The in fl uence of silane coupling agent and poplar particles on the wettability, surface roughness, and hardness of UF-bonded wheat straw (Triticum aestivum L.)/poplar wood particleboard

Seyedeh Masoumeh Hafezi ? Kazem Doosthoseini

The in fl uence of silane coupling agent and poplar particles on the wettability, surface roughness, and hardness of UF-bonded wheat straw (Triticum aestivum L.)/poplar wood particleboard

Seyedeh Masoumeh Hafezi ? Kazem Doosthoseini

We used silane coupling agents to improve the bonding ability between wheat straw particles and UF resin, and investigated surface properties (wettability and surface roughness) and hardness of particleboard made from UF-bonded wheat straw (Triticum aestivum L.) combined with poplar wood as affected by silane coupling agent content and straw/poplar wood particle ratios. We manufactured one-layered particleboard panels at four different ratios of straw to poplar wood particles (0%, 15%, 30% and 45% wheat straw) and silane coupling agent content at three levels of 0, 5% and 10%. Roughness measurements, average roughness (Ra), mean peak-to-valley height (Rz), and root mean square roughness (Rq) were measured on unsanded samples by using a fi ne stylus tracing technique. We obtained contact angle measurements by using a goniometer connected to a digital camera and computer system. Boards containing greater amounts of poplar particles had superior hardness compared to control samples and had lower wettability. Panels made with higher amounts of silane had lower Rqvalues.

wheat straw particleboard, poplar wood, surface properties, wettability, silane coupling agent, hardness

Introduction

Approximately 95% of the lignocellulosic material available for particleboard production is wood. Decreasing availability of raw material and the need to conserve natural resources initiated research regarding the use of non-wood fi bers in particleboard production (Dahmardeh Ghalehno et al. (2011). Cereal straw is annually-renewable and available in large quantities in many regions of world, the worldwide production of cereal straw is estimated at 1.5 billion m3annually (Grigoriou 2000). Cereal straw has high fibre content. Traditionally, straw feed to livestock, use as a fuel for heating and cooking, in India/Nepal, combine it with cattle dung to produce fuel farmers harvest grain, Also in no-till systems, it remains on the soil to be incorporated as a contributor to organic content. In North America, straw is baled for later use as bedding material and fodder. It typically burn or otherwise dispose the residues (stalks and husk). Burning wheat straw causes environmental problems such as air pollution, soil erosion and a decrease in soil biological activity (Grigoriou 2000).

In the last two decades, use of straw has been gaining research attention as a potential alternative fi brous raw material replacing wood for making particleboards (Azizi et al. 2011). However some problems still exist, including seasonality of availability, storage, scattered sources and bondability. Of these problems, bondability is a major unsolved technical problem, especially when urea-based resins are applied (Han et al. 1999). Morphologically, straw is more complicated than wood. Straw contains a relatively large number of elements, including the actual fibers, parenchyma cells, vessel elements, and epidermal cells, which contain high amounts of ash and silica .The epidermal cells of straw are the outermost surface cells covered by a thin wax layer. This surface layer reduces absorbance by straw of moisture from water-based adhesives such as urea-formaldehyde (UF) resin (Markessini et al. 1997). The layer therefore acts as a barrier to the gluing of straw with UF resin. Removing this bonding barrier layer from straw materials is a technical problem for performance enhancement of straw panels (Markessini et al. 1997; Han et al. 1999). Isocyanate is an alternative resin that can be used to improve the properties of these strawboards, but the use of isocyanate is hindered by its high cost; hence, it is not commonly utilized, especially in developing countries (Han et al. 1999). In addition, silane coupling agents are generally added when using isocyanate because they improve the adhesion between organic and inorganic materials (Han et al. 1998). We used silane cou-pling agents to modify the characteristics of the inorganic surface by fixing organic functional groups onto it (Han et al. 1998). Particleboard is widely used as substrate for thin overlays such as laminates, resin impregnated papers, foils and as a direct fi nish to surface uses including furniture, counter and desk tops, cabinets, fl oor, wall, ceiling panels, door skin and of fi ce dividers. Roughness is a measure of the fi ne irregularities on a surface. The surface roughness of particleboard plays an important role since surface irregularities can show through thin overlays, reducing the fi nal quality of the panel. When particleboard is used as substrate for surface coating, the particleboard surfaces must be capable of resisting peeling. Fine irregularities on the board surface will show through overlays, and this lowers the grade of the final product, and its quality, fi nishing and gluing. Wettability is an index of how fast a liquid will wet and spread on the particleboard surface, or whether it will be repelled and not spread on the surface. Wettability is crucial for good adhesion in bonding between particleboard and coatings. Liquid surface coatings or adhesives must wet, fl ow and penetrate the cellular structure of wood to establish tight contact between molecules of the composite surface and its coating. The contact angle (CA) method is commonly used to determine the wettability of particleboard. A CA value of zero indicates perfect wetting of a surface. Liquids can wet surfaces at CA values less than 90° (Baharoglu et al. 2011).

