Influence of SPS casing treatment on axial flow compressor subjected to radial pressure distortion

Li Fnyu,Li Jun,Dong Xu,Sun Dkun,*,Sun Xiofeng

aScience and Technology on Plasma Dynamics Laboratory,Air Force Engineering University,Xi’an 710038,ChinabCo-Innovation Center for Advanced Aero-Engine,Beihang University,Beijing 100083,China

Influence of SPS casing treatment on axial flow compressor subjected to radial pressure distortion

Li Fanyua,b,Li Juna,Dong Xub,Sun Dakunb,*,Sun Xiaofengb

aScience and Technology on Plasma Dynamics Laboratory,Air Force Engineering University,Xi’an 710038,ChinabCo-Innovation Center for Advanced Aero-Engine,Beihang University,Beijing 100083,China

Axial compressor;Casing treatment;Fan stability;Inlet distortion;Rotating stall

The present work is about the stall margin enhancement ability of a kind of stall precursor-suppressed(SPS)casing treatment when fan/compressor suffers from a radial total pressure inlet distortion.Experimental researches are conducted on a low-speed compressor with and without SPS casing treatment under radial distorted inlet flow of different levels as well as uniform inlet flow.The distorted flow fields of different levels are generated by annular distortion flow generators of different heights.The characteristic curves under these conditions are measured and analyzed.The results show that the radial inlet distortion could cause a stall margin loss from 2%to 30%under different distorted levels.The SPS casing treatment could remedy this stall margin loss under small distortion level and only partly make up the stall margin loss caused by distortion in large level without leading to perceptible additional efficiency loss and obvious change of characteristic curves.The pre-stall behavior of the compressor is investigated to reveal the mechanism of this stall margin improvement ability of the SPS casing treatment.The results do show that this casing treatment delays the occurrence of rotating stall by weakening the pressure perturbations and suppressing the nonlinear amplification of the stall precursor waves in the compression system.

1.Introduction

Modern aircrafts,especially the military fighters,are often subjected to complex flight conditions.Their propulsion systems using air-breathing gas turbine engine often suffer from distorted inlet conditions.For example,the flow separation at the nacelle lip when planes take off or fly with large angle of attack can lead to a pressure inlet distortion.The crosswinds at the inlet and the growth of the boundary layer in the inlet duct can also cause a pressure loss inside the inlet.In addition,the S-duct inlet can cause a couple of counter rotating vortexes at the interface of the duct and the engine,which will finally result in a distorted inlet flow.In the multispool engine,the rotating stall occurring in the upstream compressor stages seems to be a rotating pressure inlet distortion to the downstream stages.For fighters,in the formation flying,the separation flow and exhaust gases from the former flight may cause non-uniform temperature and total pressure inletcondition to the later flight.When launching missiles,the fighter may ingest the exhaust gases from the weapon,which can also lead to non-uniform temperature pro files.These aero-engine distorted inlet conditions directly in fluence the performance and stability of its compression system,such as fan/compressor,and then reduce the operation function,safety and fuel economy of the engine.Thus,the investigation of various inlet distortions and their in fluences on the performance and stability of the compression system are of great signi ficance for researchers and aero-engine companies.

Among these different types of inlet distortion,the total pressure distortions are more common.According to whether the distortion area is transient or not,the total pressure distortion can be classified as the steady type containing radial inlet distortion,circumferential inlet distortion and their combination,and the unsteady type including rotating inlet distortion and swirl inlet distortion.Lots of works have been carried out to study the impact of the circumferential and radial total pressure distortion,1–8the rotating inlet distortion9–11and the swirl inlet distortion12–14on the performance and stability of the fan/compressor.Summarily,the circumferential and radical total pressure distortion can often lead to an impairment in the performance and a decrease of stall margin.The rotating and swirl type inlet distortion can also cause adverse impacts under some conditions.While in other special circumstances,they can even bring benefits to the performance and stall margin.All these studies on different types of inlet distortion and their impacts on the performance and stall margin of fan/compressor in aero-engine are very important and meaningful.Furthermore,the research works on how to decrease or even overcome these negative influences of the inlet distortion have more significance in practice.

As we all know,there are many techniques to increase the stall margin of fan/compressor,such as the active rotating stall/surge control and casing treatment technique.The idea of compressor instability active control was originally presented by Epstein et al.15and first realized in laboratory by Ffowcs Williams and Huang on a centrifugal compressor.16After that,many active rotating stall control researches were carried out.17–22Some of them were conducted to remedy the stall margin loss caused by inlet distortion.Van Schalkwyk et al.20used an active feedback control approach to stabilize the circumferential inlet distortion induced instability associated with rotating stall onset on a three-stage low-speed compressor.The results showed that the stabilization allowed stallfree operation to be extended below the natural(distorted flow)stall point by up to 3.7 percent for a 0.8 dynamic head distortion.For a 1.9 dynamic head distortion,40 percent of the mass flow range lost due to inlet distortion was regained through active control.Spakovszky et al.attempted to stabilize rotating stall in a single-stage transonic axial flow compressor with radial21or circumferential22inlet distortion by active feedback control using 12 jet-injectors annularly arrayed upstream of the rotor tip.The results showed that under radial inlet distortion,steady axisymmetric injection of 4%of the compressor mass flow could make a reduction in stalling mass flow of 9.7%and unsteady non-axisymmetric injection could achieve a further 7.5%reduction.21Under circumferential total pressure distortion of about one dynamic head and a 120-degree extent,steady axisymmetric,unsteady asymmetric and unsteady non-axisymmetric injection resulted in 6.2%,9%and 16.4%reduction of stalling mass flow,respectively.22

On the other hand,casing treatment technique is well known as an effective approach to extend stall margin.This approach was first found by Koch23in experiments accidentally.Since then,research works about the stall margin enhancement of fan/compressor with this technique and the mechanism behind it were conducted.24–26Some works also have been carried out to study its ability to make up the stall margin loss caused by the distorted inlet flow.Langston27studied some techniques to minimize the adverse effects of inlet distortion and found that the use of honeycomb blade tip shrouds could reduce the sensitivity of compressor to distortion.Madden and West28experimentally and numerically investigated the effects of the rotor casing treatment on a single stage military fan with tip-low total pressure radial inlet distortion.The results showed that the stability line can be successfully extended by using the rotor casing treatment.However,the designs of these kinds of casing treatment are based on trial and error method by experiments.Its perforated ratio is often more than 50%.Using this technique to extend the stall margin loss will bring additional efficiency loss with respect to the efficiency decrease caused by inlet distortion.24,28

Recently,a kind of stall precursor-suppressed(SPS)casing treatment29–35has been proposed to overcome the weakness of conventional casing devices.Its mechanism is based on the interaction of the pressure wave and the vortex wave,which can add some damping on the boundary of the compression system and influence the evolution of stall precursors near the rotating stall.29,30And the design of this casing treatment is guided by a 3D compressible stability model rather than trial-and-error methods.30,33Its ability to enhance the stall margin has been confirmed theoretically30,33and experimentally.31,32,34The experimental results from two low-speed compressors and a transonic compressor all showed that the SPS casing treatment could extend the stall margin by 8–18%.More importantly,this technique has obvious advantages over the traditional casing treatment because it can improve the stall margin without obviously changing the variation trend of the pressure-rise characteristics or leading to a recognizable efficiency loss.Further works were also conducted to study its ability to make up the stall margin loss caused by the rotating inletdistortion35and circumferential total pressure inlet distortion.The results showed that the SPS casing treatment,under the co-rotating inlet distortion,could not only make up the stall margin loss caused by inlet distortion but also enhance the stall margin compared to the solid wall casing under the clean inlet condition.35With the circumferential total pressure inlet distortion,the SPS casing treatment could remedy the stall margin loss caused by inlet distortion in small level and partly recover the stall margin loss caused by inlet distortion in large level.At the same time,the additional efficiency variation caused by the SPS casing treatment was less than 1%under both situations,which was within the range of the experimental error.Now,it is natural to wonder whether this technique can also take effects on the stall margin extending with radial inlet distortion,and how it will work in this condition.

In the present paper,experiments are conducted to study the effectiveness of SPS casing treatment to make up the stall margin loss caused by the radial total pressure inlet distortion on a low speed compressor.The radial distorted inlet flow fields are generated by annular distortion flow generators.The characteristic curves are measured under the conditions with and without SPS casing treatment and radial inlet distor-tion in different levels as well as uniform inlet flow.With these experimental data,the stall margins are accordingly calculated,along with studying the stall margin loss caused by distorted inlet flow and the ability of the SPS casing treatment to recover this stall margin loss.The per-stall behavior of the compressor is also studied to discuss the mechanism behind the stability enhancement.

2.Experimental facilities and instruments

The experiments conducted in this paper are based on these facilities and instruments discussed below.

