Thermal behavior of an isolator with mode transition inducing back-pressure of a dual-mode scramjet

Yang Qinghun,Bao Wen,Chetehouna Khaled,Zhang Silong,Gasoin Niolas

aSchool of Astronautics,Beihang University,100083,China

bSchool of Energy Science and Engineering,Harbin Institute of Technology,150001 Harbin,China

cINSA Centre Val de Loir,88 Boulevard Lahitolle,18000 Bourges,France

Thermal behavior of an isolator with mode transition inducing back-pressure of a dual-mode scramjet

Yang Qingchuna,b,*,Bao Wenb,Chetehouna Khaledc,Zhang Silongb,Gascoin Nicolasc

aSchool of Astronautics,Beihang University,100083,China

bSchool of Energy Science and Engineering,Harbin Institute of Technology,150001 Harbin,China

cINSA Centre Val de Loir,88 Boulevard Lahitolle,18000 Bourges,France

Combustion mode;Dual-mode scramjet;Isolator;Mode transition;Thermal behavior

Combustion mode transition is a valuable and challenging research area in dual-mode scramjet engines.The thermal behavior of an isolator with mode transition inducing backpressure is investigated by direct-connect dual-mode scramjet experiments and theoretical analysis.Combustion experiments are conducted under the incoming airflow conditions of total temperature 1270 K and Mach 2.A small increment of the fuel equivalence ratio is scheduled to trigger mode transition.Correspondingly,the variation of the coolant flow rate is very small.Based on the measured wall pressures,the heat-transfer model can quantify the thermal state variation of the engine with active cooling.Compared with the combustor,mode transition has a greater effect on the isolator thermal behavior,and it significantly changes the isolator heat-flux and wall temperature.To further study the isolator thermal behavior from flight Mach 4 to Mach 7,a theoretical analysis is carried out.Around the critical point of combustion mode transition,sudden changes of the isolator flowfield and thermal state are discussed.

1.Introduction

The abilities to fly at wide-range velocities and for long periods are the inexorable demands for future development of scramjets.1,2A high-performance dual-mode scramjet can operate in the range of flight Mach numbers from 4 to 7,which would face different combustion modes.3The isolator is a very key component of the dual-mode scramjet engine.4,5For a high flightMa0,the scramjet will operate in the supersonic combustion mode and the isolator is shock-free.Flow is supersonic inthe whole engine.However,for a low-mediumMa0,a relatively enthalpy increase due to combustion is very high and the engine will operate in the subsonic combustion mode.Thus,flow will be thermally choked with combustion mode transition from supersonic to subsonic,leading to a rapid pressure rise.This back-pressure induced by thermal chocking will cause a shock train/pseudo-shock in the isolator,to prevent the back-pressure from disturbing the inlet.

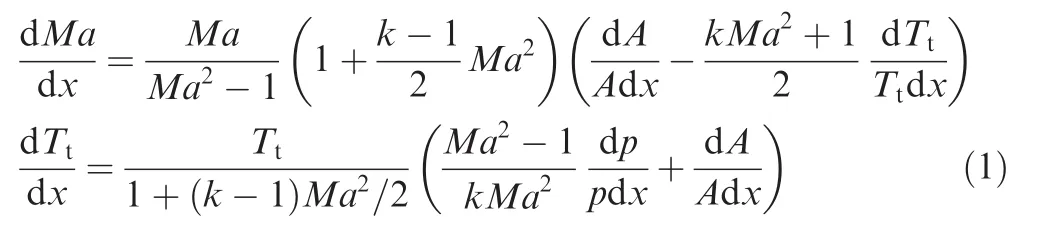

Numerous advanced experimental measurement technologies6,7and numerical methods8,9have been applied in scramjet engines to approach the mechanism of combustion mode transition in recent years,particularly for the flow characteristics of an isolator triggered by the back-pressure with MT(short for mode transition).Because of the interaction between the backpressure and the boundary-layer,a sequence of bifurcated shocks forms a shock train to adapt the pressure rise,as shown in Fig.1.10,11The shock train will cause the appearance of boundary separation and high static-enthalpy flow in the isolator.Consequently,it significantly increases the wall heat flux,even up to 2 times more.12Considering that the shock train induced by mode transition may vary with the flightMa0and other operating conditions,it brings difficult challenges for design of the thermal protection system of the vehicle,especially considerable uncertainties in the high heat flux associated with mode transition.Therefore,itis ofgreat signi ficance to precisely predict the change of the isolator heat flux with mode transition for developing strategies to provide the amount of cooling needed.

