Effects of Fiber Surface Pretreatment and Composite Post- treatment on Mechanical Properties of 2D-Cf/Phosphate Geopolymer Matrix Composites

Peigang He, Zhanlin , Shuai Fu, tao Wang, Xiaoming Duan, , * #

(1. Institute for Advanced Ceramics, Department of Materials Science, Harbin Institute of Technology, Harbin 150001, China;2. Key Laboratory of Advanced Structural-Functional Integration Materials & Green Manufacturing Technology,Harbin Institute of Technology, Harbin 150001, China)

Abstract: Geopolymers are an important class of materials with potential applications because of their heat resistance, flame resistance, environmental friendliness, and possibilities of being transformed into ceramic matrix composites at low cost. However, the low mechanical properties as well as the intrinsic brittleness limit their technological implementations, and it is necessary to enhance the mechanical properties of geopolymers by adopting various kinds of reinforcements. In this work, therefore, two-dimensional continuous carbon fiber (Cf) reinforced phosphate-based geopolymer composites (Cf/geopolymer) were prepared through ultrasonic-assisted impregnation method. Effects of acetone treatment and high-temperature treatment on the properties of Cf/geopolymer composites were studied by X-ray photoelectron spectroscopy (XPS), X-ray diffraction (XRD), and scanning electron microscopy (SEM). Results of the study proved that acetone treatment plays a key role in ameliorating the interfacial interaction between Cf and phosphate matrix, which can thus enhance the mechanical properties of Cf/geopolymer composites. The Cf/geopolymer composites prepared by acetone-treated Cf had a flexural strength of 156.1 MPa and an elastic modulus of 39.7 GPa in Y direction. Moreover, an additional Sol-SiO2 re-impregnation treatment could further enhance the mechanical properties of the acetone-treated Cf/geopolymer composites by repairing the cracks and filling the pores. The results in this paper not only provide insights into the surface modification of Cf, but also report a facile and low-cost preparation route for Cf/geopolymer composites with potential applications in aerospace and defense technology.

Keywords: geopolymer; carbon fiber; composite; surface modification; mechanical properties

1 Introduction

Geopolymer, with a heat-resistant temperature up to 1 300-1 600 ℃, is a high-temperature material developed on the basis of cement, ceramic, and refractory materials. In addition to its intrinsic characteristics such as heat resistance, flame resistance, high specific strength, and low density, geopolymer also exhibits advantages like facile processing, low cost, low energy consumption, and environmental friendliness. These unique features make geopolymer promising in the fields of transportation, national defense, aerospace, and nuclear energy, for instance in the fire-resistant components of aeroengine, aerofoil, aerospace vehicle, and geopolymer cement for nuclear waste treatment[1-2]. However, in order to overcome its disadvantages of intrinsic brittleness, large shrinkage stress, and low reliability, it is necessary to strengthen and toughen the geopolymer matrix by means of efficient reinforcing phases. Owing to its low-temperature (30-150 ℃) moulding nature, a wide range of materials can in principle serve as reinforcing phases to ameliorate mechanical properties of phosphate matrix, including metal and ceramic particles, short fibers, and continuous fibers. Among them, fibers reinforced geopolymer composites exhibit good mechanical properties, high-temperature resistance, and stability, which thus have gained extensive concerns and attentions in recent studies[3-5].

In recent years, carbon fiber (Cf) has been widely recognized as a promising reinforcing phase in the field of composite materials due to its high specific modulus and specific strength, especially for the development of low-cost and environmental friendly refractory composites. It not only meets the requirements of strength, rigidity, light weight, fatigue resistance, high temperature resistance, and corrosion resistance, but also possesses unique features such as high conductivity, high thermal conductivity, and low expansion coefficient[6-8]. However, the surface of pure carbon fiber is chemically inert and shows a weak interaction with matrix, which results in poor interlayer shear strength of the composites[9]. To realize better interfacial bonding between carbon fiber and matrix, it is of great importance to treat carbon fibers in advance by using appropriate methods for surface modification[10-11].Another problem regarding to the refractory applications of Cf/geopolymer composites lies in their thermal evolution. A fundamental understanding of the temperature dependence of phase composition and mechanical properties of Cf/geopolymer composites remains elusive.

In this work, two-dimensional continuous Cfwas used as the reinforcing phase to fabricate Cfreinforced geopolymer composites (Cf/geopolymer). Acetone treatment process was performed to improve the interfacial bonding between Cfand phosphate matrix. Effects of acetone treatment, high-temperature treatment, and Sol-SiO2re-impregnation treatment on the properties of Cf/geopolymer composites were systematically investigated.

