brittle fracture was modified by the presence of secondary ceramics. Fractography of particle depleted zone of A333/BC/TiC hybrid FGMMC reveals (Fig.12a) deep micro cracks and irregular planar facets. Whereas, particle rich zone of A333/BC/TiC hybrid FGMMC reveals (Fig.12b) rigorous dendritic micro crack propagation and sharp inter-granular cleavages.Similarly,particle depleted zone of A333/BC/SiC hybrid FGMMC reveals (Fig.12c) trans-granular tear ridges and negligible ductile dimples.Particle rich zone of A333/BC/SiC hybrid FGMMC reveals (Fig. 12d) large number of micro void coalescence and deep valley cleavages due to micro crack propagation around the ceramic particles.Features like intergranular particle wreckage,tear ridges and deep facets significantly highlights brittle mode of fracture[40]for both hybrid composites.

3.5. Reciprocatory tribological performance

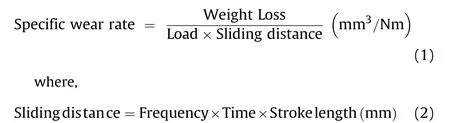

One-directional reciprocating tribology performance was assessed using a DUCOM make pin-on-plate linear reciprocating tribometer, under dry environment at room temperature. Test specimens of cylindrical dimension (φ9.56 × 15 mm) were prepared as per ASTM G133 standards, from all three zones (inner,middle and outer)of cast hollow cylindrical composite component.During the tests, prepared sample specimens of required dimensions were slid at a constant frequency (7 Hz) against the flat plate(EN 31 steel of hardness-267 VHN and surface roughness-076 Ra)of standard dimension(40×40×5 mm).Test parameters were fixed as per the standard range of load varying from 10 N to 50 N at a definite increment of 10 N, and sliding distance ranging from 500 m till 1500 m at a definite increment of 500 m.Specific rate of wear was calculated using weight loss, applied load and sliding distance as shown in equation(1). Sliding distance parameter was compute using frequency, time and stroke length as per equation(2).The average value of three repeated laps were measured at each cycle, for calculating wear rate.

Fig.12. Fracture morphology for(a)particle depleted zone of A333/B4C/TiC(b)particle rich zone of A333/B4C/TiC(c)particle depleted zone of A333/B4C/SiC(d)particle rich zone of A333/B4C/SiC Hybrid FGMMCs.

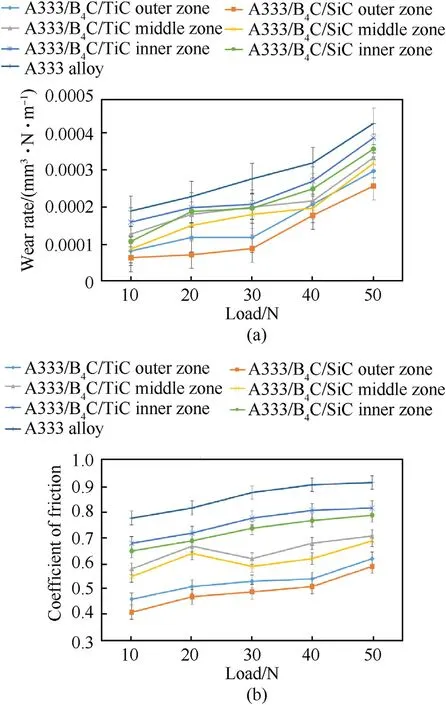

3.5.1. Effect of load

Applied load showed a significant direct influence(Fig.13a)over the wear rate of alloy and hybrid composites, irrespective of their zones. Load is varied within a range of 10 and 50 N, at a constant interval of 10 N keeping sliding distance constant at 1000 m.Trend shows a proportional rise from 10 N to 50 N obeying Archard's Law.Among samples of alloy and hybrid composites tested from all three zones, outer zone of A333/BC/SiC Hybrid FGMMC exhibits least wear rate(0.000066 mm/Nm)at the minimum applied load of 10 N.This was 27%and 130%lower than outer zone of A333/BC/TiC Hybrid FGMMC and alloy respectively. The curve shows an abrupt rise beyond 30 N with the formation of Mechanically Mixed Layer (MML). These layers restricts proper interfacial contact and were scrapped off with repeated cycles of high load(>30 N).Alloy shows the peak rate of wear(0.000429 mm/Nm)when compared at 50 N load condition.This affirms the fact that the rate of wear is largely dependent over the fraction of ceramic distribution within the matrix and applied normal load. The presence of secondary ceramics and their clustering tendency plays a significant role in improving wear resistance and lowering Co-efficient of Friction(COF)at outer zone comparing the other zones.

