FLOW CHARACTERISTICS IN ENERGY DISSIPATION UNITS OF LABYRINTH PATH IN THE DRIP IRRIGATION EMITTERS WITH DPIV TECHNOLOGY*

LIU Hai-sheng, LI Yun-kai

College of Water Conservancy and Civil Engineering, China Agricultural University, Beijing 100083, China, E-mail: liyunkai@126.com

LIU Yan-zheng

Beijing Vocational College of Agriculture, Beijing 102442, China

YANG Pei-ling, REN Shu-mei

College of Water Conservancy and Civil Engineering, China Agricultural University, Beijing 100083, China WEI Run-jie

Beijing Lifangtiandi Sci-Tech Development Limited Company, Beijing 100089, China

XU Hong-bing

R and D Center for Plastic Manufacturing, Beijing Chemical Engineering Research Institute, Beijing 100013, China

(Received May 18, 2009, Revised July 23 2009)

FLOW CHARACTERISTICS IN ENERGY DISSIPATION UNITS OF LABYRINTH PATH IN THE DRIP IRRIGATION EMITTERS WITH DPIV TECHNOLOGY*

LIU Hai-sheng, LI Yun-kai

College of Water Conservancy and Civil Engineering, China Agricultural University, Beijing 100083, China, E-mail: liyunkai@126.com

LIU Yan-zheng

Beijing Vocational College of Agriculture, Beijing 102442, China

YANG Pei-ling, REN Shu-mei

College of Water Conservancy and Civil Engineering, China Agricultural University, Beijing 100083, China WEI Run-jie

Beijing Lifangtiandi Sci-Tech Development Limited Company, Beijing 100089, China

XU Hong-bing

R and D Center for Plastic Manufacturing, Beijing Chemical Engineering Research Institute, Beijing 100013, China

(Received May 18, 2009, Revised July 23 2009)

The energy dissipation mechanism and anti-clogging properties of drip irrigation emitters are closely related to flow characteristics of the fluid in its flow paths, and flow field tests using modern flow visual technologies were carried out by a large number of designers. The Digital Particle ImageVelocimetry (DPIV) system was built for un-disturbed flow tests in the labyrinth path. In this article, the flow field was measured in the flow path section, the structural unit and the local region near sawtooth. Under the pressure level of 10 Kpa, 50 Kpa, 100 Kpa and 150 Kpa, the flows in the two labyrinth paths were in the turbulence state, with flow stagnation regions and whirlpool regions in the structure of the labyrinth path sections. The flow stagnation regions should be eliminated as much as possible. But the vortex should be fully developed, which could increase the self-cleaning capacity and the anti-clogging capacity of the emitter. With respect to the anti-clogging performance and the energy loss efficiency of the emitter, the M-type flow path is better than the K-type flow path.

drip irrigation emitter, labyrinth path, Particle Image Velocimetry (PIV), flow characteristics, energy dissipation

1. Introduction

Emitter is one of the most critical components of

the drip irrigation system. The irrigation uniformity, the anti-clogging performance and the service life of the drip irrigation system are closely related to the performance, advantages and disadvantages of the emitter. The flow characteristics of the fluid in the flow path have a great bearing on the hydraulic performance and the anti-clogging properties of the emitter, so the flow state in the flow path should be well understood before designing a high-performance emitter. Wang et al.[1],Wei et al.[2], Zhang et al.[3,4], Salvador et al.[5], Li et al.[6-9]and Wang et al.[10]explored the flow characteristics of water in the emitter flow path with the CFD method. However, as the choice of the laminar flow model or the turbulencemodel is not an easy job in the use of the CFD method, it is important but difficult testing the flow field in the emitter flow path to check results of the CFD simulation. Wei et al.[11]constructed the amplificatory emitter model enlarged by using similarity principles, to observe the fluid flow of the internal enlarge model by using the Laser Doppler Velocimetry (LDV), which, however, is only a single-point measurement technology and can not be used to obtain the whole flow field and to make the transient measurement. Moreover, the flow boundary layer similarity is not duly considered for the amplifier model of the drip irrigation emitter. Li et al.[12]carried out two-dimensional un-disturbed tests for the flow path with the DPIV technology, which provides a good approach to study the flow characteristics of fluid in the emitter.

The flow path of the drip irrigation emitter is usually made up of lots of similar units. Li et al.[7]found that the head loss in the unit of the sawtooth-labyrinth paths was the same by the linear superposition rule, the circular tube turbulent flow field analysis theory and the CFD technology. And the flow characteristics in the labyrinth flow path unit were similar, which provides a convenient way to study flow characteristics in the flow path. Based on this, the labyrinth path was selected, as the most advanced flow path pattern, and flow characteristics within the flow path were studied from the flow path section, the structural unit to the local region near the sawtooth with the DPIV technology, which might be used in the parameter optimization of the labyrinth path of emitter.