Our objective was to investigate the in fl uence of silane coupling agents and percentages of poplar wood particles on the surface roughness, wettability and hardness of UF-bonded wheat straw (Triticum aestivum L.)/poplar wood particleboards.

Materials and methods

Wheat straw and poplar wood particles

We obtained poplar logs from forests in northern Iran. The agricultural lignocellulosic fi ber was from wheat straw (Triticum aestivum L.) in Karaj, near Tehran. We prepared straw and poplar particles using a Pallmann knife ring flaker. All particles were air-dried to about 3% moisture content. Subsequently, we screened particles by handle sieve and oversize and undersize particles were removed. The average size of straw particles was 34 mm × 2.56 mm × 0.33 mm and that of poplar particles was 23 mm × 5.6 mm × 0.85 mm. Slenderness ratios for wheat straw and poplar particles were 80 and 27, respectively. The fractional analysis of straw particles in comparison to poplar particles is listed in Table 1.

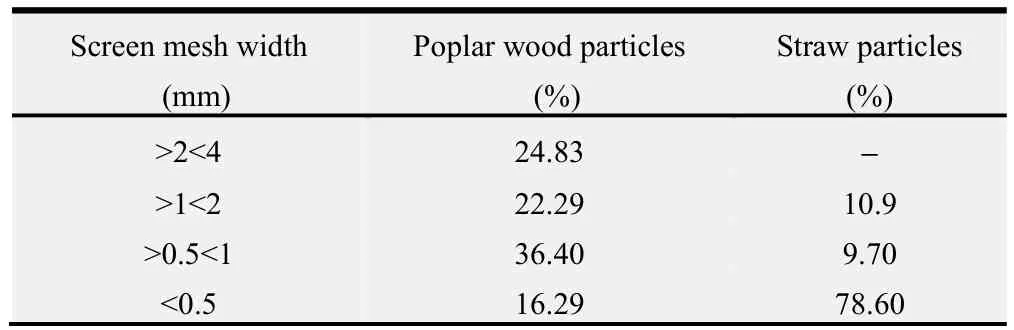

Table 1: Fractional (%) weights of straw and poplar wood particles

Silane coupling agent

We used amino silane coupling agent NH2-C3H6-Si (OC2H5)3in our assessment of the properties of the straw/poplar wood particleboards. The silane coupling agents (Merck Chemistry Company, Germany) had molar mass of 221.37 g?mol-1, density of 0.95 g?cm-3at 20°C, boiling point of 217°C, flash point of 93°C, pH (20 g?mol-1, H2O, 20°C) of 11, solubility temperature of 20°C, and ignition temperature of 300°C.

UF resin

We obtained commercial UF resin from Tiran Chemistry Company, Iran. The resin was water dispersed with a solid content of 62%, viscosity of 125 cp, gelation time of 54 s, pH of 7.5 and mass of 1.28 g/cm3.

Board manufacture

The UF resin was sprayed onto the particles in a blender at 10% resin content based on the oven-dried weight of particles. Silane coupling agent was mixed with the UF resin prior to blending, based on the weight of the resin solid. Based on the weight of the resin solid, 1% of NH4Cl was added as the curing catalyst. Sample boards were pressed into hand-formed mats 14 mm thick using distance bars at 180°C for 5 min and mats were pressed under a pressure of 35 kg?cm-2. The board size was 400 mm × 400 mm × 14 mm with targeted density of 0.70 g?cm-3. We tested four ratios of straw to poplar (100/0, 85/15, 70/30 and 55/45) and three levels of coupling agent (0, 5% and 10%). Our experimental schedule is shown in Table 3.

