Computational chemical engineering - Towards thorough understanding and precise application☆

Zaisha Mao,Chao Yang

Key Laboratory of Green Process and Engineering,Institute of Process Engineering,Chinese Academy of Sciences,Beijing 100190,China

1.Paradigms of Chemical Engineering

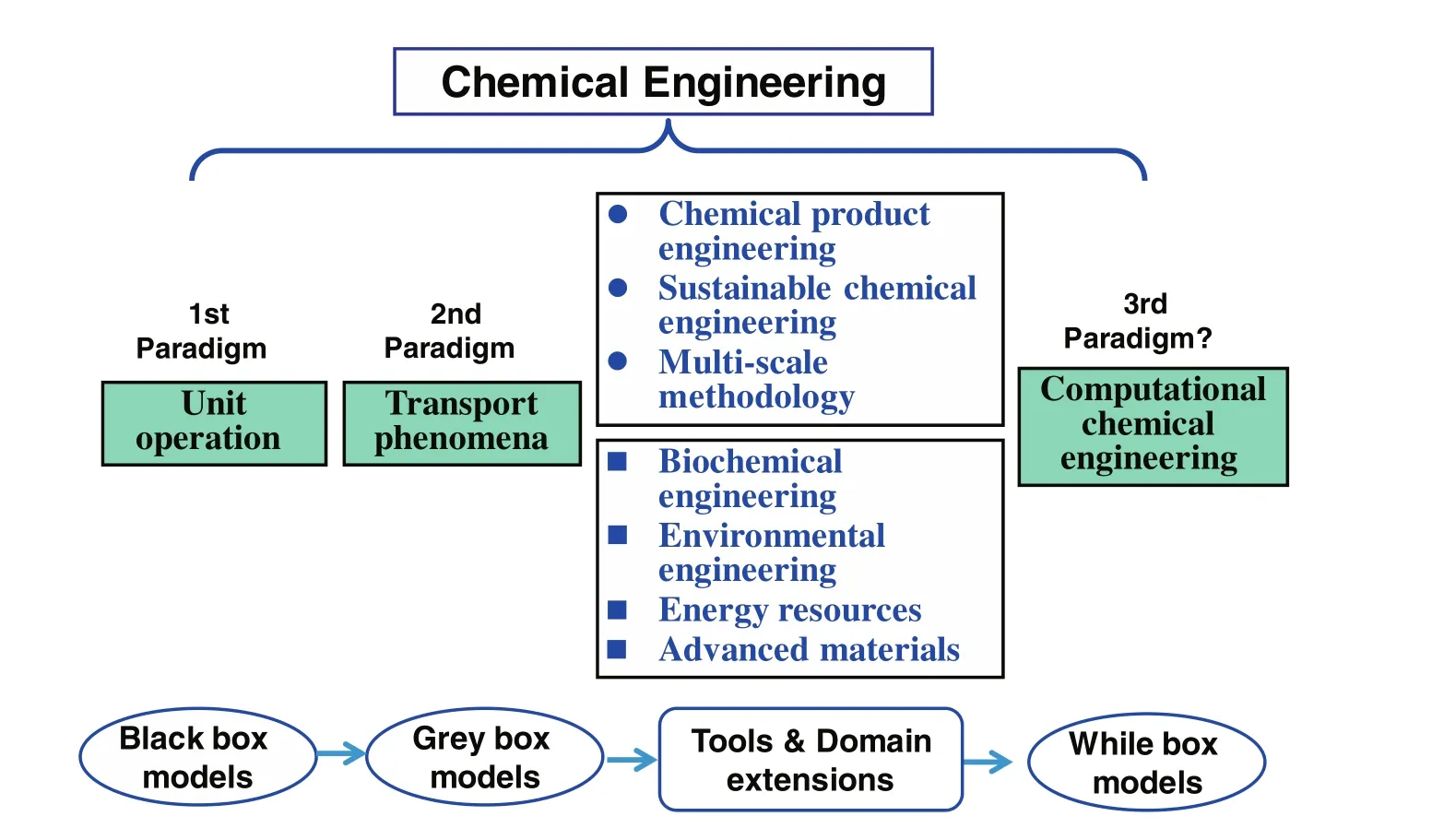

While chemical engineers are constantly striving to gain more thorough understanding of the discipline of chemical engineering and apply this knowledge efficiently to general process industries,they do look retrospectively from time to time at the history of the development of Chemical Engineering over more than a century.It is generally acknowledged that there are two paradigms in the early development of the chemical engineering discipline[1-3].

The first paradigm isUnit Operations.This term was first used in 1911 by A.D.Little in a report(see[2]),and also symbolized by George Davies'sHandbook of Chemical Engineeringpublished in 1901 and the textbookPrinciples of Chemical Engineeringby H.Walkeret al.in 1923(see[4]).These works were essentially a systematic reduction of the to-date chemical production processes into their constituting elements—unit operations.After macro-scale engineering analysis of each unit operation being done,chemical engineers could understand a whole chemical process more thoroughly and would be able to integrate necessary operation units into a new chemical process,with higher efficiency than just empirically copying the existing ones.The first paradigm appeared in response to the call of systematization and generalization of chemical industry practice.

The first paradigm established the discipline of chemical engineering,as a sublimation from pure industrial practices.In this frame,the empiricism in chemical industry was systematized into a matrix of concepts,principles,and basic laws.Chemical engineers can build a chemical process by splitting the target into a series of unit operations,choosing suitable types of device,connecting and matching them,so as to build a relatively optimized entity with balanced specificity and flexibility.However,due to the limitation in the development of applied mathematics,each unit operation was treated as a device in subject to the overall conservation of mass,species and energy.The interior non uniformity and its influence on the unit performance were intractable at that period.

