Review: Recent Progress on Poly(ether ether ketone) and Its Composites for Biomedical, Machinery, Energy and Aerospace Applications

Shuai Yang, Yang He and Jinsong Leng

(Center for Composite Materials and Structures, Harbin Institute of Technology, Harbin 150080, China)

Abstract: Poly(ether ether ketone) (PEEK) has drown researchers’ wide attention because of the exceptional performances such as mechanical properties, thermal stability, chemical resistance, and biocompatibility. These properties endow it with broad potential use in biomedical, engineering, and aerospace applications. In addition, multifunctional fillers have been intensively incorporated into PEEK matrix, as it is conducive to the enhanced properties, and has the desired properties in concrete applications. This review introduced the basic content and synthesis pathway of PEEKs and their composites, focusing on the various applications, including biomedical, machinery, energy storage, and aerospace applications. Considerable efforts have been devoted to explore the concrete modified method to obtain the desired performances of PEEK based materials. At the end, existing problems and development directions for the PEEK based materials were analyzed and predicted.

Keywords: poly(ether ether ketone); applied patterns; biomedical applications; machinery engineering; aerospace applications

1 Introduction

As a class of semi-crystalline thermoplastic polymer, poly(ether ether ketone) (PEEK) has attracted much attention due to the exceptional mechanical performances and thermal stability[1-3]. PEEK is a kind of homopolymers which could be synthesized via a stepwise polymerization method. Besides, the physical and chemical performances could be determined by chemical composition, molecular chains, and crystalline structures[4]. The regular molecular arrangements and chemical structures make it highly resistant to chemical and radiation damage[5]. In addition, the great biocompatibility and non-toxicity endow it with wide potential use to replace metal or ceramic counterparts in biomedical and aerospace applications[6]. In addition, PEEK possesses plenty of exceptional performances such as superior wear resistance, great processability, inertness, corrosion resistance, and so on[7].

PEEK possesses the elevated temperature steadiness above 300 ℃ and Young′s modulus of 3.6 GPa[8], which requires neither cross-linking nor preserving agents[9]. Moreover, PEEK is highly tunable through various monomers, functionalizing with amination, sulphonation, and nitration[8]. PEEK was first patented by the Imperial Chemical Industries for engineering applications in 1978[10], and then was commercialized for industrial manufacture applications. In 1998, it was utilized in biomedical area by Invibio Ltd. (UK)[11].

Excellent performances make PEEK material widely applicable in biomedical, machinery, energy storage, and aerospace fields. Besides, PEEK based composites has gained researchers’ wide attention, due to the synergized incorporation of excellent performances of PEEK matrix and unique desirable properties of functional fillers. This review summarized the preparation of PEEK based materials, emphasizing on their various applications in biomedical, machinery, energy storage, and aerospace fields. Besides, the existed problems, modified methods, and development directions were put forward, aiming to provide effective ideas to develop the fabrications and universal applications of PEEK based materials.

