Effect of Drying on Particle Size and Sensitivities of Nano hexahydro-1,3,5-trinitro-1,3,5-triazine

Jie LIU,Wei JIANG,Jiang-bao ZENG,Qing YANG,Yu-jiao WANG,Feng-sheng LI*

National Special Superfne Powder Engineering Research Center of China,Nanjing University of Science and Technology,Nanjing 210094,China

Effect of Drying on Particle Size and Sensitivities of Nano hexahydro-1,3,5-trinitro-1,3,5-triazine

Jie LIU,Wei JIANG,Jiang-bao ZENG,Qing YANG,Yu-jiao WANG,Feng-sheng LI*

National Special Superfne Powder Engineering Research Center of China,Nanjing University of Science and Technology,Nanjing 210094,China

Nano hexahydro-1,3,5-trinitro-1,3,5-triazine(RDX)was prepared using a bi-directional rotation mill and dried under different conditions (liquid,temperature and drying).It shows that the samples cake seriously and the particles grow up obviously by ordinary drying in different liquids at 70°C,which occurs again after vacuum drying.With the increase of temperature,the degrees of caking and aggregation are enhanced. Well dispersed sample maintaining constant particle size is extracted by supercritical drying,especially freeze drying.Furthermore,the mechanical sensitivities of I-RDX,O-RDX and F-RDX,of which the average sizes are 88.03 μm,15.32 μm and 0.16 μm,respectively,are evaluated.Compared with I-RDX,the friction,impact and shock sensitivities of O-RDX are slightly lower.However,the friction,impact and shock sensitivities of F-RDX are reduced by 30%,99.0%and 59.9%,respectively.

Nano-RDX;Drying;Particle size;Mechanical insult;Sensitivity

1.Introduction

The brisant explosive hexahydro-1,3,5-trinitro-1,3,5-triazine(RDX)with high detonation heat,detonation velocity and detonation pressure has been extensively used in plastic bonded explosives(PBX)[1-3],propellants[4-6]and pyrotechnics[7].However,the industrial RDX (I-RDX) (d50=50~100 μm)is very sensitive to the mechanical stimuli,which seriously threatens the safety of the ammunitions,and the reduction in mechanical sensitivities had become a research focus.The studies have shown that the sensitivities of nitramine explosives are affected obviously bythe sizes and distribution of the explosive particles[8-11]. The impact sensitivities of explosives were cut down effectively by reducing the particle sizes[12].If the nano particles were obtained,the mechanical sensitivity is greatly decreased [13].Because of the complicated technological parameters, the bad reproducibility of experiments and the small capacity of material processing,the general ways to prepare nano-RDX,such as solvent/nonsolvent recrystallization[14]and Rapid Expansion of Supercritical Solution(RESS)[15],are very diffcult to achieve large-scale production.

As an inspiring fact,nano-RDX was produced in batch using a wet ball mill[16],and the pulverized particles were characterized with regular shape and narrow size distribution [17].However,in order to insure the safety of mechanical milling,the raw materials must be addressed in the liquid environments.Then,how to get the nano particles effciently from the slurry has become the key constraint of the promotion for its industrial application.In this paper,the particle size,dispersion state and mechanical sensitivities of the dried samples under different conditions were researched,and a proper way to extract nano-RDX was found.

2.Experiment

2.1.Preparation of nano-RDX

I-RDX,produced by Gansu Yinguang Chemical Industry Group Co.,Ltd.of China,is suspended in a miscible liquid which is a mixture of deionized water,ethanol and isopropanol,with the volume ratio of 10:10:1.The suspension containing 1000 g RDX with its mass concentration of 15%is put into a bi-directional rotation mill[18]for 6 h,of which the axle and the barrel rotate reversely and simultaneously.The rotation speeds of the axle and the barrel are controlled in the range of 90-150 rpm and 60-90 rpm,respectively.The flling content of grinding media is controlled within 65%-70%. During pulverization,the machine is cooled down by the cycling water.The yield is about 97%.

