Experimental investigation and development of newcorrelation for Influences of temperature and concentration on dynamic viscosity of MWCNT-SiO2(20-80)/20W50 hybrid nano-lubricant

Kazem Motahari ,Mohammad Abdollahi Moghaddam *,Mojtaba Moradian

1 Department of Chemical Engineering,Faculty of Engineering,Arak University,Arak 38156-8-8349,Iran

2 Young Researchers and Elite Club,Malayer Branch,Islamic Azad University,Malayer,Iran

1.Introduction

Nano fluid is a fluid with size of stably suspended particles in the base fluid between 1 and 100 nm.This concept is the first nano fluid classification presented by Choi in 1995[1].Nanoparticle addition triggers changes in thermo-physical properties of standard normal fluids like viscosity and thermal conductivity.Nano fluids'higher transport capacities in comparison with base fluid would have the desirable Influences that these alterations may develop[2].In heat transfer systems,the use of nano fluids would have advantages such as reduction in the size and better heat transfer of heat exchanger[3].In engineering applications,two key fluids are water and ethylene glycol(EG)or their mixture.Some researchers showed that the addition of nanoparticles to these fluids would enhance thermal conductivity;for instance,28.3%enhancement for 5 vol.%of Al2O3/water[4],43%enhancement for 2 vol.%of Cu–TiO2/water–EG(60:40)[5],33.8%enhancement for 2 vol.%of CuO/EG–water(40:60),and 37.5%enhancement for 5 vol.%of Zn O–EG[6].

Viscosity can be considered as the inner fluid resistance of a fluid to flow.For all thermal systems dealing with the fluids,this property is significant.The nano fluids'viscosity depends on various parameters including nano fluids'temperature,nanoparticles'amount,particle sizes and shape,and the way nano fluids have been prepared[7–12].Three prevalent nanoparticles commonly used are carbon nanotubes(CNTs)[15],metal oxides[14]and metallic particles[13].Ghozatlooa et al.[16]studied the effect of morphology of nanoparticles on the nano fluids'viscosity.CNT,graphene nanosheets,and SiO2nanoparticles were dispersed in ethylene glycol and water with 0.05 vol%to 1.5 vol.%volume fraction.The results showed that the viscosity nonlinearly increased with the increase in nanoparticles volume fraction,and the maximum viscosity value related to maximum graphene volume fraction in EG.

In another work,Serebryakova et al.[17]studied thenano fluid physical properties using Al2O3nanoparticles in a solution of 10%water and 90%ethylene glycol.The solid phase volume fractions were in 0–1.5%range.As a function of nanoparticles'volume fraction and shear stress,the rheological properties were analyzed and measured.They reported that the thermal conductivity dependence on solid volume fraction is related to the Maxwell theory[18],but dependence of viscosity significantly surpasses the values estimated by Batchelor theories[20],and Einstein[19].

Moreover,a recently developed nano fluid consisting of various nanoparticles was investigated by researchers.These nano fluids,known as hybrid nano fluids,are mainly constituted from different combination compositions of two species which are suspended in the base fluid[9,21,22].

There are a fewstudies on deriving the thermo-physical properties of hybrid nano fluids from experimental view.As carbon nanotube(CNT)triggers changes on nano fluids thermo-physical properties,in base fluid,dispersing them would have considerable Influences on fluids'dynamic viscosity and thermal conductivity.Moreover,the addition of oxide nanoparticles along with metal nanoparticles or carbon nanotubes would enhance the stability and the carbon nanotubes or metal nanoparticles'suspension[23].The Influence of single-walled carbon nanotube on the lubricants viscosity was investigated by Vakili-Nezhaad et al.[24].Kinematic viscosity of single walled carbon nanotubes/lube oil cuts nano fluids comprised of 0.01 wt%–0.2 wt%single walled carbon nanotubes(SWCNTs)was evaluated experimentally at 25–100 °C.It was found that nano fluids'kinematic viscosity would increase with the decrease of temperature,and increase of particle mass fraction.The viscosity of oilbased SWCNT nano fluid was improved up to 32.94%at a 0.2%mass fraction.

Regarding viscosity,scarce information is available about the nano fluids'viscosity.In this study,dynamic viscosity of hybrid nanolubricant comprising multi walled carbon nanotube(MWCNT)and SiO2was investigated for the first time.In the automotive industry,engine oils have various applications.It has been demonstrated that it would be possible to enhance the pure 20W50 lubrication potential by the addition of nanoparticle.A new correlation was suggested for the prediction of hybrid nano-lubricant viscosity.