2 Synthesis Approaches

2.1 Synthesis of Neat PEEK

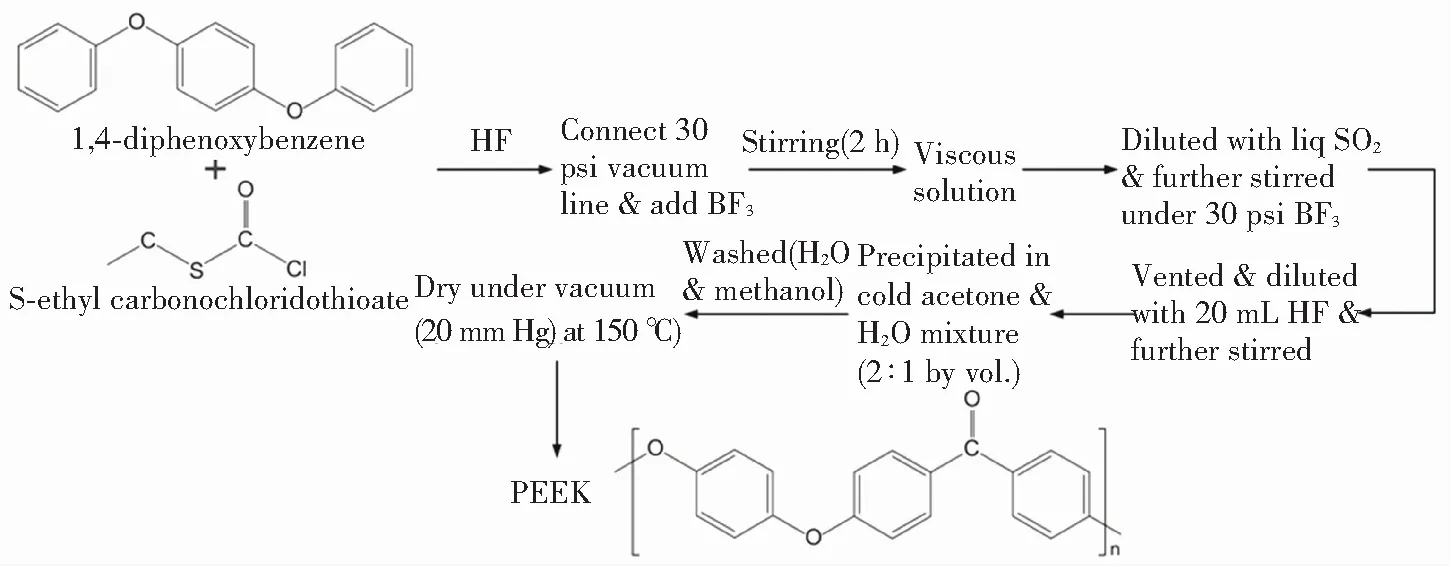

The synthesis of neat PEEK was firstly reported by Colquhoun et al.[12]via electrophilic substitution reaction, which is also called as Friedel-Crafts acylation. They dissolved the 4-(4-phenoxy) phenoxy benzoic acid in the solvent of TFMSA, in the presence of a small quantity of 1,4-di(4-carboxyl) phenoxy benzene or 1,4-diphenoxybenzene as an end-capping agent, to successfully synthesize neat PEEK(Scheme 1).

Neat PEEK was synthesized by using a difunctional aromatic compound dissolved in polar solvent, which was then derived to thiocarbonic acid (Scheme 2)[13].

Scheme 1 Synthesis pathway of PEEK in TFMSA[12]

Scheme 2 Synthesis of PEEK in polar solvent[13]

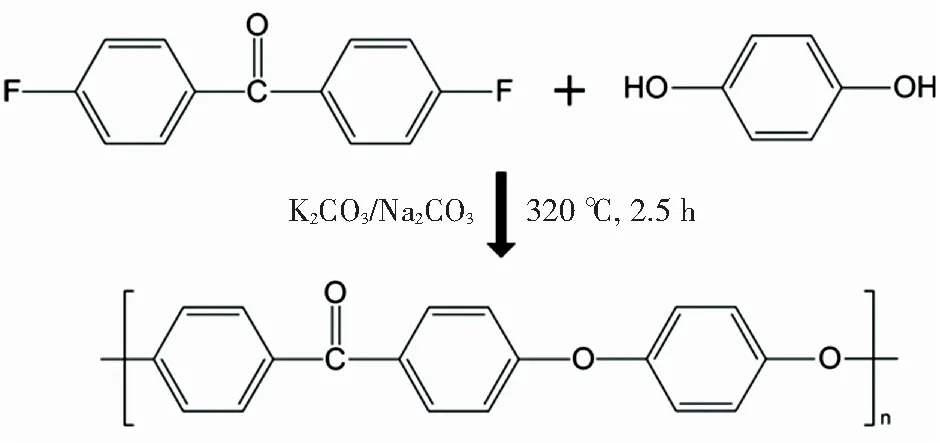

At present,common PEEK is synthesized via a nucleophilic substitution route[13]. 4, 4′-difluorobenzophenone and hydroquinone are chosen as reacted monomers. Diphenyl sulfone acts as solvent, and alkali metal carbonate is employed as catalyst system(Scheme 3).

