Experimental mass transfer coefficients in a pilot plant multistage column extractor

Mehdi Asadollahzadeh ,Ahad Ghaemi,Meisam Torab-Mostaedi,Shahrokh Shahhosseini

1 Department of Chemical Engineering,Iran University of Science and Technology(IUST),P.O.Box 16765-163,Tehran,Iran

2 Nuclear Fuel Cycle Research School,Nuclear Science and Technology Research Institute,P.O.Box 11365-8486,Tehran,Iran

1.Introduction

Liquid-liquid extraction is a widely utilized separation process in the chemical,petroleum,pharmaceutical,hydrometallurgical and nuclear industries.It is a complex operation involving several phenomena:formation and coalescence of drops,transfer through an interface and axial diffusion induced by a concentration gradient.A further difficulty arises when these phenomena are limited not only by the geometry of the equipment but also by the operating conditions and the physical properties of the mixtures[1-3].

Knowledge of mass transfer performance is of fundamental importance for the design and development of practical extraction columns.Mixing is often applied to the extraction columns such as Mixer-Settler,RDC,Kühni,and multistage columns in order to improve the phase contact.The performance of the apparatus is often ameliorated by the use of impellers.The agitation modifies the apparatus hydrodynamics by inducing turbulence in the flow thus improving the inter phase contact and intensifying the mass transfer[4].

The knowledge of axial mixing in extraction column is necessary for understanding the fundamental processes involved in the mass transfer.Failure to account for axial mixing may lead to large errors in column dimensions.It has been reported that axial dispersion in extraction columns lowers the process efficiency as much as 30%[5].

A usual process engineering approach to represent the hydrodynamics of phases in these columns is the axial dispersion model(ADM).It is simply a plug flow model with some degree of back mixing on it[6].

The investigation has been focused to study the axial dispersion in continuous phase of liquid-liquid extraction columns such as spray towers[7,8],reciprocating plate extraction columns[9,10]and pulsed sieve plate extraction columns[11].Although,a few studies can be found in which this effect has been taken into account.

Among the various types of extraction columns,the multistage column is an extractor that its applications have rarely been referred to in the literature.The column has been used in the chemical processes such as gas-liquid contacting,solid-liquid contacting and extraction[4].

The multistage column is neither a compartmental nor truly continuously differential device,but has some properties of both.Compartments are separated by horizontal stator rings and the vertical component of velocity of any droplet within each stator opening determines whether or not it moves to the next compartment.The droplet behavior within the circulating flow of each compartment determines the column operating characteristics[12].

Rushtonet al.[13]investigated the measurement of mass transfer coefficients in multistage columns.They observed that the volumetric mass transfer coefficient decreased when viscosity of either phase was increased,and the coefficient increased approximately as the square of the impeller speed.

Komasawa and Ingham[14]investigated the effect of the system properties on the performance of a multistage column and mass transfer rate.They reported that the mass transfer performance is characterized more by the effects of inter facial instability on the dispersed phase hydrodynamics,than by the direct enhancement in the rate of mass transfer.

The mass transfer coefficients were dependent on the hydrodynamics of the continuous phase,the size of the drops,the mobility of the interface,slip velocity and the physical properties of the system[15].

Choi and Kim[16]investigated the effects of axial dispersion in the continuous phase and holdup of the dispersed phase.The empirical equations correlating the dispersion coefficients with the system parameters were reported.

The knowledge concerning the design and performance of these columns is stillfar from satisfactory.In order to develop an appropriate design procedure for this type of extractor,the knowledge of the overall mass transfer coefficientin terms of the operating variables,column geometry and liquid physical properties is essential.

This research work examines the ability of an axial dispersion model with correlations to predict the performance of a multistage column.New correlations are proposed to describe the effects of agitation conditions,phase velocities,physical properties of the liquid-liquid system on the overall mass transfer coefficients.

2.Literature Correlations

Several studies have reported that mass transfer is an important parameterin liquid-liquid columns and has to be taken into accountto design industrial columns.Mass transfer in the continuous phase is commonly changed by a combination of molecular diffusion,and natural or forced convection within the drop[17].

A variety of solutions for mass transfer has been achieved by using the equation of continuity for axisymmetric flow around a sphere,assuming constant physical properties.For a drop is internally stagnant and when the continuous phase velocity is zero,the equation forkcis:

which is reported by Langmuir[18].The above equation provides a limiting value ofkc;any fluid motion causeskcto be greater.