2.2.Instruments and devices

TheMalvern Zetasizer3000HSA laserparticlesize analyzer is used to measure the size distribution of nano-RDX before drying.The particle size and morphology are then characterized by JEOL JEM-200CX Transmission Electron Microscope(TEM).The dried RDX is characterized by Malvern Mastersizer Micro laser particle size analyzer and S-4800II Scanning Electron Microscope(SEM)made by Hitachi High-Technologies Corporation.

A water bath oven,a vacuum oven,a supercritical drying equipment and a vacuum freeze drying device are used to dry the slurry of nano-RDX respectively.

2.3.Tests of mechanical sensitivities

The friction sensitivities of 3 RDX samples are tested at 90°and 3.92 MPa.Fifty times of tests are carried out to obtain the mean explosion probability(P,%).

The impact sensitivity is characterized by the characteristic height(H50),which is statistically calculated by 25 effective test values obtained by using a 2.5 kg drop-hammer.

The small scale gap test(SSGT)is taken to measure the shock sensitivity.In this test,the donor column is made from RDX refned by acetone,with a density of 1.48 g/cm3,the gap material is PMMA,and the acceptor column has a density of 1.63 g/cm3.The gap thickness(δ)is calculated by 25 effective values.

2.4.Symbols and abbreviations

I-RDX:industrial RDX;

O-RDX:ordinarily dried RDX;

F-RDX:freezingly dried RDX;

Ordinary drying:dried in a water bath oven;

Vacuum drying:dried in a vacuum oven;

Supercriticaldrying:dried in a supercriticaldrying

equipment;

Freeze drying:dried in a vacuum freeze drying device.

3.Results and discussion

3.1.Size distributions and micrographs of industrial RDX and Nano-RDX

The particle size distributions and micrographs of I-RDX and nano-RDX are shown in Figs.1 and 2,respectively.

As shown in Figs.1 and 2,the I-RDX particles are irregular and heterogeneous,with an average particle size of 88.03 μm and a wide size distribution.However,the prepared nano-RDX particles before drying are found to become semispherical and homogeneous,with an average particle size of 63.7 nm.

Fig.1.Particle size distributions of nano-RDX(a)and I-RDX(b).

Fig.2.SEM image of I-RDX and TEM image of nano-RDX.

3.2.Effect of liquid on the dispersion state and particle size of Nano-RDX

The dispersion states of O-RDX dried in different liquids at 70°C are shown in Fig.3.

Fig.3.The dispersion states of RDX dried in different liquids.

As shown in Fig.3,the RDX samples are caked seriously after ordinary drying.When it is dried in ethyl acetate,its surface is frothy to a certain extent.While it is dried in ethanol,some holes and cracks are observed on its surface. There are sags and crests on its surface after it is dried in isopropanol and there are a few pores on its surface after it is dried in water.The surface is smooth after it is dried in the miscible liquid.The different dispersibilities of RDX in different liquids resulted in the different dispersion states after drying.

The particle size distributions and SEM images of O-RDX dried in different liquids at 70°C are shown in Figs.4 and 5.

Fig.4.The particle size distributions of RDX dried in different liquids.

As shown in Figs.4 and 5,the nano-RDX particles after drying in different liquids became much bigger and presented wide size distributions.Their average size is 32.02 μm,and the sizes of mos particles are 20-50 μm after being dried in ethyl acetate.When nano-RDX is dried in ethanol,the average particle size is 20.46 μm and the size distribution is very wide, with some particles with the size of about 40 μm being covered by the submicron particles.The average particle size is 18.86 μm and the sizes of most particles are 1-20 μm after it is dried in isopropanol.The average particle size is 18.10 μm and some small particles are implanted into the regular large particles after it is dried in water.When it is dried in the miscible liquid,the average particle size is 15.32 μm,and the sizes of most particles are less than 20 μm and in micron-size.

