High-Thermal Conductive Coating Used on Metal Heat Exchanger*

LI Jing (李靜)**, LIANG Ju (梁劇) and LIU Yeming (劉業(yè)明)School of Chemistry and Chemical Engineering, South China University of Technology, Guangzhou 510640, China

High-Thermal Conductive Coating Used on Metal Heat Exchanger*

LI Jing (李靜)**, LIANG Ju (梁劇) and LIU Yeming (劉業(yè)明)

School of Chemistry and Chemical Engineering, South China University of Technology, Guangzhou 510640, China

Based on modified silicon polyester resin in addition to several functional fillers such as corrosion-resistant fillers, heat-resistant fillers and thermal conductive fillers, a high thermal conductive coating can be made. On the basis of boronnitride (BN) and aluminum nitride (AIN) used as thermal conductive fillers and by means of the testing system of hot disk and heat transfer experiment, researches on the varieties of thermal conductive fillers and the effects of the contents of high-thermal conductive coating have been done, which shows that the thermal conductivity of coating increases with the increase of the quality fraction and the coefficient of thermal conductivity of the thermal conductive fillers of coating. With guaranteeing better heat resistance, stronger corrosion resistance and adhesive force, the coefficient of coating can reach a level as high as 3 W·m?1·K?1.

thermal conductivity, heat exchanger, coating

1 INTRODUCTION

Metal heat exchanger is a common piece of equipment in chemical industry [1] and the corrosion problem in the process of production seriously affects the life span of the heat exchanger. As coating is important to protect heat exchangers from corrosion, and the thermal conductivity of coating is important for metal heat exchange [2, 3], in order to reduce the disadvantages caused by corrosion problem, it is necessary to prepare an excellent anti-corrosion coating with high thermal conductivity and good heat resistance to be applied to metal heat exchanger for using a long time. At present, there are successive reports on thermal conductivity of coating. For example, Leivo [4] found that the thermal conductivity of coating was improved by adding thermal conductive filler. Lu [5] found that BN/silicon resin system had excellent heat dissipation properties. Fukushima [6] found that the thermal conductivity of coating was sharply increased with increasing quantity of graphite fillers. However, there are very few reports about high-thermal conductive coating applied to metal heat exchanger. This article provides a coating of thermal conductivity of 2.5 W·m?1·K?1which is higher than 1.25 W·m?1·K?1reported by Zhou [7] and studies the relationship between thermal conductivity of coating and thermal conductive particles.

2 EXPERIMENTAL

2.1 Preparation of raw materials

Silicon modified polyester resin is chosen as the matrix resin because of its good heat resistance, good corrosion resistance and excellent adhesion. In addition, amino resin is chosen to increase the crosslink density which improves abrasive resistance and water resistance of coating. Mixed solvents consisting of butyl acetate, PMA and xylene are also chosen with each of their boiling points about 140 °C to match the curing temperature of 180 °C needed for coating. Besides, butyl acetate and phorbol-12-myristate-13-acetate (PMA) have good solubility to the resin, and xylene helps reduce the cost of coating. The characters of fillers directly produce effect on the performance of coating, especially on the thermal conductive particles. AlN, BN, BaSO4, TiO2, SiO2and glass powder are choosen as fillers. Properties of the materials used in the experiment are shown in Table 1.

2.2 Characterization and measurement

Thermal conductivity is performed by means of Hot Disk (Sweden TPS2500) and thermo-gravimetric analysis (TGA) is made by use of a TGA analyzer (SDTQ600, TA, USA) with a heating rate of 10 °C·min?1from 30 to 1000 °C under 5% O2and 95% N2in volume fraction. Heat transfer experiment is conducted with a small size heat exchanger.

2.3 Coating preparation

Silicon modified polyester resin, amino resin, mixed solvent, BaSO4, TiO2, glass power and AlN(BN) are successively put into the container, then zirconium bead weighing 1.5 times of the total components is also put into the container, and they are separately ground for 1 hour. Filter them out when the grain size is ≤30 μm, and adjust the viscosity to 14-16 s (tested by 4#cup).

