Chromatic variability of larch wood impacted by high-temperature thermal treatment and oil-wax coating

ZHANG Jingyuan, CHESNOKOVA Tatiana, ZHANG Baoyuan, ZHAN Jianfeng

(College of Material Science and Engineering, Northeast Forestry University, Harbin 150040, China)

Abstract: In terms of aesthetical perception, color is one of the most fundamental physical properties of wood materials, and surface color differences have decisive influences over the customer’s acceptance of solid wood products. This study investigated the effect of thermal treatment and surface oil-wax coating on the chromatic variability of larch wood. Green larch lumber samples were kiln-dried with conventional technology and further high-temperature thermally treated in atmospheric superheated steam conditions. Subsequently, the larch samples were surface-painted with the transparent oil-wax coating, and the colorimetric variables of the earlywood and latewood of specified larch samples were further determined separately by a specially designed image colorimetry method. The colorimetric variable differences between the earlywood and latewood were calculated, aiming at quantitatively analyzing the chromatic variability of larch earlywood and latewood in specified cases. Comparing with the kiln-dried samples, under the circumstance of N2 oil-wax coating option and thermal treatment at 180 ℃ for 1 h, the saturation variable difference ΔS* between the earlywood and latewood increased by 60.8%, while the general colorimetric variable difference ΔE* remained at the same magnitude level. The variability mechanism behind the chromatic alterations of larch samples, induced by the combination of thermal treatment and surface oil-wax coating, was proposed as the interaction between the existing chromogen groups and the newly emerging ones brought about by these technical processes. Due to the inhomogeneous distribution of resin contents inside each annual ring, the latewood tissue, which contains more resin canals than the earlywood, could act as the diffusion barrier for the oil-wax compound and postpone the penetration of plant oils. In the light of this circumstance, the disrupt distribution behaviors of larch resins partially contributed to the chromatic variabilities between these two types of wood tissues. The test results demonstrated that a proper combination of thermal treatment and oil-wax coating could be used for improving softwood colorimetric properties, enhancing the surface characteristics of larch wood, promoting it as a sustainable alternative wood resource.

Keywords:chromatic variability; wood kiln-drying; larch; oil-wax coating; thermal treatment

1 Introduction

For a specified softwood species, the desired appearance of its solid wood products is mainly determined by anatomical characteristics (referring mainly to earlywood (EW)-latewood (LW) density difference, and how abruptly density changes along the EW-LW boundary), moisture content (MC), extractives and resins, and manufacturing processes[1]. From the perspective of the aesthetic appreciation, for the ordinary customers, the wood color and texture would have the most fundamental impact on how to choose the favorable finishes of final products[2-3]. Furthermore, an appropriate chromatic variability among the EW-LW band, or proper differences in color between the sapwood and heartwood, would provide additional influences on each individual’s perception of the wooden decoration materials.

Larch (Larixgmelinii) is a widely distributed plantation softwood species in northeastern regions of China, with abrupt-transition annual rings, a relative higher density (around 600 kg/m3) and mechanical properties, mainly suitable for construction materials[4]. A large number of studies concerning larch wood utilization have been carried out, mainly focusing on drying technologies, preservation approaches, finishing characteristics and weathering capacities[5-8]. Some studies showed that there are persistent difficulties related to wood processing and applications of this species[9]. Recently, high-temperature thermal treatment has been proved as a potentially efficient approach for altering some of the unfavorable properties of softwood lumber[10-15]. According to some researchers, from the aesthetic point of view, thermal treatment could be utilized to improve the chromatic properties of softwood lumber, such as improving the wood value for high-quality applications[16], imitating high-priced tropical wood color, making the treated wood more appealing to furniture markets than the original one[17], and enhancing the color homogenization of timber products[18].

Nevertheless,given that larch wood presents a harsh transition between EW-LW bands (concerning density, color and resin content), and a distinctive color difference between sapwood and heartwood, the resulting variability of the surface color and annual ring distributions were still challenging disadvantages that limited the utilization of thermal treatment in wood industry. Schnabel et al.[19]investigated the discoloration of weathered larch lumbers at different locations, and proposed a model which could be used for estimating color changes of larch in exterior applications. Forsthuber et al.[7]tried to utilize a calibrated photo-scanning colorimetry to evaluate the discoloration of EW and LW of Siberian larch (Larixsibirica) and its transparent coatings. Under their analysis approaches, there was a higher amount of discoloration in the EW band, and it was possible to evaluate the colorimetric changes by coating for EW and LW separately. In order to reduce the surface color variability of thermally treated blue gum wood (Eucalyptusglobulus), an enlightening method consisting of color pre-grading and homogeneity thermal treatment was proposed by Griebeler et al.[18]. This method could potentially be utilized to reduce the surface color variability of blue gum wood and enhance the exploitation of low-quality wood.

Natural plant oil-wax belongs to a kind of penetration-type, and transparent coating, which is formulated from healthy and eco-friendly raw materials, including dry oils (such as linseed oil), wax, resins and additives, with protection-decoration dual effectiveness for wooden products[8]. Plant oil-wax finishing is often used for wooden buildings, forest recreation facilities, and high-quality furniture for retaining a visible wood texture with easy maintenance[20]. Using these oil-wax paints, the color change and grain transition of treated wood could be mitigated, especially for pigmented ones[21].