The nano-RDX would be dissolved to some extent in different liquids.When the liquid is removed by evaporation, the nano particles would tend to agglomerate and grow up so that the huge specifc surface energy is overcome.The worse the dispersibility is,the greater the agglomeration is.The higher the solubility is,the stronger the size increment is. Therefore,various dispersion states and size distributions are exhibited after it is dried in different liquids.

3.3.Effect of temperature on the dispersion state and particle size of nano-RDX

The dispersion states of O-RDX dried in the miscible liquid at different temperatures are shown in Fig.6.

Fig.5.The SEM images of RDX dried in different liquids.

As shown in Fig.6,the RDX samples are caked apparently after they are dried at different temperatures.When the sample is dried at 90°C,it is particularly seriously caked with some cracks being observed on its surface.

The particle size distributions and SEM images of O-RDX dried at different temperatures are shown in Figs.7 and 8.

As shown in Figs.7 and 8,after RDX is dried at different temperatures,the particles with wide size distributions become bigger apparently,and the average particle size increases with the increment of temperature.When RDX is dried at 90°C,the average particle size is 21.77 μm and the sizes of most particles are 10-40 μm.The average particle size is 15.32 μm and the sizes of most particles are less than 20 μm after it is dried at 70°C.With the further reduction of the temperature,the number of small particles is increased and the number of big particles is decreased,which results in the reduction of the average particle size.

When the drying temperature is increased,the solubility of nano-RDX in the miscible liquid is strengthened,the thermal motion of the particles is aggravated,and the evaporation of the liquid is accelerated.The agglomeration trend of nano particles to grow up is enhanced.As a result,the average particle size is increased and the caking phenomenon is more serious.

Fig.7.The particle size distributions of RDX dried at different temperatures.

3.4.Effect of drying on the dispersion state and particle size of Nano-RDX

The dispersion states of RDX dried in the miscible liquid using different drying methods are shown in Fig.9.

Fig.6.The dispersion states of RDX dried at different temperatures.

Fig.8.The SEM images of RDX dried at different temperatures.

Fig.9.The dispersion states of RDX dried using different methods.

Fig.10.The particle size distributions of RDX dried using different methods.

As shown in Fig.9,whether nano-RDX is ordinarily dried or dried in vacuum at 70°C,it is caked seriously,and there are many pores on its surface after vacuum drying.It can be seen from Fig.9 that the sample is fuffy and there are a few granular aggregates on its surface after supercritical drying.In particular,the sample is very fuffy and its dispersity is very good after freeze drying.

The particle size distributions and SEM images of RDX dried using different methods are shown in Figs.10 and 11.

As shown in Figs.10 and 11,after ordinary drying or vacuum drying at 70°C,the particles grow up obviously,the average particle sizes are 15.32 μm and 18.69 μm respectively, and most of the particles are in the level of micron after vacuum drying.When the sample is dried by supercritical drying,the particle size distribution is narrow and the sizes of most particles are 200-300 nm.While the nano-RDX is dried through freeze drying,the particle size distribution is very narrow and the particles are semispherical with an average size of about 100 nm.

The solubility of nano-RDX and the evaporation rate of liquid in vacuum environments are higher than those at room pressure.When the liquid in vacuum is removed,the particles would tend to grow bigger.The effect of supercritical expansion,especially the freezing effect,could prevent the nanoparticles from agglomerating effciently,so the samples are fuffy,the average particle sizes are small and the particle size distributions are narrow.

3.5.Mechanical sensitivities of RDX samples

The friction,impact and shock sensitivities of I-RDX (d50=88.03 μm),O-RDX(d50=15.32 μm),which is ordinarily dried in a water bath oven at 70°C,and F-RDX (d50=0.16 μm),which is freezingly dried,are tested and listed in Tables 1-3.

As listed in Table 1,the friction sensitivity is measured at 90°and 3.92 MPa,and the average explosion percentage of IRDX is 80%,which is 8%and 30%higher than those of ORDX and F-RDX,respectively.

