An experimental study of elastic properties of dragonfly-like flapping wings for use in biomimetic micro air vehicles(BMAVs)

Prveen Nir Sivsnkrn,Thoms Arthur Wrd,Erfn Slmi,Rubentheren Viypuri,Christopher J.Ferdy,Mohd Rfie John

aDepartment of Mechanical Engineering,University of Malaya,Kuala Lumpur 50603,Malaysia

bSchool of Engineering and Physical Sciences,Heriot-Watt University Malaysia,Putrajaya 62200,Malaysia

cDepartment of Electrical Engineering,University of Malaya,Kuala Lumpur 50603,Malaysia

An experimental study of elastic properties of dragonfly-like flapping wings for use in biomimetic micro air vehicles(BMAVs)

Praveena Nair Sivasankarana,Thomas Arthur Wardb,*,Erfan Salamia,Rubentheren Viyapuria,Christopher J.Feardayc,Mohd Rafie Johana

aDepartment of Mechanical Engineering,University of Malaya,Kuala Lumpur 50603,Malaysia

bSchool of Engineering and Physical Sciences,Heriot-Watt University Malaysia,Putrajaya 62200,Malaysia

cDepartment of Electrical Engineering,University of Malaya,Kuala Lumpur 50603,Malaysia

ABS;Acrylic;Biomimetic micro air vehicle;Flapping mechanism;PLA;Wing structure

This article studies the elastic properties of several biomimetic micro air vehicle(BMAV)wings that are based on a dragonfly wing.BMAVs are a new class of unmanned micro-sized air vehicles that mimic the flapping wing motion of flying biological organisms(e.g.,insects,birds,and bats).Three structurally identical wings were fabricated using different materials:acrylonitrile butadiene styrene(ABS),polylactic acid(PLA),and acrylic.Simplified wing frame structures were fabricated from these materials and then a nanocomposite film was adhered to them which mimics the membrane of an actual dragonfly.These wings were then attached to an electromagnetic actuator and passively flapped at frequencies of 10–250 Hz.A three-dimensional high frame rate imaging system was used to capture the flapping motions of these wings at a resolution of 320 pixels?240 pixels and 35000 frames per second.The maximum bending angle,maximum wing tip deflection,maximum wing tip twist angle,and wing tip twist speed of each wing were measured and compared to each other and the actual dragonfly wing.The results show that the ABS wing has considerable flexibility in the chordwise direction,whereas the PLA and acrylic wings show better conformity to an actual dragonfly wing in the spanwise direction.Past studies have shown that the aerodynamic performance of a BMAV flapping wing is enhanced if its chordwise flexibility is increased and its spanwise flexibility is reduced.Therefore,the ABS wing(fabricated using a 3D printer)shows the most promising results for future applications.

1.Introduction

Micro air vehicles(MAVs)are a relatively new and rapidly growing area of aerospace research.They were first defined by the US Defense Advanced Research Projects Agency(DARPA)in 1997 as unmanned aircraft that are less than 15 cm in any dimension.Later in 2005,the DARPA defined aircraft with all dimensions less than 7.5 cm and lighter than 10 g(carrying 2 g payload)as nano air vehicles(NAVs).MAVs(or NAVs)generally fit into one of the three categories:fixed wing,rotorcraft,or biomimetic.Biomimetic MAVs(BMAVs)mimic the flapping wing motion of flying organisms(e.g.,insects,birds,bats,etc.).This allows lift and thrust to be achieved from a relatively small wing surface area.This allows BMAVs to be potentially smaller and more lightweight than the other two types.These characteristics make BMAVs ideally suited for flight missions in con fined areas(e.g.,around power lines,narrow streets,indoors,etc.).Therefore,BMAV structural components must be ultra-lightweight,compact,and flexible.Most past MAV research has focused on fixed wings,which are essentially scaled-down versions of wings on conventional fixed-wing aircraft.These wings are unsuitable for BMAVs due to their lack of flexibility,so a new type of structural wing design is required for BMAVs.In this work,a dragonfly wing structure is mimicked to construct a new BMAV wing design.A dragonfly(Odonata)was selected for biomimicry,because they are highly maneuverable flyers,capable of hovering,rapid forward flight,and reverse flight.Therefore,structurally analyzing their wings could yield results that bioinspire the design of more effective wings for BMAVs.This article follows on from research discussed in a previous article(written by the authors)that analyzed the static strength of dragonfly-like wing frames fabricated from common materials used in unmanned aircraft(balsa wood,black graphite carbon fiber,and red pre-impregnated fiberglass).1

Several past research studies have been conducted on flying insect wing structures to understand their elastic properties.Wootton et al.2conducted numerical investigations on a tethered desert locust(Schistocerca gregaria).They concluded that the wings must undergo an appropriate elastic wing deformation(through the course of a wing beat)in order to achieve an efficient aerodynamic flow suitable for lift and thrust generation.Several studies showed that flexible wings,capable of changing their camber,generate higher peak lift forces than those of rigid wings.2,3Wing flexibility also prevents small tears or warping from occurring.Young et al.4suggested that dragonfly wings appear to be adapted for reversible failures in response to excess loads,enabling them to avoid permanent structural damages.Zhu et al.5conducted a study on the effect of flexibility on flapping wing performance during forward flight.A two-dimensional numerical simulation was done by solving the unsteady incompressible Navier-Stokes equations,coupled with the structural dynamic equation for the motion of a wing.The results showed that the flexibility of a flapping wing can largely in fluence its aerodynamic characteristics.The flexibility can simultaneously increase both the propulsive and lifting ef ficiencies of the wing.Kei et al.6conducted a study in which deformation of wings was modeled to examine the effects of bending and torsion on the aerodynamic forces.Their numerical simulations demonstrated that flexible torsion reduces flight instability.They concluded that living butterflies have structurally flexible wings that improve both the aerodynamic efficiency and flight stability.Their experimental measurements showed that a uniformly flexible wing generates lower aerodynamic forces than those of rigid wings under steady-state conditions.However,the presence of wing veins can substantially enhance aerodynamic performance to match or improve the rigid airfoil.These observations agree with those of Zhao et al.7who concluded that flexible insect wings generate greater forces due to an enhanced camber in flight.

Luo and Tian et al.8,9found that the chordwise deformation of an elastic wing is greater during upstroke than during downstroke.In a study conducted by Ha et al.,10the asymmetric bending of anAllomyrina dichotomabeetle’s hind wing was investigated.Five differently cambered wings were modeled using the ANSYS finite element analysis software.These models were subjected to loads and pressures from the dorsal and ventral sides.The results revealed that both the stressed stiffening of the membrane and the wing camber affect the bending asymmetry of insect wings.In particular,increasing the chordwise camber increased the rigidity of the wing when a load was applied on the ventral side.Alternatively,increasing the spanwise camber increased the rigidity of the wing when a load was applied on the dorsal side.These results explained the bending asymmetry behavior of flapping insect wings.Yang et al.11conducted research on the effects of chordwise and spanwise flexibility on the aerodynamic performance of micro-sized flapping wings.Four flapping motions were described:pure rigid flapping(no deformation),pure spanwise flapping,pure chordwise flapping,and combined chord-spanwise flapping motions.Their results showed that a large spanwise de flection reduces the aerodynamic performance(e.g.,lift and thrust generation)and a large chordwise de flection increases the performance.They further suggested that the design of a flexible flapping wing should incorporate characteristics that will create a suitable chordwise deformation angle(25?and above)and limit the spanwise deformation angle(5?and below).

Mountcastle and Combes12conducted an experiment using artificially stiffened bumblebee wings(in vivo)by applying a micro-splint to a single flexible vein joint.The bees were then subjected to load-lifting tests.Bees with stiffened wings showed an 8.6 percent maximum lift reduction.This reduction cannot be accounted for by changes in gross wing kinematics,since the stroke amplitude and flapping frequency were unchanged.The results revealed that flexible wing design and the resulting passive wing deformations enhance the load-lifting capacity in bumblebees.Wu et al.13presented a multidisciplinary experiment that correlated a flapping wing’s elasticity and thrust production,by quantifying and comparing overallthrust,structural deformation, and airflow. Six pairs of hummingbird-shaped membrane wings of different properties were examined.The results showed that,for a specific spatial distribution of flexibility,there is an effective frequency range in thrustproduction.Thewing deformation at thrustproducing wing beat frequencies indicated the importance of flexibility.Both bending and twisting motions interact with aerodynamic loads to enhance wing performance.

Most past research,that is similar to the objectives of this article,examined the effects of wing flexibility on aerodynamic performance by either using numerical models or experimentation.However,very few researchers have attempted to mimic the detailed structure of an actual insect wing.In this article,biomimicry of a dragonfly wing(frame structure and membrane)is done by fabricating them with different materials:acrylonitrile butadiene styrene(ABS),polylactic acid(PLA),and acrylic.The focus of this article is solely on the flexibility of the fabricated wing structures,not the resulting aerodynamic forces that are generated.The wings were fixed to a flapping mechanism and flapped at variable wing beat frequencies.An actual dragonfly has a natural frequency of 120–170 Hz and a wing beat frequency of 30 Hz.The mechanism used in this study was able to flap up to a maximum wing beat frequency of 250 Hz.This allowed us to study the deformation of wing motions at frequencies beyond the ability of an actual dragonfly.The resulting wing tip deflection,twisting angles,twisting speed,and bending angles were measured using imagery generated by two high frame rate cameras.Comparisons were made with a real dragonfly wing in passive flapping motion.