Table 1 Preparation of raw materials

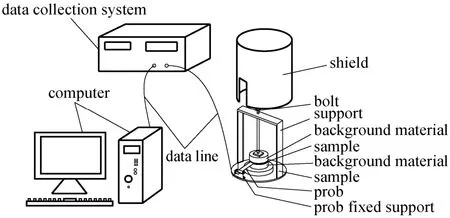

Figure 1 Hot Disk test system

3 RESULTS AND DISCUSSION

3.1 Thermal conductivity of coating

Generally speaking, heat is transmitted from high temperature to low temperature by the thermal motion of molecules, atoms or free electrons in metal crystal. However, for nonmetal crystal, the thermal conduction mechanism is realized by the thermal vibration of the crystalline grains. The thermal conductivity of metal crystal is always higher than nonmetal crystal because of plenty of free electronics existing in metal crystal but not in nonmetal crystal. However, those which have been orderly rowed in crystalline grains inside crystal also have good thermal conductivity. Resin belongs to nonmetal crystal but does not have the orderly rowed crystalline, resulting in its very low thermal conductivity ranging from 0 to 1 W·m?1·K?1. However, the thermal conductivity of resin can be significantly improved by adding a certain amount of thermal conductive particles to form thermal conductive chains or reticulation [8].

Making the coating into thin films, and testing thermal conductivity of coating film through hot disk test system. The measuring principle of Hot Disk is based on transient plane source method (TPS). In this method, Ni metal double helix sensor probe is placed among two samples. The temperature of probe increases when electric current passes through the Ni probe, and generates heat diffusing from Ni probe to the sides of samples. Heat diffusion speed depends on the thermal conductivity of the properties of samples, and thermal conductive efficiency can be achieved by recording the temperature and the response time of the probe. The schematic of hot disk test system is shown in Fig. 1.

The relationship between the thermal conductivity of coating and the mass fraction of BN fillers is shown in Fig. 2 (a). With the increase of mass fraction of BN fillers and binder ratio, the thermal conductivity of coating improves. The thermal conductivity reaches 3.283 W·m?1·K?1when the binder ratio is 3, but the influence of high binder ratio is still negative, which seriously weakens other performances of coating, suchas adhesion force, corrosion resistance, water resistance and flexibility. In addition, as shown in Fig. 2 (a), the increase trend changes when the mass fraction of BN fillers reaches 30%. When the mass fraction of BN transcends (is more than)>50%, it is a little different from the results reported by Zhou [6]. Zhou used two kinds of thermal conductive particles including SiN and Al2O3with different sizes, but we uses BN as thermal conductive particles. The smaller Al2O3particles might hinder the contact between SiN particles which causes low thermal conductivity of composed materials. Fig. 2 (b) shows that the thermal conductivity of coating consists of two different thermal conductive particles such as AlN and BN. The thermal conductivity of coating consists of BN particles is higher than that of AlN particles. The thermal conductivity of BN particles is 250 W·m?1·K?1, while that of AlN particles is 70 W·m?1·K?1. The thermal conductivity of coating discussed in this paper is 2.824 W·m?1·K?1with binder ratio of 2 and BN mass fraction of 60%.