Fig.13. a)Dependency of wear rate on varying applied normal load,b)Dependency of co-efficient of friction on varying applied normal load.

Variation of COF (Fig. 13b) is in direct relation with applied normal load and percentage of secondary ceramics. Hard ceramics as secondary reinforcements improves the wear resistance and significantly influences COF of hybrid composites[41].COF is higher at particle-depleted inner zones of both hybrid composites.This is due to the minimal particle pull-outs from the ceramic rich outer zones during wear experiment cycles. COF of A333/BC/SiC hybrid FGMMC is lower to A333/BC/TiC hybrid FGMMC at all zones,because superior cohesive nature of SiC particles cut downs the rate of particle pull-outs comparing to TiC particles.Strain fields initiate at the ceramic-matrix interfacial cites during solidification due to thermal conductivity variance. This strain field formation hinders the crack propagation thereby resisting the material loss during sliding contact. Also, the excellent affinity between primary and secondary ceramics have significantly prevented the particle detachment from the matrix. Heterogeneity in ceramics impart dislocation barrier [42] and arrests the inter-granular crack propagation to improve the overall tribo-mechanical performance of both hybrid composites. Hence comparing all, alloy reveals the maximum COF at all load conditions.At high load of 50 N,it shows 48%and 60%improvement to the particle rich zones of TiC and SiC based hybrid composites respectively. This emphasizes the significant role of ceramics in hybrid composites that promotes load distribution and reduction in area of direct contact during sliding.

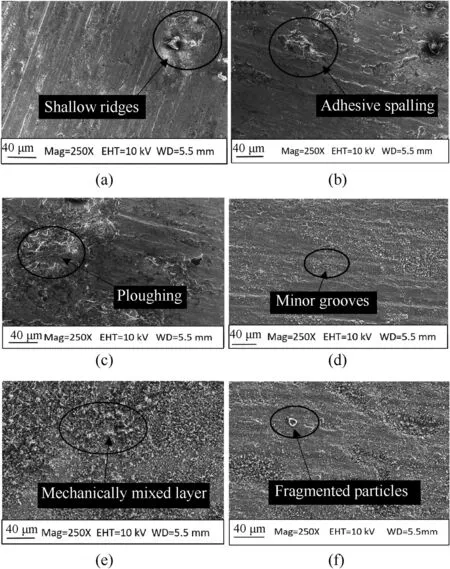

Worn surface analysis was conducted on specimens from particle rich zones of both hybrid composites using Zeiss make FESEM.Three specimens of each hybrid FGMMC worn at extreme load conditions (10 and 50 N) are compared (Fig.14) along with intermediate load condition (30 N), maintaining a constant sliding distance of 1000 m. At a load condition of lower extreme -10 N,shallow ridges and minor scratches are seen (Fig. 14a) along the worn surface of A333/BC/TiC Hybrid FGMMC. For the same composite, adhesive spalling phenomenon is observed (Fig.14b) at intermediate load (30 N) conditions. This later transforms to deep cuts and ploughing at higher loads (50 N) as seen in Fig. 14c. An effective combination of Si with hybrid ceramics at this zone ensures superior resistance to surface cuts of counter material. This reduces the rate of wear at this zone in comparison to other zones.Abrasive wear mechanism is observed as the predominant wear mechanism at this zone. Whereas, worn surface analysis of A333/BC/SiC Hybrid FGMMC at low load condition (10 N) reveals(Fig. 14d) minor grooves and whisker scratches. These minor scratches result in floating debris (Fig. 14e) along the sliding interface. This results in a third body abrasion mechanism at intermediate load condition (30 N). These contributions from both the counter surfaces result in formation of MML, which limits the friction at the sliding interface. At high load (50 N), these MML(Fig.14f)gets scrapped off with repeated cycles revealing protruded ceramic particles and results in fragmented particles.

