Research on the energy consumption mechanism and characteristics of the gallium indium tin liquid metal arcing process

Yaguang MA(馬亞光),Guoqiang GAO(高國(guó)強(qiáng)),Yu XIANG(向宇),Wei PENG(彭偉),Keliang DONG(董克亮),Pengyu QIAN(錢鵬宇),Bingyan YOU(游炳妍),Zefeng YANG(楊澤鋒),Wenfu WEI(魏文賦) and Guangning WU(吳廣寧)

School of Electrical Engineering,Southwest Jiaotong University,Chengdu 610031,People’s Republic of China

Abstract For high-voltage direct current(HVDC)power grid transmission with higher voltages,the energyconsuming branch of the DC circuit breaker is required to dissipate huge energies of more than megajoules in a short time in the case of a fault and short circuit.The requirements for huge volume and weight are difficult to meet with energy-consuming equipment based on ZnO.In this paper,a new energy consumption method is proposed based on gallium indium tin(GaInSn)liquid metal in the arcing process,and a test platform with adjustable short-circuit current is built.The mechanism triggering GaInSn liquid metal arcing energy consumption is studied.It is found that short-circuit current and channel aperture are the key parameters affecting the energy consumption of liquid metal arcing.The characteristics of GaInSn liquid metal energy consumption are investigated,and four stages of liquid metal energy consumption are found:oscillatory shrinkage,arc breakdown,arc burning phase change and arc extinction.The influence of short-circuit current and channel aperture on the energy consumption characteristics of GaInSn liquid metal is investigated.To further explore the physical mechanism of the above phenomena,a magneto-hydrodynamic model of energy consumption in the GaInSn liquid metal arcing process is established.The influence of short-circuit current and channel aperture on the temperature distribution of the liquid metal arc is analyzed.The mechanism of the effect of short-circuit current and channel aperture on peak arc temperature and the temperature diffusion rate is clarified.The research results provide theoretical support for this new liquid metal energy consumption mode DC circuit breaker.

Keywords: GaInSn liquid metal,trigger mechanism,oscillatory shrinkage,arcing energy consumption,temperature diffusion

1.Introduction

The high-voltage direct current(HVDC) grid and its connections are the key points in the power grid for carbonpeaking and carbon neutrality.A DC circuit breaker is a device for constructing and ensuring the reliability and flexibility of the DC grid power supply.

The energy consumption of circuit breakers in a HVDC power grid is a difficult problem.With the development of higher-level DC transmission,the DC circuit breaker isrequired to consume huge energies within 10-20 ms.With the traditional energy consumption method,the number and volume of ZnO resistors need to be continuously increased.This leads to a significant increase in cost and cannot meet the development requirements of HVDC power grids in the future[1-3].GaInSn liquid metal has the advantages of small size and fast energy consumption for use in DC circuit breakers and will become the focus of research in the future.Therefore,it is of great significance to study the energy consumption characteristics and influencing factors of GaInSn liquid metal to try and solve the energy consumption problem of highvoltage DC circuit breakers.

GaInSn liquid metal has excellent properties such as high conductivity,high thermal conductivity and a low melting point.In the field of electrical engineering,the research into liquid metals currently focuses on microfluidic switches[4-6],energy storage [7-11] and current limiting [12,13].Relevant simulations and experiments have been carried out for GaInSn.In terms of microfluidic switches,GaInSn liquid metal can be used as a good switching device because of its high conductivity and strong fluidity.As a power electronic switch or strong current control switch,it has the advantages of high action reliability and sensitivity [4,5].In terms of energy storage,GaInSn liquid metal has been studied with its advantages of high energy density,strong cycling performance and low cost,and is used as a liquid positive electrode to achieve energy release and storage for batteries[7].In terms of current limiting,numerous studies have been performed on liquid metal current limiters with a self-shrinkage effect[14-21].The arc characteristics were investigated by simulating short-circuit inrush currents using LC pulse charging and discharging circuits in the through-hole of liquid metal current limiters [14,15].A multiphysics simulation of the magnetic fluid was carried out using the finite element method to analyze the hoop effect,and the turbulence effect was calculated and simulated under magnetic drive[16].Thesset alintroduced an H-through model to calculate the critical current as the threshold for the hoop effect,which is further simplified by the analytical model given in [17,18].Liuet alsimulated the dynamic self-shrinking process of liquid metal using a threedimensional magneto-hydrodynamic(MHD) model and calculated the relevant parameters of the arc plasma [19,20].Yanget alproposed a hybrid topology of a liquid metal current limiter combining fast switching and liquid metal units for medium-voltage DC applications [21].Although the above studies confirmed the great current-limiting effect of liquid metal,the energy consumption characteristics of GaInSn liquid metal were not mentioned.As the phase change process of GaInSn liquid metal arcing is accompanied by huge energy transfer,it can be considered for the energy transfer absorption circuit of DC circuit breakers.The energy dissipation power density of HVDC circuit breakers is improved by using GaInSn liquid metal energy consumption devices together with ZnO resistors.The number of ZnO resistor valves can be reduced,and the development of small and lightweight HVDC breaking systems can be promoted [22].Therefore,this work studies the energy consumption mechanism and characteristics of the GaInSn liquid metal arcing process.