On the other hand,to solve the high heat flux issues,active cooling with fuel used as coolant is proposed for scramjet engines.13,14Considering that a physical heat sink of fuel cannot meet cooling requirements,cracking of endothermic hydrocarbon fuel is used to improve the chemical heat sink.15Thus,active cooling with hydrocarbon fuel used as coolant for an isolator is adopted in this research.In order to get a better understanding of the effects of back-pressure variation with MT on thermal behavior,this paper carries out experimental and theoretical quantitative analysis in a dual-mode scramjet engine,particularly for the isolator.

2.Experimental setup and computational model

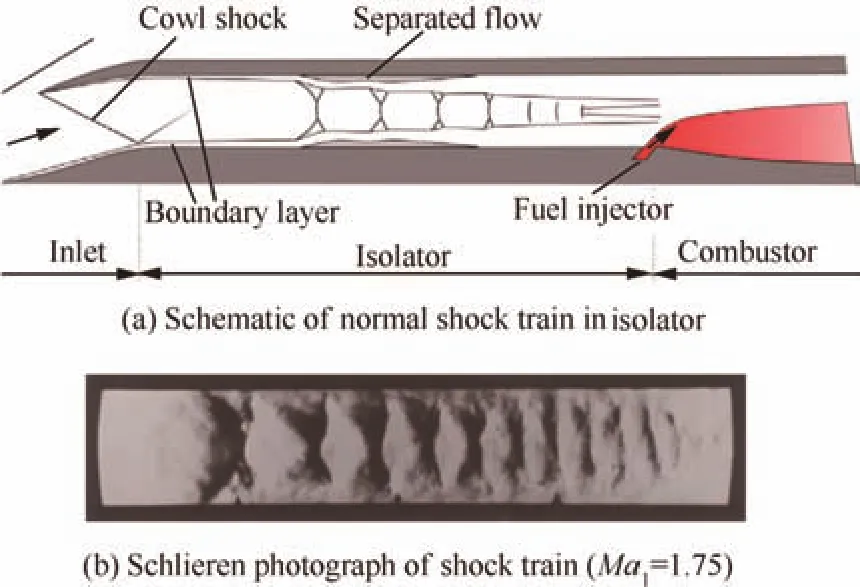

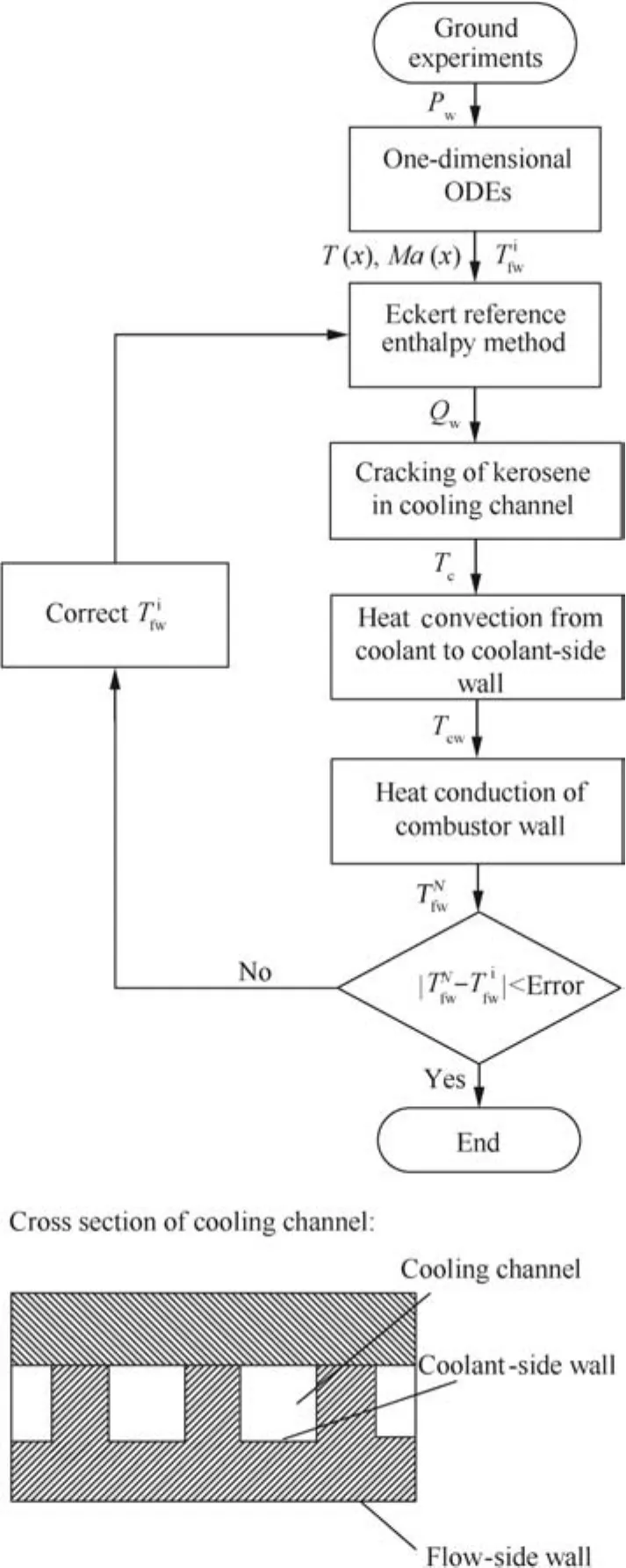

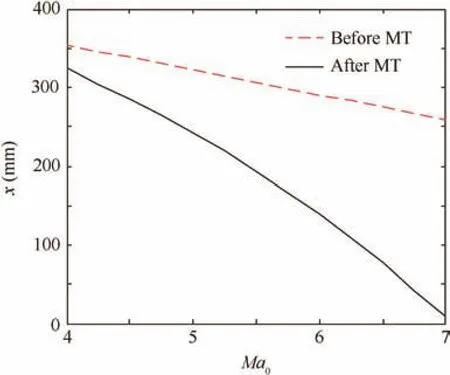

