Effects of Rapid Cooling Rate on Microstructure Formation and Microhardness of Binary Ti-44Al Alloy

Xiaoyu Chen, Hongze Fang, Qi Wang, Ruirun Chen*, Hongsheng Ding, Yanqing Su and Jingjie Guo

(1. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;2. School of Electromechanic Engineering, Qingdao University, Qingdao 266071, Shandong, China)

Abstract: In order to refine microstructure grains and improve mechanical properties of TiAl alloys, Ti44Al (at.%) alloy was rapidly solidified by melt spinning under different cooling rates. Microstructure and microhardness of the alloy before and after rapid solidification were investigated. XRD results show that the ratio of α2 phase in binary alloy increased with the cooling rates, which is caused by more α phases directly transforming to α2 phases. Grain morphology changed from long dendrite to the mixture of equiaxed and dendrite to equiaxed with the increase of cooling rates. The grain size was refined from 200-600 μm of as-cast to 18 μm of the alloy cooled at 4.9×105 K/s, which is caused by the undercooling induced from rapid solidification. Lamellar spacing was decreased from 4.5 μm of as-cast to 1.1 μm by rapid solidification. With the increase of cooling rate, the content of α2 phase increased and γ phase decreased gradually. Rapid solidification can reduce the segregation of elements. The microhardness was improved from 247 HV to 556 HV, which results from grain refinement strengthening, reduction of lamellar spacing, and more content of α2 phase.

Keywords: Ti-44Al alloy; microstructure; microhardness; melt spinning; solidification path

1 Introduction

TiAl-based alloys have been applied in aviation and astronautics, military, vehicle engineering, and biomedical engineering, due to their low density, high intensity, good creep resistance, and excellent properties at high temperature[1-5]. However, the as-cast microstructures are coarse columnar lamellar (α2+γ) grains which produce low fracture toughness and poor room-temperature ductility[6-7]. Improving the ductility of TiAl-based alloys has recently been a focus of research. It is suggested that rapid solidification is an important branch in the field of materials science and engineering, which generates smaller grains, homogenous microstructures, and more excellent properties than conventional solidification[8-10]. The microstructures, the primary phase, and the microhardness of rapid solidified TiAl alloys can also be changed with increasing undercooling[11-13].

The microstructures of binary TiAl alloys are controlled by the volume fraction ofα2/γ. According to thermodynamic equilibrium theory, the volume fractions ofα2/γof binary alloys are mainly affected by the content of aluminum[14-16]. Kenel and Leinenbach[17]used the CALPHAD approach to predict and explain the microstructure of binary TiAl alloys under high cooling rates. They found that when Al ≤ 45 at.%, the alloys formed a coarse-grainedα/α2microstructure, while the alloys showed mixed microstructure consisting of coarseα/α2grains when 45 < Al < 48 at.% with local gamma grains and lamellarα2+γ. Ti-48Al alloy exhibits dendritic microstructure of lamellarα2+γdendrites and interdendritic gamma grains. Liu et al.[18]concluded that the two-phase (αandγ) coupled growing morphology in Ti-(51-54) Al (at.%) changes from regular lamellar to irregular blocks and equiaxed structures with the decrease of temperature gradient during growth. The solute diffusion and the dissolution ofγphase play important roles in coupled microstructure evolution. The transformation from a peritectic (L+α→γ) to metastable eutectic reaction (L→α+γ) of TiAl alloys induces the formation of two-phase coupled growth morphologies[19]. Actually, the study about binary TiAl alloys via rapid solidification is expected to be further studied and improved.

Chill-block melt-spinning method is frequency used to prepare TiAl-based alloys ribbons[20-21]with a flat surface and a thin thickness. Images captured by high speed infrared imaging revealed that ribbon formation is controlled by thermal transfer[22]. Most of the cooling rates are calculated by counting the rate of heat flow in Newton′s cooling mode[23-24]. The roll wheel speed and the cooling rate are in linear correlation, and the cooling rate increases with the increase of roll wheel speed.

Controlling microstructure of TiAl-based alloys strongly depends on both Al concentration and cooling rates. In this paper, the chill-block melting-spinning method was used to prepare the binary TiAl alloy. Its phases, microstructures and mechanical properties were analyzed. Based on these data, the microstructure and its effect on mechanical properties of rapidly solidified Ti-44Al alloy were elucidated.