3.2 Heat transfer performance of high-thermal conductive coating

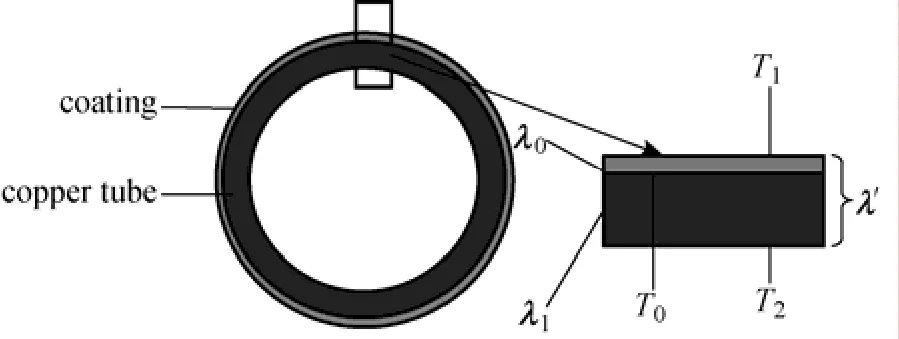

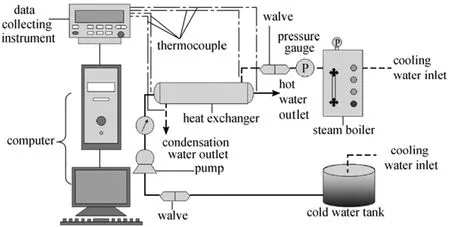

In order to test the heat transfer performance of high-thermal conductive coating prepared, a heat transfer experiment with a heat exchanger is carried out. The surface of copper is coated and then0λ is defined as the thermal conductivity of coating,1λ as the thermal conductivity of copper tube, λ′ as the composite thermal conductivity of copper and coating, h as the thickness of copper pope wall, δ as the thickness of coating, T0as the temperature of interface of coating and copper tube wall, T1as the outside wall temperature of coating and T2as the internal wall temperature of copper tube. The schematic of coated copper tube is shown in Fig. 3 and the schematic of heat transfer experimental process and device is shown in Fig. 4.

Figure 2 Influences of thermal conductive filler on the varieties and contents of thermal conductivity of coating

Figure 3 Schematic of coated copper tube

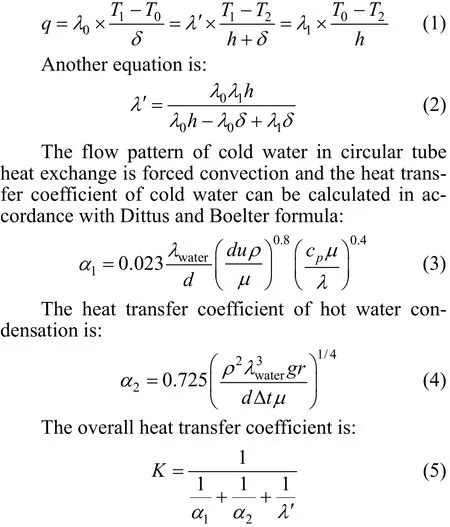

Based on the theory of heat transfer and fluid mechanics, it is known that in one-dimensional steady heat conductivity, the change of temperature is continuous and the heat-flow density q is constant. According to Fourier’s law, the following equations is obtained [9, 10]:

Figure 4 Schematic of heat transfer experimental process and device

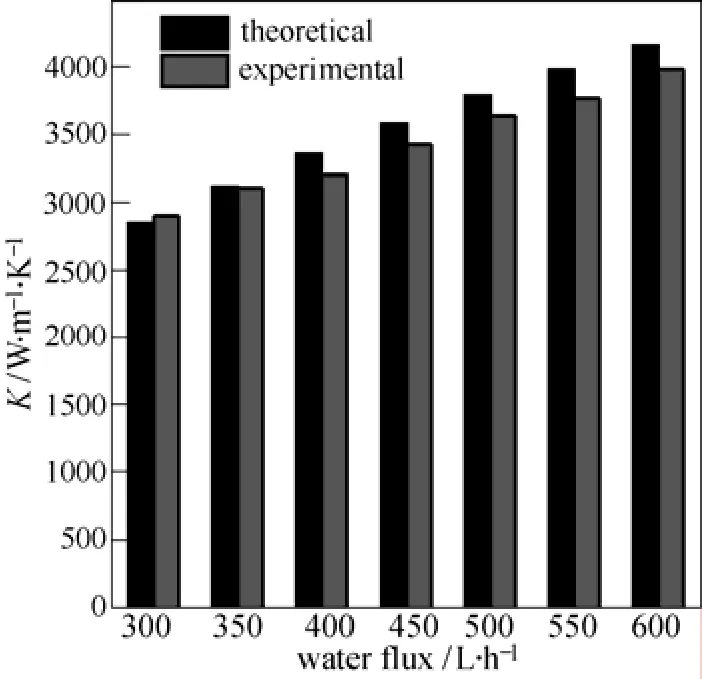

The empirical Eqs. (1)-(5) are used to calculate the total heat transfer coefficient for comparison with the results obtained from the heat transfer experiment, as shown in Fig. 5. The comparison of experimental and theoretical results indicates that they match each other quite well.

Figure 5 Comparison of experimental and theoretical results

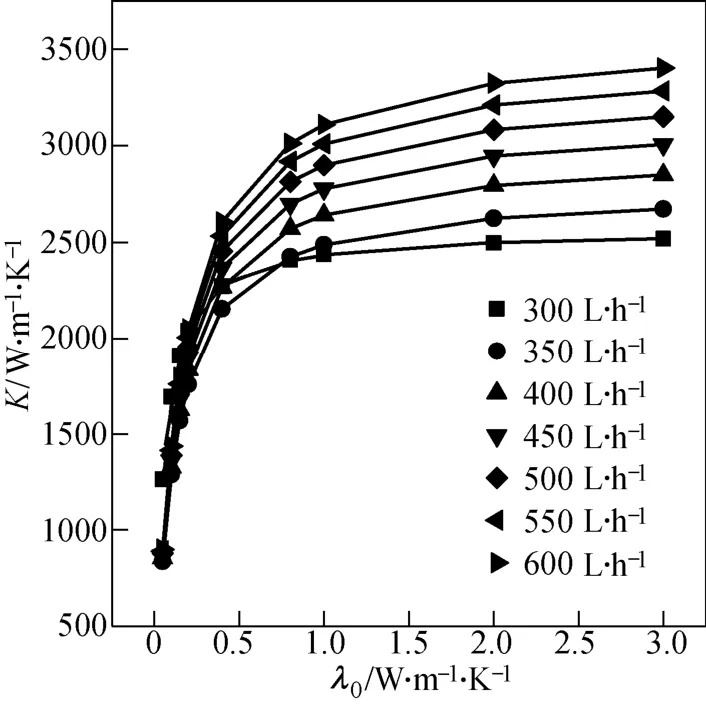

Figure 6 Effect of thermal conductivity of coating on heat transfer coefficient

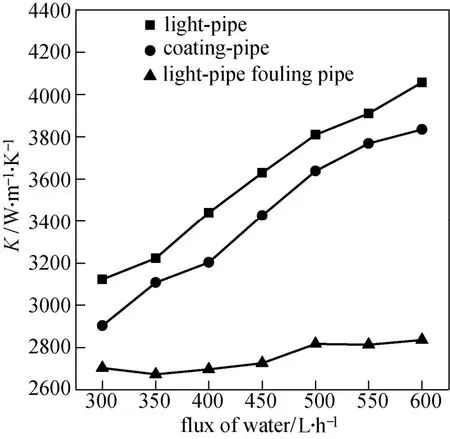

Figure 7 The heat transfer coefficient of three copper tubes under different flux

The effect of thermal conductivity of coating on heat transfer performance obtained from the experiment is shown in Fig. 6. It can be seen that the total heat transfer coefficient increases as the thermal conductivity of coating is strengthening. When the thermal conductivity of coating ranges from 0 to 1 W·m?1·K?1, the heat transfer performance in heat exchange is significantly affected. When the thermal conductivity of coating ranges from 1 to 2 W·m?1·K?1, the effect on the heat transfer performance in heat exchange is relatively weak. When the thermal conductivity of coating reaches more than 2 W·m?1·K?1, the effect on the heat transfer performance in heat exchange is significant. Thermal conductivity of coating used in this paper is 2.824 W·m?1·K?1.