2.Materials and methodology

2.1.Wing design and fabrication

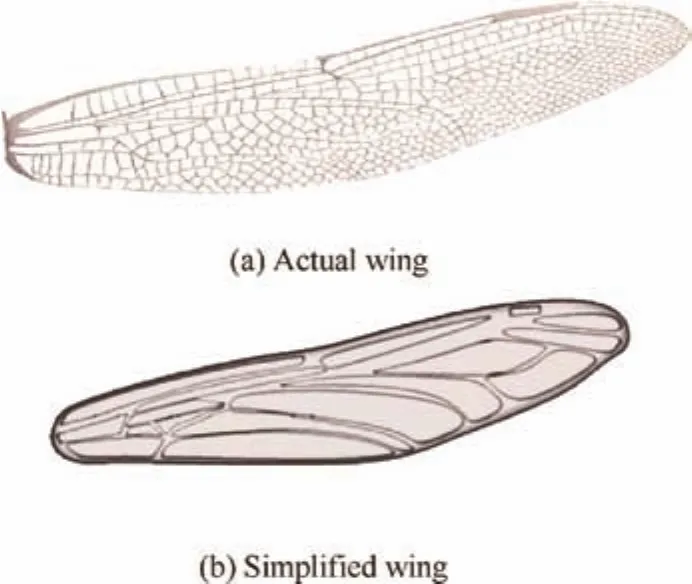

Fig.1 shows the comparison between an actual dragonfly wing(Diplacodes Bipunctata)and the simplified wing frame structure used in this study.The simplified frame structure was designed based on spatial network analysis,which has been described in a previous article written by the authors.14This analysis utilizes geometric objects within a region specified by vertices or edges.Although this method is commonly used in geographical information systems(GIS)to explore geographic spatial patterns,the idea of applying this algorithm to a biological structure was first introduced in this article.It was inspired by observing the compactly arranged geometrical patterns inherent to dragonfly wings.This method allows this complex biological structure to be mimicked by a simplified frame structure that can be fabricated by machining or 3D printing.

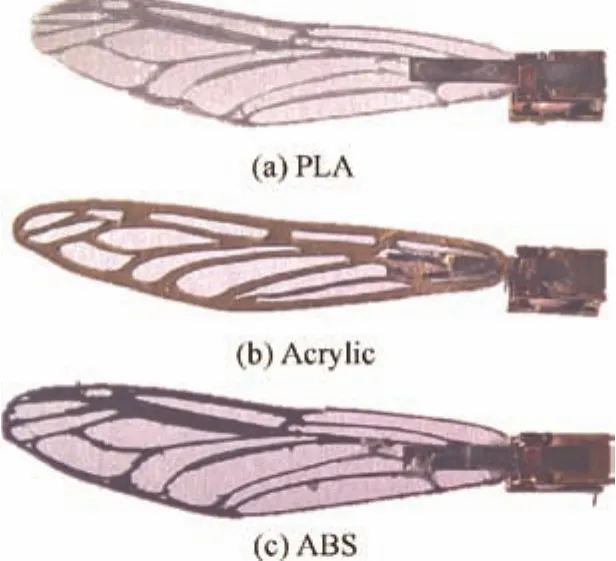

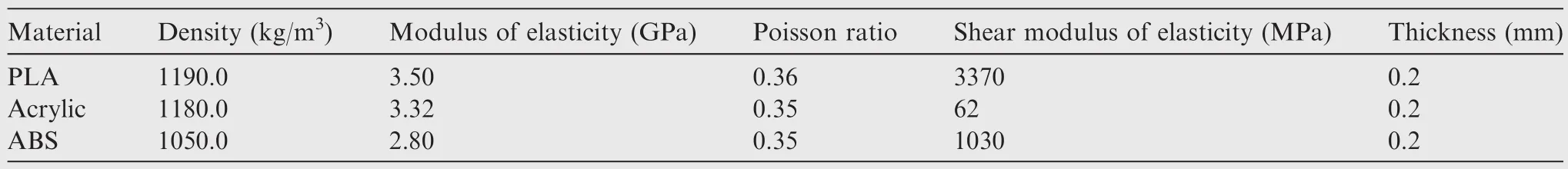

All of the simplified frame structures were fabricated to be approximately 55 mm in length and 0.05 mm thick.As previously mentioned,they were constructed of three different materials:ABS,PLA,and acrylic(see Fig.2 and Table 1).The ABS and PLA wings were fabricated using a Maker Bot Replicator 2X 3D printer.The acrylic wings were fabricated using micro laser machining.Acrylic or PLA is generally known for its resistance to breakage,elasticity,and flexibility.15,16ABS and PLA are the two most dominant plastics used for 3D printing.ABS is chosen due to its strength,flexibility,and machinability,10while PLA is chosen for its biodegradability,lightweight,flexibility,and elasticity.17The densities of ABS,PLA,and acrylic are 1.05,1.19,and 1.18 g/cm3,respectively.A finite element analysis on von Mises stress was conducted to simulate the flexibility of the materials tested.

A chitosan nanocomposite film was bonded to the wing frames to serve as a thin(3 mm),ultra-lightweight wing membrane.This chitosan nanocomposite film was developed by our research team for this specific purpose and has been the subject of another article.18It has similar properties to those of the chitin membranes of real dragonflies.It is formed by reinforcing a chitosan suspension with nanometer-scaled nanocrystalline cellulose(NCC)particles and tannic acid.This allows both the mechanical properties and water resistivity of the chitosan film to be controlled to achieve suitable design values.The use of NCC as a filler material elevates the film’s mechanical properties(e.g.,rigidity).The addition of tannic acid as a cross-linking agent reduces the swelling behavior,solubility,and rigidity of the nanocomposite film.The film was adhered to a wing frame by firstly submerging the frame into the nanocomposite solution.This procedure also ensured that the film membrane would have a prescribed,uniform thickness and that both sides of the frame structure were evenly coated.The suspension was then transformed into a film by the casting evaporation method.Once cured,the film created a shiny,transparent film layer that adhered firmly to the frame structure.

Fig.1 Dragonfly wing structure comparison.

Fig.2 Wing frame materials of PLA,acrylic,and ABS,respectively.

2.2.Wing flapping mechanism

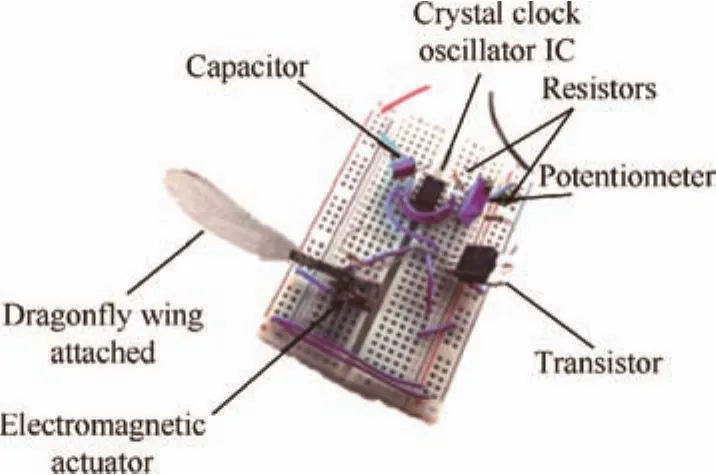

The wing flapping mechanism used in this study was an electromagnetic flapping wing actuator.The power supply usedin this flapping wing drive was 9 V DC.An LM555 crystal clock oscillator integrated circuit(shown in Fig.3)was used to generate a stable oscillation.The free running frequency and duty cycle were accurately controlled with two resistors and one capacitor.The generated oscillation was fed to a Power MOSFET fast switch.The output of the Power MOSFET was used to actuate the miniature PC Board Relay.The frequency of the switch(corresponding to the wing beat frequency)can be adjusted by a 22 kX potentiometer.Each of the different wings was attached to a flat iron plate(2 mm long and 2.75 mm thick)using super glue.This plate(wing platform)was oscillated by an electromagnetic actuator(3 mm?3 mm).Fig.3 shows a wing structure attached to the actuator.The plate was attached to the hinge of the wing to mimic the joint of an actual dragonfly.This flapping mechanism is able to create a linear up-down stroke motion at variable wing beat frequencies,up to a maximum frequency of 250 Hz.The flapping degree was set to be 60?which corresponds to an actual dragonfly wing flapping angle during hovering flight.15,19

Table 1 Mechanical properties of frame structure materials.15,17

Fig.3 Flapping mechanism used in this study.