2.1.Low-speed test compressor

The experiments conducted in present paper are carried out with a low-speed test compressor called TA36,which is shown in Fig.1.This low-speed compressor is a high load rig with small aspect ratio,consisting of an inlet duct(1 in Fig.1(b)),an axial rotor(8 in Fig.1(b)),an axial stator(9 in Fig.1(b)),an exhaust duct(13 in Fig.1(b))and a throttle composed of a fixed cone(15 in Fig.1(b))and a movable annular sleeve(16 in Fig.1(b))around the cone.

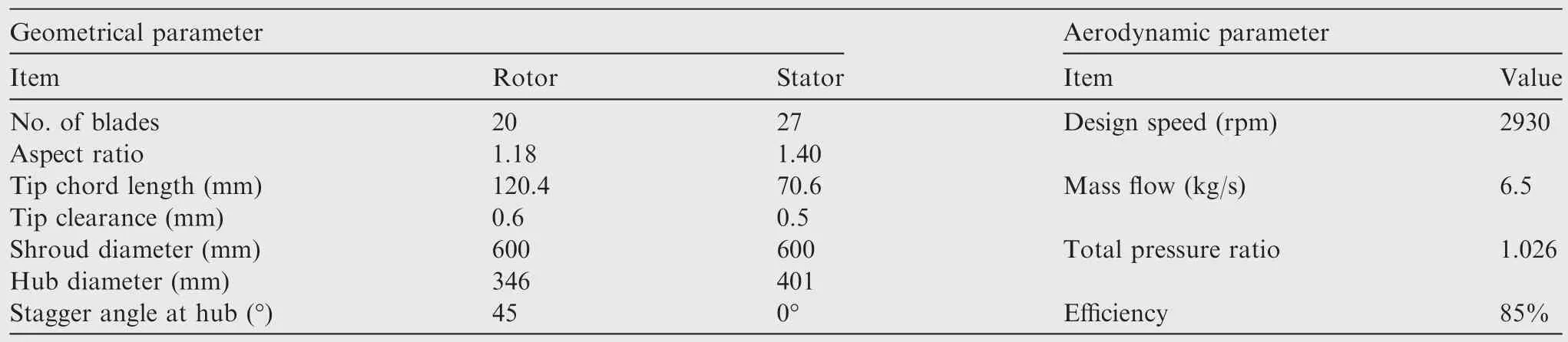

The rotor is driven by an asynchronous ac-motor(14 in Fig.1(b))with the normal rated power of 15 kW.The rotational speed is controlled by a frequency converter and can vary from 0 to the design value.The load of blades is varied by adjusting the axial position of the annular sleeve to change the area of the outlet.In this way,the operating point can accurately and slowly approach the rotating stall and quickly move away from it.The main design parameters of TA36 are displayed in Table 1.

2.2.SPS casing treatment

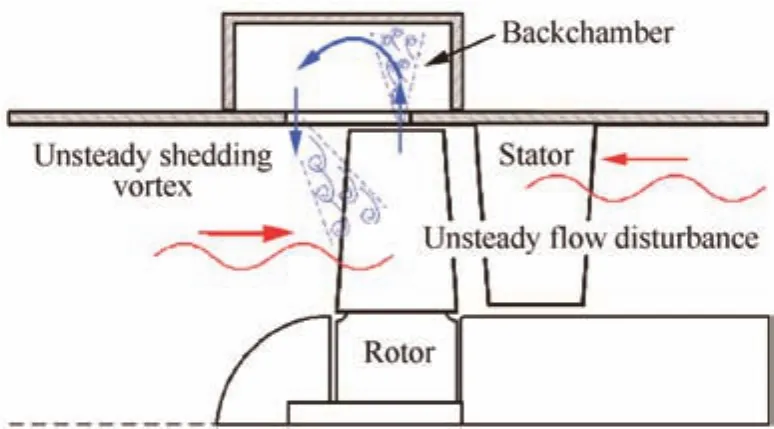

The SPS casing treatment(10 in Fig.1(b))is installed on the upstream of the rotor blade row and has an overlap with the rotor tip region.A typical configuration of SPS casing treatment is depicted in Fig.2.It contains an annular backchamber and a perforated plate.The chamber’s height is about 50 mm and its length can be adjusted from 100 to 200 mm.The length of the perforated plate is 75 mm and its open area ratio can be adjusted by a controller from 0%to 6.4%so that the casing can switch between the ordinary solid wall casing condition and the SPS casing treatment condition.The SPS casing treatment is designed in terms of the mechanism of the vortex wave and pressure wave interaction(Fig.3)to add some damping into the system,which can influence the stall inception or the evolution of stall precursors.

Fig.1 Exterior and configuration of TA36.

2.3.Radial inlet distortion generator

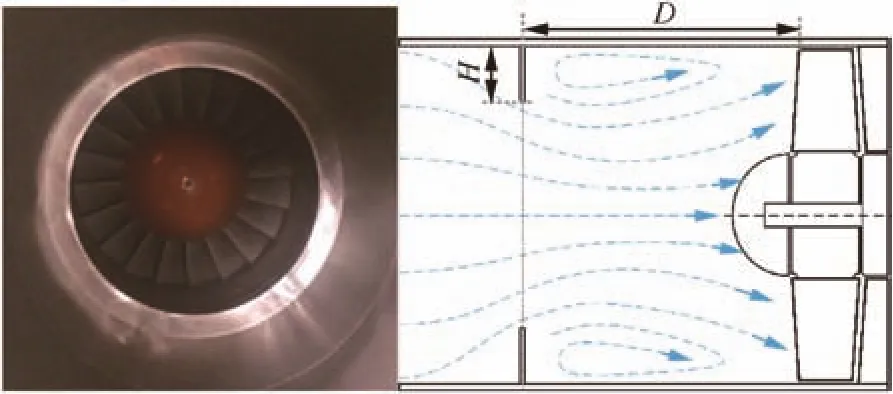

The radial inlet distortion generator(RIDG)(4 in Fig.1(b))is installed on the casing upstream of the rotor.The distance from the generator to the rotor blade tip(Din Fig.4)is about 450 mm.The RIDGs with different heights(Hin Fig.4)are designed to cover the area of the inlet from 10%to 30%.Using different distortion generators can generate radial distortion inlets with different intensities.

Table 1 Design parameters of TA36.

Fig.2 Configuration of SPS casing treatment.

Fig.3 Mechanism of SPS casing treatment.

Fig.4 Radial inlet distortion generator.

2.4.Measurement and data acquisition system

The measurement system contains the inlet flow field measurement part,the steady-state characteristic measurement part,the dynamic pressure measurement part and data acquisition part.

2.4.1.Inlet flow field measurement part

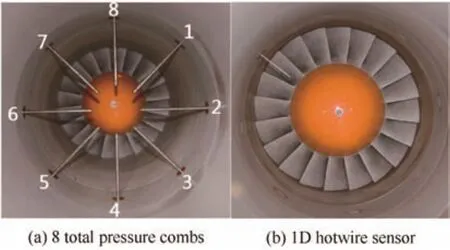

Inlet flow field measurement part is designed to obtain the distortion flow field structure of the selected inlet cross section(plane III in Fig.1(b)).Eight total pressure combs shown in Fig.5(a)are used to measure the inlet total pressure distribution of the whole cross section.There are 40 Kulite highfrequency response pressure sensors installed in these combs(5 for each).As the distortion of the flow field studied in this paper is almost axisymmetric and mainly near the casing wall,a 1D hotwire sensor shown in Fig.5(b)is used to detailedly measure the flow field near the casing wall.

Fig.5 Inlet flow field measurement part.

2.4.2.Steady-state characteristic measurement part

The steady-state characteristics measurement part contains an inlet total pressure comb(2 in Fig.1(b)),4 inlet static pressure sensors(3 in Fig.1(b)),an outlet total pressure comb(11 in Fig.1(b))and 4 outlet static pressure sensors(12 in Fig.1(b)).As shown in Fig.1,the inlet and outlet sensors are mounted in the plane I and plane V to measure the inlet/outlet total and static pressure,respectively.Each total pressure combcontains 5 sensors in the radial direction and 4 inlet/outlet static pressure sensors circumferentially equidistantly mounted on the casing.All characteristic parameters can be calculated from these measures as well as geometrical dimensions of the compressor.