2 Materials and Experimental Methods

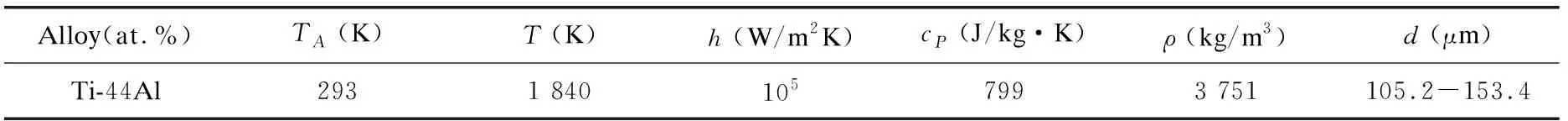

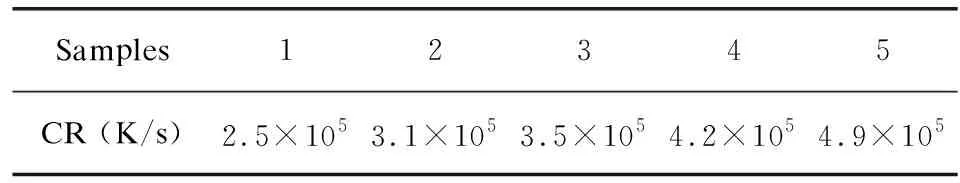

As-cast ingot with nominal composition of Ti-44Al (at.%) was prepared from titanium sponge (>99.9 %, wt. %) and aluminum (> 99.9 %, wt. %) using vacuum consumable arc-melting. The samples were cut into smaller pieces for melt spinning technique. In this experiment, the wheel material was pure copper and was set at different speeds. Table 1 shows the physical parameters of alloys for calculating cooling rates. The cooling rates were calculated by Newton heat transfer model[25]in the interface, as shown by Eq.(1). The physical parameters used in Eq. (1) are listed in Table 1, and the calculated results are listed in Table 2.

(1)

whereQis the heat transfer in the direction of heat flow,his the heat transfer coefficient,Ais the boundary area of heat flow,Tis the temperature of alloy droplet,TAis the temperature of copper roll,ρis the density of alloy,cPis the specific heat capacity, anddis the thickness of the thin strip produced by vacuum belt rejection.

Table 1 Physical parameters of Ti-44Al alloy

Table 2 Cooling rates (CR) of rapidly solidified Ti-44Al alloy

Samples12345CR (K/s)2.5×1053.1×1053.5×1054.2×1054.9×105

The rapidly solidified specimens were polished and etched with the reagent of 5%HF+5%HNO3+90%H2O (volume fraction). Phase constitution and crystal structure were analyzed by X-ray diffraction (XRD). Microstructures were observed by scanning electron microscopy (SEM) and transmission electron microscopy (TEM, Tecnai G2 F30), compositions were measured by energy dispersive X-ray spectrometry (EDS), and microhardness was tested by HVS-1000 Digital Microhardness Tester.