This study aimed at investigating the chromatic variability of larch lumber impacted by high-temperature thermal treatment and oil-wax transparent coating. Larch lumber samples were kiln-dried using conventional technology and thereafter thermally treated in atmospheric superheated steam conditions, respectively. Furthermore, these kiln-dried and thermally treated larch samples were pre-sanded and surface-coated with the specified natural oil-wax paints. In order to obtain a thorough and panoramic view of the chromatic changes of larch samples, a specially designed image colorimetric approach was utilized to measure, calculate, and analyze the color variables of the EW and LW bands of larch lumber separately. A reusable two-way analysis of variance (ANOVA) test was carried out to reveal the significance of the thermal treatment and oil-wax coating over the specified color variables of larch wood samples.

2 Materials and methods

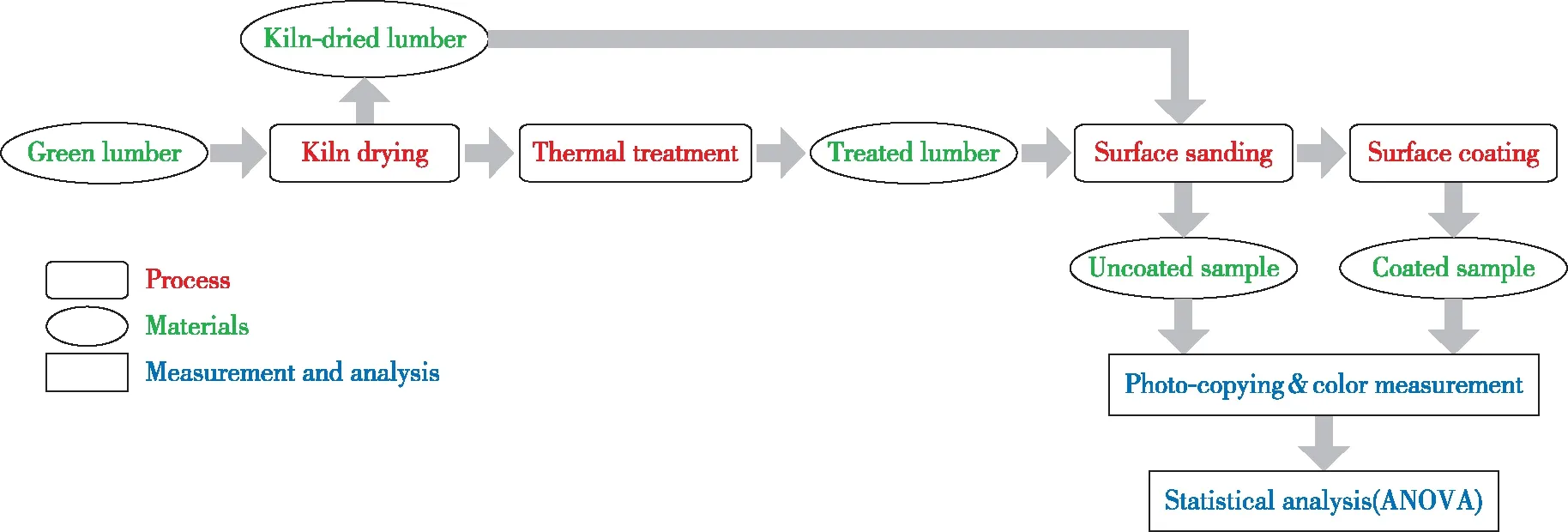

The technical route of the experimental setup is presented in Fig. 1.

Fig. 1 Workflow route of the overall experiment

2.1 Materials

In this test, four green larch (Larixgmelinii) lumber samples, which were cut from one tree trunk obtained from Hegang region, Heilongjiang Province (northeast China), were chosen as the raw materials, with original dimensions of 4 000(L) mm×250(T) mm, average basic density of 600 kg/m3(standard deviation of 35 kg/m3) and average green moisture content of 70% (standard deviation of ±2.5%). These lumber samples were further planned and cut into flat-sawn lumber specimens (with a dimension of 600(L) mm×250(T) mm×45(R) mm), without big knots, severe discolorations and other visual defects. For each type of coating test, there were 4×6=24 coated samples. A total of 288 larch samples [60(L) mm×60(T) mm×40(R) mm] were used for 4×3=12 groups of drying-thermal treatment-coating experiments. The labels “L”, “T”and“R” refer to the longitudinal, tangential and radial directions, respectively.