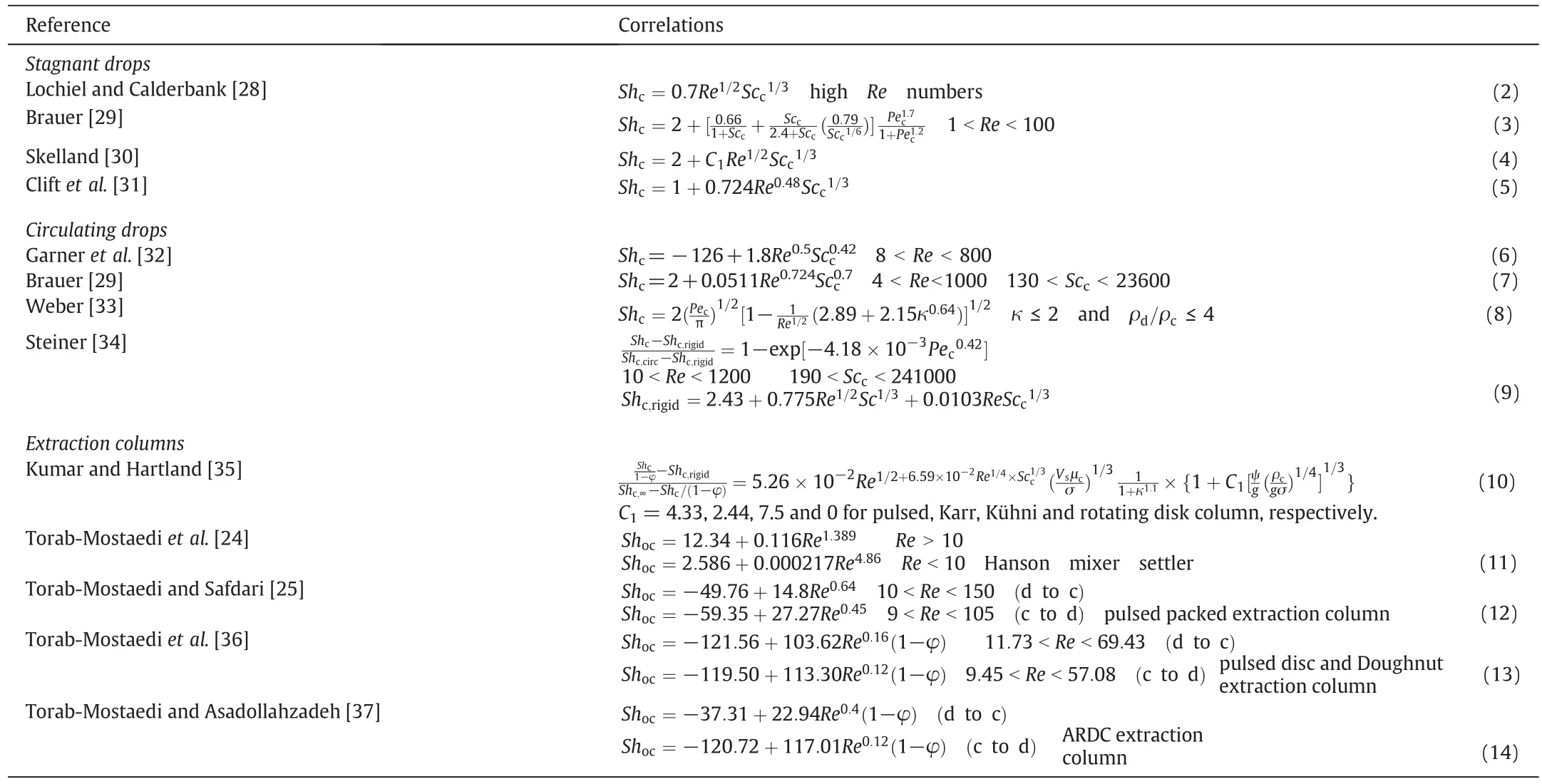

A number of empirical equations to predict mass transfer in a single drop and different types of extraction columns are available.Table 1 brie fly gives a list of the published related correlations.

3.Experimental

3.1.Liquid-liquid system

The liquid system studied was toluene-acetone-water.The European Federation of Chemical Engineering(E.F.C.E)has adopted this system as a recommended system.The experiments were carried out in both mass transfer directions.In all of the experiments,dilute solutions were investigated with approximately 3.5 wt%acetone as transferred solute in the organic or aqueous phase.

When starting a run,the solvent and water phases were first mutually saturated,after which acetone was added to the dispersed or continuous phase.

Distilled water was used as the continuous phase and technical grade of toluene was used as the dispersed phase.The physical properties of the chemical system are given in Table 2.

Table 2Physical properties of liquid systems at 20°C[27]

In the present work,the values of the physical properties have been assumed to correspond to the mean values of acetone concentration in the continuous and dispersed phases.The mean value of acetone concentration was obtained by averaging the values obtained along the column.

Table 1Previous correlations for estimation of mass transfer coefficient in single drop systems and extraction columns

3.2.Experimental column

The schematic flow diagram of the pilot plantmultistage column extractor is shown in Fig.1 and the specifications of this column and the range of operating variables are listed in Table 3.The column was built of a cylindrical glass section and was equipped with impellers that have accurate speed control,whereas the internal parts were constructed of stainless steel.The main section is made of Pyrex glass,113 mm I.D,and the height of the column with eighteen stages is 700 mm.Mixing is done by 6-blade impellers of 50 mm diameter located at the center of each stage.Nine sampling valves are provided at67 mm intervals along the column length.

Toluene(dispersed phase)and water(continuous phase)were fed into the column at the bottom and top,respectively in counter-current flow.Two flow-meters were employed to supply and monitor the fixed flow rates of the continuous and dispersed phases.The inlet and outlet of the column were connected to four tanks,each of85 L capacity.The interface was maintained at the required level by using an optical sensor as previously described[19].All of the experiments were carried out far from flooding conditions.

In each experiment the following variables were measured:

(1)Acetone concentration along the column for continuous and dispersed phase using UV-visible spectroscopy(Cary Model spectrophotometer).

(2)Dispersed phase holdup(φ)along the column using shutdown procedure,when the operation became steady state,the dispersed phase and continuous phase inlet and outlet valves were quickly closed.The dispersed phase was allowed to settle and the difference in the interface level location was used to measure the total holdup.The holdup was de fined as the ratio of the displaced dispersed phase volume to the total volume of the extraction region.

(3)Sauter mean diameter of droplets(d32),in the way that pictures of four different heights of the column have been captured ineach experiment by means of a very high-resolution Nikon D5000 camera and have been compared with the stators thickness served as the reference for the drop size measurements.The Sauter mean diameter was calculated from the following equation:

Table 3Technical description of the pilot plant multistage column extractor

wherenidenotes the number of drops of diameterdi.

The specific inter facial area was obtained by the following equation:

Fig.1.Schematic flow diagram of pilot plant multistage column extractor.

