Study on tensile damage characteristicsof sandstone under freeze-thaw cycles

Hui Liu ,YeHui Yun ,Long Jin ,JiangHao Lin ,Yao Zhang ,Yong Luo ,JianXi Ren *

1.Collegeof Architecture and Civil Engineering,Xi'an University of Science and Technology,Xi'an,Shaanxi710054,China

2.CCCCFirst Highway Consultants Co.LTD,Xi'an,Shaanxi 710075,China

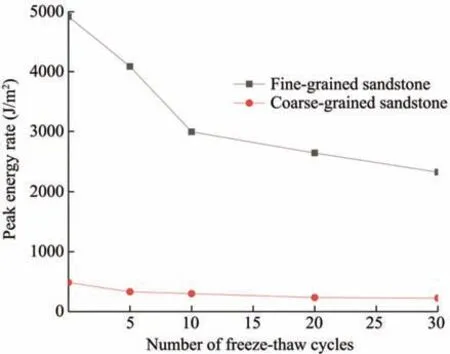

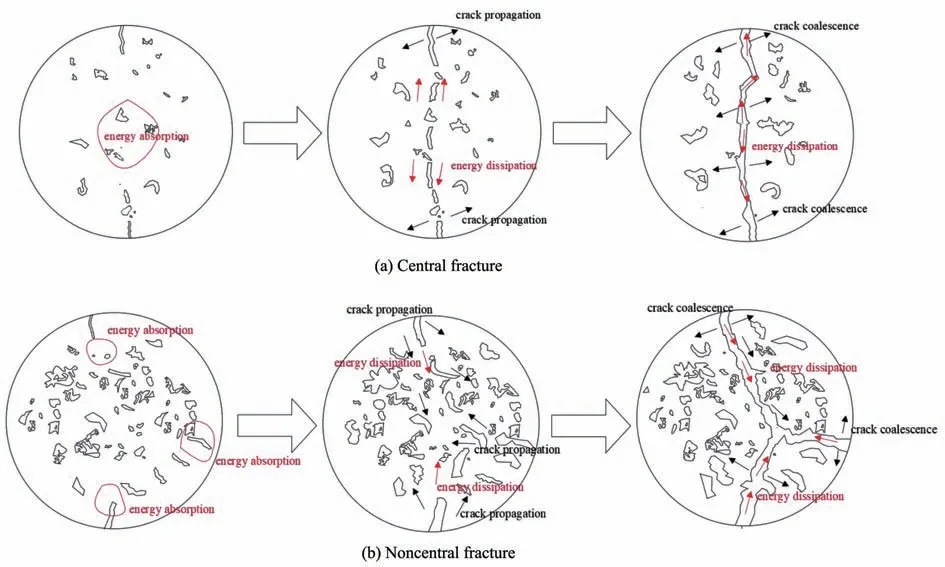

ABSTRACT The meso-structure of sandstone has a significant effect on its mechanical properties under external loads.In this paper,by taking two types of sandstone with different grain sizes as the study objects,the effects of grain size and freeze-thaw cycles on tensile strength and damage mode of sandstone are analyzed using a combination of laboratory tests,theoretical analysis,and numerical calculation.The Brazilian splitting tests are carried out on sandstone samples subjected to freeze-thaw cycles.The results show that:(1)The Brazilian splitting mode of the fine-grained sandstone is dominated by the central fracture,whereas that of the coarse-grained sandstone is controlled by a noncentral fracture.(2)The freeze-thaw cycles aggravate the initial damage of sandstone,and the cumulative freeze-thaw damage has a greater impact on the Brazilian splitting damage mode of the coarse-grained sandstone than on the fine-grained sandstone.(3)The numerical analysis software RFPA 2D system can simulate the Brazilian splitting failure process of the two types of sandstone with varying grain sizes under different freeze-thaw cycles.It is shown to be an effective method to reveal the tensile failure process and deterioration mechanism of sandstone under freeze-thaw cycling.(4)The formation mechanisms of the two splitting modes are analyzed according to the energy principle.The energy release of coarse-grained sandstone forms a noncentral splitting mode along the rock sample internal weak structural plane,whereas the fine-grained sandstone sample's energy accumulates in the rock sample center and releases it instantaneously at its center,showing the failure mode of central splitting.In addition,based on damage mechanics theory,the damage evolution equation of sandstone subjected to freeze-thaw cycles under tension is established,and the influence of energy release and dissipation on the sandstone's tensile properties is quantitatively analyzed.

Keywords:freeze-thaw;sandstone;damage mode;energy

1 Introduction

Tensile failure is a severe problem in rock tunnel‐ing,rock roof and floor failure,rock drilling,and min‐eral extraction technology.In particular,the tensile strength of rocks is considerably lower than their com‐pressive strength.China is one of the countries with an extensive distribution area of cold regions,and the persistent freezing and thawing regions account for more than 70%of the total land area(Xu et al.,2010).Rocks in cold regions are frequently exposed to vari‐ous types of weathering,among which cyclic freezethaw is one of the most common and destructive weathering factors.Cyclic freeze-thaw causes signifi‐cant damage to the construction and maintenance stag‐es of geotechnical operations(Zhang et al.,2004;Lai et al.,2012).The tensile performance of rocks subject‐ed to freeze-thaw cycles has become an important me‐chanical index for evaluating the stability of geotech‐nical engineering structures in cold regions;the ten‐sile strength of rocks is an essential parameter in the design and stability analysis of rock structures.Under‐standing sandstone's tensile failure process and dam‐age characteristics under freeze-thaw cycles is essen‐tial for practical engineering in cold regions.

Thus far,many studies have been done on rock de‐terioration caused by freeze-thaw cycles(Altindag et al.,2004;Karaca et al.,2010;Mustafa and Ismail,2015;Walbert et al.,2015;Wang et al.,2016).Al‐though an in-depth understanding of the effect of freeze-thaw cycling on the physical properties and compressive strength properties of rocks has been es‐tablished,limited attention has been paid to sandstone tensile properties.Nova et al.(1990)developed an anisotropic tensile failure criterion for an orthotropic material using an asymmetric tensile strength tensor to describe the directional dependency of strength.The tensile properties of rocks at normal atmospheric tem‐perature have been studied by some scholars(Niu et al.,2012;Basu et al.,2013;Yang et al.,2019).Wang et al.(2020)investigated the effect of bedding on crack growth characteristics under tensile loading.Rock has apparent anisotropy under the Brazilian splitting test(Hou et al.,2016;Qi et al.,2019).Liu et al.(2016)found that the tensile strength of rock is affected by the internal bedding structure,and it decreases with the in‐crease of bedding angle.Furthermore,the tensile prop‐erties of red sandstone are more sensitive to freezing and thawing(Zhang and Yang,2012),as the rock's mesostructure changes in a freeze-thaw environment(Liu et al.,2016).Water content has an important in‐fluence on the mechanical properties of freeze-thaw conditioned sandstone(Zhang and Yang,2013).