2.2 Synthesis of Modified PEEK

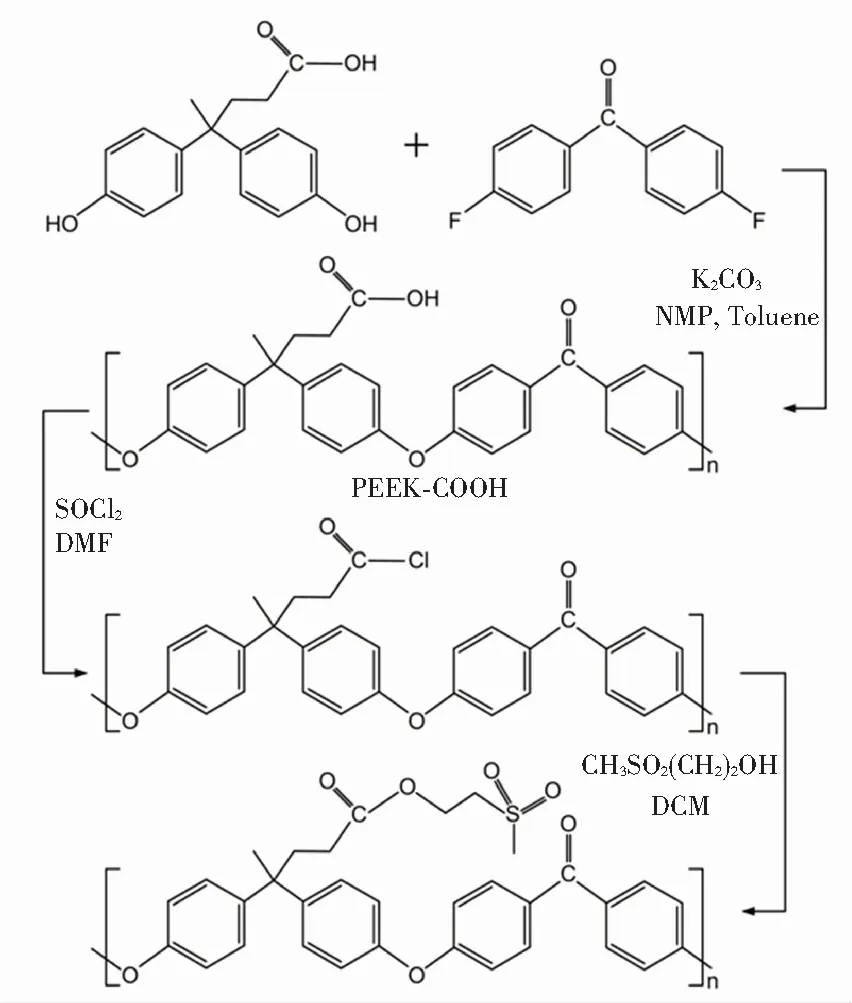

Functional groups have been commonly introduced into the neat monomers, or other functional monomers are chosen to synthesize the modified PEEK. Wei et al.[14]fabricated a new type of PEEK through the post functionalization of carboxyl groups decorated PEEK (PEEK-COOH)(Scheme 4).

Scheme 3 Synthesis pathway of common PEEK via nucleophilic substitution route

Scheme 4 Synthesis pathway of PEEK-SO2through post functionalization of the corresponding PEEK-COOH[14]

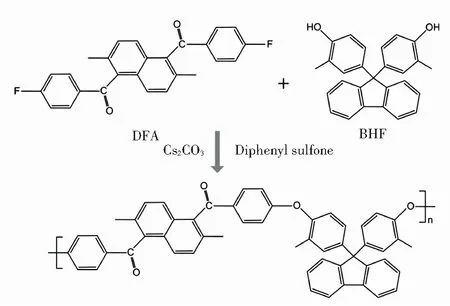

Karthikeyan et al.[15]obtained PEEK containing propargyl groups through the post reaction of hydroxyl terminated PEEK. The integration of propargyl groups effectively increased the thermal stability, mechanical performance, and fracture toughness for high-performance engineering applications. Fluorene-based PEEKs (F-PEEK) could be normally synthesized using a 9,9-diarylfluorene-containing biphenol and a naphthalene-containing dihaloarene[16], through a two-step polycondensation of 9,9-bis(4-hydroxy-3-methylphenyl)fluorene (DFA) and 1,5-bis(4-fluorobenzoyl)-2,6-dimethylnaphthalene (BHF) with cesium carbonate for accelerating reactions. The synthesis pathway is shown in Scheme 5.

Scheme 5 Synthesis pathway of F-PEEK[16]

3 Performances of PEEK Material

As a kind of widely used material, PEEK possesses plenty of indispensable advantages, such as excellent mechanical properties, dimensional stability, thermal stability, chemical stability, biocompatibility, etc. The regular molecular chains ensure the desired strength and stability, and the intrinsic thermal plastic endows it with great processing and reprocessing capacity, promoting the feasibility in widespread applications[17-18].

The preparation of PEEK material has attracted researchers’ wide attention due to the excellent performances. The exceptional processability endows PEEK material with various applied patterns, such as membrane[19], nanofibers[20], aerogel[21], microfiller[22], matrix materials[23-24], and 3D printing component[25]. Every applied pattern owns its unique merits and could be used in various application fields. The affluent benzene rings on main chains and regular molecular arrangements give it the excellent mechanical properties and thermal stability, which could replace traditional metal or ceramic counterparts. The great chemical resistance is attributed to that there are not active reactive functional groups on PEEK chains. Meanwhile, it has great corrosion and irradiation resistance. In addition, PEEK material has been employed widely in biomedical applications due to the great biocompatibility and non-toxicity.