As listed in Table 2,the special heights of O-RDX and FRDX are 1.6 cm and 49.3 cm higher than that of I-RDX, respectively.In other words,the impact sensitivities of O-RDX and F-RDX are 3.2%and 99.0%lower than that of I-RDX, respectively.Additionally,the standard deviation(Sdev.)shows a decreasing trend while the average particle size(d50)is reduced,which reveals better detonation stability under impact when thed50is cut down.

Fig.11.The SEM images of RDX dried using different methods.

Table 1The friction sensitivity of RDX samples.

Table 2The impact sensitivity of RDX samples.

Table 3The shock sensitivity of RDX samples.

As listed in Table 3,compared with I-RDX,the gap thicknesses of O-RDX and F-RDX are decreased by 2.78 mm and 9.21 mm,respectively,which means that their shock sensitivities are decreased by 18.1%and 59.9%,respectively. Furthermore,the standard deviation (Sdev.) exhibits a decreasing trend with the reduction of the average particle size (d50),which states that the detonation stability of RDX under shock is better ifd50is decreased.

4.Conclusions

When nano-RDX was dried by either ordinary drying or vacuum drying,the samples were caked and the particles had an obvious tendency to grow up.The worse dispersibility led to the greater caking phenomenon,and the larger solubility led to bigger average particle size.The effect of supercritical expansion,especially the freezing effect,could prevent the nano-particles from agglomerating and the growing effciently. The mechanical sensitivities were decreased and the detonation under impact or shock was stabilized by the reduction ofd50.

Different dispersion states,size distributions and mechanical sensitivities of nano-RDX were exhibited after drying on different conditions.The small processing capacity of the supercritical drying restricts its application,and the freeze drying is proper.It is promising to promote the industrial applications of nano-RDX,such as Insensitive Munitions.

[1]Yan QL,Zeman S,Elbeih A.Recent advances in thermal analysis and stability evaluation of insensitive plastic bonded explosives(PBXs). Thermochimica Acta 2012;537:1-12.

[2]Jaidann M,Abou-Rachid H,Lafeur-Lambert X.Atomistic studies of RDX and FOX-7-based plastic-bonded explosives:molecular dynamics simulation.Procedia Comput Sci 2011;4:1177-85.

[3]Kumar Adapaka S,Rao Vepakomma B,Sinha Rabindra K.Evaluation of plastic bonded explosive(PBX)formulations based on RDX,Aluminum, and HTPB for underwater applications.Propell Explos Pyrotech 2010;35:359-64.

[4]Zhang Wei,Fan Xuezhong,Wei Hongjian.Application of nitramines coated with nitrocellulose in minimum signature isocyanate-cured propellants.Propell Explos Pyrotech 2008;33:279-85.

[5]Luman JR,Wehrman B,Kuo KK.Development and characterization of high performance solid propellants containing nano-sized energetic ingredients.Proc Combus Inst 2007;31:2089-96.

[6]Damse RS,Singh A,Singh H.High energy propellants for advanced gun ammunition based on RDX,GAP and TAGN compositions.Propell Explos Pyrotech 2007;32(1):52-60.

[7]Krishnan KRR,Ammal RA,Hariharanath B.Addition of RDX/HMX on the ignition behaviour of boron-potassium nitrate pyrotechnic charge.In: 4th International High Energy Materials Conference and Exhibit (HEMCE)[C]2003.

[8]Song XL,Li FS,Zhang JL.Infuence of particle size,morphology and size distribution on the safety and thermal decomposition properties of RDX.J Solid Rocket Technol 2008;31(2):168-72[in Chinese].

[9]Siviour CR,Gifford MJ,Walley SM.Particle size effects on the mechanical properties of a polymer bonded explosive.J Mater Sci 2004;39(4):1255-8.

