Study on mechanical properties of soil-rock mixture of various compactness subjected to freeze-thaw cycles

Zhong Zhou,HaoHui Ding,WenYuan Gao,LinRong Xu

School of Civil Engineering,Central South University,Changsha,Hunan 410075,China

ABSTRACT The soil-rock mixture,a collection of soil particles and rock blocks,is inherently heterogeneous and anisotropic due to sig‐nificant particle size and material strength differences.This study conducts triaxial tests on soil-rock mixture samples of various compactness subjected to varying freeze-thaw cycles.A mesoscopic simulation is carried out by particle flow code(PFC)to analyze the effects of freeze-thaw cycles on the mechanical properties of soil and rock particles.The results show that the mechanical properties of the soil-rock mixture under freeze-thaw cycles are greatly affected by the initial compac‐tion.In general,when the degree of compaction is higher,the influence of freeze-thaw cycles on the soil-rock mixture is greater.The stress-strain curves of the samples with different compactness demonstrate strain-softening behavior.The freeze-thaw cycles greatly influence the failure strength of the samples with a higher degree of compaction but have little impact on the samples with a lower degree of compaction.On the microscopic level,during freeze-thaw cycles,the pore volume in the highly compacted sample is too small to accommodate the volume expansion from ice crystal formation,causing significant strength loss among the soil and rock particles and deterioration of the macroscopic properties of the soil-rock mixture.

Keywords:soil-rock mixtures;freeze-thaw cycle;degree of compaction;particle flow code

1 Introduction

The soil-rock mixture is a complex and discrete geomaterial that exists widely in nature.It is a collec‐tion of soil particles and rock blocks and is inherently heterogeneous and anisotropic due to significant parti‐cle size and material strength differences.The soil-rock mixture has the characteristics of good deformation re‐sistance,high shear strength,strong bearing capacity,excellent water permeability,among others.It is an im‐portant filling material commonly used in local engi‐neering projects.However,due to the lack of studies on its engineering properties,engineers often had to treat the soil-rock mixture as soils.This leads to unnec‐essary waste or potential problems in many projects.By conducting specific experiments,the mechanical properties of the soil-rock mixture have been thorough‐ly studied and gradually applied to engineering.For ex‐ample,Wei et al.(2018)studied the effects of particle size grading,water content,and shear strain rate on the mechanical properties of the soil-rock mixture.The re‐sults show that the shear strength of the soil-rock mix‐ture increases with increasing rock size and shear strain rate and decreasing moisture content.

At present,there are many studies on the effects of freeze-thaw cycles on rock or soil.It is recognized that freeze-thaw cycles cause successively accumulat‐ed damage to the internal structure of rock or soil,re‐sulting in rock or soil deformation and mechanical property deterioration.Regarding experimental inves‐tigations,Wang et al.(2005,2007)conducted triaxial tests on compacted silty clay subjected to freeze-thaw cycles.The results show that the soil transitioned from an unstable state to a dynamically stable state with increasing freeze-thaw cycles.The failure strength first decreases and then increases,and finally remains constant.The cohesion gradually declines while the internal friction angle fluctuates within a certain range.Qi et al.(2008)studied the influence of one freeze-thaw cycle on soil structural change and engineering properties of Lanzhou loess,including dry unit weight,strength parameters,preconsolidation pressure,and moduli.Dong et al.(2010)examined the impact of freeze-thaw cycles on compacted loess.The results show that the cohesion of the compacted loess decreases first and then rises as the number of freeze-thaw cycles increases,with the lowest value oc‐curring within ten freeze-thaw cycles.In contrast,the internal friction angle is not affected.Wang et al.(2011a,2011b)conducted unconsolidated and und‐rained(UU)triaxial tests on compacted modified clay.The results show that the stress-strain curve changes from strain-softening to strain-hardening af‐ter freeze-thaw cycles.The cohesion of the sample gradually decreases with the increase of freeze-thaw cycles,and the change in the internal friction angle is irregular.Further,Li et al.(2013)studied the influ‐ence of water content on the mechanical properties of cohesive soils during freeze-thaw cycling.Notably,Kong et al.(2014)used a piezoelectric ceramic intelli‐gent aggregate sensor to monitor the soil freeze-thaw process in real-time.Zhou et al.(2016,2017,2019)analyzed the influence of freeze-thaw cycles on soil structure and physical and mechanical properties.Masrur et al.(2019)studied the freeze-thaw perfor‐mance of fly ash-treated soil with the addition of a phase change material(PCM).

A few studies focus on the behavior of soil-rock mixtures or construction waste mixtures.Xing et al.(2018)investigated the effects of freeze-thaw on the damage mechanisms of soil-rock mixtures with differ‐ent stone contents in the macro-meso scale.The results show that the contact between crushed stone particles for the samples with high stone contents accounts for most of the damage,and the contact between homoge‐nous particles is less affected by freeze-thaw than that between soil and rock particles with mismatched elas‐ticity.Xing et al.(2019)prepared a soil-rock mixture by the equivalent substitution method,considering the influence factors such as water content and confining pressure.The results show that the soil-rock mixture samples show slight strain-softening and strain-harden‐ing at low water content and high water content,re‐spectively.It is worth noting that Li et al.(2019)exam‐ined the effects of freeze-thaw on the mechanical prop‐erties and porosity of construction waste mixtures of various proportions,including recycled brick,concrete,and mortar.They suggested that the freeze-thaw cycles destroy the original structure,thus leading to the deteri‐oration of soil properties.

In terms of theoretical and numerical analyses,Ma et al.(2016)analyze the temperature field and thaw depth of wide highway embankments in perma‐frost regions by numerical simulation.Shoop et al.(2008)suggested that ice crystal accumulation in lowdensity soils is generated during freezing due to the expansion of excess water inside the soil.Gao et al.(2021)proposed a constitutive model to describe the strength loss based on the stress-strain characteristics of the rock samples after freeze-thaw cycles.The R2(Goodness of Fit)of the model is greater than 0.93,showing a good fit with the actual data.Han et al.(2018)studied the mechanical properties of saline soil under freeze-thaw cycles through UU triaxial com‐pression tests.They considered the two-factor shear strength damage empirical formula under the influ‐ence of freeze-thaw cycles and salt effects,and the co‐efficient of determination R2is greater than 0.985.