4.Modeling

The axial mixing is a key factor for designing and scaling up of the extraction column,which has a strong influence on the mass transfer performances.It is a parameter,which quantifies the deviation from the ideal plug flow.The factors contributing to the axial mixing are the presence of circulatory flow,molecular diffusion,small eddies and channeling.In the present study,the mass transfer data are interpreted in terms of this model as described by Pratt and Stevens[20].

The equations of this model for the dispersed and continuous phases at the constant superficial velocitiesVcandVdat any given rotor speed can be written as:

wherePc=HVc/Ec,Pd=HVd/Ed,Z=h/H,Noc=KocaH/Vc.

The three boundary conditions are as follows:

At the top of the column(Z=0):

At the bottom of the column(Z=1):

By using the continuous phase axial dispersion coefficient,the measured dispersed and continuous phase concentrations,together with the equilibrium data,and the boundary conditions,the experimental values of volumetric overall mass transfer coefficients are calculated from Eqs.(17)and(18).

In the present study,the dispersed phase axial dispersion(Ed)was assumed to be negligible,while the continuous phase axial dispersion(Ec)was estimated by the following correlation given by Tsouris[21]:

5.Results and Discussion

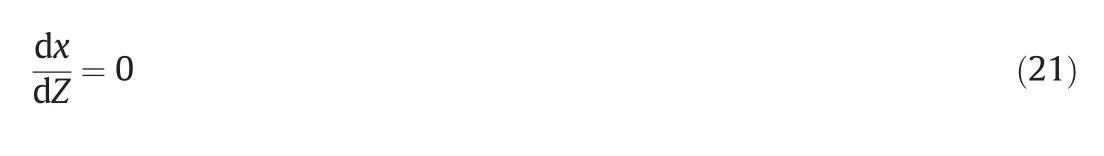

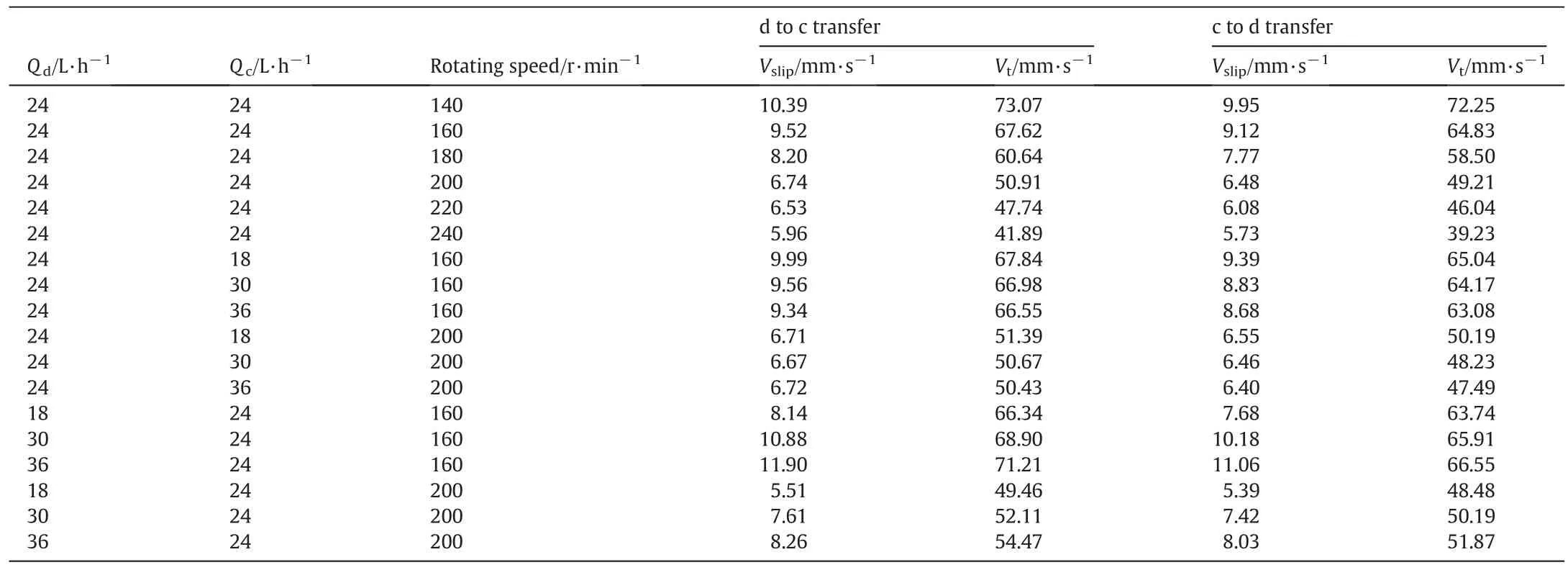

The overall performance of an extraction column can be de fined in terms of the inter facial area(a),and the overall mass transfer coefficient(Koc).Fig.2 describes the concentration pro file for the organic and continues phase for two directions of mass transfer.The effect of the operating variables such as continuous and dispersed phase velocities and rotor speed on the volumetric overall mass transfer coefficient in the multistage column are evaluated as shown in Figs.3 to 5.The experimental results obtained in these experiments for slip and terminal velocities are given in Table A1 in Appendix.