4 Applications of PEEK Material

PEEK materials have been used in various applied patterns and application fields. Electrospun nano/micro-fibers have attracted researches’ wide attention, because of the extremely high specific surface area and porosity, which are used widely in various fields[26]. As a kind of engineering plastics, PEEK matrix composite materials have been widely used in engineering and aerospace applications[24]. Sulfonated PEEK (SPEEK) electrospun nanofibers[20], and un-sulfonated PEEK microfibers[27]which exhibited homogeneous and defect-free morphology, extend the applications of PEEK in the field of energy storage. 3D printing with PEEK materials allow widespread utility of the materials for practical applications[28-31]. Wang et al.[30]used fused deposition modeling (FDM) method to achieve 3D printing of PEEK. Obtaining designed structure of PEEK material leads to a wide application prospect. Not only inherent merits, such as excellent mechanical property, thermal stability, chemical resistance, and biocompatibility, but also feasible various processing technologies and precise structures endow PEEK material with wide potential usage in lots of fields such as biomedical implants, machinery engineering, energy storage, and aerospace applications.

4.1 Biomedical Applications

Owing to the high mechanical strength, good chemical resistance, and biocompatibility, PEEK has been employed as a promising material in biomedical engineering[32-34], which could be widely used in orthopedic, trauma, and dental fields[35-37]. The processing pattern of PEEK used for biomedical applications has been developed widely, such as molding pressing, injection mold[38], 3D printing[39-41], and so on. Molding pressing and injection mold make it possible to prepare PEEK material with controllable mechanical performances[42]. 3D printing system could help researchers obtain urgently needed structures, which are conducive to the allowance of the initiation of cell attachment and osseintegration, and consequently contribute to tissue growth[43].

Due to the suitable mechanical performances, PEEK has been widely used in orthopedic and dental fields, as the elastic modulus (3-4 GPa) is close to the human bone[29], conducive to the homogeneous stress distribution from surrounding tissues. The matching of elastic modulus can avoid the phenomenon of bone resorption, which happens owing to stress shielding between metal implants and bones[44]. Besides, PEEK enables the adhesion of human osteoblasts and fibroblasts under inflammatory environmental conditions[45-46]. In addition, radiographic radiolucency and low density (1.32 g/cm3) make it suitable for biomedical implants[47].

4.1.1Bioactivitymodification

The inherent bioinertness hampers the application of PEEK in bone repair/substitution, due to the poor osteogenesis capability. Thus, improving the bioactivity of PEEK is a major challenge that must be solved to fully realize the potential benefits. Meanwhile, PEEK, because of the inherent bioinertness, has sometimes been considered to be a bioinert material, since it does not cause any adverse reaction to the human tissues[48]. Improving the bioactivity of PEEK materials without compromising the mechanical properties is a major challenge, which can be solved by two main strategies, surface modification and composite preparation[49-50]. Appropriate surface modification could effectively modify the osseointegration of PEEK implants[51]. Fabrication of composites can enable researchers to obtain variable combinations of mechanical properties required for any particular application[52-54]. Functional biofillers have been incorporated into PEEK matrix to endow it with the desired performances[53].

·Surfacemodification

The adhesion and integration of biomaterials is highly important for the tissue regarding the improving of surface performances, including hydrophilicity and roughness[54-55]. Besides, the cell differentiation and substrate osseointegration could be effectively controlled by the surface texture of PEEK material[56]. Surface modification of PEEK could effectively improve the bioactivity, and concurrently maintain the most advantageous properties. The concrete modification methods mainly include physical treatment modification, coating modification, and chemical modification.

Laser[57], gaseous plasma[58], and irradiation methods[59-60]could be used to modify the surface morphology of PEEK and improve the bioactivity. Omrani et al.[57]performed laser treatment for surface modification of PEEK, to gain the appropriate roughness and wettability, both of which are essential for cell adhesion,which is used in bone implant. Plasma surface treatment and Accelerated Neutral Atom Beam could be reliable alternative methods to improve the surface activity of PEEK material[58-60].

Surface properties of PEEK could be improved through the coating of growth factors and bioactive nanoparticles[61-62]. Wan et al.[56]immobilized the dual growth factors (insulin-like growth factor-1 and bone morphogenetic proteins-2) onto PEEK surface, and used polydopamine to obtain a bioactive coating. Besides, the aggregation of bioactive Ti-Mg alloy thin film onto PEEK material could effectively enhance the adhesion strength[63].

