Joint Bearing Mechanism of Coal Pillar and Backfilling Body in Roadway Backfilling Mining Technology

Zhengzheng Cao, Ping Xu,, Zhenhua Li, Minxia Zhang, Yu Zhao and Wenlong Shen

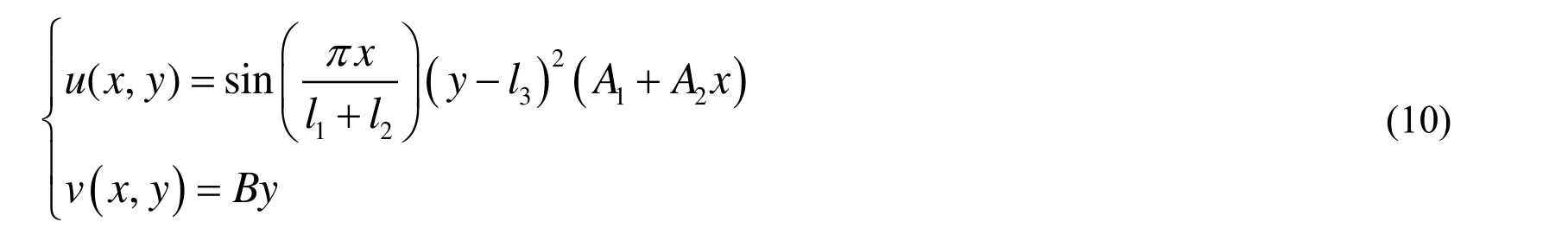

1 Introduction

In order to solve the increasingly serious problem of mining under building, railway and water body at present [Zhou, Guo, Cha et al. (2008); Miao (2012); Cao, Du, Xu et al.(2017)], and reasonably dispose the wastes stacked on the mine like coal gangue and coal ash [Zhang, Zhang, Zhao et al. (2007); Zhang, Miao and Guo (2015); Xin and Ji (2016)],the roadway backfilling mining technology, a kind of safe and high-efficiency coal mining technology, is developed specially and has already obtained good popularizing and application [Qian (2010); Ding, Zhou, Xu et al. (2013); Teng, Wang, Gao et al. (2016)]. In roadway backfilling mining technology, the roadheader is employed for coal cutting in roadway driving work, which conveys the solid backfilling materials, (such as ground gangue, coal ash, loess and aeolian sand) to the mined roadway underground after the materials have been processed on the ground [Miao, Zhang and Guo (2010); Xue, Cao, Cai et al. (2017)], for the purpose of mining three-under coal (coal trapped under buildings,waters-bodies and railways) or the corner residual coal resource, controlling roof in the gob, preventing surface subsidence, and disposing solid wastes [Teng, Wang, Gao et al.(2016); Guo, Li and Liu (2017)]. Therefore, the roadway backfilling mining technology can be adopted for mining three-under coal and corner residual coal in certain conditions in small and medium-size coal mines [Ju, Li, Zhang et al. (2014); Cao, Du, Li et al. (2017)].Advances in the roadway backfilling mining technology over the last ten years have seen various research methods and results [Hu, Zhang, Gao et al. (2006); Qian, Miao and Xu(2008); Miao, Huang and Ju (2012); Jia, Qiao and Jiang (2016); Xue, Ranjith, Gao et al.(2017)]. In order to solve the technical problems of mining strip extraction coal-pillar and waste disposal, Zhang et al. [Zhang, Miao, Mao et al. (2007)] proposed the waste substitution extraction by the roadway backfilling mining technology, which determines the layout with two waste filling roadway (the width and height are 4.0 m and 5.0 m) placed in middle of strip extraction coal-pillar (the width is 4.0 m), by reference to the numerical analysis of the stability of substitution extraction coal-pillar and vertical stress distribution of basic roof in strip and substitution extraction. Li et al. [Li, Mao, Bu et al. (2008)]established the mechanical model of waste-filling in roadway and obtained the elastic displacement solution of coal pillar; based on elastic-viscoelastic correspondence principle,viscoelastic displacement solution of coal pillar was found out by importing Maxwell model, therefore, the rule of the compression and the lateral deformation of coal pillar change with time and backfilling material characteristics was achieved. On the basis of strip mining characteristics, Yu et al. [Yu and Wang (2011)] described the exchanging technology of gangue backfill and analyzed the characteristics of quadratic strata movement, according to subject of strata movement and quadratic stability of coal-pillar under three circumstances exchanged by gangue backfill; Besides, the analytic formula of the bearing body of “bearing rock strata and gangue filling support body” was deduced by means of the elastoplastic theory and based on the actual force and ultimate strength of the gangue filling support body. Deng et al. [Deng, Zhang, Zhou et al. (2014)] proposed the longwall-roadway cemented backfilling mining technology to solve the engineering technical problems in extra-thick coal seam, such as low recovery rate and the difficulty in controlling the mining surface subsidence and overlying strata movement and deformation;meanwhile, the layout of filling mining system, main equipment and technics was explained systematically, based on the principle of longwall-roadway cemented backfilling mining technology in extra thick coal seam. Zhou et al. [Zhou, Li, Zhang et al. (2016)]proposed a roadway backfill method during longwall mining, so as to improving coal recovery and preventing the geohazards in room and pillar mining method in Chinese western coal mines; besides, the reasonable ratio of backfill materials for the driving roadway during longwall mining was determined by testing mechanical properties of backfill materials, and the roadway layout and the backfill mining technique were introduced; meanwhile, the distance between roadways and a driving and filling sequence for multiple-roadway driving was designed, based on the effects of the abutment stress from a single roadway driving task. In order to guard against coal pillar instability, mine earthquake, surface subsidence, vegetation deterioration, and other environmental problems in traditional room mining technology, Zhang et al. [Zhang, Sun, Zhou et al.(2016)] proposed the roadway backfill coal mining method and presented the technical principle and key equipment; further, coal pillar stress, plastic zone change, and surface deformation of the roadway backfill coal mining schemes were studied with the FLAC3D numerical simulation software, and a reasonable mining scheme of “mining 7 m and leaving 3 m” was determined. For the sake of dealing with the low coal recovery and environmental problems caused by the traditional coal mining technology in Chinese western ecological fragile coal mining area, Sun et al. [Sun, Zhang, Yin et al. (2017)]proposed the longwall roadway backfill coal mining method and established the mechanical model of coal mining in stope, on the basis of the strata movement characteristics in the roadway backfill coal mining; then, the equation of roof deflection curve with corresponding mechanical analysis and the calculation formulas of coal pillar were deduced.

It can be seen that the current researches mainly focus on the stability of coal pillar and technical practice in roadway backfilling mining technology. Nevertheless, the joint bearing mechanism of coal pillar and backfilling body is the key to success of roadway backfilling mining technology, which should be research systematically to provide an important basis for theoretical research and process design in roadway backfilling mining technology. In this paper, the elastic and viscoelastic solution expression of coal pillar deformation is obtained by establishing the mechanical model of bearing system of coal pillar and backfilling body, on the basis of basic characteristics of overlying strata deformation in roadway backfilling mining technology. Then, the time formula required for coal pillar and backfilling body to play the joint bearing function is obtained and the joint bearing mechanism of coal pillar and backfilling body in roadway backfilling mining technology is achieved, by analyzing the compressive mechanical property of backfilling body.

2 Mechanical model of bearing system of roadway backfilling mining

The roadway backfilling mining technology is an effective approach to mining the corner residual coal resource and the quality coal resource under buildings, railways, rivers, which is an important part of coal green mining system. The key equipment of roadway backfilling mining technology includes the bulldozer, continuous miner, belt stage-loader mechanism, and high-speed conveyer (fully hydraulically driven). The high-speed conveyer is entirely mounted on a crawler unit. The basic process in the roadway backfilling mining is as follows: firstly, move out related mining equipment after finishing one cycle of roadway mining with continuous miner; secondly, convey backfilling material to the mined roadway with high speed conveyer under coordination of belt stage-loader mechanism; finally, compact the backfilling materials (such as ground gangue, coal ash,loess and aeolian sand) gradually in mined roadway with bulldozer.

The control process of overlying strata movement in roadway backfilling mining technology can be divided into three stages, namely coal pillar bearing stage, backfilling body dynamic compaction stage and coal pillar and backfilling body combined load bearing stage. In the coal pillar bearing stage, the overburden load is mainly supported by coal pillars on both sides of the roadway; In backfilling body dynamic compaction stage,the backfilling body gradually restores bearing capacity under the compaction action of surrounding rock of roadway, which begins to play a role of bearing upper strata; In combined load bearing stage, the coal pillar and backfilling body play the joint bearing effect on the overlying strata, and achieve long time stability.

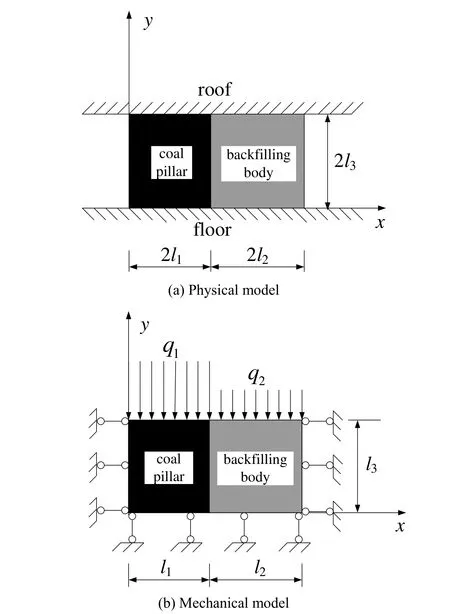

Figure 1: Mechanical model of bearing system of roadway backfilling mining

In the roadway backfilling mining technology, collar pillar is a long cylindrical body, and the support conditions do not vary in length direction; besides, the volume force and surface force parallel to the cross section do not vary in length direction. Meanwhile, the displacement vector in coal pillar is parallel to the cross section, and the axial displacement does not occur. Similarly, this is the same to the backfilling body in the roadway backfilling mining. Therefore, the coupling mechanism of coal pillar and backfilling body in roadway backfilling mining can be attributed to a plane strain problem. In order to analyze the mechanical feature of coal pillar and backfilling body in roadway backfilling mining, the assumptions below are given: the coal pillar and backfilling body are both the continuous,homogeneous and isotropic elastic body; the weak surface does not exist in coal pillar and backfilling body; the full thickness mining method is adopted in roadway backfilling mining, thus the cohesive forces (such as the friction, pressure) exists in the interface between coal pillar, backfilling body and roof, floor; the backfilling body occupies the entire roadway.