Mechanical and physical testing

Prior to testing the physical and mechanical properties of sample boards, the boards were conditioned at (20±1)°C and (65±5)% relative humidity (RH) until they reached a constant weight. The surface properties of the samples were determined by the use of a fi ne stylus pro fi lometer (Mitutoyo SJ-201P). Based on these variables, 12 board formulations were manufactured with three boards of each type, resulting in 36 boards in total. Three samples were used from each type of panel for surface roughness measurements. Three roughness parameters described by DIN 4768 standard (1990) as average roughness (Ra), mean peak-to-valley height (Rz), and root mean square roughness (Rq) were measured to evaluate the surface properties of the panels. Surface roughness parameters were calculated from digital information. The vertical displacement of the stylus was converted into an electrical signal by a linear displacement detector before the signal was ampli fi ed and converted into digital information. Rais the arithmetic mean of the absolute values of the pro fi le deviations from the mean and is the most commonly used parameter in surface fi nish measurement. The surface roughness of the samples was measured to a sensitivity of 0.5 μm. Measuring speed, pin diameter and pin top angle of the tool were 0.5 mm?s-1,4 μm and 90°C, respectively. The length of tracing line (Lt) and cut-off were 12.5 mm and 2.5 mm (γ), respectively. Measuring force of the scanning arm on the samples was 4 mN (0.4 gf). Measurements were done at room temperature and the pin was calibrated before the tests (Jarusombuti et al. 2010).

The wetting behavior of the particleboard samples was characterized by the contact angle method (goniometer technique). The contact angles were obtained using a KSV Cam-101. By the sessile drop method, the most widely used procedure, the contact angle was determined simply by aligning a tangent with the sessile drop pro fi le at the point of contact with the solid surface. The drop image was stored using a video camera and an image analysis system calculated the contact angle (h) from the shape of the distilled water drop at room temperature. An imaging system was used to measure contact angle, shape, and size of water droplets for the tested sample surfaces. The image of the liquid drop was captured by a video camera and the contact angle was measured by digital image-analysis software. After a 5 μL droplet of the distilled water was placed on the sample surface, contact angles from the images were measured at one fi fth of a second. Three board samples measuring 50 mm × 50 mm × 14 mm were used from each type of formulation for contact angle measurements (Ayrilmis and Winandy 2010).

The hardness behavior of the particleboard samples was characterized by Instron 4486 instrument and the Brinel method as described by ASTM 1037 standards (1990). Three samples of 50 mm × 50 mm × 14 mm were used from each type of board formulation for hardness measurements.

Statistical analysis

The experiment was designed as factorial using a completely randomized design arrangement. The Duncan method was used to compare means (p <0.05). Statistical analysis was conducted using SPSS? software.