2.4.3.Dynamic pressure measurement part

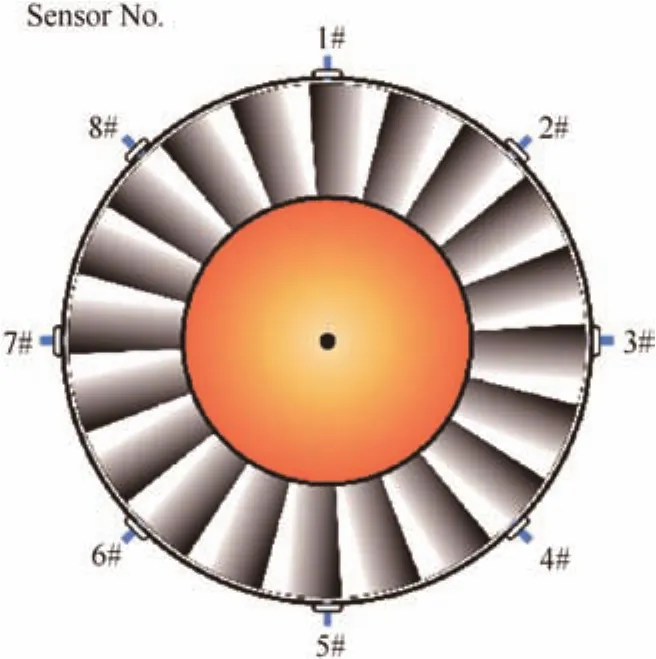

The dynamic pressure measurement part contains 8 highfrequency response dynamic pressure sensors(Fig.1).They are circumferentially equidistantly installed on the casing wall in the plane IV(Fig.6)which is about half a chord length upstream of the rotor blade tip.This part is used to record the static pressure perturbations near the rotor tip region.

2.4.4.Data acquisition part

The data acquisition part is mainly a NI-PXI system.This system contains 6 acquisition devices.It can totally provide 48 data acquisition channels.The maximum sampling rate can be up to 100 kHz.

3.Experiment description

3.1.Experimental conditions

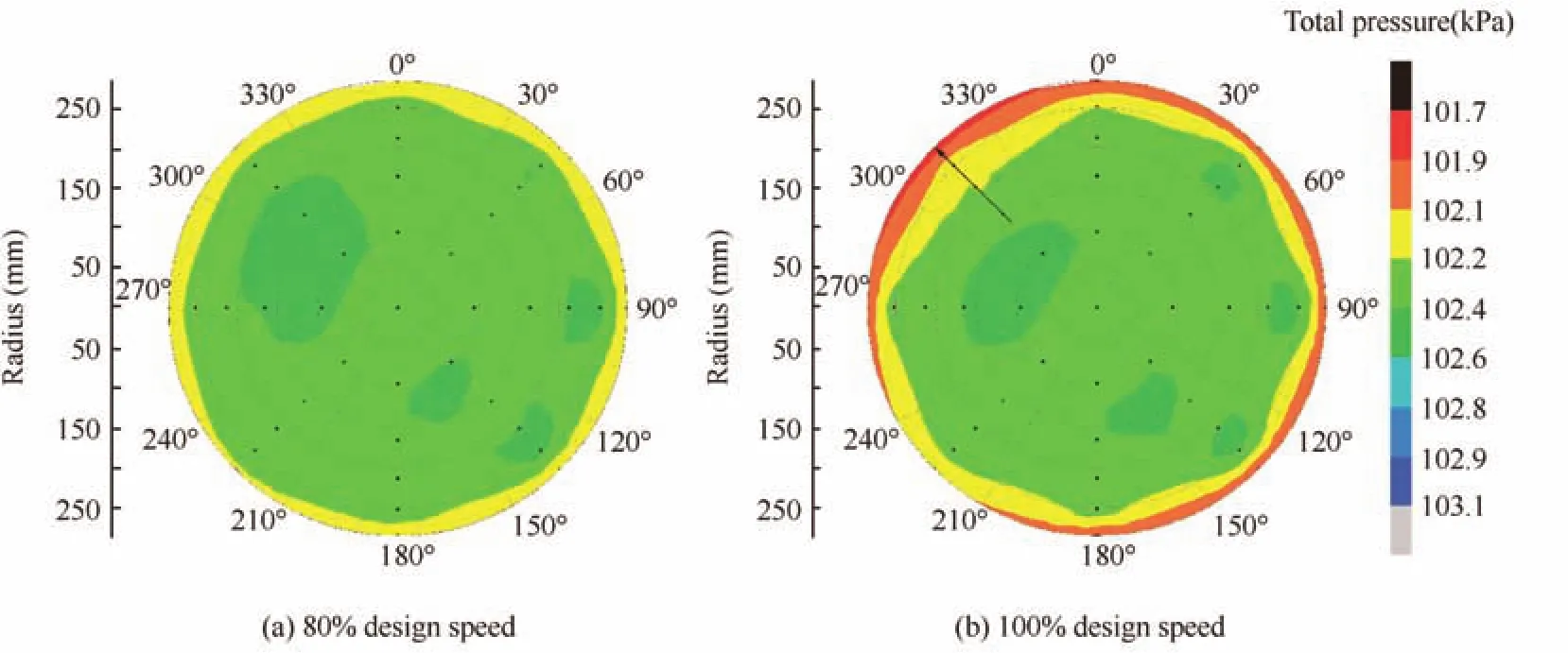

In this paper,the radial inlet distortion with 4 kinds of different intensities is studied.Different intensities of distortion are generated by RIDGs with different heights.The area covered by the RIDG in percentage of the total area of the inlet is used to reflect the intensities of the distortion flow field.For example,10%means that the RIDG’s area covers 10%of inlet area.The intensities of the distortion flow field studied in the present work and their corresponding height of RIDG are shown in Table 2.

Under each intensity of inlet distortion together with the uniform inlet flow,experiments are conducted at 100%and 80%design speeds.Under each rotor speed,the inlet distor-tion flow field is measured at plane III when the downstream throttle is completely opened.Then the throttle is closed slowly to move the work point from large flow condition to rotating stallcondition.During this period,the pressure rise characteristic and efficiency characteristic are recorded.From the pre-stall to rotating stall condition,the near casing wall static pressure near the rotor tip region is recorded to analyze the evolution of the pressure perturbations just before stall occurs.

Fig.6 Dynamic pressure measurement part.

Table 2 Intensities of distortion flow field.

3.2.Parameter calculation

The parameters used in this paper are calculated based on the following formulas.Thecompressorcharacteristicisin the form of the total-to-static pressure rise coefficient versus the flow coefficient.The total-to-static pressure rise coefficient w is calculated as

Fig.7 Total inlet pressure field structure under 10%radial inlet distortion.

Fig.8 Radial distribution of axial velocity under different radial inlet distortions.

whereNris the rotor speed andrmthe radius at mid-span of the blade.The flow coefficient u is calculated as

whereVxis the axial inlet velocity,QVthe volume flow,andAthe area of the inlet.The efficiency g is expressed as

