A hybrid DEM/CFD approach for solid-liquid flows*

QIU Liu-chao (邱流潮)

College of Water Resources and Civil Engineering, China Agricultural University, Beijing 100083, China, E-mail: qiuliuchao@cau.edu.cn

WU Chuan-yu

Department of Chemical and Process Engineering, University of Surrey, Guildford, Surrey, GU2 7XH, UK

A hybrid DEM/CFD approach for solid-liquid flows*

QIU Liu-chao (邱流潮)

College of Water Resources and Civil Engineering, China Agricultural University, Beijing 100083, China, E-mail: qiuliuchao@cau.edu.cn

WU Chuan-yu

Department of Chemical and Process Engineering, University of Surrey, Guildford, Surrey, GU2 7XH, UK

(Received May 24, 2013, Revised September 1, 2013)

A hybrid scheme coupling the discrete element method (DEM) with the computational fluid dynamics (CFD) is developed to model solid-liquid flows. Instead of solving the pressure Poisson equation, we use the compressible volume-averaged continuity and momentum equations with an isothermal stiff equation of state for the liquid phase in our CFD scheme. The motion of the solid phase is obtained by using the DEM, in which the particle-particle and particle-wall interactions are modelled by using the theoretical contact mechanics. The two phases are coupled through the Newton’s third law of motion. To verify the proposed method, the sedimentation of a single spherical particle is simulated in water, and the results are compared with experimental results reported in the literature. In addition, the drafting, kissing, and tumbling (DKT) phenomenon between two particles in a liquid is modelled and reasonable results are obtained. Finally, the numerical simulation of the density-driven segregation of a binary particulate suspension involving 10 000 particles in a closed container is conducted to show that the presented method is potentially powerful to simulate real particulate flows with large number of moving particles.

discrete element method (DEM), computational fluid dynamics (CFD), solid-liquid flows, sedimentation, two-phase flow, numerical simulation

Introduction

The solid-liquid flows can be found in many processes in chemical, petroleum, agricultural, biochemical and food industries. To improve the design of the process equipment while avoiding tedious and time consuming experiments, numerical approaches were widely employed during the last decades and a number of numerical models were developed. For example, Rong and Zhan[1]used the DEM-CFD approach for modelling spouted beds, Wan and Turek[2]applied the multigrid fictitious boundary method (MFBM) to simulate solid-liquid flows, Tong et al.[3]used a DEMCFD method to simulate the powder dispersion in a cyclonic flow, Cate et al.[4]simulated a single sphere settling under gravity using the lattice-Boltzmann method (LBM), Chen et al.[5]applied a dissipative particle dynamics (DPD) for simulating a single sphere settling in a square tube, Yang et al.[6]adopted the discrete particle method for analysing the sedimentation of microparticles, Potapov et al.[7]and Qiu[8]modelled the liquid-solid flows using a coupled smoothed particle hydrodynamics (SPH) and DEM. Over the last two decades, a coupled DEM/CFD was developed and advanced for modelling the fluid-solid flows, and for efficiently analyzing the gas-solid flows[9,10]. In addition, detailed information at the micro-scale can be obtained with the DEM/CFD.

However, most DEM/CFD methods were developed for compressible fluids (i.e., gases) based upon the ideal gas law, which cannot be used for the particle motion in liquids that are generally incompressible. The liquid flow is conventionally simulated by using the incompressible Navier-Stokes equations and the pressure is obtained by solving a Poisson equation. Solving the pressure Poisson equation is often the most costly step in these schemes, to hinder their applications in analyzing particulate systems. An alternative approach for numerical modelling of particulatesystems involving a nearly incompressible Newtonian fluid is proposed in this study, which is stimulated by the weakly compressible flow method developed by Brujan[11]as the fluid solver. Instead of solving the pressure Poisson equation, the compressible volumeaveraged continuity and momentum equations are used, but with an isothermal stiff equation of state for the fluid phase.

This paper is organized as follows. The numerical methods are first discussed, followed by the model validation. Then the numerical simulation of the density-driven segregation of a binary particulate suspension in a closed container is presented. The conclusions and discussions are at the end.

1. The CFD/DEM method

In order to model incompressible fluids in the DEM/CFD, an equation of state for weakly compressible fluids is adapted in place of the ideal gas law. This is incorporated into the DEM/CFD model originally developed by Kafui et al.[9], with the original algorithms kept intact to retain its capability for gassolid flows. For completeness, the theoretical aspect of the modified DEM/CFD is presented in this section.