The degree of compaction,or relative compaction,is a basic index to evaluate the compactness of materi‐als.It also has a significant influence on the behavior of the roadbed consisting of soil and rock mixtures in permafrost regions during freeze and thaw.Zheng et al.(2015)studied the effects of freeze-thaw cycles on soil pores through a series of indoor tests and dis‐cussed the intrinsic effects of the freeze-thaw cycles on the soil.It is found that the response of water phase change and migration to soil particles and pores is the leading cause of soil structural change.Vikland‐er(1998)suggested that loose soil and compacted soil tend to have a steady pore ratio after freeze-thaw cy‐cles,and the mechanical properties also change ac‐cordingly.Wang et al.(2019)established a particle flow model of a soil-rock mixture by combining multi-layered method compaction and random poly‐gon generating method and proposed a uniformity co‐efficient as an indicator to measure the heterogeneity of a soil-rock mixture.Yan et al.(2013)conducted UU triaxial tests on silty sands considering compact‐ness and water content.The results show that the de‐gree of compaction has a certain effect on the mechan‐ical properties of soils under freeze-thaw cycles.The freeze-thaw effects of loose soil and compacted soil are opposite,causing them to reach similar densities after a certain number of freeze-thaw cycles.Sun et al.(2019)considered the influence of particle grading and shape in the direct shear test and established a re‐lationship between the micro-destruction mechanism and macro-intensity parameter.Hu et al.(2017)con‐ducted a series of triaxial tests with different relative compaction under freeze-thaw cycles to identify the effect of the initial compactness on the variation in mechanical properties of silty clay in the Qinghai-Ti‐bet Plateau.The results show that water redistribution is one of the reasons for the different soil behaviors af‐ter freeze-thaw cycles.Zheng et al.(2019)studied the effects of the number of freeze-thaw cycles,dynamic stress,confining pressure,loading frequency,initial moisture content,and degree of compaction on the cu‐mulative plastic strain of compacted subgrade filling.The results show that the cumulative plastic strain is positively correlated with the number of freeze-thaw cycles,dynamic stress,and initial water content but inversely correlated with the confining pressure,load‐ing frequency,and degree of compaction.

In summary,compactness is not studied as an inde‐pendent variable when the effects of freeze-thaw are ex‐amined.Given its significant impact,it is necessary to study the physical and mechanical properties of soil-rock mixtures subjected to freeze-thaw under differ‐ent compactness conditions.In this paper,triaxial tests are carried out on the soil-rick mixture samples of vari‐ous relative compaction subjected to increasing freeze-thaw cycles.The mechanical properties of the soil-rock mixtures with different compactness under freeze-thaw cycles are described in detail.The mecha‐nism regarding how the compactness impacts the me‐chanical propertiesof soil-rock mixtures isalso clarified.

2 Test method

2.1 Experiment materials

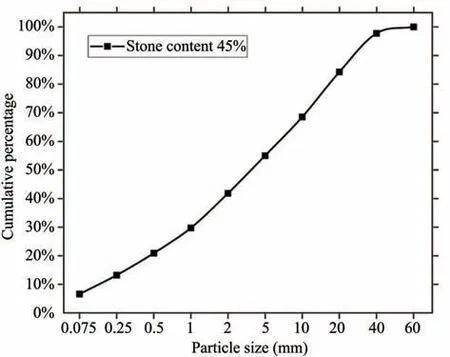

Considering the size effects of large particles,a large-scale triaxial apparatus was used to obtain the stress-strain behavior of soil-rock mixture samples of 60 cm in height and 30 cm in diameter subjected to freeze-thaw cycles.In this test,the soil-rock mixture sample is prepared by mixing sandy clay,crushed stones,and stone blocks according to the design gra‐dation of a passenger line roadbed.The sharp and an‐gular stone blocks of 5 to 60 mm consist of blue-gray,hard sandstone without impurities such as soil parti‐cles or organic matter.The crushed stones derived from the same stone blocks range from 0.5 to 5 mm in diameter.The soil-rock mixture contains 45%stone blocks by weight and has an optimal water content of 6%.Figure 1 depicts the particle size distribution.

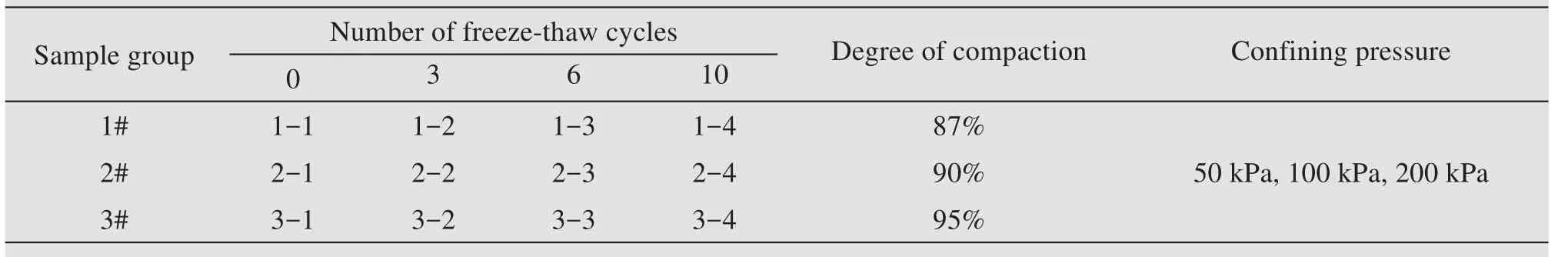

According to a previous study(Zhou,2017),the effect of early freeze-thaw cycles on the soil-rock mixture is the most significant,with the mechanical properties stabilizing after six freeze-thaw cycles.For the indoor triaxial test in this study,the number of freeze-thaw cycles was set to be 0,3,6,or 10.

2.2 Sample preparation

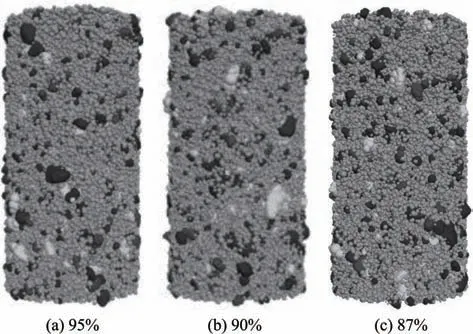

The standard requires that the subgrade and roadbed filling achieve relative compaction of 95%and 90%,re‐spectively.Therefore,three groups of samples were pre‐pared,corresponding to 95%,90%,and 87%relative compaction at the optimum moisture content(i.e.,6%).Figures 2a,2b,and 2c depict the sandy clay,crushed stones,and stone blocks used to prepare the soil-rock mixture,respectively.The sample was com‐pacted layer by layer in cylinder molds,as depicted in Figure 2d.After demolding,the samples were tightly sealed with a plastic film to prevent moisture loss and simulate a closed freeze-thaw system in an environ‐mental chamber.