5.1.Effect of continuous phase velocity

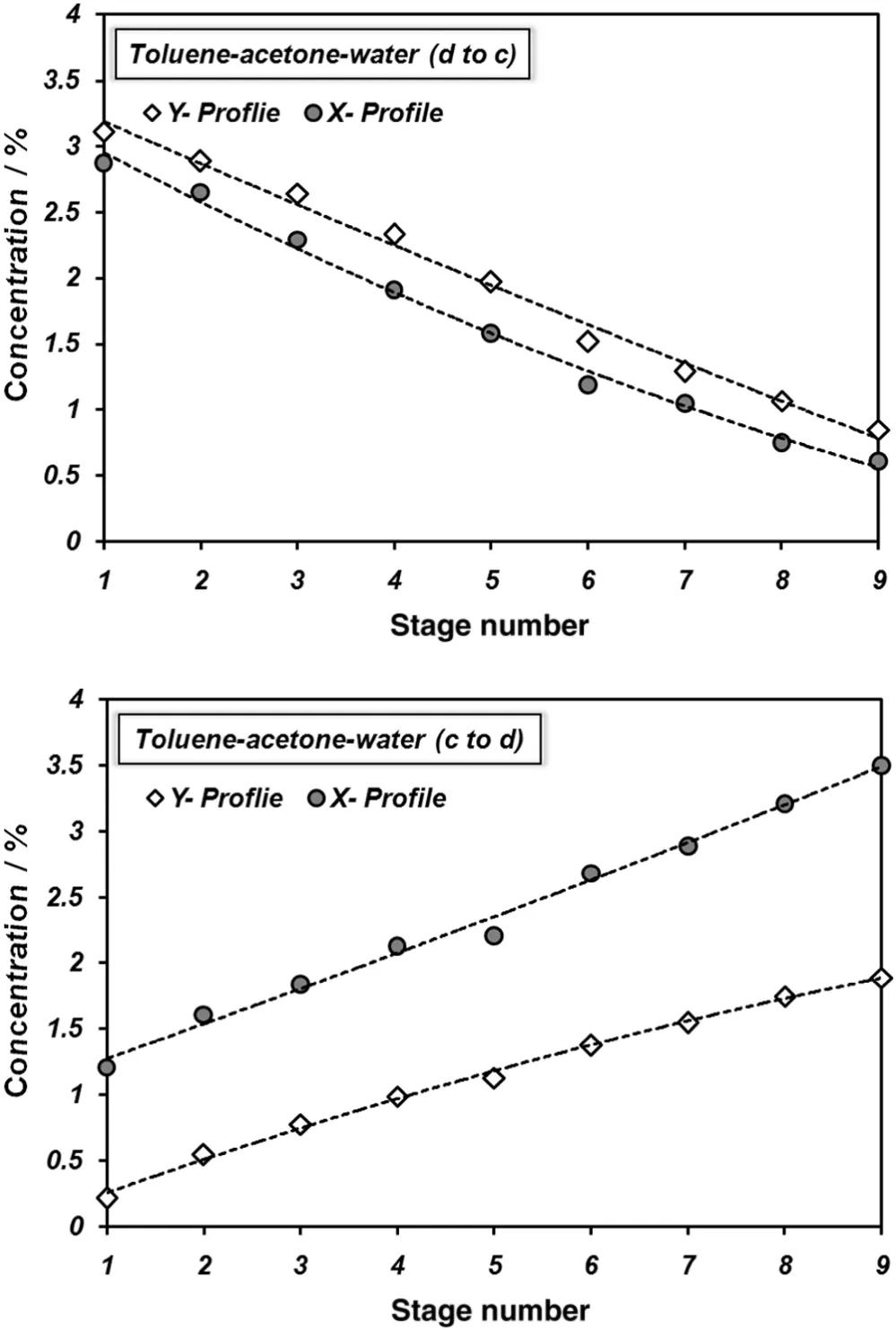

Fig.3 shows the variation in the inter facial area,Sauter mean drop diameter and volumetric overall mass transfer coefficient as a function of continuous phase velocity for both mass transfer directions.It can be seen that the volumetric overall mass transfer coefficient and inter facial area increase with an increase in continuous phase velocity in the range of velocities studied.

Fig.2.Concentration pro file along the column(N=140 r·min-1,V d=V c=0.66 mm·s-1).

The dispersed phase holdup increases with the increase in continuous phase velocity due to a reduction of the relative velocity between the drops and continuous phase.Moreover,this effect is not appreciable on the size of the dispersed drops(Fig.3b).Therefore,the inter facial area increases with the increase in holdup.The overall mass transfer coefficient increases withVcdue to an increase in drag forces arising from the relative velocity between a drop and the continuous phase.Consequently,the mass transfer performance increases with the increase in the inter facial area and overall mass transfer coefficient.

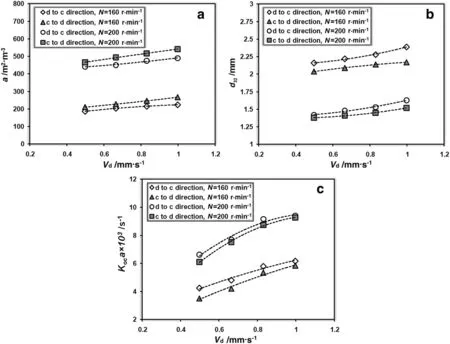

5.2.Effect of dispersed phase velocity

The effect of the dispersed phase velocity in the inter facial area,Sauter mean drop diameter and volumetric overall mass transfer coefficient is illustrated in Fig.4.A greater volume of the organic phase is fed into the column leads to an increase in the holdup with increasing Vd.A higher dispersed phase velocity tends to increase proportionally the average drop size(Fig.4b),since a higher organic phase velocity leads not only to a larger drop formation but also to higher coalescence frequencies.

This observation shows that the effect of holdup on interfacialarea is larger than that of drop size,i.e.,the interfacialarea increases with an increase in the dispersed phase velocity(Fig.4a).In addition,internal circulation inside the drop leads to an increase in overall mass transfer coefficient.Therefore,an increase inVdincreases the mass transfer performance(Fig.4c).