In summary,most of the previous studies focused on the mechanical properties of rocks at normal atmo‐spheric temperatures,and the research of rock me‐chanical properties at low temperatures mainly focus‐es on compressive properties.There are few studies on the tensile failure process and failure mode of freeze-thaw rock.However,the failure process and failure mode of freeze-thaw rock in tensile state have an important influence on engineering structure in cold regions.This paper describes the tensile failure process and failure mode of rock under low tempera‐ture.From the energy perspective,this paper discuss‐es the different tensile failure modes and damage evo‐lution characteristics of two types of sandstone with different grain sizes at low temperatures.It provides a reference for the stability evaluation of engineering structures in cold regions.

2 Materials and test procedures

2.1 Specimen preparation

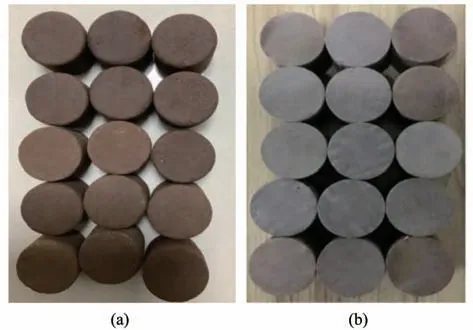

Two types of rock samples were collected from Weinan and Xianyang for comparative analysis.The rock samples have good homogeneity and integrity.Both types of sandstone are argillaceous cemented.The rock samples are mainly composed of gravel and argillaceous cementation.According to conventional rock mechanics test standards,the rock samples are 50mm×50mm cylindrical specimens with a height-todiameter ratio of 1:1(Figure 1).

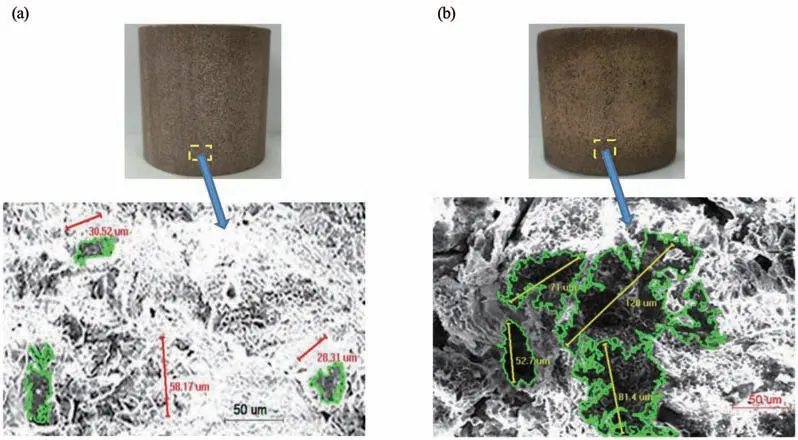

Figure 1 Test sample.(a)the coarse-grained sandstone;(b)the fine-grained sandstone

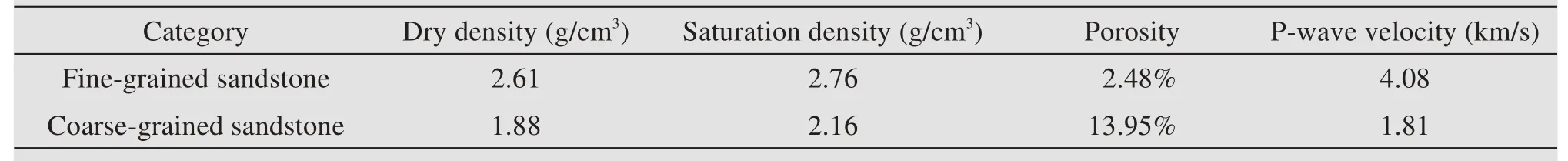

A wave velocimeter was used to measure the lon‐gitudinal wave velocity of the rock samples,select the rock samples in similar wave velocity and divide them into a group to ensure similar initial damage and physical properties among groups of rock samples.There are five groups of each type of sandstone and three blocks in each group.All rock samples were placed in an oven to dry at 105°C for 24 h,and the dried rock sample was placed in a drying dish to cool to room temperature.Subsequently,the rock samples were saturated using a vacuum saturation instrument(vacuum for 2 h and saturated for 22 h),and their mass and size were measured after saturation.The av‐erage values of the initial physical parameters of the two types of rock samples are listed in Table 1.

Table 1 Average values of initial physical parameters of two types of rock sample

2.2 Test procedures

The test procedure is as follows:

(1)Observe the surface microstructure of two types of rock samples with a scanning electron micro‐scope(SEM).The magnification of the SEM can vary from 20 to 15,000 times;for this test,a magnification of 400 times was selected.

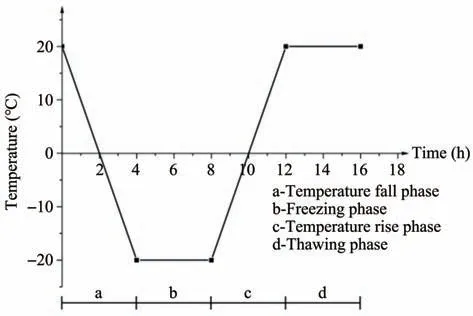

(2)All rock samples were conditioned in a TMS9018-R20 programmable low-temperature ther‐mostat(Figure 2).The TMS9018-R20 programmable low-temperature thermostat has a temperature range of?30 to 40℃,a temperature accuracy of±0.5℃,and can be programmed to a specific number of freeze-thaw cycles at a temperature range.According to the temperature situation in cold regions of China and"the rock test regulations of hydropower and wa‐ter conservancy projects",the temperature range of freeze-thaw cycling selected for this test is?20 to 20℃.The samples were frozen at?20℃for four h and thawed at 20℃for four h to form a freeze-thaw cycle.The temperature conditions of freeze-thaw cy‐cling test are shown in Figure 3.There are five groups in each type of sandstone,with each subjecting to 0,5,10,20,or 30 freeze-thaw cycles.

Figure 2 View of the TMS9018-R20 programmable low-temperature thermostat

Figure 3 Schematic diagram of temperature conditions for freeze-thaw cycling test

(3)A WDW-100 low-temperature electronic uni‐versal testing machine(Figure 4)was used to conduct the Brazilian splitting test on the rock samples.

Figure 4 View of the WDW-100 low-temperature electronic universal testing machine

3 Test results and discussion

3.1 Initial mesostructure and damage

A SEM was used to observe the two types of rock samples,and the initial mesostructure images are shown in Figure 5 with the observation positions indi‐cated.The pores and grains were measured and marked(Figure 5).