2.Experimental

2.1.Materials

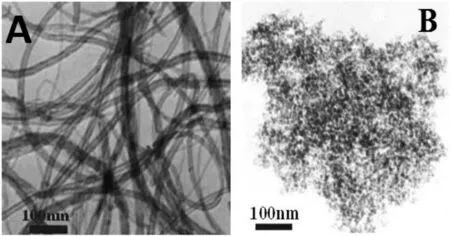

The studied nano fluid was a hybrid nano fluid containing two components:SiO2and multiwalled carbon nanotube(MWCNT)provided by US Research Nanomaterials,Inc.The mean diameters were 40 nm and 20 nm for SiO2and MWCNT respectively.An image by transmission electron microscope(TEM)of both nanoparticles of SiO2and MWCNT can be seen in Fig.1.In addition,physicochemical properties of the MWCNT and SiO2are shown in Table 1.Engine oil was the base fluid with API SJ/CF/CF-4 and SAE 20W50 degree,a product of Behran Oil Company,Iran.The oil properties are listed in Table 2.

2.2.Nano-lubricant preparation

To provide nano-lubricants with nanoparticles'volume fractions in the range of 0.05%,0.1%,0.2%,0.4%,0.8%and 1%,nanoparticles were weighted.In all of the volume fractions the nanoparticles'contributions for MWCNT and SiO2were 20%and 80%respectively.To disperse nanoparticles in the pure 20W50,two-step approach was applied.Two crucial issues in the preparation of nano fluids would be the nanoparticles'agglomeration and sedimentation in the pure 20W50 which should be avoided.Therefore,a magnetic stirrer was applied after the addition of nanoparticles to the pure 20W50 in 2–3 h,to disperse the nanoparticles.Next,a 1200 W,25 k Hz ultrasonic vibrator was applied for suspension system homogenization and agglomerations break down for 3–4 h(USH650 model vibrator,Nano Pars Lima Co.,Ltd.).Because of decreased surfactant concentration found in suspension system there would be no alterations in nano fluid thermos-physical properties(about 0.01 vol%).No sedimentation was noted,after a minimum of 72 h,for all nano-lubricant samples.In Fig.2,all pure 20W50 and nanolubricants are illustrated.

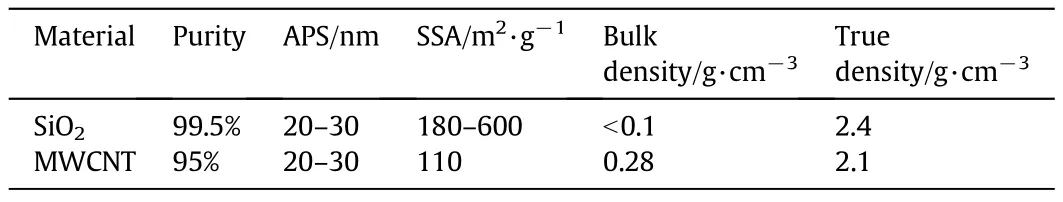

Table 1 Nanoparticles'specification

Table 2 SAE 20W50 engine oil properties

2.3.Dynamic viscosity measurement

For the measurement of MWCNT-SiO2/oil hybrid nanolubricant dynamic viscosity,the MYR V2L rotary viscometer was employed based on ISO 2555/ASTM(Brook field method)provided by Viscotech Hispania.The MYR viscometer has repeatability of±0.2%,and for full scale,has the accuracy of±1%.Moreover,to the MYR viscometer a thermometer is connected to the MYR viscometer to measure the temperature of nano fluid which includes a range between?15 and 180°C,with±0.1°C accuracy,and resolution of 0.1°C.

Fig.1.The TEM image of A)MWCNT[25]and B)SiO2 nanoparticle[26].

Fig.2.Illustrations of nano-lubricant and 20W50 samples.

3.Results and Discussions

3.1.Rheological behavior

In order to perceive the MWCNT-SiO2/oil nano-lubricant behavior,the viscosity was assessed at variousshear stresses.The fluids Newtonian equation is as follows:

where μ is the dynamic viscosity(Poise),τ represents the shear stress(Pa)and˙γ stands for shear rate(s?1).