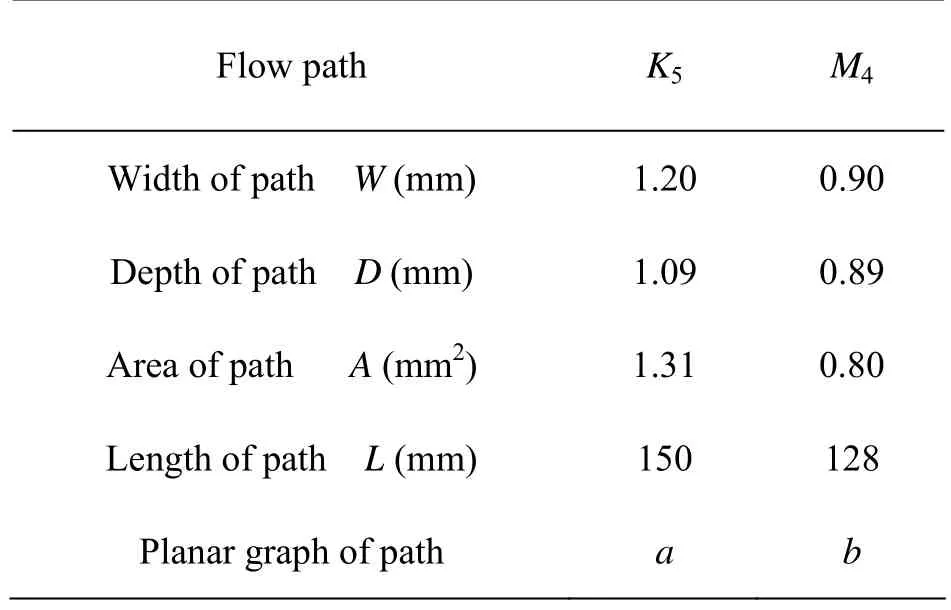

Table 1 The flow path geometry parameters

2. Materials and method

2.1 Test design

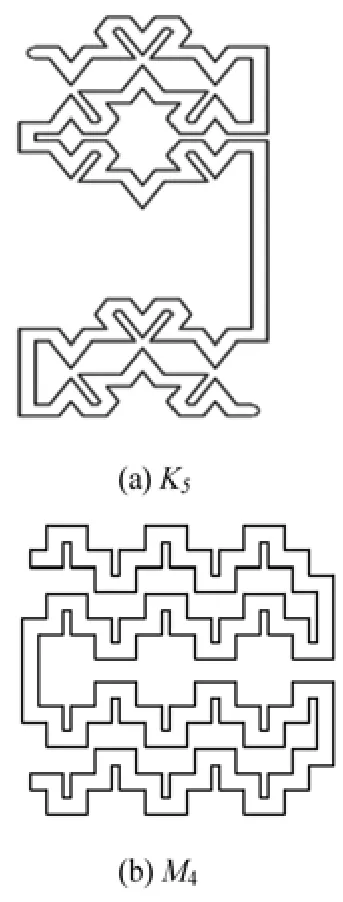

The two types of flow paths of the emitter were selected, as designed according to the fractal path (a labyrinth path) method by Li et al.[13]. The parameters of the flow path geometry are shown in Table 1. The tested emitters were made as the plane model[14], whose flow path is shown in Fig.1. The water was supplied by the voltage supply platform, invented by the project team[15].

Fig.1 Planar graph of the flow path

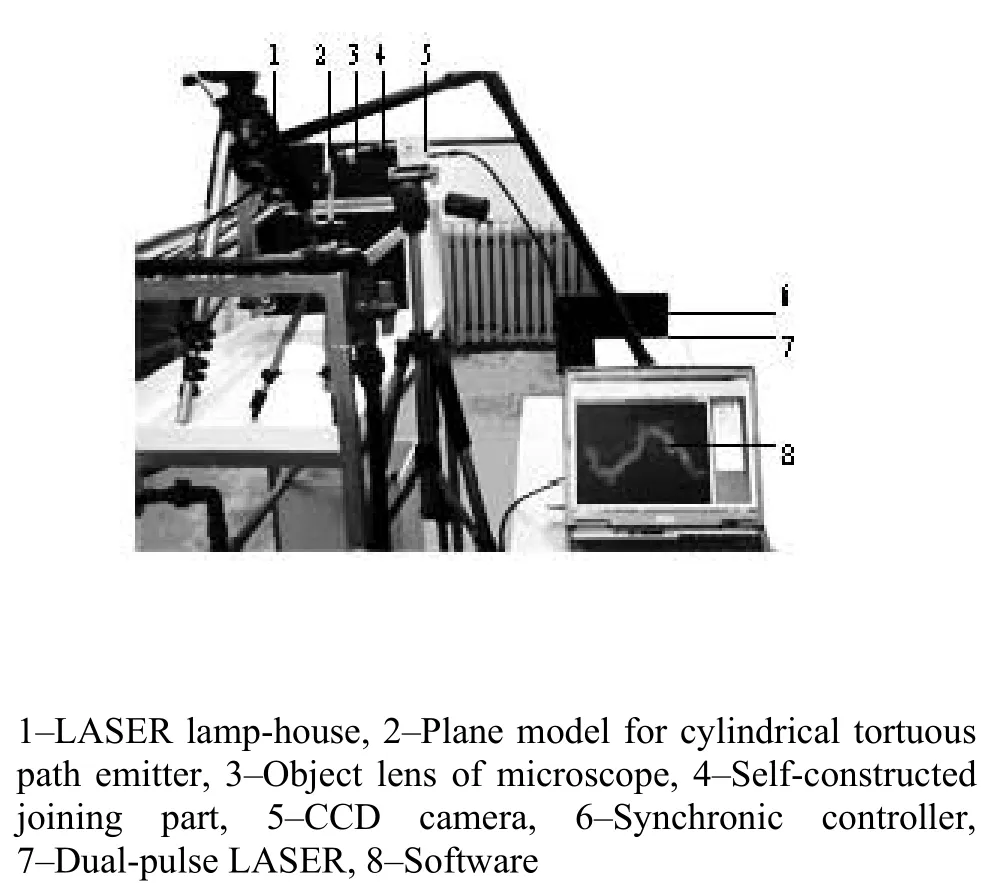

Fig.2 Visual display system of the flow fields within the tortuous flow path of emitters with DPIV

2.2 The DPIV system

The DPIV system used to measure the internal flow within the emitter consists of hardware and software components. The hardware component includes a dual-pulse LASER, a CCD camera, a synchronic controller, an image-collection board, and a computer. The software component is designed to achieve image-collection, display, velocity calculation, and velocity field analysis[16-18].The system is shown in Fig.2.