2 Materials and Experiment

2.1 Materials

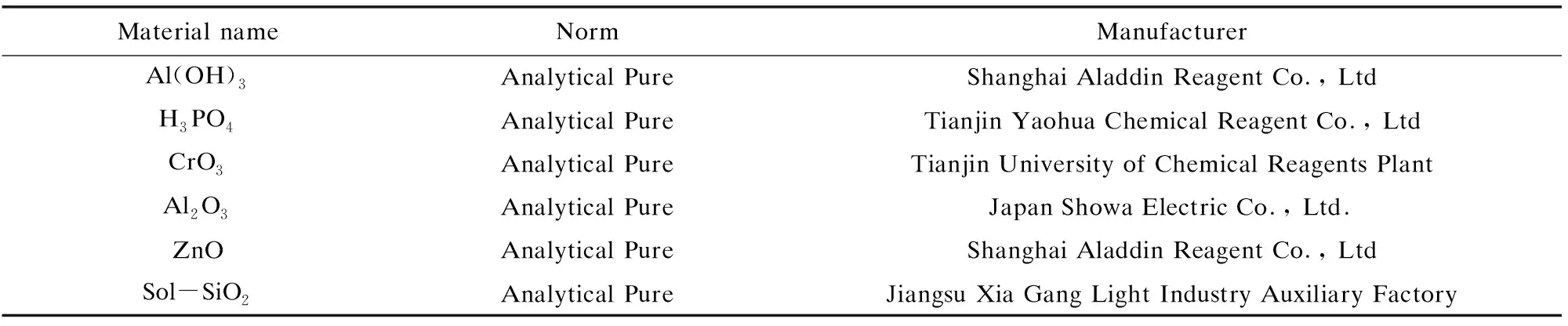

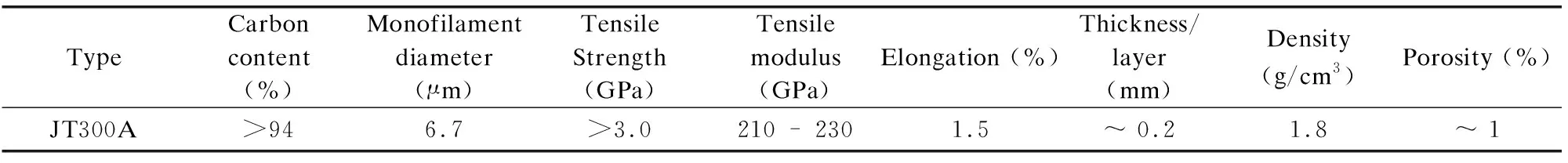

The information of raw materials and the properties of Cfused in this study are listed in Table 1 and Table 2, respectively.

Table 1 Information of raw materials used in this study

Table 2 Properties of woven carbon fiber cloth used in this study

2.2 Preparation of C f/Geopolymer Composites

To achieve a better interfacial bonding between fiber and geopolymer matrix, carbon fibers were treated in acetone by immersing for 24 h. H3PO4and Al(OH)3were employed as raw materials to prepare the phosphate solution. Meanwhile, a small amount of CrO3and CH3OH were introduced into the solution. After that, curing agents and fillers (Al2O3) were added and the mixture was milled by mechanical ball milling for a certain time to get geopolymer matrix . Two-dimensional woven carbon fiber cloth was cut into squares (10 cm×10 cm), which were then placed into the geopolymer matrix under the ultrasonic field for impregnation (5 min). The impregnated carbon fiber cloth was then fished out and stacked together layer by layer. Finally, the stacked carbon fiber cloth with a layer number of 25-40 was placed in the mold, pressurized and cured at 60 ℃ for 7 d for geopolymerization. The composites were further high-temperature treated in Ar atomosphere, and the high-temperature treated samples were impregnated by Sol-SiO2solution for 3 times.

2.3 Characterizations

Mechanical properties of the obtaiend composites were tested by electronic universal tester (AGX-plus 20 kN, Japan). Chemical state of carbon was investigated by X-ray photoelectron spectroscopy (ESCALAB 250Xi, ThermoFisher, America). Surface wetting angles of carbon fibers before and after acetone treatments were determined by wetting angle tester (VAF-30, China). Simultaneous thermogravimetry and differential thermal analysis were performed by thermal analyzer (TG/DTA, Netzsch STA 449 C, Germany). Phase compositions of the composites were characterized by X-ray diffractometer (XRD, Rigaku-D/max-γB, Japan). Surface morphologies of Cfand fractographies of the composites and their high-temperature products were studied by scanning electron microscope (SEM, FEI HELIOS NanoLab 600i, America). Flexural strength and Young’s modulus of the composites were measured on specimens (4 mm3 mm36 mm) using a three-point bending fixture on an Instron-500 tester (America) with a span length of 30 mm at a cross-head speed of 0.5 mm/min. Results from two loading directions, i.e., perpendicular (X) to the laying-up direction and parallel (Y) to the laying-up direction, were measured.

3 Results and Discussion

3.1 Effects of Acetone Treatments on Properties of C f/Geopolymer Composites

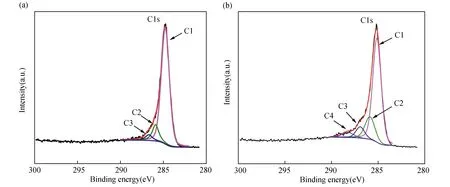

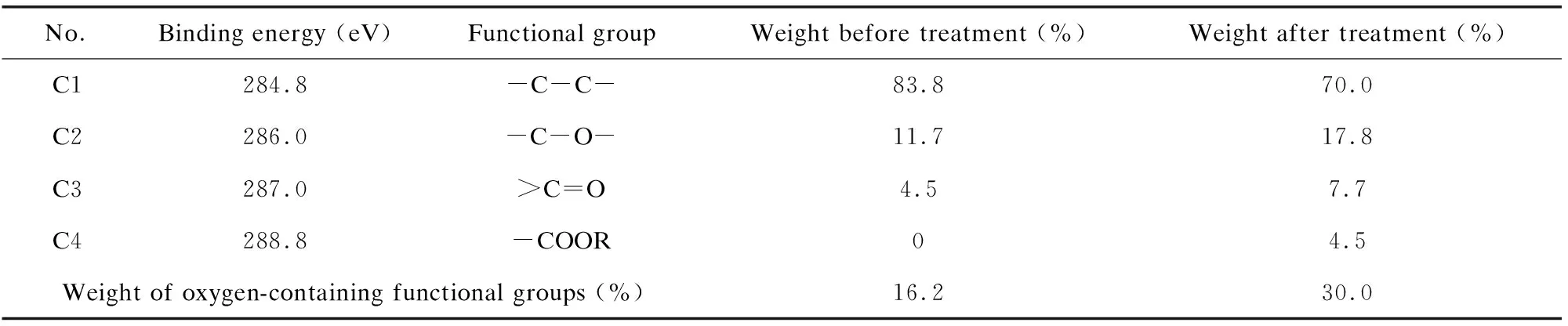

In this section, acetone was used to treat Cfand the properties of Cfbefore and after acetone treatments were compared. The role of acetone treatments in modifying the properties of Cfwas discussed. Fig.1 shows the XPS spectra of Cfbefore and after acetone treatments. In both cases, the main characteristic peaks (C1), presenting (-C-C-) functional group, were found to be at 284.8 eV. However, C4 characteristic peak appearred after acetone treatments, indicating the emergence of acidic functional groups such as carboxyl (-COOH) and ester (-COOR). C2 and C3 characteristic peaks also became more pronounced in acetone-treated Cf, corresponding to increasing contents of -C-O- and >C=O, respectively. Table 3 lists the binding energy and weight of different characteristic peaks before and after acetone treatments. It can be seen that after acetone treatments, the weight of C1 characteristic peak (-C-C-) decreased from 83.8% to 70% , whereas those of oxygen-containing functional groups (i.e., C2, C3, and C4) increased to varying degrees. In particular, the weight of acidic functional groups ( i.e., C4) increased to 4.5% after acetone treatments.