Figure 1 Particle size distribution of the soil rock mixture with 45%stone blocks

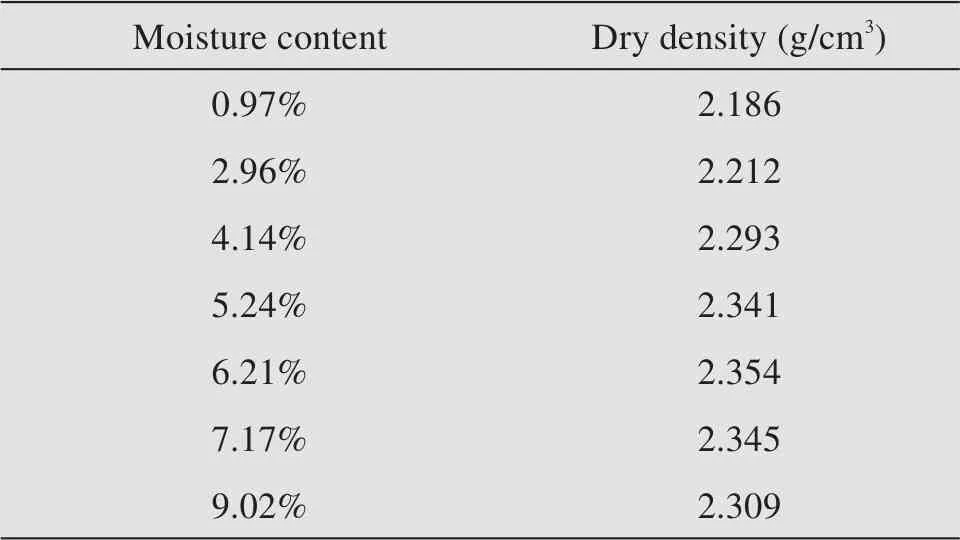

The relative density of particles larger than 5 mm(ρs-R)was found to be 3.45 g/cm3by the standard test method for specific gravity of coarse aggregate.Meanwhile,the relative density of particles finer than 5 mm(ρs-S)was found to be=2.67g/cm3by the hy‐drometer method.Based on the weighted average,the relative density of the soil-rock mixture(ρs-SRM)contain‐ing 45%rock blocks was found to be 2.97 g/cm3.Table 1 lists the dry density of the soil-rock mixture and the corresponding moisture content at which the mixture wascompacted.From Table 1,the maximum dry densi‐ty is 2.354 g/cm3,and corresponding moisture content,i.e.,6.21%,is the optimal moisture content.

2.3 Experimental design

The relative compaction and number of freeze-thaw cycles are selected as test variables to in‐vestigate the effects of initial compactness on the me‐chanical properties of a soil-rock mixture during freeze-thaw.According to a previous study(Zhou,2017),the minimum value of a soil-rock mixture strength generally appears within six cycles and tends to be stable.Therefore,the number of freeze-thaw cy‐cles is set to 0,3,6,or 10 for a total of four cases.

Table 1 Relationship between dry density and moisture content of the soil-rock mixture by the compaction test

The freezing and thawing processes were carried out using a custom-designed freeze-thaw chamber,with the freezing temperature set at-5°C and the thawing temperature set at 20°C.According to Wang(2011),the freezing and thawing process of clay sam‐ples under the same conditions would complete with‐in 12 hours.Therefore,the freezing and thawing peri‐ods are set to 12 hours for the soil-rock mixture sam‐ples in this study to ensure that the sample is com‐pletely frozen or fully thawed.In other words,a freeze-thaw cycle is completed in 24 hours.

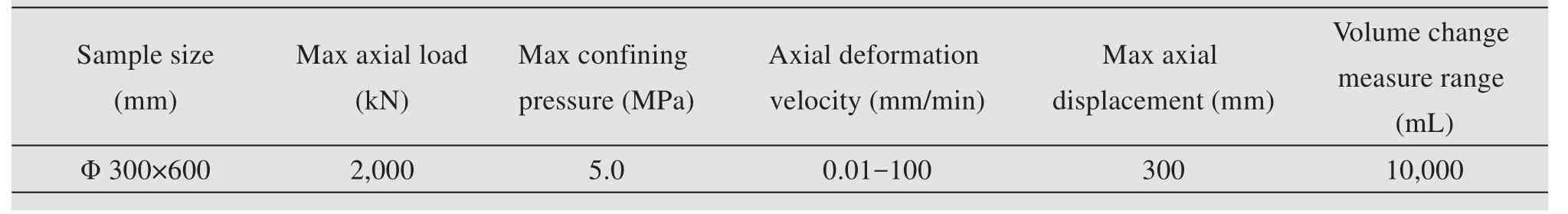

Triaxial compression testing of the soil-rock mix‐ture samples was carried out on the TAJ-2000 largescale static and dynamic triaxial apparatus(Figure 3)Table 2 summarizes the key technical specifications of the apparatus.And Table 3 summarizes the experi‐mental design,with a total of 36 samples.