The second paradigm isTransport Phenomena,which is also the title of a textbook by Birdet al.in 1960[5].It addressed the three basic physical processes of momentum,energy and mass transfer,in a general sense but with strong chemical engineering background.Using the more sophisticated theoretical tools,the models on unit operation were upgraded from“black box”to“gray box”ones.Chemical engineers learned to analyze unit operations as quantitatively as possible by using underlying fundamental chemical and physical principles.With the tools of the new paradigm,a unit operation device,previously considered as a black box,could either be analyzed integrally as a whole to get an approximate or effective formulation,or be further analyzed by using relevant differential equations to understand more details of local behavior,and then its total behavior be evaluated by integrating the differential equations with suitable boundary conditions enforced.

In general,unit operations are usually governed by a set of nonlinear differential equations(the Navier-Stokes equation as a typical example),which are difficult to integrate analytically.Such mathematical difficulties motivated chemical engineers in association with mathematicians to seek alternative approaches such as numerical integration,perturbation,series expansion,etc.to getanalytical results of reasonable accuracy.Thus,the understanding of operation units was upgraded to the gray-box level,and the design and operation of commercial production processes in chemical industry were greatly benefited.

Chemical engineering as a discipline has been developing rapidly in the latter half of the 20th century.New advanced chemical techniques,which emerged accompanied by new concepts and principles,were well summarized in a review by Villermaux in 1993[6].He made quite a long listing,covering mass-heat-momentum analogies,reaction transfer coupling,effective media and properties,population balance,residence time distribution,axial dispersion,continuous stirred tank,non-lineardynamics,energy and entropy management,structure of condensed matteretc.,all being achievements along the routes paved by the first two paradigms.It seems that chemical engineering as a discipline was doing well in acquiring deep understanding of chemical processing practice and gaining a full formulation of its scope,concept,theory and application.While chemical engineers strived to serve the industry and economy,they also pondered where the chemical engineering developed to and what the next paradigm of chemical engineering would be.

Late in 1980s,a group of leading American chemical engineers gathered to explore the frontiers of our discipline and published an influencing report by the Committee on Chemical Engineering Frontiers in 1988[1].After retrospecting the past development of chemical engineering and observing the trend of academic chemical engineering moving away from the industry,they proposed the new frontiers for chemical engineering to motivate chemical engineers to invest their efforts and wisdom:biochemical engineering,new energy sources,advanced materialsetc.Of course,this field expansion notonly demands the traditional chemical engineering approaches,but also calls for serious innovation in concepts,methods and techniques,as well as seamless integration with adjacent physical,chemical and biological disciplines[7].Indeed there exist the frontiers for theory,research and development in chemical engineering,but all these seem to expand the scope of this discipline,and the new contributions of chemical engineers in the adjacent industrial and engineering fields may be deemed as the new territories of chemical engineering.

Has the chemical engineering discipline evolved to a distinctively new stage?Is the present theory of chemical engineering now more impeccably formulated,has its range of application extended widely enough,are the mechanisms in chemical processes thoroughly understood,or are its methods perfect and sophisticated?If it is not,what do we need for the chemical engineering to achieve a new paradigm?Chemical engineers have keen interest in these answers.

2.What is the Next Paradigm?

The second paradigm excited the continuous growth of chemical engineering.Coming to 1980s and 1990s,chemical engineers seem to get uneasy about the direction of further development of chemical engineering discipline and become eager to prove the necessity of chemical engineering science.They did their best to expand the scope of application of chemical engineering to neighboring fields as the new frontiers.Typically,after the 1988 report of the Committee on Chemical Engineering Frontiers[1]published,many chemical engineering departments were renamed as chemical and biochemical(environmental,biomolecular or advanced materials)engineering departmentto show their determination of embracing the new frontiers.The seamless chemical engineering science was advocated as an emerging paradigm[7].Incidentally,the authors-affiliated Institute of Chemical Metallurgy,Chinese Academy of Sciences also changed its name to Institute of Process Engineering in 2001 to serve more sectors in industry.Meanwhile,many Chemical engineers had deep concerns on the further development of chemical engineering discipline in last two or three decades.Several representative propositions on the next paradigm were put forward and aroused much attention among peer chemical engineers.

2.1.Chemical product engineering

Products,including chemical products,are generally manufactured along such a route:(1)collecting raw natural materials(food,plant,animal parts,mineral,metaletc.),(2)physical and chemical processing(physical treatment,chemical reaction)to produce man-made raw materials,(3)producing the products ready for consumer use.Usually these steps apply to most of chemical products and partly to merchandise made of chemical products.Since these steps are mostly conducted in different plants,the systems engineering analysis of the entire production process,from very beginning to store shelves,is necessary for saving energy and reducing raw material waste.Around the beginning of the 21st century,many chemical engineers realized that thorough analysis of the whole life cycle of a merchandise product is necessary in response to the urgent pressure from the natural resources shortage and the environmental/ecological protection.This trend is expressed by the advocation ofChemical Product Engineeringas the 3rd paradigm,as first hinted in 1988[1].In the new century,the basics ofChemical Product Engineeringhave been addressed in detail in a monograph by Cussler and Moggridge(2001)[8].They formulated a five-step strategy for the development of a new product.Hill[3]and Woinaroschy[4]also supportedChemical product engineeringas the 3rd paradigm.