The physical model of roadway backfilling mining is shown in Fig. 1(a), which is the overburden movement supported by coal pillar and backfilling body. Thewidth ofcoal pillar is , and the width and height of backfilling roadway is and ,respectively. In consideration of the symmetry of boundary conditions and external loads,the mechanical model is established, by taking a quarter of right-upper coal pillar and a quarter of left-upper coal pillar, which is shown in Fig. 1(b).

According to the symmetry of physical model of roadway backfilling mining, the right boundary of backfilling body and left boundary of coal pillar are both the horizontal simple support constraint; the lower boundary of coal pillar and backfilling body is the vertical simple constraint; the upper boundary condition of coal pillar and backfilling body is the chain constraint in the horizontal direction. Besides, the displacement is continuous in the interface () between coal pillar and backfilling body. Therefore, the displacement boundary condition of mechanical model in roadway backfilling mining is obtained,

In roadway backfilling mining, the load weight of overlying strata is regarded as uniform distributed load;is the average weight of overburden, andis the mining depth of coal seam. The overburden load is supported jointly by coal pillar and backfilling body, namely

Along the roadway in unit length, the sinking displacement of coal pillar and backfilling body can be expressed as follows:

In coal pillar and backfilling body combined load bearing stage, the sinking displacement of coal pillar is equal to that of backfilling body, namely, thus

Combining formula (4) and formula (5), the calculative expression of uniform loadis obtained,

The compressive characteristic of backfilling body is the key point in roadway backfilling mining technology. The related research result [Miao, Zhang, and Guo (2010)] indicates that the exponential function rule exists in stress-strain relationship of backfilling body,

When coal pillar and backfilling body play the joint bearing function in roadway backfilling mining, the stressin backfilling body is equal to the uniform load supported by backfilling body. Combining formula (6) and formula (7), the strain of backfilling body in steady state is obtained,

3 Elastic analysis of coal pillar deformation

The elastic deformation solution of coal pillar is analyzed by the basic principle of Ritz method, according to the displacement boundary condition of mechanics model, the expressions of displacement field, including some undetermined coefficients, are assumed to satisfy displacement boundary condition; then, the specific values of undetermined coefficients are determined by the displacement variation equation; thus, the elastic solution of displacement field is obtained.

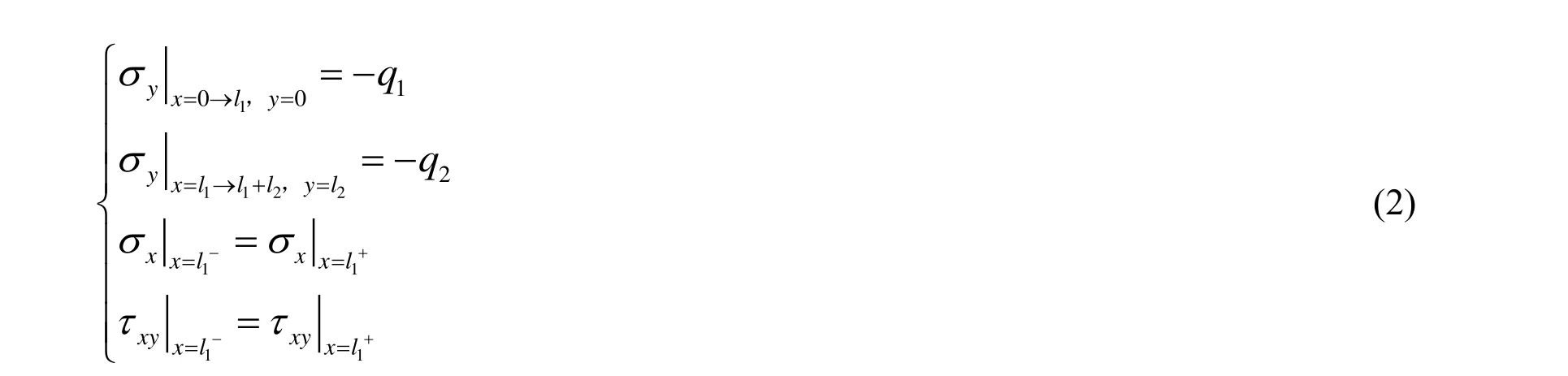

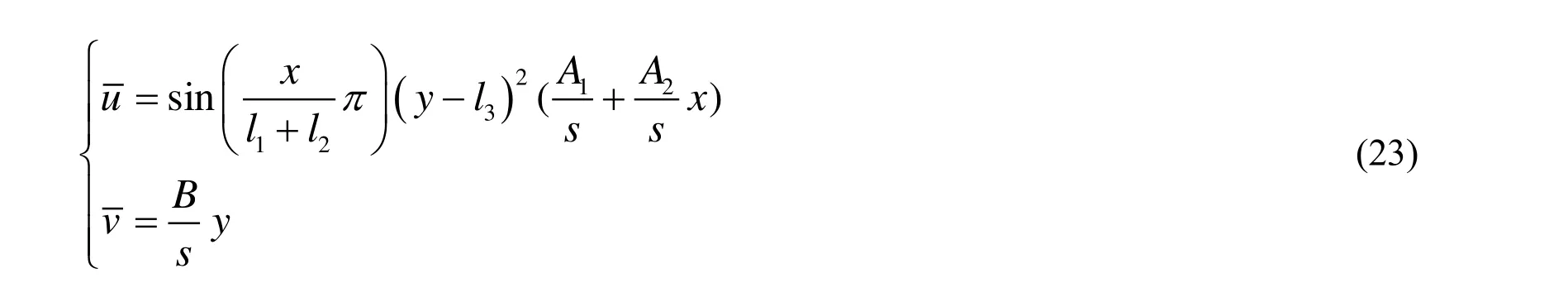

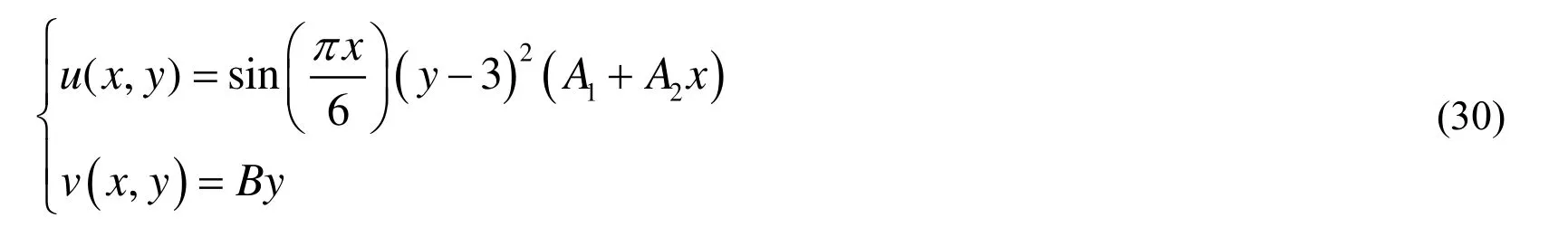

Based on the displacement boundary condition of mechanical model, the displacement field expression is assumed as follows:

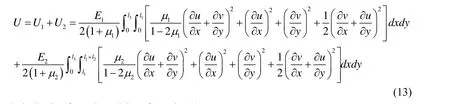

The deformation potential energyof coal pillar and deformation potential energyof backfilling body is expressed as follows:

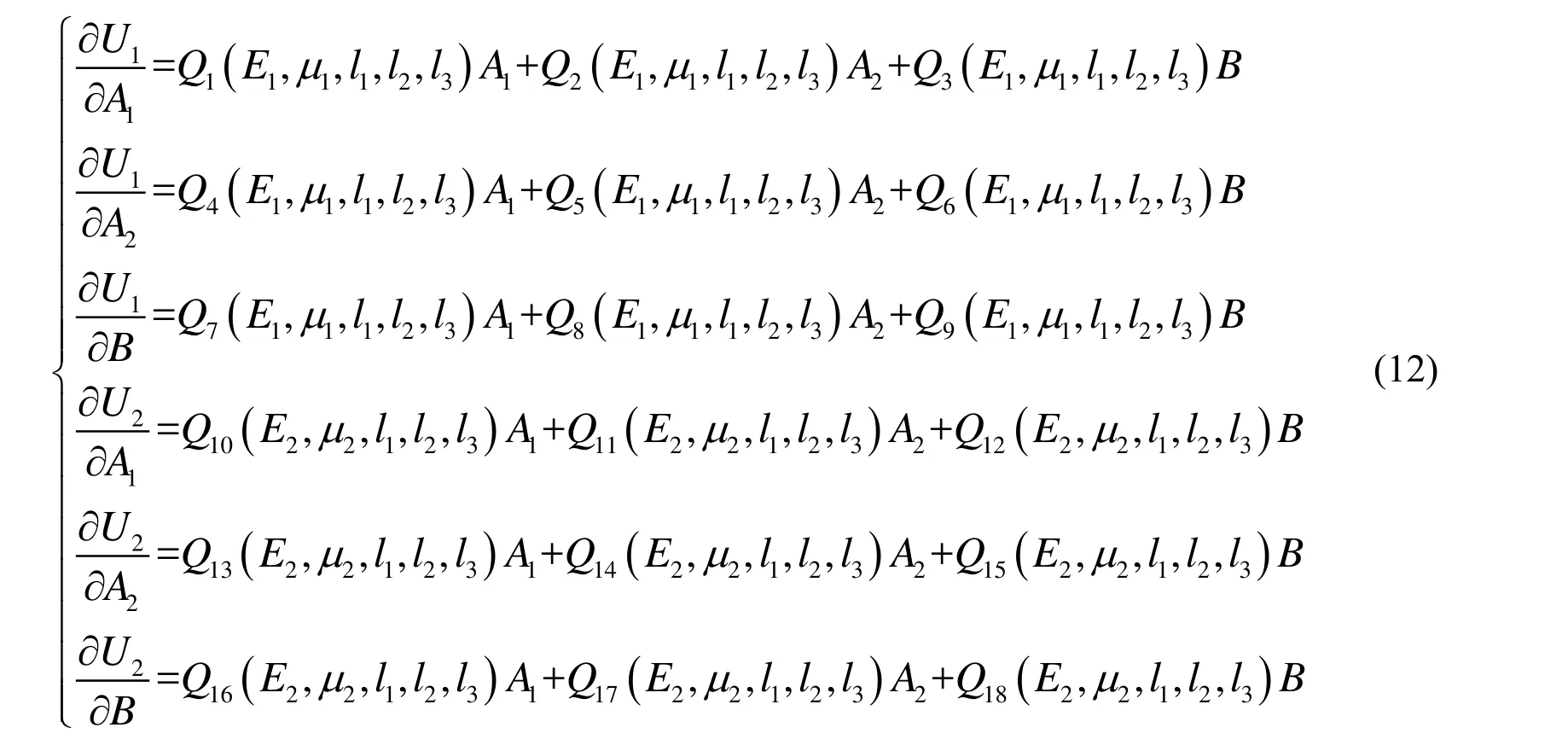

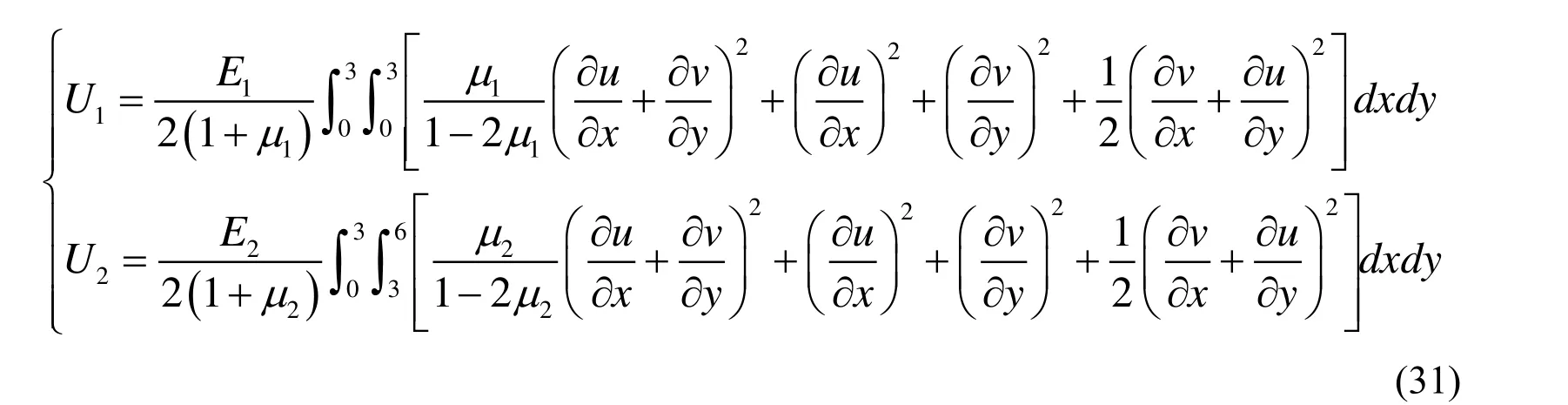

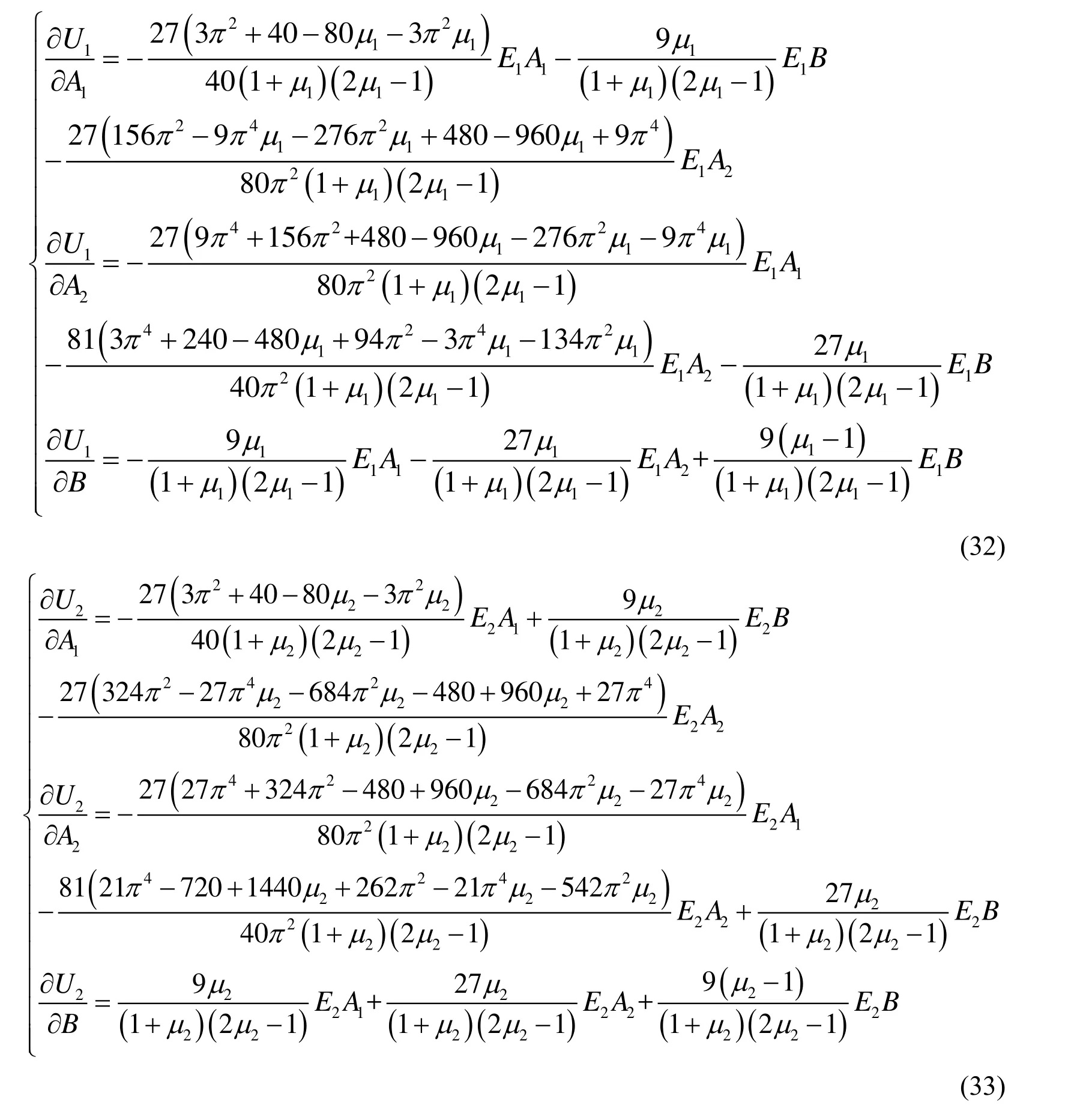

Substituting formula (10) into formula (11),

The total deformation potential energy of mechanical system is obtained,

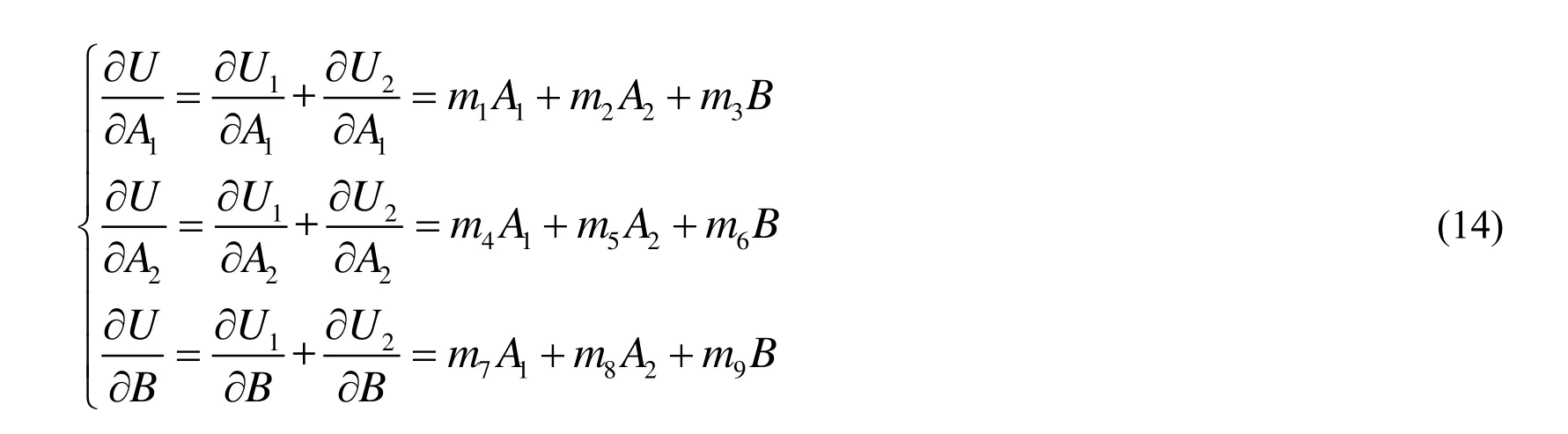

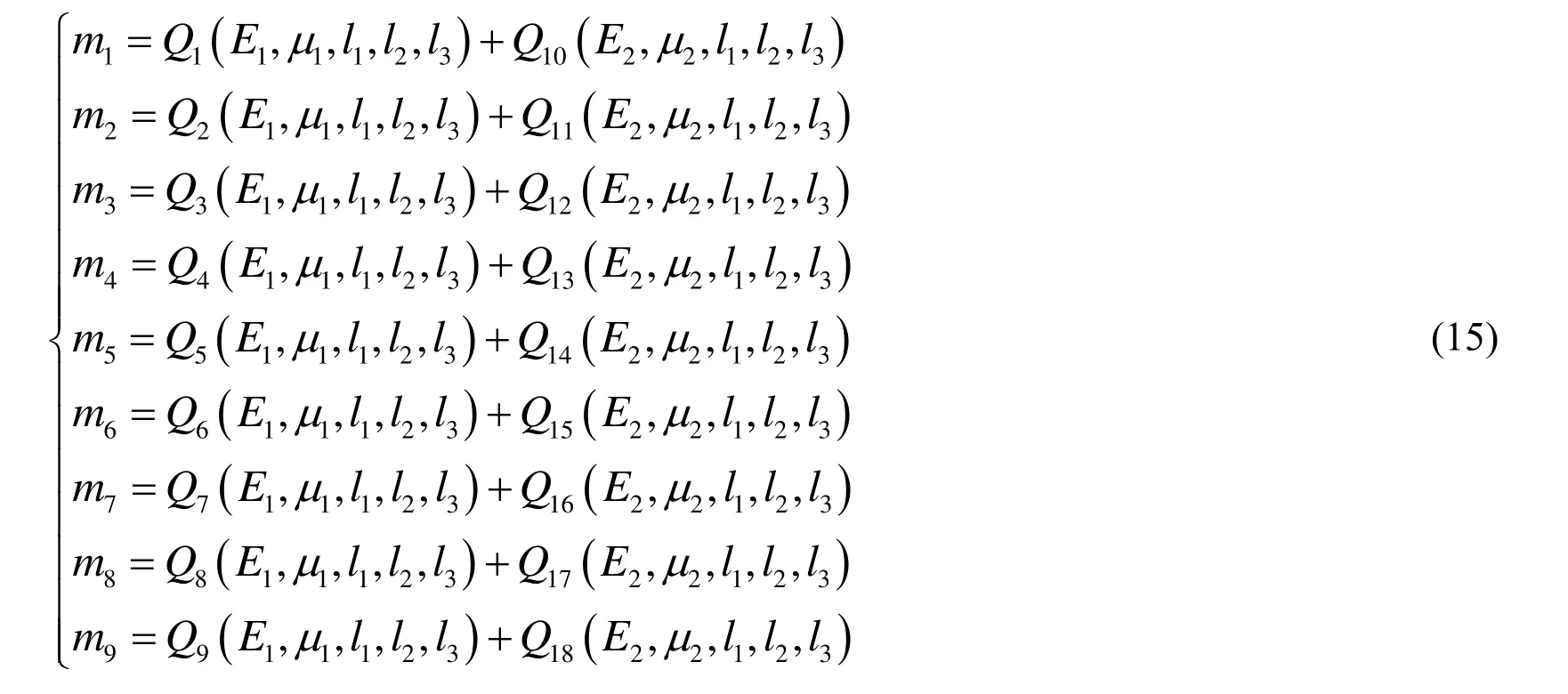

Substituting formula (12) into formula (13),

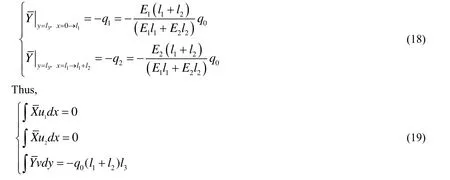

According to the stress boundary condition of coal pillar, the relationship is true,