Figure 2 Sample preparation

Figure 3 Large-scale triaxial apparatus and test sample

Table 2 Key technical specifications of the TAJ-2000 triaxial apparatus

Table 3 Summary of sample groups and testing parameters

3 Experiment results

3.1 Stress-strain relationship

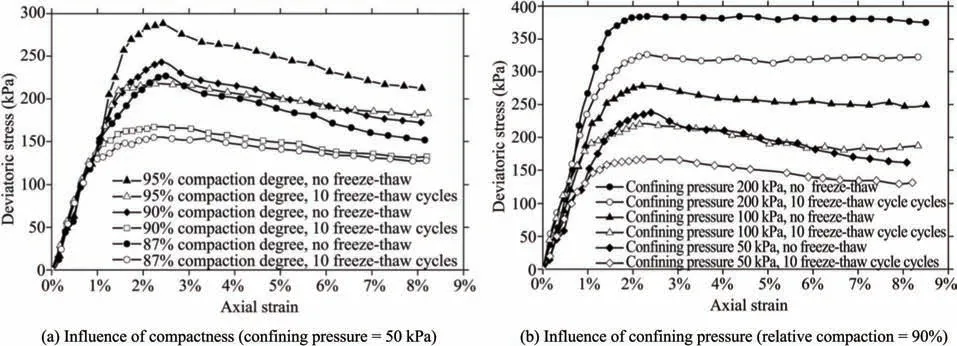

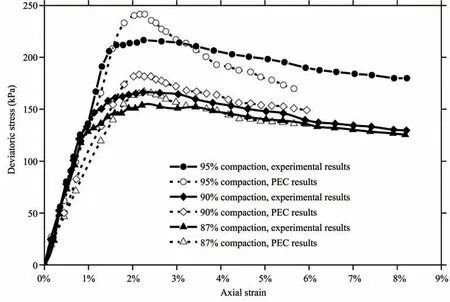

The stress-strain curve obtained from the triaxial compression test can reflect the mechanical proper‐ties of the soil-rock mixture.Figures 4a,4b illus‐trates the stress-strain curves of the samples of vari‐ous compactness subjected to different freeze-thaw cycles under varied confining pressure.According to Figure 4a,under a confining pressure of 50 kPa,the stress-strain curves of the samples with three rela‐tive compaction values without freeze-thaw all dem‐onstrate strain-softening behavior.The freeze-thaw cycling has an evident influence on the stress-strain characteristics of samples with 95%relative compac‐tion,with its strength decreased significantly.The stress-strain curves of the samples with various compactness subjected to freeze-thaw cycling are of the strain-softening type and gradually converge,indicating that the freeze-thaw process has different influences on samples with different compactness,and the internal structure and particle arrangement tend to become consistent.It can be seen from Figure 4b,for samples with 90%relative compac‐tion,the stress-strain curve tends to transform into strain-hardening with the increase of confining pressure,which also reflects that the freeze-thaw process strengthens the stress-strain characteristics of less compacted samples.

Figure 4 Stress-axial strain curves from triaxial compression tests of samples with various compactness with or without freeze-thaw cycling

The freeze-thaw processes lead to water migration within the sample,with the surface moisture content higher than the internal one.The reason is that the soil-rock mixture sample has poor thermal conductivi‐ty,delaying the heat transfer between the sample sur‐face and the inside.During freezing,the sample sur‐face cools before the interior,resulting in the freezing of the surface water and migration of moisture from the interior towards the freezing front on the surface.The formation of ice crystals in the pores near the sur‐face leads to volumetric expansion and decreases the dry density.During thawing,the sample surface tem‐perature rises first,leading to the melting of ice crys‐tals near the surface,while the sample interior temper‐ature rises slowly.Under the joint action of soil water potential gradient and temperature gradient,part of the water generated by thawing near the surface flows back to the interior.When the relative compaction is high,the pores between the particles are relatively small,reducing the water conductivity and diffusivity of the soil,which is not conducive to water migration.Consequently,when the sample is refrozen during the next freeze-thaw cycle,more water will freeze to form ice crystals,causing larger volumetric expansion and more damage between the particles.

3.2 Variation of static strength

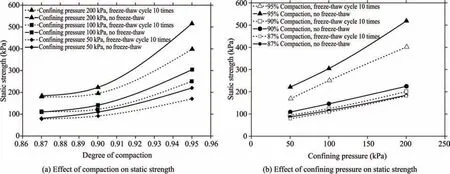

Different methods are used to define the failure stress(termed as static strength in this paper)for stress-strain curves with strain-softening or strainhardening behavior.For strain-softening curves,the deviatoric stress value at the peak point is taken as the failure strength.For the strain-hardening curves,the deviatoric stress corresponding to 15%axial strain is taken as the failure strength(Ministry of Transport of the People's Republic of China,2020).The static strength of the samples with different compactness af‐ter ten freeze-thaw cycles is depicted in Figure 5.

Figure 5 Static strength of samples subjected to freeze-thaw cycles

According to Figure 5a,the failure strength will increase significantly with the increase in relative compaction,and the rate of growth gradually increas‐es.The higher the relative compaction is,the greater difference between the failure strength before and after freeze-thaw cycling.This phenomenon indicates that the strength damage caused by freeze-thaw cycling to the soil-rock mixture will increase with the increase in relative compaction under the optimal moisture content.The reason is that the pore volume of the samples with higher relative compaction is relatively low,which is not enough to accommodate the volumetric expansion from the freezing of pore water.Hence,the structure of the soil-rock mixture with higher relative compaction is damaged more significantly.

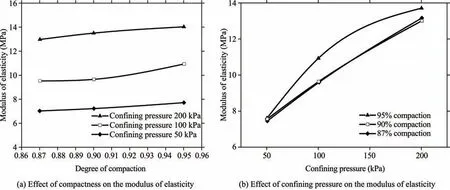

In fact,the confining pressure will help compact the sample,too.And the higher the confining pres‐sure,the larger the relative compaction.On the con‐trary,the freeze-thaw cycles will increase the pore volume,leading to a decrease in sample compactness.After sorting the data in Figure 5b into Table 4,one can see that under the combined action of confining pressure and freeze-thaw cycles,the failure strength loss ratios of the soil-rock mixture with relative com‐paction of 95%and 90%are stable.The pore volume of the sample with 87%relative compaction is larger,and the effect of confining pressure on its compact‐ness is stronger.Therefore,for the samples with 87%relative compaction,the confining pressure can"re‐pair"the strength loss after freeze-thaw cycles to a certain extent.The higher the confining pressure is,the higher the degree of repair is.