1.1Governing equations for liquids

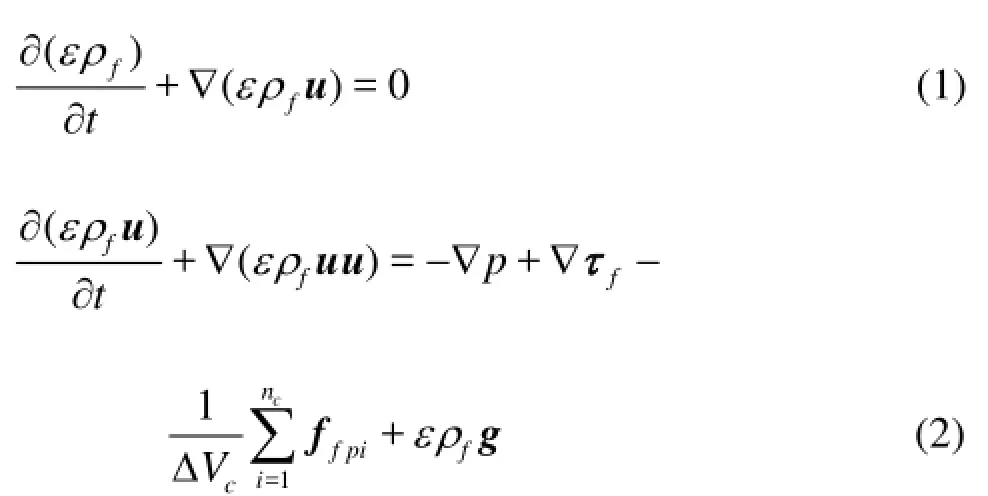

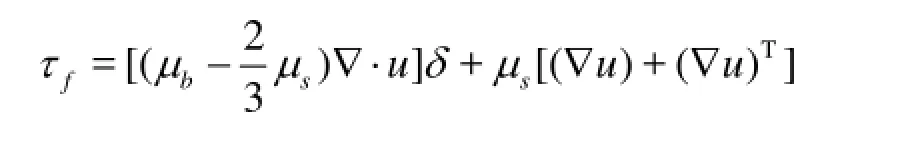

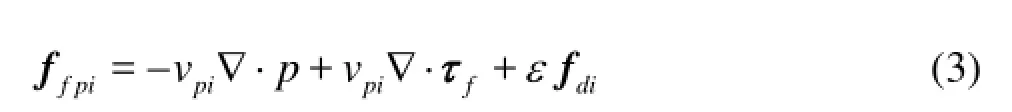

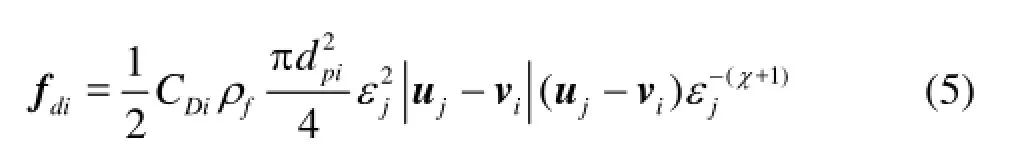

The compressible volume-averaged Navier-Stokes equations of continuity and momentum with an additional stiff equation of state are used for modelling liquid flows. The volume-averaged compressible equations of continuity and momentum conservation for fluid motions are[9]: whereu,ρfandεare the velocity, the density and the volume fraction of the fluid, respectively,gis the gravity acceleration,τfis the fluid viscous stress, evaluated as whereδis the Kroneker delta,μbandμsare the bulk viscosity and the shear viscosity, respectively.ffpiis the fluid-particle interaction force acting on particlei,ncis the number of particles in a fluid cell of volume ΔVc,ffpiis given as wherevpiis the volume of particlei, andfdiis the drag force in the direction of the relative velocity between fluid and particle. In the above equations, the fluid volume fractionεis obtained from the relation Sincefdiis a quantity usually obtained from experimental correlations, the specific form of the drag force

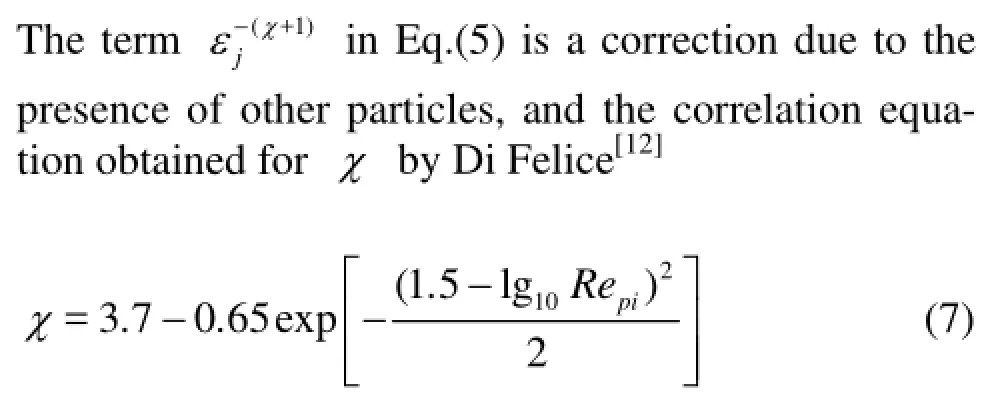

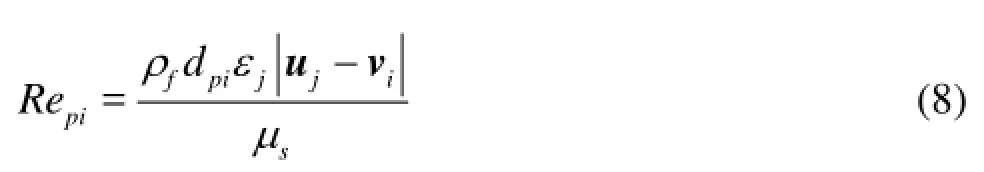

drag forcefdion particleiwhere the subscriptjfor the fluid velocity and the void fraction represents the computational fluid cell in which the particleiresides andCDi, the fluid drag coefficient for a single, unhindered particle, is evaluated by using takes account of the variation of this exponent in the intermediate flow regime as well as the near constant values in the low and high Reynolds number flow regimes. The particle Reynolds numberRepi, based on the superficial slip velocity between fluid and particle, is

