Drop impact on substrates with heterogeneous stiffness

Yang Cheng(成陽) Jian-Gen Zheng(鄭建艮) Chen Yang(楊晨)Song-Lei Yuan(袁松雷) Guo Chen(陳果) and Li-Yu Liu(劉靂宇)

1Chongqing Key Laboratory of Soft Condensed Matter Physics and Smart Materials,College of Physics,

Chongqing University,Chongqing 400044,China

2School of Optoelectronic Engineering,Chongqing University of Posts and Telecommunications,Chongqing 400065,China

Keywords: drop impact,stiffness-patterned substrate,splash

1. Introduction

Drop impact often occurs in daily life. When a drop hits a solid substrate, depending on impact condition, the drop can exhibit different behaviors such as spreading,[1–3]bouncing,[4–6]or splashing.[7–9]The impact of drops has been actively studied in the last decade and is of great significance in areas such as printing,[10,11]agriculture,[12]and forensic medicine.[13]

Extensive studies have been performed to control the impact behavior of a drop by optimizing the droplet properties,[14]including, but not limited to, droplet composition,[15,16]droplet shape,[17,18]and liquid properties of drops.[19]For instance, Liu and Tran demonstrated that a compound droplet consisting of water and silicone oil exhibits a transition from spreading to splashing by varying the volumetric oil ratio in the droplet.[15]Some other research groups attempted to investigate drop impact by changing the environment conditions.[20–22]Xuet al.observed a striking phenomenon, whereby splashing can be completely suppressed by reducing the pressure of the surrounding gas.[21]Of all the approaches, changing the surface properties of substrates is usually used most and is the most efficient in regulating drop impact in practical applications.[23–26]For example, Liet al.showed that the translational motion of an impacting droplet can be converted into gyration, with a maximum gyratory speed exceeding 7300 gyrations per min, through heterogeneous surface wettability regulations.[25]In addition to the surface hydrophobicity, a recent study revealed that the substrate stiffness can also play an important role in drop impact by changing the splashing threshold.[27]In their work, Howlandet al. released ethanol droplets onto uniform silicone or acrylic substrates with stiffness varying from 5 kPa to 500 kPa,and they showed that droplets on the softest substrates require over 70% more kinetic energy to splash than on rigid substrates. Inspired by this work, we proposed that a substrate composed of the same material, but distributed with different stiffness (heterogeneous stiffness) regions, would likely experience a splashing behavior of the drop, which behavior is different from what happens to a substrate with uniform stiffness.

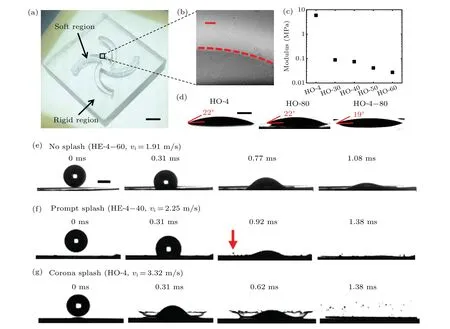

In this study, we introduce a simple preparation scheme for substrates with heterogeneous stiffness, and successfully produce a group of stiffness-patterned substrates consisting of soft spirals surrounded by a rigid region as shown in Fig.1(a).The design of this spiral heterogeneous structure was also inspired by the work of Liet al.[25]The scanning electron microscope(SEM)image in Fig.1(b)demonstrates that the surface is flat and smooth. The red dashed line points to the boundary between the soft region and the rigid region, and no gap can be observed in between. An ethanol drop with a diameter of 2.00 mm±0.10 mm(R=1 mm)subsequently impacts one of these substrates and its splash behavior is studied. We find that the splash of a drop on a heterogeneous substrate exhibits significantly different characteristics from those on a homogeneous substrate,The critical impact velocity for prompt splash is the smallest on substrate with the greatest heterogeneity of stiffness. Moreover, the splash intensity of droplets on the heterogeneous substrate is generally much stronger than that on the corresponding homogeneous substrates, which is reflected in its higher splash velocity,especially at a higher impact velocity.The difference in drop splashing between homogeneous substrate and heterogeneous substrate is largely due to the stiffness heterogeneity of the substrate, rather than the variation of overall stiffness. The use of spiral shape provides a feasible solution for introducing stiffness heterogeneity of substrate. Our study enriches the understanding of drop impact on complex substrates, may provide some guidance on drop splash optimization based on substrate design, and can find useful applications in industries related to drop impact.