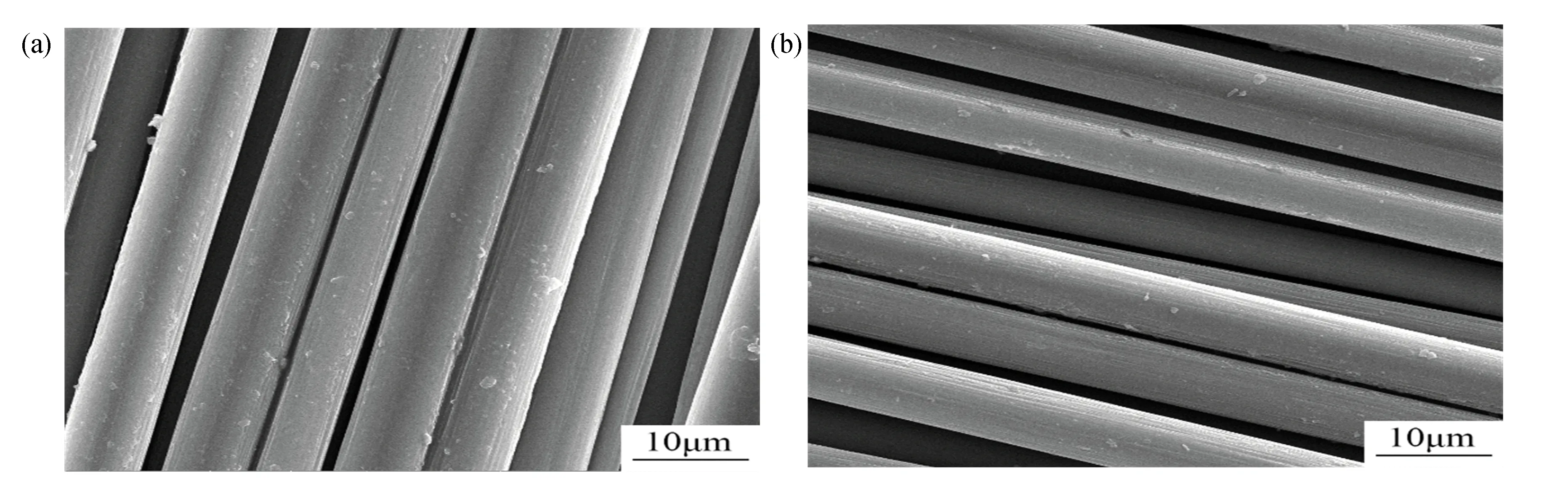

Fig.2 presents the surface morphology of Cfbefore and after acetone treatments. It is apparent that the surface of the untreated Cfis covered by a gel-like substance (Fig.2(a)), which can be removed by using acetone treatments, as shown in Fig.2(b). The acetone-treated Cfexhibits a relatively smooth surface and the intrinsic patterns of Cfcan be observed more clearly.