3 Results and Discussion

3.1 Microstructures of As-Cast Ti-44Al Alloy

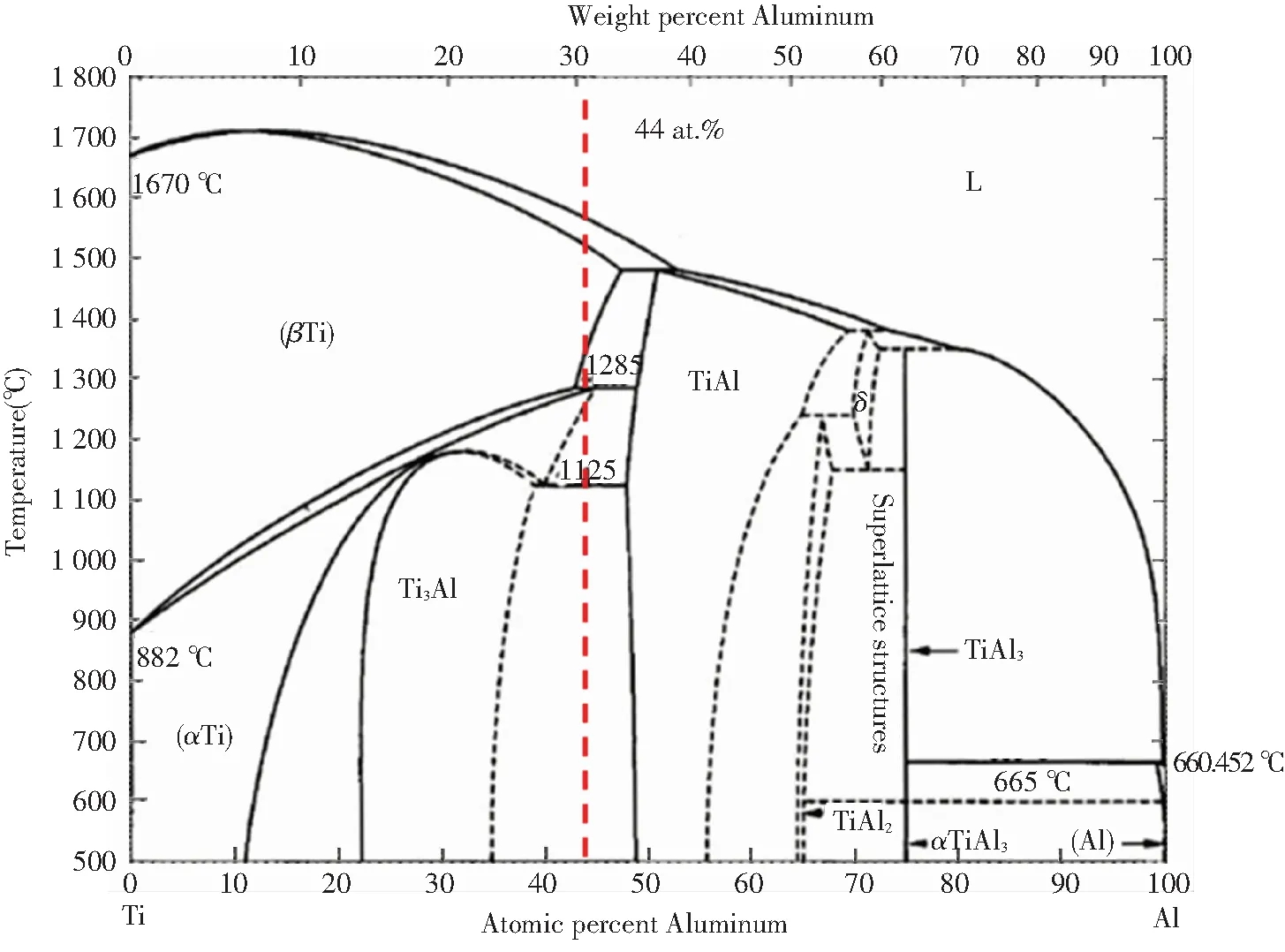

Based on binary TiAl alloy phase diagram, the transformation of Ti-44Al alloy followsL→L+β→β→β+α→α→α+γ→α2+γ, as shown in Fig.1.

