Fabrication of High-Efficiency Polyvinyl Alcohol Nanofiber Membranes for Air Filtration Based on Principle of Stable Electrospinning

GAO Tingting(高婷婷), ZHENG Junmei(鄭軍妹), 2*, WANG Danyang(王丹陽(yáng))

1 Ningbo Fotile Kitchen Ware Company, Ningbo 315336, China

2 Key Laboratory of Healthy &Intelligent Kitchen System Integration of Zhejiang Province, Ningbo 315336, China

Abstract:A mass flow matching model (MFMM) was established for studying the stable status of solution electrospinning. The study of the solution droplet status at the needle tip focused on various combinations of applied voltages and injection rates to figure out their influence on steadily fabricating polyvinyl alcohol (PVA) nanofibers prepared from PVA spinning solutions with two different mass fractions (10% and 16%). The results revealed that during the stable electrospinning, the influence resulted from the change of the injection rate approximately canceled out the impact brought by adjusting the applied voltage, leading to almost the same morphology as that of the PVA nanofibers. And the mass fraction of PVA in the spinning solution dominated the structure and the diameter distribution of the electrospun nanofibers. Under stable electrospinning conditions, the composite membrane was produced by depositing PVA nanofibers on the polyethylene terephthalate (PET) nonwoven substrate for an air filtration test. Furthermore, the prepared composite membrane exhibited a high air filtration efficiency (99.97%) and a low pressure drop (120 Pa) for 300-500 nm neutralized polystyrene latex (PSL) aerosol particles, demonstrating its potential as an alternative for a variety of commercial applications in air filtration.

Key words:polyvinyl alcohol(PVA); nanofiber; stable electrospinning; air filtration; membrane

Introduction

With the growth of economy and global industrialization, air pollution has become a problem all over the world. Particulate matter (PM) is the main culprit of air pollution, causing haze in many areas and seriously threatening human health[1].Especially, PM1.0, the PM with a particle diameter less than 1.0 μm, can survive longer in the air and carry the virus into the blood system[2].

Most of the filter components used in the market are high-efficiency particulate air (HEPA)filters made by melt-blown microfibers. Although HEPA filters have a relatively high filtration efficiency, the air resistance will rise sharply with the increase of dust as the usage time increases, resulting in a large amount of energy consumption[3].Nanofibers can be used in filters for a better filtration effect due to their large specific surface areas, low densities, high porosity, easy binding with nanoscale active substances, low resistance, and so on[4-5]. There are many ways to prepare nanofibers, among which electrospinning is widely used for its simple operation, wide applications, good process controllability and relatively high production efficiency. It is a direct method to prepare polymer nanofibers[6].

At present, there is little discussion on stable and continuous electrospinning, and more attention is paid to the immediate changes brought by the specific factors in the laboratory, which has little guidance on actual production and continuous work. We believe that stable electrospinning is the primary principle to be met in actual production, and preparations and adjustments of fibers need to meet this basic principle.

In this paper, based on the principle of stable electrospinning, with the single needle electro spinning equipment, the applied voltage (hereafter referred to as voltage)and the injection rate as the easily adjustable variables are focused on. Their effects on the stable electrospinning are mainly studied.The polyvinyl alcohol(PVA) composite membranes with high efficiency for air filtration are obtained.

1 Experiments

1.1 Materials

PVA has many excellent physical and chemical properties, such as chemical resistance, good biocompatibility, high melting temperature, and nontoxicity. In addition, it has a good fiber-forming property, so it is selected as the research object. The PVA powder with an average relative molecular mass of 67 000, a polymerization degree of 1 700-1 800, and a hydrolysis degree of 87.0%-89.0% was purchased from Aladdin Chemical, Shanghai, China. Distilled water was made by a Millipore super pure water machine(RiOs30,USA). Conventional polyethylene terephthalate(PET) nonwoven substrate for air filtration was purchased from Shanghai Mingguan Purification Material Co., Ltd., Shanghai, China. All chemicals were of analytical grade and were used without further processing.