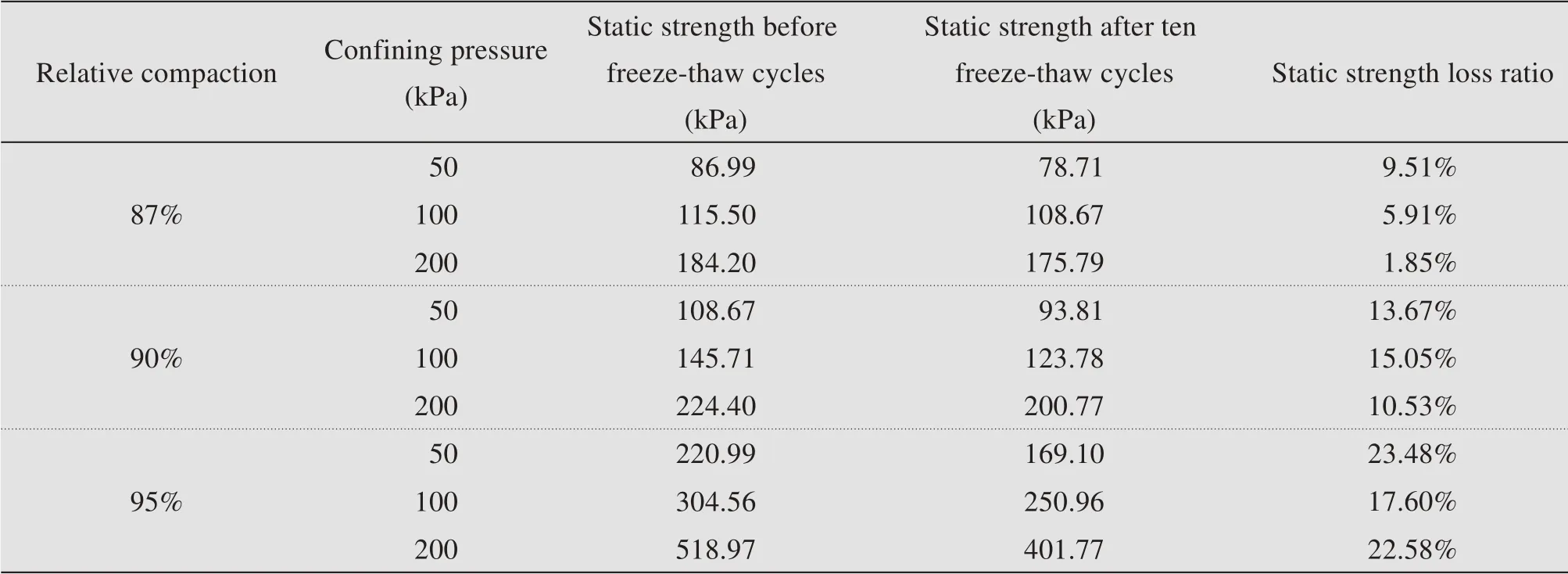

3.3 Modulus of elasticity

In this paper,the secant modulus at which the axi‐al strain increases from 0 to 1/3 of the strain corre‐sponding to the static strength is defined as the elastic modulus of the soil-rock mixture.

According to Figure 6a,the degree of compaction is not the main factor influencing the elastic modulus of the soil-rock mixture.Still,in general,the increase in relative compaction can slightly improve the elastic modulus of the soil-rock mixture.It can be seen from Figure 6b that the elastic modulus of the soil-rock mix‐ing rises the increase of confining pressure,revealing a prominent effect of the confining pressure on the stiff‐ness of the mixture.The reason is the soil-rock mixture is a loose accumulation of granular materials.Under triaxial compression,the confining pressure restricts the lateral deformation of the soil-rock mixture,and hence enhances its resistance to vertical deformation,i.e.,the material stiffnessor elastic modulus.

Table 4 Loss of static strength due to freeze-thaw cycles

Figure 6 Modulus of elasticity of samples subjected to freeze-thaw cycles

3.4 Shear strength

Mohr-Coulomb failure criterion is the most wide‐ly used soil shear strength theory,in which cohesion,c,and internal friction angle,φ,are used to represent shear strength.While cohesion is mainly determined by the distance between particles and the bonding force of cementing materials,internal friction angle primarily reflects the friction characteristics between particles,including sliding friction and interlocking.The shear strength parameters are found by using the method of Mohr circles,and the influence of freeze-thaw cycles on the parameters is analyzed in this section.

3.4.1Cohesion

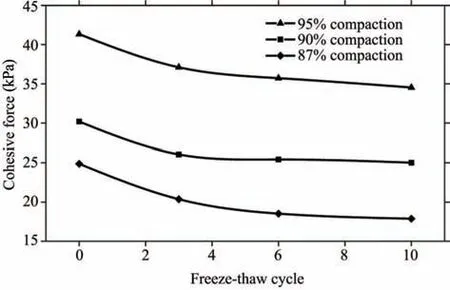

The variation in the cohesion of the soil-rock mix‐ture with the number of freeze-thaw cycles is shown in Figure 7.With the increase in the freeze-thaw cy‐cles,the cohesion values of samples with various compactness decreases gradually and tends to be sta‐ble.By comparing the variation of the three curves,it can be found that the freeze-thaw effect of the sam‐ples with higher relative compaction lasted longer.At the initial few freeze-thaw cycles,the formation of ice crystals leads to the increase in the distance between soil particles and weakening of the cementation be‐tween particles,resulting in the decrease in the soilrock mixture cohesion.The higher the degree of com‐paction,the greater the reduction in cohesion.For soil samples with lower relative compaction,the soil struc‐ture reaches dynamic equilibrium after several freeze-thaw cycles since there is enough space for wa‐ter to freeze and expand.In other words,the effect of freeze-thaw cycling on the less compacted samples only occurs in the early few freeze-thaw cycles,and the effect of phase transition on the cohesion is relatively small.

Figure 7 Variation in the cohesion with the number of freeze-thaw cycles

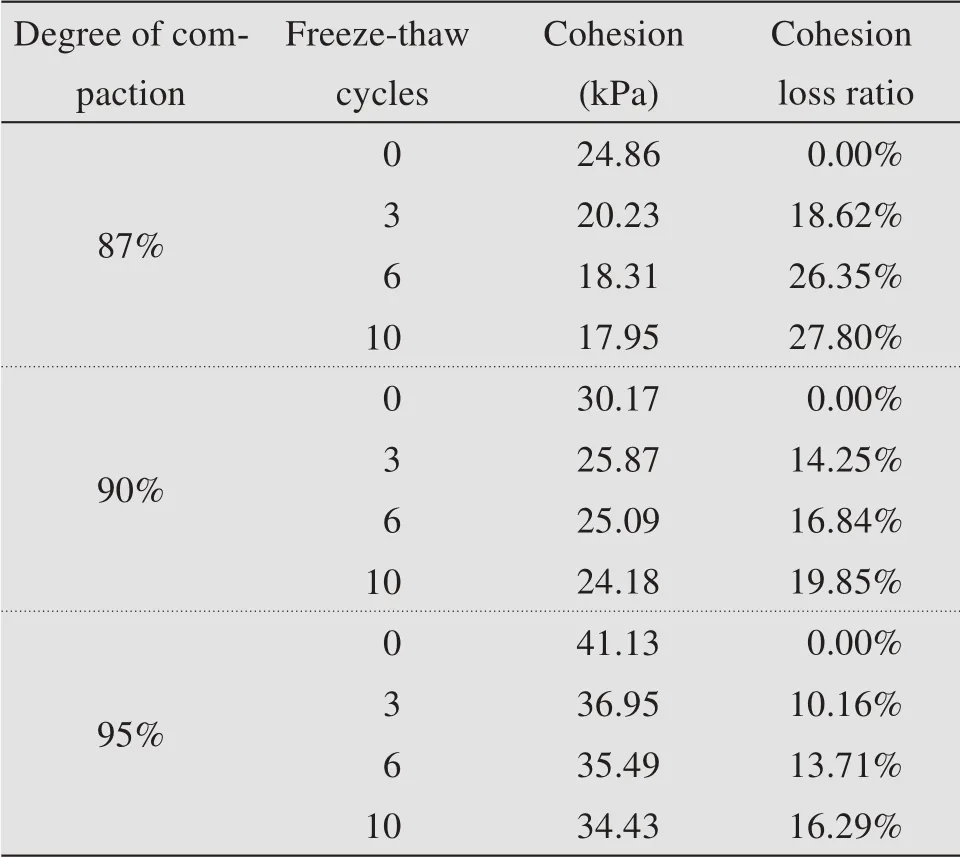

The cohesion of samples under different compact‐ness and freeze-thaw cycles and its decrease in rela‐tion to the value without freeze-thaw is listed in Table 5.It can be seen from Table 5 that freeze-thaw cy‐cling has a significant impact on the cohesion of the soil-rock mixture samples.Specifically,the cohesion of the samples with different compactness all decreas‐es significantly at the initial few freeze-thaw cycles and continues to decrease gradually with the number of freeze-thaw cycles.After ten freeze-thaw cycles,the cohesion of the samples with 87%,90%,and 95%relative compaction decreases by 27.8%,19.9%,and 16.3%,respectively.