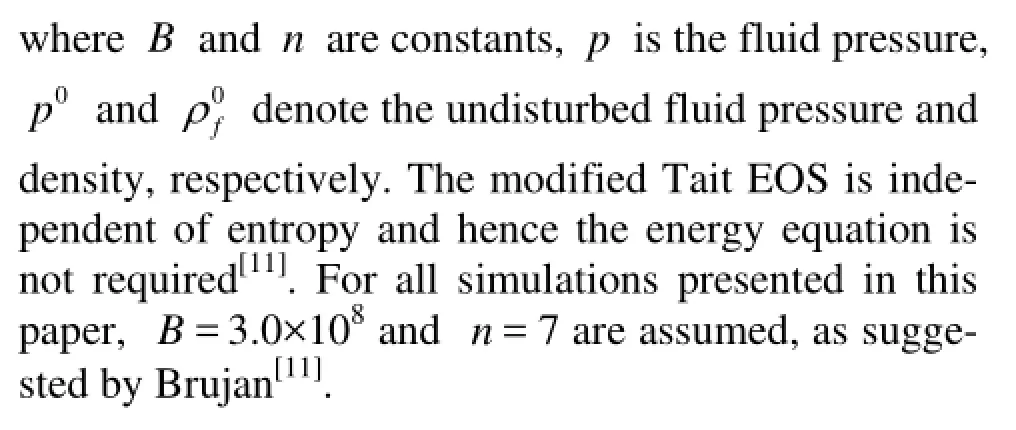

To close the system, an equation of state (EOS) relating the density to the pressure is required. For the liquid-solid flow systems to be considered in this study, a pressure-density relationship of the modified Tait equation of state[11]is incorporated, i.e.,

1.2Governing equations for particles

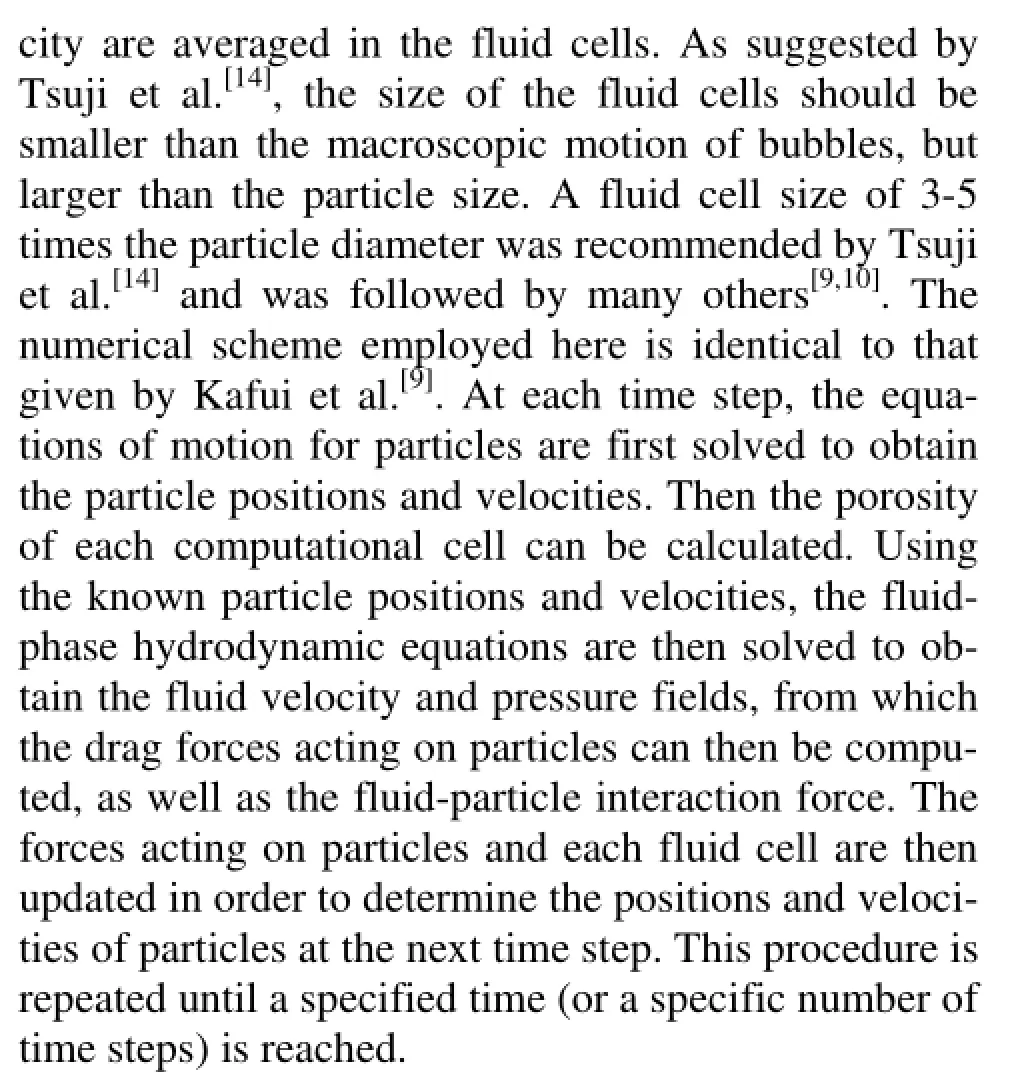

The particle motion is governed by the Newton’s second law of motion as follows:

in whichmiandIiare the mass and the moment of inertia of the particle, respectively,viandωiare the linear and angular velocities of the particle,Tiis the torque arising from the tangential components of the contact force,fciis the particle-particle and particle-wall contact force andffpiis the fluid-particle interaction force.