2. Experimental methods

To achieve different stiffnesses,the polydimethylsiloxane(PDMS) prepolymer and crosslinker were mixed with different mass fractions, and cured for 12 h at 70?C. The specific mass ratios of prepolymer to crosslinker were 4:1,30:1,40:1,50:1, 60:1, and 80:1, and the corresponding substrates were named HO-4,HO-30,HO-40,HO-50,HO-60,and HO-80,respectively.

Fig. 1. (a) Picture of the stiffness-patterned substrates consisting of soft spirals surrounded by a rigid region. The scale bar is 1 mm. (b) SEM-view image showing that the surface is flat and smooth. The red dashed line points to the boundary between the soft region and the rigid region, and no gap can be observed in between. The scale bar is 250μm. (c)Modulus results of the homogeneous substrates. (d)Contact angles of ethanol drop on two homogeneous substrates(HO-4 and HO-80),and one heterogeneous substrate(HE-4–80). The scale bar is 1 mm. (e)Side-view snapshots of drop impact on heterogeneous substrate HE-4–60,and no splash is observed at an impact velocity of 1.91 m/s;the scale bar is 1 mm. (f)Side-view snapshots of drop impact on heterogeneous substrate HE-4–40,and prompt splash occurs when the impact velocity is 2.25 m/s.The red arrow points to the emitted droplet. (g)Side-view snapshots of drop impact on homogeneous substrate HO-4,and corona splash occurs at an impact velocity of 3.32 m/s.

The stiffness of the substrate was characterized by measuring its modulus with dynamic thermomechanical analyzer(DMAQ850,TA Instruments,USA),and the results are shown in Fig. 1(c). When the mass ratio of the crosslinker is lower,the modulus decreases accordingly, and even reaches a difference of two orders of magnitude. The HO-4 has a significantly larger modulus than that of the other four substrates and was therefore selected as the rigid part of the heterogeneous substrate. Spiral patterns were carved into the HO-4 substrate with a laser engraver,which were subsequently filled with the uncured PDMS mixture of a lower crosslinker mass ratio (40:1, 60:1, and 80:1). The substrates of heterogeneous stiffness were then obtained after curing for 12 h at 70 °C.The corresponding heterogeneous substrates were named HE-4–40,HE-4–60,and HE-4–80,respectively. For instance,the HE-4–40 represents the mass ratios of the PDMS prepolymer to crosslinker for the rigid and soft region of the heterogenous substrate are 4:1 and 40:1,respectively.

The liquid used in the experiment was ethanol, and the ambient temperature was 28?C.The densityρ,surface tensionγ,and viscosityμof ethanol at this temperature are 789 kg/m3,22.1 mN/m, and 1.2 mPa·s, respectively. Figure 1(d) shows the wettability of ethanol drop on two homogeneous substrates(HO-4 and HO-80), and one heterogeneous substrate (HE-4–80). The similar contact angle data demonstrate that there is no significant difference in the alcohol wettability between all soft substrates and rigid substrates. In the drop impact experiment,the drops were released through a needle connected to an injection pump (Longer Pump LSP01-2A, China). When the drops fell freely from different heights above the substrate,the impact velocity varied from 0.80 m/s to 3.32 m/s. The instant impact of millimeter-sized ethanol drops was directly visualized with a fast camera(Phantom V7.3),at a frame rate of 6500 s?1, and the exposure time of image was 50 μs. In order to make sure that our results are generally valid,the experiments with identical conditions were repeated at least three times to ensure the repeatability and accuracy of the results.