In this work,an energy consumption test platform with adjustable short-circuit current is built,and a liquid metal energy consumption cavity model with a conical hole channel structure is designed.The triggering mechanism of GaInSn arc initiation is studied,and the key parameters affecting the arcing energy consumption of liquid metal are found.The arcing energy consumption characteristics of GaInSn liquid metal are investigated,and a significant stage distribution of liquid metal energy consumption is found.The relationship between the arc starting time,arc voltage and arc burning duration in the energy consumption process is revealed,and the influence of short-circuit current and channel aperture on the arcing energy consumption characteristics of GaInSn liquid metal is analyzed.In addition,to investigate the arc temperature distribution characteristics of the energy consumption process and its influencing factors,a MHD model of GaInSn metal arcing is established,and the influence of short-circuit current and channel aperture on the temperature distribution of the liquid metal arc is analyzed.Finally,the effects of the short-circuit current and channel aperture on the arc temperature peak and temperature diffusion rate are clarified.

2.Experimental arrangement

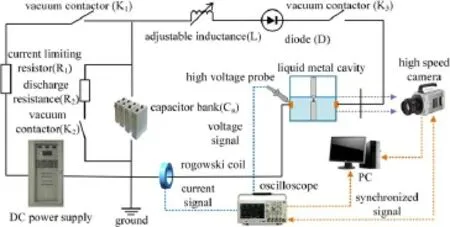

In order to study the energy consumption characteristics of liquid metal arcing a pulsed test circuit is built.A schematic diagram of the experimental system is shown in figure 1.The experimental process is divided into three stages.(1)In the charging stage,the vacuum contactor K3of the main circuit and K2of the discharge circuit are indirectly disconnected by manually controlling the secondary air switch.Then the DC power supply of 3 kV,1 A is opened,and K1is closed by manually controlling the secondary air switch.The capacitor group Cnis charged with constant voltage under the current-limiting resistor,then K1is disconnected and the DC power supply is turned off in turn when the charging voltage of Cnreaches the set value.(2) After that,the close breaker K3,capacitor group Cn,adjustable inductor L,diode and other devices constitute an oscillating circuit used to simulate the short-circuit current due to a fault.The initial expected short-circuit current peak is 20 kA without any power dissipation and the maximum current rise rate is up to 12 Aμs-1.The diode in the main circuit is used to automatically disconnect the short-circuit current after the half-cycle wave,reducing the damage to the liquid metal cavity by repeated arc burning.(3) After the experiment is completed,K3is indirectly openedand K2is closed by manually controlling the air switch; the drain resistor is used to consume the remaining energy in the capacitor.

During the experiment,the voltage between electrodes of the liquid metal cavity during the arc burning process is measured with a high-voltage probe(Tektronix P6015A).The current is measured with a Rogowski coil(PEM CWT 150B).The experimental waveform is recorded by a Tektronix oscilloscope(MDO 3024).The dynamic behavior of the arc is captured by a high-speed camera(Fastcam Nova S6);the test circuit system is shown in figure 1.