Fig.3.Effect of continuous phase velocity on(a)the inter facial area(b)Sauter mean drop diameter and(c)the volumetric overall mass transfer coefficient(V d=0.66 mm·s-1).

5.3.Effect of rotor speed

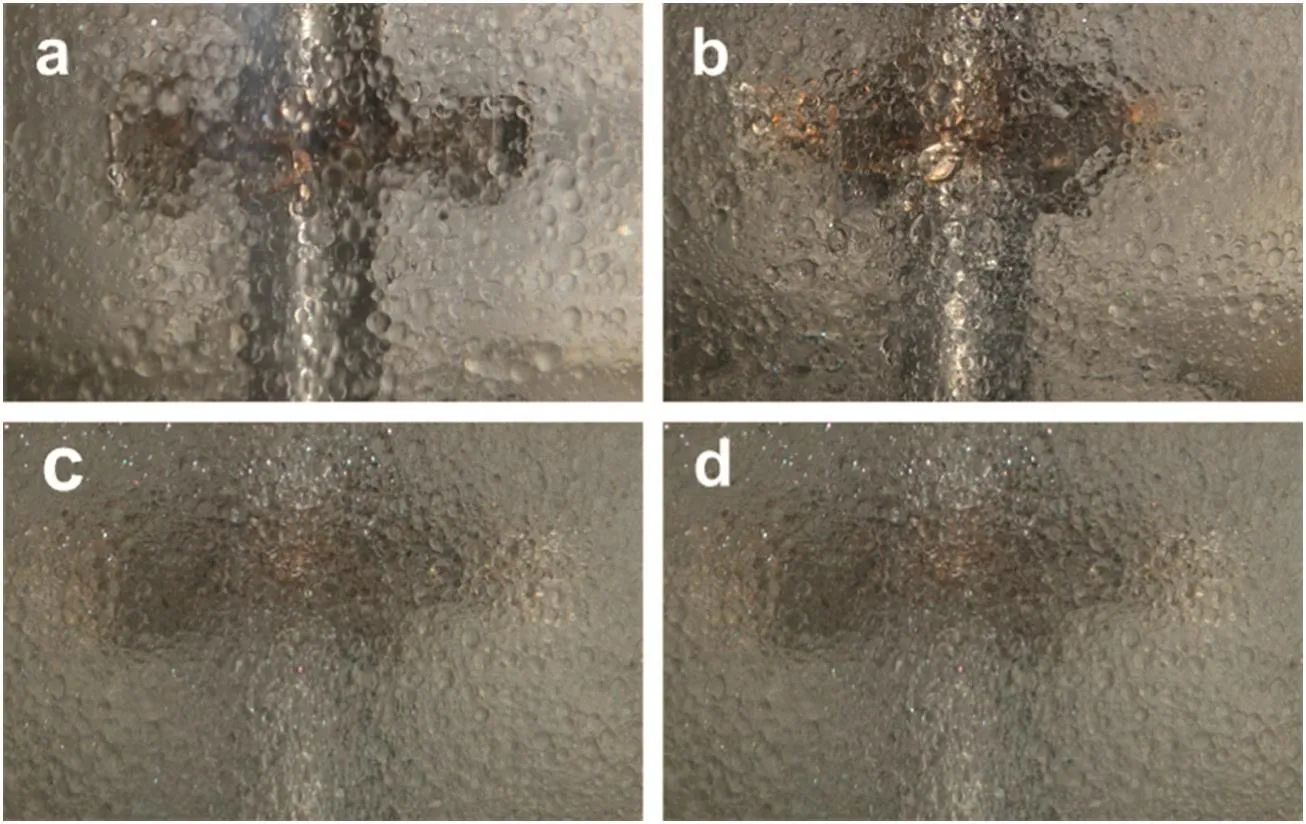

The Effect ofrotor speed on mass transfer performance is depicted in Fig.5,and the pictures of drop sizes for two directions of mass transfer with different rotor speed are shown in Figs.6 and 7.

It was found that mass transfer performance depends mainly on the stirring rate.The figure indicates that an increase in agitation speed enhances the drop breaking and consequently,the Sauter mean drop diameter decreases(Fig.5b).It is clear that the values of holdup increase with the increasing number of droplets in the column due to the decrease of the relative velocity between the dispersed phase and continuous phase.Therefore,it can be concluded that the value of inter facial area increases with both effects(Fig.5a).

It is found that the overall mass transfer coefficients significantly decrease when the drops are small,i.e.,at high rotor speeds.In this case,small droplets behave as rigid spheres,in which molecular diffusion would govern mass transfer in the system.It was found from the results in Fig.5c that the inter facial area is the dominant factor in determining the mass transfer performance and,consequently,the column performance increases with the increasing rotor speed.

Fig.5 also illustrates that the column performance varies with the direction of mass transfer.When the mass transfer happens from the dispersed to the continuous phase,the concentration of the solute in the draining film between the two adjacent drops is higher than in the surrounding continuous phase.For mass transfer in the opposite direction,the concentration is correspondingly lower.

The resulting gradients of inter facial tension accelerate the drainage and coalescence in the first case and retard the drainage and inhibit coalescence in the second case.Therefore,the direction ofdispersed to the continuous phase(d→c)transfer produces larger drops than those in the opposite direction(Fig.5b).The larger drop size results in a decrease in both dispersed phase holdup and inter facial area for mass transfer in the direction of d→c.However,the mass transfer performance in the case of c→d is lower than in the opposite direction(d→c),in spite of a larger inter facial area(larger holdup,lower drop size).

The results are in fairly good agreement with the results reported by Steineret al.[22].They reported that mass transfer enhancement in the toluene/acetone/water system is crucially dependenton the mass transfer direction.The mass transfer is higher if acetone is transferred from the dispersed phase into the continuous phase.Temoset al.[23]confirmed the enhancement of mass transfer when the solute transfer direction was d→c.