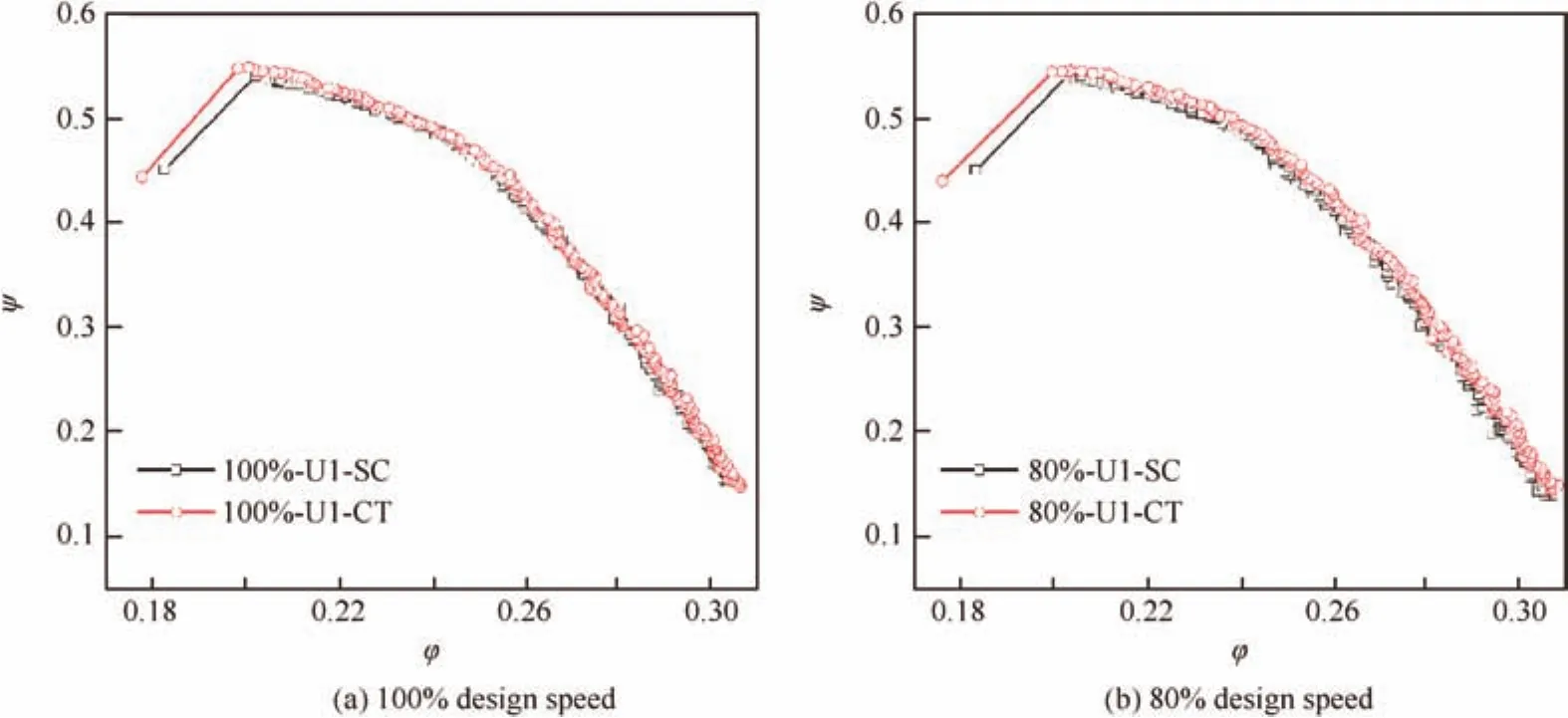

Fig.9 Stall margin enhancement ability of SPS casing treatment with uniform inlet flow.

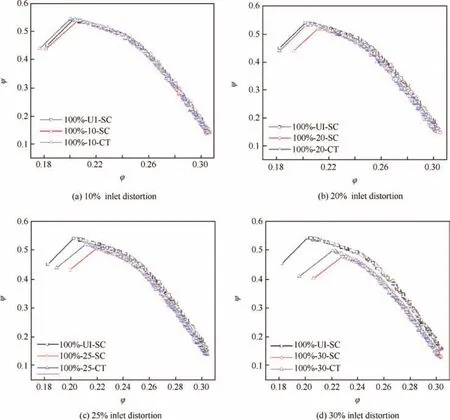

Fig.10 Pressure rise curves under 100%design speed.

To evaluate the stall margin enhancement ability of SPS casing treatment,a parameter SM is used here.Its definition is

The subscripts s and d stand for the corresponding parameters at stall point and design point,respectively.

4.Experiment results

4.1.Intensity of radial inlet distortion

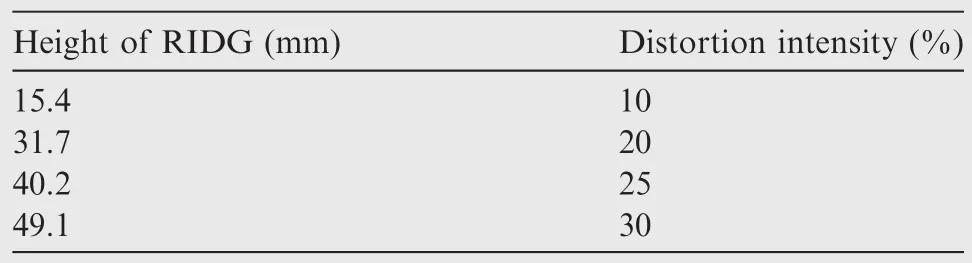

As mentioned above,different RIDG can generate radial inlet distortion of different intensities.The total inlet pressure field structures of 80%and 100%design speeds under the 10%radial inlet distortion are shown in Fig.7.These figures are recorded by 8 total pressure combs.

From the figure,the total pressure loss can be observed by the RIDG near the casing wall.The flow field is nearly axisymmetric and changes only in the radial direction.To understand this change in detail,the axial velocity is measured along a radial line(Fig.7(b))using a 1D hotwire sensor.As the static pressure on plan III is nearly uniform,the radial distribution of the axial velocity can re flect the total pressure distribution.

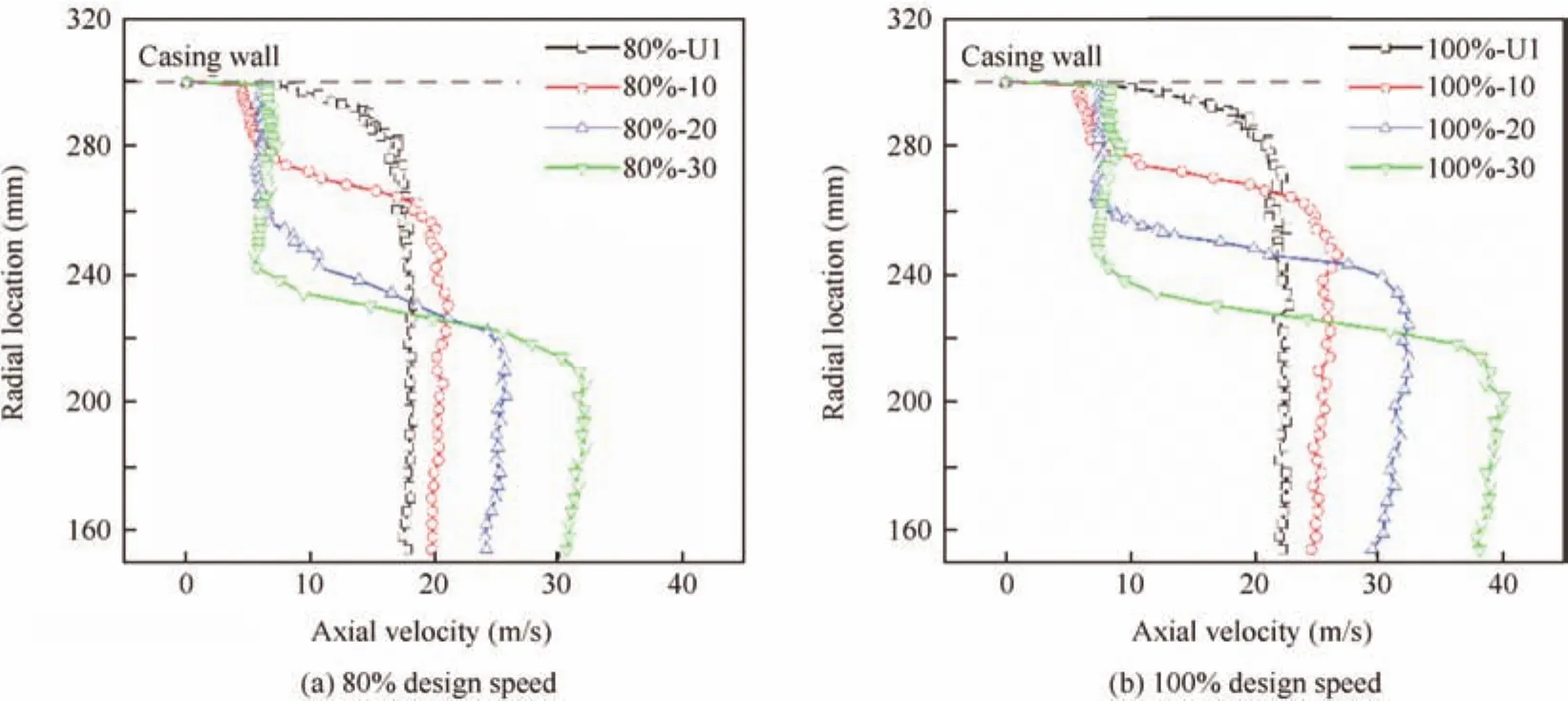

The axial velocity distribution is depicted in Fig.8.In this figure,80%-UI(uniform inlet flow)means the result of experiment at 80%design speed with uniform inlet flow,while 100%-30 means the result at 100%design speed with 30%inlet distortion.From the figure,it is seen that the axial velocity loss appears near the casing wall.The larger the intensity of inlet distortion is,the more obvious the difference between the velocities of main flow and blade tip regions becomes.For different rotor speeds,the axial velocity distribution is similar with some quantitative differences.Thus,the RIDG can generate radial inlet distortions of different intensities as it is planned to simulate the inlet flow conditions.

4.2.Stall margin enhancement

The stall margin enhancement ability of SPS casing treatment with uniform and distortion inlet flow is studied in this part.Different experimental conditions are illustrated as‘Rotating speed-Inlet flow condition-Casing condition’.For example,100%-UI-SC(solid casing)means that the experiment is conducted under 100%design speed and uniform inlet flow with a solid casing(the open area ratio of the perforated plate is 0),while 80%-30-CT(casing treatment)means that the experiment is carried out under 80%design speed and 30%distortion inlet flow with the casing treatment(the open area ratio of the perforated plate is 6.4%).