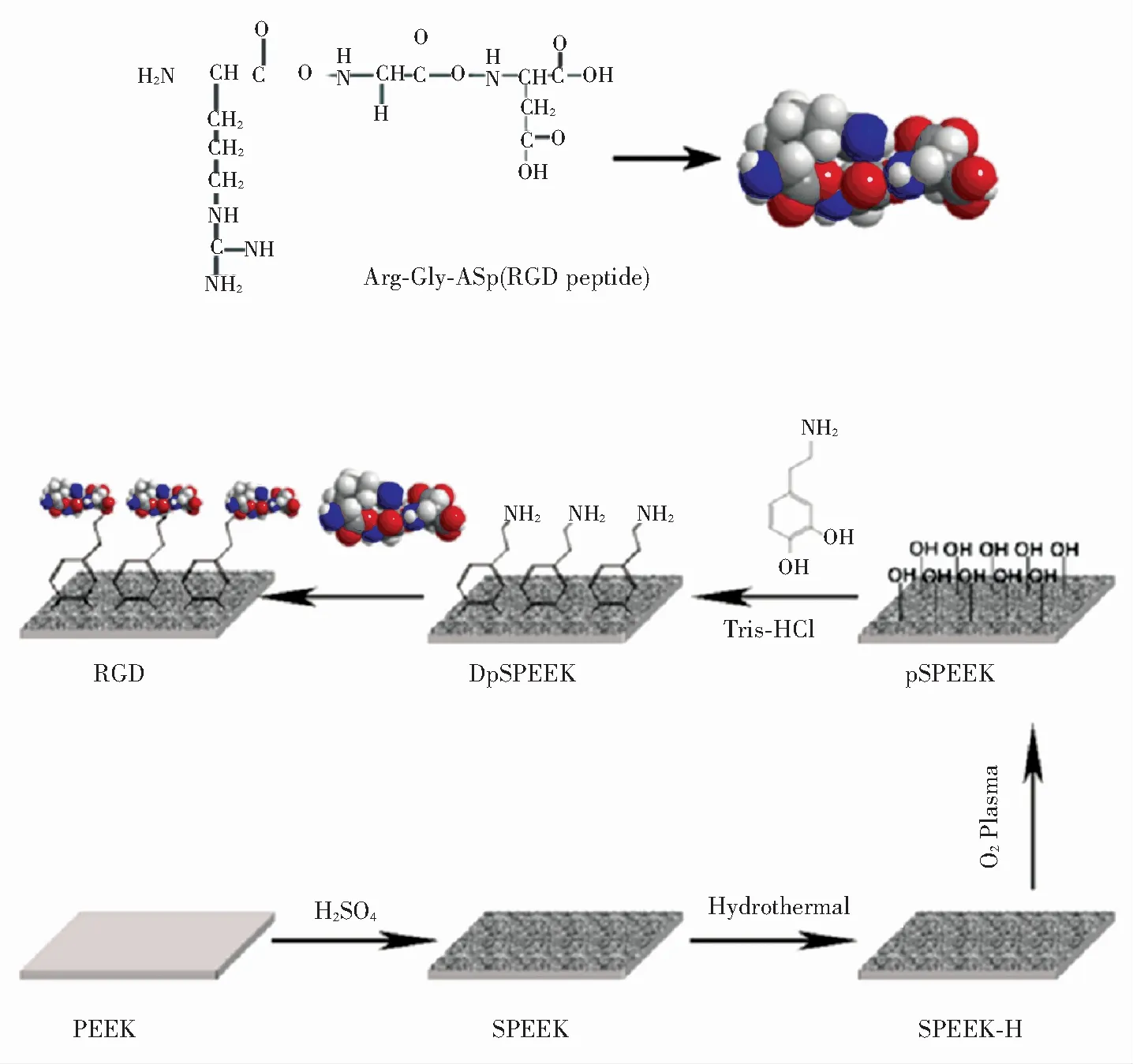

Some bioactive groups could be introduced into PEEK matrix via the corresponding chemical reaction[64-65]to modify the bioactivity of PEEK material. Masamoto et al.[66]treated PEEK with “precursor of apatite” (PrA), and achieved the stronger and faster adhesion to bone, which endows it with great bone-bonding properties. Besides, the combination of sulfonation and alkali treatment could largely improve the apatite deposition and bioactivity of PEEK rapidly[67]. In addition, the integration of tripeptide Arg-Gly-Asp (RGD) onto the PDA-coated surface of PEEK was developed to produce a bioactive and biocompatible PEEK for osteodifferentiation[68],as shown in Fig.1.