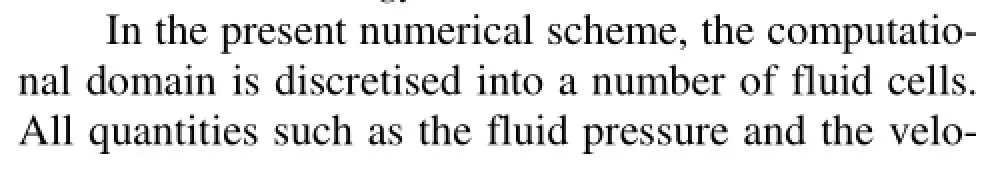

1.3Numerical strategy

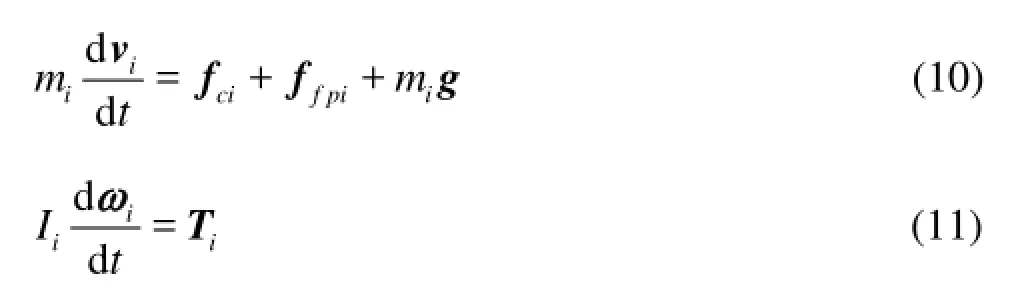

Fig.1 Schematic diagram of the sphere settling in water

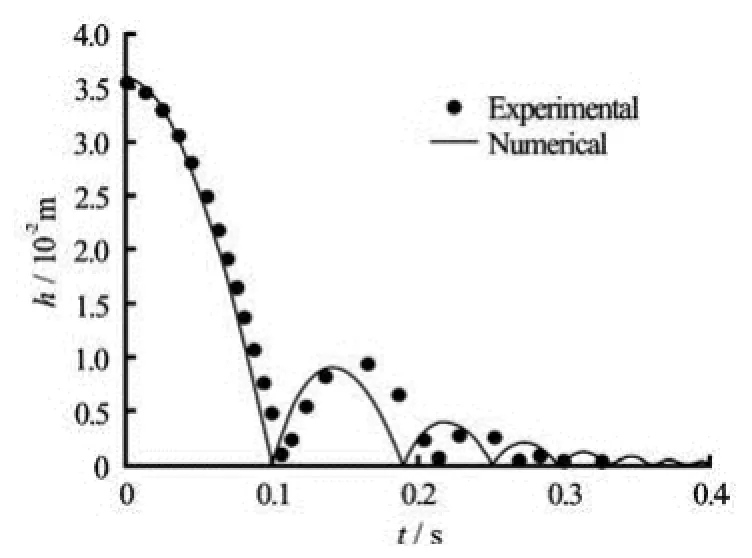

Fig.2 Evolutions of vertical position of the sphere

The time step Δtin the discrete particle model is determined by the smallest particle diameterdmin, leading to a critical time step Δtcgiven by[9]

whereλ=0.1631ν+0.876605,G,ρpandνare the shear modulus, the density and the Poisson’s ratio of the particle, respectively. In our simulations, the time step is specified as Δt=αΔtcand the value of the constantαis normally less than 0.5, depending on the problem considered.