The pressure rise curves corresponding to 100%and 80%design speeds with uniform inlet flow are depicted in Fig.9.As calculated by Eq.(5),SM is 45.95%and 45.61%at 100%and 80%design speeds with SC,respectively.After the SPS casing treatment is opened,SM is enhanced to 50.72%and 48.98%.Thus,the SPS casing treatment can improve the stall margin of the compressor with uniform inlet flow.

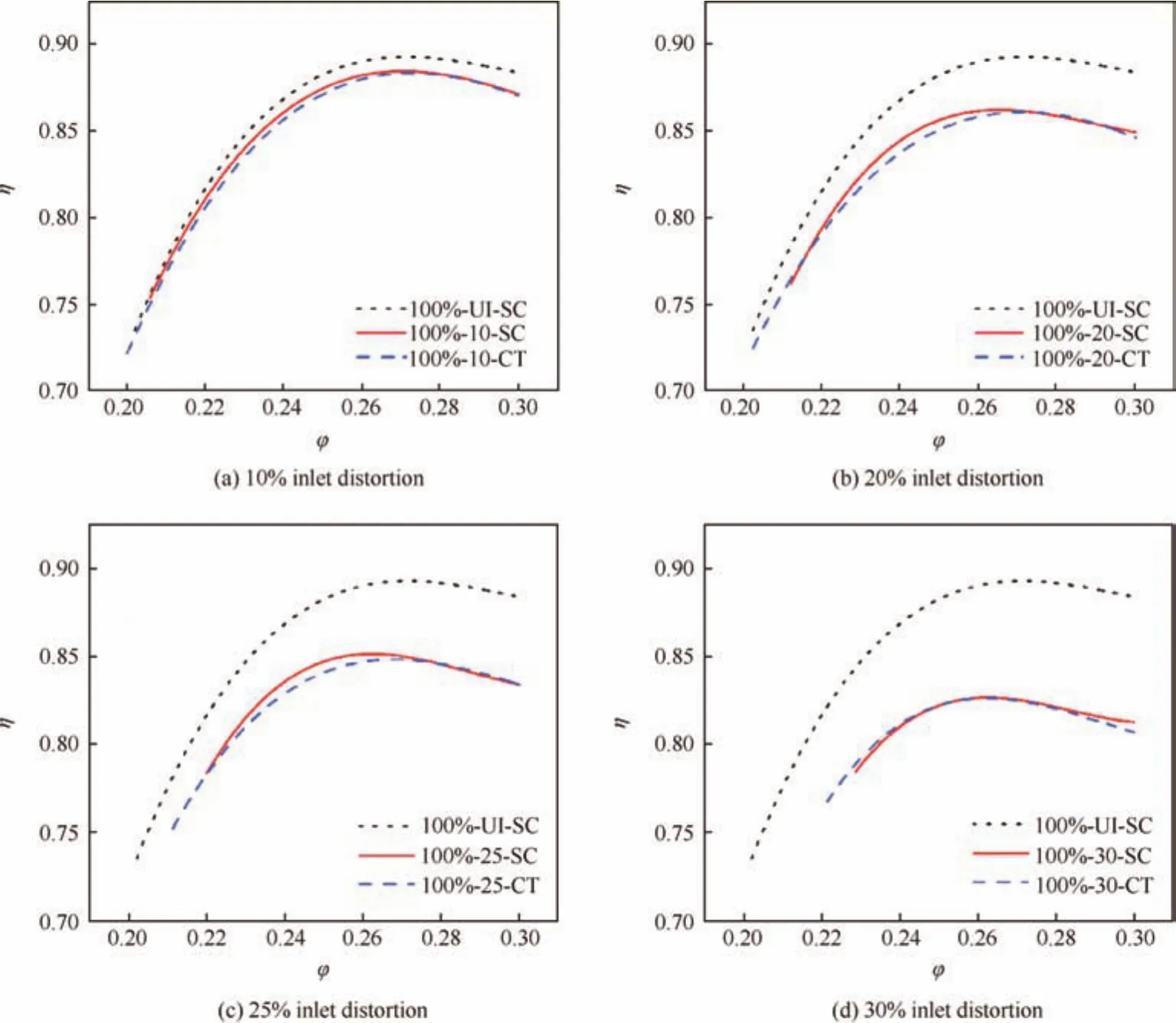

Fig.11 Efficiency curves under 100%design speed.

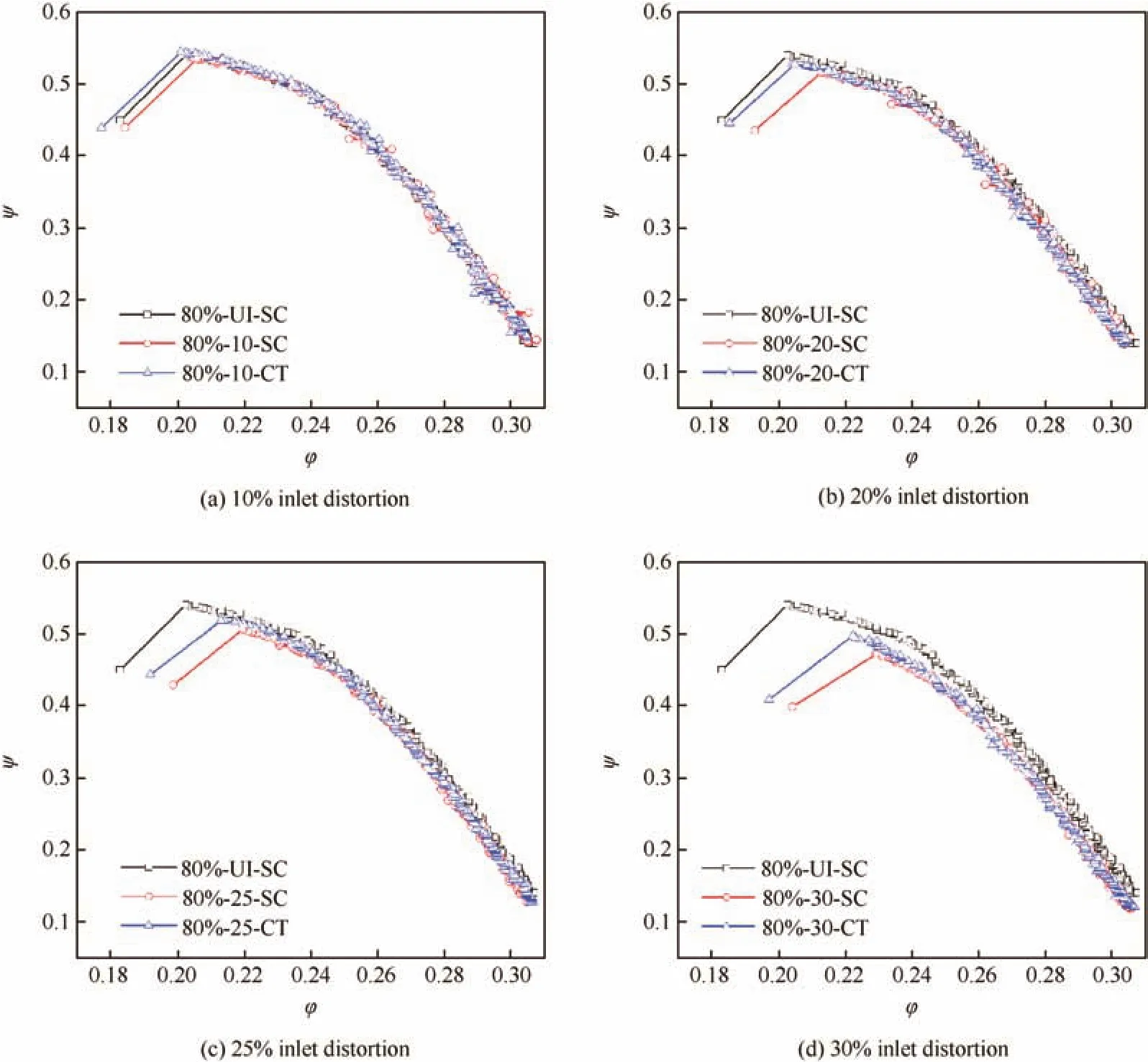

Fig.12 Pressure rise curve under 80%design speed with inlet distortion.

As we know,inlet distortion can cause stall margin loss.The pressure rise curves under 100%design speed with 10%intensity of inlet distortion are shown in Fig.10.From the figure,it is seen that the 10%radial inlet distortion causes 3.11%loss of stall margin.Under this condition,the SPS casing treatment can not only make up the stall margin loss caused by the inlet distortion but also improve the stall margin by 2.57%.

When the intensity of inlet distortion increases to 20%,which causes 12.05%loss of stall margin,the SPS casing treatment cannot totally cover the loss caused by distorted inlet,but it can enable the stall margin loss decrease from 12.05%to 2.99%(Fig.10).