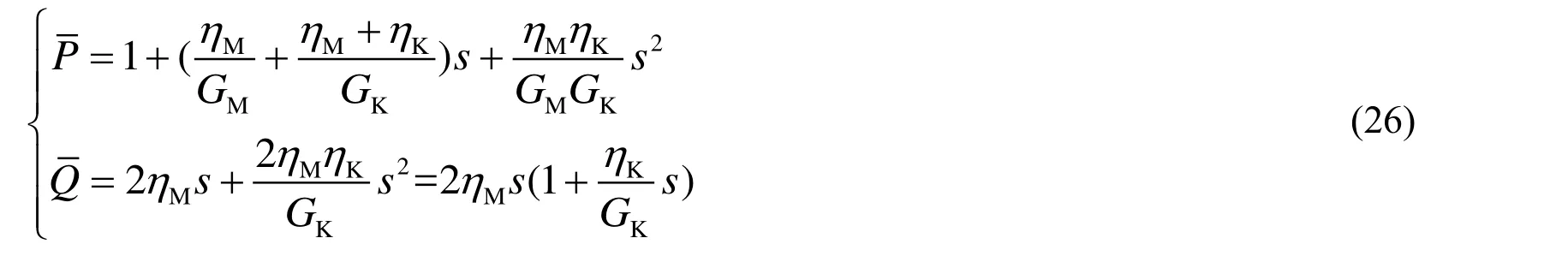

Substituting the formula (19) into the Ritz equation, namely the formula (16),

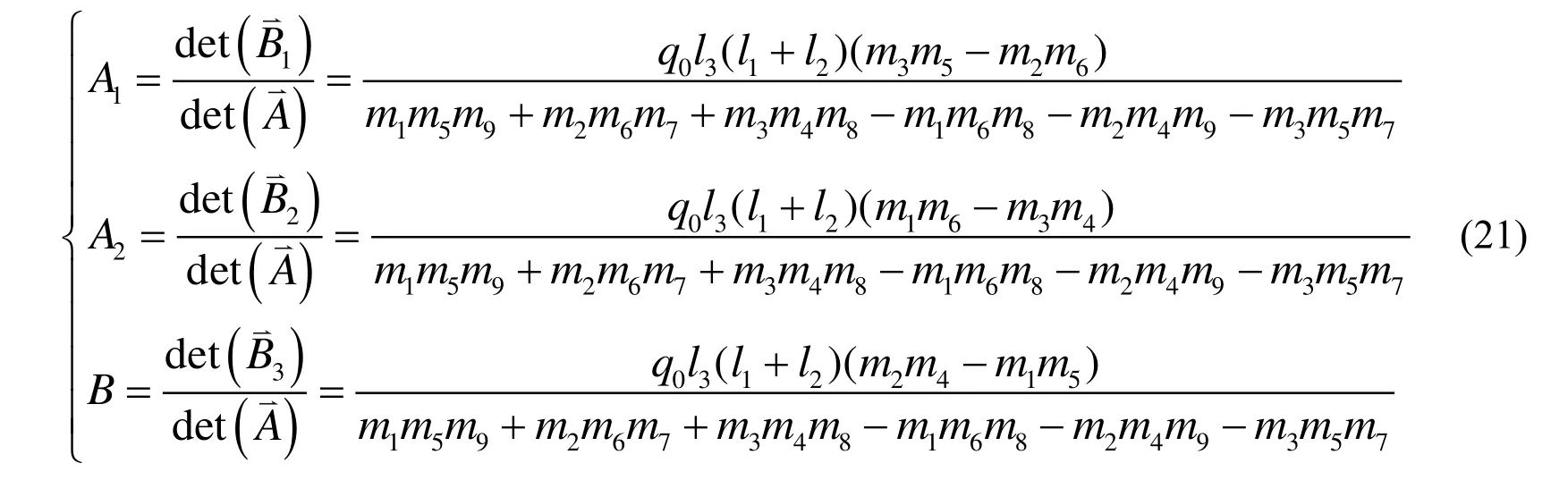

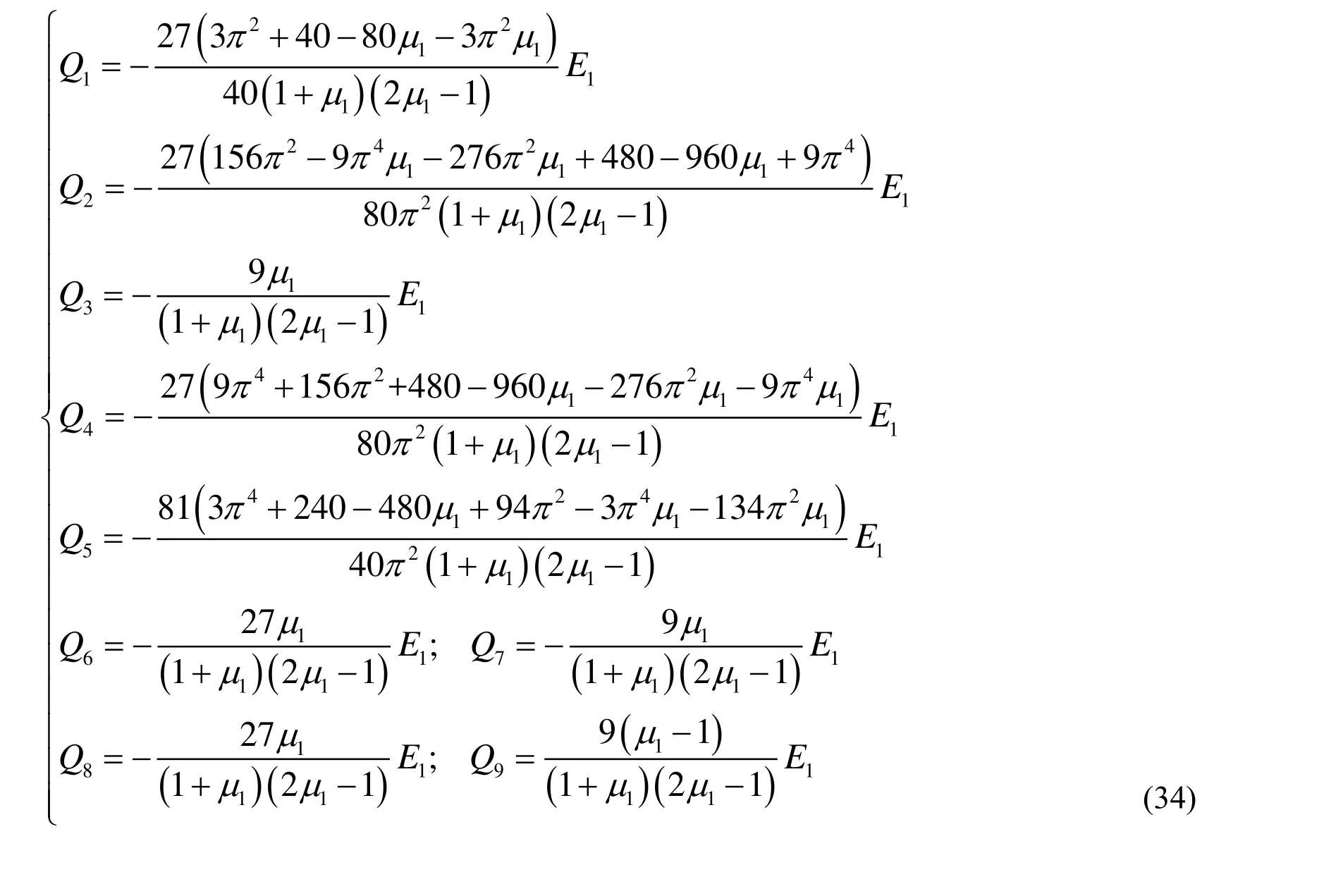

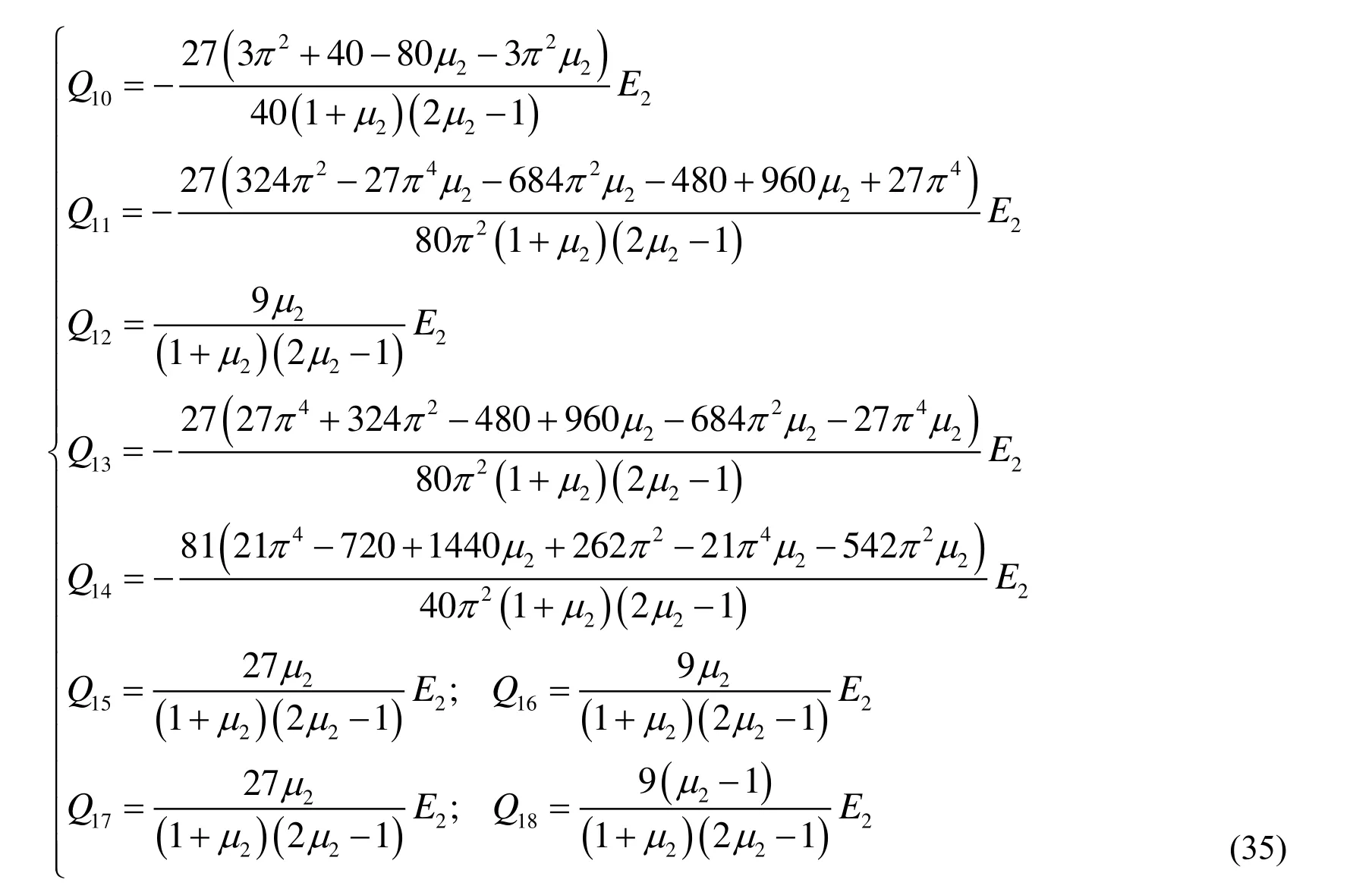

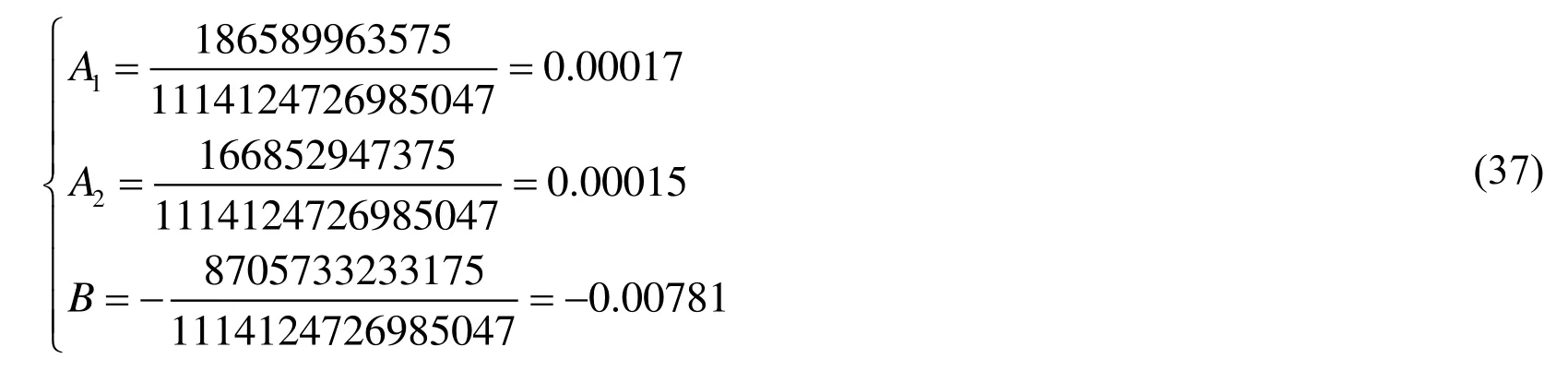

By solving the ternary nonhomogeneous equation system, the undetermined coefficients are expressed as follows:

Therefore, the analytical expressions of displacement field of coal pillar is obtained,

4 Viscoelastic analysis of coal pillar deformation

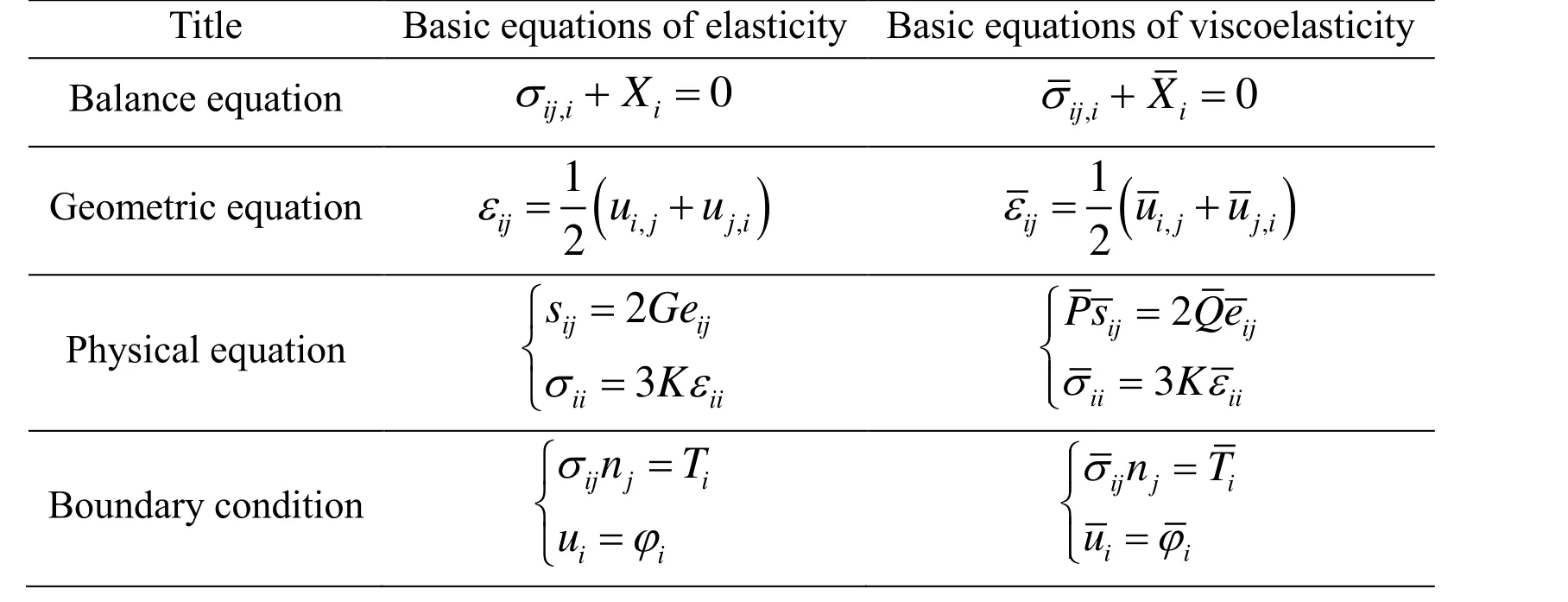

Table 1: Basic equations of elasticity and viscoelasticity

Assume that a real functionis defined on an independent variable, and thetends to convergence in a certain range of complex plane, so the functiondetermined by the integral is denoted as Laplace transform of the real functiontransform of

Based on the elastic-viscoelastic correspondence principle, Laplace transform can be done on the elastic solution of displacement field expression of coal pillar, namely the formula(10),

According to the relationship between the elastic modulus, Poisson’s ratioand shear modulus, bulk modulus, namely