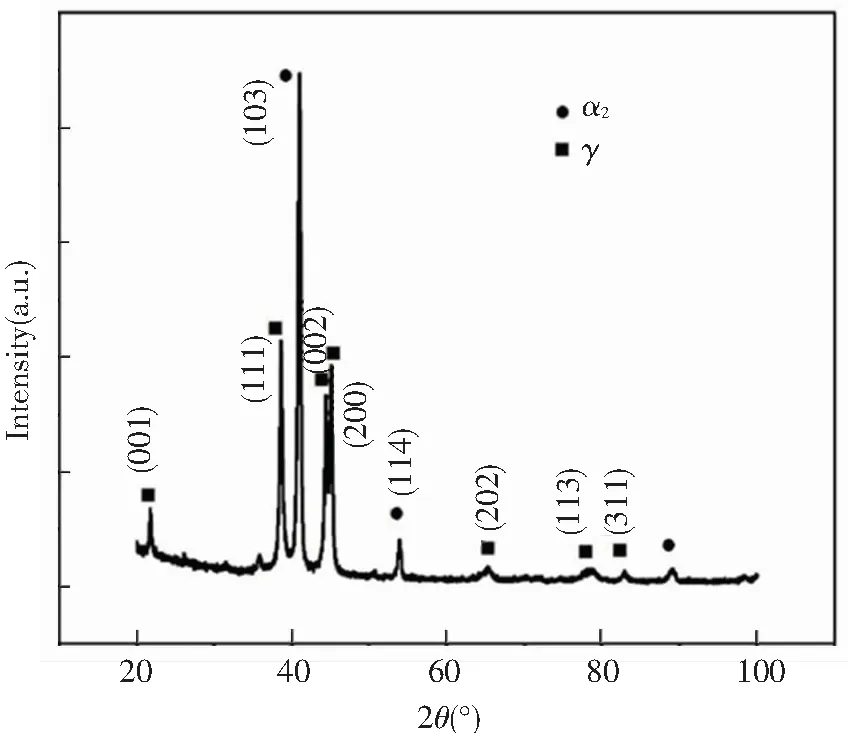

TiAl alloys with Al ≤ 45 at.% were fully solidified viaβ-Ti region, while the peritectic reaction occurred when Al is 48 at.%. Figs. 2(a)-(b) show the coarse lamellae microstructure of as-cast Ti-44Al alloy. The grain sizes of this alloy are hundreds of micros (200-600 μm), and the grain boundaries are irregular. The average lamellar spacing was measured by intercept method, which was calculated as 4.5 μm. XRD results show this alloy consists ofα2andγphases, as shown in Fig.3.

Fig.1 Equilibrium solidification diagram of Ti-Al alloys

Fig.3 XRD pattern ofas-cast Ti-44Al alloy

3.2 Microstructure of Rapidly Solidified Ti-44Al Alloy

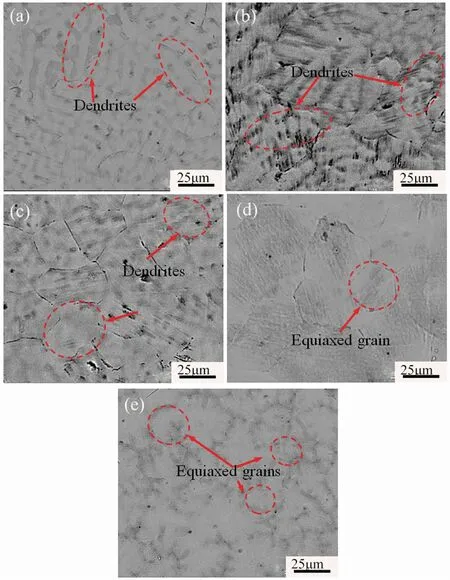

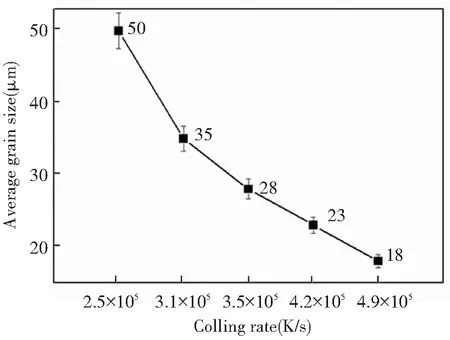

SEM-BSE microstructures of rapidly solidified Ti-44Al alloy at different cooling rates are shown in Fig.4. Dendrite morphologies are presented in Figs.4(a)-(b). It is noteworthy that the primary dendrites in Fig.4(a) are larger and longer than that in Fig.4(b). Equiaxed grains and one dendrite are displayed in Fig.4(c), while there are only equiaxed grains in Figs.4(d)-(e). It can be seen that the grain morphology changes from dendrite to mixture of equiaxed grains and dendrite to equiaxed grains with the increase of cooling rates. Meanwhile, the grain size is decreased from 50 μm (cooled at 2.5×105K/s) to 18 μm (cooled at 4.9×105K/s), the statistical results and changing trend of which are shown in Fig.5. It can be concluded that rapid solidification not only influences grain morphology, but also grain size. When the cooling rate is low (less than 3.1×105K/s), which means the roll rotation speed is low, the rapidly solidified alloy shows dendrite or near dendrite. Under this condition, the heat transfer is comparatively slow, which provides enough time for dendrite to be formed, as shown in Figs.4(a)-(b). With the increase of cooling rates, dendrite morphology decreases and equiaxed grain begins to form. When cooling rate is further increased, the equiaxed grain size decreases. The discontinuous arms are caused by the supercooled liquid surrounding the first solidified alloy, which stops most of the latent heat generated from crystallization from being transmitted. Because of the high concentration of solute and low melting point at the junction of dendrite arms, the latent heat from crystallization is released here and the temperature at the junction of dendrite arms is increased. As a result, the dendrite arms are partly melted, and then become isolated and interrupted.