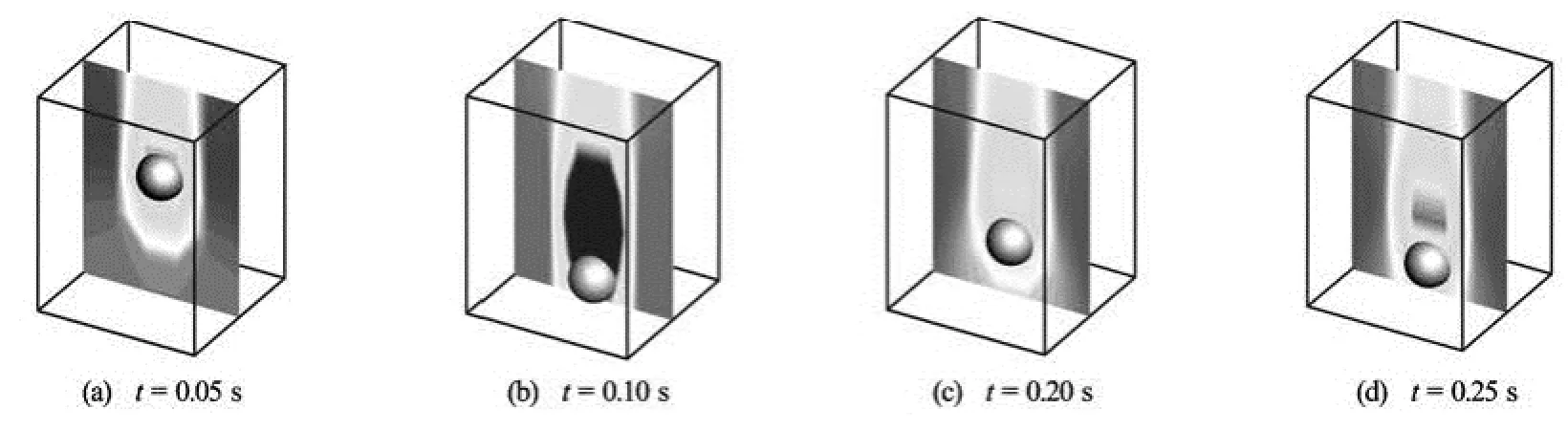

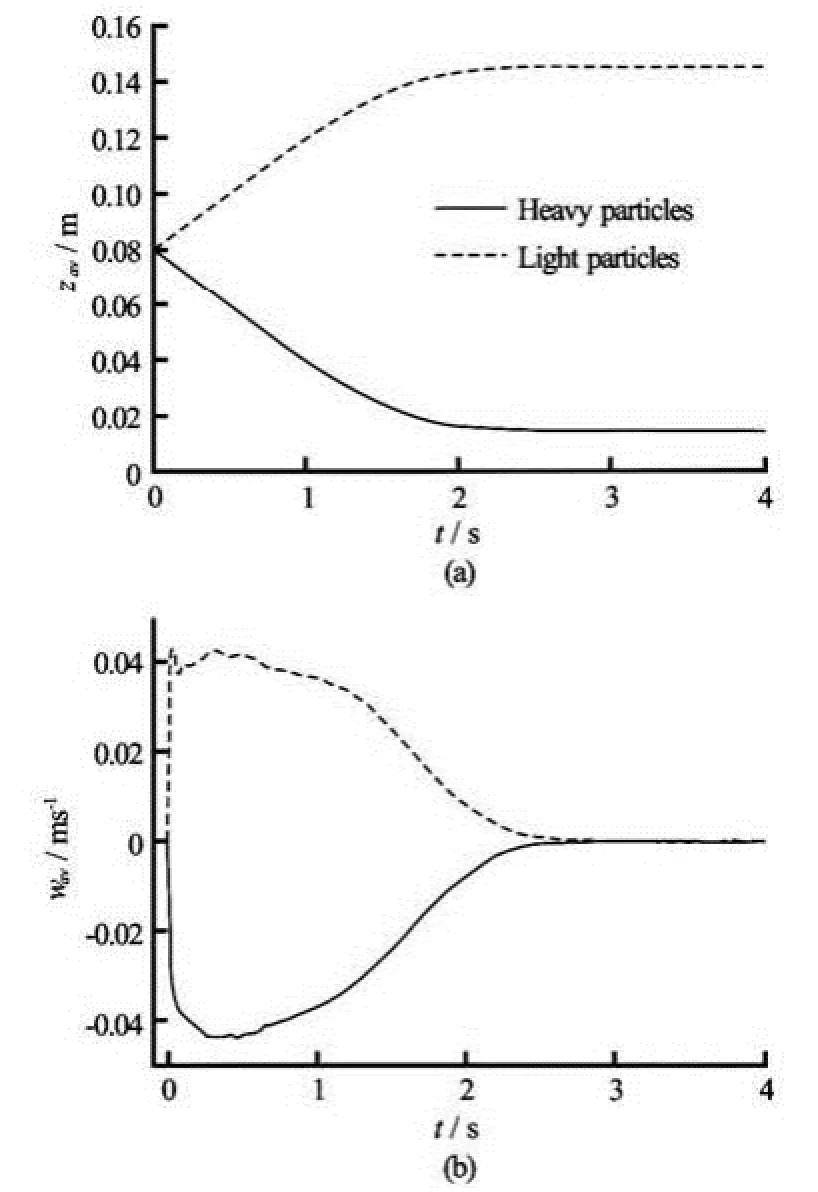

Fig.3 Snapshots of the sphere positions and the vertical velocity of the flow around the sphere at a given instant