Fig.3.Viscosity and shear stress regarding shear rate at different temperatures and solid volume fractions.

Fig.4.Viscosity versus volume fraction of nano-lubricant solid at various temperatures.

The viscosity and shear stress of hybrid nano-lubricant as a function of shear rate at different temperatures and at 1%solid volume fraction are shown in Fig.3.It can be observed that the hybrid nano-lubricant shows the Newtonian fluid behavior.Furthermore,the viscosity is closely constant with shear rate variation.

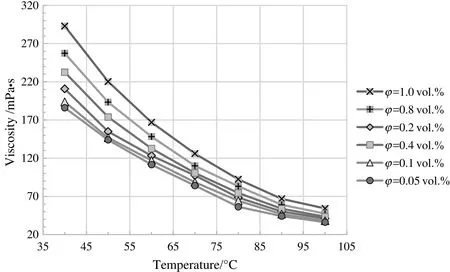

3.2.Solid volume fraction and temperature Influence

The viscosity experimental data versus temperature and solid volume fraction can be seen respectively in Figs.4 and 5.Based on Fig.4,the addition of MWCNT-SiO2in each temperature to the pure 20W50 will lead to increase in viscosity.Moreover,the higher the concentration the higher the viscosity enhancement.

As can be observed from Fig.5,by boosting the temperature,viscosity will increaseat aconstant solid volumefraction.By the increase in temperature,the particles'performance in base fluid is improved.Therefore,the friction is decreased and reduction in viscosity can be expected.

Fig.6 indicates the relative viscosity versus solid volume fraction and temperature.As can be observed,by the increase in temperature,the nano-lubricant viscosity would increase more than the pure 20W50 viscosity.At last,at solid volume fraction of 1%and 100°C temperature,the 171%viscosity increment is achieved.This viscosity improvement can be more helpful in industries than requiring the system to work with higher viscosity at higher temperature.

3.3.Experimental data evaluation by models

In Fig.7,the hybrid nano-lubricant experimental data is compared with that of Pak and Cho[27],Wang et al.[28]and Brinkman[29]models.As can be seen from the above figure,none of the models have adequate potential for the prediction of viscosities data.