The flowchart of the heat-transfer model for the dual-mode combustor with active cooling is shown in Fig.3.The cooling channel is divided into many cells in thex-axis direction.This model will be applied to every cell with a space-marching algorithm.Compared to wall pressures,the flow temperature and Mach number are very difficult to directly measure in the combustor.Thus,the other flowfield parameters in the combustor will be calculated by one-dimensional ordinary differential equations(ODEs)based on the measured pressures.Combining the conservations of equation for mass,momentum,and energy,17the following equations can be derived

Fig.1 Flow features in scramjet isolator from Refs.10,11

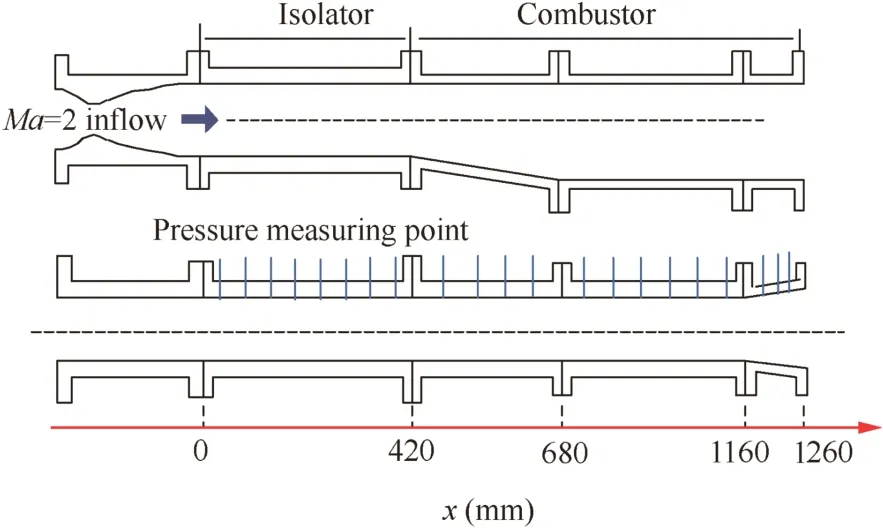

Fig.2 Schematic of dual-mode scramjet combustor model.16

Fig.3 Flowchart of heat-transfer model for scramjet with active cooling and schematic of cooling channel.

whereSt*indicates the Stanton number under the reference enthalpy.