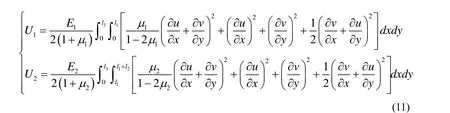

Figure 2: Burgers creep mechanical model

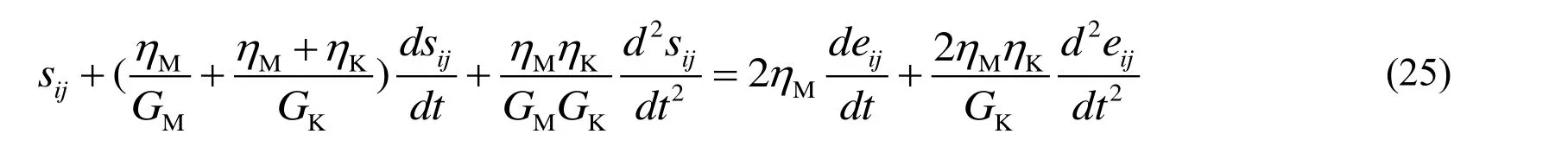

The rheological characteristic of coal pillar illustrated with the burgers creep mechanical model, which is shown in Fig. 2. The three dimensional constitutive equation is as follows,

According to the viscoelastic theory, the variables are obtained,

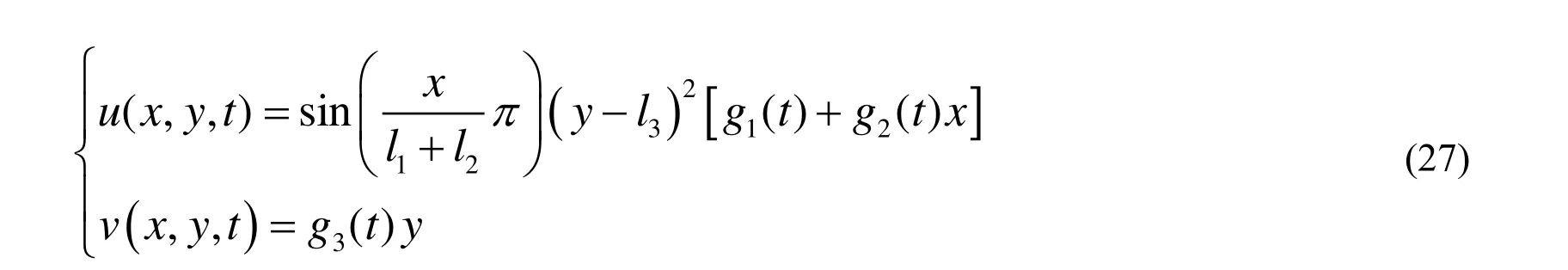

Based on the elastic-viscoelastic correspondence principle, the viscoelastic solution of displacement field expression of coal pillar can be transformed by doing the inverse Laplace transformation, which is shown in formula (27),

Therefore, when the roadway height is, the maximum value of vertical creep deformation of coal pillar is. Combining with the compaction amountof backfilling body in the steady state in formula (9), the expression of

By substituting the specific variable values into formula (28), the time required for coal pillar and backfilling body to play the joint bearing function in roadway backfilling mining technology can be obtained.

5 Engineer example analysis

5.1 Elastic solution of displacement field of coal pillar

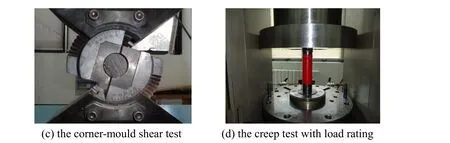

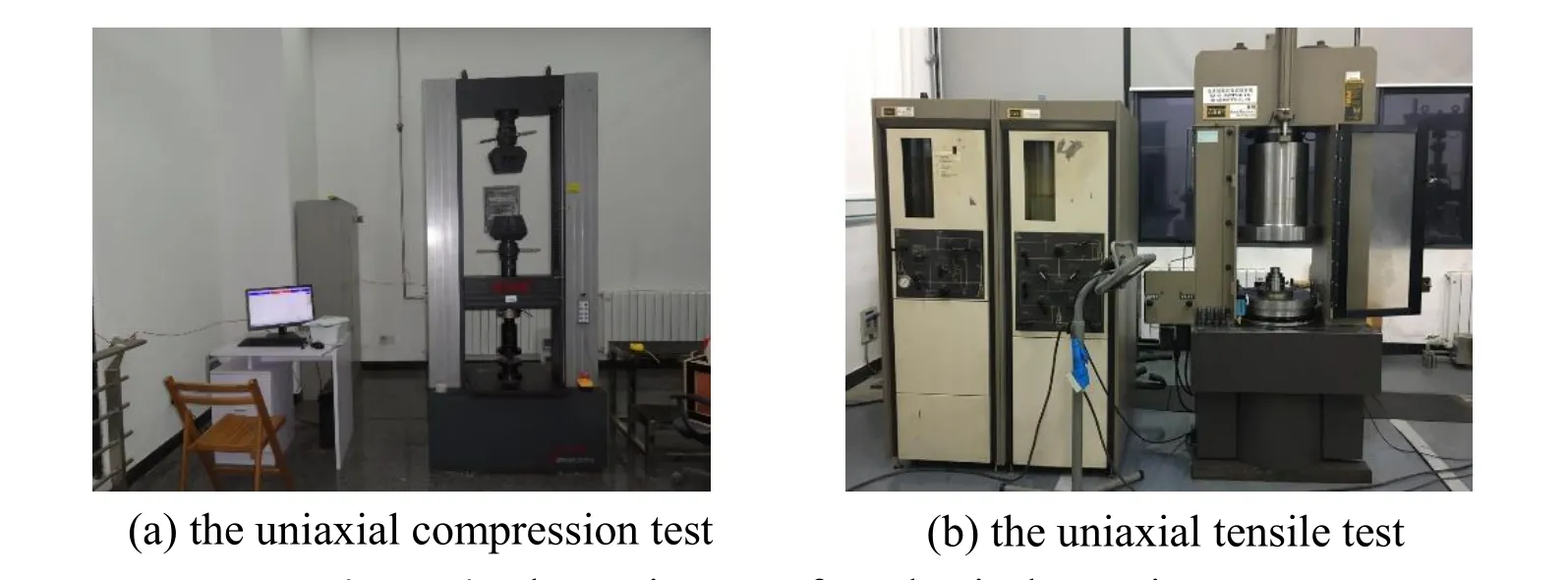

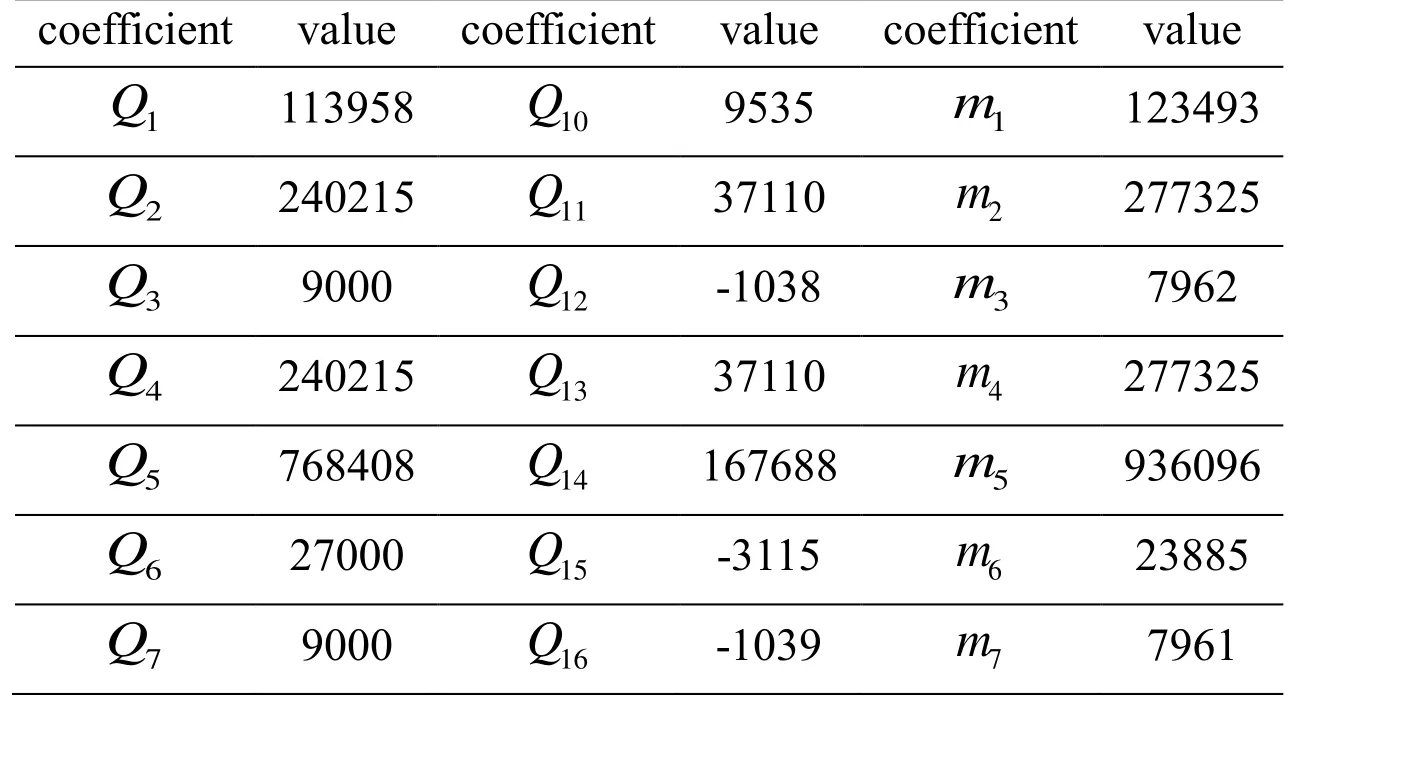

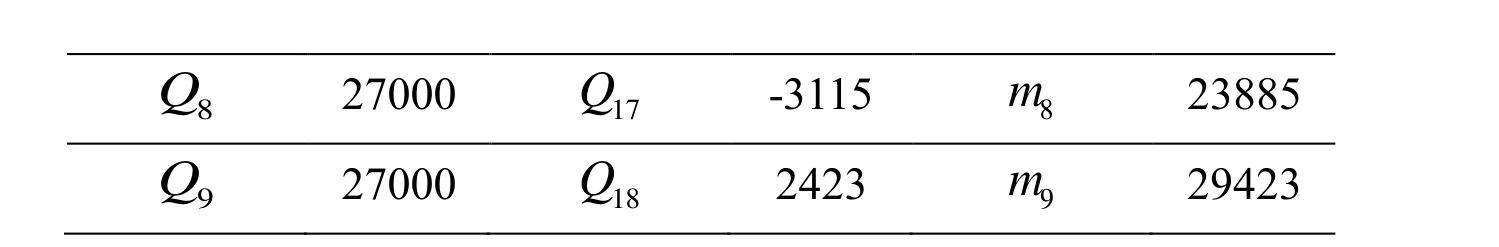

Figure 3: The mechanical experiments

Figure 4: The equipment of mechanical experiment

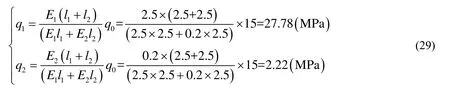

According to the calculative expression of uniform loadandin formula (6), the specific values ofandare

The displacement expression of coal pillar is

Thus, the deformation potential energy of coal pillar and backfilling body are

Substituting formula (30) into formula (31),

Thus, the specific values ofandcan be obtained,which is shown in Tab. 2.