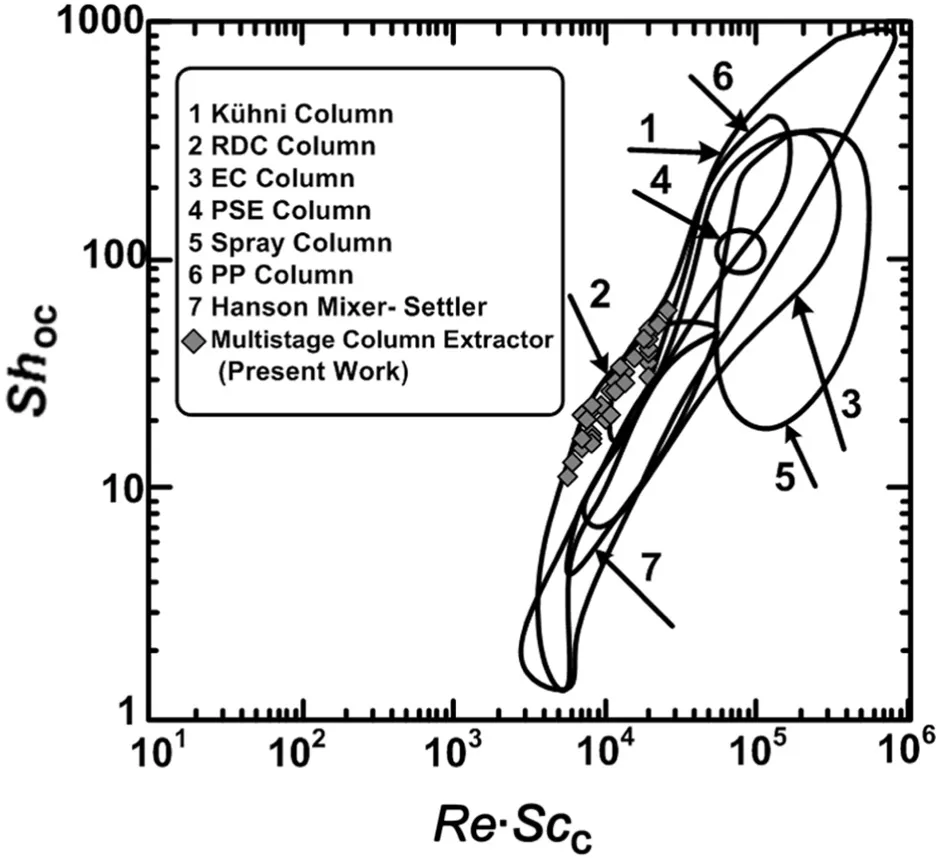

5.4.Comparison of the experimental data with the correlations of the literature

In Fig.8,the mass transfer results are presented in terms of dimensionless numbersShc,ReandSccby using the correlations reported by Torab-Mostaediet al.[24],Torab-Mostaedi and Safdari[25]and Kumar and Hartland[26].

Fig.4.Effect of dispersed phase velocity on(a)the inter facial area(b)Sauter mean drop diameter and(c)the volumetric overall mass transfer coefficient(V c=0.66 mm·s-1).

The mass transfer coefficients for various columns are shown in the diagram,but the view of the multistage column in this chart is empty.Consequently,the required data for mass transfer coefficients in the present work were added to the diagram.According to Kumar and Hartland expressions,the correlations for different extraction columns,such as a Kühni column,a rotating disc column(RDC),an enhanced coalescing column(EC),a pulsed sieve extraction column(PSE),Spray column,a pulsed packed column(PP)and Hanson Mixer-Settlerare almost the same.Fig.8 illustrates that the experimental results for the mass transfer coefficient obtained in the multistage column are also similar to those obtained in the above columns.

The average absolute values of the relative error in the predicted values of Sherwood numbers from the experimental points were investigated.The values of the error for the previous model are shown in Table 4.

The calculated values of the overall mass transfer coefficients(Koc)are then compared with those provided from single-drop correlations[Eqs.(2)to(9)in Table 1).This is affected by using one of the following expressions relating the overall to individual mass transfer coefficients:

Newman equation was used for calculation of individualmass transfer coefficients(kd)in stagnant drop[Eqs.(2)to(5)],as follows[17]:

Kronig and Brink presented another correlation considering the internal circulation of the droplets.The droplet size is so smallthat the internal circulation is laminar and is given by the following equation[17]:

Table 4The values of AARE in the predicted values of overall Sherwood number obtained by previous correlations

Fig.5.Effect of rotor speed on(a)the inter facial area(b)Sauter mean drop diameter and(c)the volumetric overall mass transfer coefficient(V c=V d=0.66 mm·s-1).

The above equation is used for calculation ofkdfor circulating drop[Eqs.(6)to(9)].

The values of error in the correlations related to these columns are rather unsatisfactory for a multistage column.A comparison between these correlations and the experimental data is shown in Fig.9.

Fig.6.Pictures of drop sizes with different rotor speeds for dispersed to continuous transfer(a)140,(b)160,(c)180,(d)200 r·min-1(V c=V d=0.66 mm·s-1).

Fig.7.Pictures of drop sizes with different rotor speeds for continuous to dispersed transfer(a)140,(b)160,(c)180,(d)200 r·min-1(V c=V d=0.66 mm·s-1).

Fig.8.Comparison of mass transfer in different columns based on relationship between Sh oc and Re·Sc c.

5.5.New correlation for mass transfer coefficients

From the above results it can be concluded that the previous correlations do not have enough accuracy to design the multistage columns.Therefore,it is of paramount importance to derive a new correlation for prediction of overall continuous mass transfer coefficient.