Considering the heat balance,Qwwill be absorbed by the coolant under a steady condition.The heat absorption of coolant includes physical absorption and chemical heat,corresponding to physical and chemical heat sink respectively,which can be expressed as

The empirical formula of Nusselt number for the heat convection between the coolant and the coolant-side wall is

whereReis coolant Reynolds number,Pris coolant Prandtl number and l is coolant viscosity.

3.Results and discussions

3.1.Experimental results

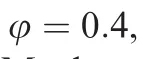

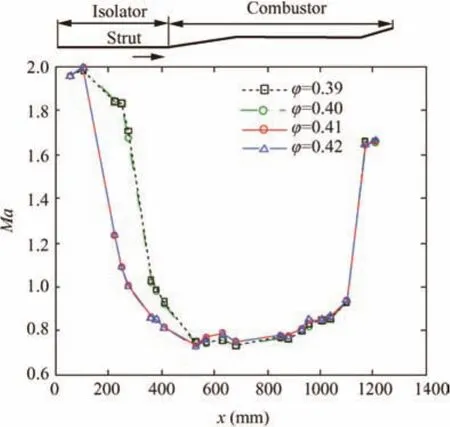

Table 1 Thermal conductivity of the Ni-based alloy.

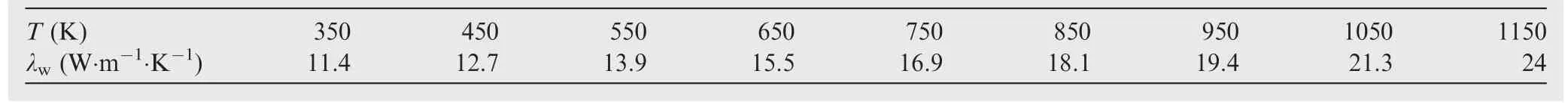

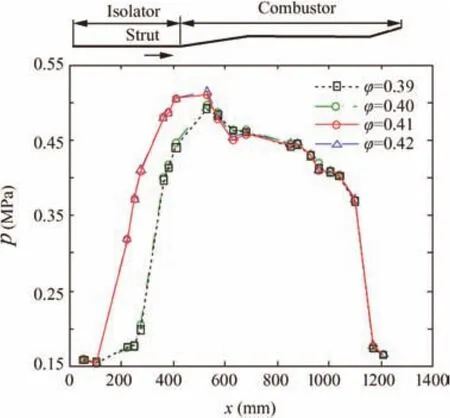

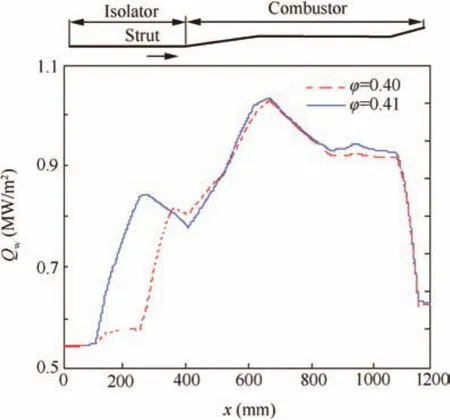

Based on these experimental wall-pressures and the heattransfer model,the engine thermal behavior is investigated near the critical point of MT,as the fuel ER increases from 0.40 to 0.41. The calculated results are shown in Figs.6 and 7.Considering that the increment of the fuel ER is only 0.01,the variation of the coolant flow rate is correspondingly small.The isolator heat flux increases by about 60%with MT from the dual-mode subsonic combustion mode to the subsonic combustion mode.Considering the fuel being used as coolant,the coolant flow rate remains nearly constant.The internal wall temperature of the isolator increases by about 20%.The length of the high heat flux zone is about 100 mm corresponding to the length of the shock train.There is little change in the combustor heat flux with MT.Therefore,in the next section,this paper will mainly study the thermal behavior of the isolator.

Fig.4 Changes of wall pressures with slightly increasing fuel equivalence ratio.

Fig.5 Changes of Ma with slightly increasing fuel equivalence ratio.

Fig.6 Wall heat flux distributions near critical point of MT.