There are three kinds of copper tubes used as the heat transfer tube in heat transfer experiment. The first copper tube is coated with high-thermal conductive coating on the outer surface, which is prepared in this article. The second copper tube is with fouling layer on the outer surface. The third one is smooth tube with nothing on the outer surface. The heat transfer coefficient of three copper tubes under different flux is shown in Fig. 7, which shows that the heat transfercoefficient under different flux of the first copper tube is close to the third copper tube, but it is much higher than that of the second copper tube. High-thermal conductive coating can ensure the heat transfer performance of heat exchanger.

3.3 Heat resistance of coating

Silicon modified polyester resin is mostly used as the matrix resin of high temperature protecting resin. The main chain of this resin is Si O bond which has higher bond energy than C C bond. The significant difference is electro negativity of Si and O atom, which enhances the stability of alkyl groups connected with SiO Si bond. The alkyl groups connected with Si atom will be more stable when Si atom exists in form of SiO Si bond, which can prevent the primary bond from fragmentation.

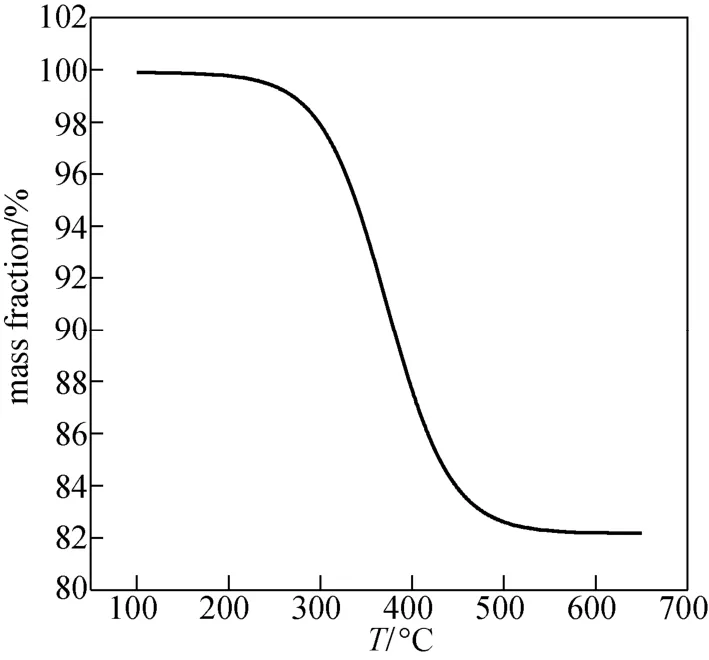

Figure 8 shows the ignition loss of high-thermal conductive coating. It is easy to find that the ignition loss increases as increase of the temperature intensifies. The ignition loss increases rapidly when the temperature exceeds 300 °C, where the organics components in high-thermal conductive coating begin to decompose. When the temperature approaches 600 °C, the degradation of organic components almost stops. The reason for this phenomenon is that the organic components in the high-thermal conductive coating are ablated when the temperature exceeds 300 °C. When the temperature exceeds 350 °C, the glass powder is to be fused, which is shown in Fig. 9. When the temperature exceeds 350 °C to approximately 600 °C, all the organic components disappear. When the temperature is about 600 °C, the fused glass powder and SiO Si bond remain unchanged [11]. The temperature of fluid in ordinary metal heat exchanger retains 100 °C-250 °C. So the high-thermal conductive coating described in this article has excellent heat resistance used in ordinary metal heat exchanger.