3.5.2. Effect of distance

Fig.14. Worn surfaces of A333/B4C/TiC Hybrid FGMMC at(a)10 N(b)30 N(c)50 N loads and A333/B4C/SiC Hybrid FGMMC at(d)10 N(e)30 N(f)50 N loads under constant sliding distance (1000 m).

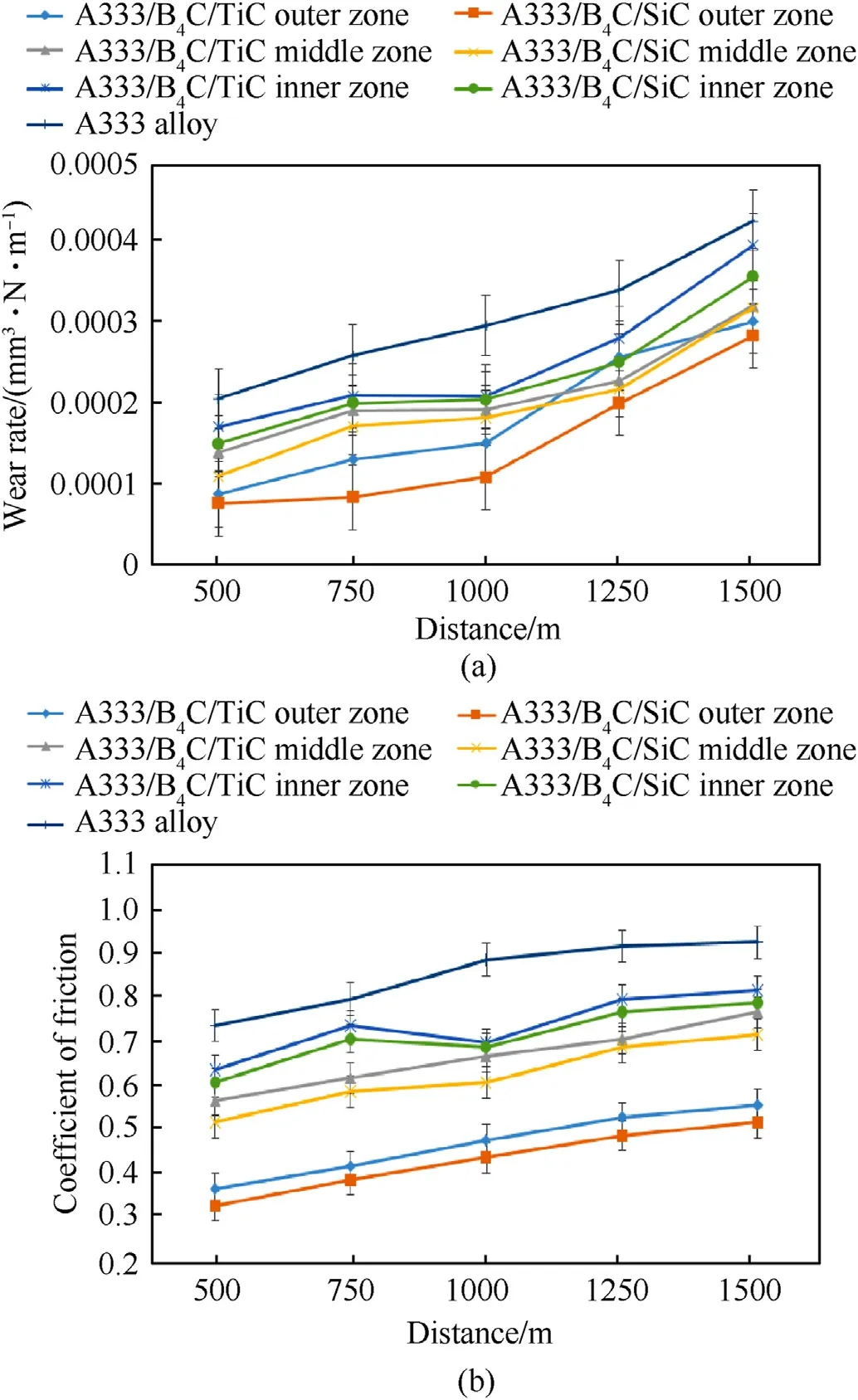

Fig.15. a)Dependency of wear rate on varying sliding distance, b)Dependency of coefficient of friction on varying applied normal load.