3.2.Theoretical predication of the isolator thermal behavior for flight Mach from 4 to 7

3.2.1.Variation of the isolator flow with MT

To utilize the heat transfer model in Fig.3,the isolator flowfield should be firstly obtained.In the range of flight Mach 4 to 7,numerous ground experiments of the scramjet are expensive.Therefore,a theoretical calculation of the flow field is essential.The flow in the isolator has two parts:shock-free zone and shock-train zone.In the shock-free zone,the isolator wall pressure keeps constant,which is the same as the isolator entrance pressure.Near the critical point of MT,the shock-train pressure rise will be obtained as follows.Based on the isolator impulse flow theory21,the exit-pressure of a frictionless constant-area isolator should satisfy the following equation:

Fig.7 Internal wall temperatures near critical point of MT.

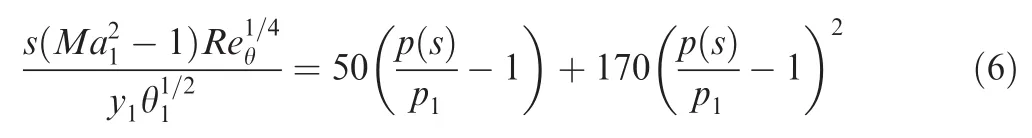

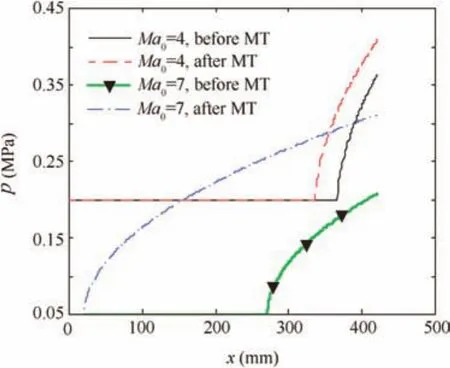

This constraint expression can obtain the discontinuous zone for the isolator pressure ratio,which cannot meet Eq.(5)when MT occurs.As shown in Fig.8,the higher the flightMa0increases,the larger the discontinuous pressure ratio becomes.In fact,this discontinuous zone is led by MT,which is an unsteady catastrophe.The grey discontinuous zone indicates the effects of MT on the isolator exit pressure in Fig.8.It is important to note that the isolator exit pressure is also the pressure at the end of the shock train.

Then,the wall pressure distributionsp(s)from the beginning to the end of the shock-train and the leading edge of the shock-train zone can be computed by the semi-empirical equation proposed by Billig,22,23which can be expressed as

wheresis axial coordinate with origin at beginning of the isolator shock-train,yis isolator height and h is boundary-layer momentum thickness at the isolator entrance.

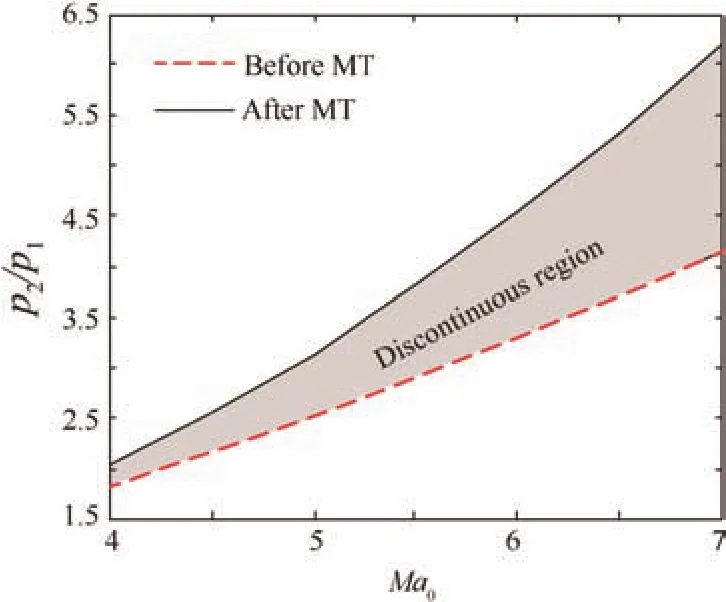

According to the pressure ratios in Fig.8,the leading edge of the shock train near the critical point of MT can be obtained by Eq.(6),as shown in Fig.9.The deviation between the upper and lower curves is the length variation of the shock train with MT.It grows as the flight Mach increases.Curves representing the axial pressure distribution have been computed and plotted in Fig.10.Compared with a low flightMa,the pressure demonstrates more dramatic changes with MT under a high flight Mach.Under the condition of flight Mach 7,the shock-train leading edge has located near the entrance of the isolator.Fortunately,the isolator can still hold up the shock train,without disturbing the inlet flow.In addition,MT refers to a combustion mode shift from dual-mode supersonic combustion to supersonic combustion,because the Mach number is above one through the whole engine for flight Mach 7.