2.3.Experimental set-up

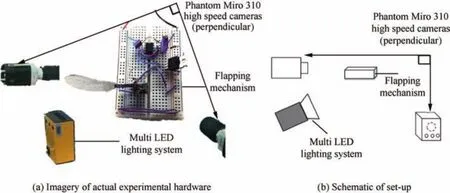

Two Phantom Miro310(Vision Research)high frame rate cameras were used to view a flapping wing from two different directions.The cameras’high frame rate enables a precise sequence of images to be captured of the flapping wing motion within a single wing beat.Two cameras were necessary in order to determine the three-dimensional shape and orientation of the wing surface(see Fig.4).The cameras were placed perpendicular to each other following the procedures established by Gui et al.20Both cameras were equipped with a Nikon F lens.A multiple LED lighting system was used to provide sufficient illumination.Imagery wasrecorded ata resolution of 320 pixel?240 pixel and a frame rate of 35000 per second,which allowed the wing beat motion to be precisely captured.The motion videos were stored to a computer via two highspeed Ethernet cables.They were played-back and analyzed using the Vision Research Phantom Camera Control Software(Version 2.6.749.0).

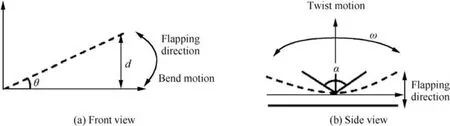

Measurements were taken of each of the three wings while flapping at varying frequencies:10–250 Hz.Fig.5 shows the front and side views of the wing motions that were measured and recorded from captured imagery.Fig.5(a)illustrates the bending angle(h)and the displaced distance or deflection(d).Fig.5(b)defines the wing tip angle(a)and the wing tip rotational twist speed(x).

3.Results and discussion

3.1.Stress simulation results(without a membrane)

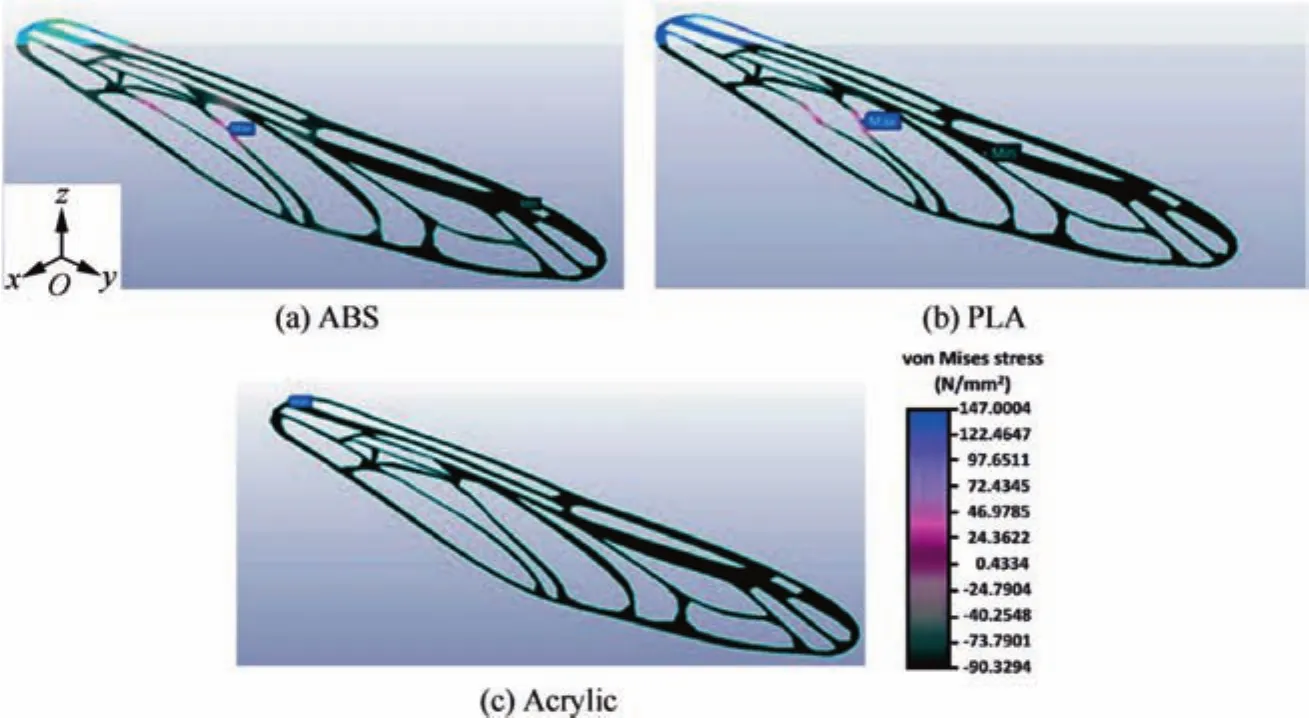

A stress simulation analysis was done on the wing frame materials(without and with a membrane)tested in this experiment using Autodesk Simulation Multiphysics 2015.These results directly relate to the flexibilities of the materials tested in this experiment.The results are shown in Figs.6 and 7.

Fig.6 shows the von Mises stress results of all the three different frame structures.The highest stresses in the forewing recorded for PLA,acrylic,and ABS are 13,17,and 23 N/mm2,respectively.This shows that ABS is the least flexible material among all three materials tested without a membrane.

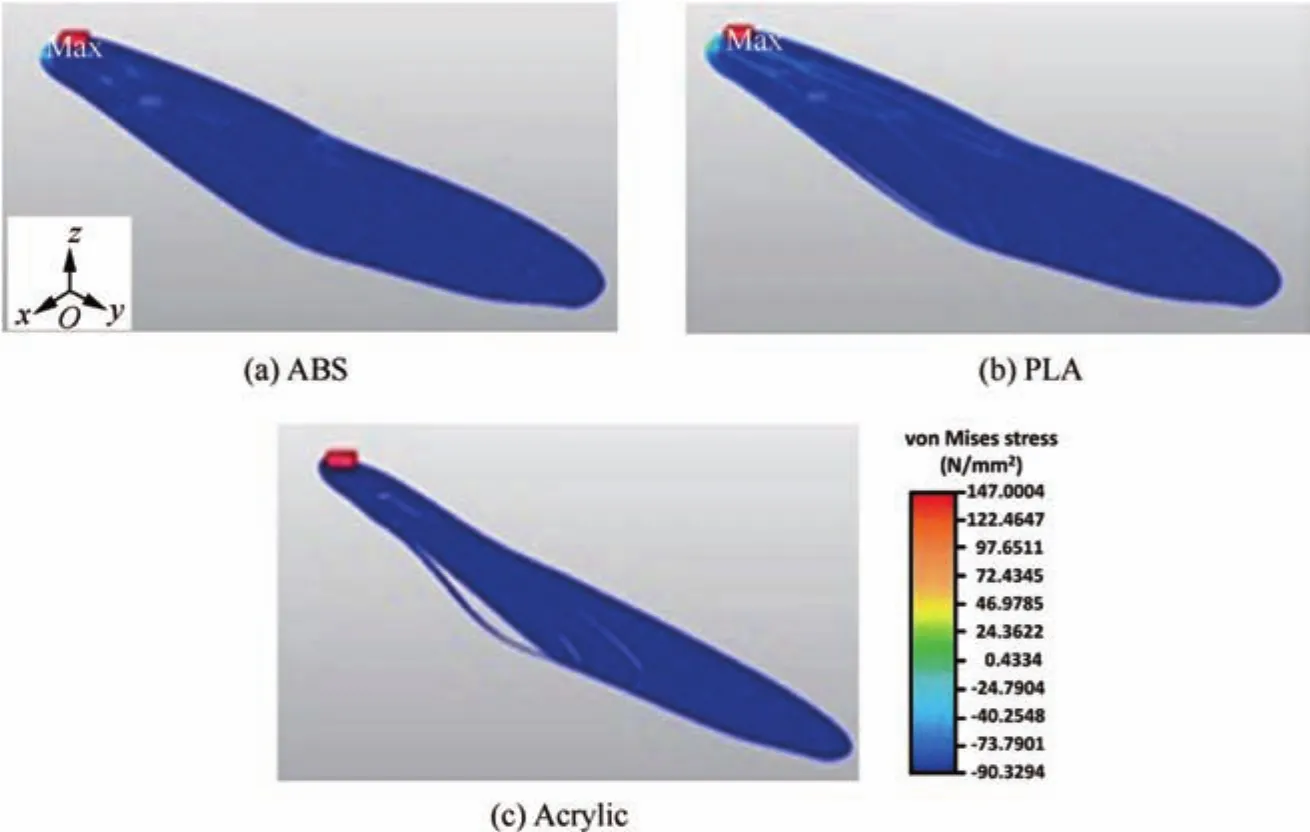

3.2.Stress simulation results(with a membrane)

Fig.7 shows the forewing models of all three materials used in this experiment.Based on Fig.6,the maximum von Mises stress occurs at approximately the same location for all three materials.The highest stresses occur in regions where the surface-to-area ratio is minimum.The maximum stresses recorded are 14.77,17.29,and 24.23 N/mm2for PLA,acrylic,and ABS,respectively.Both Figs.6 and 7 show that ABS exhibits the maximum stress among all three materials.