Fig.1 Schematic diagram of the fabrication of a functional PEEK surface[68](Reprinted with permission from Ref. [68]. Copyright 2019, American Chemical Society)

·Compositingwithbioactivematerials

Compared with the pure material, the mechanical performances of composites could be improved via the integration of low-cost enhanced material[69]. Thus, biomedical PEEK composites could achieve the tailored properties[70]. The bioactivity of PEEK could be improved through the incorporation of PEEK with other materials, such as polydimethylsiloxane (PDMS)[71], organic silicone[72], AgNPs[73], and graphene oxide (GO)[74].

4.1.2Orthopedicapplications

PEEK has many positive qualities, such as bioinertness, biocompatibility, suitable strength, and elastic properties[75-76]. Nevertheless, lack of bioactivity and biointegration might result in the failure of the graft implants and reconstructive procedure[77].

There are three main methods to improve osseointegration and bone apposition of PEEK material.

·IncorporatingbioactivematerialsintoPEEK

Tantalum, due to the excellent malleability and chemical resistance, could be introduced into PEEK matrix to modify the performances[78-79]. Besides, calcium silicate (CaS) was incorporated into PEEK matrix to endow the bioactive cage with fusion ability and stable mechanical performances[80-81].

·CoatingbiomaterialsontoPEEKimplants

Xu et al.[82]loaded the Dex/Mino liposome onto PEEK surface, gaining the improved bioactivity, which presented favorable stability and cytocompatibility. He et al.[83]constructed a chlorogenic acid/grafted peptide hydrogel system, as supported by PEEK material, which exhibited excellent bioaffinity and antibacatetial activity.

·IntroducingporosityintoPEEKimplants

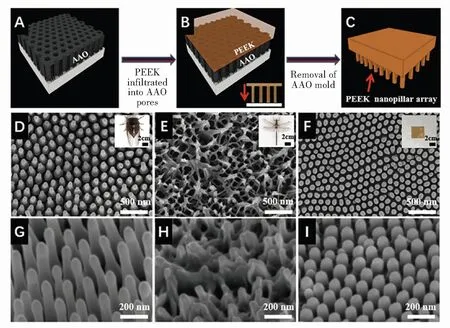

Highly micro-porous surface structure could promote the bioactivity of PEEK material[84]. A novel approach which filled a threaded PEEK hollow chamber with holes with CaS/hydroxyapatite (HA) composites and loaded active molecules, improving bone anchorage and reduced prosthetic failure[85]. Ye et al.[86]proposed a delicate cicada and catkin inspired biomimetic smart structure, using PEEK as a model implant(Fig.2). The obtained PEEK biomimetic sample could inhibit bacterial adhesion from providing wide antimicrobial range and long antibacterial performance.

Fig.2 Schematic diagram and SEM images of the nanopillars array on PEEK[86](Reprinted with permission from Ref. [86]. Copyright 2019, Royal Society of Chemistry)

In addition, to meet the enhanced strength and biocompatibility of orthopaedic implants, bioactive enhanced fillers have been integrated into PEEK matrix to fabricate the exceptional mechanical performance composites. Multi-walled carbon nanotubes (MWCNTs)[87], bioactive glass (BG)[87], and carbon fiber (CF)[88]are commonly used as the reinforced fillers for PEEK matrix. Carbon fiber reinforced PEEK (CF-PEEK) is expected to replace metal implants in orthopaedic surgery[89]. The radiolucency of CF-PEEK endows it with visualization of bone and tissue components[90-91], which could be implemented by 3D printing technology[92-94].

4.1.3Dentalprosthesis

PEEK has become a candidate for dental prosthesis[95-96]. Due to the low density and good polishability, PEEK material has been employed as a promising substitute for the fabrication of dental implant abutments[97]. Incorporating biocompatible inorganic fillers into PEEK-based composites could be used in dental implants[82].

4.2 Machinery Engineering

PEEK show high performance in applications involving relative motion. Its good chemical resistance, aging resistance, high strength, and high wear resistance make it an ideal material for machinery engineering components[98-99]. Therefore, PEEK has been used as the substitutes of such parts as transmission gears, seal rings, sliders, bushings, and bearings[100-102].