Sliding distance was varied between 500 and 1500 m at a definite increment of 250 m, in order to analyze (Fig. 15) its dependence over rate of wear of alloy and hybrid composites. Each test cycle compares the wear rate and COF at different sliding distances and constant applied normal load (40 N). Alloy reveals (Fig.15a) a proportional rise in trend,whereas for composites this rise limits to 1000 m followed by an abrupt rise till 1500 m.Analysis reveals that particle rich zone (outer) of A333/BC/SiC hybrid FGMMC at high distance (1500 m) shows a dominating wear resistance of 6% and 50%, in comparison to outer zone of A333/BC/TiC hybrid FGMMC and alloy respectively.This is seen at a minimum sliding distance of 500 m. Supreme density and hardness of secondary ceramic - SiC limits the particle pull-outs and particle wreckages at this condition, in comparison to TiC. Adhesive accumulation of wear debris and oxidized fragmented particle layering over the sliding pin surface limits the scrapping action. This leads to a lower slope of wear curve, up to intermediate sliding distance - 1000 m. Beyond this,oxide layers over the sliding surface gets scraped off at higher sliding distances (>1000 m). For both hybrid composites, lack of secondary ceramics at inner and middle zones lead to increased wear rate across all sliding distances. A similar inference was reported during dry sliding wear test of centrifugally cast Al-Si/BC/TiBhybrid FGMMC [43]. Whereas, COF is seen (Fig. 15b) rising linearly with increasing sliding distance for alloy and hybrid composites. On contrast, inner and middle zones of A333/BC/TiC hybrid FGMMC shows a slight dip in COF at the intermediate sliding distance (1000 m). This is due to the lack of secondary ceramics,which induces strain hardening that promotes thermal softening and formation of adhesive oxide layer.These surface modifications results in improper interfacial contact during sliding. This trend is not observed in case of alloy instead it shows a gradual rising trend.COF of alloy at high distance(1500 m)is higher than outer zones of TiC(78%)and SiC(66%)based hybrid FGMMCs.This emphasize the role of ceramics in formation of tribolayer. Surface texture plays a significant role in maintaining the friction coefficient during reciprocal sliding action.

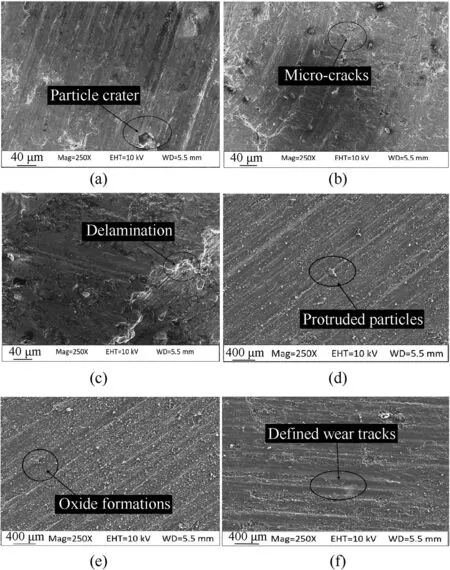

Morphology of worn surface of particle rich(outer)zone of both hybrid composites are analyzed using FESEM.Wear response(wear rate and COF) to varying sliding distance are compared between extreme sliding distances (500 and 1500 m) along with intermediate sliding distance (1000 m), maintaining a constant applied normal load of 40 N. Minor particle craters are observed (Fig.16a)over the worn surface of A333/BC/TiC Hybrid FGMMC due to particle wreckage at low sliding distance (500 m). This has transformed to micro crack formations at intermediate sliding distance(1000 m). These free debris from broken particle craters, initiate micro cracks (Fig.16b) at intermediate sliding distance. Such free bodies transform as agglomerated clusters developing superficial delamination(Fig.16c)at high sliding distance(1500 m).Such nonlocalized agglomerates lead to random surface peel-offs. These features affirm the fact of tribo-layer (MML) formation at intermediate sliding distance (1000 m) and cyclic transformation to abrasive wear mechanism at higher sliding distance (1500 m).