1.2 Fabrication of PVA nanofibers

The principle of stable electrospinning was proved by two different fiber structures, and the PVA mass fraction in the spinning solution was the most important parameter of the fiber structure and the spinnability.Generally speaking, the greater the difference in PVA mass fractions, the greater the difference in fiber structures. When the PVA mass fraction was less than 10%, the solution was not stretched into fibers but sprayed; when it was greater than 16%, the surface tension was too large to stretch into fibers. Therefore, the PVA solutions with mass fractions of 10% and 16% were used, and they were named S10 and S16, respectively.

The PVA solutions were prepared by dissolving the PVA powder in distilled water at 70 ℃ with continuous magnetic stirring for 3-4 h. Afterwards, composite solutions were kept overnight for air bubbles to vanish. Typically, the solution was loaded into the plastic syringe (50 mL) and pumped through the stainless steel needle with an inner diameter of 0.75 mm. The electrospun fibers were collected on the rotating dumb at a speed of 500 r/min. The gap distance between the needle tip and the collector electrode was fixed at 15 cm. The environmental temperature was about 30 ℃, while the relative humidity was below 65%. The voltage and the injection rate were chosen as the variables in this research. The fabrication process was performed in an electrospinning machine, provided by MTI Group Inc., USA, schematically depicted in Fig.1.

Fig. 1 Schematic diagram of electrospinning with PVA solution

To research the conditions of the stable electrospinning, different combinations of the voltage and the injection rate were adopted, and the electrospun fibers were directly deposited on aluminum foils. The details are exhibited in the following section.

For the air filtration test, S16 was employed to prepare the nanofiber membranes at a voltage of 17.9 kV and an injection rate of 10 μL/min. Five types of samples were obtained at different depositing time(10, 20, 30, 40, and 50 min). The nanofibers were deposited on PET nonwoven fabrics to form the membranes and then they were dried at 40 ℃ for 12 h.

1.3 Air filtration test

The air filtration performance of PVA nanofiber membranes was evaluated by the SX-L1053U filter efficiency test bench provided by Sothis Purification Equipment Factory, Suzhou, China. The device generated poly dispersed polystyrene latex (PSL) aerosols with a broad distribution of the geometric mean size (particles with the diameter no less than 0.3 μm occupied over 70% quantitatively). The neutralized PSL aerosol particles were fed into a membrane holder and passed through the membrane with an effective area of 100 cm2at an airflow rate of 32 L/min, so the face velocity in the test was 5.3 cm/s. In the filter test, the particle counting method was used to measure the filtration efficiency. The filtration resistance was measured with the combination of a flow meter and two electronic pressure transducers which detected the pressure drop during filtration.