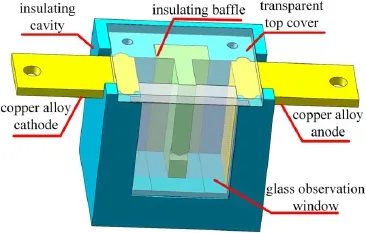

To observe the behavior of liquid metal arc burning,a translucent liquid metal cavity is designed; the cavity structure is shown in figure 2.The size of the cavity model is 80 mm×70 mm×70 mm,with an L-shaped tungsten-copper electrode and an epoxy material through-hole on the internal edge.The spacer through-hole is designed with a conical hole that is 12 mm long and 5 mm in diameter,which makes it possible to start the GaInSn metal arc faster and obtain energy consumption.The distance between the epoxy-insulated spacer and the electrode is 24 mm.Under the impact of a large current,an arc is generated at the through-hole of the insulating partition and consumes energy.The phase change of the liquid metal material caused by the arc will generate strong pressure in the cavity.To release this pressure,some space needs to be left in the liquid metal cavity.In order to avoid the pressure generated in the process of arcing causing the insulation spacer to move,a fixed plate is installed on the top of the cavity.In order to prolong the service life of the cavity,the material of the cavity and insulation partition is made of sheet molding compound(SMC).In order to facilitate the observation of the arcing process,transparent plexiglass is used on the front of the cavity.

3.Liquid metal arcing process and energy consumption characteristics

3.1.Analysis of the liquid metal pre-arc process

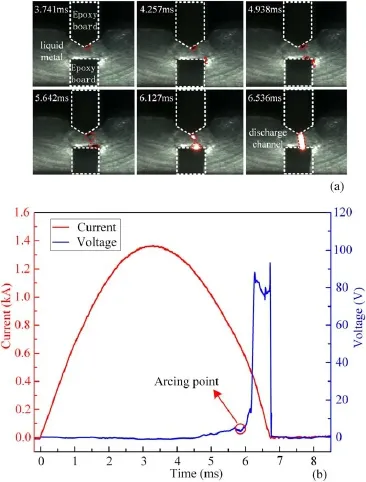

To investigate the shrinkage process of GaInSn liquid metal arc initiation,images of liquid metal self-shrinking with a current peak of 1.35 kA are captured by a high-speed camera.The experimental results are shown in figure 3.Beforet=3.741 ms,the liquid metal in the cavity is still relatively stable owing to the small current.Aftert=3.741 ms,with the increase in current,the ampere force generated by its magnetic field increases,and fluctuation of the liquid level in the conical hole channel driven by the ampere force is observed.The liquid metal gradually separates from the surface of the insulating plate and concaves downward.Att=4.938 ms,visible small bubbles are formed in the channel,and the volume of the bubbles enlarges with the violent flow of liquid metal.Att=5.642 ms,the small bubbles at the tip of the conical insulated channel start to extend into its interior,reducing the cross-sectional area of the liquid metal in the channel.Att=6.127 ms,a partial breakdown occurs within the bubble in the through-flow hole,generating a tiny arc and subsequently forming an arc channel.Figure 3(b)shows the volt-ampere characteristic curve of the shrinkage process of liquid metal arcing at the peak current of 1.35 kA.As can be seen from the figure,the voltage at both ends of the electrode will change when the liquid metal shrinks before the arc starts.Att=6.127 ms,local breakdown occurs,which is consistent with images captured by the high-speed camera.The arc voltage will also rise rapidly to enter the arc burning stage.

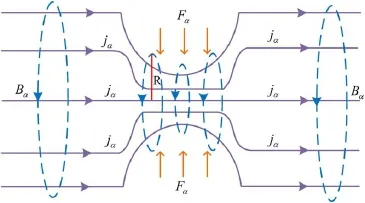

To further analyze the energy consumption mechanism of pre-arcing liquid metal,figure 4 shows the liquid metal self-shrinkage effect.Under the effect of inhomogeneouscurrent densityjα,the figure shows the distribution of magnetic induction intensityBαand ampere forceFαin the cavity.When a short-circuit fault occurs,the current increases sharply and the ampere force in the hole increases,subsequently driving the self-shrinkage of liquid metal arcing.To investigate the key parameters affecting the energy consumption of liquid metal arc initiation,the following equation is derived [23,24]:

It is deduced from equation(1) that

whereBαis magnetic induction intensity,IAis through-hole current,μ0is magnetic permeability,Fαis ampere force andRis the radius of the through-hole.The major factors affecting shrinkage arcing are through-hole current and through-hole radius.