The predictive correlation for mass transfer coefficient in conjunction with holdup,drop size and physicalproperties are proposed to predict the performance of the columns as expressed by the following equations:

The experimental data are compared with the calculated results from the above equations in Fig.10.This figure indicates that the suggested equation can estimate the overall continuous phase Sherwood number with high accuracy.These correlations predict the results with a reduced average error of 4.3%.

Fig.9.Comparison of the values calculated previous models with experimental results(a)d to c direction and(b)c to d direction.

Fig.10.Comparison between experimental data and the estimated values using Eq.(26).

5.6.New correlations for holdup and Sauter mean drop diameter

Two correlations are proposed for prediction of the holdup and Sauter mean drop diameter in the pilot plant multistage column extractor.The correlation for holdup can be given as follow:

The dispersed phase holdup calculated with this correlation reproduces the experimental data with an average error of 4.32%.Fig.11 shows the agreement between the experimental data obtained in the present study and the predicted data,using Eq.(27).

Fig.11.Comparison between experimental data and the estimated values using Eq.(27).

Fig.12.Comparison between experimental data and the estimated values using Eq.(28)for estimation of Sauter mean drop diameter.

The new correlation is derived for the mean drop size in the pilot plant multistage column extractor based on the operating parameters as follows:

The comparison of the experimental results with the calculated values from the above correlation is shown in Fig.12.This equation reproduces the experimental data with an average error of 3.71%.

6.Conclusions

Design procedures for a multistage column still depend on collecting large amounts of data.The experimental work was carried out in this column to predict the overall mass transfer coefficients.Several parameters,which could control the overall mass transfer coefficient,were investigated.The results showed that the mass transfer performance increased by increasing the operating parameters such as rotor speed,as well as continuous and dispersed phase velocities.In addition,the direction of mass transfer greatly influenced on the performance of the column.Acorrelation for mass transfer coefficients in the column is proposed based on the concept of Reynolds number,holdup and physical properties that can be applied in two directions(c to d and d to c).Also,two correlations were proposed for prediction of dispersed phase holdup and Sauter mean drop diameter in multistage column extractor.These correlations would be useful to design the multistage columns.

Nomenclature

ainter facial area,m2·m-3

Bnnth coefficient in equations,m

Dmolecular diffusivity,m2·s-1

Dccolumn diameter,m

Dirotor diameter,m

d32Sauter mean drop diameter,m

Eaxial mixing coefficient,m2·s-1

gacceleration due to gravity,m·s-2

Heffective height of the column,m

Koverall mass transfer coefficient,m·s-1

Nrotor speed,s-1

Noxnumber of‘true’transfer unit

PPéclet number(=HV/E)

Peccontinuous-phase Péclet number(=d32Vs/Dc)

Qflow rate of the continuous or dispersed phase,m3·s-1

ReReynolds number(=d32Vsρc/μc)

ScSchmidt number[=μ/(ρD)]

ShSherwood number(=kd32/D)

Shocoverall continuous-phase Sherwood number(=Kocd32/D)

ttime,s

Vsuperficial velocity,m·s-1

Vsslip velocity,m·s-1

Vtterminal velocity,m·s-1

xmass fraction of acetone in continuous phase

x* equilibrium mass fraction

ymass fraction of acetone in dispersed phase

Δρ density difference between phases,kg·m-3

Appendix

λnnth coefficient in Eqs.(23)and(24)

κ viscosity ratio(=μd/μc)

μ viscosity,Pa·s

ρ density,kg·m-3

σ inter facial tension,N·m-1

φ dispersed phase holdup

ψ power dissipated per unit mass,m2·s-3

Superscripts and Subscripts

c continuous phase

d dispersed phase

o overall value

* equilibrium value

° inlet to column

Table A1Experimental data obtained in the experiments for toluene-acetone-water system

[1]V.S.Kislik,Solvent extraction:Classical and novel approaches,Elsevier,New York,2012.

[2]A.Rahbar-Kelishami,H.Bahmanyar,New predictive correlation for mass transfer coefficient in structured packed extraction columns,Chem.Eng.Res.Des.90(5)(2012)615-621.

[3]M.Ghadiri,S.N.Ashra fizadeh,M.Taghizadeh,Study of molybdenum extraction by trioctylamine and tributyl phosphate and stripping by ammonium solutions,Hydrometallurgy144-145(2014)151-155.

[4]G.M.Ritcey,A.W.Ashbrook,Principles and applications to process metallurgy,Elsevier,New York,1984.

[5]N.N.Li,E.N.Ziegler,Effect of axial mixing on mass transfer in extraction columns,Ind.Eng.Chem.59(3)(1967)30-36.

[6]P.V.Danckwerts,Continuous flow systems,distribution of residence times,Chem.Eng.Sci.2(1)(1953)1-13.

[7]J.E.Henton,S.D.Cavers,Continuous-phase axial dispersion in liquid-liquid spray towers,Ind.Eng.Chem.Fundam.9(3)(1970)384-392.

[8]C.J.Geankoplis,J.B.Sapp,F.C.Arnold,G.Marroquin,Axial dispersion coefficients of the continuous phase in liquid-liquid spray towers,Ind.Eng.Chem.Fundam.21(3)(1982)306-311.

[9]M.M.Hafez,M.H.I.Baird,I.Nirdosh,Flooding and axial dispersion in reciprocating plate extraction column,Can.J.Chem.Eng.57(2)(1979)150-158.

[10]P.Parthasarathy,G.Sriniketan,N.S.Srinivas,Y.B.G.Varma,Axial mixing of continuous phase in reciprocating plate columns,Chem.Eng.Sci.39(6)(1984)987-995.