Fig.1 XPS spectra of Cf(a) before and (b) after acetone treatments

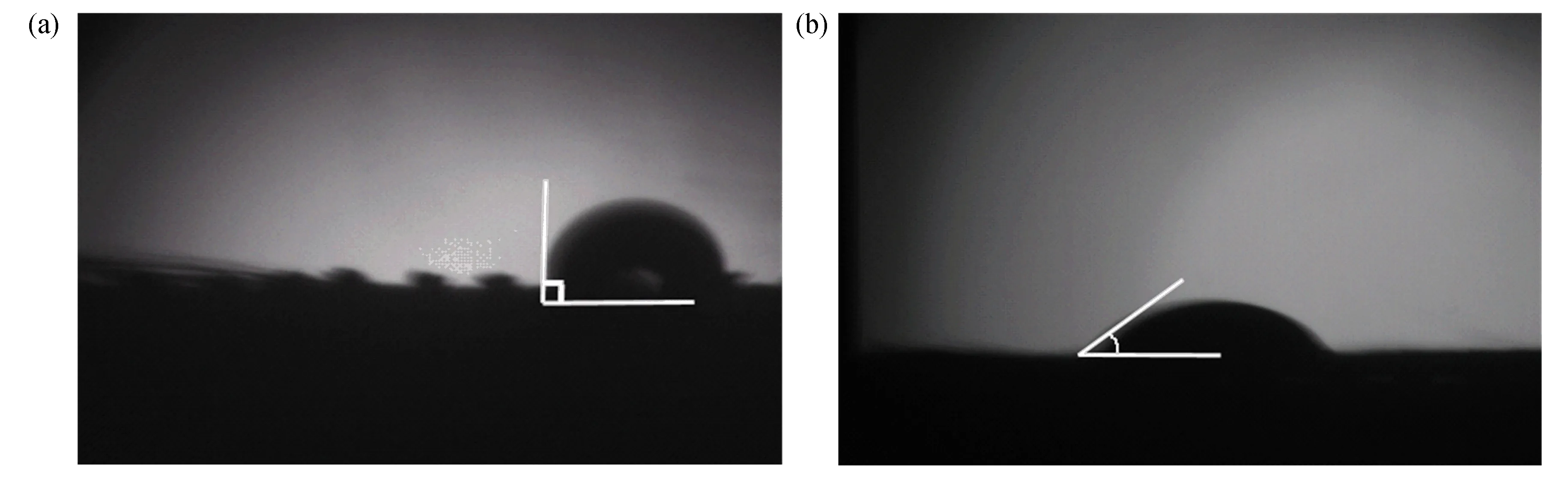

To further understand how acetone treatments affect the surface properties of Cf, wetting angles were tested for acetone-treated and non-treated Cf, respectively. The wettability of a solid surface is mainly determined by the nature of the atoms and/or the atomic groups on the interface. As the surface of the untreated Cfis dominated by the hydrophobic gel-like substance (Fig.2(a)), the non-treated Cfshows a relatively big wetting angle around 90° (Fig.3(a)). During the acetone treatments, such hydrophobic gel-like substance gradually dissolves into the medium, and the intrinsically undulating patterns of Cfgovern the surface (as shown in Fig. 2(b)). Owing to its greater surface roughness and bigger wetting force, acetone-treated Cfshows a much smaller wetting angle (~40°), and thus has better wettability.

Table 3 Binding energy and weight of different characteristic peaks before and after acetone treatments

No.Binding energy (eV)Functional group Weight before treatment (%)Weight after treatment (%)C1284.8-C-C-83.870.0C2286.0-C-O-11.717.8C3287.0>C=O4.57.7C4288.8-COOR04.5Weight of oxygen-containing functional groups (%)16.230.0

Fig.2 Surface morphologies of Cf(a) before and (b) after acetone treatments

To further understand how acetone treatments affect the surface properties of Cf, wetting angles were tested for acetone-treated and non-treated Cf, respectively. The wettability of a solid surface is mainly determined by the nature of the atoms and/or the atomic groups on the interface. As the surface of the untreated Cfis dominated by the hydrophobic gel-like substance (Fig.2(a)), the non-treated Cfshows a relatively big wetting angle around 90° (Fig.3(a)). During the acetone treatments, such hydrophobic gel-like substance gradually dissolves into the medium, and the intrinsically undulating patterns of Cfgovern the surface (as shown in Fig. 2(b)). Owing to its greater surface roughness and bigger wetting force, acetone-treated Cfshows a much smaller wetting angle (~40°), and thus has better wettability.