4.Correlation Proposal

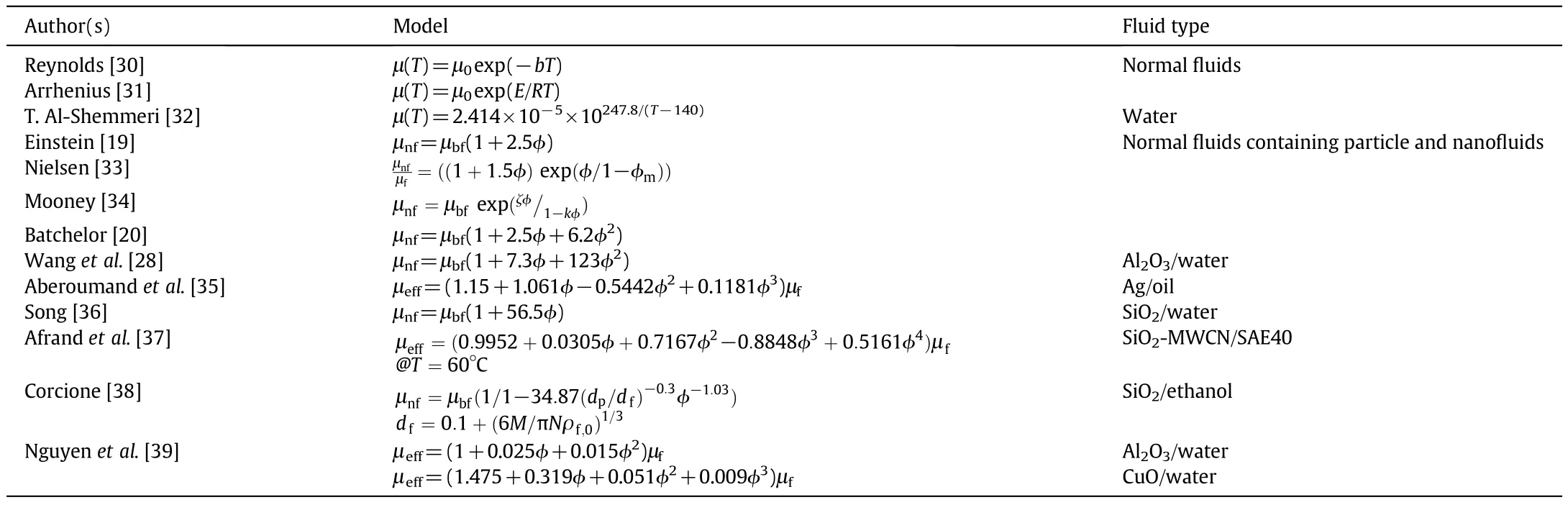

In the engineering applications,often there is a need to show the rmophysical properties in the form of equations or using mathematical software in order to use the nano fluids'properties.Nano fluids and normal fluids dynamic viscosity models,according to solid volume fraction(φ),temperature(T),and activation energy(E)have been reported in several studies,and a summary regarding these findings can be seen in Table 3.

Fig.5.Viscosity versus temperature at various solid volume fractions.

Fig.6.Relative viscosity versus temperature and solid volume fraction.

By obtaining a correlation,the specifications of dynamic viscosity of MWCNT-SiO2/oil hybrid nano-lubricant are evaluated.By considering the temperature and solid volume fraction impacts,the correlation is substantiated.

The proposed correlation would be between 40 and 100°C temperature range and up to 1%of the solid volume fractions.Curve fitting goodness is shown in Table4.Moreover,the average deviation obtained is equal to 1.75%.

Fig.7.The experimental data versus estimated data by models.

Table 3 A summary of the studies concerning viscosity models

Table 4 The regression goodness

The new suggested correlation considering temperature and solid volume fraction is as follows:

Fig.8 shows a comparison between the suggested correlation and the evaluated relative viscosity experimental data.The deviations between suggested model and the viscosity experimental data in the studied temperature range are very low.

4.1.Deviation measurement

Fig.9 indicates the deviation from the target calculated by Eq.(3)in various temperatures and solid volume fractions.As can be observed,the deviations are slight,meaning that the suggested correlation can sufficiently predict the MWCNT-SiO2/oil dynamic viscosity.

5.Conclusions

In this research,different solid volume fractions of 0.05 vol%to 1 vol.%MWCNT-SiO2in pure SAE20W50 were dispersed.Subsequently,the dynamic viscosity at different temperatures of 40 to 100°C was assessed applying MYRrotary viscometer for each solid volumefraction.The results illustrated that by the increase in solid volume fraction,the relative viscosity would be improved.At the other extreme,at a certain solid volume fraction,increase in temperature leads to increase in relative viscosity at a specific solid volume fraction.At 1 vol%solid volume fraction and 100°C temperature,the viscosity enhancement was 171%.Through curve fitting on experimental data,a new correlation for the dynamic viscosity prediction of MWCNT-SiO2/oil was introduced.The suggested correlation and experimental data accommodation showed that the introduced correlation hasgood consistency with experimental data.

Fig.8.Comparison between viscosity experimental data and correlation out put sat various temperatures.

Fig.9.Measured deviation versus nanoparticle volume fraction at various temperatures.

[1]S.U.S.Choi,Enhancing Thermal Conductivity of Fluid s With Nanoparticles,Proc.1995 ASME Int.Mech.Eng.Congr.Expo.,66(1995)99–105.

[2]S.Shamshirband,A.Malvandi,A.Karimipour,M.Goodarzi,M.Afrand,D.Petkovi?,M.Dahari,N.Mahmoodian,Performance investigation of micro-and nano-sized particle erosion in a 90°elbowusing an ANFIS model,Powder Technol.284(2015)336–343.

[3]K.Motahari,M.Abdollahi Moghaddam,A.Rezaei,An experimental investigation of reduced water consumption of coolers using various concentrations of CuO/water nano fluid instead of pure water,4th Annu.Int.Conf.Chem.Chem.Eng.Chem.Process 2016,pp.248–251.

[4]M.Hemmat Esfe,A.Karimipour,W.-M.Yan,M.Akbari,M.R.Safaei,M.Dahari,Experimental study on thermal conductivity of ethylene glycol based nano fluids containing Al2O3nanoparticles,Int.J.Heat Mass Transf.88(2015)728–734.