Fig.4 Experimental set-up:two high-speed cameras perpendicular to each other along with multi LED lighting.

Fig.5 Front and side views of wing motion captured(and measurement axes).

Fig.6 Stress simulation results for ABS,PLA and acrylic(without a membrane).

Fig.7 Stress simulation results for ABS,PLA,and acrylic(with a membrane).

3.3.Dragonfly wing flapping motion

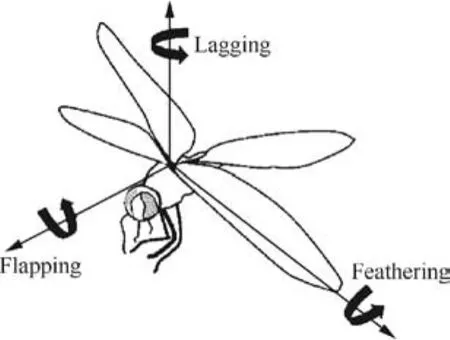

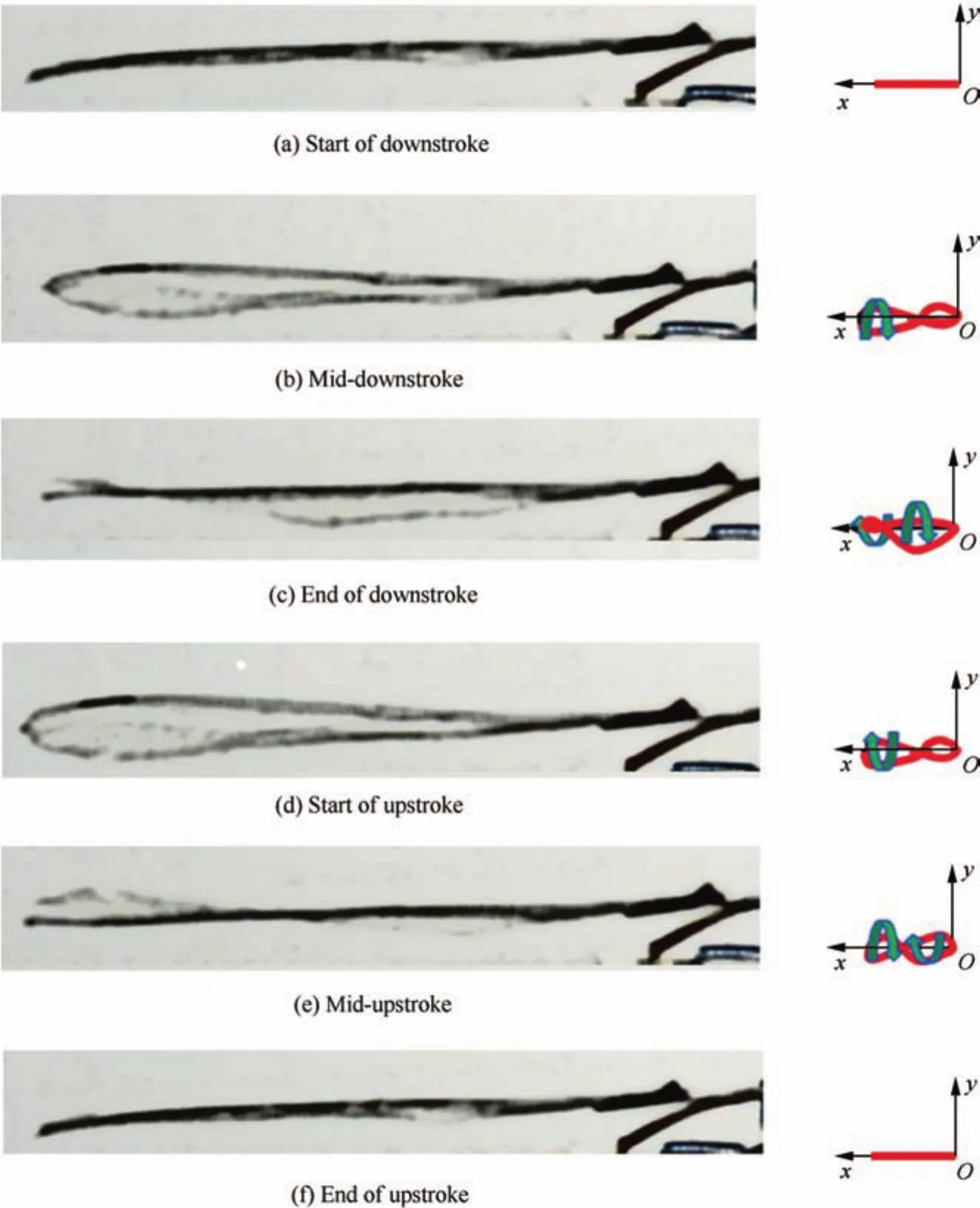

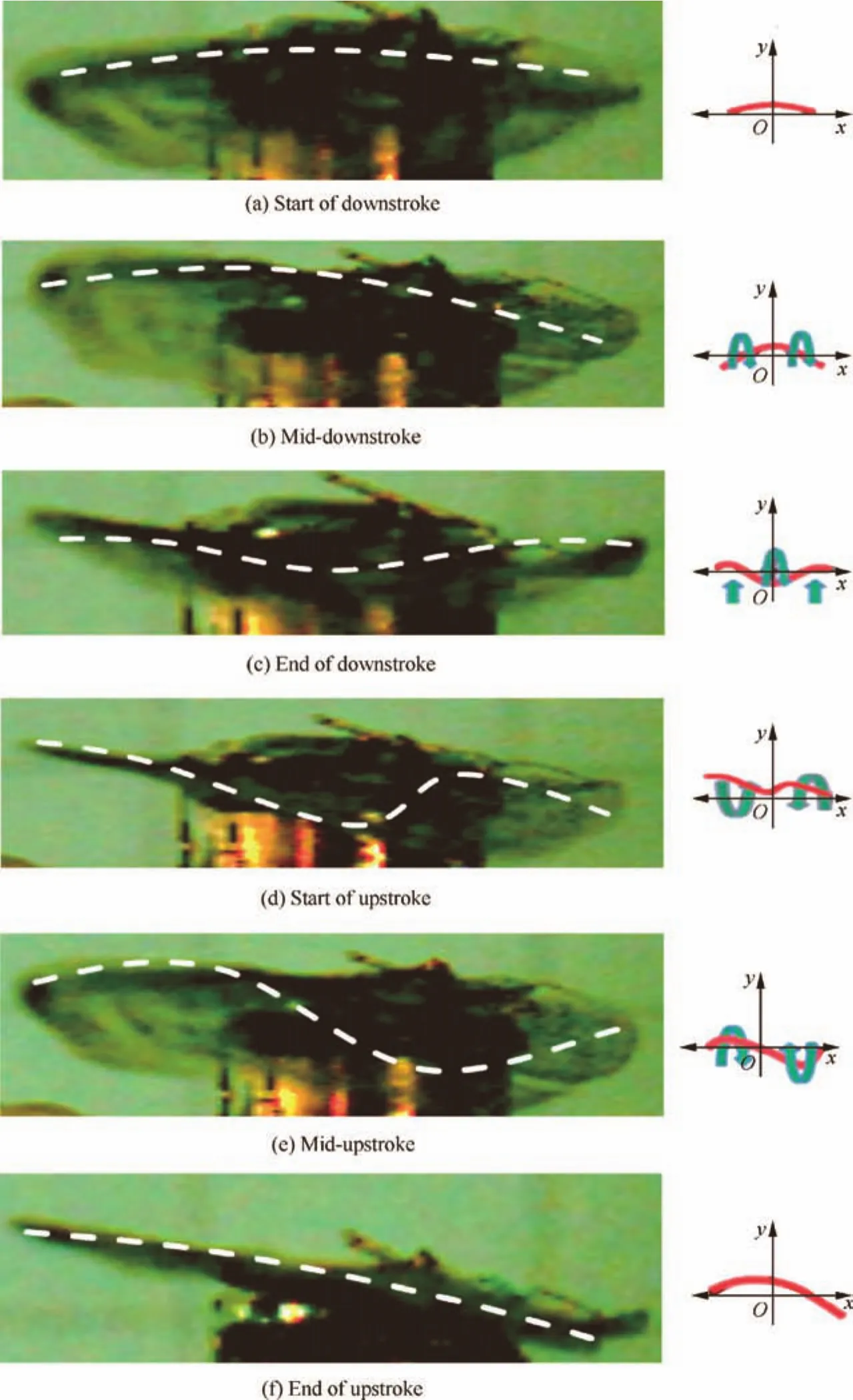

The experiment was conducted on each of the three types of wings(both with and without the chitosan membrane).This was done to study the flexibility of each wing frame material and to determine the best material for use in a BMAV.An actual dragonfly wing(Diplacodes Bipunctata)was also tested to study its motion during passive flapping at different frequencies and compare it with the fabricated wings.The nomenclature for wing rotation about different axes is shown in Fig.8.21Figs.9 and 10 show a sequence of images,illustrating the wing motion of an actual flapping dragonfly wing during one complete flapping cycle.The wing beat frequency for these images was 30 Hz,which is the nominal wing beat frequency of this species of dragonfly.