Fig.3 Surface wetting angles of Cf(a) before and (b) after acetone treatments

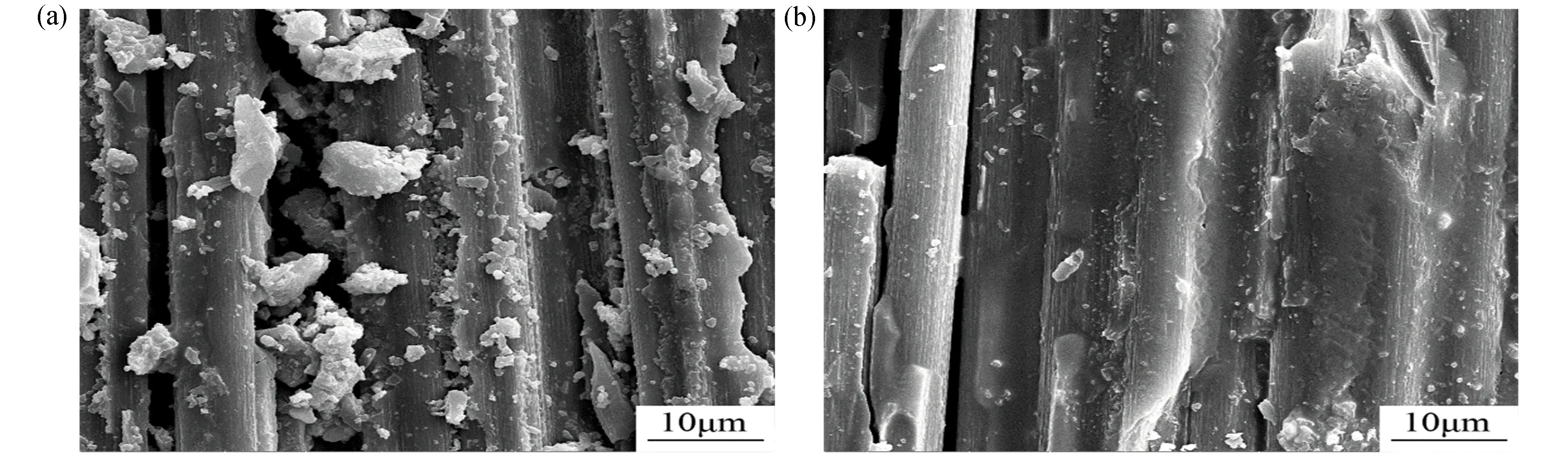

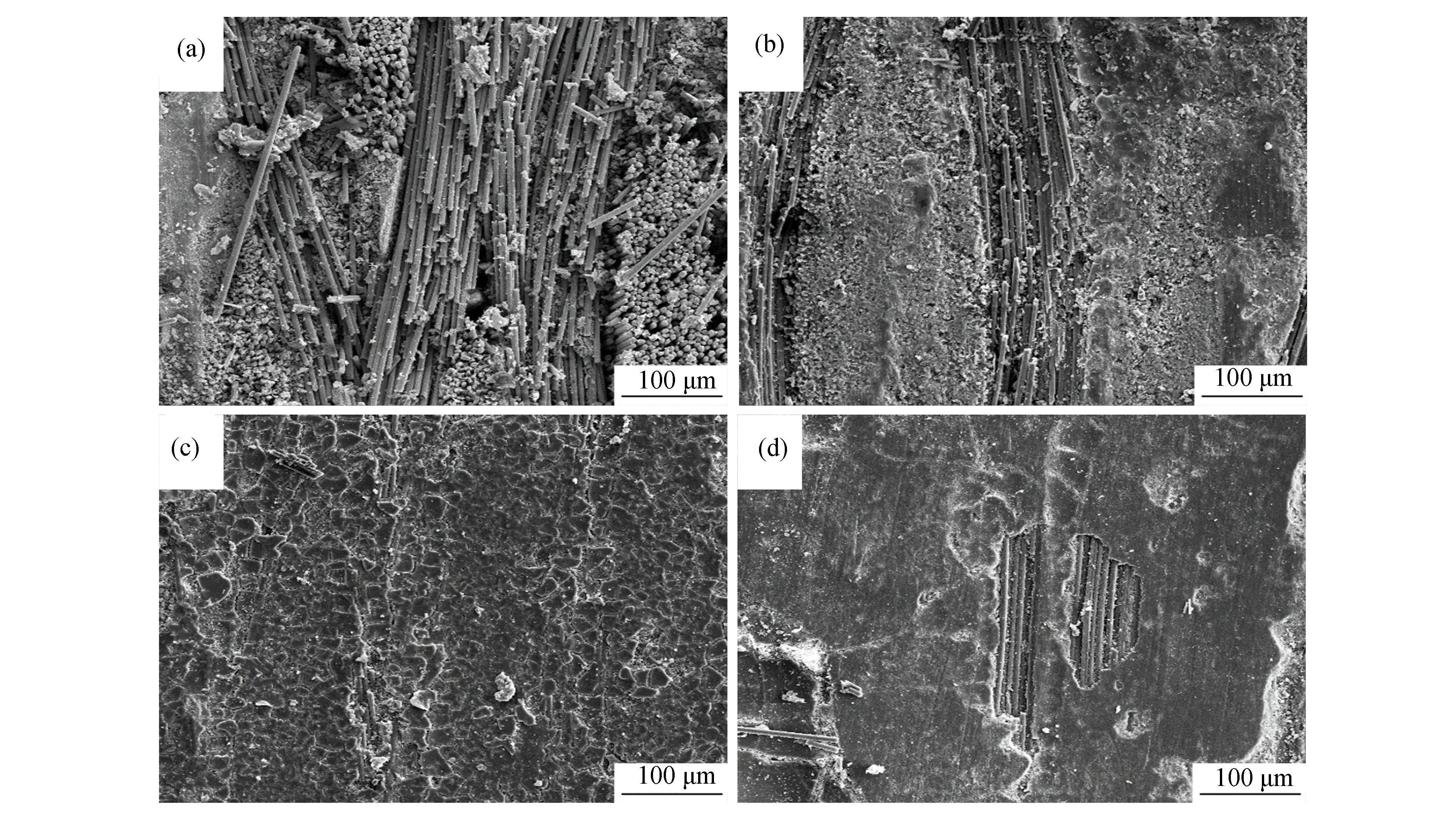

Both acetone-treated and non-treated Cfwere used to prepare Cf/geopolymer composites. Fig.4 displays the fracture surfaces of Cf/geopolymer composites without (Fig.4(a)) and with (Fig.4(b)) acetone treatments. It is obvious that the composites reinforced by acetone-treated Cfhave more continuous and homogeneous surfaces, which further reflects the fact that acetone treatments help to improve the wettability of Cfsurfaces, leading to a stronger interaction between Cfand phosphate matrix.

Fig.4 Fracture surfaces of Cf/geopolymer composites (a) without and (b) with acetone treatment