2.2 Kiln drying

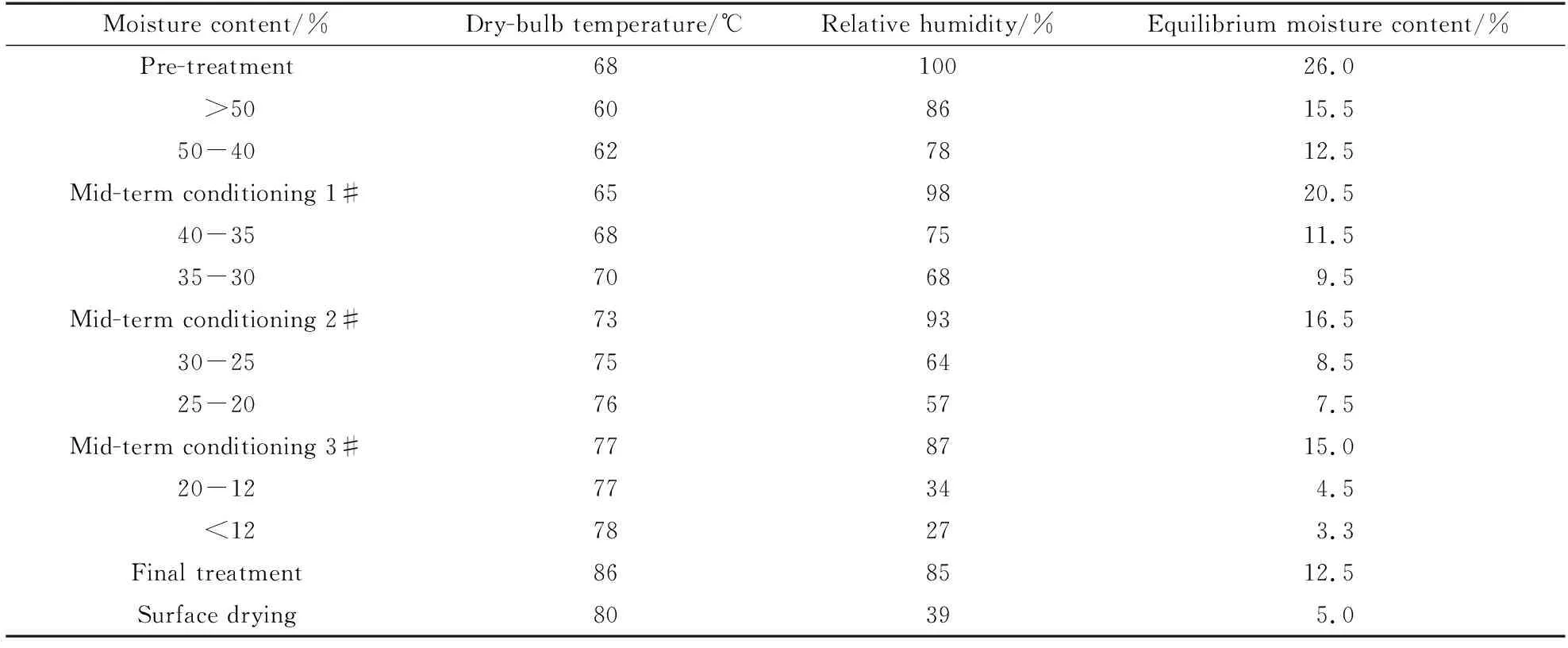

Conventional kiln-drying tests were carried out in an environmental test chamber (Xinda Test Equipment Co., LTD, HS-240). The detailed technical parameters of the drying schedule are listed in Table 1. It took 275 h for the 45 mm thick lumber specimens to be dried to a targeted average moisture content of 10.0%. After the conventional drying, the comprehensive drying quality of all lumber samples was evaluated based on the China national standard (Drying quality of sawn timber, GB/T 6491—2012). According to this analysis, a second-grade quality was achieved for all the kiln-dried lumber samples and the average moisture content of larch lumbers was (10.2±0.2)%.

Table 1 Drying schedule of larch lumber

2.3 High-temperature thermal treatment

Upon the completion of the drying test, all the kiln-dried specimens were taken out of the chamber and the moisture content of each sample was calculated accordingly. Three-quarters of these specimens were then chosen for the thermal treatment test and the remaining one-quarter as the control specimens for the kiln-drying test. Altogether, three thermal treatment tests were performed in the same chamber for the drying test, each with one-quarter of the kiln-dried lumbers.

The detailed procedures of the thermal post-treatment consist of the following stages: 1)Preheated to 103 ℃ for 2 h; 2)Maintained at (103±2) ℃ for 4 h; 3)Heated to 120 ℃ for 0.5 h; 4)Heated to the final treatment temperature for 2 h; 5)Maintained at the final treatment temperature for 1 h; 6)Cooled down to under 80 ℃ for 8 h. The final treatment temperature was chosen as 160 ℃ (T1), 180 ℃ (T2) and 200 ℃ (T3), respectively. The kiln-drying case was denoted as “T0”. During the stage 3-5, the atmospheric overheated steam was injected into the chamber as the protecting medium for the lumber heat treatment.

2.4 Natural oil-wax painting test

Among the above-mentioned larch lumber, including both kiln-dried control specimens and thermally treated ones, two-third samples of which were selected as the oil-wax coating samples, and the remaining one-third as uncoated control ones. All the larch specimens were firstly planned and cut into the required dimension of the coated samples [600(L) mm×60(T) mm×40(R) mm]. Since the bound moisture inside wooden materials could act as auxochromic groups (—OH stretching), in order to counteract this impact on the colorimetric variables and also to release residue stresses, all larch samples were then conditioned for two months in a conditioning chamber (Xinda Test Equipment Co., LTD, GDS-150) at 25 ℃ and 55% RH to constant weight. The average moisture contents of the four types of specimens, namely, kiln-dried, 160 ℃, 180 ℃, 200 ℃ treated ones, were 9.7%, 8.5%, 7.4% and 6.2%, respectively.