Dragonfly wings greatly deform during flight.This was observed in our experiment as well as by others.22Despite having a certain degree of rigidity,dragonfly wings undergo a considerable amount of bending,twisting,and rotational motions.Figs.9 and 10 show the motion of a flapping wing in one complete cycle at 30 Hz(side and front views).It was shown that in both directions(chord and spanwise),an asymmetric twist-bend motion was observed.Figs.9(d),(f),and 10(d)clearly show these asymmetric motions mentioned.At the end of an upstroke(observed in Fig.9(f)),the wing momentarily exhibited a symmetrical twisting motion.A large feathering rotation range of 154?–179?of the entire wing was observed at the beginning of the downstroke and the end of the upstroke(for all frequencies)(Figs.10(a)and(f)).Even during the steady phase(passive moment occurring when the flapping angle was zero),the wing was observed to undergo internal torsion.This corresponds well to previous findings made by Wootton et al.2,23

Besides the nominal 30 Hz wing beat frequency,the dragonfly wing was also flapped at frequencies ranging from 10 to 250 Hz.The pattern of deformations was similar for all of the frequencies observed.The measured bending angle,wing tip deflection,wing tip twist angle,and speed for the different wing frames(without and with a membrane)were plotted in comparison to the results obtained from an actual dragonfly wing in Figs.11–14.

Fig.8 Degrees of freedom for wings of a flying insect.21

3.4.Bending angle versus flapping frequency

Fig.9 Side view of dragonfly flapping wing(gray scale)captured by high speed camera during one flapping cycle at 30 Hz.

The bending angle is directly proportional to the flexibility of a wing.Both inertial and aerodynamic loads influence it.Wootton23found that most insect wings have relatively stiff supporting zones near the wing base and leading edge.Adding to this in a later article,Wootton24wrote that the wing veins taper in diameter from base to tip.The resulting reduction in stiffness reduces the inertial load at the wing tip,reducing the energy expenditure and stress at the wing base.Ennos and Wootton25showed that wings having a tapered stiffness distribution from base(high)to tip(low)are well suited to with stand torques.This article also showed that spanwise bending moments due to the inertia of flapping wings are approximately two times larger than those due to aerodynamic forces.A structural finite element analysis by Jongerius and Lentink26of a dragonfly wing model also showed that the inertial forces along the wingspan are 1.5–3 times higher than the aerodynamic forces.Similarly,Combes and Daniel27modeled dragon fly and hawkmoth wings,and found that the flexural stiffnessdeclined exponentially from wing baseto tip.Although inertial loading dominates,Young et al.4showed that aerodynamic forces(e.g.,lift and thrust)generated by a flapping wing also has an in fluence on wing flexibility.

This study focuses only on the chordwise flexibility of a passive flapping wing.Bending angles were measured along the chordwise direction.Kang and Shyy22also investigated chordwise flexibility,but for simple,non-anisotropic wing structures.They presented a detailed assessment of the effects of structural flexibility on the aerodynamic performance of flap-ping wings.The Reynolds number(Re=100)considered in this study is relevant to small insect flyers,such as fruit flies.However,this study only includes the roles of chordwise flexibility and passive pitch in two-dimensional plunging motions.

Fig.10 Front view of dragonfly flapping wing captured by high speed camera(gray scale)during one flapping cycle at 30 Hz.

Fig.11 Bending angles of different wing frames.

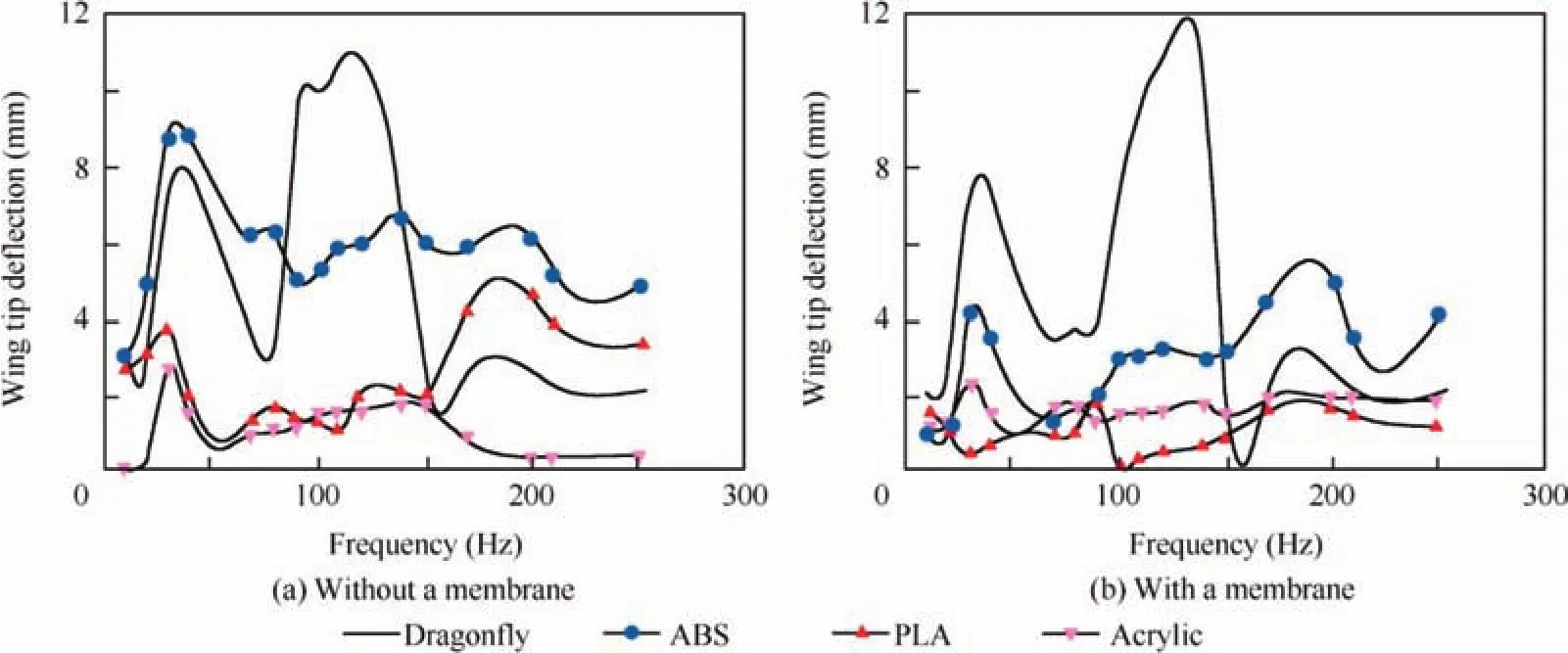

Fig.12 Wing tip deflection of different wing frames.

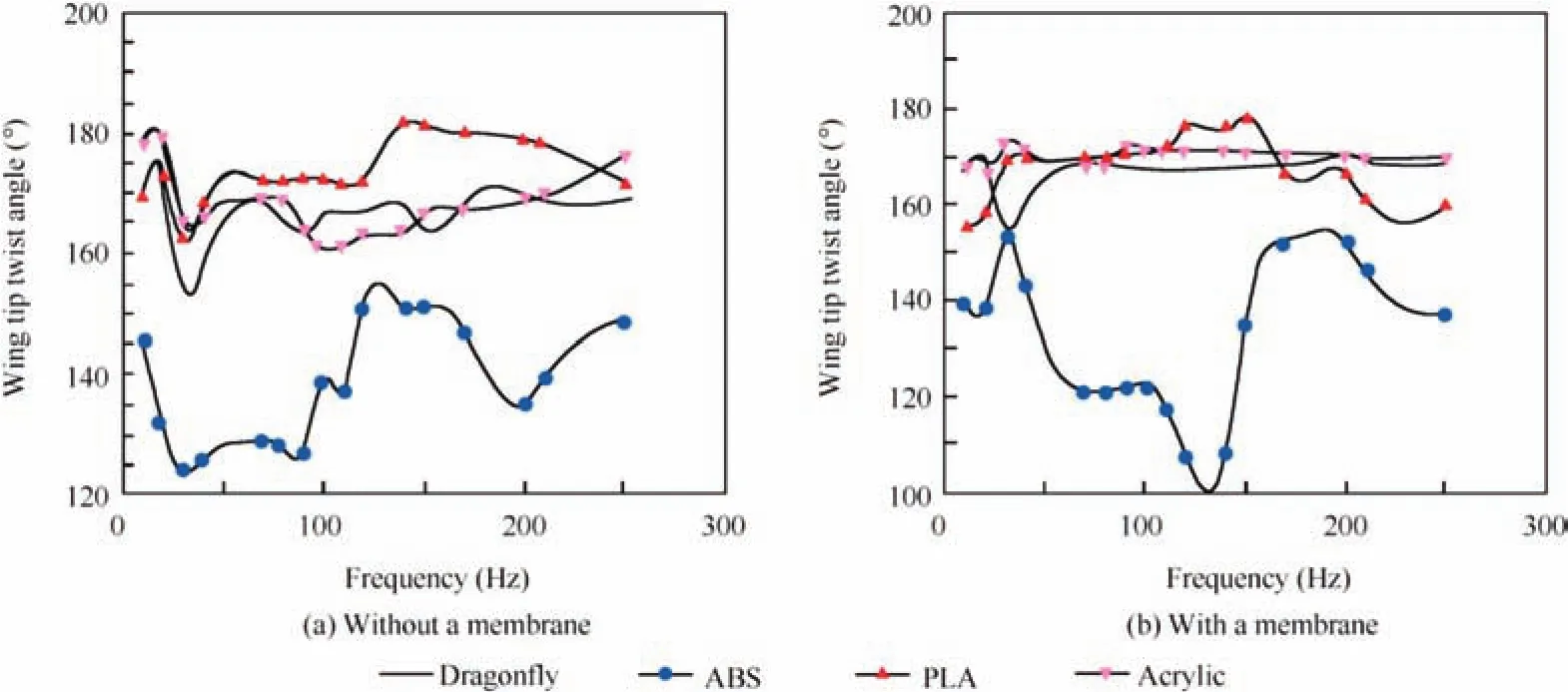

Fig.13 Wing twist angle of different frames versus flapping frequency.