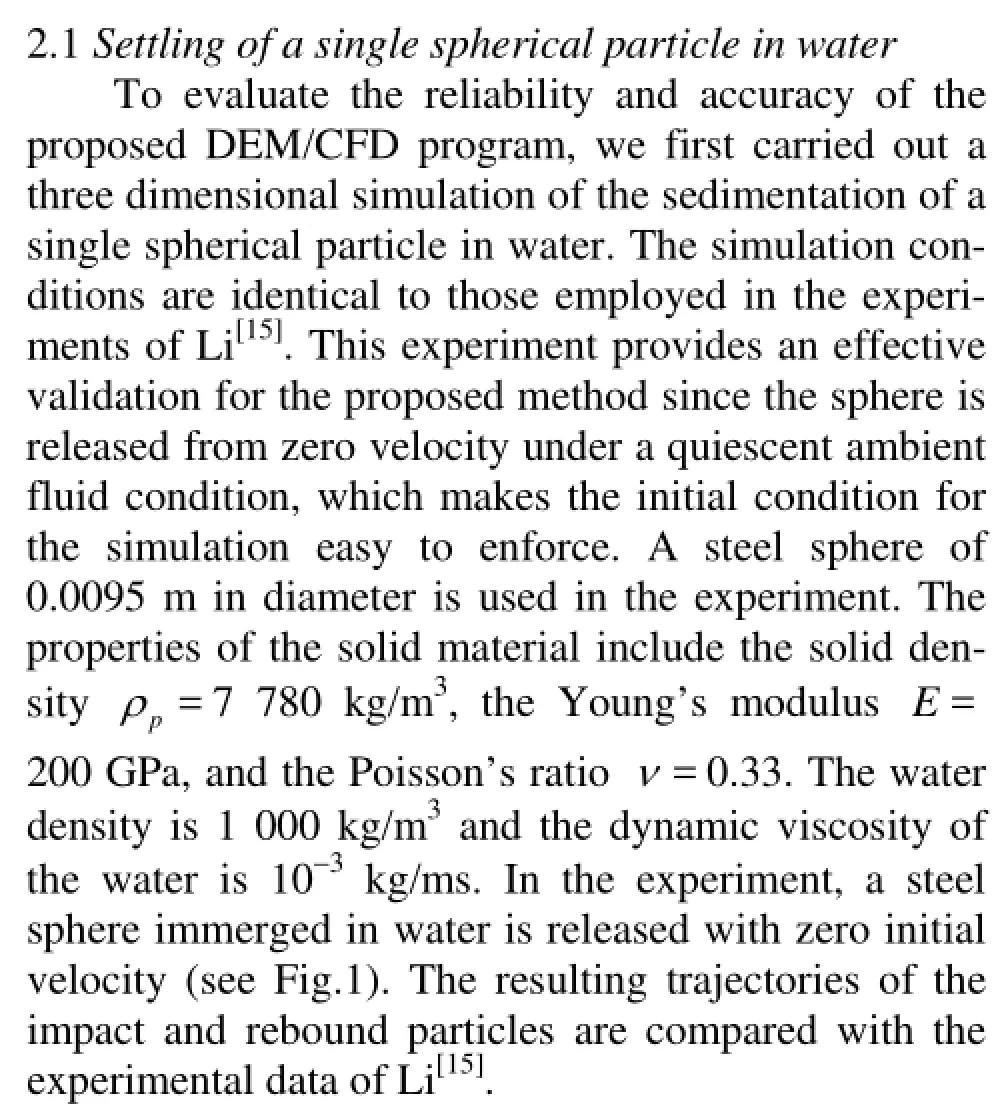

2. Numerical examples

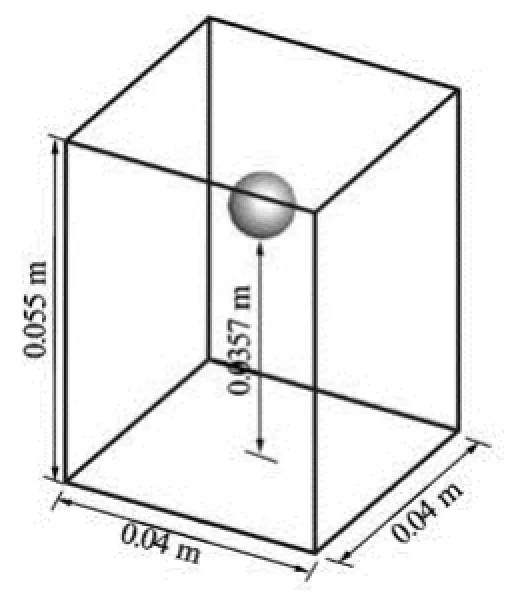

The computational domain is 0.040 m×0.040 m× 0.055 m in thex-,y- andz- directions, respectively. Gravity acts in thez- direction with the gravitational accelerationgz=–9.81 m/s2. In the simulations, walls are treated as impermeable with no slip boundaries. The computational domain is discretised with a grid of 5×5×6 fluid cells. The time step is specified as Δt=αΔtcand the value of the constantαis set to 0.5 and Δtcis calculated using Eq.(12).

Figure 2 shows the evolutions of the vertical positionhfor the solid sphere, in which the experimental result of Li[15]is also displayed, and our numerical results are shown to be in agreement with the experimental data at an acceptable level. It is clear that once the sphere is released, it accelerates under gravity until touches the container bottom, at which the sphere boundary will contact the wall and then rebound. Thereafter, the sphere repeatedly contacts and rebounds in water until reaches a rest position due to the damping of water.

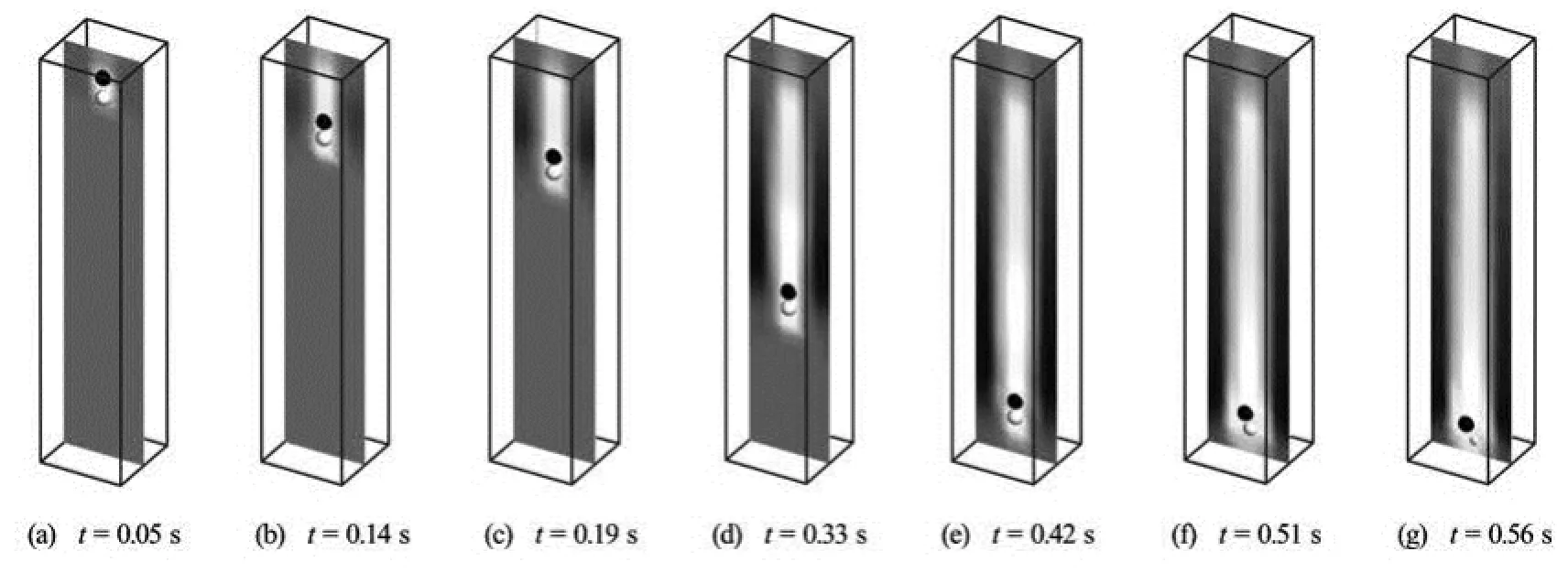

The numerical simulation using the proposed model captures not only the dynamics of the particles but also the evolution of the surrounding flow field during the falling and rebounding process. Figure 3 shows the snapshots of the sphere position and the vertical velocity field of the flow around the sphere at different instants. The first instants of contact between the sphere and the container bottom is about =t0.1 s (see Fig.3(b)). Figure 3(c) shows an instant of the sphere rebound after the contact. The simulated results indicate that the present DEM/CFD method can capture the sedimentation process in a viscous liquid including the trajectory of a particle as it accelerates from zero velocity after release, collides with a wall, rebounds and falls again until it comes to rest.