[5]M.H.Esfe,S.Wongwises,A.Naderi,A.Asadi,M.R.Safaei,H.Rostamian,M.Dahari,A.Karimipour,Thermal conductivity of Cu/TiO2–water/EG hybrid nano fluid:Experimental data and modeling using artificial neural network and correlation,Int.Commun.Heat Mass Transfer 66(2015)100–104.

[6]M.Hemmat Esfe,S.Saedodin,A.Naderi,A.Alirezaie,A.Karimipour,S.Wongwises,M.Goodarzi,M.bin Dahari,Modeling of thermal conductivity of Zn O-EG using experimental data and ANN methods,Int.Commun.Heat Mass Transfer 63(2015)35–40.

[7]H.Li,L.Wang,Y.He,Y.Hu,J.Zhu,B.Jiang,Experimental investigation of thermal conductivity and viscosity of ethylene glycol based ZnO nano fluids,Appl.Therm.Eng.88(2015)363–368.

[8]S.Nabati,J.Jamali,M.Keshavarz,Electrical conductivity,viscosity,and density of different nano fluids:An experimental study,Exp.Thermal Fluid Sci.74(2016)339–346.

[9]A.Menbari,A.A.Alemrajabi,Y.Ghayeb,Investigation on the stability,viscosity and extinction coefficient of CuO–Al2O3/Water binary mixture nano fluid,Exp.Thermal Fluid Sci.74(2016)122–129.

[10]M.K.Meybodi,S.Naseri,A.Shokrollahi,A.Daryasafar,Prediction of viscosity of water-based Al2O3,TiO2,SiO2,and CuO nano fluids using a reliable approach,Chemom.Intell.Lab.Syst.149(2015)60–69.

[11]Gaganpreet,S.Srivastava,Viscosity of nano fluids:Particle shape and fractal aggregates,Phys.Chem.Liq.53(2015)174–186.

[12]G.Colangelo,E.Favale,P.Miglietta,M.Milanese,A.de Risi,Thermal conductivity,viscosity and stability of Al2O3–diathermic oil nano fluids for solar energy systems,Energy 95(2016)124–136.

[13]M.Khoshvaght-Aliabadi,M.H.Akbari,F.Hormozi,An empirical study on vortexgenerator insert fitted in tubular heat exchangers with dilute Cu–water nano fluid flow,Chin.J.Chem.Eng.24(2016)728–736.

[14]T.Perarasu,M.Arivazhagan,P.Sivashanmugam,Experimental and CFD heat transfer studiesof Al2O3–water nano fluid in a coiled agitated vessel equipped with propeller,Chin.J.Chem.Eng.21(2013)1232–1243.

[15]M.Abdollahi Moghaddam,K.Motahari,Experimental investigation,sensitivity analysis and modeling of rheological behavior of MWCNT-CuO(30-70)/SAE40 hybrid nanolubricant,Appl.Therm.Eng.(2017)http://dx.doi.org/10.1016/j.applthermaleng.2017.05.200.

[16]A.Ghozatloo,S.Azimi Maleki,M.Shariaty-Niassar,A.Morad Rashidi,Investigation of nanoparticles morphology on viscosity of nano fluids and newcorrelation for prediction,J.Nanostruct.5(2015)161–168.

[17]M.A.Serebryakova,S.V.Dimov,S.P.Bardakhanov,S.A.Novopashin,Thermal conductivity,viscosity and rheology of a suspension based on Al2O3nanoparticles and mixture of 90%ethylene glycol and 10%water,Int.J.Heat Mass Transfer 83(2015)187–191.

[18]J.C.Maxwell,A Treatise on Electricity and Magnetism Dover Publications,Unabriged Third ed.Vol.One 29(1954)265–273.

[19]A.Einstein,Eine neue bestimmung der moleküldimensionen,Ann.Phys.324(1906)289–306.

[20]G.K.Batchelor,Brownian diffusion of particles with hydrodynamic interaction,J.Fluid Mech.74(1976)1–29.

[21]M.Afrand,D.Toghraie,B.Ruhani,Effects of temperature and nanoparticles concentration on rheological behavior of Fe3O4–Ag/EG hybrid nano fluid:An experimental study,Exp.Thermal Fluid Sci.76(2016)133–138.

[22]M.Asadi,A.Asadi,Dynamic viscosity of MWCNT/ZnO-engine oil hybrid nano fluid:An experimental investigation and newcorrelation in different temperatures and solid concentrations,Int.Commun.Heat Mass Transfer 76(2016)41–45.