SEM test results demonstrate that the initial dam‐age degrees of the two types of sandstone are quite different.There are few micro-cracks and micro-pores between the fine-grained sandstone mineral particles,the area of these micro-cracks and pores is small,and their distribution is relatively sparse.The structure be‐tween the mineral particles is compact,and no notice‐able cracks exist.In contrast,the area of the pores and micro-cracks in the coarse-grained sandstone is larger,their distribution is compact,the surface is rougher,and the structure between the mineral particles is loose and broken.The initial damage of the finegrained sandstone is significantly less severe than the coarse-grained sandstone.

3.2 Brazilian splitting test results for freeze-thaw conditioned sandstone

3.2.1 Tensile strength change law

After 0,5,10,20,and 30 freeze-thaw cycles,the two types of sandstone were subjected to the Brazil‐ian splitting test.According to Formula(1),the tensile strengthσxis calculated,and the average tensile strength of each group of the rock sample is obtained,as shown in Figure 6.where P is the maximum load value(N)when frac‐ture failure of the specimen occurs,and R and L are the diameter and height of the cylindrical rock speci‐men(m),respectively.

Figure 5 Microstructure of two types of sandstone.(a)fine-grained sandstone;(b)coarse-grained sandstone

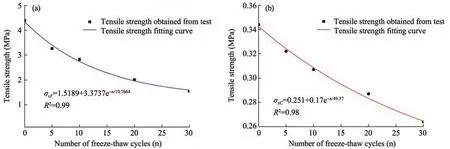

In Figure 6,σxFis the fitting value of tensile strength of the fine-grained sandstone,andσxCis the fitting value of tensile strength of the coarse-grained sandstone.

Figure 6 Relationship between the number of freeze-thaw cycles and tensile strength of two types of sandstone.(a)the fine-grained sandstone;(b)the coarse-grained sandstone

The ability of the two types of sandstone to with‐stand external load is weakened,and their tensile strength decreases with the increase in the number of freeze-thaw cycles.The tensile strength of the two types of sandstone has the largest attenuation ampli‐tude during the first ten freeze-thaw cycles.Apparent‐ly,the relationship between their tensile strength and the number of freeze-thaw cycles can be represented by an exponential function.The tensile strength of the fine-grained sandstone is approximately 8?10 times that of the coarse-grained sandstone,which is related to the initial structural damage of the rock sample.Compared to the coarse-grained sandstone,the initial structural damage of the fine-grained sandstone is smaller,and the intergranular structure is tighter;when subjected to external loading,the effective bear‐ing area of the cross-section is larger,and thus,the tensile strength is relatively higher.

3.2.2 Failure mode

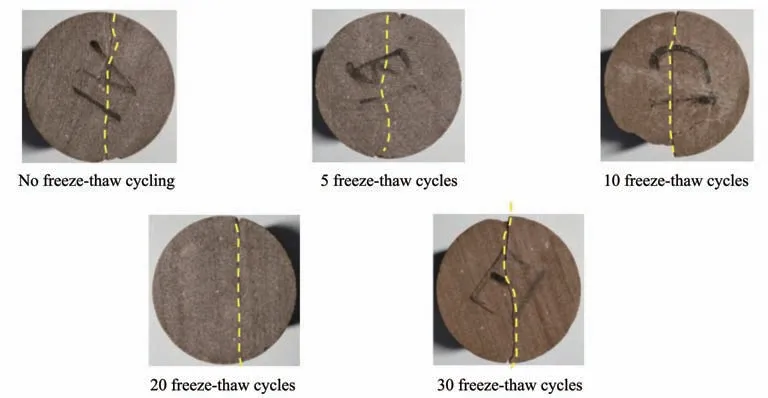

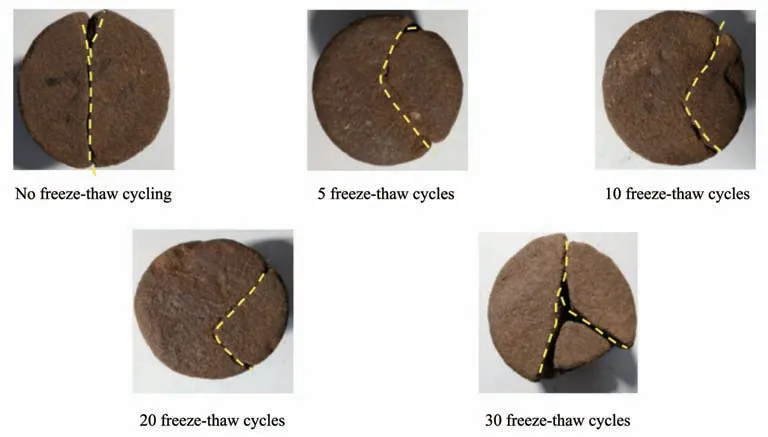

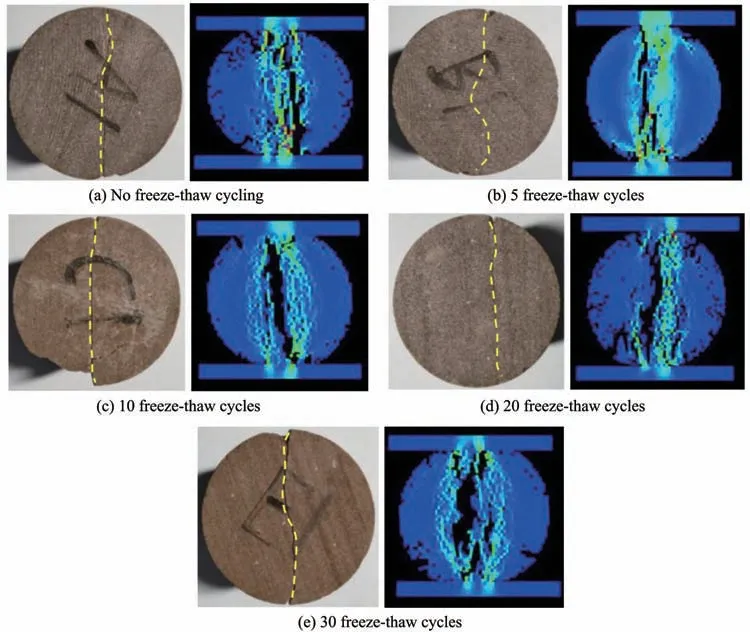

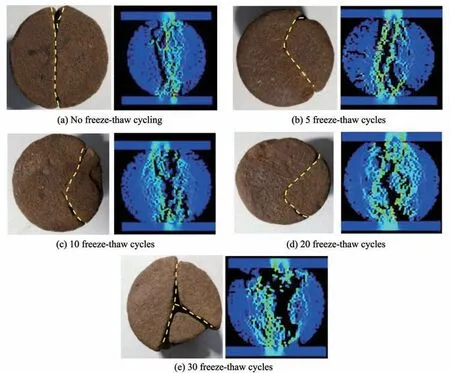

The failure mode diagrams of the two types of rock samples were obtained from the Brazilian split‐ting tests.A group of typical rock samples was select‐ed from each type of sandstone owing to a large num‐ber of images,as shown in Figures 7 and 8.