2.2Two equal spheres settling in a closed container

filled with liquids

In order to further validate the presented method, we perform a 3-D simulation of the motion of two equal spheres sedimenting in a closed container filled with a viscous liquid and reproduce the drafting, kissing and tumbling phenomenon as a very important mechanism that controls the particle microstructure in flows of a Newtonian fluid.

The dimensions of the container are 0.080 m× 0.080 m×0.400 m in the -x, -yand -zdirections,respectively. Gravity acts in thez- direction with the gravitational accelerationgz=–9.81 m/s2. The diameter of the two spheres isd=0.015 m. The mass densities of the spheres and the liquid areρp=2 800 kg/m3andρf=1 000 kg/m3, respectively. The dynamic viscosity of the liquid is 10-3kg/ms. In the simulations, the walls are treated as impermeable with no slip boundaries. The computational domain is discretised with a grid of 7×7×35 fluid cells. The time step is specified as Δt=αΔtcand the value of the constantαis set to 0.5 and Δtcis calculated using Eq.(12).

Att=0 s the two spheres are placed in the container above each other atzc=0.36 m andzc= 0.38 m, respectively. The upper and lower spheres have the same horizontal position withxc=yc= 0.04 m. The fluid and the spheres are initially at rest.

Fig.4 Snapshots of the process of drafting-kissing-tumbling. Color in slice indicates the values of vertical velocity field of the flow around the spheres at a given instant

Figure 4 displays a sequence of the numerically simulated process of drafting-kissing-tumbling. After the two spheres are released in the container at =t0 s, they fall downwards under gravity and there is a wake with low pressure at the back of a sedimenting sphere. Since the upper sphere is caught in the wake of the lower sphere, it experiences a reduced drag from the surrounding fluid and thus falls faster than the lower sphere. This is called drafting, after the well-known bicycle racing strategy based on the same principle. Figures 4(a)-4(c) show the snapshots of the drafting process. The increased speed of falling impels the upper sphere into a kissing contact with the lower sphere. Kissing particles form a long body and the vertical alignment during this stage is unstable and the sphere move quickly around each other towards a more horizontal alignment. Figures 4(c)-4(e) show the snapshots of the kissing process. At the end of the kissing stage the spheres move apart from each other, referred to as the tumbling stage. This is illustrated in Figs.4(e)-4(g).

2.3Sedimentation of suspension composed of 10 000 particles

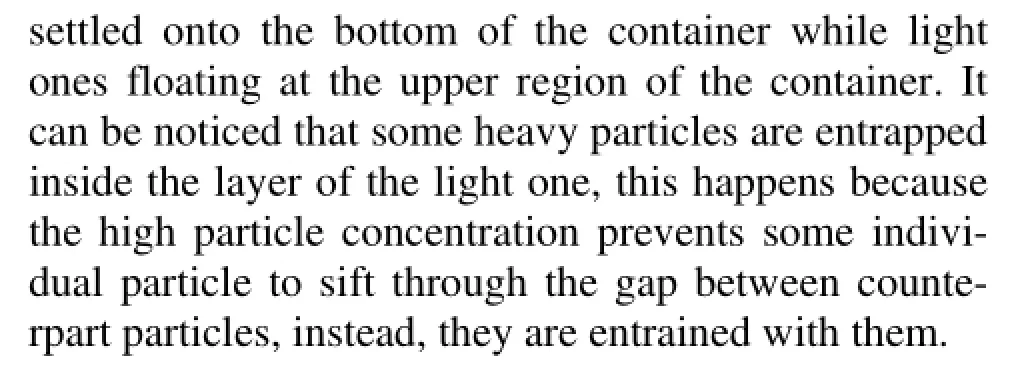

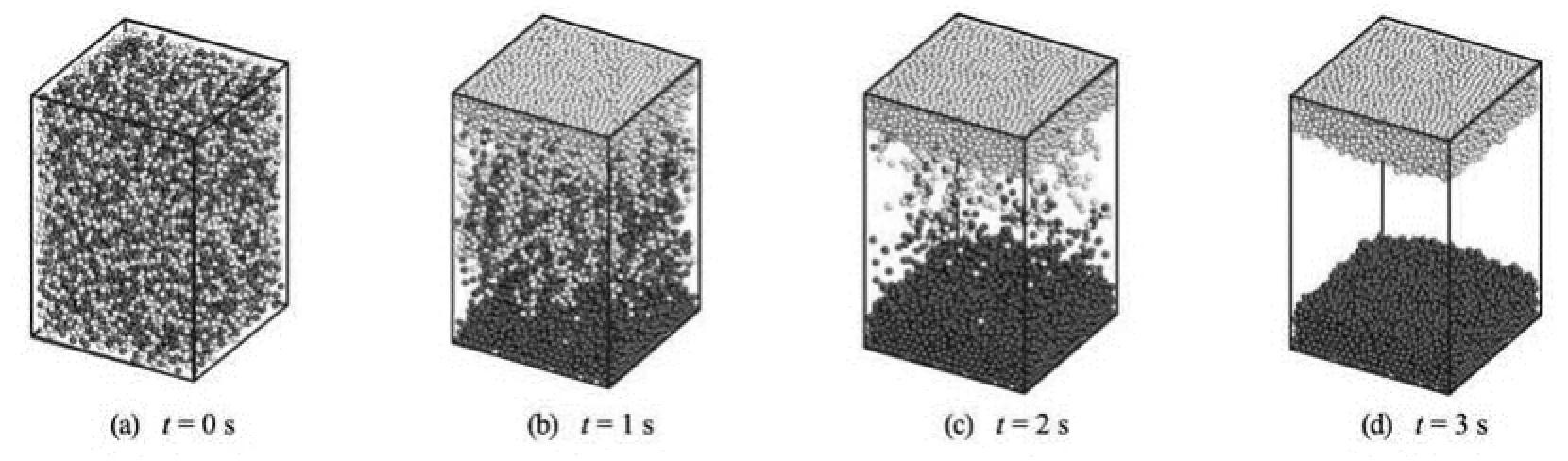

Fig.5 Snapshots of sedimentation of a suspension of heavy (black) and light (gray ) particles