Figure 8 TGA of heat conductive coating

Figure 9 Glass powder

3.4 Anticorrosion properties

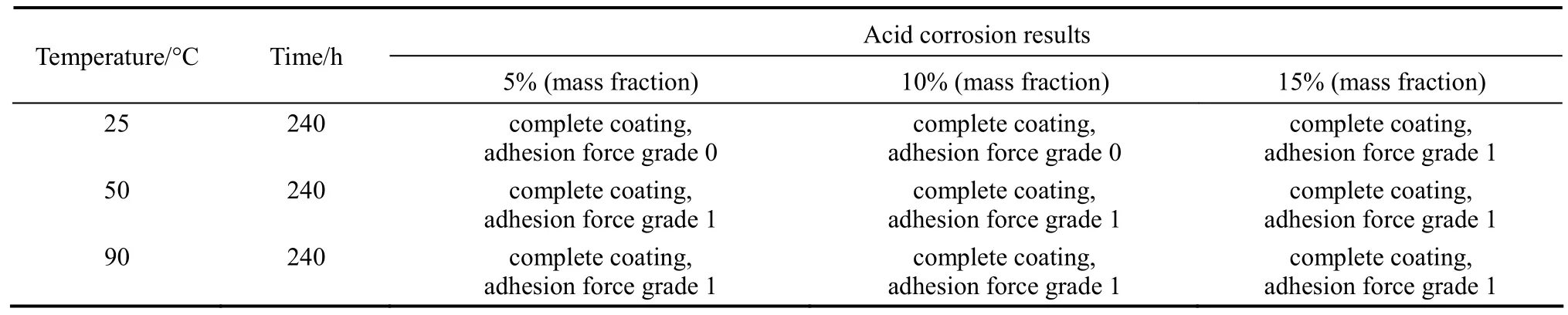

The corrosion of heat exchanger in chemical production process mainly includes hydrogen corrosion and oxygen corrosion, which can be solved by the excellent anticorrosion coating with high thermal conductivity and good heat resistance. Table 2 shows the anticorrosion properties of the high-thermal conductive coating described in this article. The coating remains flawless and perfect after it is placed in acid solution for 240 hours in such temperatures as 25 °C, 50 °C and 90 °C, and the adhesion force is in Grade 1. In this paper, the grade of adhesion force ranges from 0 to 5.0 means the optimal value of adhesion force and 5 means the worst value.

4 CONCLUSIONS

Table 2 Acid corrosion results

(1) The coating of thermal conductivity of heat exchanger is improved by adding thermal conductive particles, and the thermal conductivity increases with increasing thermal conductivity and mass fraction of thermal conductive particles.

(2) Thermal conductivity of coating greatly affects the total coefficient heat transfer when the thermal conductivity of coating is less than 2.0 W·m?1·K?1.This can be used as a reference when choosing the coating for heat exchanger.

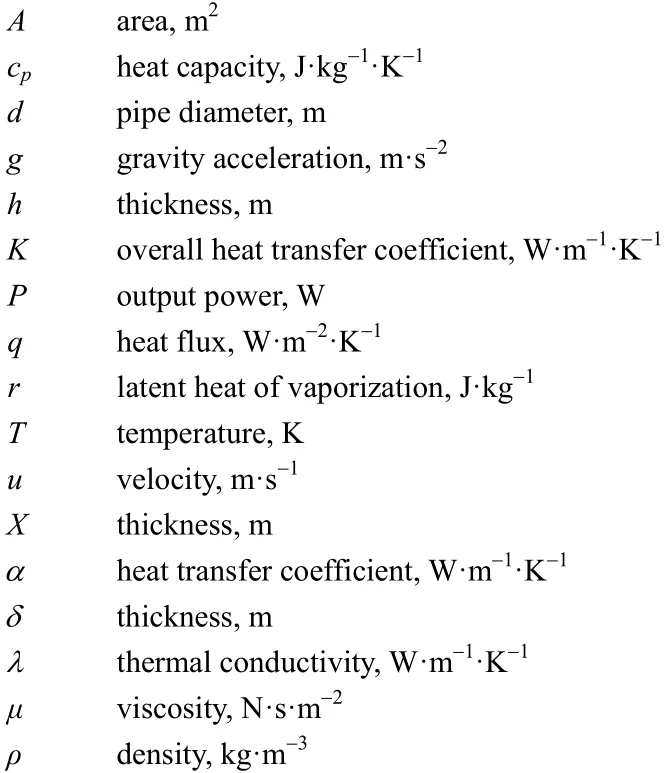

NOMENCLATURE

REFERENCES

1 Guan, Z.Z., “Study of high temperature anti-corrosion coating on heat exchanger”, Master Thesis, South China University of Technology, China (2010). (in Chinese)