Figure 7 Brazilian splitting failure mode of the fine-grained sandstone(the yellow dotted line is crack propagation path)

Figure 8 Brazilian splitting failure mode of the coarse-grained sandstone(the yellow dotted line shows crack propagation path)

3.3 Morphological characteristics of split fracture

The macroscopic tensile failure of sandstone is caused by the accumulation of internal microscopic damage.In the tensile failure process,the inoculation and growth of the internal defects leave marks on the fracture(fracture surface).Studying the traces in the destruction process can explain the macroscopic fail‐ure characteristics of sandstone and clarify their fail‐ure mechanism.The fracture morphology character‐istics of two types of sandstone after failure are shown in Figure 9.For the fine-grained sandstone,the fracture surface is smooth and perpendicular to the principal stress direction without an evident deforma‐tion,and the whole is slightly undulating,indicating it is a brittle fracture.The coarse-grained sandstone ex‐hibits a brittle fracture when it is not subjected to freeze-thaw cycling.However,after freeze-thaw cy‐cling,the fracture surface slips,and deformation is no‐ticeable,signifying a ductile fracture.The fracture morphology of the fine-grained sandstone does not change significantly with the sandstone splitting into two whole pieces along the loading direction.Howev‐er,the fracture morphology of the freeze-thaw condi‐tioned coarse-grained sandstone presents significant changes.During the fracture process,the rock sample broke into several pieces,the phenomenon of shed‐ding occurs,and the integrity is low.In summary,the cumulative damage caused by repeated freezing and thawing influences the fracture surface morphology of the coarse-grained sandstone more than that of the fine-grained sandstone.

Figure 9 Fracture morphology of two types of sandstone before and after freeze-thaw cycling