3.2.Energy consumption characteristics of GaInSn liquid metal

To investigate the self-shrinking process of energy consumption during GaInSn liquid metal arcing,the volt-ampere characteristic curve and the total energy dissipation of the energy consumption process at the expected peak short-circuit current of 2.65 kA are given in figure 5.Therefore,according to the volt-ampere characteristic curve and the development of the total energy loss during the discharge process,the above process is divided into four stages.The first stage is the oscillatory shrinking stage,where the rate of change of the current is maximum at the moment when the short-circuit current rises.At the same time,due to the liquid metal fluidity and strong conductive properties,the internal liquid produces an unstable change process.The gradual increase in the current causes a stronger contraction force on the liquid metal column.The internal shrinkage phenomenon is obvious,as shown in figure 3(a).By comparing the expected short-circuit current and the current waveform of liquid metal arcing,it is found that the pre-arc oscillation shrinkage stage has a certain current-limiting effect.This stage mainly depends on the Joule heat generated by the liquid metal in the through-hole,leading to a rise in temperature of the liquid metal.The second stage is the arc breakdown stage: the liquid metal in the through-hole continuously shrinks until the discharge channel is formed,thus generating an arc.The third stage is the arc burning phase change stage: the liquid metal arc expands in the edge of the through-hole,and air pressure increases in the through-hole.The liquid metal is spattered on both sides of the through-hole,thus intensifying the expansion of the arc.By comparing the expected short-circuit current and the current waveform of liquid metal arcing,it is found that the current-limiting effect is obvious at this stage.In this process,GaInSn liquid metal fully contacts with the arc and absorbs energy to cause phase transformation.The fourth stage is the arc extinguishing stage: the electrical energy is not sufficient to maintain the arcing.So the arc is extinguished and the arc voltage rapidly decreases.Att=4.863 ms,the arc is completely extinguished with a high-speed camera,and the liquid metal absorbs the remaining energy of the arc.It is found that the total energy consumption rate increases the fastest and most energy is consumed in the development stage of arc burning.Therefore,the arc burning phase change stage dominates the whole energy consumption process.

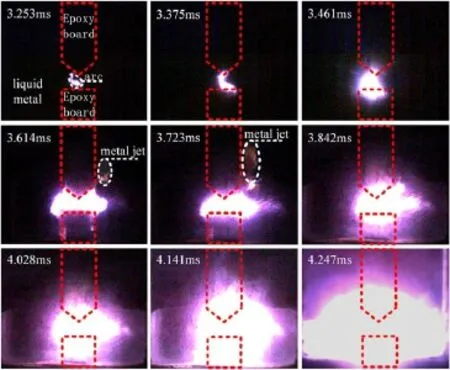

To further investigate the arc burning process of GaInSn liquid metal,figure 6 shows the variation of the morphology of the liquid metal arc for a conical hole of length 12 mm and channel aperture of 5 mm when the peak current is 2.4 kA.Att=3.253 ms,the tip of the conical hole breaks through the arc and the arc voltage jumps at the moment of breakdown.A‘crescent-shaped’ small and narrow arc is formed in the through-hole.After that,the arc expands from the middle to both sides,and its brightness gradually increases.Att=3.614 ms,the arc extends to the edge of the conical flowhole,and the GaInSn liquid metal is in full contact with the arc,absorbing energy to make the temperature rise and the phase change.The internal pressure increases,causing an obvious liquid metal splash at the edge of the through-hole.With increasing time,the arc extends to the outside of the through-hole and extends upward along both sides of the insulation partition.The liquid metal covering the arc will be pushed into the upper space of the compartment.