Fig.6 Evolutions of mass centres (a) and velocities (b) of two particle groups

3. Conclusion

A hybrid DEM-CFD method for the numerical simulation of particulate flows is presented. In the proposed approach, the motions of the solid particles obtained by using the DEM while the motion of the liquid is obtained by using the weakly compressible volume-averaged Navier-Stokes equations of continuity and momentum with an additional stiff equation of state. 3-D Numerical simulations of the sedimentation of a single spherical particle and the drafting, kissing and tumbling of two particles are carried out to validate the method. The separation of a binary suspension is simulated to demonstrate that the present DEM-CFD method is capable of modelling complex flows with large number of moving particles. Thenumerical results show that the presented method provides a robust and efficient approach to simulate solid-liquid flows.

[1] RONG Liang-wan, ZHAN Jie-min. Improved DEMCFD model and validation: A conical-base spouted bed simulation study [J]. Journal of Hydrodynamics, 2010, 22(3): 351-359.

[2] WAN De-cheng, TUREK S. Modeling of liquid-solid flows with large number of moving particles by multigrid fictitious boundary method[J]. Journal of Hydrodynamics, Ser. B, 2006, 18(3Suppl.): 93-100.

[3] TONG Z. B., YANG R. Y. and CHU K. W. et al. Numerical study of the effects of particle size and polydispersity on the agglomerate dispersion in a cyclonic flow [J]. Chemical Engineering Journal, 2010, 164(2): 432-441.

[4] CATE T. A., NIEUWSTAD C. H. and DERKSEN J. J. et al. Particle imaging velocimetry experiments and lattice-Boltzmann simulations on a single sphere settling under gravity[J]. Physics of Fluids, 2002, 14(11): 4012-4025.

[5] CHEN S., PHAN-THIEN N. and KHOO B. C. et al. Flow around spheres by dissipative particle dynamics, Physics of Fluids, 2006, 18(10): 103605.

[6] YANG C., DING Y. and YORK D. et al. Numerical simulation of sedimentation of microparticles using the discrete particle method[J]. Particuology, 2008, 6(1): 38-49.

[7] POTAPOV A. V., HUNT M. L. and CAMPBELL C. S. Liquid-solid flows using smoothed particle hydrodynamics and the discrete element method[J]. Powder Technology, 2001, 116(2): 204-213.

[8] QIU Liu-chao. Numerical modeling of liquid-particle flows by combining SPH and DEM[J]. Industrial Engineering Chemistry Research, 2013, 52(33): 11313-11318.

[9] KAFUI K. D., THORNTON C. and ADAMS M. J. Discrete particle-continuum fluid modelling of gas-solid fluidised beds[J]. Chemical Engineering Science, 2002, 57(13): 2395-2410.

[10] GUO Y., KAFUI K. D. and WU C. Y. et al. A coupled DEM/CFD analysis of the effect of air on powder flow during die filling[J]. AICHE Journal, 2009, 55(1): 49-62.

[11] BRUJAN E. A. A first-order model for bubble dynamics in a compressible iscoelastic liquid[J]. Journal of Non-Newtonian Fluid Mechanics, 1999, 84(1): 83-103.

[12] DI FELICE R. The voidage function for fluid-particle interaction systems[J]. International Journal on Multiphase Flow, 1994, 20(1): 153-159.

[13] MINDLIN R. D., DERESIEWICZ H. Elastic spheres in contact under varying oblique forces[J]. Journal of Applied Mechanics, 1953, 20(3): 327-344.

[14] TSUJI Y., KAWAGUCHI T. and TANAKA T. Discrete particle simulation of two-dimensional fluidized bed[J]. Powder Technol, 1993, 77(1): 79-87.

[15] LI X. An Experimental and numerical study of normal particle collisions in a viscous liquid[D]. Doctoral Thesis, Pasadena, California, USA: California Institute of Technology, 2010.

10.1016/S1001-6058(14)60003-2

* Project supported by the National Natural Science Foundation of China (Grant No. 11172321).

Biography: QIU Liu-chao (1971-), Male, Ph. D.,

Associate Professor

水動(dòng)力學(xué)研究與進(jìn)展 B輯2014年1期

水動(dòng)力學(xué)研究與進(jìn)展 B輯2014年1期

- 水動(dòng)力學(xué)研究與進(jìn)展 B輯的其它文章

- Equivalent pipe algorithm for metal spiral casing and its application in hydraulic transient computation based on equiangular spiral model*

- Scale analysis of turbulent channel flow with varying pressure gradient*

- Simulation of buoyancy-induced turbulent flow from a hot horizontal jet*

- Deepwater gas kick simulation with consideration of the gas hydrate phase transition*

- An ocean circulation model based on Eulerian forward-backward difference scheme and three-dimensional, primitive equations and its application in regional simulations*

- Influences of soil hydraulic and mechanical parameters on land subsidence and ground fissures caused by groundwater exploitation*