Ideal design of a product has to meet many expectations from differ entangles of view,including techno-economic efficiency,environment benignness,durability for consumer use,and waste disposal with minimized negative impact to the nature,etc.But its realization is restricted by many factors needing human decision.In the eyes of chemical engineers,the task is finally turned into a job of multiobjective optimization with heavy reliance on heuristics and empiricism.Cumbersome and complex optimizations are necessary for chemical product engineering and so this job is inevitably resorted to the systems engineering methodology.That's why this proposal of the 3rd paradigm is easily accepted by many systems engineering experts,who are skillful in multi-objective non-linear programming.Chemical product engineeringmakes great contribution in lifting the traditional manufacturing industry to a high ethnic standard in line with the long-term interests of mankind.However,it seems not to add much to the theory and methodology of chemical engineering.

2.2.Sustainable chemical engineering

Having realized that mankind is creating too much burden for the nature and consuming excessively the natural resources,the public makes a strong voice demanding a sustainable development of the global economy and setting up even higher standard on chemical and process industries[9].All these factors promote the formulation ofSustainable chemical engineeringsince late 1990s.The Brundtland report[10] first raised the concept of sustainability or sustainable development,de fined as“the development that meets the needs of the present without compromising the ability of the future generations to meet their own needs”.Sustainability has attracted great attention from different sectors of the world[4].

Clift[11]argued that the sustainable development relies on the system-based tools already embodied in the chemical engineering discipline,which are now applied to broader systems than those conventionally covered in chemical engineering.Clean technology and industrial ecology are new approaches to process selection,design and operation,which combine conventional chemical engineering with some of these system-based environmental managementtools.Sustainable development requires a fusion of chemical engineering with other disciplines including natural science,toxicology,economics and social science.

From the point of view of chemical engineers,the most concerns with respectto sustainable development are environmental and energy resources issues.The strong interdisciplinary base of chemical engineering with universal analytical tools on unit operation and chemical systems makes chemical engineering and chemical engineers a pivotal role in sustainable development[12].Development of sustainable chemical processes,plants,and the whole industry relies heavily on the systems engineering tools,especially the multi-objective optimization[13,14].It seems that the sustainable chemical engineering is a stride of extension of chemical engineering from chemical or process industry to the broader economy sector of the human society.

2.3.Multiscale methodology

Multiscale methodology is progressively gaining recognition and application.Maybe consciously or unconsciously,we have been dealing with multiscale physical and chemical phenomena in chemical engineering.Since long chemical engineers recognize that chemistry on the molecular scale plays the essentialrole in a commercial chemical reactor,and try to incorporate it into the chemical product manufacture on the macro-scale.However,they were troubled with difficulties in developing multiscale models that they had the ability to solve and get mathematical solutions.With the development of Scientific theories and instruments,many chemical engineering researchers addressed an integrated multidisciplinary and multiscale approach for chemical product engineering and process systems engineering.Li&Kwauk[15,16]used a multiscale methodology to model the circulating fluidized bed riser with incorporation of mechanisms and phenomena on two different scales and termed their EMMS(energy minimization multi-scale)model as a variational multiscale methodology.Li and coworkers have been continuing to develop the formulation for applications in other multiphase systems.Lerou and Ng[17]later generalized more formally the multiscale approach(fromplant,reactor,hydrodynamics and transport,catalyst and reaction chemistry,way down to molecular and electronic scales),and suggested that the design of a reaction system for a desirable product can be implemented by taking full advantage of plant design methods,computational fluid dynamics,catalyst design methodologies and computational chemistry.Charpentier[18]also advocated the multiscale methodology for chemical product engineering and process system engineering as the 3rd paradigm of chemical engineering in view of its central role for process intensification and product design and engineering.He emphasized on the computer-aided multiscale modeling and simulation of real-life projects from the molecular-scale to the production-scale.Those propositions remained largely conceptual rather than technically feasible for many years.

The difficulty is how to incorporate the lower scale knowledge into the upper level modeling of chemical engineering phenomena.For example,particulate flows are involved with the interaction between particles and a continuous fluid,which includes drag force,buoyancy,pressure gradient force,and virtual mass force.For each force,experimental studies have offered a great deal of data on single particles and clusters.From these data,a reliable correlation in form of simple single-valued function is numerically fitted,which can thus be easily incorporated into the modeling and calculation of particulate flow in a unit operation.This is the simplest way of incorporation but less accurate(strategy A).

A more accurate approach is to model the phenomena simultaneously on two scales.At present,the main frame of modeling is set on the macro-scale for a certain domain with many particles embedded in the continuous phase,and the phase interaction may be fulfilled in one-way or two-way coupling(strategy C).In 1990s,the number of solid spheres can be handled by the contemporary digital computer was up to 32000[19],but for deformable 3D drops under good resolution,the number was only around 125 as simulated in a liquid-liquid system[20].Nowadays,up to 1166400(2D)75-μm solid particles and 129024(3D)particles can be simulated in particulate flow with tolerable precision[21].This achievement is largely owing to the rapid progress in both computing hardware and simulation method,but it still does not meet the need of application to commercial chemical devices.

To resolve the time-being difficulty,the behavior of a particle cluster(including bubble and drop swarms)must be known sufficiently,because the hydrodynamic behavior of a heterogeneous particulate system can be suitably modeled in terms of clusters on the messo scale.Aparticle in a cluster is subjected to a drag force which is different from that of a single one in an in finite fluid medium,and the cluster itself follows its own rules when it is taken as an entity.As a modeling alternative in between(strategy B),the heterogeneous particulate flow may be considered as many clusters and single particles in motion in the turbulent continuous fluid phase,where clusters are recognized as a meso-scale phenomenon between the particle and device scales.Thus,the detailed strategy C computation is converted to much simple and computer-load-efficient strategy B.Even so,the interaction between dominant mechanisms at the intermediate meso-scale still leads to difficulty in accurate formulation of the whole macro-scale phenomena.So the meso-scale investigation is not just a provisional tactics,it is a necessity when the particle-scale(or micro-scale)information is to be embedded into the operation unit scale(or macroscale)[22,23].The meso-scale study also adds colorful complexity to the multi-scale methodology.Recognizing that particle clusters represent largely the meso-scale feature of heterogeneous particulate flow,the efficiency of the cluster-based discrete-continuum model of particulate flow is demonstrated with up-to-date supercomputing[24].