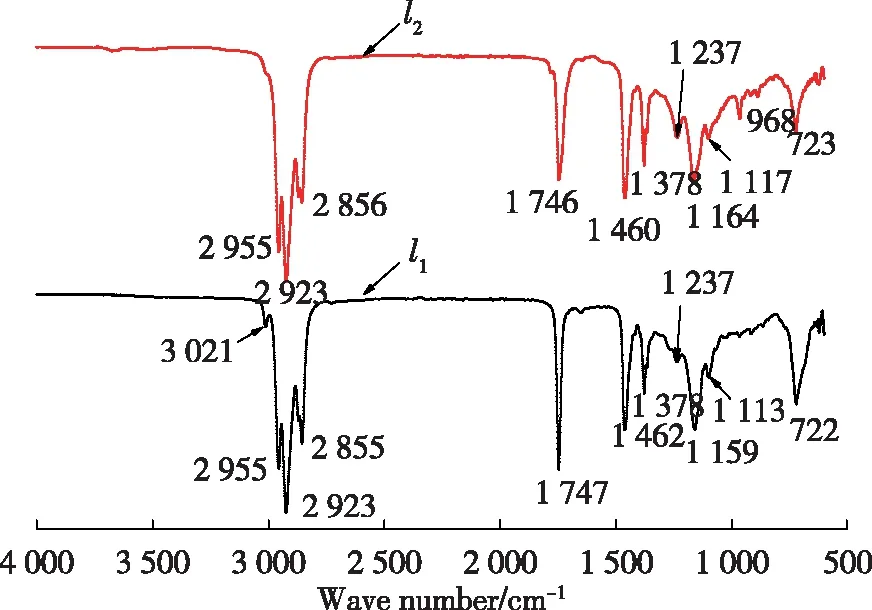

Two kinds of finishes, namely, livos-261(l1) and livos-244-002(l2), were selected as the oil-wax paint for the larch samples. These oil-wax products were commercially available and prepared mainly from linseed oil, natural resin, and drying agents. The oil-wax coating tests were divided into three groups, namely, Group N0 (without oil-wax coating), Group N1 (oil-wax coating withl1), and Group N2 (oil-wax coating withl1andl2), respectively.

Two types of transparent coatings, namely, N1 and N2, were applied. For instance, in the case of N1, the coating sample was firstly sanded with sanding paper with a grain size of 200# followed by 400# for all of its six faces. Subsequently, the surface-sanded samples were painted with oill1manually in one layer with an oil brush according to manufacturer’s guideline[8]. As for the operation procedure of N2, two layers of clear oil-wax coatings were applied. Firstly, an identical process, the same one as that ofl1, was performed. After a drying period of at least 24 h at 25 ℃/55% relative humidity, the second and top coating layer was applied manually on the corresponding coated faces with oill2. On the completion of the finishing tests of N1 and N2, the oil-wax coating should undergo an additional drying period of 24-48 h under 25 ℃/55% relative humidity, during which a stable oil-wax-wood interface could come into being retained firmly.

2.5 Chromatic variable measurement

The chromatic properties of larch samples were determined according to the CIE 1976 L*a*b*color space (ISO 11664—4, 2019) on the basis ofL*,a*andb*color coordinates, where:L*is lightness from 0 (black) to 100 (white);a*is chromaticity coordinate (red-green); andb*is chromaticity coordinate (yellow-blue). In order to get a complete color analysis, a polar coordinate system was also introduced to describe chromatic properties. The parametersS*(saturation) andH*(hue angle) could be used for the substitution of the values ofa*andb*variables on the color circle around the lightness axisL*. The chromatic variablesS*andH*were calculated according to Equations 1 and 2, respectively.

(1)

(2)

The chromatic variable changes ΔL*, Δa*, Δb*, ΔS*and ΔH*(i.e. changes between the EW sections and the corresponding LW ones) were determined based on the following equations:

(3)

(4)

(5)

(6)

(7)

Where, the subscripts “L” and “E” refer to latewood sections and early wood ones, respectively.

Finally, according to the Euclidean distances, the total color differences ΔE*were calculated based on the following equation:

(8)

In order to gain a more quantitative comparison of the visual contrast enhancement effect, possibly induced by the thermal treatment and oil-wax painting, it is strongly recommended that the discoloration differences of EW and LW sections of larch samples should be investigated separately. However, the fixed aperture size of conventional spectrophotometer (4, 8, 11, 13, 15 mm) made it limited to measure a highly inhomogeneous texture of wood surface, such as the plantation larch sample with harsh EW-LW transition. Given this specific circumstance, a modified image colorimetry was used to measure and calculate the chromatic variable of larch samples. Similar to a method proposed by Forsthuberet et al.[7], the image colorimetry methodology chosen in this test consisted of image acquisition, image analysis, and calculation of chromatic values, which are described briefly in the following sections.

Image acquisition: A digital camera (Cannon EOS 600D) was used to get the digital image of all larch samples, including the control, thermally treated and oil-wax coated ones. The image resolution was set to be 72 pixel/inch.

Image analysis: 1)The chromatic variablesL*,a*andb*were transformed from RGB mode to L*a*b*space; 2)The color areas of specified samples were clustered into three distinctive sections in a*b*space using the Euclidean distance metric by K-means clustering strategy, namely, EW, LW, and the relative intermediate; 3)Extraction of the corresponding chromatic variablesL*,a*andb*from the specified image regions were performed using Adobe Photo Shop CS5; 4)The chromatic variables obtained through above procedures were repeatedly calculated and further verified in L*a*b*color space for each region color-based segmentation approach provided by MATLAB R2012a Image Processing Toolbox.

Calculation and statistical analysis of chromatic values: The determination of variables ΔL*, Δa*, Δb*, ΔS*and ΔH*and their statistical standard deviations were carried out using Microsoft Excel. Subsequently, two-way ANOVA tests were carried out on the chromatic variability between the EW and LW bands of larch samples using MATLAB R2012a[22].