[11]A.Kumar,S.Hartland,Prediction of continuous-phase axial mixing coefficients in pulsed perforated-plate extraction columns,Ind.Eng.Chem.Res.28(10)(1989)1507-1513.

[12]D.R.Arnold,C.J.Mumford,G.V.Jeffreys,Drop size distribution and inter facial area in agitated contractors,International solvent extraction conference ISEC’74 1974,p.1619.

[13]J.H.Rushton,S.Nagata,T.B.Rooney,Measurement of mass transfer coefficients in liquid-liquid mixing,AICHE J.10(3)(1964)298-302.

[14]I.Komasawa,J.Ingham,Effect of system properties on the performance of liquidliquid extraction columns-II,Chem.Eng.Sci.33(4)(1978)479-485.

[15]S.Sarkar,C.R.Phillips,C.J.Mumford,Characterization of hydrodynamic parameters in rotating disc and Oldshue-Rushton columns.Hydrodynamic modeling,drop size,hold-up and flooding,Can.J.Chem.Eng.63(5)(1985)701-709.

[16]Y.K.Choi,C.Kim,A study on flow characteristics in a rotating screen blade extraction column,Korean J.Chem.Eng.11(2)(1994)81-88.

[17]A.H.P.Skelland,Mass transfer and inter facial phenomena,in:J.D.Thornton(Ed.),Science and practice in liquid-liquid extraction,Oxford University Press,Oxford,1992.

[18]I.Langmuir,The evaporation of small spheres,Phys.Rev.12(1918)368-370.

[19]M.Torab-Mostaedi,A.Ghaemi,M.Asadollahzadeh,Flooding and drop size in a pulsed disc and doughnut extraction column,Chem.Eng.Res.Des.89(12)(2011)2742-2751.

[20]H.R.C.Pratt,G.W.Stevens,Axial dispersion,in:J.D.Thornton(Ed.),Science and practice in liquid-liquid extraction,Oxford University Press,Oxford,1992.

[21]C.Tsouris,R.Ferreira,L.L.Tavlarides,Characterization of hydrodynamic parameters in a multistage column contactor,Can.J.Chem.Eng.68(6)(1990)913-923.

[22]L.Steiner,G.Oezdemir,S.Hartland,Single-drop mass transfer in the water-tolueneacetone system,Ind.Eng.Chem.Res.29(1990)1313-1318.

[23]J.Temos,H.R.C.Pratt,G.W.Stevens,Mass transfer to freely moving drops,Chem.Eng.Sci.51(1)(1996)27-36.

[24]M.Torab-Mostaedi,S.J.Safdari,M.A.Moosavian,M.G.Maragheh,Mass transfer coefficients in a Hanson mixer-settler extraction column,Braz.J.Chem.Eng.25(3)(2008)473-481.

[25]M.Torab-Mostaedi,J.Safdari,Mass transfer coefficients in a pulsed packed extraction column,Chem.Eng.Process.48(8)(2009)1321-1326.

[26]A.Kumar,S.Hartland,Mass transfer in a Kuhni extraction column,Ind.Eng.Chem.Res.27(7)(1988)1998-1203.

[27]T.Mí?ek,R.Berger,J.Schroter,Standard test systems for liquid extraction studies,EFCE Publ.Ser,1985.

[28]A.C.Lochiel,P.H.Calderbank,Mass transfer in the continuous phase around axisymmetric bodies of revolution,Chem.Eng.Sci.19(7)(1964)471-484.

[29]H.Brauer,Stoffaustausch einschliesslich chemischer reaktionen,Verlag Sauerlander,Aarau,Switzerland,1971.

[30]A.H.P.Skelland,Diffusional mass transfer,Wiley,New York,1974.

[31]R.Clift,J.R.Grace,M.E.Weber,Bubbles,Academic Press,New York,Drops and Particles,1978.

[32]F.H.Garner,A.Foord,M.Tayeban,Mass transfer from circulating drops,J.Appl.Chem.9(1959)315-323.

[33]M.E.Weber,Mass transfer from spherical drops at high Reynolds numbers,Ind.Eng.Chem.Fundam.14(4)(1975)365-366.

[34]L.Steiner,Mass-transfer rates from single drops and drop swarms,Chem.Eng.Sci.41(8)(1986)1979-1986.

[35]A.Kumar,S.Hartland,Correlations for prediction of mass transfer coefficients in single drop systems and liquid-liquid extraction columns,Chem.Eng.Res.Des.77(5)(1999)372-384.

[36]M.Torab-Mostaedi,A.Ghaemi,M.Asadollahzadeh,P.Pejmanzad,Mass transfer performance in pulsed disc and doughnut extraction columns,Braz.J.Chem.Eng.28(3)(2011)447-456.

[37]M.Torab-Mostaedi,M.Asadollahzadeh,Mass transfer performance in an asymmetric rotating disc contactor,Chem.Eng.Res.Des.94(2015)90-97.

Chinese Journal of Chemical Engineering2016年8期

Chinese Journal of Chemical Engineering2016年8期

- Chinese Journal of Chemical Engineering的其它文章

- Synthesis of hierarchical dendritic micro-nano structure ZnFe2O4 and photocatalytic activities for water splitting☆

- Simultaneous desulfurization and denitrification of sintering flue gas via composite absorbent☆

- Non-catalytic conversion of wheat straw,walnut shell and almond shell into hydrogen rich gas in supercritical water media

- Synthesis and characterization of poppy seed oil methyl esters

- Biodieselproduction fromgreen seaweed Ulva fasciata catalyzed by novel waste catalysts from Pakistan Steel Industry

- Increasing isobutanol yield by double-gene deletion of PDC6 and LPD1 in Saccharomyces cerevisiae☆