3. Results and discussion

Three kinds of impact phenomena are identified under different values of impact velocity(vi). When the impact velocityviis low,the drop spreads rapidly along the substrate to reach its maximum spreading distance, and then stops after a slight retraction.No splash occurs in this situation as shown by the side-view snapshots of drop impact on heterogeneous substrate HE-4–60 at an impact velocity of 1.91 m/s in Fig.1(e).However, when the impact velocity increases to more than a certain value, the drop exhibits splash which can be split into two categories,prompt and corona. In the prompt splash regime,the droplets are ejected from small finger-like jets directly at the surface[28]as shown by the side-view snapshots of drop impact on heterogeneous substrate HE-4–40 at an impact velocity of 2.25 m/s in Fig. 1(f). The red arrow points to the ejected droplets. In the corona splash regime, the spreading liquid separates from the surface,forming a crown-like lamella that subsequently breaks up into secondary droplets[28]as illustrated by the side-view snapshots of drop impact on homogeneous substrate HO-4 at an impact velocity of 3.32 m/s in Fig.1(g). Compared with prompt splash,corona splash occurs under the condition of higher impact velocity. We also notice that the drop splashing on our stiffness-patterned substrate is still axisymmetric in experiment. This is not in discrepancy with the results of Liet al.’s work,[25]because the rotation of the droplet bouncing found by Liet al. is caused by the asymmetric surface wettability on its spiral structure,whereas in this work, the drop wettability exhibits no significant difference on surfaces with different stiffness as demonstrated by the contact angle characterization in Fig.1(d).

Fig.2. (a)Splashing behavior of ethanol drops on all substrates at different impact velocities of the drop. The black crosses, red stars, and blue circus represent no splash,prompt splash,and corona splash,respectively. (b)Different splash behaviors on HE-4–80 and HO-4 substrates at the same impact velocity. The red arrow points to the emitted droplet. The scale bar is 1 mm.(c)Estimated percentage of drop energy remaining after impact and spreading on homogeneous and heterogeneous substrates at an impact velocity of 0.80 m/s. The remaining energy of a drop on the substrate with the largest stiffness heterogeneity (HE-4–80) is clearly higher than that on the other substrates.

All splash results are summarized in Fig. 2(a). At a low impact velocity,no splash of the ethanol drop appears on any of the seven substrates. The critical impact velocity at which splash starts to occur becomes different on different substrates.By comparing the splash results of HO-4,HO-40,HO-60,and HO-80, it is found that for a homogeneous substrate, the impact velocity required for splash is smaller if the substrate is more rigid. This conclusion is qualitatively consistent with a previous study.[27]Specifically,when the impact velocity is 2.25 m/s,prompt splash already occurs on HO-4 and HO-40,but no splash is observed on HO-60 and HO-80. It should also be noted that the splash intensity of a drop on HO-4 is much stronger than that on other homogenous surfaces at the same impact velocity, which is reflected in a larger splash amount and higher splash velocity. Similarly,corona splash is also the first to be found on HO-4 and HO-40,when the impact velocity reaches 3.32 m/s.

A noticeable phenomenon occurs on the heterogeneous substrate HE-4–80, which has the greatest heterogeneity of stiffness. When the impact velocity is 1.91 m/s,prompt splash starts to appear on HE-4–80,but no splash is observed on other substrates,even on the most rigid homogeneous substrate HO-4 as demonstrated in Fig. 2(b). Hence, we attempt to understand this phenomenon from the perspective of energy dissipation. The energy of a drop just before touching the substrate includes kinetic energy and surface energy, which can be expressed asWi=2πR3ρv2i/3+4πR2γ. The gravitational potential energy of the drop before the contact can be ignored since it has already been converted into the kinetic energy of the drop(2πR3ρv2i/3). Some energy is dissipated during impact and spreading, and this part of energy is converted into the interfacial energy between the drop and the substrate, the elastic energy of the substrate, heat energy,etc. The dissipated energy is not easy to calculate straightforward, but can be estimated by calculating the surface energy of the drop at its maximum spreading radiusRmax. At this point,the kinetic energy of the drop is approximately zero, and its surface energy approximately equals 2γπR2max.By comparing the energy differences of the drop itself between these two moments,we can analyze how much energy the drop dissipates through the substrate during the impact process. We measure the percentage of energy remaining after impacting and spreading at an impact velocity of 0.8 m/s, since there is no need to consider the energy taken away by the ejected micro-droplets at this sufficiently low impact velocity, and the results are shown in Fig. 2(c). Although the energy dissipations on all substrates vary by only a few percent,it can still be found that the remaining energy of the drop on HE-4–80 is the highest, indicating that the drop has the smallest energy dissipation on HE-4–80.Therefore,this slight advantage of energy dissipation may be the reason why the prompt splash first occurs on HE-4–80.Liquid drops are more prone to splashing on a stiff heterogeneous substrate than on a homogeneous one. This finding may provide guidance for the optimization of drop splash based on structural design.