3 Results and discussion

3.1 Effects of thermal treatment and surface coating on larch color

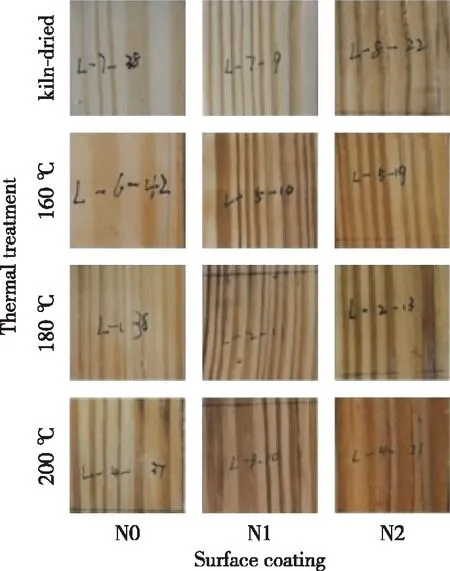

The visual changes in color of larch samples after thermal treatments and surface coatings are presented in Fig. 2. The sample of kiln-dried-N0 is shown as the non-thermal-treated and uncoated reference.

Fig. 2 Color variations caused by thermal treatment and oil-wax coating

According to Fig. 2, under the circumstance of non-coating case, with the increase of the treatment temperature, the surface color of larch samples became progressively darker and redder. This kind of familiar color changes had also been partially achieved as the corresponding samples were surface-painted with oil-wax, such as the colorimetric changing behaviors of kiln-dried samples under the N2 coating option. It should also be mentioned that, under the suitable combination of specified thermal treatment and oil-wax coating, such as the “T2+N2” or “T3+N2”, with the samples’ color becoming both darker and warmer than other neighbor options, a gentle and contrasting color differences between EW and LW could be achieved properly. These kinds of visually colorimetric behaviors will be further discussed quantitatively in the upcoming analysis.

The discoloration of EW and LW triggered by the thermal treatment and oil-wax coating should be examined at an accurately designated location. For this purpose, the areal distribution of the EW and LW on the sample surface had to be determined properly. An image processing strategy involving color-based segmentation K-means clustering was utilized to separate the color areal of LW from that of EW. Consequently, the average value and standard deviation of the colorimetric variables, namely,L*,a*andb*, were calculated using an algorism named color-based segmentation using the L*a*b*color space. The main contents of this calculation procedure included the following steps: 1)Acquire image; 2)Calculate sample colors in L*a*b*color space for each region; 3)Classify each pixel using the nearest neighbor rule; 4)Display results of nearest neighbor classification; 5)Display “a*” and “b*” values of the labeled colors. The original wood sample (kiln-dried and surface coating N1) and its corresponding cluster distributions were plotted as shown in Fig. 3. Two of the three clusters (Fig. 3c and 3d.) give the areal distribution of LW and EW, respectively. The third one (Fig. 3e) shows the transition area between EW and LW, which was not considered for the color calculation. The calculation of colorimetric average and its standard deviation was performed based upon the areal information provided by Fig. 3c and 3d, for the LW and EW areas, respectively.

Fig. 3 Color-based segmentation of larch sample using the K-means clustering and L*a*b*color space