Fig.4 Microstructure of rapid solidified Ti-44Al alloy under different cooling rates (a) 2.5×105K/s (b) 3.1×105K/s (c) 3.5×105K/s (d) 4.2×105K/s (e) 4.9×105K/s

Fig.5 Effect of cooling rates on different average grain sizes of Ti-44Al alloy

Figs.4(c)-(e) show irregular equiaxed grains. With the increase of cooling rate, the grain size gradually decreases to about 18 μm. When the cooling rate is 3.5×105K/s, the alloy begins to form ribbon, and the microstructure consists of equiaxed dendrites and irregular equiaxed grains (Fig.4(c)), which is the critical state of transformation from the dendrite to the equiaxed. When the cooling rate is 4.2×105K/s, the microstructure consists solely of irregular equiaxed grains with obvious lamellae and several light dark structures distributed around grain boundaries, as shown in Fig.4(d). When the cooling rate is 4.9×105K/s, there is no irregular equiaxed grain boundary, and the light dark structure becomes thinner and presents continuous network distribution. Based on the lamellar microstructure of Ti-44Al alloy and the X-ray diffraction pattern, it is considered that the gray matrix phase obtained by rapid solidification is composed ofγphase andα2phase.

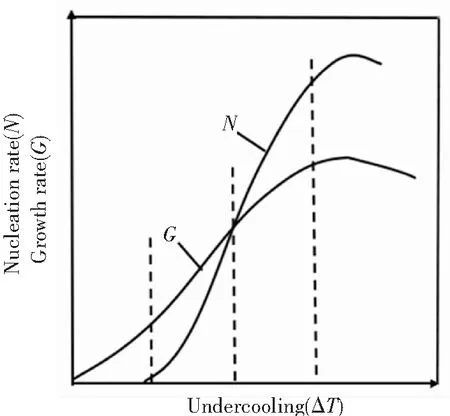

From Fig.5, with the increase of cooling rates, the grain size of Ti-44Al alloy decreases gradually. Supercooling has an effect on nucleation rate and growth rate. Increasing supercooling in a certain range will increase the nucleation rate and growth rate at differentrates of increase. The rate of increase of nucleation rate is faster than that of growth rate, as shown in Fig.6. In the supercooling range of general metals, the larger the undercooling degree is, the larger the ratio of nucleation rate to growth rate is, and the smaller the grain size is. In this study, the method of increasing supercooling is to increase the cooling rate of liquid metal, which changes in the order of 105K/s. Rapid solidification technology is an efficient method to obtain fine grains. In addition, the rapid solidification at a higher cooling rate of more than 105K/s can rapidly cool the molten liquid metal and obtain great degree of supercooling. The atoms have no time to diffuse to maintain the short-range ordered arrangement of the liquid, and to solidify to obtain the solid metal, which is the amorphous metal.