4 Numerical tests and analysis

4.1 Numerical test process and results

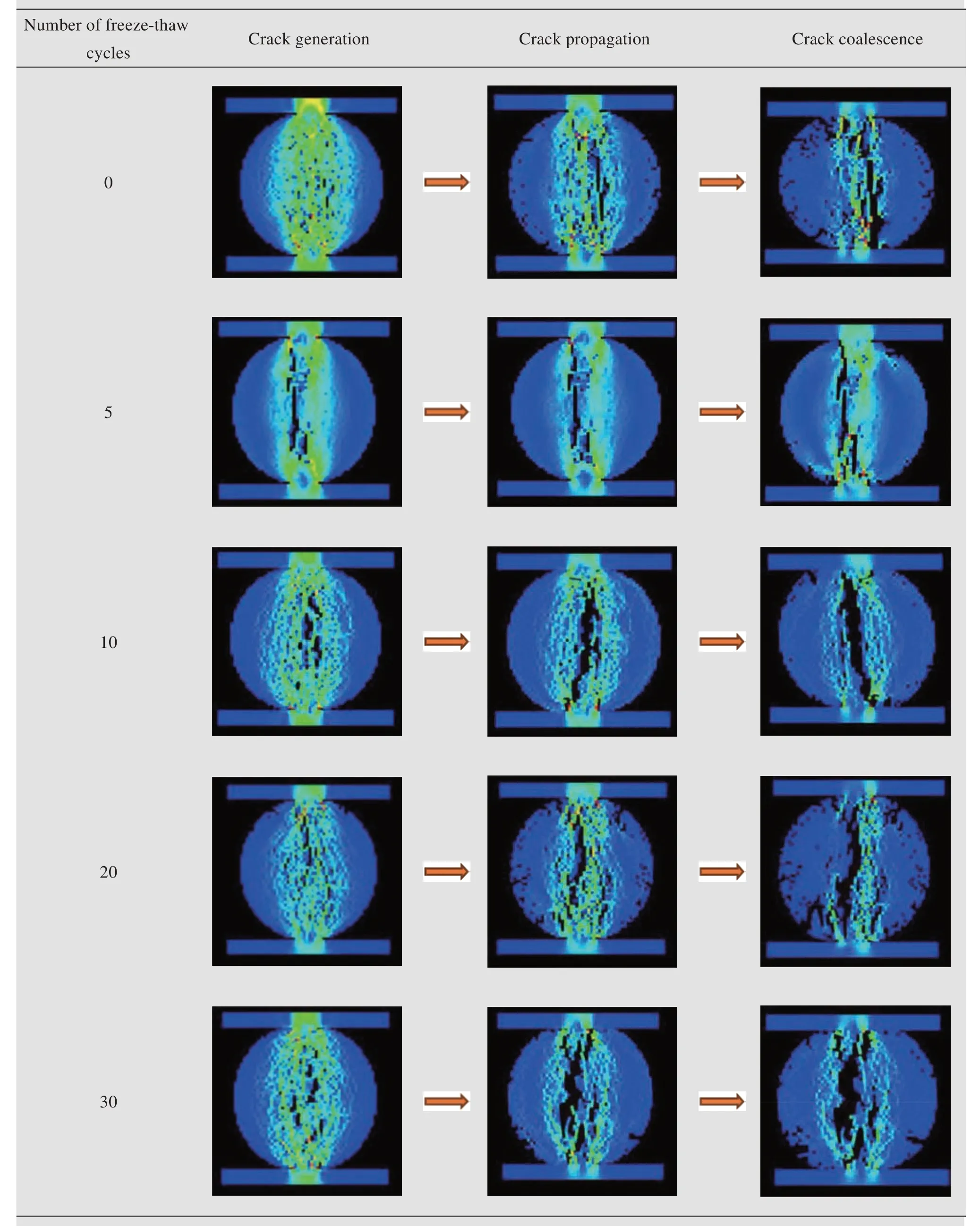

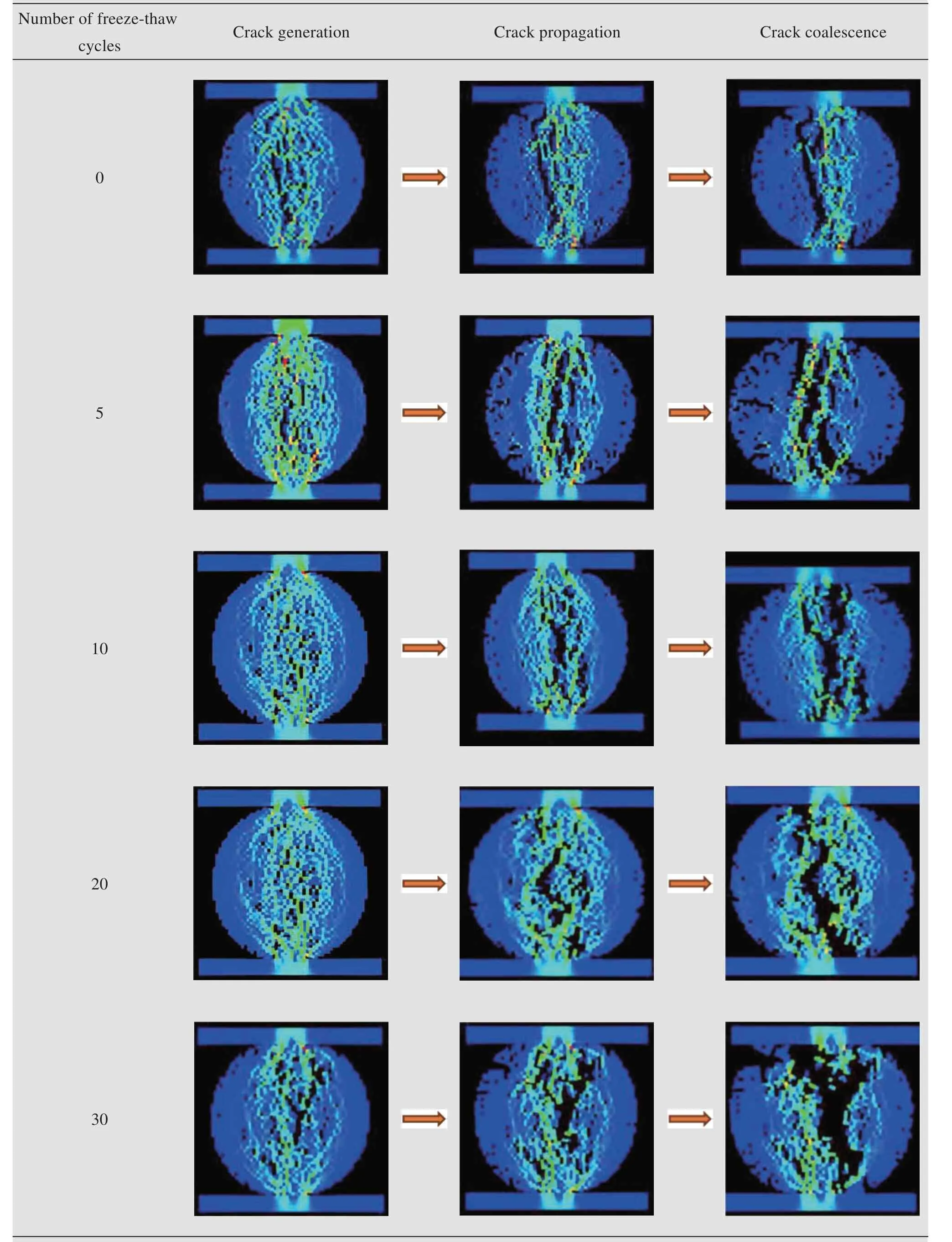

To better explore the tensile failure mechanism of sandstone under freeze-thaw conditions,the RFPA2Dsystem was used to simulate the failure process of both types of sandstone under a different number of freeze-thaw cycles.Numerical tests can further help understand the tensile failure modes and damage char‐acteristics of sandstone.According to the theory of damage mechanics and the principle of strain equiva‐lence,the strain caused by the stressσacting on a damaged material is equivalent to that caused by the effective stress acting on an intact material.The con‐stitutive relationship of the damaged material unit dur‐ing the tensile process of a freeze-thaw sandstone can be obtained by the nominal stress in the intact materi‐al(Zhu et al.,2003),as expressed in Formula(2).

where E and E0are the elastic and initial elastic modu‐li of the damaged element respectively;σandσ~are stress and effective stress respectively;εis strain and D is the damage variable.