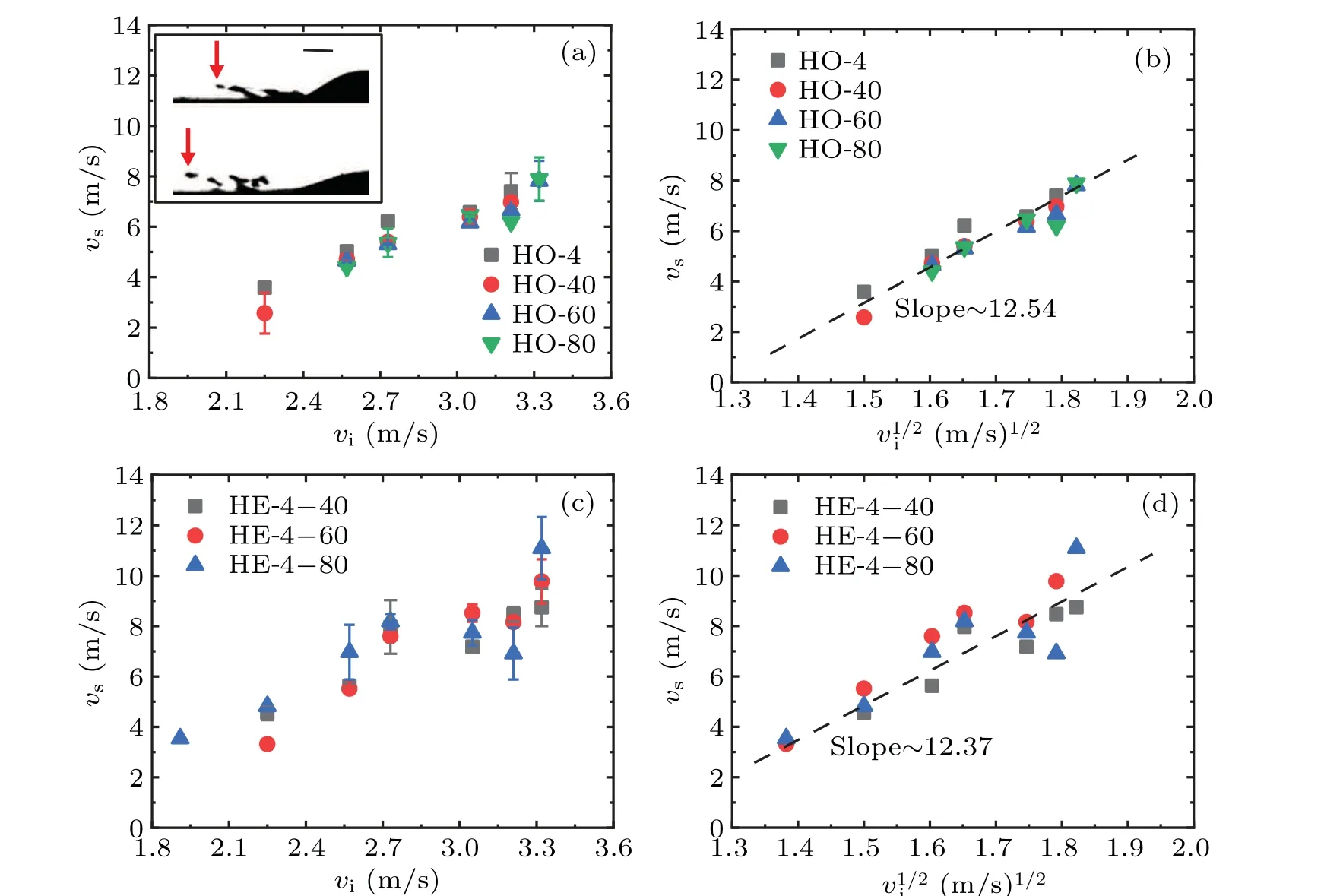

Fig. 3. (a) Variations of splash velocity of ejected droplets (vs) versus impact velocity (vi) on homogeneous substrates. The inset shows two images at adjacent moments (time interval is 0.15 ms), and the red arrows point to the outermost edges of the elliptic secondary droplet that has just been splashed out. The scale bar is 1 mm. (b)Plots of vs versus v1/2i for homogeneous substrates,showing a good linear relationship with a slope of 12.54.(c) Variations of splash velocity of the ejected droplets (vs) with impact velocity (vi) on stiffness-patterned substrates. (d) Plot of vs versus v1/2i on heterogeneous substrates. All data fit well a straight line with a slope of 12.37.