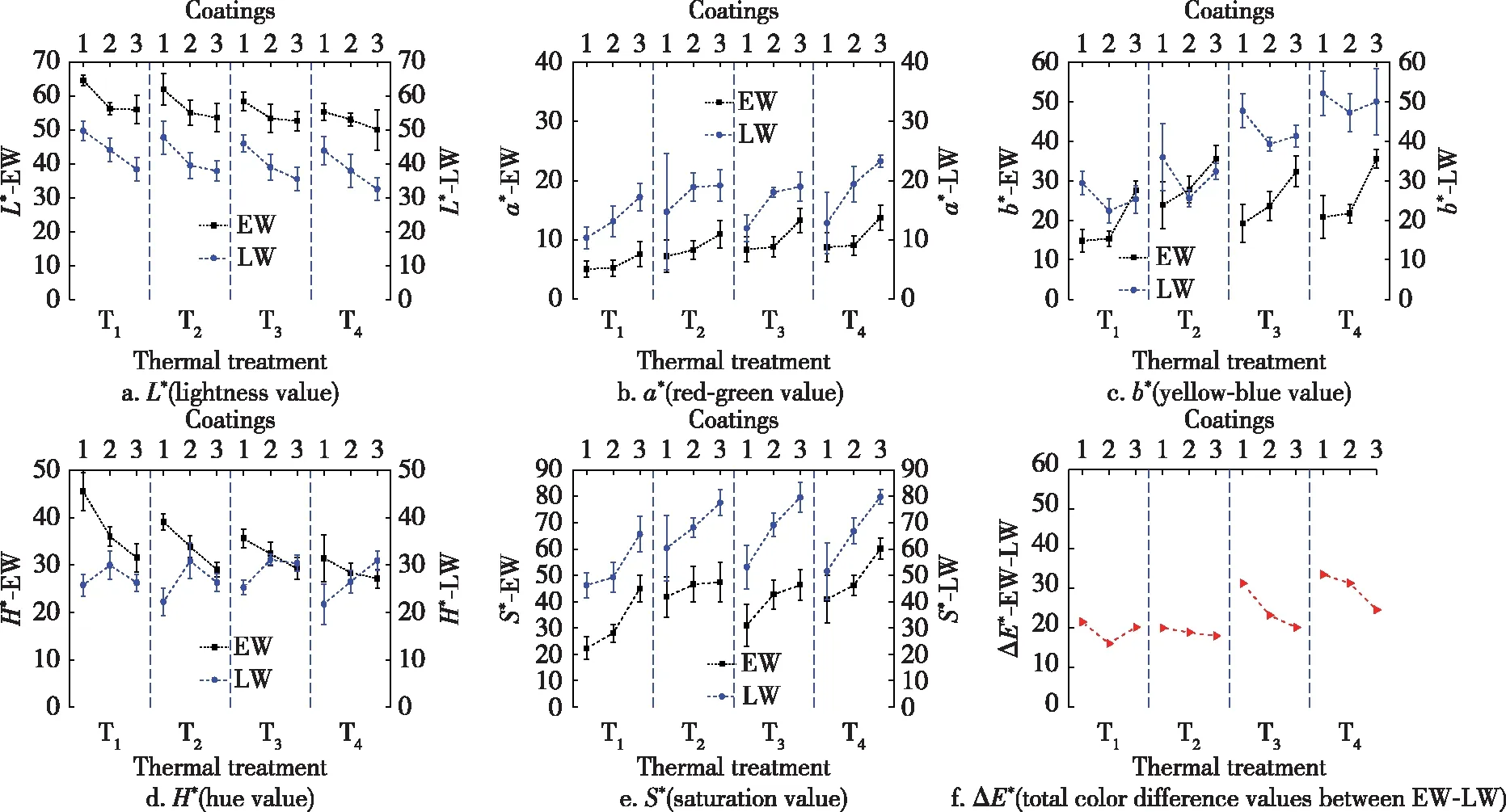

For the purpose of explicit description and comparison of chromaticvariability between EW and LW, the averaged values of the chromatic variables for the EW and LW sections of wood samples are depicted in Fig. 4.

Fig. 4 Impact of thermal treatment and surface coating on the chromatic variables of EW and LW sections of larch wood