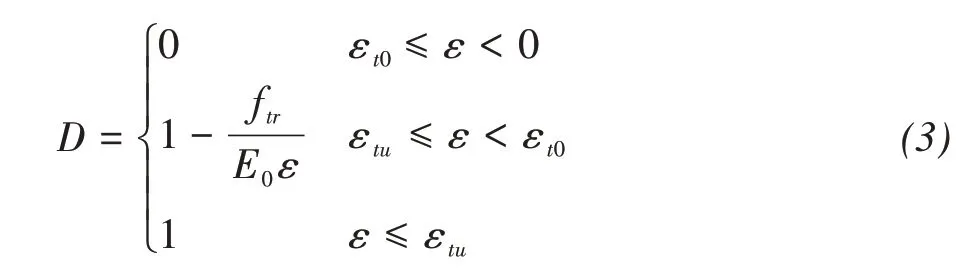

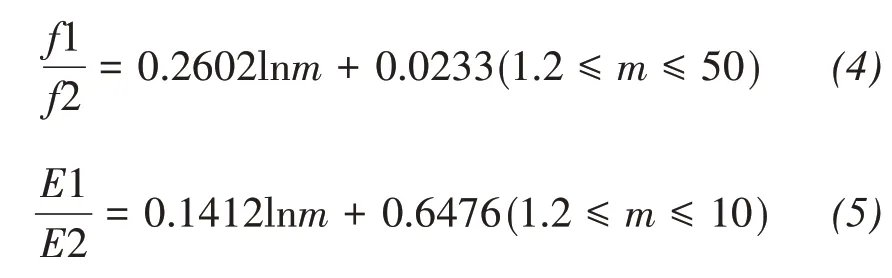

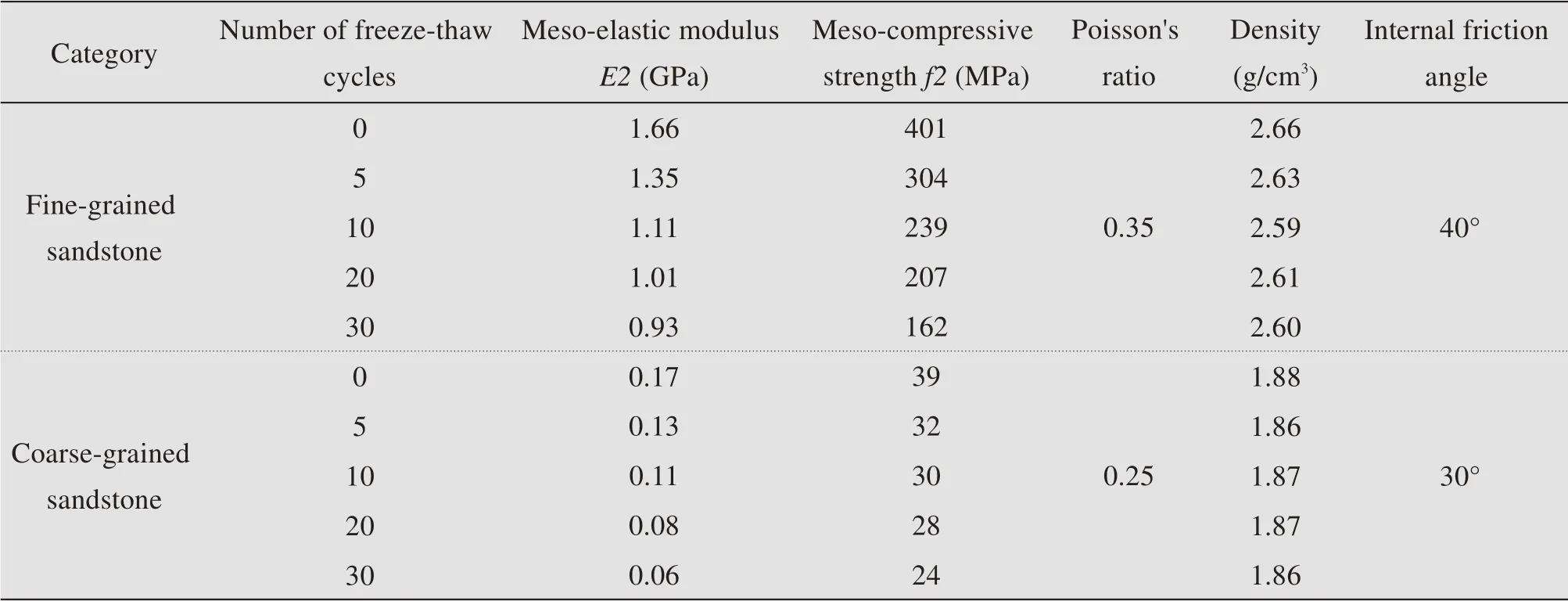

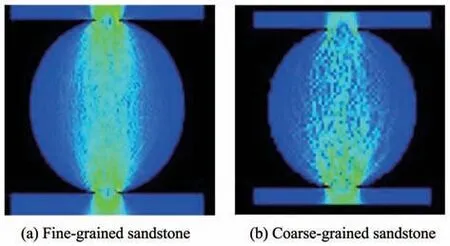

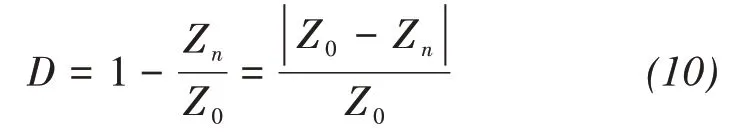

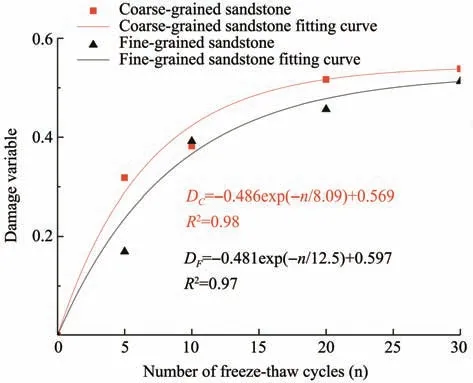

D=0 and 1 correspond to the states of undamaged and completely damaged(fracture or failure),respec‐tively.In addition,0 The element damage variable is expressed as follows: where ftris the residual strength of the element,εt0is the tensile strain corresponding to the elastic limit,that is,the tensile damage strain threshold;andεtuis the ultimate tensile strain of the element.When the el‐ement tensile strain reaches the ultimate tensile strain,the element will be completely damaged and reach a tensile fracture(failure)state.In this case,the damage variable D=1.The size and loading conditions of the numerical test model are consistent with the Brazilian splitting test conditions in the paper. The material parameters set in the RFPA2Dsystem are mesoscopic,while the rock mechanical parame‐ters obtained from conventional mechanical tests are macroscopic.Therefore,it is necessary to convert the macro parameters obtained from conventional mechan‐ical tests into the meso mechanical ones according to Formula(4)and Formula(5)(aslisted in Table 2). In Formulae(4)and(5),f1 and E1 are the com‐pressive strength and elastic modulus in macro-scale,respectively;f2 and E2 are the compressive strength and elastic modulus in mesoscale,respectively.f2 and E2 are input values calculated by RFPA2Dsystem.In RFPA2Dsystem,the distribution of material strength parameters is controlled by homogeneity coefficient m.A larger value of m corresponds to a more uniform rock sample and higher strength.Therefore,the value of homogeneity coefficient m is also related to the test results.After many tests,the homogeneity coefficient m of the fine-grained and coarse-grained sandstone was taken as 3 and 2,respectively.The calculation model diagrams of the two types of sandstone are shown in Figure 10. Table 2 Input parameter values for numerical simulation using RFPA 2D system Figure 10 Rock sample model diagram The RFPA2Dsystem was used to obtain the failure images of two types of sandstone at different stages under tension,as summarized in Tables 3 and 4.Light green indicates stress concentration,the blue rectan‐gles are the upper and lower plates of the loading de‐vice,and the blue disc indicates the rock sample. The numerical simulation results of two types of sandstone under different freeze-thaw cycles are com‐pared with the test results,asshown in Figures11 and 12. The rock sample was discretized into a numerical model composed of meso elements according to RF‐PA.Due to the disorder of mesostructure,the spatial ar‐rangement of the elements is significantly different.This disorder in meso-level just reflects the unique dis‐crete characteristics of the rock sample.Therefore,the numerical simulation effectively reflects the tensile fail‐ure characteristics and failure process of freeze-thaw conditioned sandstone.According to Figure 11 and Figure 12,there are some differences between the fail‐ure modes obtained from numerical simulation and experiment.However,the failure evolution trends and failure patterns of the two types of sandstone from the numerical simulation are consistent with those from the experiment:the tensile failure of fine-grained sandstone exhibits a central fracture mode,whereas the coarse-grained sandstone subjected to freeze-thaw cycling features a clear noncentral fracture. With the increase of freeze-thaw cycles,the crack width and number of fine-grained and coarse-grained sandstone increase significantly.The difference be‐tween the initial microstructure and damage is the main reason for the different tensile failure modes of the two types of sandstone.When the rock is stressed,it is easy to form stress concentration in the internal pores,micro-cracks,and other defects of the rock,so that the rock will be destroyed along these stress con‐centration zones.There are many microcracks and pores in the coarse-grained sandstone.The freezethaw cycling intensifies the growth of initial damage.Under tension,the pores and microcracks in the coarse-grained sandstone experience stress concentra‐tion,leading to crack propagation.With continued ten‐sile loading,the original and new cracks continuously expand,nucleate,and coalesce,producing multiple fracture surfaces;this causes the cracks on the surface of the rock sample to bend and eventually changes the failure mode of the coarse-grained sandstone,forming a noncentral fracture mode.The initial damage of the fine-grained sandstone is small,and the inter-particle structure is tight.Therefore,during tensile failure,crack generation and expansion are approximately parallel to the loading direction,forming a central fracture. Table 3 RFPA 2D simulated crack propagation process of the fine-grained sandstone under different freeze-thaw cycles Table 4 RFPA 2D simulated crack propagation process of the coarse-grained sandstone under different freeze-thaw cycles Figure 11 Comparison of experimental and numerically simulated failure modes of the fine-grained sandstone under different freeze-thaw cycles Figure 12 Comparison of experimental and numerically simulated failure modes of the coarse-grained sandstone under different freeze-thaw cycles Rock failure is an abrupt process caused by energy dissipation under certain conditions.From the perspec‐tive of mechanics,the deformation and failure of rock is a transition from local energy dissipation to local in‐stability to overall instability and destruction.From a thermodynamic perspective,energy dissipation is an ir‐reversible process.In this process,the total work of the external load increases the rock's elastic strain energy.In addition,a part of the energy is dissipated,causing irreversible damage to the rock.Therefore,investigat‐ing the energy dissipation and release process can re‐veal the deterioration mechanism of the tensile proper‐ties of freeze-thaw conditioned sandstone. According to thermodynamics,the transformation of energy is the core of changing the physical and me‐chanical properties of matter.Under an external load,with deformation development,the work done by the external force on a rock sample is continuously trans‐formed into the internal energy of the rock and dissi‐pated.The deterioration of the tensile performance of a freeze-thaw conditioned sandstone is a macroscopic instability phenomenon induced by energy dissipa‐tion.The energy in the process of rock failure can be obtained by the definite integral of the load?displace‐ment curve(Figure 13)(Zhu et al.,2018). where Ziis the energy generated during the loading process of the rock sample,P is the load,x0is the dis‐placement corresponding to the peak load,and x is the displacement generated by the load. The energy of the fracture surface per unit area can be expressed as follows. whereγis the peak energy rate,R and L are the diame‐ter and height of the rock sample,respectively,and Z is the energy generated during loading.Figures 14 and 15 can be obtained from Formulae(6)and(7). Figure 13 Relationship between the Brazilian splitting load and axial displacement of two types of sandstone.(a)The fine-grained sandstone;(b)the coarse-grained sandstone Figure 14 Relationship between freeze-thaw cycles and peak energy rate of two types of sandstone The energy and peak energy rate of the finegrained sandstone are significantly higher than the coarse-grained sandstone(Figure 14).Note that the change in the peak energy rate reflects the difference in the tensile strength of the rock sample,which is closely related to the sample's initial damage.The ce‐mentation of the coarse-grained sandstone is weaker than that of the fine-grained sandstone.Therefore,un‐der freeze-thaw cycling,the internal grain strength and inter-particle bonding of the coarse-grained sand‐stone are reduced.During the tensile failure process,the energy absorbed and dissipated by the coarsegrained sandstone is less than that by the fine-grained sandstone. It can be seen from Figure 15 that during tensile failure of the freeze-thaw conditioned sandstone,as the loading progresses,the energy growth rate be‐comes increasingly higher.Since the microcracks and pores inside the rock sample have not fully expanded and developed in the initial stage of loading,they are in the compaction deformation stage,resulting in small energy absorption and dissipation.As the loading continues,the initial cracks in the rock sample expand,and new cracks are generated.The energy absorption and dissipation are mainly responsible for the continu‐ous expansion of the internal defects in the sample.Therefore,as the axial load ratio increases,the energy growth rate of the rock sample rises.During crack propagation,energy absorption and dissipation occur to overcome the resistance between the particles.Com‐pared with the coarse-grained sandstone,the finegrained sandstone has a dense structure and stronger cementation between grains,so the energy absorption and dissipation of the fine-grained sandstone arelarger. Figure 15 Relationship between the energy of two types of sandstone and axial load ratio.