Results and discussion

Physical properties

Surface roughness

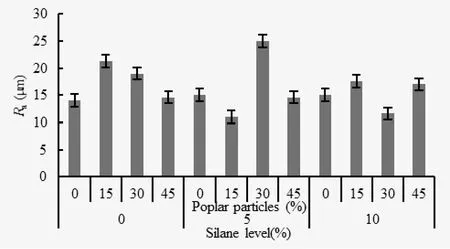

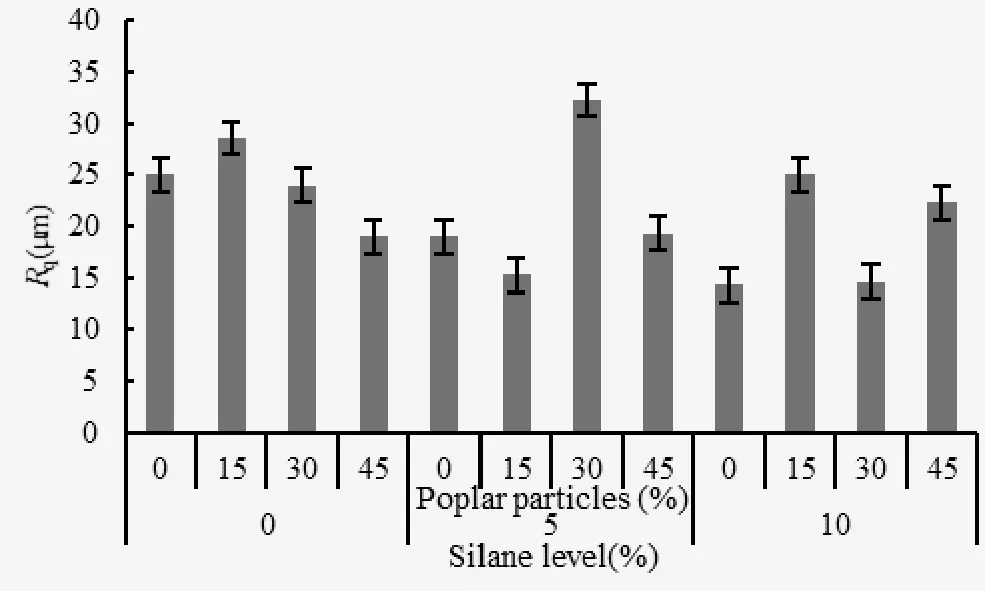

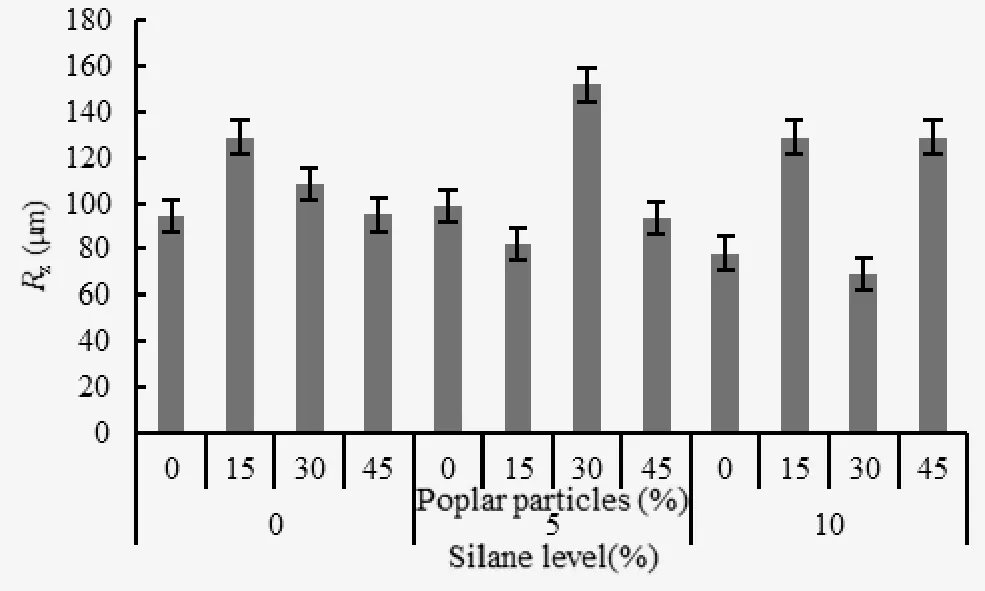

Surface quality of sample particleboards increased with increasing ratios of poplar to straw and increasing levels of silane coupling agents (p < 0.05 in both cases, Figs. 1, 2 and 3).

Increased concentrations of silane coupling agents reduced surface roughness as indexed by Rq values. This might have been due to better interfacial interaction between wheat straw and UF resin. The boards made with 10% silane coupling agent and 30% poplar particles had the smoothest surfaces. A typical commercially manufactured particleboard could have Ra values ranging from 3 to 6 μm (H?z?roglu 1996). Our samples exceeded this range, suggesting that the surfaces of our panels was too rough to be accepted as a substrate without preparatory sanding. However, if the panels were sanded with a sequence of 150, 180 and 220 grit sandpaper, their surfaces could be improved to meet the requirements for substrates for overlays (Hiziroglu and Holcomb 2005).