Substituting the related values into formula (20),

Table 2: Q and m values

?

The undetermined coefficients can be solved,

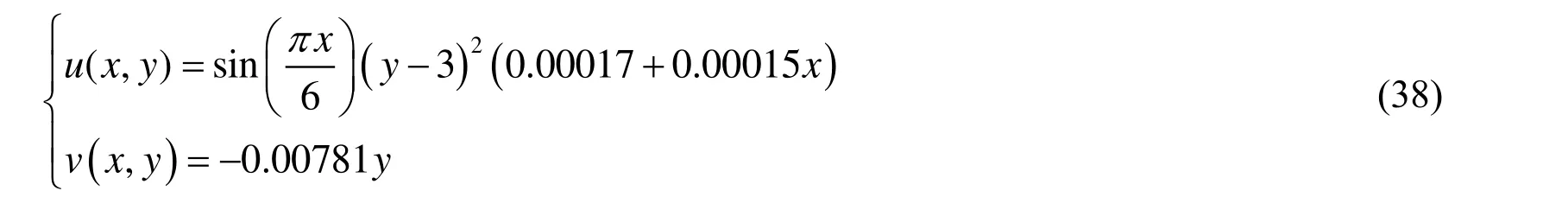

Then, the elastic solution of displacement field of coal pillar is obtained,

The height of coal pillar is 6 m, substitutey=6 into formula (38), so the maximum vertical deformation of coal pillar is approximately 0.045 m, which is reasonable in practice engineer.

5.2 Viscoelastic solution of displacement field of coal pillar

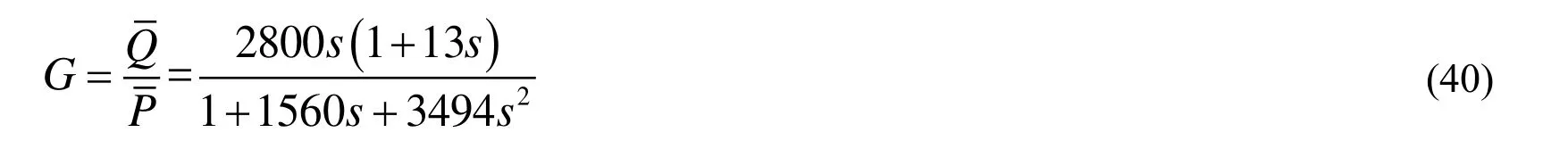

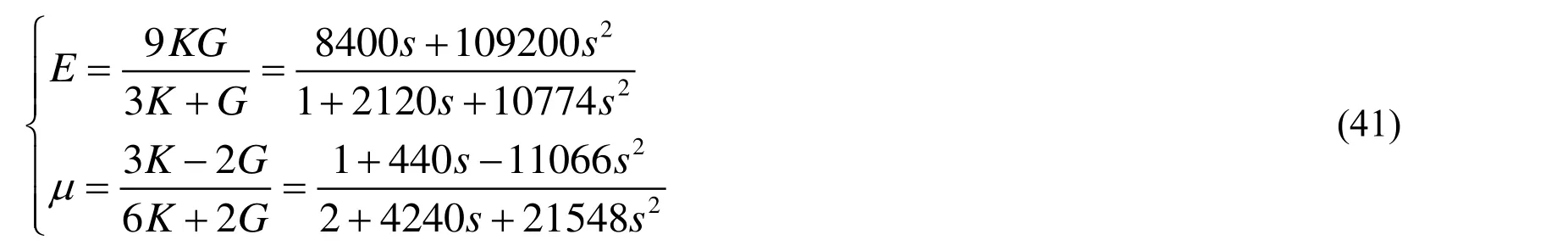

Based on the elastic-viscoelastic correspondence principle, the specific values of creep variable,,andare substituting into formula (26),

Based on the elastic-viscoelastic correspondence principle, the elastic modulusand Poisson’s ratioin viscoelastic theory is shown as follows,

Substituting formula (41) into formula (34),

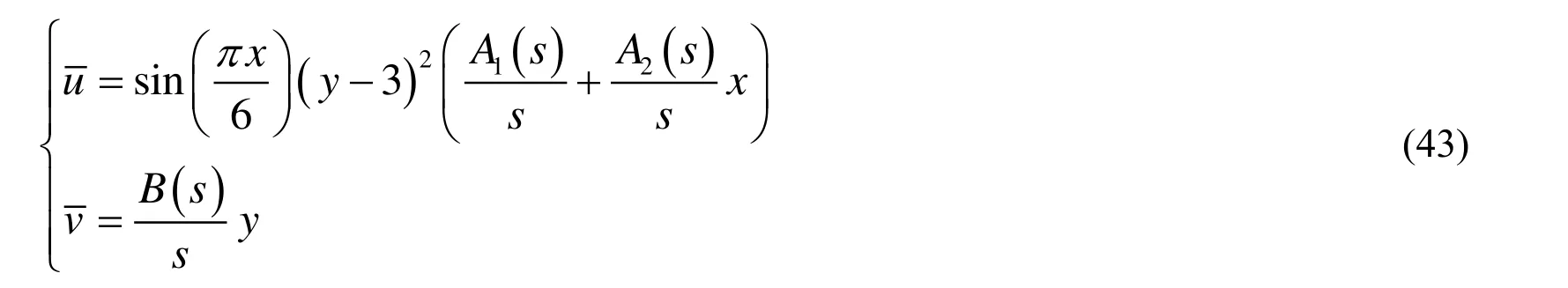

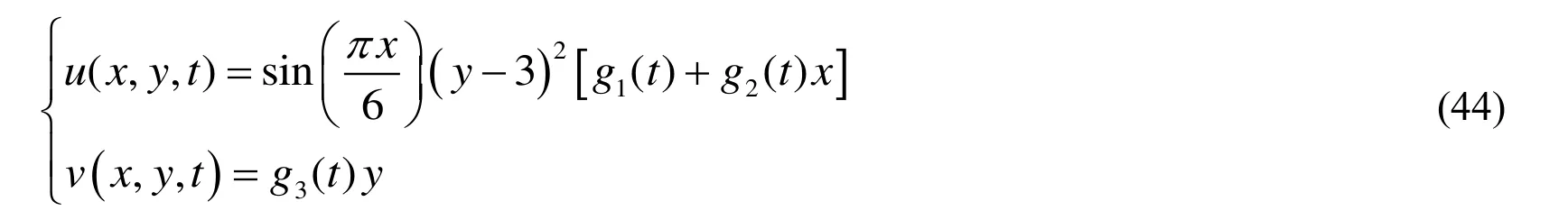

Combining formula (15) with formula (21), the analytical expression of undetermined coefficients),)and)can be obtained; therefore, the formula (23) can be expressed as follows:

Based on the elastic-viscoelastic correspondence principle, the viscoelastic solution of displacement field of coal pillar can be transformed, which is shown in formula (44),

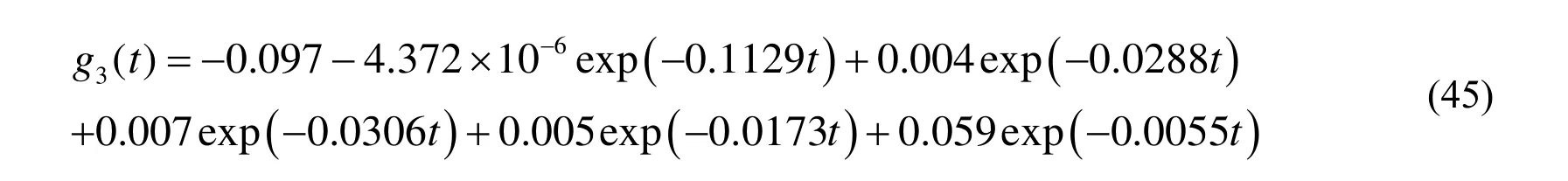

In formula (44), the specific expression ofis

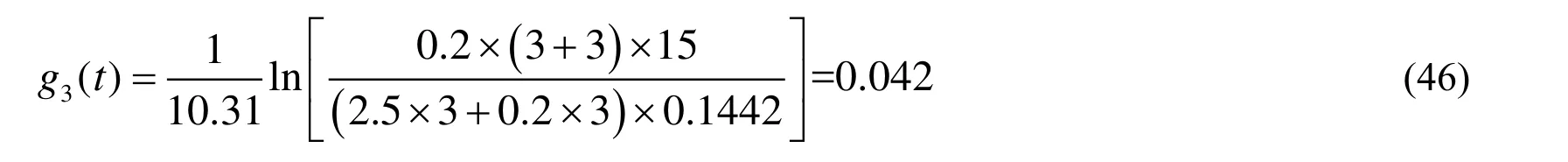

When the backfilling body is coal gangue (particle size is 20-25 mm), the specific values of regression coefficientsandis 0.1442 MPa and 10.31, respectively.Substituting the specific values into formula (28),

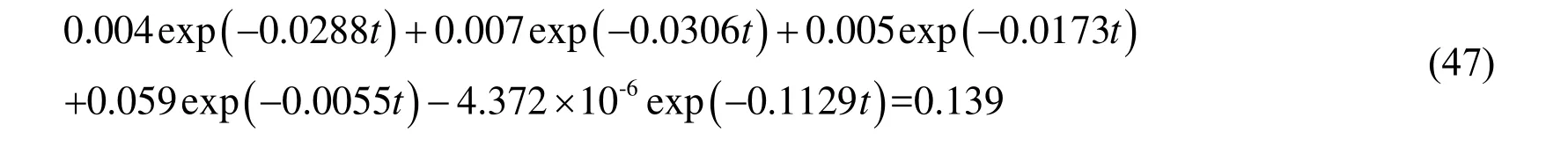

Combining formula (45) and formula (46), the time formula required for coal pillar and backfilling body to play the joint bearing function in roadway backfilling mining technology is obtained,

By solving the formula (47), the time is. Therefore, the time required for coal pillar and backfilling body to play the joint bearing function in roadway backfilling mining technology is 140 days.