2.2.1 Image collection and processing

The digital camera was a Kodak MEGAPLUSⅡ(with resolving power of 1600×1200, 2M). The emitter flow paths are of dimensions of 0.5×10-3m -1.2×10-3m with dentition intervals within 3.0×10-3m -5.0×10-3m, between micro scale (1μm-1.0 mm) and conventional scale (>1mm ) critical dimensions of fluid flow problems. When using the conventional DPIV system for measurement, the large viewing area results in a low image quality and test accuracy. When using the Micro - DPIV system, the viewing area is so small, being 0.5×10-3m×0.5×10-3m, that the system could not catch the flow movement characteristics around each dentition. In this study, the CCD camera was modified by installing a G10-2111(Beijing Daheng camera Company) microscope object lens (fourfold), which could take both advantages of the conventional DPIV system and the Micro-DPIV system, with the filming region and the digital image resolution in a harmony and unity (area), with a viewing area of 4×10-3m×4×10-3m. Different parts of the unit results about the average flow field observed are combined together through a software to realize the Mosaic full field measurement.

2.2.2 Laser light source

The dual-pulse laser emitter used in this DPIV system is a Q-Nd:YAG (LABEST Company), with a work frequency of 10 Hz, wave length of 5.32×10-7m, laser energy of 0.02 J, pulse width of 4×10-9s -6×10-9s, radiating angle of 0.6 mrads, in super Gauss facula mode and a dual-pulse time interval of less than 1× 10-6s.

2.2.3 Analysis software

The DPIV system analysis software used is MicroVec Version 2.0 developed by Wei from Beijing University of Aeronautics and Astronautics. The window iteration technique and the window deformation technique were adopted by this software. The interpretation area was 32 pixel×32 pixel, the step length was 16 pixel×16 pixel, and overlap was 50%. The vector space resolution was 0.08 mm × 0.11 mm. 100 pieces of photos were used to compute the instantaneous speed, so the speed obtained is the average of 50 pieces of the instantaneous speed. Tecplot 10.0 was used for dealing with the results of tests and displaying the whole fields.

2.2.4 Tracing fluorescence particles

In order to remove the surface noise and ensure the accuracy of measurements, the custom-made fluorescent particles that can suspend in water with a micro-disturbance were chosen, which were made from polystyrene (density of 1.02 Kgm-3), with an average diameter of 1×10-5m -1.5×10-5m. An appropriate concentration of fluorescence particles was 1%-2%.

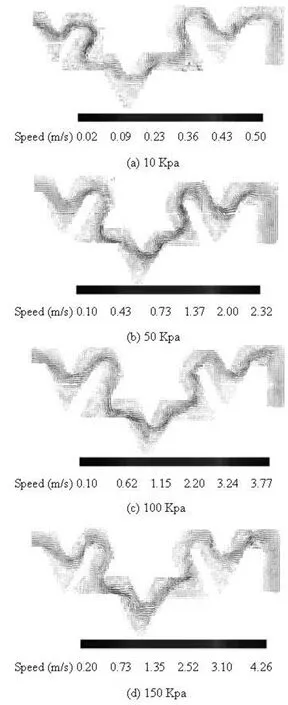

Fig.3 The velocity distribution in the flow path (K5) under different pressures with DPIV (m/s)

3. Results and analyses

3.1 Characteristics of fluid flow in the flow path section

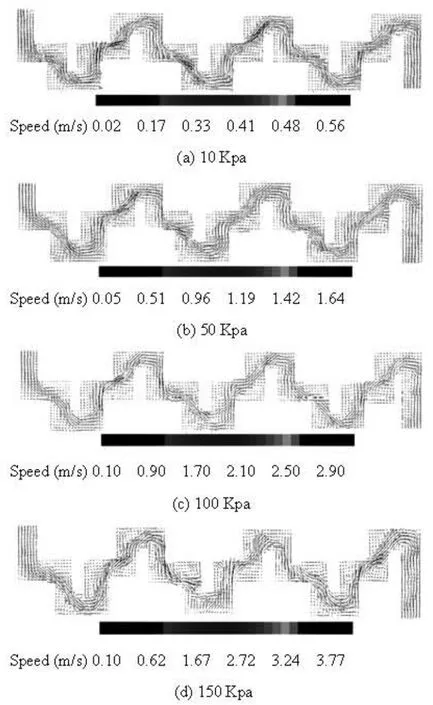

The velocity distributions in two fractal flow paths of emitters were measured under the pressures of 10 kpa, 50 kpa, 100 kpa and 150 kpa, by using the DPIV system according to the method proposed by Li et al.[12]. The results of tests were treated by Adobe Photoshop CS4, and are shown in Figs.3-4.