(a)The fine-grained sandstone;(b)the coarse-grained sandstone According to the Griffith strength criterion,the cause of rock fracture is the concentration of tensile stress at the tips of tiny cracks within the rock(Xie et al.,2011;Cai et al.,2013).Cracks propagate along the regions with the lowest energy;in other words,cracks propagate along the path of least resistance(Mao,2018).The part with the lowest energy in the freeze-thaw conditioned sandstone is the area with more defects and damage.The driving force of crack propagation depends on the difference between ener‐gy W released during the crack development,and en‐ergy U required for new plane generation.When the following conditions are reached,a crack will start to expand: The left side of Formula(8)depends on the shape and elastic characteristics of the rock,while the right side is related to the deformation and fracture process that occurs at the crack tip before the unstable crack propagation starts. The critical stressσfrequired for the fracture can be expressed as: In Formula(9),E is the elastic modulus,Gc is the critical energy release rate when the crack grows,andαrepresents half of the crack length,andγis the energy of the fracture surface per unit area.Two new surfaces are produced when the crack propagates,leading to the following crack propagation relation:Gc=2γ. When the external stress is greater than the critical stressσf,the cracks inside the sandstone propagate.The elastic modulus of the sandstone under tension decreases as the number of freeze-thaw cycles increas‐es.It can be seen from Figure 14 thatγdecreases with the increase in the number of freeze-thaw cycles,so does Gc.In summary,based on Formula(9),as the number of freeze-thaw cycles rises,the critical stress required for the rock sample fracture gradually de‐creases,and the degree of deterioration of the tensile performance of the rock sample increases. The difference in the internal damage of two types of sandstone leads to two diametrically opposite fail‐ure modes.Several weak structural surfaces exist in the coarse-grained sandstone,and the expansion of the initial damage is aggravated by freeze-thaw cy‐cling.The weakly cemented surface increases,energy is released along the weak structural surface within the rock sample,and the cracks expand in the direc‐tion that is conducive to expansion(weak cementa‐tion).Thus,the initial damage propagates,penetrates,and generates new cracks along weakly bonded sur‐faces.Original cracks and new cracks propagate,nu‐cleate,and coalesce,eventually developing a noncen‐tral fracture.The initial damage of the fine-grained sandstone is small,and the absorbed energy continu‐ously increases with the load.When the peak load is reached,the energy accumulates at the center of the rock sample,reaches the maximum value,and then re‐leases instantaneously to cause an overall rock failure.The crack propagation induced by energy first evolves in the center of the rock sample and subse‐quently expands along the loading direction,creating the a central fracture. Based on the numerical simulation and laborato‐ry test results,we propose an evolution diagram of the tensile failure mode of sandstone subjected to freeze-thaw cycles.Two failure modes of sandstone with different grain sizes are obtained,and the fail‐ure process is illustrated in Figure 16. Figure 16 Schematics of different failure modes during the Brazilian splitting test The tensile failure of the sandstone shows two modes: (1)Central fracture:The porosity of the finegrained sandstone is small,and the structure between grains is relatively close,which is not conducive to energy dissipation.The tensile stress in the center of the rock sample increases gradually,reaching the ten‐sile strength of the rock and forming a vertical crack through the sample.As the loading continues,the crack gradually expands and propagates along the di‐rection parallel to the loading direction. (2)Noncentral fracture:There are many pores and microcracks in the coarse-grained sandstone,which enhance the anisotropy of rock samples.The crack usually propagates from the edge of a rock sample.Under external load,the generation and propagation of some cracks deviate from the loading direction.The penetration of cracks leads to the rotation of the principal stress direction inside the rock sample,form‐ing multiple fracture surfaces.This situation is also conducive to energy dissipation.With the progress of loading,the crack propagates gradually and deviates from the direction of loading until the rock sample is destroyed. The damage variable is a quantity that describes the degree of internal destruction of a material or structure.Based on the analysis of energy,the energy change during the tensile failure of sandstone can ef‐fectively reflect the damage evolution.Therefore,the damage variable D can be defined as follows: where Z0and Znare the energy produced during the tensile failure of the rock sample that has undergone 0 and n freeze-thaw cycles,respectively. A regression analysis was performed on the dam‐age variables and the number of freeze-thaw cycles,and the results are shown in Figure 17.The damage variables of both types of sandstone increase exponen‐tially with the rise in the number of freeze-thaw cy‐cles,and the correlation coefficients(R2)are greater than 0.95.Their damage evolution is relatively severe in the first ten cycles and gradually stabilizes after the 20th cycle,which is consistent with the trend of the tensile strength.Analyses based on the damage me‐chanics theory show that there is a close correlation between the tensile strength characteristics of the sandstone and energy.Freezing and thawing cause ir‐reversible deterioration of the tensile properties of the sandstone,and the dissipation and release of energy are the internal factors that damage the tensile proper‐ties of the sandstone subjected to freeze-thaw cycles. Figure 17 Relationship between the damage variable and number of freeze-thaw cycles for the two types of sandstone Based on the energy principle and damage me‐chanics theory,combined laboratory tests and numeri‐cal simulations were used to analyze the tensile prop‐erties of sandstone subjected to freeze-thaw cycling.The influence of grain size and the number of freeze-thaw cycles on the tensile properties of sandstone are dis‐cussed from the energy dissipation perspective.The deterioration mechanism of tensile properties and fail‐ure mode and fracture morphology of sandstone with two grain sizes under freeze-thaw cycles are summa‐rized.The main conclusions are as follows: (1)The tensile properties of the two types of sand‐stone decrease with the increase in the number of freeze-thaw cycles.The fracture mode of the finegrained sandstone is dominated by a central fracture,whereas the coarse-grained sandstone often fails with a noncentral fracture.The effect of freeze-thaw cy‐cling on the tensile properties of the coarse-grained sandstone is greater than on those of the fine-grained sandstone. (2)The RPFA2Dsystem can simulate the failure process of the Brazilian splitting of two types of sandstone under different freeze-thaw cycles.It is shown to be an effective method for studying the tensile failure process and deterioration mechanism of freeze-thaw conditioned sandstone. (3)Energy is the main reason for the formation of the two completely different damage modes when the freeze-thaw conditioned sandstone is damaged by ten‐sion.The energy of the coarse-grained sandstone is re‐leased along the weak structural surface inside the rock sample,forming a noncentral fracture.In con‐trast,the energy of the fine-grained sandstone accu‐mulates at the center of the rock sample and is re‐leased instantaneously,creating a central fracture.The damage evolution equation established with the ener‐gy in the tensile failure process as the damage vari‐able can reflect the tensile process and deterioration of the sandstone. Acknowledgments: This research was supported by the National Natural Science Foundation of China(41702339,41971095,11872299),National Key Research and Development Plan(2018YFC0808705),Funded by the Natural Sci‐ence Basic Research Program of Shaanxi Province(2018JQ4026,2020JZ-53)and Key R&D Program of Shaanxi Province(2017ZDXM-SF-082).