3.4.2Angle of internal friction

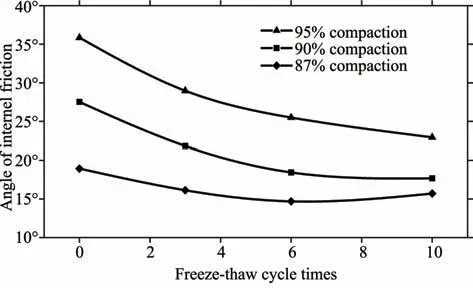

The influence of freeze-thaw cycles on the inter‐nal friction angle is illustrated in Figure 8.With the in‐crease in the freeze-thaw cycles,the internal friction angle of the samples with 95%and 90%relative com‐paction decreases gradually.In comparison,the inter‐nal friction angle of the samples with 87%relative compaction declines first and then rises.During freeze-thaw cycling,the increase in the interparticle distance caused by the formation of ice crystals can significantly reduce the interlocking friction.After freeze-thaw cycles,the water migration within sam‐ples of different compactness could increase inter‐nal friction angle,and this phenomenon is more evi‐dent for samples with lower relative compaction(Hu,2017).In other words,the decrease in friction resistance caused by frost heave and the increase in internal friction due to water migration co-occur within a freeze-thaw cycle.The total frictional resis‐tance as reflected by the internal friction angle may fluctuate depending on which one of these two actions dominates.

Table 5 Cohesion of samples with different compactness

Figure 8 Variation in internal friction angle with the number of freeze-thaw cycles

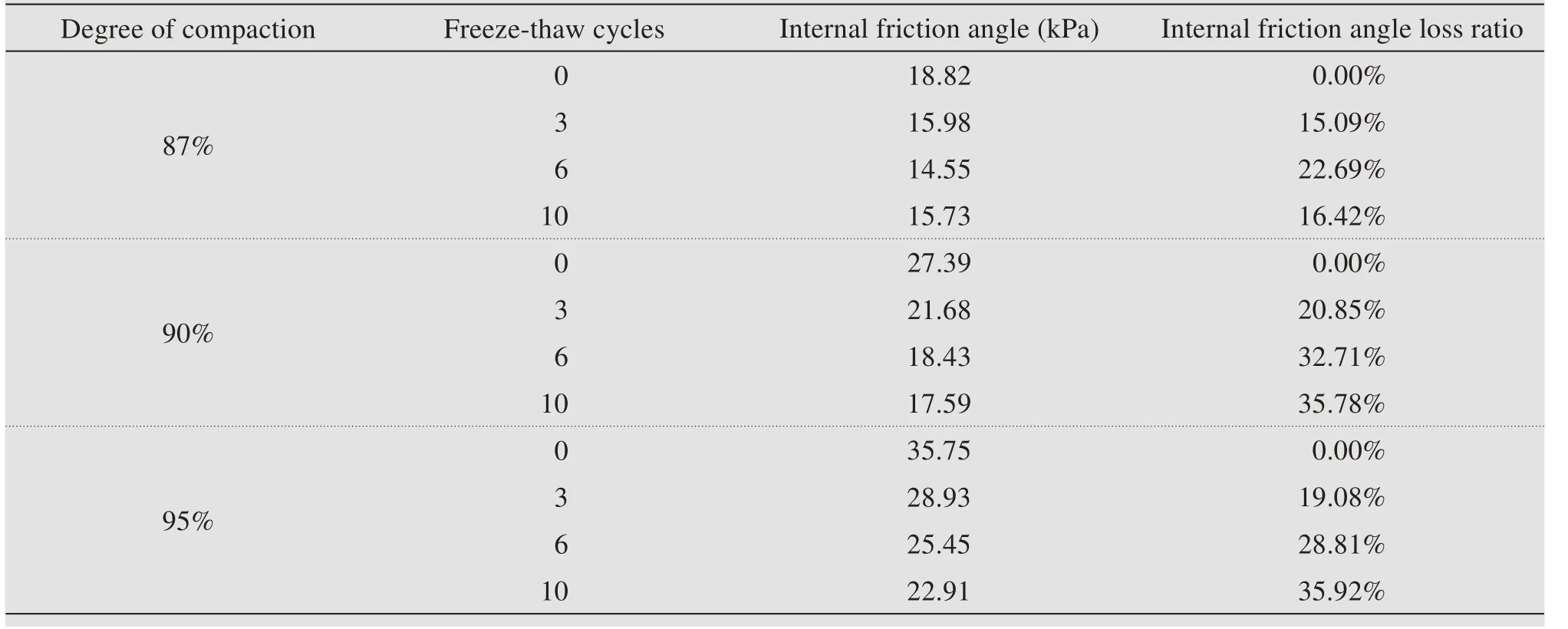

The variation in the internal friction angle and its loss ratio with compactness and freeze-thaw cycles is summarized in Table 6.The internal friction angle of samples with different compactness all decreases.Moreover,the higher the degree of compaction,the more the reduction in internal friction angle.After ten freeze-thaw cycles,the internal friction angle of sam‐ples with 87%,90%,and 95%relative compaction de‐ creases by 16.4%,35.8%,and 35.9%,respectively.

Table 6 Variation in internal friction anglesof samples with different compactness and freeze-thaw cycles

4 Simulation of particle flow

As an emerging software for discrete element sim‐ulation,particle flow code(PFC)has been widely used in numerical simulation of rock and soil.The particle flow approach adopts Newton's equation of motion and can model large deformation.Its capabili‐ty of simulating individual particle movement is very suitable for analyzing materials with large size differ‐ences,such as a soil-rock mixture.