It is shown that the fluid flow in the two types of paths is in a complex turbulence state under four levels of the pressure. As the pressure increases, no transition is observed from laminar to turbulent flows. The velocity distribution could be divided into twovelocity regions. One is the mainstream region, with relatively high velocity and near the center of the path, the other is low velocity non-mainstream regions, at the side of the path. The low-speed flow increases the risk of clogging. The fluid flow in the mainstream region continuously swings between the sides of the path, and the fluid flow in two regions mix in the border areas, affected by the liquid viscocity and the role of the side-wall barrier. With the increase of the pressure, the mass velocity in the mainstream region in the path increases significantly, and the mass velocity in the non-mainstream regions in the path increases but slightly. Under the pressure level of 10 kpa -150 kpa, the range of the maximum speed changes significantly, and the variation of the minimum value in the non-mainstream areas is not significant. So the impact of the variation of pressure on the mass velocity in the region of non-mainstream is not significant. It can also be seen from the figure that the flow velocity at the inlet and the outlet of the flow path section is low.

Fig.4 The velocity distribution in the flow path (M4) under different pressures with DPIV (m/s)

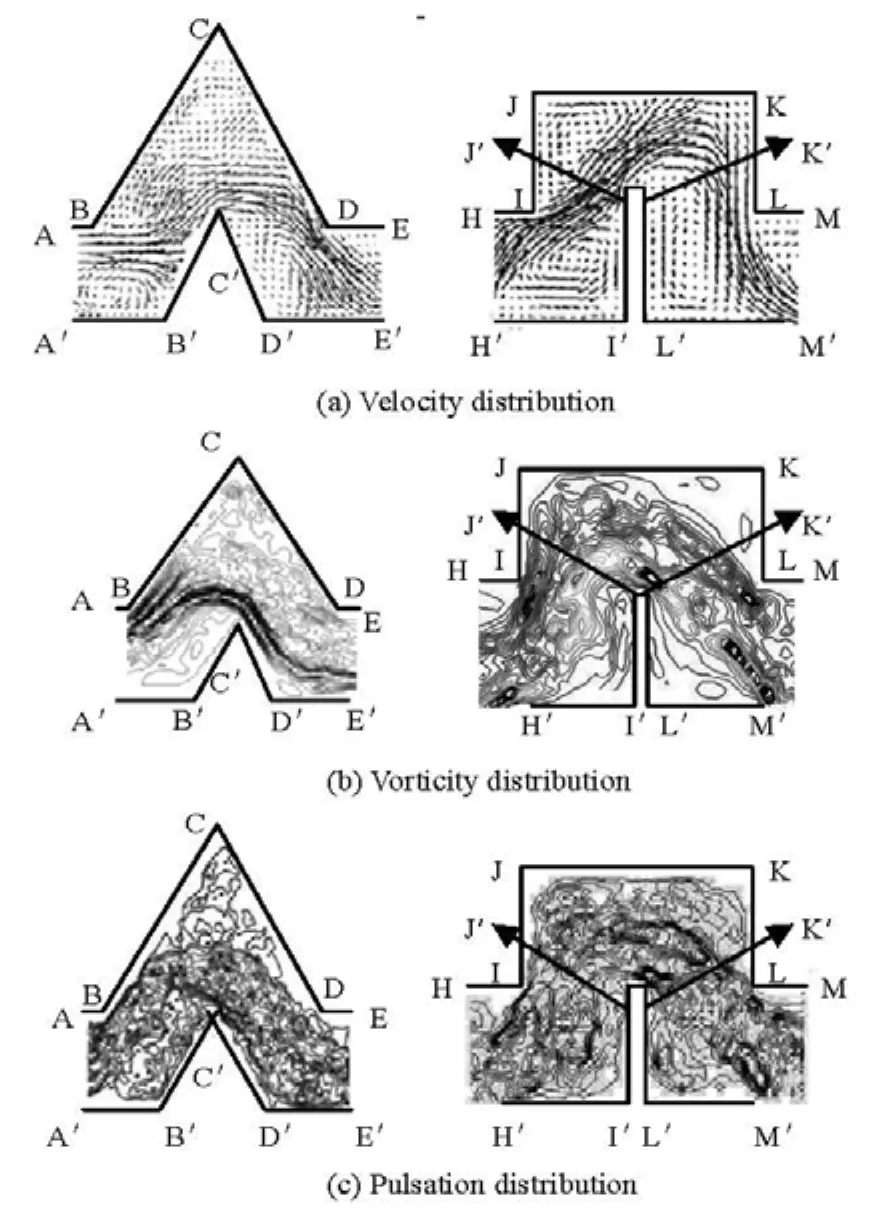

Fig.5 The velocity distribution in the unit structure of flow path

3.2 Flow characteristics inside the structural unit

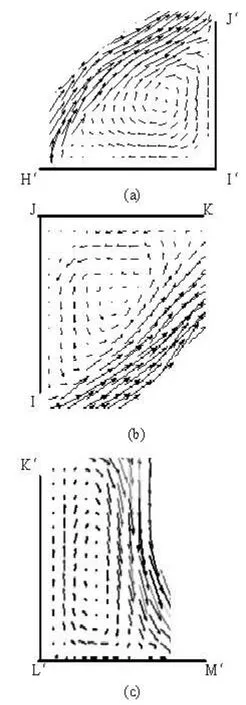

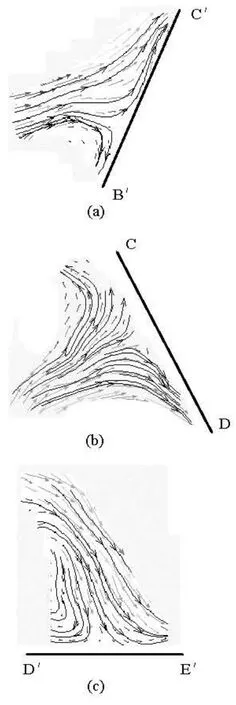

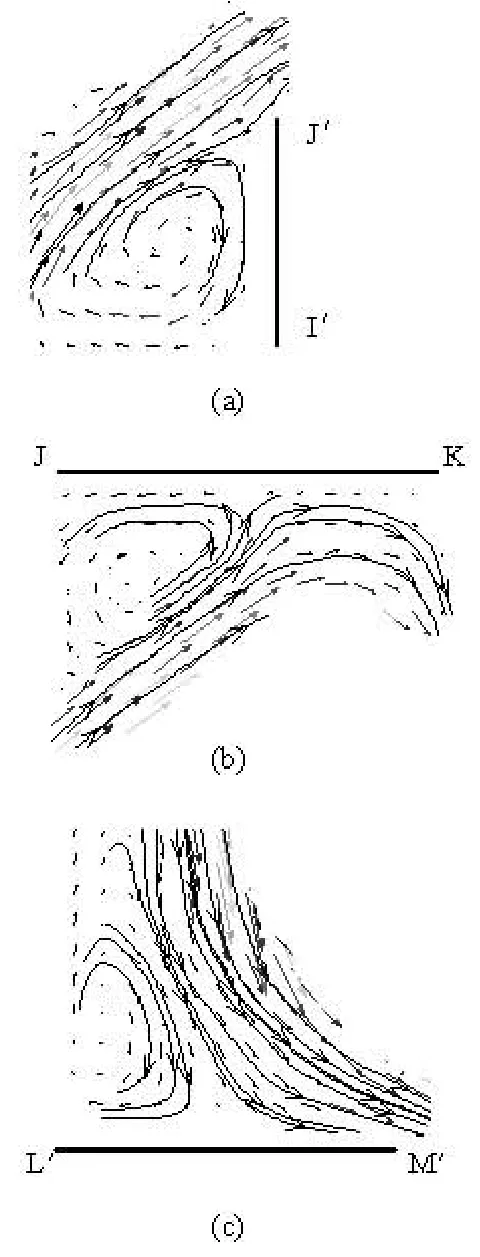

The velocity, vorticity and pulsation distributions in the structure units of the K-type and M-type flow paths (with the pressure 100 kpa condition for example) are shown in Fig.5. Figures 6 and 7, respectively show the flow vortex structure characteristics in K-type and M-type flow paths.

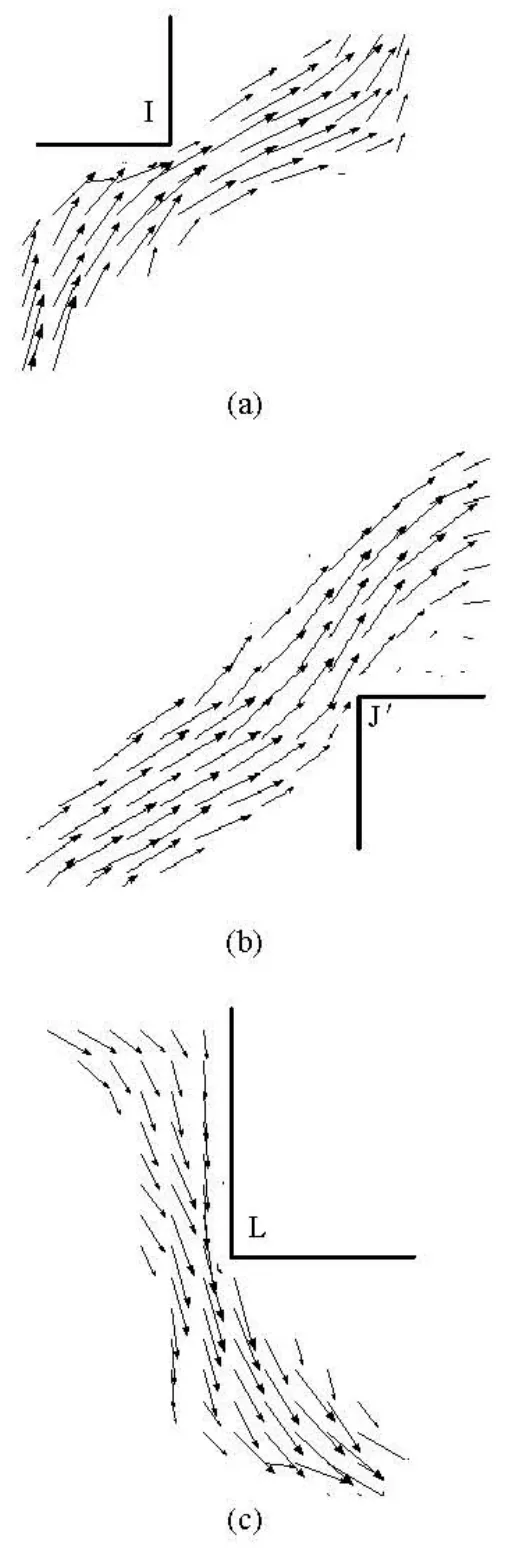

In Fig.5, the turbulence characteristics in the unit structure of the flow path come obviously from the vorticity and pulsation distributions, and the flow shows the vortex state in the corner of two kinds of the path side wall in the velocity distribution figure. In the K-type path, the vortex is mainly concentrated in the acute triangle region composed of lines CD and BC, the Pre-obtuse whirlpool region composed of lines AB′ and B′C′ and the back obtuse whirlpool region composed of lines C′D′ and D′E′. In the M-type flow path, the vortex is mainly concentrated in three orthogonal regions, called, respectively, the orthogonal H′I′J′ region, the orthogonal IJK region and the orthogonal K′M′L′ region along the flow path (the direction of flow is shown by arrows in the picture).