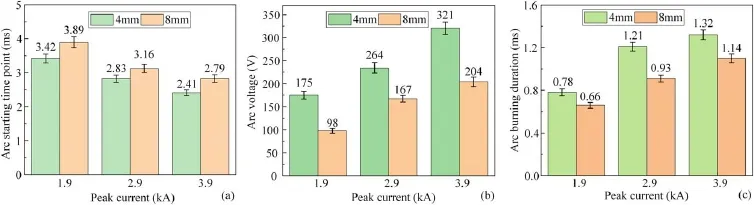

To further investigate the effect of peak current and channel aperture on the parameters related to the arc initiation process,this work compares and analyzes the variation law for arc starting time,arc voltage and arc burning duration under different peak currents and different channel apertures.Figure 7 shows the average values of arc starting time,arc voltage and arc burning duration for channel apertures of 4 mm and 8 mm and the peak currents of 1.9 kA,2.9 kA and 3.9 kA,which are obtained in the experiment.In figure 7,it can be found that the arc starting time decreases with increase in the peak current when the channel aperture is constant.The arc voltage and arc duration increase as peak current increases.When the peak current is constant,the arc starting time of the channel with an aperture of 4 mm is earlier than that of the channel with an aperture of 8 mm.The arc voltage and arc duration of the channel with an aperture of 4 mm are greater than those of the channel with an aperture of 8 mm.The reason for this phenomenon is as follows: whether the peak current increases or the channel aperture reduces,it will make the contraction stronger and the energy flow density greater.As a result,the arc starting time is shortened,the arc burning voltage is increased and the arc burning duration is increased.The variation trend of arc voltage is consistent with that of arc burning duration.

3.3.Effect of peak current and channel aperture on liquid energy consumption characteristics

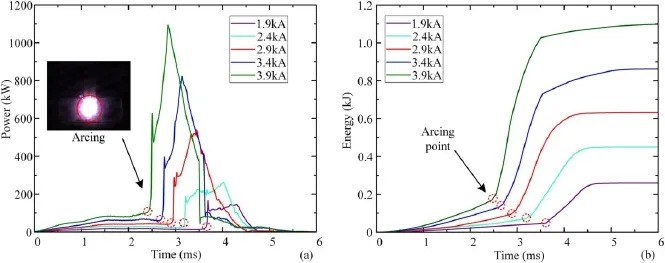

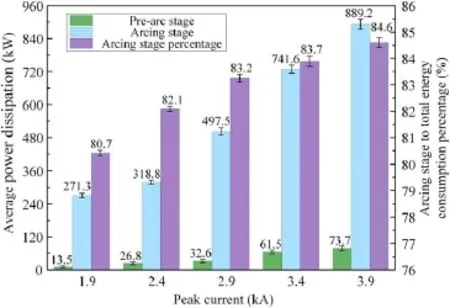

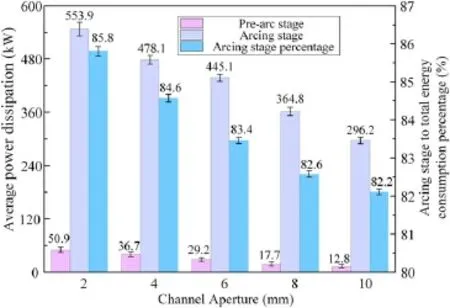

To further investigate the effect of peak current on power dissipation and total energy consumption,the curves of power dissipation and total energy consumption at different peak currents for a channel aperture of 5 mm and liquid surface height of 10 mm are shown in figure 8.With the increase in peak current,the power dissipation and total energy consumption increase.In the oscillatory contraction stage before the arc starts,with the increase in the peak current,the liquid column gradually contracts.The trend of energy consumption gradually increases,but the rate of increase is small.This stage of energy consumption mainly involves Joule heat.At the moment when the arc starts,the power dissipation increases rapidly and fluctuates.The instantaneous power dissipation of arc extinction drops sharply until it becomes zero.After the arcing,the rate of rise of total energy consumption is larger than before.After the arc is extinguished,the rate of increase of total energy consumption gradually tends to become smooth.At the peak current of 4.2 kA,the maximum power dissipation during arc burning reaches 1100 kW and the total energy consumption is 1.1 kJ.Figure 9 shows the proportion of average power dissipation and the energy consumption in the arc burning stage at different peak currents.It can be seen that the average power dissipation in the arc burning stage is about five times higher than that in the oscillating contraction stage.The percentage of energy consumed in the arc burning stage is obtained by dividing the consumption of energy in the arc burning stage by the total energy consumption; the energy consumed in the arc burning stage accounts for more than 80% of the total energy consumption,and increases with increase in the peak current.Therefore,it is found that increasing the power dissipation in the arc burning stage can promote rapid energy consumption.The reasons for the difference in power dissipation and total energy under different peak currents are as follows.First,as the peak current increases,the current density increases,resulting in an increase in the self-magnetic field.The rate of shrinkage of liquid metal increases and the arc starting time is earlier at the same liquid level.Second,as the current increases,the energy flow density increases and the degree of arc burning is more intense.The arc burning stage is the main consumer of energy.Therefore,power dissipation and total energy consumption will also increase.