In the machinery applications, PEEK material is often rubbed against other counterface. Thus, the PEEK-metal interface is crucial in determining the tribological properties of PEEK-metal tribopairs, including contact temperature, friction coefficient, and wear resistance[103-105]. Besides, different friction responses of PEEK material are related to the variation manner of temperature[106-108]. To modify the tribological performance, surface modification might be effective. Besides, inorganic particles are incorporated into PEEK matrix to improve the abrasion resistance[109].

4.2.1Surfacemodification

The tribological properties of metal interfaces have been commonly improved via the deposition of PEEK coating. For example, Ti-6Al-4V alloy substrate was coated with PEEK to develop a better surface topography, which showed a lower friction coefficient as well as higher wear resistance[110]. In addition, the surface topography of PEEK could be modified through the Friedel-Crafts reaction and successive epoxidation to obtain high adhesion strength[111].

4.2.2EnhancementofPEEKwithinorganicparticles

The incorporation of inorganic particles into PEEK matrix could effectively improve the tribological performances[112]. Cenosphere fillers have been incorporated into carbon fiber reinforced PEEK composites to enhance the wear resistance under different load conditions[113]. Bartolomeu et al.[114]gathered Ti6Al4V and PEEK properties in a cellular structured component, which is conducive to a good compromise between the primary stability and wear performance.

4.2.3PEEK-CFcompositeswithtribologicalcoatings

In machinery engineering, it is important to ensure the mechanical properties of load-bearing component, overlapping joints, and contacted interface[115]. Thus, PEEK-based enhanced composites have been developed for machinery applications which desire excellent mechanical and tribological properties[116]. Hassan et al.[117]built a lubricating PEEK-CF composites by coating polyetherimide (PEI) and COOH-functionalized MWCNTs. The miscibility was improved through the hydrogen bonding and π-π interaction among components, significantly enhancing the mechanical performances.

4.3 Energy Storage

PEEK, due to the great chemical resistance and mechanical properties, has been employed in energy storage, especially as batteries separators. It is essential for lithium-ion batteries (LIBs) that separators possess superior mechanical properties, thermal stability, and electrolyte wettability[118-125]. Li et al.[126]synthesized F-PEEK polymers as well as fabricated the porous LIBs separators via an electrospinning method, which improved the safety and electrochemical properties. Li et al.[127]exploited hydroxymethyl functionalized PEEK (HOPEEK) as the separator of LIBs. Solid HOPEEK backbone endowed it with high thermal stability and high conductivity. Li et al.[121]reported a sponge-like porous PEEK membrane, which exhibited high thermal stability and mechanical performances.

4.4 Aerospace Application

It is important for aerospace materials to be application specific, lightweighted, and stable[128]. PEEK has a promising application prospect with its low density, high glass transition temperature, and stability under ultra-high vacuum condition[129-130]. The applications of PEEK material in aerospace fields are universal, such as aviation parts, connector, fastener, high temperature insulation ring, insulation heat sink, etc. It is noteworthy that PEEK’s stability under conditions close to real processing[131]and suitability under space environment conditions[132]are really significant for space applications.

To meet the harsh condition in space environment, PEEK based enhanced composites have been developed widely, which could be more viable candidates for aerospace applications[133]. PEEK composites exhibit a viable composition of creep resistance and ductility, which is attractive to manufacturers and engineers[134-135]. Upon the addition of reinforced fillers, the adhesive strength[136], reliability[137], stiffness, and structural integrity[138]of PEEK matrix could be greatly improved. Commonly, the reinforced fillers which could be used in enhancing the performances of PEEK matrix mainly include CF[139], CNTs[140], graphene nanoplates (GNPs)[6], and other carbon-precursor fillers[141]. Li et al.[142]prepared the enhanced conductivity MWCNT/nickel-coated carbonized Loofah fiber (CLF) (Ni@CLF)/PEEK. Composites exhibited excellent electromagnetic shielding properties and outstanding compressive performance,as shown in Fig.3.

Li et al.[143]fabricated GNP/CLF/PEEK composites by compressive moulding technology. The composite showed application potential in harsh environments like aerospace, warships, and special devices as structural and functional integrated materials.

Fig.3 Schematic illustration the preparation process of Ni-coated CLF (a) and MWCNT/Ni@CLF/PEEK composite (b)[142](Reprinted with permission from Ref. [142]. Copyright 2019, American Chemical Society)

Among the various reinforced fillers, CF has been the most indispensable fillers to enhance the performances of PEEK matrix. Continuous PEEK-CF composites have attracted particular attention owing to the excellent mechanical properties[144-145], thermal-assistance[146-147], and corrosion-assistance[148-149]. Caballe-Serrano et al.[33]synthesized nickel-plated CF (Ni-CF) via electroplating, and fabricated Ni-CF/PEEK composites by melt-mixing method. Conductive Ni-CF/PEEK composites are suitable for electromagnetic interference shielding. It is noteworthy that the interfacial properties between CF and PEEK matrix should be investigated and modified effectively[150-152]. Hassan et al.[153]improved the interaction between CF and PEEK through chemical grafting method. The mechanical properties were enhanced by regulating the interface of CF and PEEK.