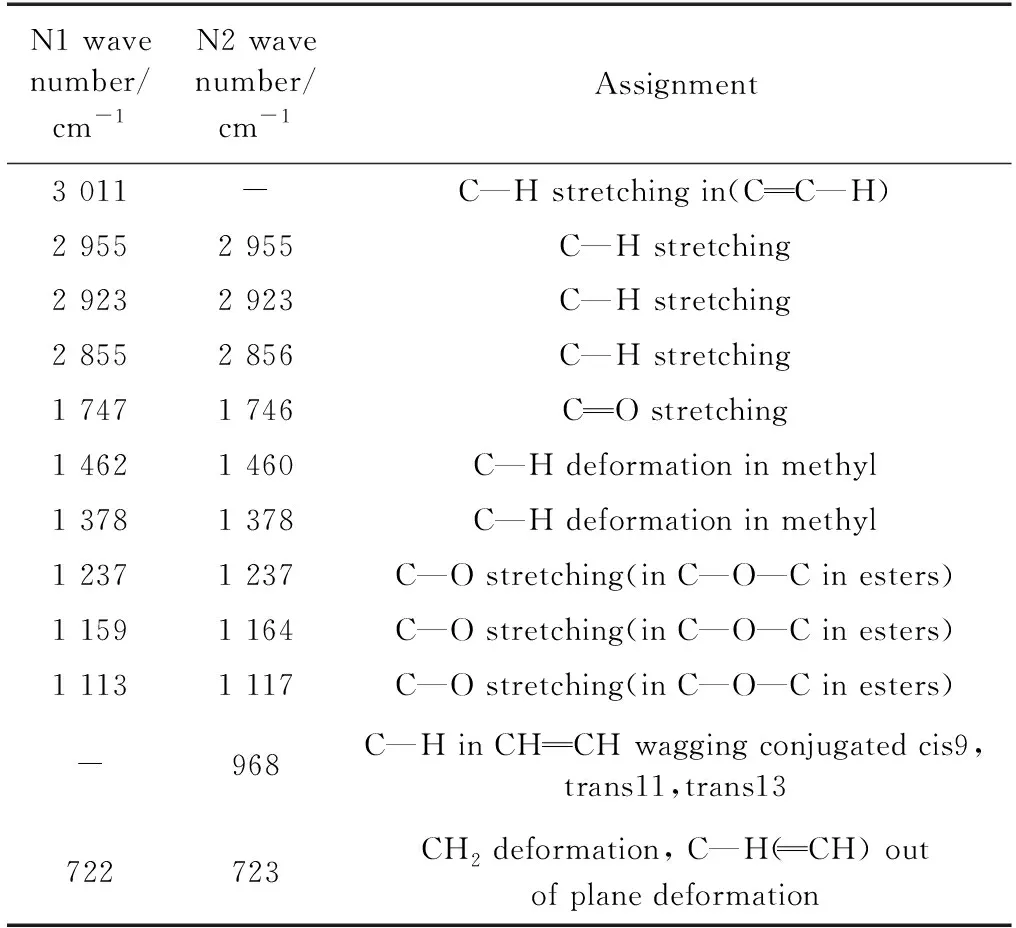

According to Fig. 4a and 4e, two explicit and distinctively opposite changes were revealed for the lightness valueL*and saturation valueS*, respectively, which could also be figured out from Fig. 2. Under a specified thermal treatment, as larch samples were painted with N1 option, and further with N2 option,L*andS*(including both EW and LW bands), exhibited progressive decreasing (EW>LW) and increasing (EW As for the impact of thermal treatment overL*andS*, with the increase of the thermal treatment temperature, the overall ranges ofL*andS*presented a general decreasing and increasing trend respectively, including both LW and EW. Taking the EW section as an example, in the case of N0, as treatment temperatures increased from 160 ℃, to 180 ℃, and finally to 200 ℃, theL*value decreased from 61.59 to 58.46, and finally to 55.32, representing a decreasing rate relative to the controlT0(64.64) as 4.2%, 9.6% and 14.4%, respectively; in the case of N1, theL*value decreased from 55.05 to 53.41, and finally to 53.00, representing a decreasing rate relative to the controlT0(56.24) as 2.2%, 5.1% and 5.8%, respectively; as for the case of N2, theL*value decreased from 53.59 to 52.63, and finally to 50.01, representing a decreasing rate relative to the controlT0(56.00) as 4.3%, 6.0% and 10.7%, respectively. Due to the interaction between thermal degradation alterations of larch wood and chromogens imported by the wax-oil compounds, the influencing mechanisms of thermal temperature over the saturationS*of larch samples were somewhat complicated. Taking the LW section as an example, in the case of N1, as the treatment temperatures increased from 160 ℃ to 180 ℃, and finally to 200 ℃, theS*value increased from 68.18 to 69.09, and finally to 66.77, representing an increasing rate relative to the controlT0(49.03) as 38.3%, 40.1% and 35.4%, respectively; as for the case of N2, the increasing trends were more straight forward. The respective increasing rates were 18.1%, 21.2% and 21.5% for 160, 180 and 200 ℃. Based on the information revealed through Fig. 4b and 4c, the following changing trends on red-green valuesa*and yellow-blue valueb*could been extracted. In the case of EW band, under an individual thermal treatment, the oil-wax coating would trigger a straightforward increasing trend fora*andb*. Nevertheless, for LW band, in the same circumstance, a somewhat complicated trend (a decrease for N1 followed by an increase for N2) emerged. Additionally, as the thermal treatment temperatures increased, the overall value ranges fora*andb*all exhibited a general increasing trend, including both EW and LW. For the purpose of quantitative analysis and comparison of chromatic variability between EW and LW, the total colorimetric differences between these two types of wood sections are presented in Fig. 4f. As the thermal treatment conditions intensified, the overall chromatic difference ΔE*in the case of N0, N1 and N2 all exhibited an increasing trend, indicating an increased contrast between EW and LW. According to Esteves et al. ’s work[16]on thermally treated pine (Pinuspinaster), chemical component changes and mass losses were the major factors affecting wood color changes, and the EW/LW rate would impose strong impacts over the actual wood color modes. Additionally, two-way ANOVA tests also showed that the thermal treatment temperature had a significant influence on the yellow-blue difference Δb*(P≈0). Under this circumstances, with the increase of the thermal temperature, Δb*increased accordingly, indicating that surfaces of LW were yellower than those of EW[2]. The impact of oil-wax coating on the chromatic differences between EW and LW is depicted in Fig. 5. In comparison with the circumstance of the thermal treatment, it seemed like that the transparent oil-wax coating presented more explicit impact over the colorimetric differences between EW and LW. Interestingly, with larch samples being coated with oil-wax N1 (l1) and N2 (l1+l2), the chromatic variable differences ΔL*and Δb*all exhibited decreasing trends, indicating the surface of LW was relatively darker, bluer than that of EW. Two way ANOVA tests verified that the color difference variable ΔL*and Δb*between EW and LW were significantly influenced by oil-wax coating (P=0.04 andP≈0). Nevertheless, an insignificant decrease of ΔE*induced by oil-wax coating was also found (P=0.08) under specified thermal treatments. As larch samples were oil-wax coated, the ΔS*between EW and LW of thermally treated samples increased accordingly, but in an insignificant way (P=0.12). Fig. 5 Impact of transparent oil-wax coating over the colorimetric difference between EW and LW The ΔE*value was affected by the thermal treatment and oil-wax coating through two significantly opposite directions (Fig. 4f and Fig. 5). Under the circumstance of a specified thermal treatment, the transparent coatings provided by oil-wax would decrease ΔE*, gradually. Taking theT2-N0 case as the control (31.32), due to the impact of coating options N1 and N2, the ΔE*value decreased by 25.8% and 35.7%, respectively, while the ΔS*values increased by 19.1% and 50.2%. However, the ΔE*value also exhibited general increasing trends as the results of thermal treatment. For instance, in the case ofT0-N1 as the control (16.09), due to the influence of thermal treatmentT1,T2andT3, the ΔE*value increased by 17.5%, 44.5% and 94.8%, respectively. Simultaneously, the ΔS*value only showed relatively minor fluctuations, changed by 1.4%, 23.9% and -3.2%, respectively. The above mentioned effects of the thermal treatment and oil-wax coating on colorimetric variables, namely,L*,a*andb*, resulted in this inter-counteracting action over the ΔE*-ΔS*values between these two technical processes, which in turn, could be utilized to improve the colorimetric properties of larch wood. However, this inter-counteraction mechanism should involve some complicated chemical changes of wood components brought by wood thermal degradations and oil-wax coatings, which will be further discussed in the following section. According to two factor ANOVA tests, the thermal treatment exhibited significant influences on ΔE*(P=0.01), oil-wax coating showed non-significant impacts on ΔE*(P=0.07). It should be mentioned that, for all types of larch samples, the average ΔE*values between EW and LW, ranged from “16.1” to “30.3”, well above the thresh hold “3.0”, which was proposed by Sandermann et al.