[23]W.Duangthongsuk,S.Wongwises,Measurement of temperature-dependent thermal conductivity and viscosity of TiO2–water nano fluids,Exp.Thermal Fluid Sci.33(2009)706–714.

[24]G.Vakili-Nezhaad,A.Dorany,Effect of single-walled carbon nanotubeon theviscosity of lubricants,Energy Procedia 14(2012)512–517.

[25]MWCNTs(>95%,OD:20–30 nm),(n.d.).http://www.us-nano.com/inc/sdetail/228(accessed March 19,2017).

[26]Silicon dioxide(SiO2)nanopowder/nanoparticles(SiO2,99.5+%,20–30 nm,amorphous),(n.d.).http://www.us-nano.com/inc/sdetail/408(accessed March 19,2017).

[27]B.C.Pak,Y.I.Cho,Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles,Exp.Heat Transfer Int.J.11(1998)151–170.

[28]X.Wang,X.Xu,S.U.S.Choi,Thermal conductivity of nanoparticle– fluid mixture,J.Thermophys.Heat Transf.13(1999)474–480.

[29]H.C.Birkman,The viscosity of concentrated suspensions and solution,J.Chem.Phys.20(1952)571.

[30]O.Reynolds,On the theory of lubrication and its application to Mr.Beauchamp Tower's experiments,including an experimental determination of the viscosity of olive oil,Proc.R.Soc.Lond.40(1886)191–203.

[31]S.A.Arrhenius,Influence of temperature on the rate of inversion of sucrose,Z.Phys.Chem.4(1889)226.

[32]T.Al-Shemmeri,Engineering Fluid Mechanics,Bookboon,2012.

[33]L.E.Nielsen,Generalized equation for the elastic moduli of composite materials,J.Appl.Phys.41(1970)4626–4627.

[34]M.Mooney,The viscosity of a concentrated suspension of spherical particles,J.Colloid Sci.6(1951)162–170.

[35]S.Aberoumand,A.Jafarimoghaddam,M.Moravej,H.Aberoumand,K.Javaherdeh,Exp erim ental stud y on the rheological behavior of silver-heat transfer oil nano fluid and suggesting two empirical based correlations for thermal cond uctivity and viscosity of oil based nano fluids,Appl.Therm.Eng.101(2016)362–372.

[36]S.Song,C.Peng,M.A.Gonzalez-Olivares,A.Lopez-Valdivieso,T.Fort,Study on hydration layers near nanoscale silica dispersed in aqueous solutions through viscosity measurement,J.Colloid Interface Sci.287(2005)114–120.

[37]M.Afrand,K.N.Najafabadi,M.Akbari,Effects of temperature and solid volume fraction on viscosity of SiO2-MWCNTs/SAE40 hybrid nano fluid as a coolant and lubricant in heat engines,Appl.Therm.Eng.102(2016)45–54.

[38]M.Corcione,Empirical correlating equations for predicting the effective thermal conductivity and dynamic viscosity of nano fluids,Energy Convers.Manag.52(2011)789–793.

[39]C.T.Nguyen,F.Desgranges,G.Roy,N.Galanis,T.Maré,S.Boucher,H.Angue Mintsa,Temperature and particle-size dependent viscosity data for water-based nano fluids—Hysteresis phenomenon,Int.J.Heat Fluid Flow28(2007)1492–1506.

Chinese Journal of Chemical Engineering2018年1期

Chinese Journal of Chemical Engineering2018年1期

- Chinese Journal of Chemical Engineering的其它文章

- Preparation of water-soluble magnetic nanoparticles with controllable silica coating☆

- Bi-/multi-modal pore formation of PLGA/hydroxyapatite composite scaffolds by heterogeneous nucleation in supercritical CO2 foaming☆

- Comparative experimental study on reactive crystallization of Ni(OH)2 in an airlift-loop reactor and a stirred reactor☆

- The green hydrolysis technology of hemicellulose in corncob by the repeated use of hydrolysate☆

- Determination of 4-nonylphenol and 4-tert-octylphenol compounds in various types of wastewater and their removal rates in different treatment processes in nine wastewater treatment plants of Iran

- Lipid enhancement in microalgae by temporal phase separation:Use of indigenous sources of nutrients