Fig.6 Effect of undercooling on nucleation rate and growth rate

3.3 Lamellar Structure of Rapidly Solidified Ti-44Al Alloy

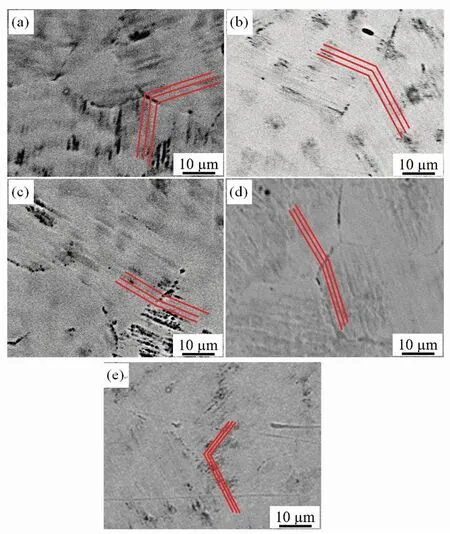

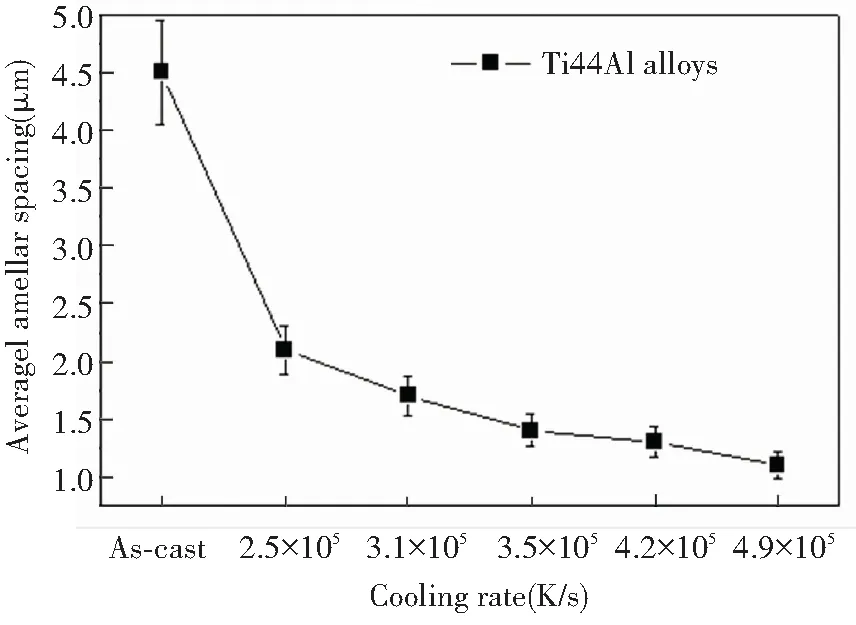

Lamellar structure is a very important aspect for TiAl alloys. Not only lamellar colony size, but also lamellar spacing influences their mechanical properties. Lamellar structure with higher magnification is shown in Fig.7. Lamellar spacing was measured and the average lamellar spacing was calculated. The results are shown in Fig. 8. Lamellar spacing is decreased from 4.5 μm of as-cast to 1.1 μm of rapidly solidified at 4.9×105K/s. It can be seen that rapid solidification can decrease the lamellar spacing, and lamellar spacing decrease with the increase of cooling rates.