3.2.2.Variation of the isolator thermal behavior with MT

Since the isolator flow is obtained,the isolator thermal state can be computed by the heat transfer model near the critical point of MT.Note that the total temperature keeps constant in the whole isolator,which is equal to the free-stream total temperature.TheMaratio between the flightMa0and the isolator entranceMa1is 0.38 as proposed in Ref.10Figs.11–14 indicate the isolator internal wall temperature and the heat flux with different flight Mach numbers.

Fig.8 Change of isolator pressure ratio with MT in the range of lf ight Ma 4 to 7.

Fig.9 Effect of MT on leading edge of shock train with different flight Mach numbers.

Fig.10 Axial isolator pressure distributions near critical point of MT.

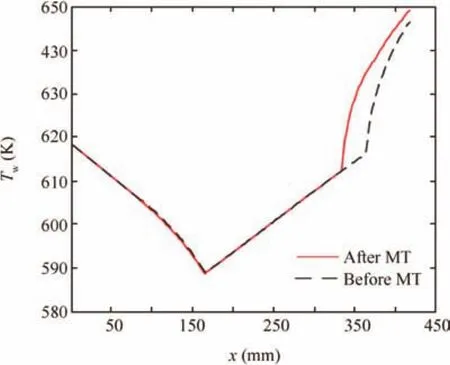

Compared with the shock-free zone,Fig.11 indicates that the internal wall temperature increases faster in the shocktrain zone.It might also be noted that heat-transfer deterioration occurs near the entrance of the isolator,which will result in a wall temperature rise.Through the cooling channel,the coolant temperature is low near the entrance of the isolator.Correspondingly,its density and viscosity become larger,and then the coolant velocity andRebecome smaller.Therefore,the heat transfer deterioration appears at this position.In order to enhance the heat transfer at the entrance,the cooling channel entrance area should be reduced to increase the coolant velocity.Thus,the internal wall temperature firstly decreases,and then increases due to the rise of the coolant temperature along the cooling passage.

Fig.11 Isolator internal wall temperature near critical point of MT for flight Ma 4.

Under the condition of flight Mach 7,Fig.12 shows that the internal wall temperature rapidly increases after MT.Then,it is kept around 800 K until the exit of the isolator,which is quite different from that for Mach 4.Although the internal wall temperature deviation caused by MT is not large in the exit of the isolator,it demonstrates a large difference in the shock-train zone induced by MT.Moreover,the location of the high-temperature zone can be found through Fig.9.