6 Conclusions

(1) The control process of overlying strata movement in roadway backfilling mining technology can be divided into three stages, namely coal pillar bearing stage, backfilling body dynamic compaction stage and coal pillar and backfilling body combined load bearing stage. The coal pillar and backfilling body play the joint bearing effect on the overlying strata and achieve long time stability in combined load bearing stage.

(2) The mechanical model of bearing system of coal pillar and backfilling body is established, on basis of the deformation characteristics of overlying strata in roadway backfilling mining technology. Besides, the elastic solution expression of coal pillar deformation is deduced with the Ritz method in energy variation principle, and the viscoelastic solution expression of coal pillar deformation is obtained, based on elasticviscoelastic correspondence principle, combining with the burgers rheological constitutive model and Laplace transform theory.

(3) By analyzing the compressive mechanical property of backfilling body, the time formula required for coal pillar and backfilling body to play the joint bearing function in roadway backfilling mining technology is obtained. The engineer example analysis indicates that the time required to play the joint bearing function is 140 days.

Acknowledgement:This work was supported by the National Natural Science Foundation of China (51504081, 51774110, 51508166, U1404527), the Science and Technology Breakthrough Project by Henan Province (162102210221, 162102310427), the Foundation for Higher Education Key Research Project by Henan Province (15A440013), the Ph.D.Programs Foundation of Henan Polytechnic University (B2018-65, B2018-4, B2016-67).

Akbarov, S. D.; Negin, M.(2017): Generalized rayleigh wave dispersion in a covered half-space made of viscoelastic materials.Computers Materials & Continua, vol. 53, no.4, pp. 307-341.

An, B. F.; Qi, W. Y.; Lan, L. X.; Mei, X. C.; Zhou, Z. et al.(2017): Critical failure time of roof and standing pillars in China western mining area.Journal of China Coal Society,vol. 42, no. 2, pp. 397-403.

Cao, Z. Z.; Du, F.; Li, Z. H.; Wang, Q. T.; Xu, P. et al.(2017): Research on instability mechanism and type of ore pillar based on the fold catastrophe theory.Computer Modeling in Engineering & Sciences, vol. 113, no. 3, pp. 287-306.

Cao, Z. Z.; Du, F.; Xu, P.; Lin, H. X.; Xue, Y. et al.(2017): Control mechanism of surface subsidence and overburden movement in backfilling mining based on laminated plate theory.CMC: Computers Materials & Continua, vol. 53, no. 3, pp. 187-202.

Deng, X. J.; Zhang, J. X.; Zhou, N.; An, T. L.; Guo, S.(2014): The research and application of longwall-roadway cemented backfilling mining technology in extra-thick coal seam.Journal of Mining & Safety Engineering, vol. 31, no. 6, pp. 857-862.

Deng, X. J.; Zhang, J. X.; Klein, B.; Zhou, N.; Dewit, B.(2017): Experimental characterization of the influence of solid components on the rheological and mechanical properties of cemented paste backfill.International Journal of Mineral Processing, vol.168, pp. 116-125.

Ding, Y. L.; Zhou, Y. J.; Xu, P.; Peng, G.; Cao, Z. Z.(2013): Mechanism analysis of restraining surface cracks and protecting Tetraena mongolice maxin with backfilling mining.Journal of Mining & Safety Engineering, vol. 30, no. 6, pp. 868-873.

Guo, W. B.; Li, Y. T.; Liu, D. C.(2017): Application of strip pillar mining technology under dense constructions within industrial square.Journal of Henan Polytechnic University (Natural Science), vol. 36, no. 6, pp. 8-14.

Hu, B. N.; Zhang, W. H.; Gao, Q. C.; Liu, P. L.(2006): Test research on permanent pillar mining with coal refuse backfilling.Coal Science and Technology, vol. 34, no. 11, pp. 46-48.

Li, M.; Zhang, J. X.; Zhou, N.; Zhang, Q.(2017): Deformation and failure analysis of river levee induced by coal mining and its influence factor.Computer Modeling in Engineering & Sciences, vol. 113, no. 2, pp. 183-194.

Li, Q.; Mao, X. B.; Bu, W. K.; Ma, Z. G.(2008): Mechanism of using waste-filling in roadway to control the deformation of covered rock strata.Journal of China University of Mining & Technology, vol. 37, no. 6, pp. 745-750.

Jia, H. S.; Qiao, A. Z.; Jiang, W. Y.(2016): Deformation-failure characteristics and supporting method of mining tunnel roof in Buertai mine.Journal of Henan Polytechnic University (Natural Science), vol. 35, no. 3, pp. 338-344.

Ju, F.; Li, M.; Zhang, J. X.; Miao, X. X.; Liu, Z.(2014): Construction and stability of an extra-large section chamber in solid backfill mining.International Journal of Mining Science and Technology, vol. 24, no. 6, pp. 763-768.

Miao, X. X.(2012): Progress of fully mechanized mining with solid backfilling technology.Journal of China Coal Society, vol. 37, no. 8, pp. 1247-1255.

Miao, X. X.; Huang, Y. L.; Ju, F.(2012): Strata movement theory of dense backfill mining.Journal of China University of Mining & Technology, vol. 41, no. 6, pp. 863-867.

Miao, X. X.; Zhang, J. X.; Guo, G. L.(2010): Study on waste-filling method and technology in fully-mechanized coal mining.Journal of China Coal Society, vol. 35, no. 1,pp. 1-6.

Qian, M. G.(2010): On sustainable coal mining in China.Journal of China Coal Society,vol. 35, no. 4, pp. 529-534.

Qian, M. G.; Miao, X. X.; Xu, J. L.(2008): On scientized mining.Journal of Mining &Safety Engineering, vol. 25, no. 1, pp. 1-10.

Sun, Q.; Zhang, J. X.; Yin, W.; Zhou, N.; Liu, Y.(2017): The study of stability of surrounding rock and characters of overburden strata movement with longwall roadway backfill coal mining.Journal of China Coal Society, vol. 42, no. 2, pp. 404-412.

Teng, T.; Wang, J. G.; Gao, F.; Ju, Y.; Jiang, C.(2016): A thermally sensitive permeability model for coal-gas interactions including thermal fracturing and volatilization.Journal of Natural Gas Science and Engineering, vol. 32, pp. 319-333.

Teng, T.; Wang, J. G.; Gao, F.; Ju, Y.; Xia, T.(2016): Impact of water film evaporation on gas transport property in fractured wet coal seams.Transport in Porous Media, vol. 113,no. 2, pp. 357-382.

Xin, Y. J.; Ji, H. Y.(2016): Study on uniaxial compression experiments for different ratio and large-scale similar simulated specimens.Journal of Henan Polytechnic University(Natural Science), vol. 35, no. 1, pp. 30-36.

Xue, Y.; Cao, Z. Z.; Cai, C. Z.; Dang, F. N.; Hou, P. et al.(2017): A fully coupled thermohydro-mechanical model associated with inertia and slip effects.Thermal Science, vol. 21,no. S1, pp. 259-266.

Xue, Y.; Ranjith, P. G.; Gao, F.; Zhang, D. C.; Cheng, H. M. et al.(2017): Mechanical behaviour and permeability evolution of gas-containing coal from unloading confining pressure tests.Journal of Natural Gas Science and Engineering, vol. 40, pp. 336-346.

Yu, W. J.; Wang, W. J.(2011): Strata movement induced by coal-pillar under three circumstances exchanged by gangue backfill and quadratic stability law.Chinese Journal of Rock Mechanics and Engineering, vol. 30, no. 1, pp. 105-112.

Zhang, J. X.; Miao, X. X.; Guo, G. L.(2015):Consolidated solid backfill mining method and its applications. Science Press.

Zhang, J. X.; Miao, X. X.; Mao, X. B.; Chen, Z. W.(2007): Research on waste substitution extraction of strip extraction coal-pillar mining.Chinese Journal of Rock Mechanics and Engineering, vol. 26, no. S1, pp. 2687-2693.

Zhang, J. X.; Sun, Q.; Zhou, N.; Jiang, H. Q.(2016): Research and application of roadway backfill coal mining technology in western coal mining area.Arabian Journal of Geosciences, vol. 9, pp. 558.

Zhang, W. H.; Zhang, J. X.; Zhao, J. S.; Wei, S. Q.; Ju, F.(2007): Research on waste filling technology and its matching equipment in coal mining.Journal of Mining & Safety Engineering, vol. 24, no. 1, pp. 79-83.

Zhou, N.; Li, M.; Zhang, J. X.; Gao, R.(2016): Roadway backfill method to prevent geohazards induced by room and pillar mining: a case study in Changxing coal mine, China.Natural Hazards and Earth System Sciences, vol. 16, pp. 2473-2484.

Zhou, Z. Y.; Guo, G. L.; Cha, J. F.; Ma, Z. G.(2008): Study on subsidence controlled of tunnel mining with coal refuse backfilling under buildings.Safety in Coal Mines, vol. 8,pp. 19-22.

Computers Materials&Continua2018年2期

Computers Materials&Continua2018年2期

- Computers Materials&Continua的其它文章

- Coverless Information Hiding Based on the Molecular Structure Images of Material

- Solution of Algebraic Lyapunov Equation on Positive-Definite Hermitian Matrices by Using Extended Hamiltonian Algorithm

- Solving Fractional Integro-Differential Equations by Using Sumudu Transform Method and Hermite Spectral Collocation Method

- The Influence of the Imperfectness of Contact Conditions on the Critical Velocity of the Moving Load Acting in the Interior of the Cylinder Surrounded with Elastic Medium