Fig. 6 The vortex distribute in the K-type flow path

Fig.7 The vortex distribute in the M-type flow path

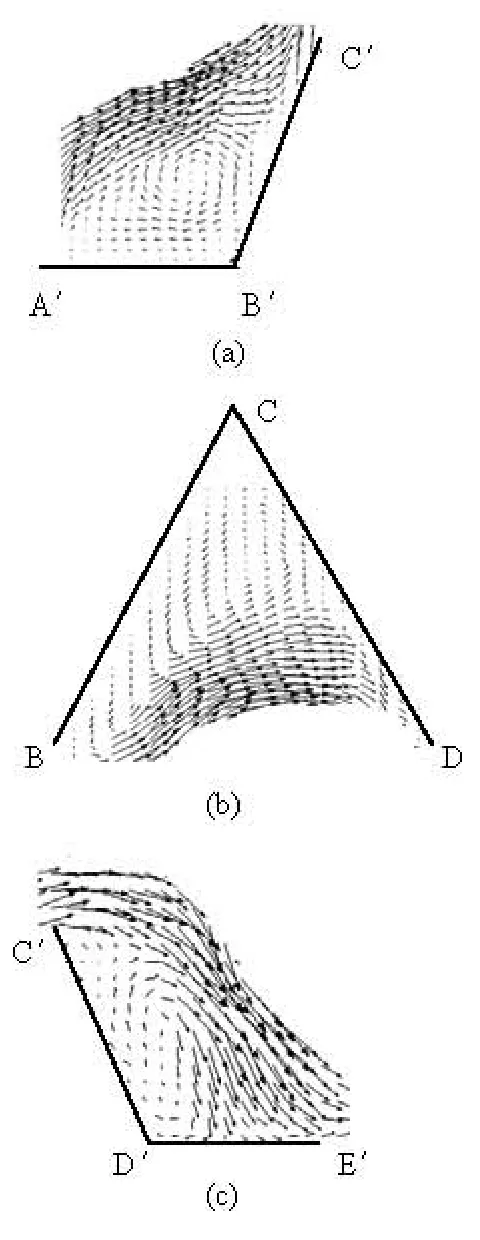

Fig.8 The flow line distribution in the regions near wall of the K-type flow path

The water entering the flow path is disturbed by the side wall of the path, which constantly blocks the flow. Figures 8 and 9, respectively, show the flow line distributions in the regions near the wall of the flow path. Figs.6 through 9 show the vortex in the K-type and M-type flow paths with the direction of the mass velocity changed by the triangle region composed of two side walls and a mainstream region. The mass velocity outside the vortex is higher than the speed of the vortex center, which could effectively avoid the flow stagnation, strengthen the relative movement between mass points and result in the energy dissipation. Comparing the vortice near 60o, 90oand 120oas shown in the Figs.6 and 7, it can be seen that the vortex formed near the angles 90ois developed fully, and the flow velocity near the wall of the path is the highest, which increases the self-cleaning capacity of the flow path. From this perspective, the anti-clogging capacity of the M-type path is higher than the K- type path.

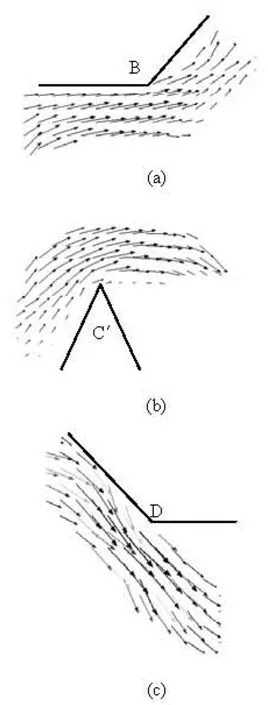

3.3 Flow characteristics of the local region near sawtooth

The local head loss is a main energy dissipation form in the labyrinth path, with 90% of head loss occuring near the sawtooth[7]. The velocitydistributions near the teeth of the K-type and M-type paths are, respectively, shown in Figs.10, 11, and the sawtooth obviously plays a role of disturbing the velocity distribution. The mass velocity near the sawtooth is lowered, when the pressure increases during the flowing. So some pressure energy of the mass points would be transformed into kinetic energy, and the direction of the flow would change. In other words, the kinetic energy is not completely transformed into the pressure energy, and after the adjustment, the particle velocity gradually increases. The friction between fluid mass points increases with the sawtooth disturbance and continuous fluid, which causes the energy transformation between the pressure energy and the kinetic energy, and finally the energy dissipation of the emitter.

Fig.9 The flow line distribution in the regions near wall of the M-type flow path

4. Discussions

The optimization of hydraulic properties and anti-clogging performance of the drip irrigation emitter is mainly achieved by the friction loss of the side wall, sawtooth and crankle of the flow path, contraction and expansion of the cross-section of the path, which makes the flow characteristics in the labyrinth path very complex. It is desirable for the emitter designer that the flow characteristics within the flow path of the drip irrigation are visualized. However the flow field testing with the emitter prototype is difficult with respect to technology and economy due to the narrow path, complex boundary and the opacity of the drip irrigation tube. So the conventional methods can not satisfy the requirements of the flow field test.