2 Results and Discussion

2.1 Principle of stable processing

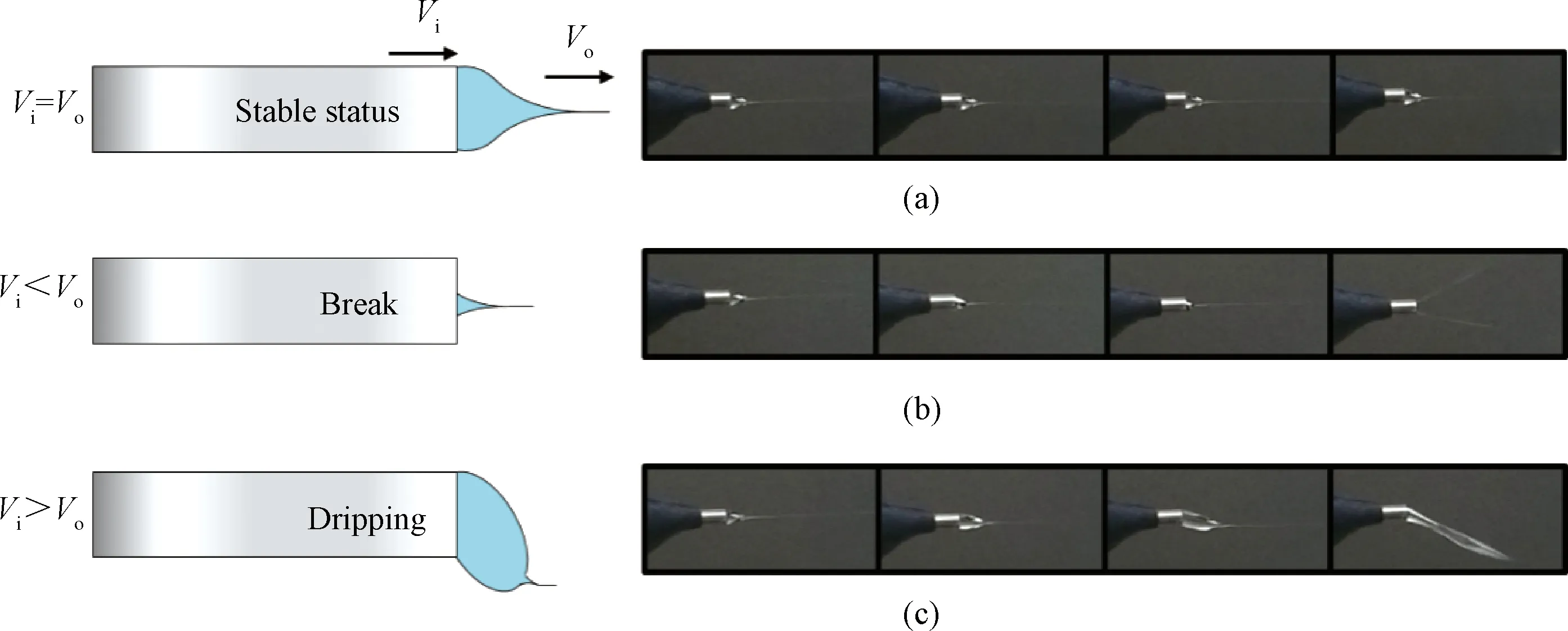

Normally, in continuous preparation of nanofibers by electrospinning, some cases would be frequently observed, such as stable status, break, and dripping, as shown in Fig.2. Break and dripping are not welcomed in electrospinning, which severely affect the morphology of the obtained nanofibers. By analyzing the forces on the droplet at the needle tip (droplet-NT), the mechanism of those phenomena could be figured out[7]. From a more comprehensive angle, an original mass flow matching model (MFMM) is established to help us analyze the status of the droplet-NT. In order to keep the stabilization of the droplet-NT, the masses of inflow and outflow should be dynamically balanced. The mass flow rates of inflow and outflow, and the mass difference are defined asVi,Vo, and Δm, respectively.

Vi=f(va,An),

(1)

Vo=f(E,D,κ),

(2)

Δm=Vit-Vot=f(va,An)t-f(E,D,κ)t,

(3)

(4)

wherevais the advance rate of the piston of the injection syringe;Anis the size of the needle;Eis the voltage;Dis the collecting distance between the needle tip and the rotating collector;κis a parameter of the spinning solution;tis the spinning time.

During the continuous electrospinning,ViandVoare unrelated to the time. Hence, ifViis equal toVo, the mass of the droplet-NT will keep consistent, which is perfect for nanofiber production by electrospinning, as presented in Fig. 2(a); ifViis persistently less thanVo, the droplet-NT will shrink until the fiber breaks and thus the spinning process is interrupted, as presented in Fig. 2(b); ifViis larger thanVo, the mass of the droplet-NT will gradually increase until the forces are out of balance, and thus the spinning process ends up in dripping, as presented in Fig. 2(c).

Fig. 2 States of droplet-NT during electrospinning: (a) stable status; (b) break; (c) dripping

The force balance of the droplet-NT is illustrated in Fig. 3. Three types of forces are defined: the surface tangential forceFt, the surface normal forceFn, and the vertical component of the volume forceFv[8].