3.4 Phase Composition of Rapidly Solidified Ti-44Al Alloy

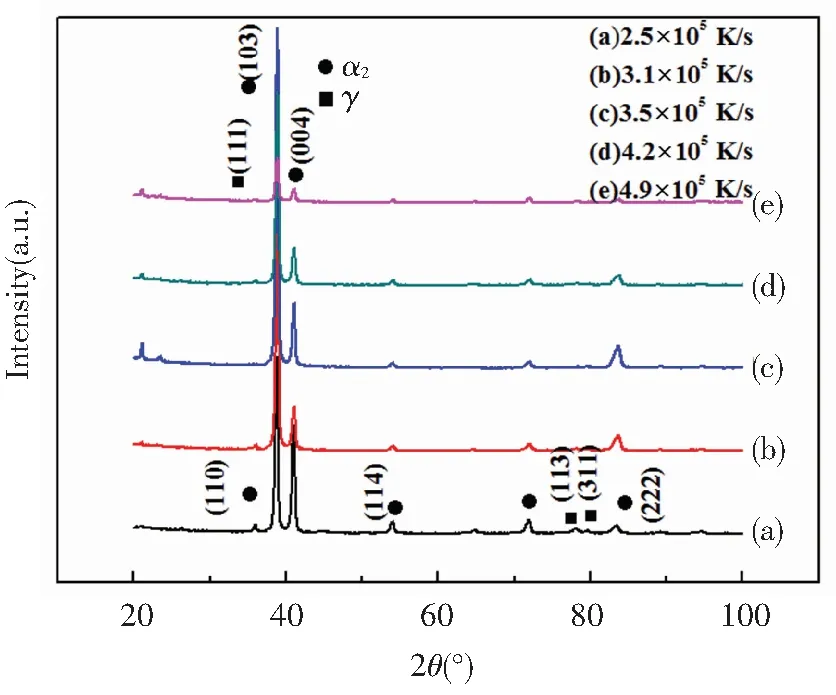

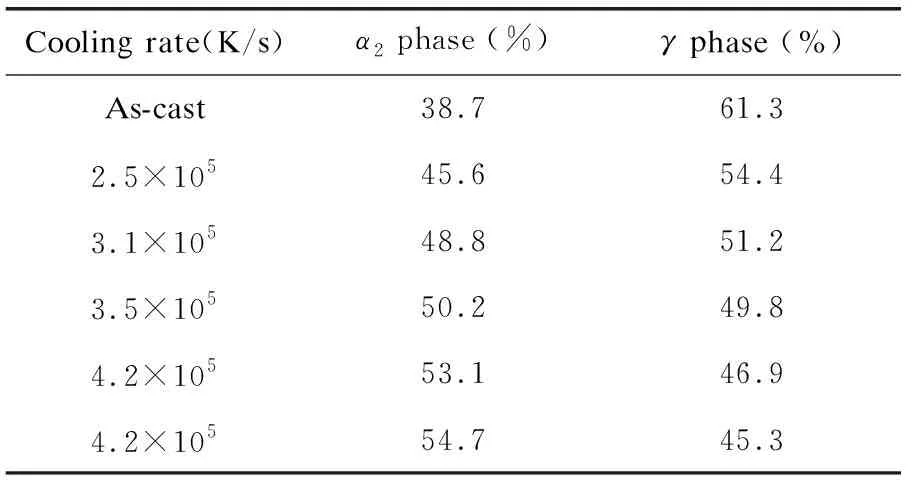

The rapidly solidified Ti-44Al alloy samples were examined by XRD. Results show that the phases are mainly composed ofα2phase andγphase, as shown in Fig.9. Main diffraction peak ofα2phase is (103) in rapid solidified Ti-44Al alloy. With the increase of cooling rate, the diffraction peaks (113) (311) ofγphase gradually decrease and disappear, which indicates the content ofγphase decreases gradually, whereasα2phase increases. The volume fraction ofγphase is lower than that of as-cast alloy. Phase volume fraction of as-cast and rapidly solidified Ti-44Al alloy with different cooling rates is listed in Table 3.

Fig.7 Lamellae structure of rapidly solidified alloy at different cooling rates (a) 2.5×105K/s (b) 3.1×105K/s (c) 3.5×105K/s (d) 4.2×105K/s (e) 4.9×105K/s

Fig.8 Lamellae spacing of rapidly solidified alloy at different cooling rates

Fig.9 XRD patterns of rapidly solidified Ti-44Al alloy

Table 3 Phase volume fraction of as-cast and rapidly solidified Ti-44Al alloy

Cooling rate(K/s)α2 phase (%)γ phase (%)As-cast38.761.32.5×10545.654.43.1×10548.851.23.5×10550.249.84.2×10553.146.94.2×10554.745.3

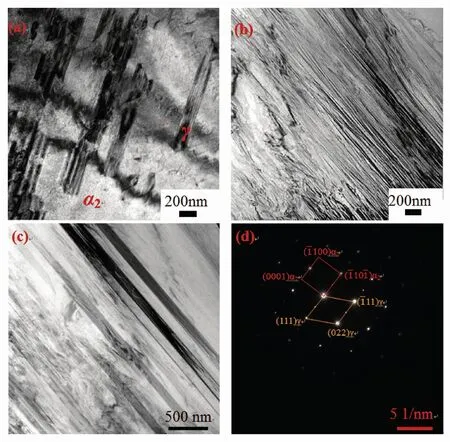

The microstructure of rapidly solidified Ti-44Al alloy was analyzed by TEM, as shown in Fig.10. The matrix is massiveα2phase, and the lathy shape isγphase. The lamellae structures are observed in other regions and the coarse lamellae are broken down into smaller lamellar. The formation of lamellar is incomplete. Based on the structural characteristics of the Ti-44Al alloy before and after rapid solidification, the primary phase of as-cast Ti-44Al alloy isβphase, while it isαphase when it is rapidly solidified. With increasing cooling rate, the stable primaryβphase was depressed, and the (L+α) metastable zone of undercooled alloys firstly solidified. Most of metastableαphase was reserved, and then orderly transformed intoα2phase instead of completely changing intoγphase. Theγphase in lathy shape always nucleates and grows at the grain boundary and some high energy areas, such as stacking fault. In addition, the lamellar structure forms incompletely, resulting from slower diffusion of elements. The higher the cooling rate is, the less time the elements diffuse. Based on the above analysis, solidification path of rapidly solidified Ti-44Al alloy isL→L+α→α+γm→α+α2+γm→(α2+γ) +α2+γm→α2+γ+γm.