To further investigate the effect of different channel apertures on the power dissipation and total energy consumption,the variation of the power dissipation and total energy consumption of liquid metal for different channel apertures with a peak current of 2.9 kA and liquid surface height of 10 mm are shown in figure 10.It can be seen that the power dissipation and total energy consumption increase with decrease in the channel aperture,and the arc starting time will shorten with decreasing channel aperture.The power dissipation curve increases exponentially at the arc ignition point.For a channel aperture of 2 mm,the maximum power dissipation can reach 648 kW and the maximum energy consumption can reach 0.798 kJ when arc burning starts.Figure 11 shows the proportion of average power dissipation and energy consumption in the arc burning stage under different channel apertures.It can be found that the channel aperture is inversely related to the average power dissipation and energy consumption in the arc burning stage.The power dissipation of the arc burning stage is several times higher than that before the arc starts,and the energy consumption ofthe arc burning stage accounts for the majority of the total energy consumed.The reasons for the difference in power dissipation and total energy consumption at different channel apertures are as follows.First,the smaller the channel aperture,the smaller the current collection area,the greater the current density and the greater the electromagnetic force on the liquid metal.As a result,the rate of shrinkage of liquid metal is affected.Second,with the decrease in the current collection area of the through-hole aperture,the energy flow density increases,resulting in more intense arc burning.

Figure 1.Liquid metal energy consumption test circuit system.

Figure 2.Diagram of the structure of the liquid metal cavity.

Figure 3.(a) Self-shrinking during the liquid metal arc starting process in a conical hole.(b)Volt-ampere characteristic curve of the shrinkage process of liquid metal arcing in a conical hole.

Figure 4.Principle of self-shrinkage of liquid metal.

Figure 5.Curve of the energy consumption characteristics of the conical hole.

Figure 6.The arc burning process of liquid metal in a conical hole.

Figure 7.Arc parameters under different test conditions:(a) arc starting time point,(b) arc voltage,(c) arc burning duration.

Figure 8.Power dissipation curve and total energy consumption curve under different peak currents.

Figure 9.Average power dissipation and energy consumption ratio in the arc burning stage under different peak currents.

Figure 10.Energy consumption power curve and total energy consumption curve for different channel apertures.

Figure 11.Average power dissipation and energy consumption ratio of the arc burning stage for different channel apertures.

Figure 12.Geometric simulation model for liquid metal energy consumption.

4.Establishment of the GaInSn liquid metal simulation model

4.1.Geometric model size and material

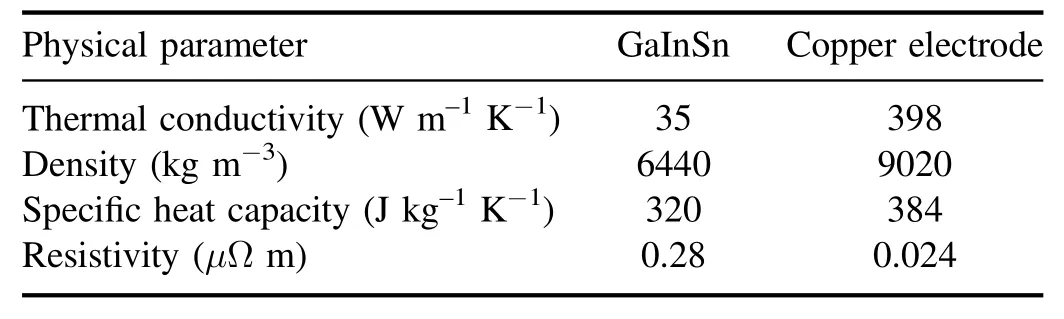

The basic structure of the two-dimensional model established in this work is shown in figure 12.The model is a rectangle with three sides closed.The calculation area of the GaInSn liquid metal arc is between the anode,cathode and insulating wall.The cathode and anode materials are copper,and the size is 70 mm×5 mm.The insulating wall is made of SMC.The distance between the insulating wall and the copper electrode is 24 mm.The diameter of the through-hole is 5 mm and the diameter of the conical shape can be adjusted.The internal part is filled with the GaInSn,and the upper part is filled with air.Table 1 lists the specific parameter settings of GaInSn liquid metal materials and copper electrodes in the model.