Ft=Fe,t-Fη,t,

(5)

Fn=Fe,n-Fst-Fη,n,

(6)

Fv=f(Fc,FG,Fe,Fη),

(7)

whereFe,tandFe,nare the tangential and the normal electric field forces on the surface of the droplet-NT, respectively;Fη,tandFη,nare the tangential and the normal viscous forces on the surface of the droplet-NT, respectively;Fstis the hydrostatic pressure caused by surface tension;Fcis the capillary force;FGis the gravity;Feis the electric field force of the overall droplet-NT;Fηis the viscous force of the overall droplet-NT[9]. During electrospinning, the following scenarios could happen.

(1)IfFv>0,Ft>0, andFn<0, then the single jet happens.

(2)IfFv<0,Ft>0, andFn>0, then the multijet happens.

(3)IfFv>0, dripping happens.

Ftplays a key role in determining whether the jet happens or not; whileFnhas a vital influence on the numbers of jets. The essential requirement of the occurrence of dripping is thatFvremains greater than zero.

Fig. 3 Analysis of force balance of droplet-NT(the superscript refers to another state): (a) surface force; (b) volume force

Besides, the stable status is somewhat resistant to the disturbance on a small scale because the changes should accumulate to a certain extent before the equilibrium condition of the forces is thoroughly broken. During the experiments, it was observed that the shape of the droplet-NT accordingly and self-adaptively changed with increasing the mass of the droplet-NT as illustrated in Fig.3. Compared with the previous status, the capillary force and the viscous force changed to achieve a new force balance, resulting in a zero vertical component of the volume force.

It was noteworthy that the droplet-NT quickly recovered to its previous stable status as the disturbance vanished. The experimental result is exhibited in Fig.4 where the voltage is used as an interference factor. Under specific conditions, to realize the most stable electrospinning, the droplet-NT always tends to maintain a constant shape regardless of the voltage changing. The phenomenon might be explained by the lowest energy principle. That is , when the droplet-NT possesses the lowest potential energy, it becomes stable.

Fig. 4 Status of droplet-NT at different voltages

2.2 Voltage and injection rate

The structure and the morphology of nanofiber membranes are severely affected by the concentration of solutions used in electrospinning[10-13]. Figure 5 presents the scanning electron microscopy (SEM) images of the PVA nanofibers prepared from S10 and S16.

It is clearly visible that the nanofibers prepared from S10 exhibit an irregular bead-string structure, while the nanofibers prepared from S16 present a smooth fiber structure. The morphology of the nanofibers prepared from the same spinning solution does not change with voltages or injection rates, which demonstrats the reported opinion[3]that the morphology of the nanofibers is mainly determined by the concentration of the spinning solution. The detailed information is presented in Table 1.

Fig. 5 SEM images of PVA nanofibers prepared from S10 and S16 at different voltages and injection rates: (a) S10, 8.4 kV, 6 μL/min; (b) S10, 9.5 kV, 8 μL/min; (c) S10, 12.5 kV, 10 μL/min; (d) S10, 16.6 kV, 14 μL/min;(e) S16, 8.7 kV, 3 μL/min; (f) S16, 12.5 kV, 5 μL/min; (g) S16, 17.9 kV, 10 μL/min; (h) S16, 22.0 kV, 14 μL/min

Table 1 Detailed information on PVA nanofibers prepared under different conditions

More interestingly, besides the irregular bead-string structure, S10 with a lower PAV mass fraction also leads to a more heterogeneous distribution of nanofibers, because the charges might be less uniformly distributed along the spinning jet and this might potentially postpone the uniform stretching of the nanofiber. Polymer chains are more entangled at higher concentrations, which is helpful to produce broader and more even fibers.