Other proposals include:Seamless chemical engineering scienceby Mashelkar(1995)[7],andMolecular computational scienceby Wei(2002)[25]and Liuet al.[26].Peers'thoughts do roam high and wide,such as environmental protection,manufacturing efficiency,hybrid chemical engineering with other sciences,and more orientation to human society,just as explored by Wei[2].

All these proposals have greatly expanded the contents of chemical engineering and its application.However,there is still a critical question pertaining:What is the driving factor for the chemical engineering discipline to perfect itself in the fundamental concepts,principles,modeling skills and thorough understanding the basic mechanisms?That is another angle of view to scrutinize this discipline.

3.Computational Chemical Engineering

Computer-aided numerical simulation has entered many sectors of science and engineering,in addition to economic,social and cultural fields of our daily life.Many journals with wordComputationorNumericalin their titles appear in recent two decades.In addition toJournal of Computational Physics(1966),International Journal for Numerical Methods in Engineering(1969),Journal of Computational Chemistry(1980)etc.started earlier,many computational journals,such asInternational Journal for Numerical Methods in Biomedical Engineering(1985),International Journal of Numerical Methods for Heat&Fluid Flow(1991),Journal of Computational Methods in Sciences and Engineering(2001),andJournal of Computational Engineering(2013),are rather young.

Computers&Chemical Engineering,inaugurated in 1977 and published only about 200 pages,but published 3300 pages in 2014.Its rapid expansion in last decade is in accordance with speed-up performance upgrading of computer and the surging popularity in its applications.

Besides,academic researchers published new monographs to embody their accent on the important roles of computer-aided simulation in deep understanding in their disciplines.In addition to many book titles on computational physics,there appearedRecent Progress in Computational Heat Transferby Tao[27]andIntroduction to Computational Chemical Engineering Mass Transferby Yu and Yuan[28].We have a full ground to expect a monograph titledComputational ChemicalEngineeringto bud from the fertile soil of chemical engineering study and its wide application in process industries.It is also noted that many commercial and open-source software for computational surveys in various disciplines and techniques are introduced and used by many academic and technical professionals.

Computational technologies are helping chemical engineers to lift chemical engineering from semi-quantitative comprehensions of chemical engineering systems and applications to a fully quantitative level.

3.1.Example 1:Particulate flow

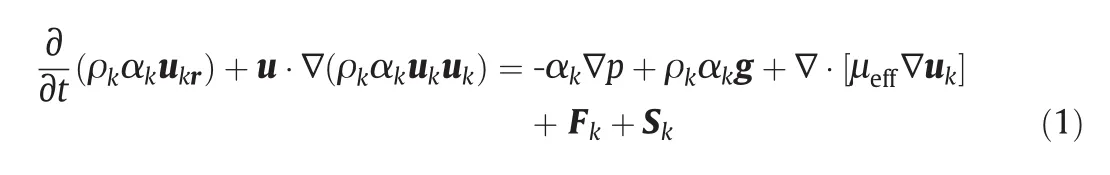

Let's see how the computational study can help in achieving the ultimate understanding of solid particles in motion.For particul atefluid flow,the flow of continuous phasekis governed by

where Fkis the force exerted by the particles in a control volume in the continuous phase,which is the sum of all physical forces-Fion particlei,and the motion of a discrete particle is governed by

So far the force on a particle is intuitively divided into several components,each of which bears more or less certain physical meaning(Fig.1):

Fig.1.Forces arising from the interaction of a particle with a continuous fluid phase[29].

Each force has been studied experimentally and theoretically for many years.As pointed out years ago[29],this division seems quite successful in simulating particulate flows so far,but its defect should not be ignored that the interaction between these components(or their underlying mechanisms)is not accounted for in a correct manner.With nowadays powerful computational capacity,systematic numerical simulation(or more expensively by experimentation)may be conducted on a single particle under different typical modes of motion in a viscous fluid to answer the following list of inquiries:Is Eq.(3)valid for a single particle?Are turbulent dispersion force and wall lubrication force sort of redundant repetition of other mechanisms?Is the Saffman force independent of Magnus force(both being the lift force lateral to the direction of particle motion)?What is the extent of their interaction?after a series of questions being answered,the solution of Eqs.(1)and(2)may give us more accurate information of the motion of a single particle in an unbound fluid medium.

As for a particle subjected to the interaction of adjacent particles,or in a cluster,the situation is more complicated.Progressively,the particles distribution in the particulate flow may be modeled as(a)uniform,(b)uniformly clustered,(c)non-uniformly distributed clusters of the same size,and(d)non-uniformly distributed clusters with a wide size distribution(Fig.2).Either of(a)to(c)is really far from being a real flow pattern.The actual local flow is quite nonuniform with randomly distributed particles as represented by recent simulation on a supercomputing system in Fig.2(d)(particles embedded in color cloud map of gas velocity).The modeling of case(d)remains a very difficult job.Although a cluster-based discrete continuum model works reasonably well for particulate flows(Geet al.,2011),an accurate evaluation of cluster size seems very difficult,either from the DNS results,from theoretical deduction,or from experimental collection of flow field images.Before the computational resources have become powerful enough for DNS of turbulent multiphase flow in an industrialscale operation unit with sufficient spatial and temporal resolutions,the present numerical simulation still helps us in understanding the motion of(1)a single particle among adjacent clusters,(2)a single particle inside a cluster,(3)a cluster among dilute single particles,(4)a cluster among clusters following certain spatial/size distribution.With such information well reduced into correlations and incorporated into the macro-scale flow simulation,the particulate flow will be much accurately predicted than ever before.It is sure that high performance numerical simulation of an operation unit based on the well-known transport phenomena principles can lead us asymptotically to the final thorough understanding of the particulate flows.