2 Zhou, H.H., “Present Situation and Development of Anticorrosion Coatings in China”, Surface Technology, 31 (1), 5-8 (2002). (in Chinese)

3 Yang, L., Wang, X., “Research progress of anti-corrosion coatings”, Guizhou agricultural mechanization, 35, 35-38 (2008). (in Chinese)

4 Leivo, E.M., Kellberg, T.H., Kolari, M.J., “Structure and thermal conductivity of flame sprayed polyamide 11 coatings filled with Al2O3, AlN and BN Ceramics”, In: Proceedings of the 2nd International Thermal Spray Conference, Berndt, C.C., ed., ASM International, Singapore, 327-330 (2001).

5 Xin, L., Gu, X., Hofstra, P.G., Bajcar, R.C., “Moisture-absorption, dielectric relaxation, and thermal conductivity studies of polymer composites”, Journal of Polymer Science, 36 (13), 2259-2265 (1998).

6 Fukushima, H., Drzal, L.T., Rook, B.P., Rich, M.J., “Thermal conductivity of exfoliated graphite nanocomposites”, Journal of Thermal Analysis and Calorimetry, 75 (1), 235-238 (2006).

7 Zhou, W.Y., Qi, S.H., Wang, C.F., Guo, J., “High temperature and insulating heat conductive coating”, Acta Materiae Compositae Sinica, 24 (2), 28-31 (2007).

8 Chung, D.D.L., “Thermal interface materials”, Journal of Materials Engineering and Properties, 10, 56-59 (2001).

9 Yang, S.M., Heat Transfer Theory, Higher Education Press, Beijing, 45-57 (1987). (in Chinese)

10 Zhong, S.Y., Wang, J., Fluid Mechanics and Thermal Theories, China Machine Press, Beijing, 45-47 (2011). (in Chinese)

11 Martan, J., Semmar, N., Leborgne, C., Menn, E.L., Mathias, J., “Thermal properties characterization of conductive thin films and surfaces by pulsed lasers”, Applied Surface Science, 247, 57-63 (2005).

2013-05-08, accepted 2013-08-27.

* Supported by the State Key Development of Basic Research of China (2001CB710703), the National Natural Science Foundation of China (51176053), the Key Technologies R&D Program of Guangdong Province (2011B090400562), the Strategic Emerging Industry Special Funds of Guangdong Province (2012A080304015), and the Key Technologies R&D Program of Guangzhou City (2010U1-D00221, 2011Y5000006).

** To whom correspondence should be addressed. E-mail: ljing@scut.edu.cn

Chinese Journal of Chemical Engineering2014年5期

Chinese Journal of Chemical Engineering2014年5期

- Chinese Journal of Chemical Engineering的其它文章

- Soft Sensor Model Derived from Wiener Model Structure: Modeling and Identification*

- Kinetics of Forward Extraction of Boric Acid from Salt Lake Brine by 2-Ethyl-1,3-hexanediol in Toluene Using Single Drop Technique*

- Influence of Solvent on Reaction Path to Synthesis of Methyl N-Phenyl Carbamate from Aniline, CO2and Methanol*

- Effect of Adsorbent Diameter on the Performance of Adsorption Refrigeration*

- A Facile Route for Synthesis of LiFePO4/C Cathode Material with Nano-sized Primary Particles*

- Filtering Surface Water with a Polyurethane-based Hollow Fiber Membrane: Effects of Operating Pressure on Membrane Fouling*