It was reported that the fiber diameter increased with the increase in the injection rate[14-15]. This might be due to the reduced bending instability resulted from an increase in the volume and the initial radius of the electrospinning jet at a higher injection rate. Oppositely, increasing the voltage reduced the fiber diameter[16-17]. Because the thinning of the spinning jet was partly dependent on the stretching force, the stretching force relied on the charges on the spinning jet within the electric field. Interestingly, it was found that during the stable electrospinning, the different combinations of the voltage and the injection rate had little impact on the morphology of the nanofibers fabricated. A higher injection rate caused more solution to jet out, while a higher voltage caused more furcation of the nano fibers. The results revealed that the influence of the voltage on the nanofibers was opposite to that of the injection rate, and their influences were exactly canceled out. However, the stacking density of the nanofibers was affected indeed. With the increase of the voltage and the injection rate, the stacking density of the nanofibers increased, as more solution was jetted out and more nanofibers were deposited on the collector. It should be noted that the adjusting range of the voltage in the stable electrospinning is limited. It is easy to understand that the voltage cannot be too high or too low. The critical voltage is the minimum voltage to motivate the jet. With the voltage going up, the instability of the electrospinning jet was gradually worsened, resulting in the undesired multijet. The voltages for stable electrospinning changed from 8.4 kV to 16.6 kV for S10 and 8.7 kV to 22.0 kV for S16(Table 1). It could be seen that the solution with a higher PVA mass fraction matched a higher voltage at the same injection rate for steadily fabricating nanofibers. Based on previous observations, it is recommended to change the specific equipment setting and other processing parameters to steadily acquire nanofibers with different morphologies.

2.3 Production and application

Nanofiber membranes with high air filtration efficiency and low air pressure drops are promising candidates for air filtration.

As mentioned in the above section, S16 was chosen for producing nanofiber membranes supported by a nonwoven PET substrate. The voltage and the injection rate are 17.9 kV and 10 μL/min, respectively. PSL aerosol particles were intercepted after filtration as presented in Fig.6 (a).

The quality factorQFis obtained on the basis of the filtration efficiencyγand the pressure drop ΔPacross the membranes. For a comprehensive understanding of the relative overall filtration performance,QFshould be taken into consideration.QFis the independent of the area density and is defined as[19]

(8)

From this empirical correlation, it can be obviously seen that a higherQFrequires a higher filtration efficiency and/or a lower pressure drop. Figure 6 (d) reveals thatQFdecreases monotonically from 0.083 Pa-1to 0.062 Pa-1as the area density increases from 0.53 g/m2to 2.91 g/m2. To improve the filtration efficiency by increasing the area density, a higher cost of the pressure drop should be paid, which leads to the monotonous decline ofQF. Hence, it is recommended to try other methods rather than merely increasing the area density to improve the overall filtration performance. The conclusion could also be verified by the change trends of the filtration efficiency and the pressure drop along with the change of the area density. The filtration performance of these composite membranes surpassed that of many commercial filters or reported ones[20-22]. Evidently, the composite membranes can be applied as the core filter medium in the air filtration field, such as the air cleaner, the cabin air filter, and the central ventilation system.

Fig. 6 Filtration results of PVA nanofiber membranes from S16: (a) SEM image after filtration; (b) relationship between depositing time and area density; (c) filtration efficiency and pressure drop with different area densities; (d) quality factor with different area densities

3 Conclusions

In summary, we put forward a stable electrospinning model, studied the stable electrospinning state, and explained the principle by using the basic mathematical analysis and force analysis. The voltage and the injection rate were selected as variable groups, and the influences of PVA spinning solutions with different mass fractions on the morphology of nanofibers in a stable state were studied. At last, based on the stable electrospinning principle and parameters, the PVA nanofiber membranes were prepared and used for the air filtration. The prepared composite membranes showed an excellent performance with a high filtration efficiency (99.97%) and a low pressure drop (120 Pa).

Journal of Donghua University(English Edition)2023年2期

Journal of Donghua University(English Edition)2023年2期

- Journal of Donghua University(English Edition)的其它文章

- Online Fault Detection Configuration on Equipment Side of a Variable-Air-Volume Air Handling Unit

- Exact Graph Pattern Matching: Applications, Progress and Prospects

- A Class of Simple Modules for Electrical Lie Algebra of Type D5

- Modified Cepstral Feature for Speech Anti-spoofing

- Data-Driven Model for Risk Assessment of Cable Fire in Utility Tunnels Using Evidential Reasoning Approach

- Fine-Grained Sleep Apnea Detection Method from Multichannel Ballistocardiogram Using Convolution Neural Network