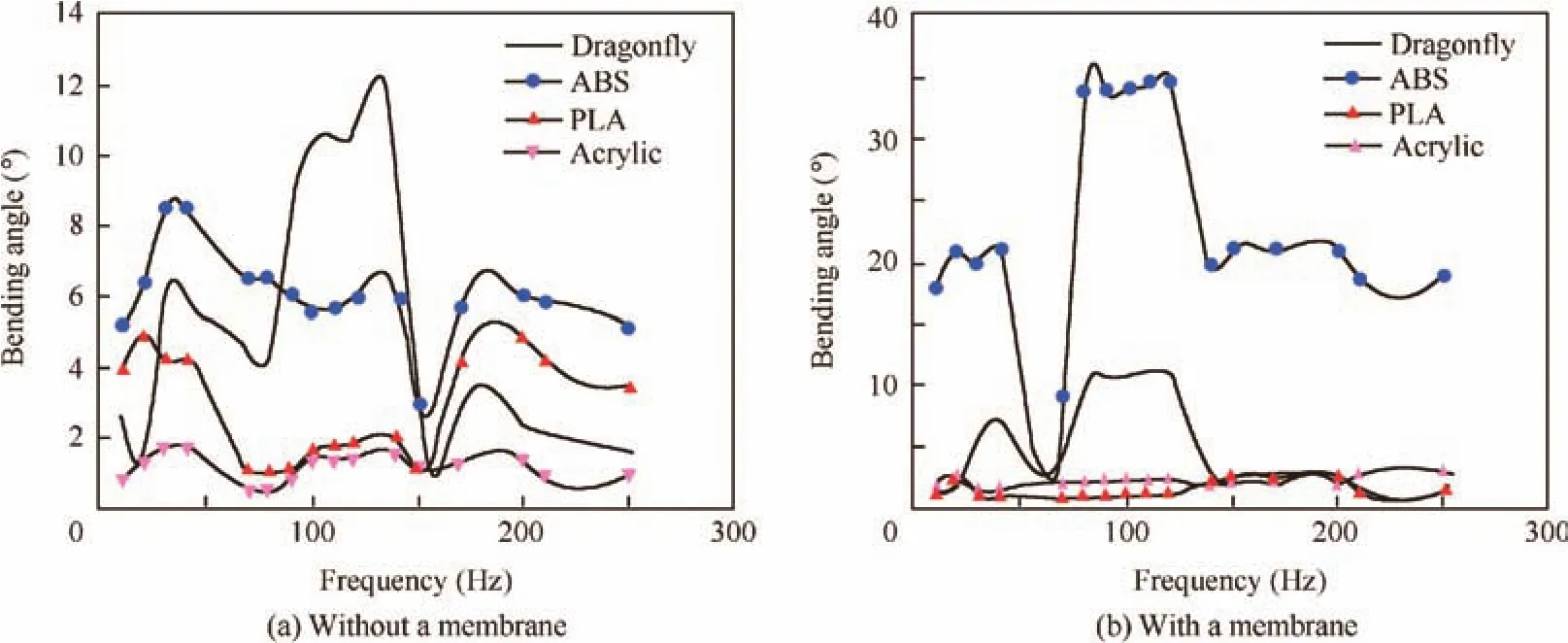

Our study involves a much more complex wing design than those in many past studies.However,tapering the thickness(declination from base to tip)of the veins in our physical models(similar to actual insect wings)was not possible due to fabrication limitations.Ourwingshave tapered flexibility(declining from base to tip and from leading to trailing edge)solely due to a reduction in the frame planform width sizes(mimicking veins)in these directions.Fig.11 shows the bend-ing angles as the wing beat frequency is varied for the three fabricated wing frames(without and with a membrane)in comparison to that of an actual dragonfly wing.Fig.11 shows that the maximum bending angle(hmax)for all the wings occurs during the upstroke.This was observed for both frames without and with a membrane.This agrees with the results of previous research done by Jongerius and Lentink,26in which this asymmetry(difference in the bending angle between the upstroke and downstroke)was attributed to the directional bending stiffness in a wing structure(e.g.,one-way hinge or a pre-existing camber in the wing surface).

The maximum bending angle of dragonfly wings at 30 Hz was recorded to be about 6?.The wings were observed to have a maximum bending angle of 10.7?at 120 Hz(natural frequency of an actual dragonfly).This is an increase of 78.3%from 30 Hz.ABS shows a high level of flexibility compared to the other two materials used.Fig.11 shows that the bending angle curves of the fabricated ABS wings are more similar to that of the actual dragonfly wing than those of the other two types.Fig.11(a)shows that the bending angle of an ABS wing(without a membrane)at 30 Hz is 8.5?and 5.9?at 120 Hz.At 30 Hz,the percentage difference between an ABS wing(without a membrane)and an actual dragonfly wing is about 42%.The PLA and acrylic wings recorded reduced percentage differences of 30%and 70%,respectively.In Fig.11(b),ABS exhibited much larger bending angles at 30 Hz when the membrane was added.The value of the ABS wing(with a membrane)is 20.1?at 30 Hz and 34.9?at 120 Hz.This angle is much larger than that of the actual dragonfly wing.The percentage increase between the ABS and the actual dragonfly wing is 233%.The other two materials(PLA and acrylic)exhibited much smaller bending angles than that of the actual dragonfly wing.The percentage reductions in PLA and acrylic(in comparison to the actual dragonfly wing)are 83%and 75%,respectively.

These observations confirm that the overall flexibility of a wing decreases after a membrane is attached,except for ABS wings.At a frequency of 120–170 Hz,the dragonfly wing bends at a very large angle.Previous research showed that dragonflies do not flap at their natural frequency(120–170 Hz).28Therefore,this result is likely due to a resonance effect caused by the wing beat frequency being proximate to the natural frequency of the wing.This result confirms that dragonflies have a maximum wing beat frequency limitation in this range.The ABS wing frame shows a similar trend at 120 Hz.The bending angle is reduced at frequencies greater than120 Hz for both the actual dragonfly wing and the three fabricated wings.