Table 1.Physical parameters of GaInSn liquid metal materials and copper electrodes.

4.2.Governing equations of the model

The liquid metal arc starting model is established based on the theory of MHD,including hydrodynamic equations and electromagnetic field equations.Among these,the fluiddynamics equation includes the fluid mass conservation equation,the momentum conservation equation and the energy conservation equation.The electromagnetic field is described by Maxwell’s equations.The arc region is considered to be in a local thermodynamic equilibrium state,and the flow in the arc region is in a laminar state.The fluid dynamics equations and the electromagnetic field equations are shown below.

The fluid mass conservation equation is

The momentum conservation equation is:

In these formulas,ν is the velocity vector of the flow field,ρis the arc density,νiis the velocity component in the direction ofi=(x,y),ηis the dynamic viscosity,pis the pressure,Jis the current density andBis the magnetic induction intensity.

The energy conservation equation is

whereTis the temperature,λ is the thermal conductivity,cpis the specific heat capacity,σis the electrical conductivity ofthe arc plasma andQis the source term of the energy equation[25].Qradis the radiation source term [26] andVis the fluid viscous dissipation term.Because the arc temperature is very high,its thermal radiation phenomenon is obvious.Therefore,this work uses the volume net emissivity method to calculate the thermal radiation

whereεnis the temperature-dependent volumetric net emissivity.

The electromagnetic field equation,according to Maxwell’s equations,can be solved to obtain the potentialφas

The current density is

The arc magnetic field can be calculated using the magnetic vector potential

In these formulasφis the electric potential,Jis the vector of the current density,Ais the magnetic vector potential andμ0is the vacuum permeability [27-31].

The boundary conditions are necessary conditions for controlling the existence of a solution.The critical boundary conditions given to the calculation model in figure 12 are as follows:for the thermal boundary conditions of the temperature field of the liquid metal energy dissipation module,the thermal boundary conditions on the insulating wall are set according to the one-dimensional conduction formula(13) [32,33]

whereiis the number of boundary elements,qu,iis the heat flow caused by thermal conduction at the element with numberion the boundary andλuis the thermal conductivity of the insulating wall.Tuiis the boundary temperature value of the element with numberion the inner surface of the insulating wall andT0is the temperature outside the model walls.The room temperature is set to 300 K anddis the thickness of the insulating wall.For the velocity boundary condition,the velocity of the gas flow field on the surface of the insulating wall is set to 0,and the electrode and the insulating wall remain stationary as a solid during the whole simulation process.For the potential boundary condition,Iis the external current and the relationship between the current area on the interfaceIunit areaHiis

5.Simulation and analysis of liquid metal arc temperature with different peak currents and channel apertures

Based on the above two-dimensional mathematical model of an arc,this study uses Comsol Multiphysics analysis software for calculation.The arc temperature is considered to be the overall temperature of the non-equilibrium plasma in the region at the moment of arc generation.To investigate the effect of discharge current and channel aperture on the arc temperature during arc energy consumption this work simulates and calculates the temperature distribution law for a conical hole liquid height of 10 mm,a period of 6 s,channel apertures of 4 mm,5 mm,6 mm and 8 mm,and peak currents of 2.9 kA,3.4 kA and 3.9 kA.

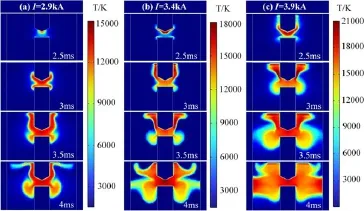

According to the simulation results,the temperature distribution law for different discharge currents during the arc stretching process is studied.Figure 13 shows the temperature distributions for a channel aperture of 5 mm and discharge currents of 2.9 kA,3.4 kA and 3.9 kA.From the figure,it is obvious that the higher-temperature region is inside the through-hole and the diffusion distribution is formed along the sides of the through-hole.The temperature of the liquid metal arc shows a decreasing trend.The reason for this is that the arc is generated in the channel aperture and continuously develops upward along both sides of the channel,and the heat exchange effect causes the temperature to subsequently spread.In addition,the change in liquid metal arc temperature is compared under different currents: the temperature in the channel is increased and the area of the diffusion region is increased with the increase in current,which is consistent with the experimental results.We also analyzed the influence of the channel aperture on the arc temperature law.Figure 14shows the temperature distributions of the arc development process for a peak current of 3.4 kA and channel apertures of 4 mm,6 mm and 8 mm.In the figure,with increase in the channel aperture,the degree of temperature diffusion of the arc development process decreases.Heat exchange with the surrounding area decreases,and the power dissipation and energy consumption also decrease at the same time,which is consistent with the experimental results.