3.2.Example 2:Micro-mixing in chemical reactor

Numerical simulation(Scientific computation)has greatly helped chemical engineers to deepen their understanding of the hydrodynamics and fluid mixing in single phase and multiphase chemical reactors[30],but the study of micro-mixing seems to lag behind.It is known long ago that the mixing displays an important role for retrieving as most desired products as possible from a complex system of fast reactions.Analyzing with the transport phenomena principles,chemical engineers realized that the interaction of diffusion of reactants and intermediate products with the chemical kinetics of competitive reactions is the controlling mechanism,and the selectivity relies on both the intrinsic reaction kinetics on the molecular scale and the mixing driven by the macroscopic transport across a reactor.To tackle the complex phenomena extended over several length and time scales,the study of mixing is split artificially into three parts:macro-,meso and micro-mixing,separately by means of experiment,modeling and simulation(refer to our reviews[31,32]).

Mathematical modeling of micro-mixing did develop along with the discipline of chemical engineering.Mao and Toor[33]proposed a simple slab model in form of partial differential equations by perceiving that two reactant feed streams were represented as two stacking slabs containing respective reactant,and the reaction proceeded as the reactants diffuse towards one another.The physical picture of the model was an acceptable approximation,but the acquisition of slab thicknesses as the key model parameter was beyond the capacity of the time-being chemical engineers.So they had to get the empirical parameter by experimenting on a very fast neutralization reaction for each hydrodynamic condition in a concrete reactor con figuration.

Fig.2.Particles and clusters in uniform(a),modeled(b,c)and real(d)particulate flows(ed.from Li&Kwauk[16];(d)from Xiong et al.[21]).

Laterresearchers tried hard to improve this simple modelby seeking for model parameters from the turbulence theory.Ottinoet al.(1979)[34],Bourne(1982)[35],Baldyga and Bourne(1984)[36]and Liet al.[37,38]developed their own micro-mixing models in different formulations with more hydrodynamic information in the reactor being accounted for.They gave more theoretically derived model parameters such as slab thickness,lamellar shrinking rate,and vortex life-time to make their models more mechanism-grounded.Since all these parameters are turbulence-related,a method had to be figured out to decide the average turbulent dissipation rate over the whole reactor or in the active reaction zone.Among these models,the E model simplified by Baldyga and Bourne[36]seems quite successful in modeling the micro-mixing effect in chemical reactors with the additional advantage of model simplicity,and becomes popular in the academic research of micro-mixing in chemical engineering to date.

In last two decades,along with the rapid development of measurement and computer techniques,more and more experimental data and numerical simulation results on hydrodynamics and turbulent details are available for being incorporated into the study of micro-mixing models and the simulation of micro-mixing-sensitive fast reactions.A chosen micro-mixing model(being necessarily adapted on the sub-grid scale)can be directly embedded into the CFD frame of numerical simulation of the whole turbulent flow field[39-41].The probability density function approach(PDF)[42]provided an intermediate platform for bridging the gap between the CFD simulated macroscopic flow field and the micro-mixing model on the molecular scale,and such a strategy was well supported by Baldyga and Makowski[43].

There is still plenty of room for the micro-mixing modeling to close up to the truth of interactive mechanism of chemical kinetics with turbulence-governed macro-mixing.First,the estimation of reaction rates in the present simulations is based on the average reactant concentrations or the alike,instead of their respective part having been dispersed uniformly on the molecular scale(the true concentration relevant to chemical reaction).Therefore,many approximations have to be introduced for getting reasonably accurate estimation of reaction rates.Secondly,the precise role of turbulence and random vortices therein are modeled approximately with the present turbulence theory.Most micro-mixing researchers used the averaged structure of fluid packets( fluid filament,slab,lamellae,swirling vortexetc.)as the simplified physical models for further modeling steps.To remove these defects,the principles in transport phenomena,turbulence theory,modern mechanicsetc.should be resorted to simultaneously with the support of modern applied mathematics and high performance supercomputer techniques.