[10]Song XL,Wang Y,An CW.Dependence of particle morphology and size on the mechanical sensitivity and thermal stability of octahydro-1,3,5,7-tetranitro-1,3,5,7-tetrazocine.J Hazard Mater 2008;159(2-3):222-9.

[11]Song XL,Li FS.Dependence of particle size and size distribution on mechanical sensitivity and thermal stability of hexahydro-1,3,5-trinitro-1,3,5-triazine.Defence Sci J 2009;59(1):37-42.

[12]Zhang XN,Xu GG,Xu JP.A study about impact sensitivity of ultrafne HMX and RDX.Chin J Explos Propell 1999;22(1):33-6[in Chinese].

[13]Liu J,Zeng JB,Li Q.Mechanical pulverization for nano HMX and study on its mechanical sensitivities.Chin J Explos Propell 2012;35(6):12-4 [in Chinese].

[14]Zhang Yongxu,Lv Chunxu,Liu Dabin.Preparation of RDX microcrystals with nanometer size by recrysatlization.Chin J Explos Propell 2005;28(1):49-51[in Chinese].

[15]Stepanov V,Krasnoperov LN,Elkina IB.Production of nanocrystalline RDX by rapid expansion of supercritical solutions.Int J Energ Mater Chem Propul 2007;6(1):75-87.

[16]Sheikhi Majid,Saeed,Hadi S.Production of nano-RDX by wet batch ball milling.In:7th International Fall Seminar on Propellants,Explosives,Pyrotechnics[C]2007.

[17]Liu J,Wang LX,Li Q.Preparation and characterization of insensitive nano RDX.Chin J Explos Propell 2012;35(6):46-50[in Chinese].

[18]LiFS.Bi-directionalrotation mill,Chinese Patent.2006,ZL 200610096755.1.

Received 23 October 2013;revised 3 December 2013;accepted 4 December 2013 Available online 17 December 2013

*Corresponding author.

E-mail address:lfs_njust@126.com(F.S.LI).

Peer review under responsibility of China Ordnance Society.

Production and hosting by Elsevier

2214-9147/$-see front matter Copyright?2014,China Ordnance Society.Production and hosting by Elsevier B.V.All rights reserved.

http://dx.doi.org/10.1016/j.dt.2013.12.006

Copyright?2014,China Ordnance Society.Production and hosting by Elsevier B.V.All rights reserved.

- Defence Technology的其它文章

- Estimation of the kinetic parameters for thermal decomposition of HNIW and its adiabatic time-to-explosion by Kooij formula

- Effect of welding processes and consumables on fatigue crack growth behaviour of armour grade quenched and tempered steel joints

- Research on design and firing performance of Si-based detonator

- Analysis of hydrodynamic characteristics of unmanned underwater vehicle moving close to the sea bottom

- Dynamic globularization prediction during cogging process of large size TC11 titanium alloy billet with lamellar structure

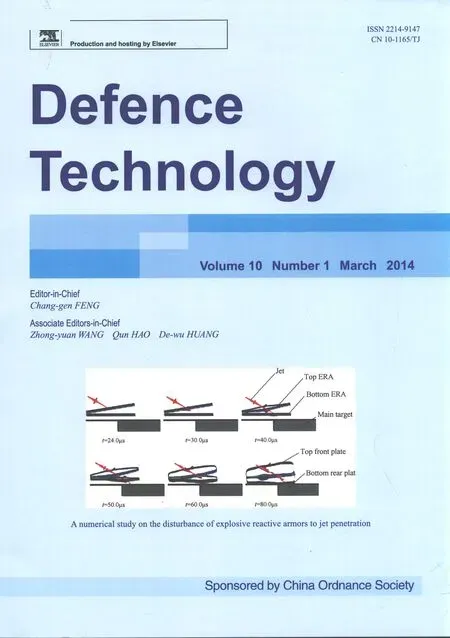

- A numerical study on the disturbance of explosive reactive armors to jet penetration