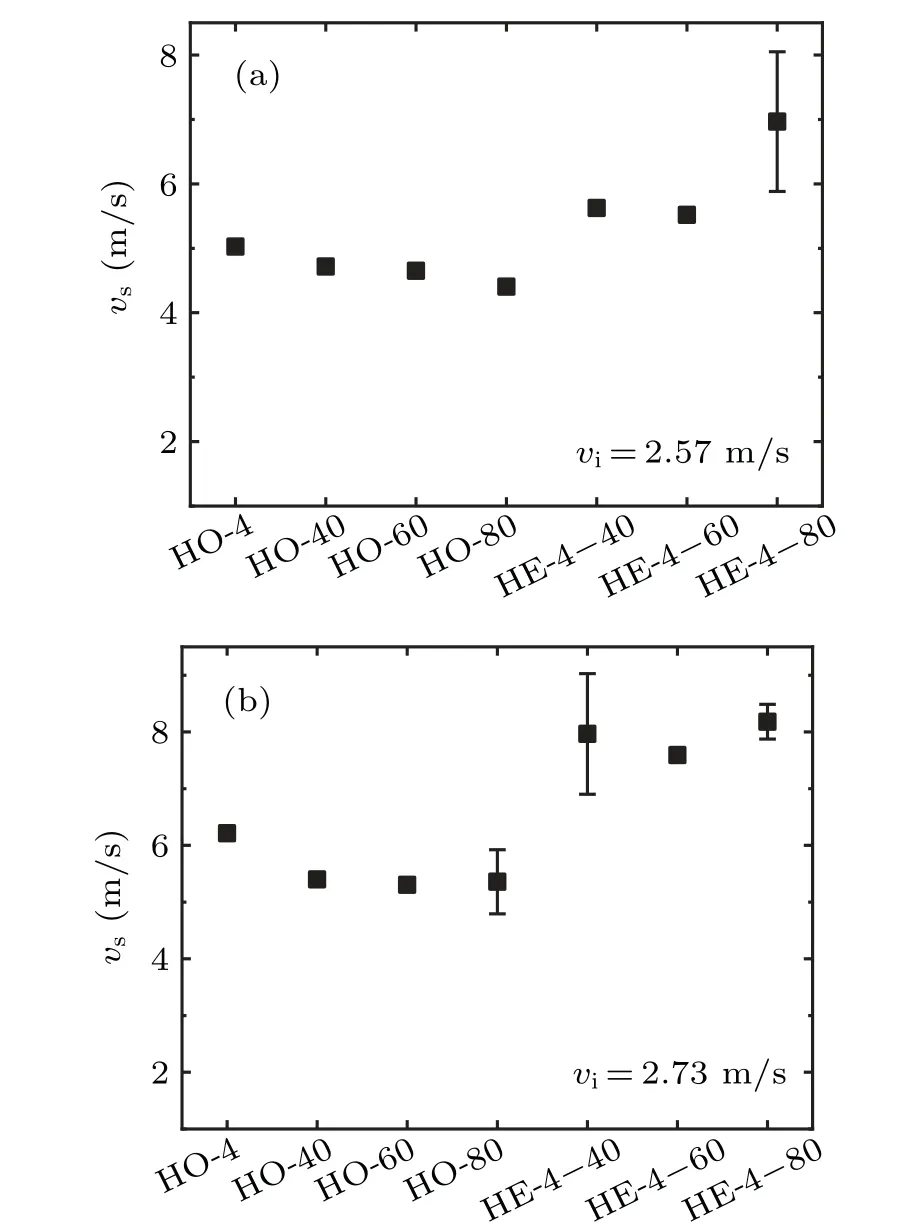

Although there is no essential difference between the underlying physical connotations of drop splash on homogeneous substrate and heterogeneous substrate,the splash intensity of a drop on heterogeneous substrate is significantly enhanced. To clarify this conclusion,we study the splash velocities of droplets on different substrates under the same impact velocity of drop. Figures 4(a)and 4(b)show the splash velocities of droplets at impact velocities of 2.57 m/s and 2.73 m/s,respectively. The splash intensity of drop on heterogeneous surface is generally higher than that on homogeneous surface, which cannot be explained simply by the difference in overall stiffness. We attribute this difference to the stiffness heterogeneity of the substrate. For a drop hitting a homogeneous substrate, the splash velocity of the emitted droplets is reduced with stiffness decreasing. This finding is consistent with the previous conclusion that the splash is reduced on soft substrate.[27]

Fig.4. Splash velocities of ejected droplets on all homogeneous and heterogeneous substrates at impact velocities of(a)2.57 m/s and(b)2.73 m/s,respectively. The splash velocity of droplets on stiffness-patterned substrates is significantly higher than that on their corresponding homogeneous substrates.

A more interesting result occurs on heterogeneous substrate. When a drop impacts a heterogeneous substrate composed of the same material,the splash velocity of ejected tiny droplet is unexpectedly higher than those on the two corresponding homogeneous substrates. For instance, when the impact velocity of a drop is 2.57 m/s, the splash velocity of droplet on HE-4–40 is approximately 12%higher than that on HO-4 and 19%higher than that on HO-40,respectively. This ratio increases to about 28%and 47%,respectively,at an impact velocity of 2.73 m/s. This finding suggests that although a softer substrate can reduce drop splash,a heterogeneous substrate consisting of two types of stiffness can significantly promote splash. This phenomenon can be comprehended through the results in Fig.2(c). As previously mentioned,the remaining energy of an impacting drop on a heterogeneous substrate is clearly higher than that on a homogeneous substrate,which means that the drop experiences less resistance when it spreads on a heterogeneous substrate. This may be the reason for the higher splash intensity of droplet on the heterogeneous substrate. Our work reveals the potential of using stiffnesspatterned substrates to control splash and may provide a guide for drop splash optimization based on substrate design.