Figure 13.Temperature distributions in the process of the arc burning of the conical hole under different peak currents.

Figure 14.Temperature distribution in the process of the arc burning of the conical hole under different channel apertures.

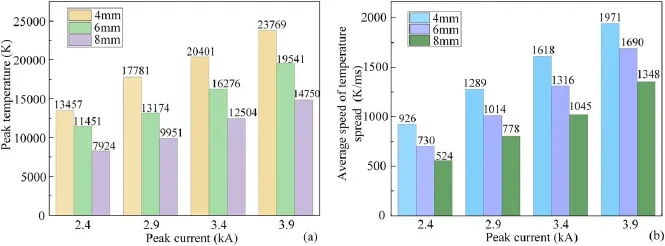

Figure 15(a) shows the change in maximum temperature under different channel apertures and different currents.When the peak current is the same,the peak liquid metal arc temperature increases with decrease in the channel aperture.At a current of 3.9 kA and a liquid level of 4 mm,the temperature reaches 23 769 K.Figure 15(b) shows the variation of the temperature diffusion rate under different channel apertures and different currents.The average temperature diffusion rate of the arc increases with increase in the peak current.The average rate of diffusion of the liquid metal arc temperature increases with decrease in the channel aperture diameter.When the channel aperture diameter is 4 mm,the average diffusion rate of the arc temperature is about 1.5-1.8 times that for a channel aperture diameter of 8 mm.

Figure 15.Changes of peak temperature and temperature diffusion rate for different channel apertures and currents.

By comparing the temperature distribution of the arc development process with the arc images captured by the high-speed camera it is found that the temperature distribution is consistent with the arc development images.This reveals that the temperature increase is the main energy consumption pathway in liquid metals.Increase in current peak value or decrease in channel aperture will increase the current density in the through-hole.The increase in the intensity of arc combustion leads to an increase in temperature maximum and thermal diffusion velocity.As a result,the power dissipation and total energy consumption increased,which is consistent with the experimental results.

6.Conclusion

The triggering mechanism for GaInSn liquid metal arc initiation is investigated.The key parameters affecting the energy consumption of liquid metal arcing are found.The characteristics of GaInSn liquid metal arcing and energy consumption are investigated,and it is found that the process of liquid metal energy consumption is divided into four stages: oscillation shrinkage,arc breakdown,arc burning phase change and arc extinction,of which the arc burning stage is dominant.

The effects of short-circuit current and channel aperture on the energy consumption characteristics of GaInSn liquid metal are investigated.The relationship between the power dissipation at the arcing stage and the power dissipation at pre-arc contraction is found.The energy consumption of the arc burning stage accounts for more than 80% of the total energy consumed.Further analysis found that the change in current density in the channel is the root cause affecting the change in energy consumption.

The MHD model for arc starting energy consumption of GaInSn liquid metal is established.The distribution characteristics of the arc temperature and the influencing factors are investigated.It is found that the arc temperature distribution and average rate of temperature diffusion increase with increasing short-circuit current.The arc temperature increases with decrease in the channel aperture,and the average rate of diffusion of temperature is negatively correlated with the channel aperture.

Acknowledgments

This work is supported by National Natural Science Foundation of China(No.U1966602) and the Excellent Young Scientists Fund of China(No.51922090).

Plasma Science and Technology2023年9期

Plasma Science and Technology2023年9期

- Plasma Science and Technology的其它文章

- Plasma Science and Technology

- The magnetic field design of a solenoid for the cold-cathode Penning ion source of a miniature neutron tube

- Chemical and physical studies of metallic alloy-based old Indian coins with LIBS coupled with multivariate analysis

- Effects of anode material on the evolution of anode plasma and characteristics of intense electron beam diode

- Simulation of DC glow discharge plasma with free-moving dust particles in the radial direction

- Experimental studies on the propagation of whistler-mode waves in a magnetized plasma structure with a non-uniform density