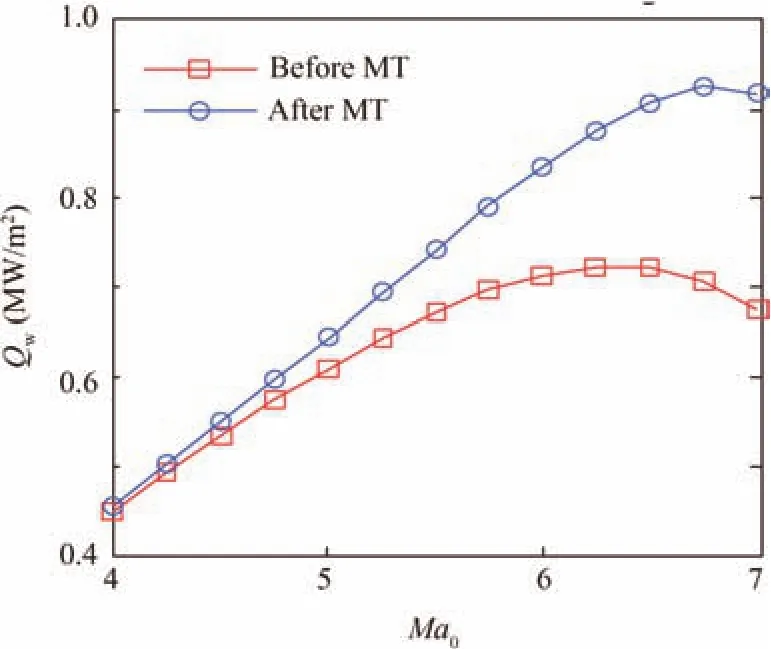

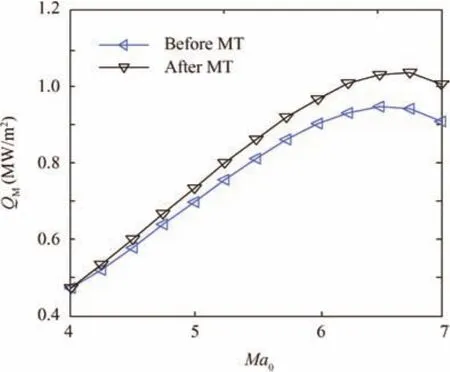

To show the overall thermal state of the isolator,Fig.13 depicts the distributions of the isolator average heat-flux under different flight Mach numbers.It increases with the flightMaand reaches the maximum aroundMa06.5.The deviation of the average heat-flux between before and after MT becomes larger and larger withMa0.The average heat-flux increases by approximately 30%while the flight Mach attains 7.Fig.14 shows the isolator maximum heat-flux distribution near the critical point of MT.Compared with Fig.13,the deviation of the peak heat- flux is smaller than the average heatflux.Evidently,it indicates that the high heat- flux zone becomes larger with MT.

Fig.13 Variation of isolator average heat-flux with MT in range of flight Ma 4 to 7.

Fig.14 Variation of isolator maximum heat-flux with MT in range of flight Ma 4 to 7.

4.Conclusions

In order to investigate the effect of mode transition on the thermal behavior of a scramjet isolator,combustion experiments are conducted with a strut-based dual-mode scramjet combustor.In addition,to further predict the variation of the isolator heat-flux during the scramjet accelerating process from flight Mach 4 to Mach 7,a theoretical study is carried out.

When the combustion mode shifts from dual-mode subsonic combustion to subsonic combustion,the fuel equivalence ratio only increases 0.01.However,the isolator heat-flux and temperature increase by approximately 60%and 20%in the shock train zone,respectively.While the combustor thermal behavior has little change with MT,the back-pressure induced by MT significantly affects the isolator thermal state.

A theoretical model to predict the isolator thermal behavior is developed in the range of flight Mach 4 to Mach 7.Near the critical point of MT,the results show that there is a sudden change for the isolator flow.The length variation of the shock train becomes larger with a rising flightMa0.The isolator temperature distribution demonstrates a significant difference with an increasing flight Mach number.The deviation of the average heat-flux induced by MT becomes larger and larger withMa0,and it is 30%for flight Mach 7.The theoretical analysis is not related to the engine structure and only depends on the value of the back-pressure,no matter using whether a strutbased combustor or a cavity-based combustor.Therefore,it can be widely applied to the scramjet thermal design.

1.Wu X,Li X,Ding M,Liu W,Wang Z.Experimental study on effects of fuel injection on scramjet combustor performance.Chin J Aeronaut2007;20(6):488–94.

2.Song WY,Li M,Cai YH,Liu WX,Bai HC.Experimental investigation of hydrocarbon-fuel ignition in scramjet combustor.Chin J Aeronaut2004;17(2):65–71.

3.Huang W,Li Y,Tan JG.Survey on the mode transition technique in combined cycle propulsion systems.Aerosp Sci Technol2014;39:685–91.

4.Le DB,Goyne CP,Krauss RH,Mcdaniel JC.Experimental study of a dual-mode scramjet isolator.J Propul Power2008;24(5):1050–7.

5.Srikant S,Wagner JL,Valdivia A,Akella MR,Clemens N.Unstart detection in a simplified-geometry hypersonic inlet-isolator flow.J Propul Power2010;26(5):1059–71.

6.Fotia ML,James FD.Ram-scram transition and flame/shocktrain interactions in a model scramjet experiment.J Propul Power2012;29(1):261–73.