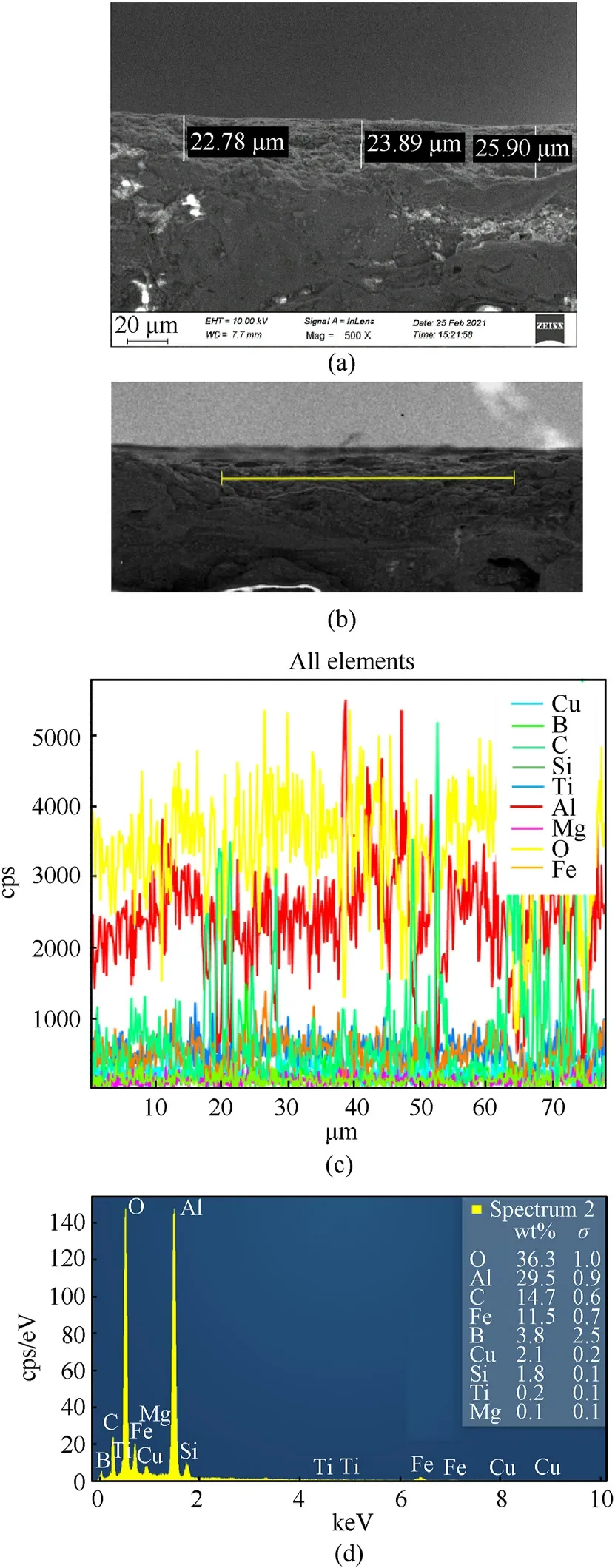

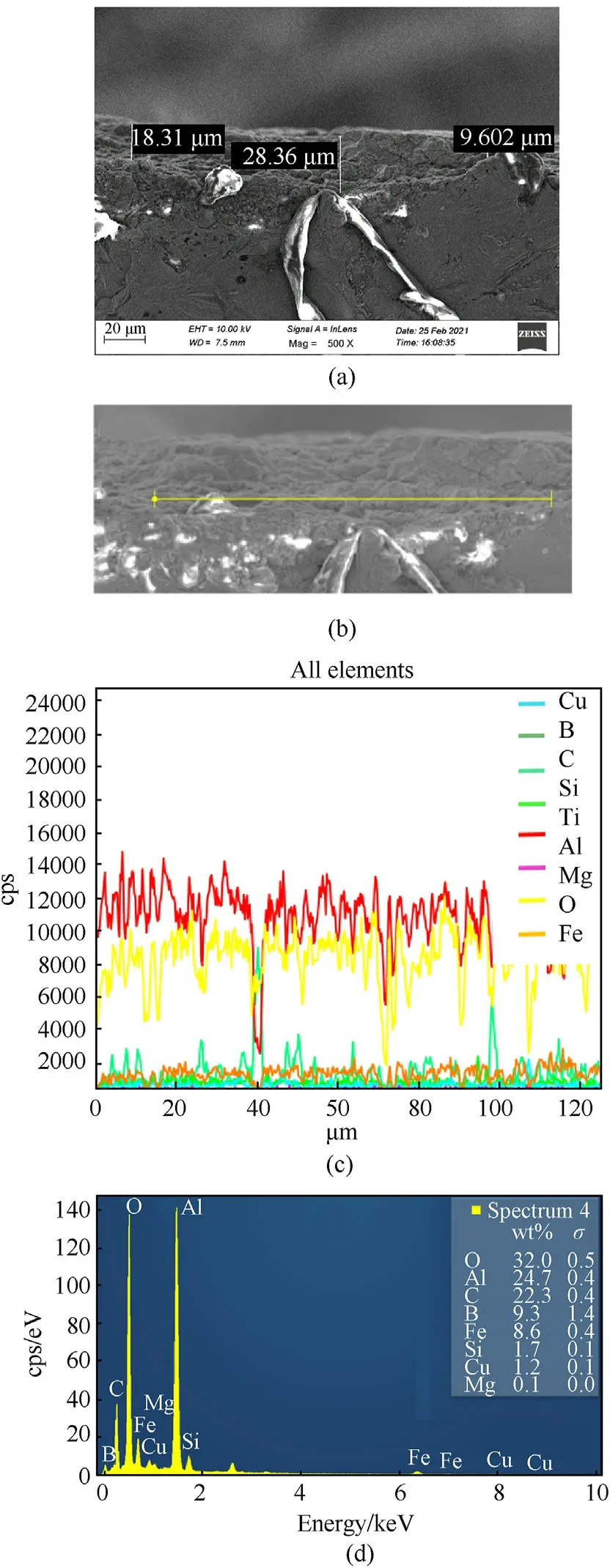

Whereas worn surface analysis for A333/BC/SiC Hybrid FGMMC at low sliding distance (500 m) reveals (Fig.16d) protruded particles on shallow wear tracks. Partial exposure of these ceramics undergoes similar mechanism of particle wreckage to form a third body at the sliding interface.These unstable debris are oxidized and gets adhered to the sliding surface, forming a tribo-layer (Fig.16e)over the specimen. This MML layer significantly limits the friction at intermediate sliding distances [44,45]. At high sliding distance(1500 m), the particle craters and MML scrap off together increasing the exposure of matrix surface during sliding. This phenomenon during repeated cycles of higher sliding distance creates defined linear wear marks (Fig. 16f) along the sliding direction, over the sliding surface of the specimen. Simultaneously resulting in higher rate of material removal and high friction along the sliding interface. The cross-section of wear tracks seen at intermediate sliding distance (1000 m) are analyzed using SEM for both A333/BC/TiC (Fig. 17a) and A333/BC/SiC (Fig. 18a) hybrid FGMMCs.The presence of tribolayer formation is confirmed across the wear track using SEM, characterized through line mapping(Figs.17b and 18b).The interaction of hybrid ceramic particle with matrix is analyzed through EDX line scan profile(Figs.17c and 18c)and line sum spectrum(Figs.17d and 18d)across the interface.This confirms the contributions from sliding pair which promoted the mixed oxide layer formation.

Fig.16. Worn surfaces of A333/B4C/TiC Hybrid FGMMC at(a) 500 m (b) 1000 m (c) 1500 m and A333/B4C/SiC Hybrid FGMMC at(d) 500 m (e)1000 m (f) 1500 m under constant sliding distance (1000 m) under constant applied load of 40 N.