The efficiency curves corresponding to 100%design speed with 10%and 20%inlet distortion are shown in Fig.11.From these figures,it is known that the radial inlet distortion can cause big efficiency loss.The 20%distortion can cause larger loss of efficiency than the 10%distortion.The use of SPS casing treatment can lead to additional efficiency loss in both cases.However,the corresponding efficiency loss from the use of the SPS casing treatment is much smaller than the loss caused by inlet distortion.The calculation results show that the maximum efficiency losses caused by the SPS casing treatment are only 0.4%and 0.62%under 10%and 20%inlet distortions,respectively.These are basically within the error range(1%)of the measurement system.

Additional results under 25%and 30%inlet distortion intensities are shown in Figs.10 and 11.With the rise of inlet distortion intensity,both the stall margin loss and efficiency loss are increased.The stall margin decreases by 20.18%under 25%inlet distortion,while this loss rises to 32.52%when intensity of inlet distortion reaches up to 30%.The SPS casing treatment still can partly cover the stall margin loss from distorted inlet flow and does not bring obvious additional eff iciency.Under 25%and 30%inlet distortions,the SPS casing treatment can offset the stall margin losses of 8.34%and 8.79%,meanwhile bringing maximum efficiency losses of 0.82%and 0.3%,respectively.

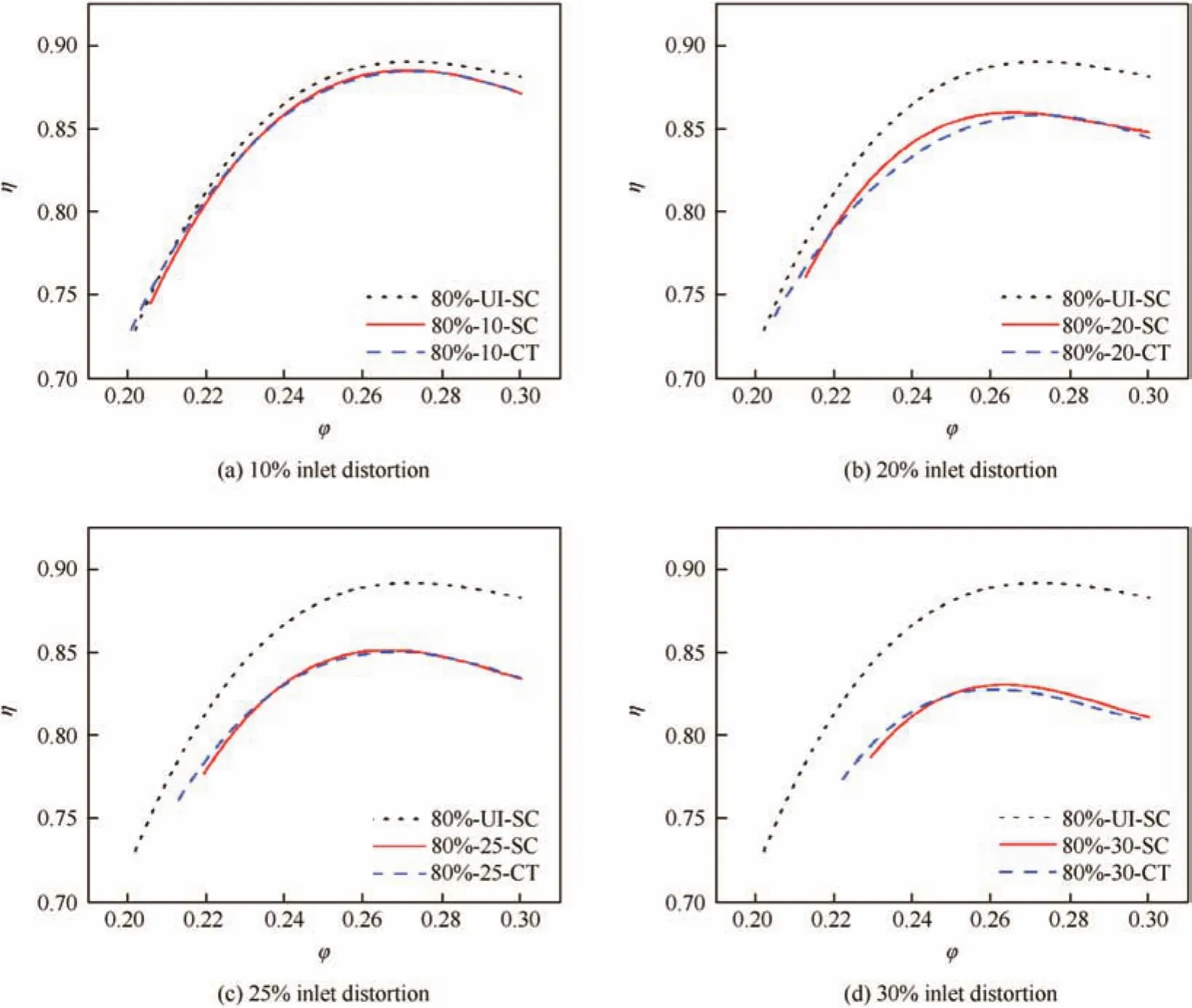

Similar studies are also conducted under 80%design speed.The results are shown in Figs.12 and 13.From these figures,the same qualitative law can be observed.

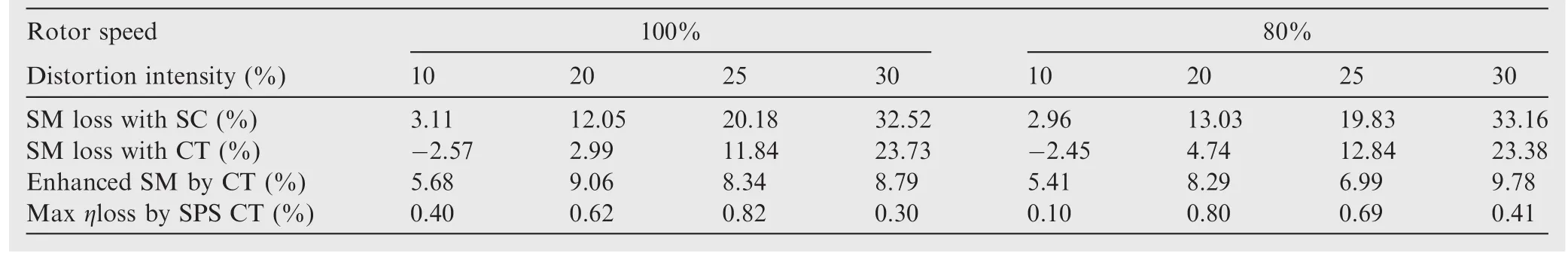

For a detailed analysis,all the results discussed above are summarized and shown in Table 3.From the table,it is found that radial inlet distortion can cause the obvious stall margin loss under both rotor speeds.The stronger the intensity of inlet distortion is,the more the stall margin loss it brings.The SPS casing treatment can make up or partly make up the stall margin loss about 5%–10%caused by radial inlet distortion.When the intensity of the inlet distortion is relatively weak,the SPS casing treatment can not only recover the lost stall margin but also extend it(minus value in Table 3).The radial inlet distortion can always bring efficiency loss.And the appli-cation of SPS casing treatment may cause additional efficiency loss.However,this additional efficiency loss is less than 1%,which is basically within the error range of the measurement system and much smaller than the loss caused by the radial inlet distortion.

Fig.13 Efficiency curves under 80%design speed with inlet distortion.

4.3.Experimental results of pre-stall behavior

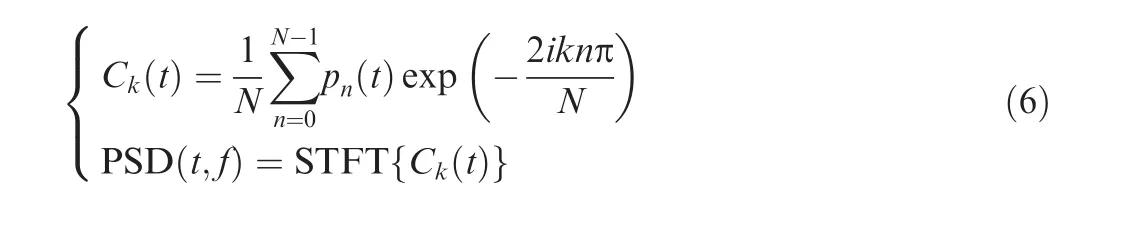

In the previous work,the mechanism of the SPS casing treatment in enhancing the stall margin of the compression system was validated theoretically and experimentally.The relevant investigations29,30show that adding some damping on the boundary of the system can weaken the energy of unsteady flow perturbations and delay the nonlinear ampli fication of the stall precursor waves.In Refs.21,35,time-frequency analysis is conducted and a parameter called power spectral density(PSD)of pressure wave is used to analyze the pre-stall behavior with solid casing and casing treatment in the compressor under uniform,rotating distorted and circumferential pressure distorted inlet flow,respectively.Here,the similar technical method is applied to investigate the pre-stall behavior in the compressor under radial inlet distortion.The definition of PSD is

Fig.14 PSD shown in time-frequency domain.