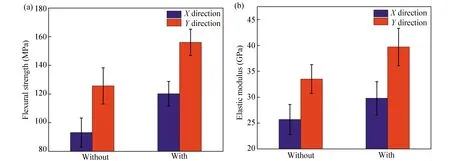

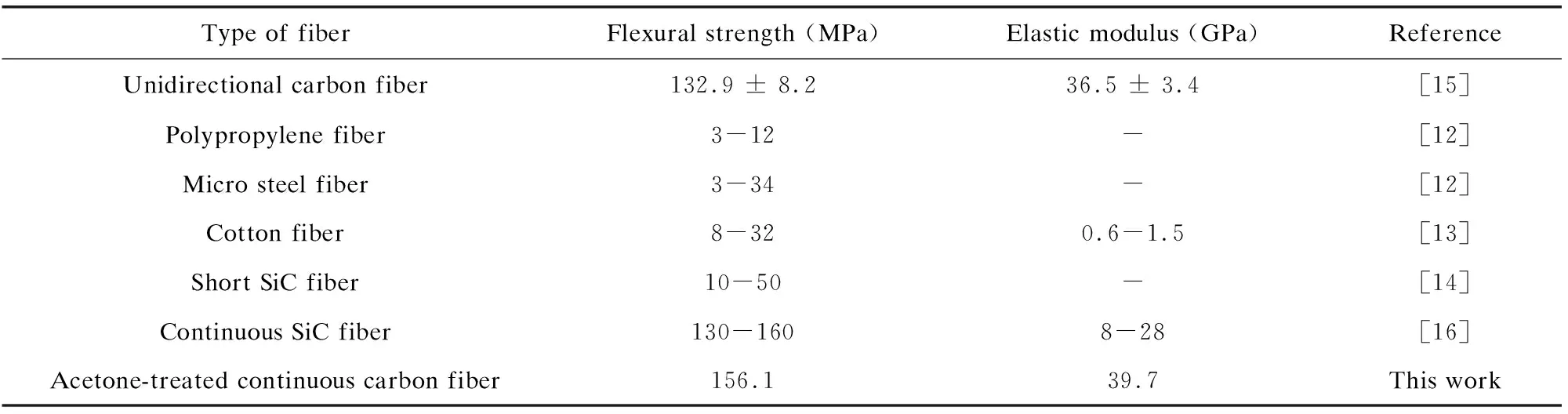

Fig.5 shows the comparison of the mechanical properties of Cf/geopolymer composites prepared by using Cfwith and without acetone treatments. The obtained Cf/geopolymer composites had anisotropic mechanical properties, mainly due to the preferred distribution of Cf. Obviously, the Cf/geopolymer composites prepared by acetone-treated Cfhave higher flexural strength (Fig.5(a)) and elastic modulus (Fig.5(b)) in bothXandYdirections than those prepared by non-treated Cf, leading to a stronger interaction between Cfand phosphate matrix as discussed above. It is noteworthy that a more compact structure may also contribute to the enhanced mechanical properties of the acetone-treated Cf/geopolymer composites due to the better matrix filling. It can also be found that the Cf/geopolymer composites prepared by acetone-treated Cfshowed a flexural strength of 156.1 MPa and an elastic modulus of 39.7 GPa in theYdirection. The mechanical properties of different fiber reinforced geopolymer composites are summarized in Table 4. Apparently, the mechanical properties of the as-prepared Cf/geopolymer composites are much higher than those reinforced by polypropylene fiber and micro steel fiber[12], cotton fiber[13], and short SiC fiber[14], and are comparable to those fabricated using unidirectional carbon fiber[15]and continuous SiC fiber[16].

Fig.5 Mechanical properties of Cf/geopolymer composites using Cf without and with acetone treatment: (a) flexural strength; (b) elastic modulus

Therefore, we attributed the enhanced mechanical properties achieved by acetone-treated Cf/geopolymer composites to the following reasons: 1) after the mild acetone treatments, the removal of hydrophobic gel-like substance on the surface of Cfallows a stronger interaction between Cfand phosphate matrix; 2) the acetone treatments may regulate the fiber to matrix ratio in the obtained composites to a more reasonable value, therefore, optimizing the interfacial bonding in the composites.

Table 4 Comparison of mechanical properties of different fiber reinforced geopolymer composites

3.2 Effects of High-Temperature Treatments on Properties of C f/Geopolymer Composites

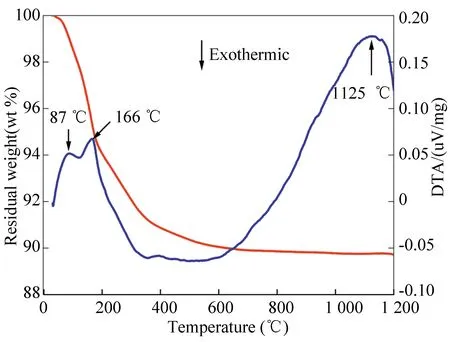

In this section, the thermal evolution of phosphate matrix and effects of high-temperature treatments on the properties of Cf /geopolymer composites were investigated. Fig.6 shows the TG/DTA curves of the phosphate matrix when being treated from room temperature to 1 200 ℃ in the air. An about 10% weight loss was observed for the matrix upon heating with a rapid weight loss process within 400 ℃ and a slow one in the temperature range of 400 ℃-600 ℃. Meanwhile, two endothermic peaks at 87 ℃ and 166 ℃ were noticed, corresponding to the evaporation of free water and organic solvents in the system and the cross-linking reaction of phosphate matrix, respectively. In addition, another endothermic peak at 1 125 ℃ was assigned to the phase transition of phosphate matrix and accompanied by no obvious weight loss. It can be concluded that the polymerization of geopolymer was almost accomplished within 400 ℃, indicating that the proposed synthetic method can serve as a low-temperature route for preparing geopolymer and phosphate-based composites.

Fig.6 TG/DTA curves of C f/geopolymer composites when being treated from room temperature to 1 200 ℃

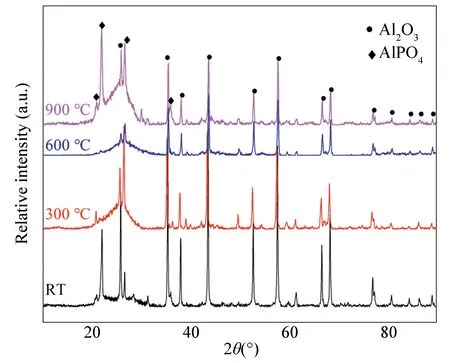

Fig.7 shows the XRD patterns of Cf/geopolymer composites before and after being treated at different temperatures. It can be seen that Al2O3andAlPO4are the main crystalline phases of Cf/geopolymer composites, regardless of the treatment temperature in the employed temperature range (from room temperature to 900 ℃). With increasing treatment temperature, AlPO4becomes more dominant, accompanied by the formation of amorphous phase (supported by the emergence of the diffuse scattering peak around 28° 2θ), which suggests a more complete geopolymerization process at high temperatures.

Fig.7 XRD patterns of C f/geopolymer composites at different temperatures before and after treatments

Fig.8 shows the microstructure of non-treated Cf/geopolymer composites after being treated at different temperatures. Matrix between neighboring fibers exhibited shrinkage and desorption behaviors to varying degrees, depending on the treatment temperature. With the increase of the treatment temperature from 300 ℃ (Fig.8(a)) to 600 ℃ (Fig.8(b)) , along with more noticeable cracks and pores in the composites, more obvious desorption behaviors of Cfwere observed. In particular, after being treated at 900 ℃ (Fig.8(c)) , the matrix which bridges surrounding fibers is almost removed, and only a small amount of matrix debris was observed. The gap between fibers became quite large, which broke the continuity of the composites. Such observation is attributed to the cross-linking reaction of phosphate matrix during high-temperature treatments. The dehydration condensation of phosphate matrix results in the desorption behaviors of Cfand the formation of cracks and pores in the composites.

Fig.9 shows the microstructure of acetone-treated Cf/geopolymer composites after being treated at different temperatures. The composites also experienced temperature-dependent shrinkage and desorption behaviors upon heating, accompanied by the emergence of cracks and pores among Cf. However, compared with those prepared by non-treated Cf, the composites made by acetone-treated Cfshowed less shrinkage and defects under same conditions. This further supports the conclusion that acetone-treated Cfpossesses better interfacial interaction with phosphate matrix than non-treated one.