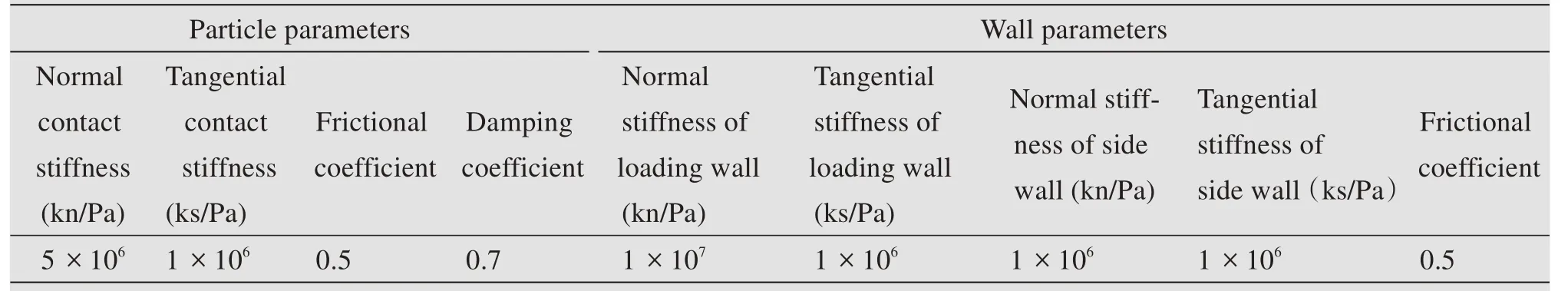

Particle flow simulation models have the same size as the cylinder specimens ofΦ300×600 mm used in the triaxial tests.Specifically,particles larger than 5 mm were modeled according to the actual di‐mensions.However,particles less than 5 mm were not modeled and assumed to be 5 mm due to limited com‐puting power.The servo and loading program of the in‐door triaxial test is simulated.Confining pressure is im‐plemented through the side boundary of the model,and vertical loading is carried out through the upper and lower loading plates of the model.According to the cal‐ibration method proposed by Chen et al.(2013)the test data,the particle flow simulation parameters are obtained and presented in Table7 and Table 8.

Table 7 Parameters for particle flow simulation

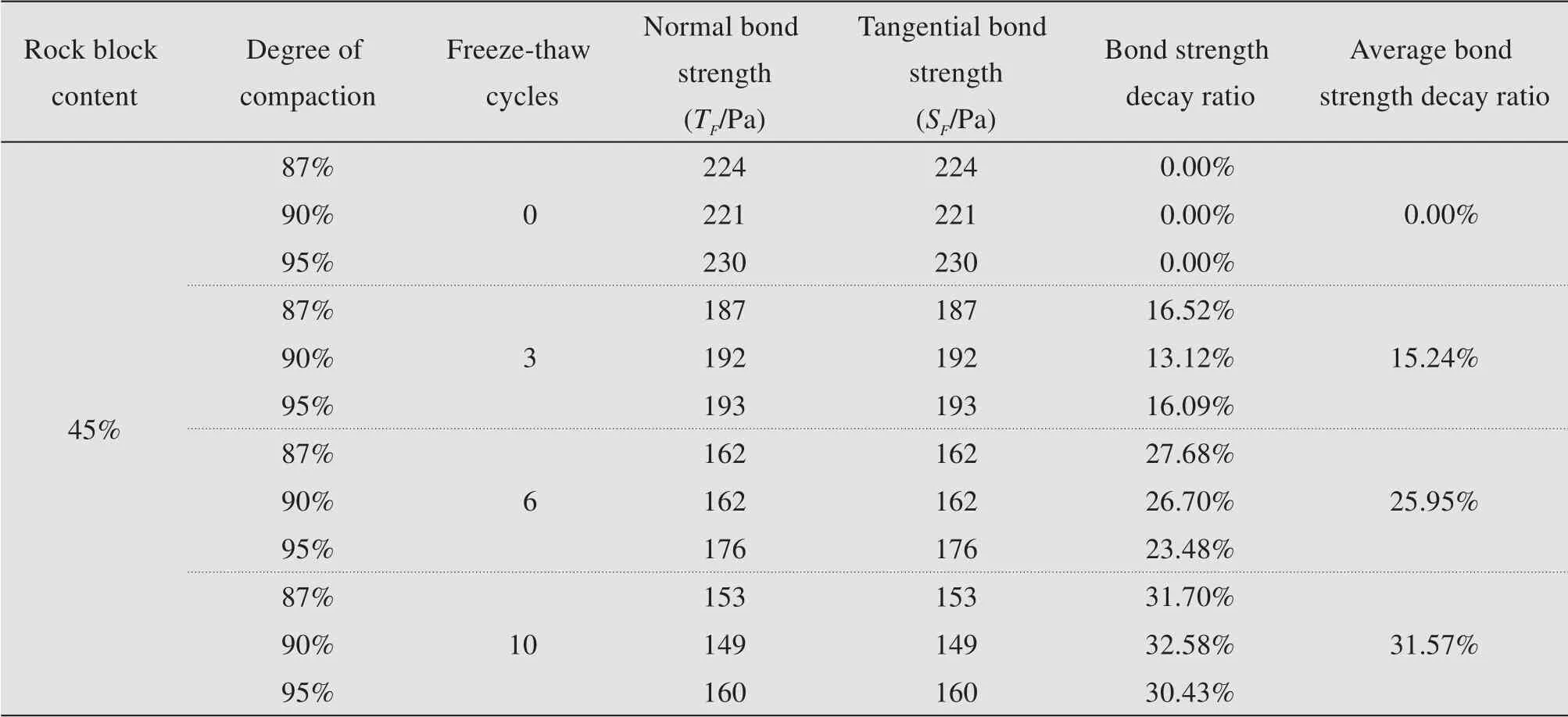

In particle flow simulation,the point bond contact model can be used to simulate the tensile and shear strength of the particle contacts in the mesoscopic model.It is assumed that the freeze-thaw cycle only damages the contact strength between particles.The effect of the freeze-thaw cycles on the mesostructure is simulated by the change in the normal and tangen‐tial bond strength,as listed in Table 8.

Since only porosity is used in PFC,relevant pa‐rameters such as the maximum and minimum porosity should be determined based on the relative compac‐tion.To this end,the method proposed by Guo(2016)was adopted.The simulation steps are:

(1)The maximum porosity.Based on the loose filling simulation method,the sample mixture is poured to freely deposit in a box under gravity and form the loosest state for evaluating the maximum porosity.

(2)The minimum porosity.Based on the vibration table method,the upper loading plate is pressurized,and the bottom wall is set to a sinusoidal motion to simulate the vibration.The vibration stops when the change in the amplitude of vibration diminishes,and the particles reach the most compacted state.