Fig.15 PSD at 100%design speed with 10%radial inlet distortion.

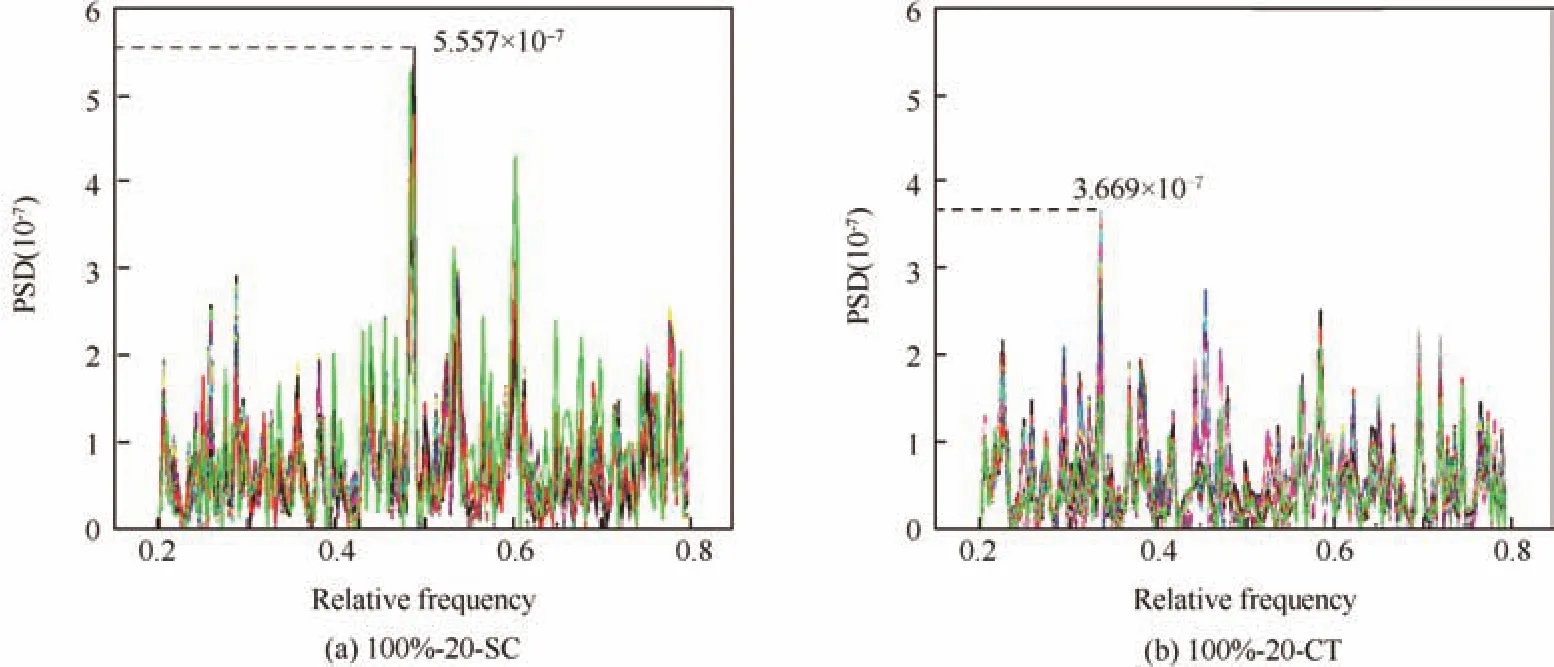

Fig.16 PSD at 100%design speed with 20%radial inlet distortion.

Table 3 The enhanced stall margin and max g loss caused by SPS casing treatment

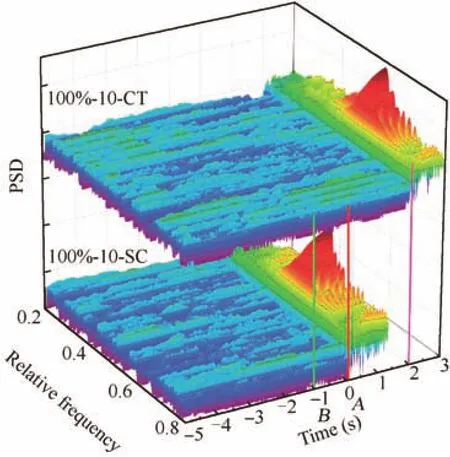

The analyzed result of one case discussed above is shown in Fig.14.Thexaxis is the relative frequency normalized by the shaft frequency of the compressor.The relative frequency is shown from 0.2 to 0.8 because pressure disturbance within this frequency interval is related to the occurrence of rotating stall.Theyaxis is the time axis.And at the same moment,the two compared cases have the same operating mass flow.Thezaxis is the value of PSD.From the view of time domain,we can see that the SPS casing treatment can suspend the nonlinear increase of the pressure disturbance and postpone the occurrence of rotating stall.

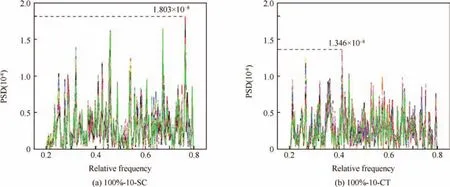

However,the comparison of the pre-stall behavior of the compression system with solid casing and casing treatment in this kind of figure is not clear.In this 3D view,it is difficult to distinctly distinguish the differences between using the solid casing and SPS casing treatment.In order to make this comparison clearly,the data within the intervalABare extracted and shown only in the frequency domain(projecting the figure on the relative frequency-PSD plane).The pointAis the stall point of the solid casing case and pointBis a near stall work point.PointBis very close to the stall pointAbecause the change of the work point is very slow and the time interval betweenAandBis only 1 s.For every time point in this interval,the flow range is equivalent for the two situations.

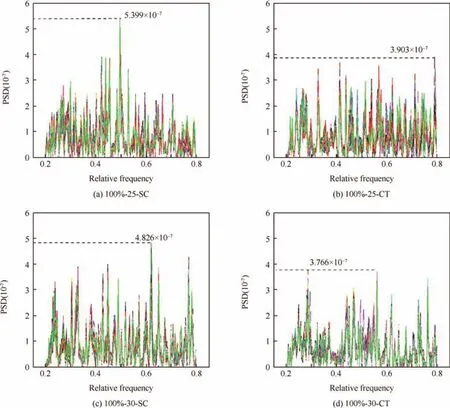

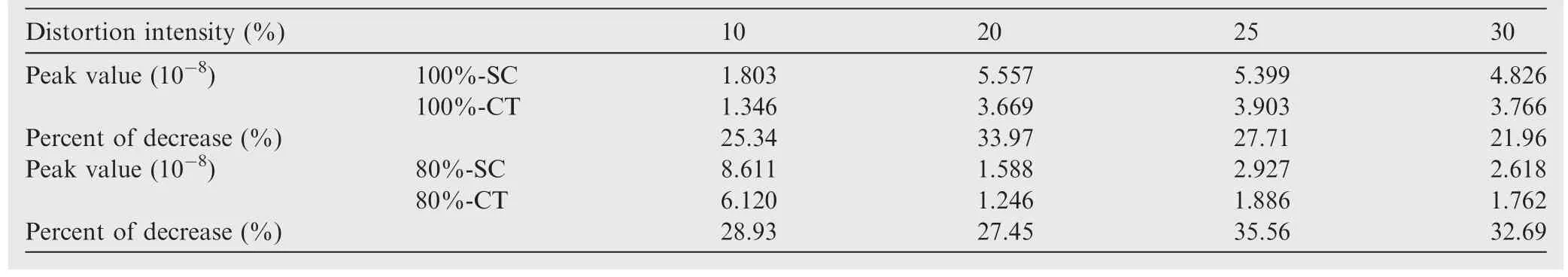

More results of the pre-stall behavior are shown in Fig.17.To show the variation with and without SPS casing treatment clearly,all the results about pre-stall behavior at 100%and 80%design speeds are summarized in Table 4,which shows the comparison of PSD peak values and its decrease due to the application of SPS casing treatment.From this table,it is seen that the value of PSD decreases when the operating speed decreases.In all of the cases,the results show that the SPS casing treatment can clearly weaken the power of the wideband pressure disturbance at pre-stall stage,and especially reduce its peak value.

Fig.17 PSD at 100%design speed with 25%and 30%radial inlet distortions.

Table 4 PSD peak value and its decrease due to SPS casing treatment.