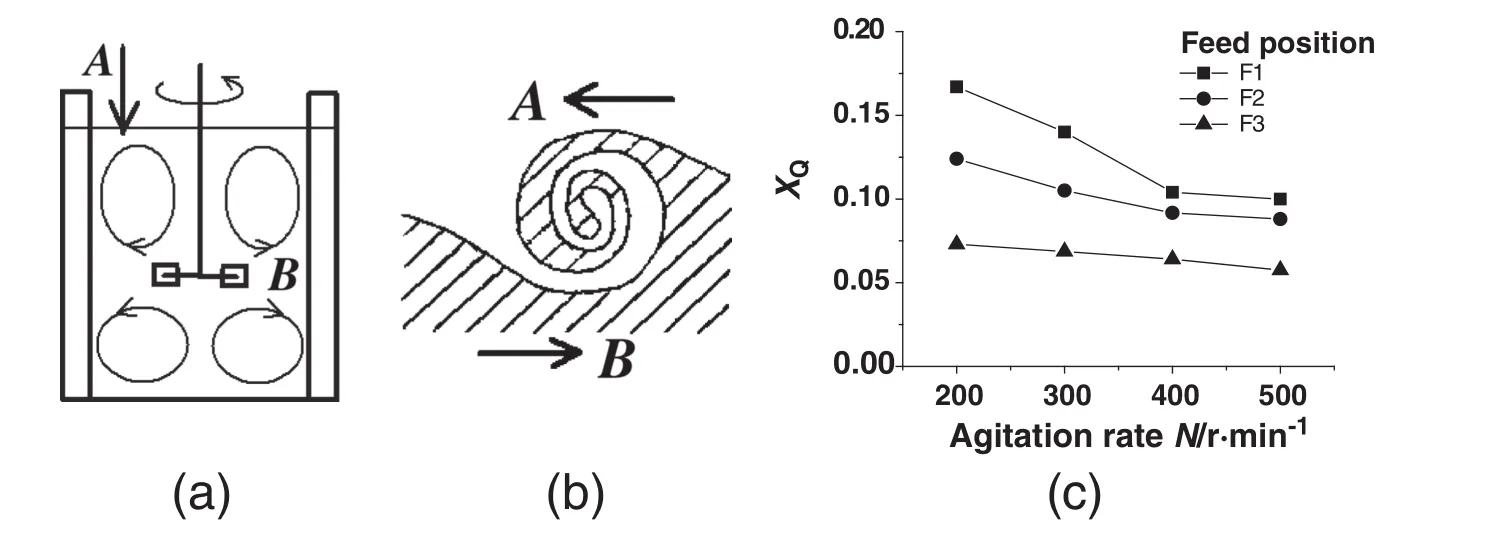

When successful simulation of competitive reactions in a stirred tank reactor(Fig.3(a))is done with sufficient spatial and temporal resolution,we would know the true picture of turbulent flow and the macro-mixing between two feed streams of reactants A and B,how the mechanism of engulfment(Fig.3(b))or other mechanisms gear to accomplish the micro-mixing step and the reactions proceed according the intrinsic kinetics at each point inside the reactor,what the local selectivity of desired products is,and how itaverages to a measurement we used to get at the reactor outlet(the segregation index in Fig.3(c)).Essentially the full numerical simulation can tell us the whole spectrum of physico-chemical processes(including macro-scale flow,convective and turbulent mixing of feed streams,lamellae formation,diffusive reactions on molecular scale)at fine enough spatial and temporal resolution,which will faithfully embody all mechanisms we have incorporated into the simulation models.If we feel this“white box”is too transparent to give us a simple and clear picture,we may choose to make artistically the simulation and modeling suitably approximated to retrieve an easily understood and executed guideline.ComputationalChemical Engineeringallows us a series of windows of variable transparency to look at chemical engineering subjects and leads to the best solutions to engineering applications at rational simulation cost.

Fig.3.Macro-and micro-mixing in a stirred tank reactor.(a)Macroscopic flow pattern,(b)striation structure on meso-scale,(c)segregation index vs.rotating speed.

3.3.What does Computational Chemical Engineering offer?

The above two examples clearly show us the capacity of what numerical simulation can do for chemical engineering.When the powerful numerical simulation is utilized at its utmost,we can get very thorough and detailed understanding of underlying mechanisms in all chemical engineering systems and processes,far beyond what we may get by working with the principles ofUnit OperationandTransport Phenomenaonly.Moreover,the exhaustive information provided byComputational Chemical Engineeringallows us to precisely design,operate and optimize the commercial chemical production of consumer goods in compliance with the ideas of energy conservation,atomic economy synthesis,green and ecological manufacturing,environmental protection,and sustainable development.Computational Chemical Engineeringwill certainly help mankind in ful filling the holy target of green production,ecological and sustainable development.Also,it is exciting that chemical engineering simulation has been applied in many cases of design,renovation and operation optimization of equipment in industrial process lines.

Chemical Engineering can do more work at folds wider application scopes and greater academic depth than ever before when no power of Scientific computation can be relied upon.The following tremendous jobs may be complemented now or in the near future:

·Optimal catalyst design,including chemical components,micro structure,special pore size distribution,preparation technology,and avoiding frequent trial-and-error procedures under the qualitative guide of catalysis chemistry.

·Accurate and optimal design of chemical reactors for complex competitive fast reaction systems with better product selectivity at high capacity efficiency,and optimized reactor con figuration.

·Numerical experiments for scaling up industrial reactors replace the traditional scale-up by multiple hot or cold model tests.At least,the number of tests can be reduced largely.

·Precise design of process units of specified capacity,so that the exact match of operation unit capacities among a process line becomes feasible.

·Optimization of an industrial garden by matching their raw materials,type and amount of products while minimizing the waste,energy consumption,internal transportation and maximizing the pro fits.

These jobs were imaginable for being accomplished before 1980s,but are now realistic.

Incidentally,the 1st paradigm corresponds to the sublimation of empiricism in chemical industrial practice,and the 2nd paradigm is the promotion of simplified overall conservation formulation to semiquantitative mechanism-based modeling(Fig.4).Computational Chemical Engineeringseems to correspond naturally to the next upgrade to fully mechanism-based in-depth understanding of the entire domain related to chemical process and production,which encompasses all forms of complexity of engineering interest(non-linearity,multiple scales,complex systems,green production,sustainabilityetc.)under the all-round support of modern computer science and techniques.