Table 8 Relationship between the bond strength and number of freeze-thaw cycles in PFC

In addition,studies have shown that particle sur‐face friction coefficient has a greater impact on poros‐ity,and different friction coefficients correspond to different maximum and minimum porosity.Therefore,samples with different porosity will be generated for different friction coefficients,and the relationship be‐tween the maximum and minimum porosity of the sample and the particle surface friction coefficient can be obtained.Then the corresponding porosity is calcu‐lated according to the formula of relative compaction.

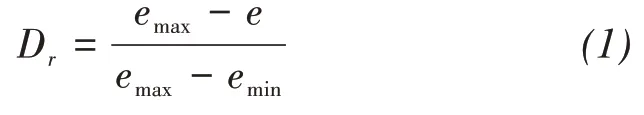

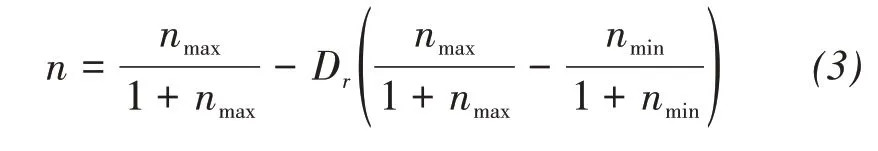

The calculation formula of relative density Dris:

where e is the void ratio;emaxand eminare the maxi‐mum and minimum void ratio,respectively.Void ratio e can be obtained through porosity n:

Substitute Equation(2)into Equation(1):

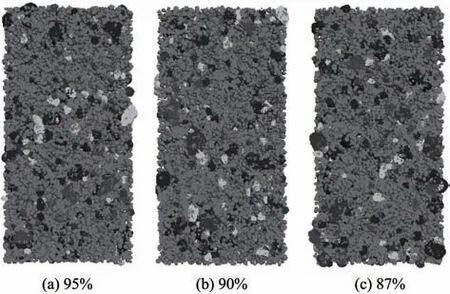

where nmaxand nminare the maximum and minimum po‐rosity,respectively.Based on these equations,the po‐rosity values of the particle flow models correspond‐ing to relative compaction of 0.95,0.90,0.87 are set to 0.29,0.32,0.34,respectively,as illustrated in Fig‐ure 9.In the particle flow models,spheres(gray)rep‐resent soil particles smaller than 5 mm,while nonspherical particles are stone blocks larger than 5 mm(black and white).

Figure 9 Particle flow models with different compactness

The stress-strain behavior of the particle flow models was simulated by PFC.For example,Figure 10 compares the simulated stress-strain relationships with those obtained from the indoor triaxial test for samples subjected to ten freeze-thaw cycles.

It can be seen from Figure 10 that the trend of the simulated stress-strain curves is consistent with that of the experimental results.Furthermore,the strain-soften‐ing behavior of the stress-strain curves obtained by nu‐merical simulation is more prominent than that ob‐tained from laboratory experiments.It can be seen that the microstructure of particles is changed during freezethaw cycles.The weakening of microstructure makes the particles"loose",which affects the macroscopic mechanical properties.The numerically simulated and experimentally derived results show that the damage hypothesis of the meso-structure contact interface is correct,but the difference between them may be due to the actual shape and distribution of the rock blocks that are hard to duplicate in the particle flow model.

Figure 10 Comparison of simulated and experimental stress-strain relationship for samples subjected to ten freeze-thaw cy‐cles at confining pressure of 50 kPa

Figure 11 depicts the internal pores of samples with different compactness at the end of the test.When the relative compaction is high,the pore distri‐bution is relatively uniform,the pore volume expands due to the freezing of pore water,and the degradation of the freeze-thaw cycle is more significant.As the relative compaction decreases,the pore distribution becomes uneven.As the freeze-thaw cycling contin‐ues,the volume expansion in the zones with large voids is more significant,leading to accumulative de‐terioration around the same zones.

Figure 11 Fracture distribution of samples with different compactness

5 Conclusions

Based on the experimental study on the effects of freeze-thaw cycling on the mechanical properties of the soil-rock mixture under different compactness,the following conclusions are drawn:

(1)At a higher degree of compaction and lower confining pressure,the samples demonstrate strain-soft‐ening behavior In contrast,at a lower degree of compaction and higher confining pressure,the samples exhibit strain-hardening behavior.Under the action of freeze-thaw cycles,the peak strength of samples with a high degree of compaction decreases significantly,whereas that of samples with a low degree of compac‐tion is less affected.For confining pressure of 100 kPa,the static strength loss is 17.60%for the sample with 95%relative compaction,15.05%for the sample with 90%relative compaction,and only 5.91%for the sample with 87%relative compaction.

(2)The static strength of the samples with differ‐ent compactness decreases with the increase in the number of freeze-thaw cycles and eventually stabiliz‐es.The static strength and other indicators of the sam‐ples with higher relative compaction(90%,95%)show a downward trend with an increasing number of freeze-thaw cycles,and the strength loss rate under different confining pressures is the same.However,the strength loss of samples with a low degree of com‐paction(87%)is greatly influenced by the"repair"ef‐fect of high confining pressure.The decrease in the static strength of samples with a low degree of com‐paction gradually decreases from 9.51%at confining pressure of 50 kPa to 1.85%at confining pressure of 200 kPa.

(3)For soil-rock mixtures with different initial compactness and freeze-thaw cycles,the nature of the contact interface between particles is destroyed during freeze-thaw cycles,leading to a weakened mesostructure.For the soil-rock mixture with higher relative compaction or smaller porosity,it is more af‐fected by freeze-thaw.Its macroscopic mechanical properties decrease as the number of freeze-thaw cy‐cles rises.

(4)Freeze-thaw cycling significantly affects the cohesion of samples with a low degree of compac‐tion(87%)but has little effect on its internal friction angle.However,for samples with a high degree of compaction(90%,95%),freeze-thaw cycling has sig‐nificant effects on both cohesion and internal friction angle.

Acknowledgments:

The study presented in this article was supported by Research Grant No.50908234 and No.51778634 from the National Science Foundation of China.

Sciences in Cold and Arid Regions2021年5期

Sciences in Cold and Arid Regions2021年5期

- Sciences in Cold and Arid Regions的其它文章

- Strength characteristics and energy dissipation evolution of thawing silty clay during cyclic triaxial loading

- Impact of brine on physical properties of saline soils

- Study on thermal-state variation of high-grade highway embankment under different pavement conditions

- Field monitoring of differential frost heave in widened highway subgrade

- Numerical simulation of electroosmosis in unsaturated compacted clay

- Study on tensile damage characteristicsof sandstone under freeze-thaw cycles