5.Conclusions

In the present work,experiments are carried out to study the influence of radial inlet distortion on the compression system and the effects of SPS casing treatment under this condition.Some conclusions can be summarized as follows:

(1)The radial inlet distortion can cause a loss of stall margin and overall efficiency.The stronger the intensity of inlet distortion is,the more stall margin and efficiency loss it brings.

(2)With uniform inlet flow,the application of SPS casing treatments can improve the stall margin without obviously changing the pressure-rise characteristics.

(3)With radial inlet distortion,the SPS casing treatment can recover or partly recover the stall margin loss caused by radial inlet distortion.When the intensity of the inlet distortion is relatively weak,the SPS casing treatment can even extend the stall margin.

(4)The SPS casing treatment may cause slightly additional efficiency loss.This additional efficiency loss is less than 1%,which is basically within the error range of the measurement system and much smaller than the loss caused by the radial inlet distortion.

(5)The pre-stall behavior with solid casing and casing treatment in the compressor is analyzed by using the timefrequency analysis.The power spectral density is calculated to evaluate the intensity of pressure disturbance at pre-stall stage.The results show that the SPS casing treatment can enhance the stall margin of the compressor by weakening the power of the unsteady pressure perturbations in broadband and suppressing the nonlinear increase of stall precursor.

Acknowledgements

This research was supported by National Natural Science Foundation of China(51236001 and 51576008),National Basic Research Program of China(2012CB720201),Aeronautical Science Foundation of China(2014ZB51018)and Fundamental Research Funds for the Central Universities.

1.Plourde GA,Stenning AH.Attenuation of circumferential inlet distortion in multistage axial compressors.J Aircraft1968;5(3):236–42.

2.Cook R.Design and test of a highly-loaded three-stage,axial-flow compressor.Reston:AIAA;1976.Report No.:AIAA 1976–6.

3.Tamaki T,Nagano S.Effects of inlet distortions on a multi-stage compressor.Reston:AIAA;1979.Report No.:AIAA 1979–7003.

4.Maekawa A,Higashi T,Tanaka S.Performance of rotating cascades under the inlet-distortions:1st report,performance under the radial distortions.Bull JSME1979;22(165):333–9.

5.Seo N,Nakatani T,Tanaka S.Performance of rotating cascades under the inlet-distortions:2nd report,performance under the circumferential distortions.Bull JSME1981;24(190):628–33.

6.Hynes TP,Greitzer EM.A method for assessing effects of circumferential flow distortion on compressor stability.J Turbomachinery1987;109(3):371–9.

7.Hah C,Rabe DC,Sullivan TJ,Wadia AR.Effects of inlet distortion on the flow field in a transonic compressor rotor.J Turbomachinery1998;120(2):233–46.

8.Lesser A,Niehuis R.Transonic axial compressors with total pressure inlet flow field distortions.New York:ASME;2014.Report No.:ASME GT2014-26627.

9.Longley JP,Shin H,Plumley RE,Silkowski PD,Day IJ,Greitzer EM,et al.Effects of rotating inlet distortion on multistage compressor stability.J Turbomachinery1996;118(2):181–8.

10.Peters T,Bu¨rgener T,Fottner L.Effects of rotating inlet distortion on a 5-stage hp-compressor.New York:ASME;2001.Report No.:ASME 2001-GT-0300.

11.Peters T,Fottner L.Effects of co-and counter-rotating inlet distortions on a 5-stage hp-compressor.New York:ASME;2002.Report No.:ASME 2002-GT-30395.

12.Pazur W,Fottner L.The influence of inlet swirl distortions on the performance of a jet propulsion two-stage axial compressor.J Turbomachinery1991;113(2):233–40.

13.Schmid NR,Leinhos DC,Fottner L.Steady performance measurements of a turbofan engine with inlet distortions containing co-and counter rotating swirl from an intake diffuser for hypersonic flight.J Turbomachinery2001;123(2):379–85.

14.Sheoran Y,Bouldin B,Krishnan PM.Compressor performance and operability in swirl distortion.J Turbomachinery2012;134(4):1–13.

15.Epstein AH,Ffowcs Williams JE,Greitzer EM.Active suppression of aerodynamic instabilities in turbomachines.J Propulsion Power1989;5(2):204–11.

16.Ffowcs Williams JE,Huang XY.Active stabilization of compressor surge.J Fluid Mech1989;204(1):245–62.

17.Day IJ.Active suppression of rotating stall and surge in axial compressors.J Turbomachinery1993;115(1):40–7.

18.Paduano JD,Epstein AH,Valavani L,Longley JP,Greitzer EM,Guenette GR.Active control of rotating stall in a low speed axial compressor.J Turbomachinery1993;115(1):48–56.

19.Haynes JM,Hendricks GJ,Epstein AH.Active stabilization of rotating stall in a three-stage axial compressor.J Turbomachinery1994;116(2):226–39.

20.Van Schalkwyk CM,Paduano JD,Greitzer EM,Epstein AH.Active stabilization of axial compressors with circumferential inlet distortion.J Turbomachinery1998;120(3):431–9.

21.Spakovszky ZS,Weigl HJ,Paduano JD,Van Schalkwyk CM,Suder KL,Bright MM.Rotating stall control in a high-speed stage with inlet distortion:Part I—Radial distortion.J Turbomachinery1999;121(3):510–6.

22.Spakovszky ZS,Van Schalkwyk CM,Weigl HJ,Paduano JD,Suder KL,Bright MM.Rotating stall control in a high-speed stage with inlet distortion:Part II—Circumferential distortion.J Turbomachinery1999;121(3):517–24.

23.Koch CC.Experimental evaluation of outer case blowing or bleeding of single stage axial flow compressor.Washington,D.C.:NASA;1970.Report No.:NASA CR-54592.

24.Kang CS,Mckenzie AB,Elder RL.Recessed casing treatment effects on fan performance and flow field.New York:ASME;1995.Report No.:ASME 95-GT-197.

25.Kroeckel T,Hiller SJ,Jeschke P.Application of a multistage casing treatment in a high speed axial compressor test rig.New York:ASME;2011.Report No.:ASME GT2011-46315.

26.Pixberg CT,Schiffer H,Ross MH,Cameron JD,Morris SC.Stall margin improvement by use of casing treatments.New York:ASME;2013.Report No.:ASME GT2013-95842.

27.Langston CE.Distortion tolerance:by design instead of by accident.New York:ASME;1969.Report No.:ASME 69-GT-115.

28.Madden DS,West MA.Effects of inlet distortion on the stability of an advanced military swept fan stage with casing treatment.New York:ASME;2005.Report No.:ASME GT2005-68693.

29.Sun X,Sun D,Yu W.A model to predict stall inception of transonic axial flow fan/compressors.Chin J Aeronautics2011;24(6):687–700.

30.Sun X,Sun D,Liu X,Yu W,Wang X.Theory of compressor stability enhancement using novel casing treatment,Part I:Methodology.J Propulsion Power2014;30(5):1224–35.

31.Sun D,Liu X,Jin D,Gui X,Sun X.Theory of compressor stability enhancement using novel casing treatment,Part II:Experiment.AIAA J Propulsion Power2014;30(5):1236–47.

32.Dong X,Liu X,Sun D,Sun X.Experimental investigation on sps casing treatment with bias flow.Chin J Aeronautics2014;27(6):1352–62.

33.Sun D,Liu X,Sun X.An evaluation approach for the stall margin enhancement with stall precursor-suppressed casing treatment.J Fluids Eng2015;137(8):1–16.

34.Sun D,Nie C,Liu X,Lin F,Sun X.Further investigation on transonic compressor stall margin enhancement with stall precursor-suppressed casing treatment.J Turbomachinery2016;138(2):1–13.

35.Dong X,Sun D,Li F,Jin D,Gui X,Sun X.Effects of rotating inlet distortion on compressor stability with stall precursorsuppressed casing treatment.J Fluids Eng2015;137(11):1–15.

19 April 2016;revised 3 September 2016;accepted 4 September 2016

Available online 22 December 2016

*Corresponding author.

E-mail address:sundk@buaa.edu.cn(D.Sun).

Peer review under responsibility of Editorial Committee of CJA.

CHINESE JOURNAL OF AERONAUTICS2017年2期

CHINESE JOURNAL OF AERONAUTICS2017年2期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- High-temperature tribological behaviors of a Cr-Si co-alloyed layer on TA15 alloy

- Analysis and control of the compaction force in the composite prepreg tape winding process for rocket motor nozzles

- Impact of lubricant traction coefficient on cage’s dynamic characteristics in high-speed angular contact ball bearing

- Variable stiffness design of redundantly actuated planar rotational parallel mechanisms

- Adaptive formation control of quadrotor unmanned aerial vehicles with bounded control thrust

- Constrained adaptive neural network control of an MIMO aeroelastic system with input nonlinearities