4.2 Comparative analysis of numerical and laboratory tests

5 Discussions

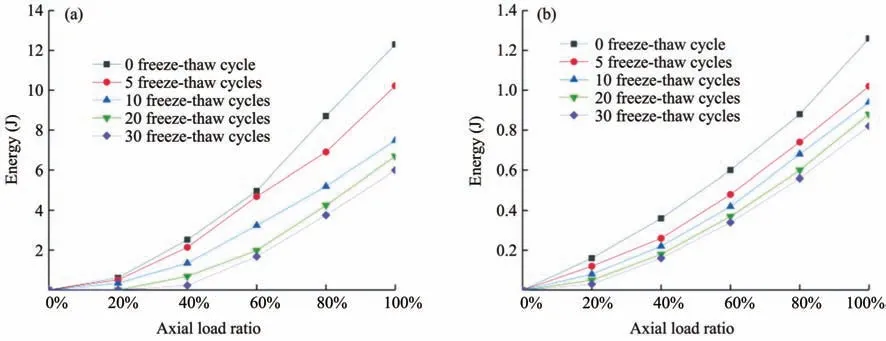

5.1 Influence of freeze-thaw cycles on energy dissipation of sandstone

5.2 Analysis of formation mechanism of tensile damage mode

5.3 Tensile failure modes of two types of sandstone

5.4 Damage evolution analysis based on energy principle

6 Conclusions

Sciences in Cold and Arid Regions2021年5期

Sciences in Cold and Arid Regions2021年5期

- Sciences in Cold and Arid Regions的其它文章

- Study on mechanical properties of soil-rock mixture of various compactness subjected to freeze-thaw cycles

- Strength characteristics and energy dissipation evolution of thawing silty clay during cyclic triaxial loading

- Impact of brine on physical properties of saline soils

- Study on thermal-state variation of high-grade highway embankment under different pavement conditions

- Field monitoring of differential frost heave in widened highway subgrade

- Numerical simulation of electroosmosis in unsaturated compacted clay