5 Summary and Outlook

This review highlighted the basic content, synthesis pathway,and applied pattern of PEEK as well as its various applications in biomedical, machinery, energy storage, and aerospace fields. The synthesis of PEEK productions with the desired properties and the concrete modification method of PEEK based materials has been introduced and exemplified towards various fields of application, including machinery engineering, separator, and aerospace. In addition to the great biocompatibility, it has attracted broad attention for usage in biomedical implants. Apart from the PEEK materials, PEEK based composites have been applied in various fields owing to the enhanced performances. Multifunctional fillers such as CF, CNTs, GO, etc. are often employed as the candidates for reinforcing the properties of PEEK matrix. There are loads of successful attempts in developing the elaborated performances and concrete applications of PEEK based material. However, there are many challenges in practical procedures. For biomedical implants, the bioactivity and non-immunogenicity are still the major challenges for us researchers to overcome. For machinery engineering, trobilogical performances need to be modified to promote operating efficiency. The flexibility and formability should be improved when used for film separator. In aerospace fields, the stronger mechanical properties and resistance to harsh environment should be considered and investigated. As for PEEK based composites, the compatibility between PEEK and fillers should be modified to improve the properties. The existing challenge could be the development direction, which many researchers are trying to tackle. In addition, accompanied by the fast development of smart apparatus, whether PEEK material could be applied in the field of intelligent devices is worth considering and exploring. We do believe that many researchers are ready to investigate or have investigated the PEEK based smart apparatus. It is reasonable for us to have confidence that the PEEK based materials have broad application prospects in various fields, and will be employed as indispensable substitutes in the future.

Abbreviations

PEEK Poly(ether ether ketone)

PAEK Poly(aryl ether ketone)

TFMSA Trifluoromethanesulphonic acid

PEEK-COOH PEEK containing carboxyl groups

PEEK-SO2Sulfonylated PEEK

PEEK-PR PEEK with terminal propargyl groups

PEEK-OH Hydroxyl terminated PEEK

F-PEEK Fluorene-based PEEK

DFA 9,9-bis(4-hydroxy-3-methylphenyl)fluorene

BHF 1,5-bis(4-fluorobenzoyl)-2,6-

dimethylnaphthalene

S-PEEK Sulfonated PEEK

PVA Poly(vinyl alcohol)

MMT Montmorillonite

CNTs Carbon nanotubes

FDM Fused deposition modeling

CF Carbon fiber

PDA Polydopamine

PrA Precursor of apatite

RGD Tripeptide Arg-Gly-Asp

PDMS Polydimethylsiloxane

GO Graphene oxide

Ta2O5Tantalum pentoxide

BMSCs Bone marrow derived stromal cells

CaS Calcium silicate

Ti-PEEK Titanium plasma-sprayed PEEK

CGA Chlorogenic acid

BFP Grafted peptide

HA Hydroxyapatite

MWCNTs Multi-walled carbon nanotubes

BG Bioactive glass

CF-PEEK Carbon fiber reinforced PEEK

SCF Short carbon fiber

PE Polyetherimide

LIBs Lithium-ion batteries

HOPEEK Hydroxymethyl functionalized PEEK

GNPs Graphene nanoplates

CLF Carbonized Loofah fiber

Ni-CF Nickel-plated CF

PEEK-NH2Aminated PEEK

Journal of Harbin Institute of Technology(New Series)2020年3期

Journal of Harbin Institute of Technology(New Series)2020年3期

- Journal of Harbin Institute of Technology(New Series)的其它文章

- Evolution Toward Artificial Intelligence of Things Under 6G Ubiquitous-X

- Evaluation Method of Output Waveform Quality for Neutral-Point- Clamped Three-Level Converter

- Review: Scalable Fabrication of Polymeric Nanofibers from Nano- Spinning Techniques to Emerging Applications

- Controlled Movements in Superlubric MEMS

- Modified Adsorption Capacity to Space Molecular Pollutant of Zeolite via Interface Engineering with Atomic Layer Deposition

- Random Low Patch-rank Method for Interpolation of Regularly Missing Traces