7.Turner JC,Michael KS.Mode change characteristics of a threedimensional scramjet at Mach 8.J Propul Power2013;29(4):982–90.

8.Yentsch RJ,Gaitonde DV.Unsteady three-dimensional phenomena in mode-transition simulations of the HIFiRE-2 scramjet lf owpath.49th AIAA/ASME/SAE/ASEE Joint Propulsion Conference;2013 July 14–17;San Jose,CA.Reston:AIAA;2013.

9.Kouchi T,Masuya G,Mitani T,Tomioka S.Mechanism and control of combustion-mode transition in a scramjet engine.J Propul Power2012;28(1):106–12.

10.Matsuo K,Yoshiaki M,Heuy DK.Shock train and pseudo-shock phenomena in internal gas flows.Prog Aerosp Sci1999;35(1):33–100.

11.Laurence SJ,Lieber D,Schramm JM,Hannemann K,Larsson J.Incipient thermal choking and stable shock-train formation in the heat-release zone of a scramjet combustor.Part I:Shock-tunnel experiments.Combust Flame2015;162(4):921–31.

12.Heiser WH, Pratt DT.Hypersonicairbreathingpropulsion.Reston:AIAA Education Series;1994.

13.Qin J,Zhou W,Bao W,Yu D.Thermodynamic analysis and parametric study of a closed Brayton cycle thermal management system for scramjet.Int J Hydrogen Energy2010;35(1):356–64.

14.Zhang SL,Qin J,Xie KL,Feng Y,Bao W.Thermal behavior inside scramjet cooling channels at different channel aspect ratios.J Propul Power2015;127:1–14.

15.Feng Y,Qin J,Zhang SL,Bao W,Cao Y,Huang HY.Modeling and analysis of heat and mass transfers of supercritical hydrocarbon fuel with pyrolysis in mini-channel.Int J Heat Mass Transf2015;91(5):520–31.

16.Yang QC,Bao W.Experimental study on combustion mode transition effects in a strut-based scramjet combustor.Proc Instit Mech Eng,Part G:J Aerospace Eng2014;229(4):764–71.

17.Starkey RP,Mark JL.Quasi-one-dimensional high-speed engine modelwith finite-ratechemistry.JPropulPower2012;17(6):1367–74.

18.Qin J,Bao W,Zhang S,Zhou W.Comparison during a scramjet regenerative cooling and recooling cycle.J Thermophys Heat Transfer2015;26(4):612–8.

19.Tian L,Chen L,Chen Q,Li F,Chang X.Quasi-one-dimensional multimodes analysis for dual-mode scramjet.J Propul Power2014;30(6):1559–67.

20.Torrez SM,Scholten NA,Micka DJ,Driscoll JF,Bolender MA,Doman DB,et al.A scramjet engine model including effects of precombustion shocks and dissociation.Reston:AIAA;2008,Report No:AIAA-2008-4619.

21.Fotia ML.Mechanics of combustion mode transition in a directconnect ramjet–scramjet experiment.J Propul Power2014;31(1):69–78.

22.Waltrup PJ,Frederick SB.Prediction of precombustion wall pressure distributions in scramjet engines.J Spacecraft Rockets1973;10(9):620–2.

23.Billig FS.Research on supersonic combustion.J Propul Power1993;9(4):499–514.

15 November 2015;revised 23 February 2016;accepted 23 August 2016

Available online 16 February 2017

*Corresponding authorat:SchoolofAstronautics,Beihang University,100083,China.

E-mail address:qingchun.yang@insa-cvl.fr(Q.Yang).

Peer review under responsibility of Editorial Committee of CJA.

CHINESE JOURNAL OF AERONAUTICS2017年2期

CHINESE JOURNAL OF AERONAUTICS2017年2期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- High-temperature tribological behaviors of a Cr-Si co-alloyed layer on TA15 alloy

- Analysis and control of the compaction force in the composite prepreg tape winding process for rocket motor nozzles

- Impact of lubricant traction coefficient on cage’s dynamic characteristics in high-speed angular contact ball bearing

- Variable stiffness design of redundantly actuated planar rotational parallel mechanisms

- Adaptive formation control of quadrotor unmanned aerial vehicles with bounded control thrust

- Constrained adaptive neural network control of an MIMO aeroelastic system with input nonlinearities