Fig. 1: Surface roughness (Ra) of boards

Fig. 2: Surface roughness (Rq) of boards

Fig. 3: Surface roughness (Rz) of boards

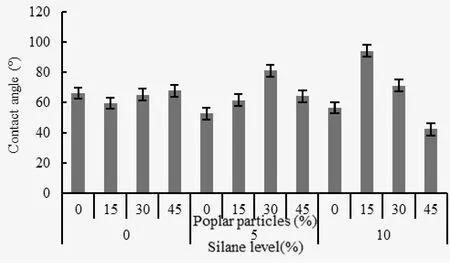

Wettability

Panels made from 15% poplar particles and 10% silane coupling agent had the highest contact angles (Fig. 4). This might have been due to reduced bonding between the wheat straw particles in 100% straw board, which increased water diffusion into this type of panel.

Adding poplar particles to a level of 30% had the positive effect of reducing wettability. This might have been due to better bonding between poplar particles than between straw particles because of the waxy layer on the latter, and the resulting improvement in compression during the pressing stage due to thegreater proportion of poplar particles. Increasing moisture content of wood from 40% to 60% significantly improved wettability and caused smoother surfaces. (Baharoglu et al. 2011).

Fig. 4: Wettability (contact angle) of boards

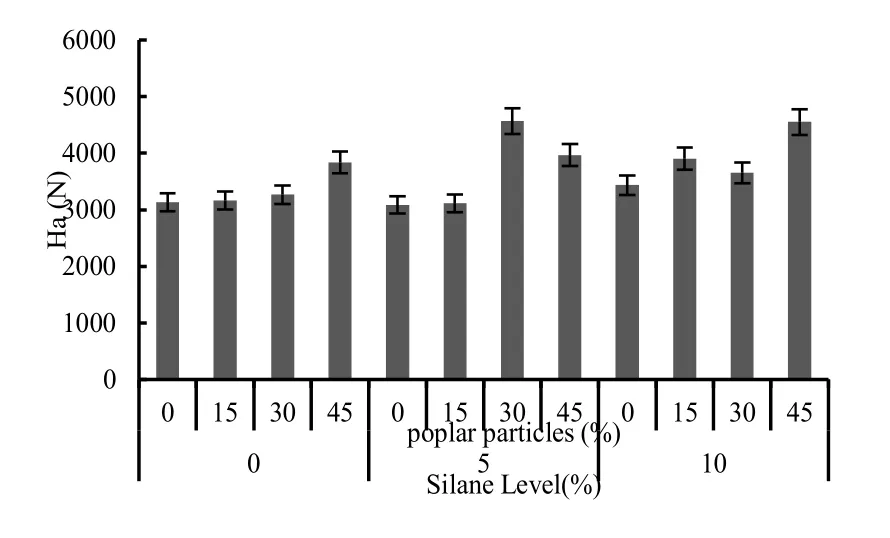

Mechanical properties: Hardness

Silane concentration had no effect on particleboard quality but the addition of poplar particles into wheat straw particleboard signi fi cantly increased hardness (Fig. 5).

Fig. 5: The Hardness (Ha) of boards

In general, boards made with greater proportions of poplar exhibited greater hardness than control samples. Maximum hardness was 4.56 N for board with 30% poplar particles and 5% silane coupling agent level. Adding poplar particles increased hardness duo to the greater compression of poplar particles in compaction with wheat straw particles during pressing. In addition, higher density in poplar particles in compression with straw particles can be a good reason for illustrating this increasing. Doosthosseini and Abdolzadeh (2010) reported that the use of recycled corrugated containers (RCCs) improved the hardness of wood composites due to improved compaction of RCCs and better compression during pressing.

Conclusion

Wettability and hardness of wheatstraw particleboard were signi fi cantly improved by the addition of poplar particles. Adding poplar particles from 15% to 45% signi fi cantly increased hardness, while adding poplar particles to 30% improved wettability. The addition of silane coupling agents resulted in smoother particleboard surfaces.

Panels made with 30% poplar particles and 5% silane coupling agent had greater hardness and less surface roughness, but panels made with 15% poplar particles and 10% silane coupling agent level had less wettability.