Fig.8 Fracture surfaces of non-treated Cf/geopolymer composites after being treated at different temperatures: (a) 300 ℃; (b) 600 ℃ ; (c) 900 ℃

Fig.9 Fracture surfaces of acetone-treated Cf/geopolymer composites after being treated at different temperatures: (a) 300 ℃; (b) 600 ℃ ; (c) 900 ℃

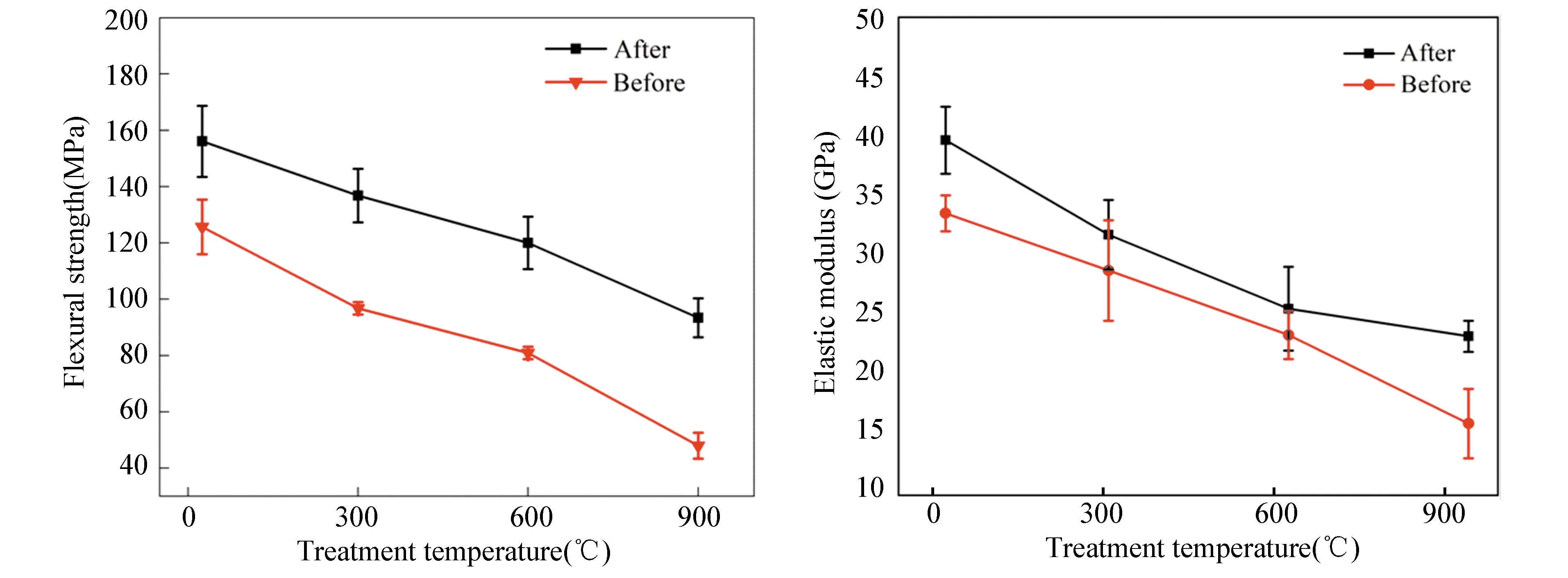

Fig.10 plots the mechanical properties of Cf/geopolymer composites prepared by acetone-treated and non-treated Cfbefore andafter high-temperature treatments. Both groups exhibited decreasing flexural strength and elastic modulus with increasing treatment temperature. However, the composites prepared by acetone-treated Cfalways had higher flexural strength and elastic modulus than those prepared by non-treated Cfafter the same high-temperature treatment. After being treated at 900 ℃, the Cf/geopolymer composites prepared by acetone-treated Cfmaintained about 60% of flexural strength, whereas those prepared by non-treated Cfonly had about 32% of flexural strength. Moreover, the elastic modulus of Cf/geopolymer composites with and without acetone treatments after 900 ℃ treatment was 23.3 GPa and 16.0 GPa, respectively. It further emphasizes that the acetone treatments are beneficial for improving the mechanical properties of Cf/geopolymer composites as well as their high-temperature products.

3.3 Effects of Sol-SiO2 Re-impregnation Treatments on Properties of Heated Cf/Geopolymer Composites

In this section, Sol-SiO2re-impregnation treatments were performed for high-temperature products (obtained at 900 ℃) of Cf/geopolymer composites, aiming for optimizing their mechanical properties.

Fig.11 presents the microstructure of the composites treated with different Sol-SiO2concentrations. In the untreated composites (Fig.11(a)), lots of fibers were pulled out of the matrix, indicating that the bonding strength between Cfand matrix is relatively weak.

Fig.10 Mechanical properties of Cf/geopolymer composites after being treated at different temperatures (Y direction): (a) flexural strength; (b) elastic modulus

Fig.11 Fracture surfaces of composites (obtained at 900 ℃ ) treated with different Sol-SiO2 concentrations: (a) 0; (b) 20%; (c) 30%; (d) 40%

However, for the composites that were treated with 20%, 30%, and 40% Sol-SiO2, the pull-out of Cfwas gradually suppressed. It can be inferred that after Sol-SiO2re-impregnation treatments, the surface of the resulting composites is covered by sol-gel coatings, and a dense substance forms between Cf, which bridges them effectively. This suggests that Sol-SiO2re-impregnation treatments can repair the cracks and fill the pores inside the resulting composites. In the employed Sol-SiO2concentration range (0-40 wt %), it was noticed that the sol-gel coating becomes denser and more homogeneous at higher Sol-SiO2concentration, leading to better continuity between Cfand matrix.