3.5 Compositional Distribution of Rapidly Solidified Ti-44Al Alloy

Besides refining the grain size of the alloy, rapid solidification can reduce the segregation of elements. Energy spectrum analysis was carried out at different areas including bright contrast area (I), dark contrast area (II), and grain boundary (III), as shown in Fig.4. The analyses results are shown in Table 4. When the cooling rate is 2.5×105K/s, the Al content of all areas are 47.30 at.%, 47.24 at.%, and 46.92 at.%, respectively, which are all more than 44 at.%. When the cooling rate is 3.1×105K/s, the Al content of bright contrast area is 42.65 at.%, which is less than 44 at.%, but those of other two areas are a little higher than normal. When the cooling rate increases to 3.5×105K/s, the contents of Al are 46.03 at. %, 45.22 at.%, and 45.28 at.%, respectively, which are close to 44 at.%. The above EDS data show that there is a segregation of Al element when the cooling rate is low. At a higher cooling rate, the Al content of the three areas are 44.35 at.%, 43.82 at.%, and 44.52 at.%, respectively, where the segregation is very little.

Fig.10 TEM images of rapidly solidified TiAl alloy at 4.9×105K/s (a)α2andγphase (b-c)α2andγlamellar (d)SAED pattern ofα2andγlamellar

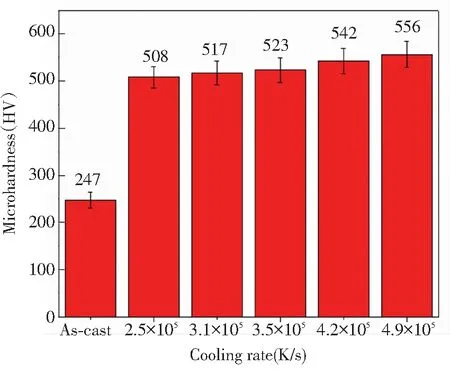

3.6 Microhardness of As-Cast and Rapidly Solidified Ti-44Al Alloy

Fig.11 shows the microhardness of as-cast and rapidly solidified Ti-44Al alloy. It is noted that the microhardness of all rapidly solidified alloy is improved more than 100 %, which increases with increasing cooling rates. When the cooling rate is 4.9×105K/s, the microhardness reaches 556 HV. The improvement of microhardness results from grain refinement strengthening, reduction of lamellar spacing, and the variation of phase proportions. It is confirmed thatβphase is the hardest in TiAl-based alloys,α2phase is intermediate, andγphase is the weakest of all. According to the above conclusion, the volume fraction ofα2phase increases in rapidly solidified Ti-44Al alloy. Consequently, it is meaningful to improve the mechanical properties of TiAl-based alloys by controlling theα2/γratio except during refining.

Table 4 EDS results of different areas of the rapidly solidified Ti-44Al alloy

Fig.11 Microhardness of as-cast and rapidly solidified Ti-44Al alloy

4 Conclusions

1) Grain morphology changes from long dendrite to the mixture of equiaxed grains and dendrite to equiaxed grains with the increase of cooling rates. The grain size was refined as 50 μm (cooled at 2.5×105K/s) and 18 μm (cooled at 4.9×105K/s) from hundreds of micros (200-600 μm) as-cast. They result from undercooling induced by rapid solidification.

2) The phases are mainly composed ofα2phase andγphase. With the increase of cooling rate, the content ofα2phase increased andγphase decreased gradually. The volume fraction ofγphase was lower than that of as-cast alloy.

3) Lamellar spacing was decreased from 4.5 μm of as-cast to 1.1 μm of rapidly solidified at 4.9×105K/s. Rapid solidification can reduce the segregation of elements. The faster the solidification rate, the more uniform the composition.

4) The microhardness of rapidly solidified Ti-44Al alloy were greatly improved, which was increased from 247 HV to 556 HV. The improvement of the microhardness results from grain refinement strengthening, reduction of lamellar spacing, and moreα2phase.

Journal of Harbin Institute of Technology(New Series)2020年3期

Journal of Harbin Institute of Technology(New Series)2020年3期

- Journal of Harbin Institute of Technology(New Series)的其它文章

- Evolution Toward Artificial Intelligence of Things Under 6G Ubiquitous-X

- Evaluation Method of Output Waveform Quality for Neutral-Point- Clamped Three-Level Converter

- Review: Scalable Fabrication of Polymeric Nanofibers from Nano- Spinning Techniques to Emerging Applications

- Controlled Movements in Superlubric MEMS

- Review: Recent Progress on Poly(ether ether ketone) and Its Composites for Biomedical, Machinery, Energy and Aerospace Applications

- Modified Adsorption Capacity to Space Molecular Pollutant of Zeolite via Interface Engineering with Atomic Layer Deposition