Computational Chemical Engineeringaccepts the concepts,principles and laws from the 1stand 2nd paradigms,and seamlessly from adjacent science and engineering branches.Computational Chemical Engineeringseems to add little to the fundamental theory of chemical engineering,but it realizes any anticipation following the first two paradigms,elevates the level of thorough understanding of the fundamentals to a height neverreached before,and allows accurate prediction of apparent behaviors and micro-scale details in chemical processing units.With the development of numerical simulation techniques,the seamless interaction with adjacent disciplines becomes technically feasible,offering even broader space for chemical engineering to extend it applications.Overall,Computational Chemical Engineeringdeserves to be called a big leap forward in the course of its growth.

It is generally accepted by the science and technology communities that Scientific computation and numerical simulation has become the third pillar to their academic advancement,in addition to other two pillars,experiment and theoretical analysis.

Experiment is never out-of-date in chemical engineering.It always offers the phenomenological trend and valuable data,against which chemical engineers verify mathematical models and numerical schemes,giving chemical engineers the con fidence in their practice.Experimental observation also points to new tasks for theory and simulation to tackle.For example,when we thought the numerical simulation of single phase flow was perfectly done,the experimentally revealed slip boundary condition alerts the necessity of novel theory and new procedure for simulation.

Fig.4.Schematic of paradigms of chemical engineering.

Theoretical analysis will continue to play an important role in guiding engineers to correctly reduce the voluminous amount of digital figures from numerical simulation into concise formulation for facile applications.Also,artistic chemical engineers always need theory based mathematical models of variable complexity to suit diversified purposes.This is the art we need in mathematical modeling in the era ofComputational Chemical Engineering.This art originates from our chemical engineering experience,the ability of theoretical analysis and the professional judgment.Chemical engineer is an artist practitioner in his technical field,rather than a robot pushing buttons of a supercomputer.

4.Closing Remarks

First two paradigms have laid solid foundations for chemical engineering,or more generally process engineering,to develop as the knowledge base and operation guideline for chemical industry and her sisters.

Experiment,theory,and numerical simulation are main essential tools for all engineering sciences,and neither of them has faded with its glory.Computational Chemical Engineering,supported by the other two pillars,allows exploration of even wider scope and deeper understanding of chemical processes and systems.

Numerical simulation is an almost universal tool in presenting the quantitative relationships among many influencing factors based on the governing differential equations encompassing the known key underlying mechanisms.Computational Chemical Engineeringmakes us in a good position to meet a broader scope of applications demanded by green production and sustainable development with a lower rate of cost and consumption of natural resources.It is still in the maturing process,and is expected to play an increasingly important role in thorough understanding and precise application in chemical engineering practice.The earlier paradigms remain vital in many practical engineering cases.Together with up-to-date Scientific and technical computation,chemical engineers can surely meet the challenges of complex or real-world chemical engineering issues.

If we admitchemical product engineering,sustainable chemical engineering,multiscale methodology etc.(each pinpointing to a subdomain or an extension of chemical engineering discipline)are the next paradigms,more paradigms of Chemical Engineering will be anticipated along with its further growth.Nevertheless,what would be the next paradigm following the ultimateComputational Chemical Engineering?That is really a hard question for us to answer at present,if it is recognized as the 3rd paradigm.

Great prosperity to maturingComputational Chemical Engineering!

[1]Committee on Chemical Engineering Frontiers,Frontiers in chemical engineering:Research needs and opportunities,National Academy Press,Washington,1988.

[2]J.Wei,A century of changing paradigms in chemical engineering,ChemTech26(5)(1996)16-18.

[3]M.Hill,Chemical product engineering—The third paradigm,Comput.Chem.Eng.33(5)(2009)947-953.

[4]A.Woinaroschy,A paradigm-based evolution of chemical engineering,Chin.J.Chem.Eng.24(2016)553-557.

[5]R.B.Bird,W.E.Stewart,E.N.Lightfoot,Transport phenomena,John Willey&Sons,Inc.,New York,1960.

[6]J.Villermaux,Future challenges for basic research in chemical engineering,Chem.Eng.Sci.48(14)(1993)2525-2535.

[7]R.A.Mashelkar,Seamless chemical engineering science:The emerging paradigm,Chem.Eng.Sci.50(1)(1995)1-22.

[8]E.L.Cussler,G.D.Moggridge,Chemical product design,Cambridge University Press,New York,2001.

[9]E.P.Byrne,J.J.Fitzpatrick,Chemical engineering in an unsustainable world:Obligations and opportunities,Educ.Chem.Eng.4(4)(2009)51-67.

[10]World Commission on Environment and Development,Our common future,Oxford University Press,Oxford,1987.

[11]R.Clift,Sustainable development and its implications for chemical engineering,Chem.Eng.Sci.61(2006)4179-4187.

[12]M.Narodoslawsky,Chemical engineering in a sustainable economy,Chem.Eng.Res.Des.91(10)(2013)2021-2028.

[13]Z.X.Liu,T.Qiu,B.Z.Chen,A study of the LCA based biofuel supply chain multiobjective optimization model with multi-conversion paths in China,Appl.Energy126(2014)221-234.

[14]Z.H.Yuan,B.Z.Chen,Process synthesis for addressing the sustainable energy systems and environmental issues,AIChE J.58(11)(2012)3370-3389.

[15]J.H.Li,M.S.Kwauk,Particle- fluid two-phase flow:The energy-minimization multiscale method,Metallurgical Industry Press,Beijing,1994.

[16]J.H.Li,M.S.Kwauk,Exploring complex systems in chemical engineering—The multiscale methodology,Chem.Eng.Sci.58(3-6)(2003)521-535.

[17]J.J.Lerou,K.M.Ng,Chemical reaction engineering:A multiscale approach to a multiobjective task,Chem.Eng.Sci.51(1996)1595-1614.