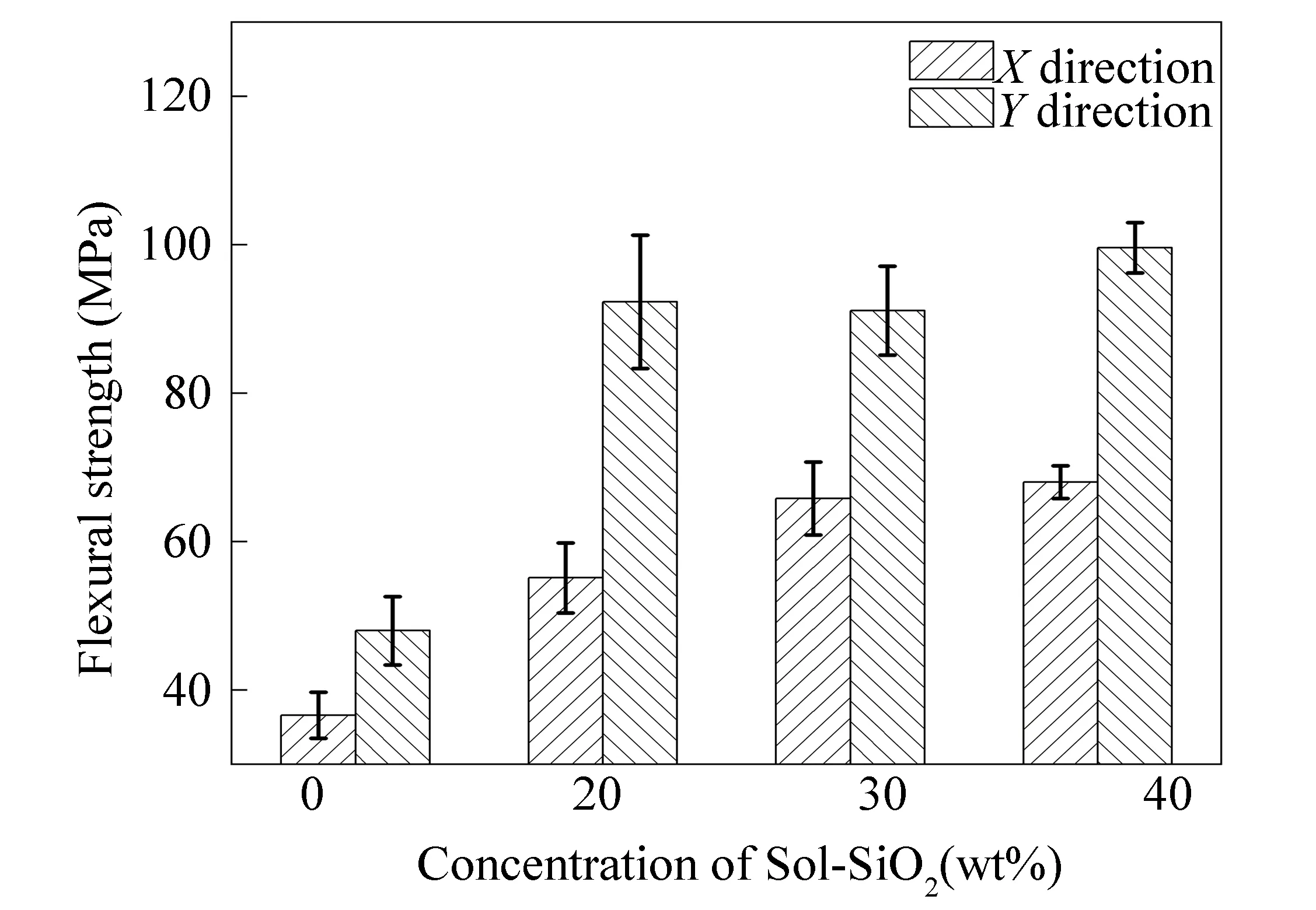

To quantitatively describe and further support our observation, the flexural strength of the resulting composites treated with different Sol-SiO2concentrations was tested in bothXandYdirections, as shown in Fig.12. As expected, by using 40 wt% Sol-SiO2as the re-impregnation agent, the flexural strength of the composites (obtained at 900 ℃) exceeded 99 MPa and was 107% higher than those without Sol-SiO2re-impregnation treatments.

Fig.12 Flexural strength of the composites (obtained at 900 ℃ ) treated with different Sol-SiO2

4 Conclusions

1) Acetone treatments had significant effects on tailoring the surface properties of Cf, which can ameliorate the interfacial interaction between Cfand phosphate matrix and improve the mechanical properties of Cf/geopolymer composites. The flexural strength and elastic modulus (inYdirection) of the acetone-treated Cf/geopolymer composites were 156.1 MPa and 39.7 GPa, respectively.

2) Upon post high-temperature treatment, Cf/geopolymer composites underwent cross-linking reaction and dehydration condensation, leading to the shrinkage of matrix. This was accompanied by the introduction of cracks and pores in the composites and the reduction in mechanical properties. However, the composites prepared by acetone-treated Cfalways showed better mechanical properties than their non-treated counterparts under the same conditions.

3) A further Sol-SiO2re-impregnation treatment on the high temperature treated Cf/geopolymer composites led to the formation of dense sol-gel coatings on the surface of the heated composites, enhancing their mechanical properties through repairing the cracks and filling the pores. By using 40 wt% Sol-SiO2as the re-impregnation agent, the flexural strength of the heated composites was 107% higher than those without Sol-SiO2re-impregnation treatments.

Journal of Harbin Institute of Technology(New Series)2020年3期

Journal of Harbin Institute of Technology(New Series)2020年3期

- Journal of Harbin Institute of Technology(New Series)的其它文章

- Evolution Toward Artificial Intelligence of Things Under 6G Ubiquitous-X

- Evaluation Method of Output Waveform Quality for Neutral-Point- Clamped Three-Level Converter

- Review: Scalable Fabrication of Polymeric Nanofibers from Nano- Spinning Techniques to Emerging Applications

- Controlled Movements in Superlubric MEMS

- Review: Recent Progress on Poly(ether ether ketone) and Its Composites for Biomedical, Machinery, Energy and Aerospace Applications

- Modified Adsorption Capacity to Space Molecular Pollutant of Zeolite via Interface Engineering with Atomic Layer Deposition