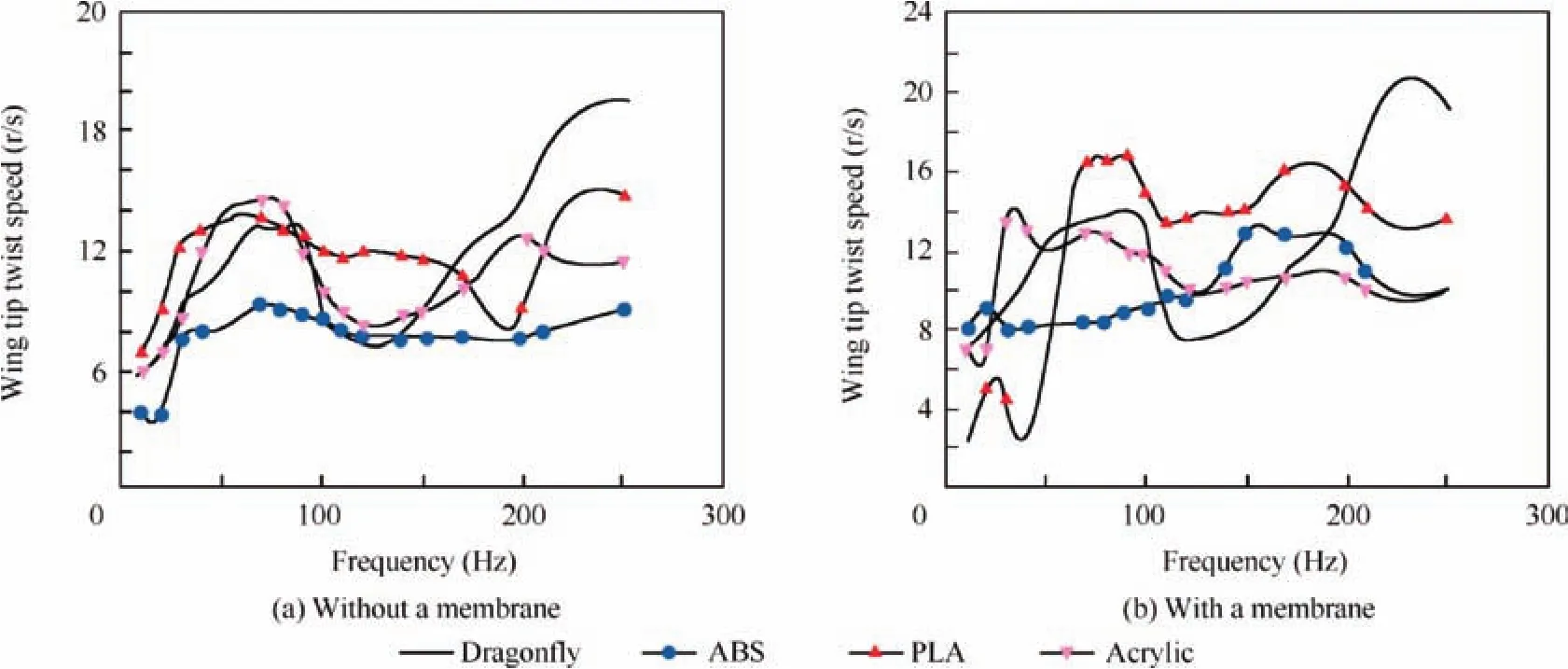

Fig.14 Wing tip twist speed of different frames versus flapping frequency.

3.5.Wing tip deflection versus flapping frequency

Fig.12 shows the wing tip deflection for varying wing beat frequencies of the three fabricated wing frames(without and with a membrane)in comparison to that of an actual dragonfly wing.Similar to the bending angle,deflection is another measurement that can be used to assess a flapping wing’s flexibility.As mentioned earlier,past studies have shown that wing flexibility has a significant effect on the wing’s ability to generate a suitable time-averaged lift or thrust.7Fig.12 shows that the maximum deflection(dmax)occurs during the upstroke.This again was observed for both frames without and with a membrane.This agrees with the results of previous research done by Luo et al.8

Fig.12(a)shows that all of the fabricated wing frames(without a membrane)deflect at magnitudes that are similar(only slightly reduced)to that of the actual dragonfly wing at 30 Hz which is about 7.1 mm.At 30 Hz,ABS has a percentage increase of 24%.PLA and acrylic both have percentage reductions of 48%and 62%,respectively.However,Fig.12(b)shows that the fabricated wing frames(with a membrane)have very different de flections from that of the actual dragonfly wing.Only the ABS wing showed a comparable level of de flection,however the dragon fly wing is 41%higher than the ABS wing.The PLA and acrylic wings have percentage reductions of 94%and 66%,respectively,compared to the dragonfly wing.The actual dragonfly wing is able to undergo a large deflection at the tip region.This supports the findings of previous studies,which explain that the difference between the deflections at the tip and the surface is created by the difference in the rigidity(due to the vein and corrugations)along the wing surface.29

The difference in deflection between the wing frames without and with a membrane shows that the attachment of a membrane causes an increase in rigidity.This increase in rigid-ity was observed to be the highest in the PLA wing.Only the ABS wing shows a curvature trend similar to that of the actual dragonfly wing around 120 Hz.At 120 Hz,a reduction in percentage of 45%(without a membrane)or 70%(with a membrane)is seen in the ABS wing frame.Compared to the PLA wing,there is a percentage reduction of 83%(without a membrane)or 95%(with a membrane).The acrylic wing has a percentage reduction of 85%,both without and with the membrane attached.The trend of the graph again shows that there is a decrease in flexibility after the membrane has been attached.Two high peaks were observed for the actual dragonfly wing(30 and 120 Hz).As already stated,the natural frequency of dragon fly wings has been reported to be between 120 to 170 Hz.28The extreme fluctuation observed in this range confirms the reporting.

3.6.Wing twist angle versus flapping frequency

Fig.13 shows the maximum wing tip twist angle of the three fabricated wing frames in comparison to that of an actual dragonfly wing.The maximum twist angle was recorded during the stroke reversal(transition from upstroke to downstroke).The twist angle for the actual dragonfly wing at 30 Hz is 154.58?.Untwisted wings have large,drag producing wing surfaces that are exposed to flow,and hence the importance of twisting in wings is justified.Wing tip twist also plays an important role in enhancement of flight performance.The mid-stroke timing of wing deformation in a butterfly,examined by Zheng et al.,29suggests that the deformation is not due to wing inertia,because the acceleration of the wing is small at this point in the stroke.They suggested that this is instead due to elastic effects,since the aerodynamic forces are very large at mid-stroke.

Figs.13(a)and(b)shows that both the PLA and acrylic wing frames(both without and with a membrane)closely match the performance of an actual dragonfly wing.At 30 Hz,the ABS wing(without and with a membrane)has percentage reductions of 20%and 1%respectively in comparison to that of the actual dragonfly wing.The PLA wing(without and with a membrane)has percentage increases of 5%and 10%,respectively.The acrylic wing(without and with a membrane)has percentage increases of 7%and 12%,respectively.At 120 Hz,the ABS and acrylic wings(without a membrane)have percentage reductions of 10%and 3%,respectively,compared to that of the dragonfly wing,while the PLA wing(without a membrane)has a percentage increase of 3%.The ABS wing(with a membrane)has a percentage reduction of 36%compared to that of the dragonfly wing,while the PLA and acrylic wings have percentage increases of 5%and 3%,respectively.Based on these results,the PLA and acrylic wings are more similar to the actual dragonfly wing than the ABS wing.The large fluctuation of the ABS wing across varying flapping frequencies(10–250 Hz)makes it a more complicated BMAV option.

Another trend observed from Fig.13 is that the wing tip twist angle of the dragonfly wing does not vary significantly as the flapping frequency is varied.This matches the finding of a previous study by Zhao et al.8(mentioned earlier)which showed that the flexibility of insect wings increases more chordwise than spanwise,due to the rigid leading edge vein.

This is true for both categories of wing frames(with and without a membrane).

3.7.Wing tip twist speed versus flapping frequency

Fig.14 shows the wing tip twist speed for the three wing frames(without and with a membrane)in comparison to that of an actual dragonfly wing.The wing tip twist speed was measured using the Vision Research Phantom Camera Control Software associated with our high frame rate cameras.Vogel30stated that the wing tip twist speed varies according to size and must exceed a ratio to flight speed(wing tip twist speed:flight speed)by 3.7 or more to enable forward flight.Fig.14 shows that the PLA and acrylic wing frames(both without and with a membrane)show a curvature trend similar to that of the actual dragonfly wing.The wing tip twist speed of the actual dragonfly wing at 30 Hz is 9.2 revolutions per second(r/s).At 30 Hz,the PLA wing shows a percentage increase of 32%(without a membrane)and a percentage reduction of 51%(with a membrane)in comparison with that of the dragonfly wing.The acrylic wing shows a percentage reduction of 4%(without a membrane)and an increase of 48%(with a membrane).The ABS wing shows percentage reductions of 16%(without a membrane)and 13%(with a membrane).At 120 Hz,all of the fabricated wing frames without a membrane attached,showed percentage increases in comparison to an actual dragonfly wing.The ABS,PLA,and acrylic wings show percentage increases of 5%,64%,and 13%,respectively,while the ABS,PLA,and acrylic wing frames without a membrane have percentage increases of 32%,88%,and 36%,respectively.The ABS wing frame shows a much different curvature trend from those of the other two,both with and without a membrane.Fig.14 shows that the wing tip twist speed is highly dependent on the flapping frequency and is less influenced by changes in the frame’s flexibility.This can be confirmed by observing the curves of the wing frames with a membrane.The observed trend is the same across varying flapping frequencies(10–250 Hz)for both types of wing frames.

Combes and Daniel31conducted a finite element analysis study on the wing structures of several different insects(including dragon flies).In all of the species that they tested,spanwise flexure stiffness was one to two orders of magnitude higher than chordwise flexure stiffness.They concluded that stiff leading edge veins played a primary role in generating this anisotropy.Moreover,as previously mentioned,the study conducted by Yang et al.11concluded that spanwise flexible deformation should be limited to a small range(by use of stiff leading edges)in order to achieve a higher aerodynamic performance for a flapping MAV.Alternatively,a larger chordwise deformation could serve to enhance the aerodynamic performance(e.g.,lift and thrust generation).

The results of our experiments in flapping an actual dragonfly wing support this observation,by showing that the chordwise deformation is very signi ficant compared to the spanwise deformation.These results suggest that BMAV wings should be designed with a stiff leading edge to limit the spanwise deformation and flexible ribs to keep the chordwise deformation within a significant but suitable range.This indicates that the ABS wing design is better suited for use in a BMAV than the PLA and acrylic wing designs.