Fig.10 The flow characteristics in the local region near sawtooth in the K-type flow path

Fig.11 The flow characteristics in the local region near sawtooth in the M-type flow path

The numerical simulations with its own characteristics and unique functions, combined with theoretical analysis and experimental research, gradually become an important means to study the fluid flow, which forms a new field: computational fluid dynamics. The CFD method is used in the numerical experiment, flow prediction, and making diagnosis, and most designers could evaluate many design programs and select the best one in the fastest and convenient ways, and achieve the optimization design. The CFD method can also greatly reduce the work of laboratory tests, and achieve the goal of the best design program under a variety of constraints. It has become an indispensable part of the emitter design. Now some exploratory researches were carried out using the CFD method to analyze the flow characteristics inside the path of emitter. The discharge of the labyrinth path emitters is generally only about 0.2 Lh-1-8 Lh-1, with a cross-sectional area of about 0.6×10-6m2-1.0×10-6m2, the cross-sectional average velocity of 0.1 ms-1-1.0 ms-1, and the Reynolds number of about 70-1000. Hence, some laminar models were used to conduct the CFD numerical simulation, according to the critical Reynolds number of 2000[1,5]. However, most emitter discharge exponents are in the range of 0.50-0.65 in China, which indicates that the internal flow is turbulent. Hence, recently, turbulent models were used[2-3,6,12]. The turbulence in the labyrinth path was confirmed with DPIV technology in 10 kpa -150 kpa pressure range, which provided a theoretical basis for the study on the emitter. However, the tests were only two-dimensional, and it is an urgent problem to obtain the velocity characteristics in the cross-section of the path. At the same time, there is a certain number of low-velocity areas (mainly including both the flow stagnation region and the vortex region) in two labyrinth paths. The flow stagnation region does not play an important role on energy dissipation, but greatly increases the risk of clogging in the emitter. While in the flow vortex area, the mass velocity at the side wall is higher than that at the center, so it increases the self-cleaning capacity and the energy dissipation efficiency. Therefore, the vortex region should be fully developed to improve simultaneously the anti-clogging performance and the hydraulic properties. The boundary of the flow path in the flow stagnation region should be optimized based on consideration of the streamline shape and the vortex full development. We should have straight lines instead of the arc lines in some taper angle region of the path, which makes the impurity in the fluid be excluded more easily.

Li et al.[10]created the K and M-type labyrinth paths with the Koch and Minkowski curves for centerlines or boundaries (a special form of the labyrinth path) to realize the full turbulent design of the flow path of the drip irrigation emitter, at the same time, to improve the hydraulic properties and anti-clogging performance of the flow path,. It is found that the velocity in the inlet and outlet of the flow path section is lower than that in the sawtooth region with DPIV technology, owing to the fact that the turbulent intensity is reduced by the joint line between the sections of the labyrinth path. So the length of the joint line should be cut down in designing the path. There are more energy dissipation points in a unit length of the fractal path section than on other common labyrinth paths because of the unique feature of the fractal curve, so higher turbulence intensity could be kept in the path. As two types of fractal paths are concerned, a higher efficiency of the energy dissipation is achieved in the M-type path for the complex geometric structure, with more flow adjustments and velocity distribution restructions possible than the K-type path. From this point of view, the M-type path is better than the K-type path.

Combining the distribution characteristics of the velocity and flow lines, the energy dissipation process in the labyrinth path of drip irrigation emitters could be obtained. The disturbance of the side wall of the flow path creates a continual adjustment of the fluid velocity structure, the reorganization of the velocity distribution, the mutations of the streamline and the production of vortice, which increases the relative movement between water particles, forces friction with viscosity, resulting in the energy dissipation.

At the same time, due to the similarity of the labyrinth path structural unit in the way that the energy is dissipated and in the flow characteristics, the research on the whole flow path could be focused on the typical section structure. Analyzing the variations of flow internal structures of the basic unit could further reveal the mechanism of the flow path. The velocity characteristics in the local region near sawtooth show the energy dissipation process more clearly. So the performance of the path of the newemitter should be evaluated from the section of the flow path, the structural unit and the local region near sawtooth, to reveal gradually its flow characteristics. The design of the flow path should be closely related to the energy dissipation, and from the local area to the whole flow path.

5. Conclusions

Four conclusions could be reached in this article:

(1) The DPIV system could be used to test the flow characteristics of three energy dissipation units, which are the section, the structural unit and the local region near sawtooth of the flow path of the drip irrigation emitter.

(2)Under the pressure levels of 10 Kpa -150 Kpa, the fluid flow in the labyrinth path of the emitter is in the turbulence state, and no transition is observed from laminar to turbulent flows. So the turbulent model could be adopted for the CFD method used to simulate the flow in the path of the emitter. With increase of the pressure, the velocity in the mainstream region increases rapidly, and the velocity in non-mainstream areas increases but slightly.

(3) There are a certain number of the flow stagnation and vortex regions in the flow filed of the K and M-type path structural units. The flow stagnation regions should be eliminated as much as possible in the design of the emitter, while the vortex flow should be fuly developed, which could improve the self-cleaning capacity of the emitter and increase the anti-clogging capacity.

(4) As far as the anti-clogging performance and the energy dissipation efficiency in the path of the emitter are concerned, the M-type flow path is better than the K-type, but the side of the non-mainstream need to be optimized.

Acknowledgement

This working was supported by the Initiating Research Fund from China Agricultural University (Grant No. 2005065).

[1] WANG Shang-jin, LIU Xiao-min and XI Guang et al. Numerical simulation of flows inside a dripfaucet by finite element method[J]. Transactions of the CSAE, 2000, 16(4): 61-63(in Chinese).

[2] WEI Q. S., SHI Y. S. and DONG W. C. et al. Study on hydraulic performance of drip emitters by computational fluid dynamics[J]. Agricultural Water Management, 2006, 84(1-2): 130-136.