Fig. 17. (a) Cross-sectional SEM of worn sample from outer A333/B4C/TiC hybrid FGMMC, (b) SEM showing particle-matrix interface with mapped line, (c) EDX line scan profile and (d) Line sum spectrum.

Fig. 18. (a) Cross-sectional SEM of worn sample from outer A333/B4C/SiC hybrid FGMMC, (b) SEM showing particle-matrix interface with mapped line, (c) EDX line scan profile and (d) Line sum spectrum.

Fig. 19. a) Elemental confirmation on worn surfaces of A333/B4C/TiC hybrid FGMMC through EDS analysis, b) Elemental confirmation on worn surfaces of A333/B4C/SiC hybrid FGMMC through EDS analysis.

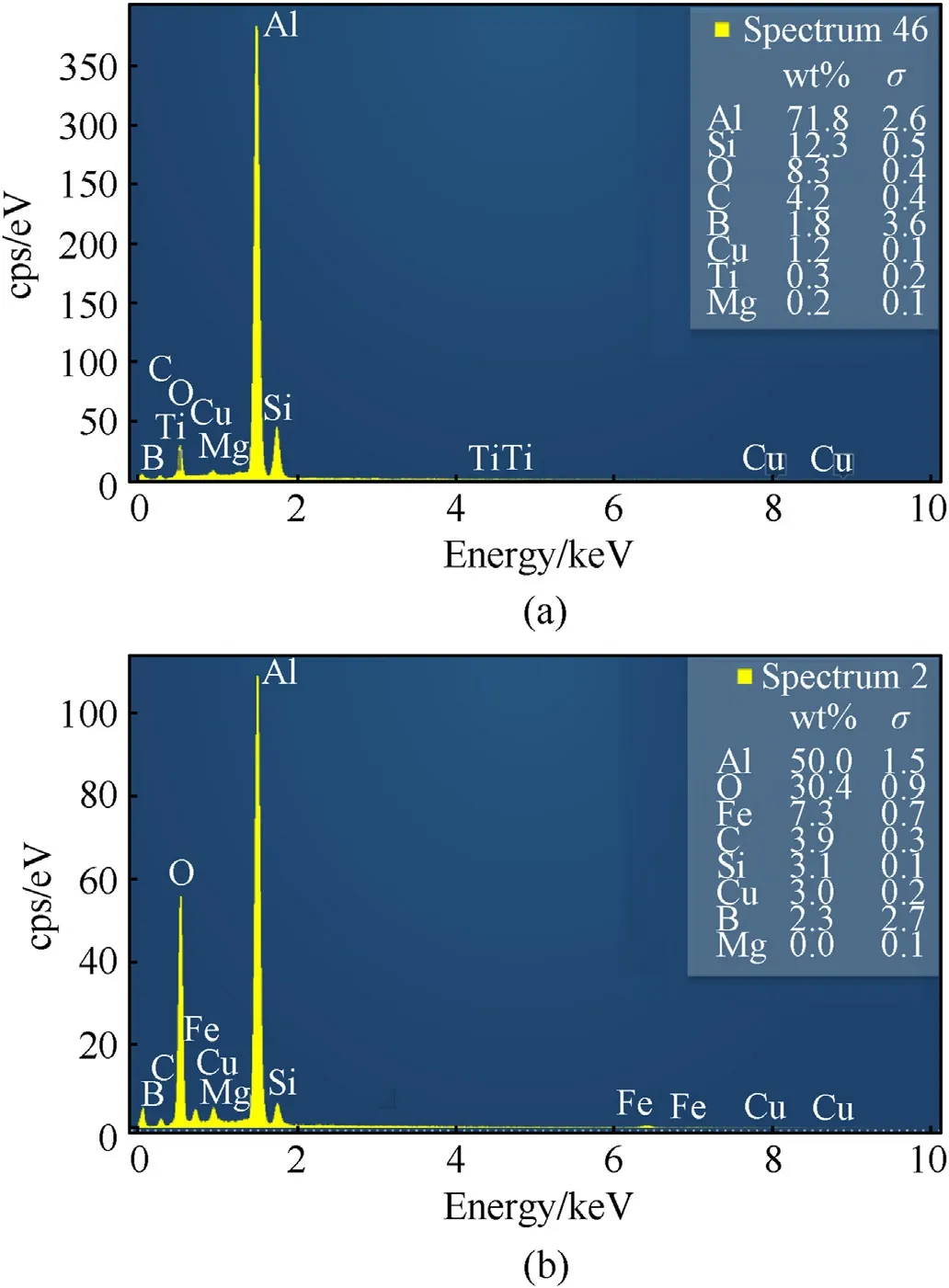

Energy Dispersive Spectroscopy (EDS) analysis was performed on the specimens worn at intermediate sliding distance (1000 m),for both the hybrid composites. Comparing the results of both the composites, presence of ‘C’ and ‘O’ confirmed the inevitable oxidation phenomenon and tribo-layer formation over the worn surface. These unstable layers act as a solid lubricant the largely influence to alleviate friction and wear of the composites [46].However, the ceramic composition elements like Ti, B and C are detected(Fig.19a)along the tribo-layer formation of A333/BC/TiC Hybrid FGMMC. Unlike specimen from A333/BC/TiC Hybrid FGMMC, specimen of A333/BC/SiC Hybrid FGMMC revealed(Fig. 19b) an additional meagre presence of ‘Fe’ affirming minor contributions from counter material for the formation of tribolayer. Primary and secondary ceramic presence was evident from Si,B and C peaks,which resulted from protruded particle wreckage.

4. Conclusion

· Hollow cylindrical samples of A333/BC/TiC and A333/BC/SiC hybrid FGMMCs were successfully fabricated through horizontal centrifugal casting technique, ensuring effective gradation of primary and secondary ceramics across the composite wall.

· Metallography analysis revealed rising gradient ceramics towards outer layer. This was achieved through ceramic density variance and centrifugal force. Ceramic presence and distribution were chromatically distinguished through elemental mapping.· Particle rich zone of A333/BC/SiC hybrid FGMMC depicted superior hardness (10% and 84%) and tensile strength (4% and 30.3%), in comparison to A333/BC/TiC hybrid composite and alloy respectively.