4. Conclusions

In summary, we conceive and produce a group of stiffness-patterned substrates consisting of soft spirals surrounded by a rigid region. Millimeter-sized ethanol drops impact these stiff heterogeneous substrates and their splash behaviors on the substrates are studied. We find that the splash behavior of a drop on the heterogeneous substrate exhibits distinct characteristics from that on a homogeneous substrate.Prompt splash is more likely to appear on a substrate with a greater heterogeneity of stiffness, which is reflected at the lower critical impact velocity. Moreover, the splash velocity of emitted droplet is significantly larger on the heterogeneous substrate than that on the corresponding homogeneous substrate, especially at a higher impact velocity of drop, indicating the stronger splash intensity on heterogeneous substrate.The difference between drop splashing behaviors for homogeneous substrate and heterogeneous substrate is largely due to the stiffness heterogeneity of the substrate,rather than the difference of overall stiffness. The use of spiral shape provides a feasible solution for introducing stiffness heterogeneity of substrate.Our study generalizes the understanding of drop impact on homogeneous substrate to the case on heterogeneous substrate, reveals the potential of using stiffness-patterned substrates to control splash, and may find useful applications in industries related to drop impact.

Acknowledgements

The authors would like to thank the Analytical and Testing Center of Chongqing University for characterizing the samples.

Project supported by the Natural Science Foundation Project of Chongqing, China (Grant No. CSTC2020jcyjmsxmX0106) and the Fundamental Research Funds for the Central Universities,China(Grant No.2020CDJ-LHSS-002).

- Chinese Physics B的其它文章

- Magnetic properties of oxides and silicon single crystals

- Non-universal Fermi polaron in quasi two-dimensional quantum gases

- Purification in entanglement distribution with deep quantum neural network

- New insight into the mechanism of DNA polymerase I revealed by single-molecule FRET studies of Klenow fragment

- A 4×4 metal-semiconductor-metal rectangular deep-ultraviolet detector array of Ga2O3 photoconductor with high photo response

- Wake-up effect in Hf0.4Zr0.6O2 ferroelectric thin-film capacitors under a cycling electric field