In general, the addition of silane coupling agent resulted in better particleboard characteristics because of better adhesion between the UF resin and the straw particles.

Ayr?lm?s N, Winandy JE. 2010. Effects of post heat treatment on surface Characteristics and adhesive bonding performance of MDF. Materials and Manufacturing Processes, 24: 594–599.

Azizi Kh, Tabarsa T, Ashori A. 2011. Performance characterizations of particleboards made with wheat straw and waste veneer splinters. Composites Part B: Engineering, 42(7): 2085–2089.

Baharoglu M, G?kay N, Sar? B, Bardak S, Ayr?lm?s N. 2011. The in fl uence of moisture content of raw material on the physical and mechanical properties, surface roughness, wettability and formaldehyde emission of particleboard composite. Composites Part B: Engineering, 43(5): 2448-2457.

Dahmardeh Ghalehno M, Madhoushi M, Tabarsa T, Nazerian M. 2011. The manufacture of particleboards using mixture of read (surface layer) and commercial species (middle layer). European Journal of Wood and Wood Products, 69(3): 341-344.

Doosthoseini K, Abdolzadeh H. 2010. Investigation on the feasibility of utilization wood and OCC fiber on the surface layer of particleboard and their effects on surface hardness and roughness. Iranian Journal of Wood and Paper Science Research, 25(1): 62-69.

Grigoriou AH. 2000. Straw-wood composites bonded with various adhesive systems. Wood Science and Technology, 34: 355–365.

Han GP, Zhang CW, Zhang DM, Umemura K, Kawai S. 1998. Upgrding of urea formaldehyde-bonded reed and wheat straw particle boards using silane coupling agents. Journal of Wood Science and Technology, 44(4): 282–286.

Han GP, Umemura K, Kawai S, Kajita H. 1999. Improvement mechanism of bond ability in UF bonded reed and wheat straw boards by silane coupling agent and extraction treatments. Journal of Wood Science and Technology, 45(4): 299-305.

H?z?roglu S. 1996. Surface roughness analysis of wood composites: a stylus method. Forest Products Journal, 46(7/8): 67–72.

H?z?roglu S, Holcomb R. 2005. Some of the properties of the three-layer particleboard made of eastern red cedar. Building and Environment, 40(5): 719–723.

Jarusombuti S, Ayr?lm?s N, Bauchongkol P, Fueangvivat V. 2010. Surface characteristics and overlaying properties of MDF panels from thermally treated rubberwood fi bers. Bioresources, 5(2): 968–978.

Markessini E, Roffael E, Rigal L. 1997. Panels from annual plant fibers bonded with urea formaldehyde resins. In: Proceedings of 31st international particleboard composite materials symposium, April 8-10, Washington State University, pp. 147-160.

2013-01-21; Accepted: 2013-04-23

DOI 10.1007/s11676-014-0505-7

The online version is available at http://www.springerlink.com

Seyedeh Masoumeh Hafezi (), Kazem Doosthoseini

Department of Wood and Paper Sciences and Technology, Faculty of Natural Resources, University of Tehran, Karaj, I. R. Iran.

Tel.: +9809112575520

E-mail: masoumeh_hafezi@yahoo.com

Corresponding editor: Yu Lei

? Northeast Forestry University and Springer-Verlag Berlin Heidelberg 2014

Journal of Forestry Research2014年3期

Journal of Forestry Research2014年3期

- Journal of Forestry Research的其它文章

- Effects of shifting cultivation on biological and biochemical characteristics of soil microorganisms in Khagrachari hill district, Bangladesh

- An integrated method for matching forest machinery and a weight-value adjustment

- Finite element analysis of stress and strain distributions in mortise and loose tenon furniture joints

- A modified Murashige and Skoog media for efficient multipleshoot induction in G. arborea Roxb.

- Genetic variation and selection of introduced provenances of Siberian Pine (Pinus sibirica) in frigid regions of the Greater Xing’an Range, Northeast China

- Characterization of expressed genes in the establishment of arbuscular mycorrhiza between Amorpha fruticosa and Glomus mosseae