[3] ZHANG J., ZHAO W. H. and WEI Z. Y. et al. Numerical and experimental study on hydraulic performance of emitters with arc labyrinth channels[J]. Computer and Electronics in Agriculture, 2007, 56(2): 120-129.

[4] ZHANG J., ZHAO W. H. and TANG Y. P. et al. Numerical investigation of the clogging mechanism in labyrinth channel of the emitter[J]. International Journal for Numerical Methods in Engineering, 2007, 70(13): 1598-1612.

[5] SALVADOR P. G., ARVIZA V. J. and BRALTS V. F. Hydraulic flow behavior through an in 2line emitter labyrinth using CFD techniques[C]. 2004 ASAE/CSAE Annual International Meeting. Fairmont Chateau Laurier, The West in Government Centre Ottawa, Ontario, Canada, 2004.

[6] LI Yong-xin, LI Guang-yong and QIU Xiang-yu et al. Modeling of hydraulic characteristics through labyrinth emitter in drip irrigation using computational fluid dynamics[J]. Transactions of Agricultural Engineering of CSAE, 2005, 21(3): 12-16(in Chinese).

[7] LI Yun-kai, LIU Shi-rong and YANG Pei-ling et al. Hydrokinetics analysis on the pressure losses in sawtooth-labyrinth path drip irrigation emitters[J]. Transactions of the CSAE, 2007, 38(12): 59-62(in Chinese).

[8] LI Yun-kai, YANG Pei-ling and REN Shu-mei et al. Hydraulic characterizations of tortuous flow in path drip irrigation emitter[J] Journal of Hydrodynamics, ser. B, 2006, 18(4): 449-457.

[9] LI Yun-kai, YANG Pei-ling and REN Shu-mei et al. Analyzing and modeling flow regime in labyrinth path drip irrigation column emitter with CFD[J]. Journal of Hydrodynamics, ser. A, 2005, 20(6): 736-743(in Chinese).

[10] WANG F., WU P. T. and FAN X. K. Numerical simulation and frame designing of emitter’s labyrinth channel[J]. Journal of Irrigation and Drainage, 2007, 26 (3): 34-38.

[11] WEI Zheng-ying, ZHAO Wan-hua and TANG Yi-ping et al. Anti-clogging design method for the labyrinth path of drip irrigation emitters[J]. Transactions of the CSAE, 2005, 21(6): 1-7(in Chinese).

[12] LI Y. K., YANG P. L. and XU T. W. et al. CFD and digital particle tracking to assess flow characteristics in the labyrinth flow path of a drip irrigation emitter[J]. Irrigation Science, 2008, 26(5): 427-438.

[13] LI Yun-kai, YANG Pei-ling and REN Shu-mei et al. Effects of fractal flow path designing and its parameters on emitter hydraulic Performance[J]. Chinese Journal of Mechanical Engineering, 2007, 43(7): 109-114.

[14] LI Yun-kai, YANG Pei-ling and REN Shu-mei et al. Plane Model of labyrinth path drip irrigation column emitter[J]. Transactions of the CSAE, 2006, 37(4): 48-51(in Chinese).

[15] THE DEPARTMENT OF INTERNATIONAL COOPERATION AND SCIENCE AND TECHNOLOGY OF THE MINISTRY OF WATER RESOURCES IN CHINA. The water conservancy technology standards kit: Irrigation and drainage volume water saving equipment and materials[S]. Beijing: China Water Power Press, 2002, 32-54(in Chinese).

[16] XU Jing-lei, SHA Jiang and LIN Chun-feng et al. PIV experimental research of instantaneous flow characteristics of circular orifice synthetic jet[J]. Journal of Hydrodynamics, Ser. B, 2007, 19(4): 453-458.

[17] LIU Zhen, HYUN Beom-soo and KIM Moo-rong et al. Experimental and numerical study for hydrodynamic characteristics of an oscillating hydrofoil[J]. Journal of Hydrodynamics, 2008, 20(3): 280-287.

[18] Daichin, ZHAO Li-li. PIV measurement of wake flow of an airfoil near free surface and the POD analysis[J]. Chinese Journal of Hydrodynamics, 2008, 23(2): 196-203(in Chinese).

10.1016/S1001-6058(09)60038-X

* Project support by the Program for Changjiang Scholars and Innovative Research Team in University (Grant No. IRT0657), the National Natural Science Foundation of China (Grant Nos. 50609029 and 50779068) , and the Key Discipline “Hydrology and Water” Project of Beijing and Post-Doctoral Science Foundation of China (Grant No. 20080430072).

Biography: LIU Hai-sheng (1984- ), Male, Master Candidate

- 水動力學研究與進展 B輯的其它文章

- VIBRATION CHARACTERISTICS OF FLUID-STRUCTURE INTERACTION OF CONICAL SPIRAL TUBE BUNDLE*

- MODELING OF FREE JUMPS DOWNSTREAM SYMMETRIC AND ASYMMETRIC EXPANSIONS: THEORITICAL ANALYSIS AND METHOD OF STOCHASTIC GRADIENT BOOSTING*

- TURBULENT FLOWS AROUND SAND DUNES IN ALLUVIAL RIVERS*

- SIMULATION OF THE OIL SLICK MOVEMENT IN TIDAL WATERWAYS*

- SEEPAGE ABILITY OF HIGH-PRESSURE HOT COMPOSITE FOAM IN POROUS MEDIA*

- VISCOSITY EFFECTS ON THE BEHAVIOR OF A RISING BUBBLE*