[23]as the limit for the human perception of wood color differences. After the application of specified combinations of the thermal treatment and oil-wax painting, the response of chromatic variables and their differences between EW and LW were notably different. The influence mechanisms concerning the interrelationship between larch chromatic properties and the corresponding treatment approaches utilized in this test were also complicated somewhat, involving wood physical and chemical property changes induced by thermal treatment, plant oil-wax impregnation, etc. According to Gao[24], for a specified wooden material, the amount and distribution of lignin units and extractives in wood cell walls determined its visual color characteristics, mainly through the interaction between the chromophoric and auxochromic groups inside these chemical components. During the thermal treatment, the chemical composition in wood was degraded through the deacetylation, catalyzed decomposition of polysaccharide, and cleavage of ether linkages or condensation of lignin, involving the alterations of the existing chromogens and the emergence of the new ones. According to Qi’s FT-IR test on high temperature steamed larch samples[25], the IR spectrum of thermally treated larch retained the similar trends as those of original samples, with the absorption band of carbonyl and, especially hydroxyl groups showcasing the decreasing trends. Zhang et al. ’s work on larch wood treated in saturated steam further verified that, as the result of polymerized lignin, increases of carbon double bond, and ether bond ruptures, the wood color became deepened after thermal treatments[26]. In the circumstances of the larch thermal modification, the above-mentioned polysaccharide decomposition, lignin molecule linkage cleavage, plus the evaporation and condensation of larch rosins, could potentially resulted in the reorganization of the available chromogens, triggered the emergence of auxochromic groups. Consequently, a distinctive colorimetric change behaviors between larch LW and EW sections emerged accordingly. Fig. 6 FT-IR spectra of oil-wax compounds l1and l2 Table 2 Characteristic FT-IR absorption bands for the oil-wax compounds Once getting in touch with wood and further penetrating into cell walls, these above-mentioned chromophoric and auxochromic groups would be combined with the carbohydrates existing in the lignin and the pinene inside resin of larch wood, forming specified chromogens[24]. Eventually, these chromogen groups would absorb visible lights with certain wavelengths, and help reshaping the visual color characteristics of the coated larch samples. It should also be pointed that, as there were abrupt variabilities of density and resins between EW and LW bands, the magnitude of oil-wax penetrating into EW sections was significantly higher than that of LW, especially in the case of N1-l1coating. In consequence of this phenomena and maybe the interaction between the unsaturated aliphatic triglyceride oil-wax and the turpentine oil located inside LW section, this could prolong the actual drying periods of oil-wax above the EW area, inducing further impact over colorimetric differences between EW and LW sections of larch wood. From the experimental tests performed herein, it was evident that the general chromatic properties of larch wood, and especially the colorimetric variable contrast between EW and LW sections could be modified, and furthermore improved through a combination of the thermal treatment and transparent oil-wax coating, making plantation larch as a potentially competitive and sustainable wood resource in the lumber markets. The objective of this research was to study the effects of high-temperature thermal treatment and transparent oil-wax coating on the color differences of larch EW and LW. Colorimetric changes of the EW and LW sections of larch samples were determined separately using the image colorimetry method. The two-way ANOVA tests clearly indicated that some explicit colorimetric difference behaviors between EW and LW were induced by the thermal treatment and oil-wax transparent coatings. Under specified coating cases, as the thermal treatment temperature increased progressively, both the total colorimetric difference ΔE*and the yellow-blue value Δb*exhibited significantly increasing trends, indicating that the LW section became sharper and yellower than that of EW. Nevertheless, as the transparent oil-wax was coated over the surfaces of larch samples, the total colorimetric differences ΔE*, yellow-blue value Δb*and lightness ΔL*all showed the decreasing trends, with Δb*and ΔL*in significant modes, and ΔE*in relatively insignificant ways. As expected, larch samples became darker, warm-colored solid materials when they were thermally heated and further painted with the oil-wax coatings. The influencing mechanisms behind colorimetric changes induced by the thermal treatment and oil-wax coating were particularly sophisticated, mainly involving the emerging chromogen groups resulted from both the thermal degradation of larch wood and the transparent coating of oil-wax compounds. Interestingly, a proper combination of the thermal treatment and oil-wax coating, for instance, thermally treating at 180 ℃ or above for 1 h plus surface coated with the N2 oil-wax option, could be used to decrease the overall chromatic differences ΔE*between EW and LW, increase the saturation differences ΔS*between EW and LW, and finally enhance the colorimetric softness of larch samples. The future work should be focused on enhancing thermal treatment conditions and investigating the chromatic differences of weathered larch samples (natural weathering and artificial weathering tests), thus contributing to optimizing the application of low-quality softwood like larch.3.2 Effects of thermal treatment on the colorimetric difference between EW and LW

3.3 Effects of transparent oil-wax coating on the colorimetric difference between EW and LW

3.4 Chemical alteration mechanism behind colorimetric changes induced by thermal treatment and oil-wax coating

4 Conclusions