4.Conclusions

One challenge in constructing a working BMAV involves the need to fabricate a highly deformable and flexible wing that has a large load-bearing capacity.An experimental study was conducted to assess elastic properties of flapping wings fabricated from three different materials(ABS,PLA,and acrylic).The structural design of each of these wings is identical and based on biomimicry of an actual dragonfly wing.The experimental results were compared to those of the actual dragonfly wing,on which they were based,in order to assess their potential applications in a BMAV design.A flapping mechanism that utilizes an electromagnetic actuator was used to flap the wings at various frequencies from 10 to 250 Hz.A high frame rate imaging system that includes two cameras was used to capture the three-dimensional motion of a flapping wing.Several different elastic parameters were measured:bending angle,wing tip deflection,wing tip twist angle,and wing tip twist speed.Analysis of the wing bending angle and wing tip deflection indicates the flexibility of the wing in the chordwise direction,while the wing tip twist angle and speed show the flexibility of the wing in the spanwise direction.The ABS wings exhibited the highest chordwise flexibility(indicated by their large bending angles and wing tip de flections).Although the PLA and acrylic fabricated wings exhibited much lower chordwise flexibility than that of the ABS fabricated wings and the dragonfly wing,their spanwise flexibility(indicated by their wing tip twist angles and speeds)closely matched that of the dragonfly wing.

These experimental results show that an actual dragonfly wing has a highly deformable structure despite its rigidity.The materials examined in this study(ABS,PLA,and acrylic)were selected due to their high flexibility,low density,and low fabrication costs.This study shows that each of these materials is able to perform like an actual dragonfly wing to varying degrees.However,the ABS wing design gave better results in matching the chordwise flexibility of the actual dragonfly wing,while limiting the spanwise flexibility to a much greater degree than those of the other two designs.

Acknowledgements

This research was done under the auspices of the Centre for Transportation Research at the Faculty of Engineering,University of Malaya.It was primarily funded by the High Impact Research Grant from the Malaysian Ministry of Higher Education(UM.C/625/1/HIR/MOHE/ENG/12,H-16001-D000012)and a secondarily by a University of Malaya Research Grant(RG155-12AET).

1.Sivasankaran PN,Ward TA,Viyapuri R,Johan MR.Static strength analysis of dragonfly inspired wings for biomimetic micro air vehicles.Chin J Aeronaut2016;29(2):411–23.

2.Wootton RJ,Evans KE,Herbert R,Smith CW.The hind wing of the desert locust(Schistocerca gregaria Forskal).I.Functional morphology and mode of operation.J Exp Biol2000;203(19):2921–31.

3.Mountcastle AM,Daniel TL.Aerodynamic and functional consequences of wing compliance.Exp Fluids2009;46(5):873–82.

4.Young J,Walker SM,Bomphrey RJ,Taylor GK,Thomas AL.Detailsofinsectwingdesignanddeformationenhanceaerodynamic function and flight ef ficiency.Science2009;325(5947):1549–52.

5.Zhu JY,Zhou CY,Wang C,Jiang L.Effect of flexibility on flapping wing characteristics under forward flight.Fluid Dyn Res2014;46(5):055515.

6.Kei S,Takuya O,Masahiko K,Naoto Y,Norio H,Makoto I.Effects of structural flexibility of wings in flapping flight of butter fly.Bioinspiration Biomimetics2012;7(2):025002.

7.Zhao L,Huang QF,Deng XY,Sane SP.Aerodynamic effects of flexibility in flapping wings.J R Soc Interface2010;7(44):485–97.

8.Luo HX,Tian FB,Song JL,Lu XY.Aerodynamic cause of the asymmetric wing deformation of insect wings.In:DFD12 meeting of the American Physical Society(APS);2012 Nov 18–20;San Diego(CA).College Park,MD:APS Division of Fluid Dynamics;2012.

9.Tian FB,Luo HX,Song JL,Lu XY.Force production and asymmetric deformation of a flexible flapping wing in forward lf ight.J Fluids Struct2013;36:149–61.

10.Ha NS,Truong QT,Goo NS,Park HC.Biomechanical properties of insect wings:The stress stiffening effects on the asymmetric bending of the Allomyrina dichotoma beetle’s hind wing.PLoS One2013;8(12):e80689.

11.Yang WQ,Song BF,Song WP,Wang LG.The effects of spanwise and chord-wise flexibility on the aerodynamic performance of micro flapping-wing.Chin Sci Bull2012;57(22):2887–97.

12.Mountcastle AM,Combes SA.Wing flexibility enhances loadlifting capacity in bumblebees.Proc R Soc London B:Biol Sci2013;280(1759):1–8.

13.Wu P,Stanford BK,Sa¨llstro¨m E,Ukeiley L,Ifju PG.Structural dynamics and aerodynamics measurements of biologically inspired flexible flapping wings.BioinspirationBiomimetics2011;6(1):016009.

14.Sivasankaran PN,Ward TA.Spatial network analysis to construct simplified wing structural models for biomimetic micro air vehicles.Aerospace Sci Technol2016;49:259–68.

15.Srigrarom S,Chan WL.Ornithopter type flapping wings for autonomous micro air vehicles.Aerospace2015;2(2):235–78.

16.Sudo S,Tsuyuki K,Yano T,Takagi K.A magnetic fluid microdevice using insect wings.J Phys:Condensed Matter2008;20(20):204142.

17.Chilson L.The difference between ABS and PLA for 3D printing.ProtoParadigm[Internet].[updated 2013 Jan 26;cited 2016 Oct].Availablefrom:http://www.protoparadigm.com/news-updates/the-difference-between-abs-and-pla-for-3d-printing/.

18.Rubentheren V,Ward TA,Chee YC,Praveena N.Physical and chemical reinforcement of chitosan film using nanocrystalline cellulose and tannic acid.Cellulose2015;22(4):2529–41.

19.Shyy W,Aono H,Chimakurthi SK,Trizila P,Kang CK,Cesnik CES,et al.Recent progress in flapping wing aerodynamics and aeroelasticity.Prog Aerospace Sci2010;46(7):284–327.

20.Gui L,Fink T,Cao Z,Sun D,Seiner JM,Streett DA.Fire ant alate wing motion data and numerical reconstruction.J Insect Sci2010;10(19):1–17.

21.Ward TA,Rezadad M,Fearday CJ,Rubentheren V.A review of biomimetic air vehicle research:1984–2014.Int J Micro Air Vehicles2015;7(3):375–94.

22.Kang CK,Shyy W.Scaling law and enhancement of lift generation of an insect-size hovering flexible wing.J Royal Soc Interface2013;10(85):20130361.

23.Wootton RJ.Support and deformability in insect wings.J Zool1981;193(4):447–68.

24.Wootton RJ.Functional morphology of insect wings.Ann Rev Entomol1992;37:113–40.

25.Ennos AR,Wootton RJ.Functional wing morphology and aerodynamics of Panorpa germanica(Insecta:Mecoptera).J Exp Biol1989;143(1):267–84.

26.Jongerius SR,Lentink D.Structural analysis of a dragonfly wing.Exp Mech2010;50(9):1323–34.

27.Combes SA,Daniel TL.Flexural stiffness in insect wings II.Spatial distribution and dynamic wing bending.J Exp Biol2003;206(17):2989–97.

28.Mingallon M,Ramaswamy S.The architecture of the dragonfly wing:A study of the structural and fluid dynamic capabilities of the anisoptera’s forewing.ASME 2011 international mechanical engineering congress and exposition;2011 Nov 11-17;Denver(CO).New York:ASME;2011.

29.Zheng LX,Hedrick TL,Mittal R.Time-varying wing twist improves aerodynamic efficiency of forward flight in butterflies.PLoS One2013;8(1):e53060.

30.Vogel S.Comparative biomechanics:Life’s physical world.2nd ed.Princeton(NJ):Princeton University Press;2013.p.251–63.;Vogel S.Comparative biomechanics:life’s physical world 2nd ed..Princeton(NJ):Princeton University Press;2013.p.251–63.

31.Combes SA,Daniel TL.Flexural stiffness in insect wings I.Scaling and the influence of wing venation.J Exp Biol2003;206(17):2979–87.

29 January 2016;revised 25 April 2016;accepted 27 October 2016

Available online 15 February 2017

*Corresponding author.

E-mail address:T.Ward@hw.ac.uk(T.A.Ward).

Peer review under responsibility of Editorial Committee of CJA.

CHINESE JOURNAL OF AERONAUTICS2017年2期

CHINESE JOURNAL OF AERONAUTICS2017年2期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- High-temperature tribological behaviors of a Cr-Si co-alloyed layer on TA15 alloy

- Analysis and control of the compaction force in the composite prepreg tape winding process for rocket motor nozzles

- Impact of lubricant traction coefficient on cage’s dynamic characteristics in high-speed angular contact ball bearing

- Variable stiffness design of redundantly actuated planar rotational parallel mechanisms

- Adaptive formation control of quadrotor unmanned aerial vehicles with bounded control thrust

- Constrained adaptive neural network control of an MIMO aeroelastic system with input nonlinearities