[18]J.-C.Charpentier,Among the trends for a modern chemical engineering,the third paradigm:The time and length multiscale approach as an efficient tool for process intensification and product design and engineering,Chem.Eng.Res.Des.88(3)(2010)248-254.

[19]A.J.C.Ladd,Sedimentation of homogeneous suspensions of non-Brownian spheres,Phys.Fluids9(1997)491-499.

[20]A.Z.Zinchenko,R.H.Davis,An efficient algorithm for hydrodynamical interaction of many deformable drops,J.Comput.Phys.157(2)(2000)539-587.

[21]Q.G.Xiong,B.Li,G.F.Zhou,X.J.Fang,J.Xu,J.W.Wang,X.F.He,X.W.Wang,L.M.Wang,W.Ge,J.H.Li,Large-scale DNS of gas-solid flows on mole-8.5,Chem.Eng.Sci.71(2012)422-430.

[22]J.H.Li,W.Ge,W.Wang,N.Yang,Focusing on the meso-scales of multi-scale phenomena—In search for a new paradigm in chemical engineering,Particuology8(6)(2010)634-639.

[23]J.H.Li,Approaching virtual process engineering with exploring mesoscience,Chem.Eng.J.278(2015)541-555.

[24]W.Ge,W.Wang,N.Yang,J.H.Li,M.S.Kwauk,F.Chen,et al.(33 in all),Meso-scale oriented simulation towards virtual process engineering(VPE)—the EMMS paradigm,Chem.Eng.Sci.66(19)(2011)4426-4458.

[25]J.Wei,Molecular structure and property:Product engineering,Ind.Eng.Chem.Res.41(8)(2002)1917-1919.

[26]Z.P.Liu,S.P.Huang,W.C.Wang,Molecular computational science:New paradigm of chemical engineering,J.Chem.Ind.Eng.(China)54(4)(2003)464-476(in Chinese).

[27]W.Q.Tao,Recent progress in computational heat transfer,Science Press,Beijing,2000(in Chinese).

[28]K.T.Yu,X.G.Yuan,Introduction to computational mass transfer—With applications to chemical engineering,Springer,Heidelberg,2014.

[29]Z.-S.Mao,C.Yang,Challenges in study of single particles and particle swarms,Chin.J.Chem.Eng.17(4)(2009)535-545.

[30]C.Yang,Z.-S.Mao,Numerical simulation of multiphase reactors with continuous liquid phase,Academic Press,London,2014.

[31]Z.-S.Mao,C.Yang,Perspective to study on macro-mixing in chemical reactors,CIESC J.66(8)(2015)2795-2804.

[32]J.C.Cheng,X.Feng,D.Cheng,C.Yang,Retrospect and perspective of micro-mixing studies in stirred tanks,Chin.J.Chem.Eng.20(1)(2012)178-190.

[33]K.W.Mao,H.L.Toor,A diffusion model for reactions with turbulent mixing,AIChE J.16(1970)49-52.

[34]J.M.Ottino,W.E.Ranz,C.W.Macosko,A lamellar model for analysis of liquid-liquid mixing,Chem.Eng.Sci.34(1979)877-890.

[35]J.R.Bourne,The characterization of micromixing using fast multiple reactions,Chem.Eng.Commun.16(1982)79-90.

[36]J.Baldyga,J.R.Bourne,A fluid mechanical approach to turbulent mixing and chemical reaction.Part II:Micromixing in the light of turbulence theory,Chem.Eng.Commun.28(1984)243-258.

[37]X.Li,G.T.Chen,S.X.Rong,Studies on micromixing(III)morphology and deformation of materials in the meso-scale,Chem.React.Eng.Technol.6(4)(1990)15-22(in Chinese).

[38]X.Li,G.T.Chen,J.F.Chen,simplified framework for description of mixing with chemical reactions.I.Physical picture of micro-and macromixing,Chin.J.Chem.Eng.4(4)(1996)311-321.

[39]O.Akiti,P.M.Armenante,Experimentally-validated micromixing-based CFD model for fed-batch stirred-tank reactors,AIChE J.50(3)(2004)566-577.

[40]Y.Han,J.J.Wang,X.-P.Gu,L.-F.Feng,Numerical simulation on micromixing of viscous fluids in a stirred-tank reactor,Chem.Eng.Sci.74(2012)9-17.

[41]X.X.Duan,X.Feng,C.Yang,Z.-S.Mao,Numerical simulation of micro-mixing in stirred reactors using the engulfment model coupled with CFD,Chem.Eng.Sci.140(2016)179-188.

[42]R.O.Fox,Computational models for turbulent reacting flows,Cambridge University Press,Cambridge,2003.

[43]J.Baldyga,L.Makowski,CFD modelling of mixing effects on the course of parallel chemical reactions carried out in a stirred tank,Chem.Eng.Technol.27(3)(2004)225-231.

Chinese Journal of Chemical Engineering2016年8期

Chinese Journal of Chemical Engineering2016年8期

- Chinese Journal of Chemical Engineering的其它文章

- Synthesis of hierarchical dendritic micro-nano structure ZnFe2O4 and photocatalytic activities for water splitting☆

- Simultaneous desulfurization and denitrification of sintering flue gas via composite absorbent☆

- Non-catalytic conversion of wheat straw,walnut shell and almond shell into hydrogen rich gas in supercritical water media

- Synthesis and characterization of poppy seed oil methyl esters

- Biodieselproduction fromgreen seaweed Ulva fasciata catalyzed by novel waste catalysts from Pakistan Steel Industry

- Increasing isobutanol yield by double-gene deletion of PDC6 and LPD1 in Saccharomyces cerevisiae☆