· Tribology performance of all three layers of both hybrid composites were compared to reveal direct dependency of wear response against varied applied normal load and sliding distance. At high load (50 N), particle rich layer of A333/BC/SiC hybrid FGMMC exhibited improved wear resistance (16% and 65%)and sliding friction(5%and 56%)in comparison to particle rich zone of A333/BC/TiC hybrid composite and alloy respectively.

· Third-body abrasion and tribo-chemical mechanisms were determined as predominant wear mechanisms for both hybrid composites during this reciprocal wear study. Presence of secondary ceramics at the particle rich zone were identified as key elements, which restricted the matrix-ploughing phenomenon improving wear resistance.

· Worn surface analysis of both hybrid FGMMCs, confirmed the formation of tribo-oxide layer, which limited the interfacial friction at intermediate sliding distance(1000 m).Contributions from counter plate surface were also identified with the detection of oxidized Fe content during EDS analysis.

This comparative analysis shows the significance and applicability of carbide-carbide reinforced hybrid aluminium FGMMC for diverse engineering applications. This versatile-functional advanced composite is suggested to meet high performance demands of military,aviation,pneumatics and mechatronic industries were reciprocating wear accounts.

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

- Defence Technology的其它文章

- A new model for the expansion tube considering the stress coupling:Theory, experiments and simulations

- Experimental and analytical assessment of the hypervelocity impact damage of GLAss fiber REinforced aluminum

- Effect of the microporous structure of ammonium perchlorate on thermal behaviour and combustion characteristics

- Modeling of bistatic scattering from an underwater non-penetrable target using a Kirchhoff approximation method

- 3,6-bis (2,2,2-trinitroethylnitramino)-1,2,4,5-tetrazine. Structure and energy abilities as a component of solid composite propellants

- Rapid preparation of size-tunable nano-TATB by microfluidics