Effects of initial particle gradation and rock content on crushing behaviors of weathered phyllite fills-A case of eastern Ankang section of Shiyan-Tianshui highway,China

Feifei Liu ,Xuesong Mao ,Yushuo Fan ,Linping Wu ,Wei Vitor Liu ,*

a School of Highway,Chang’an University,Xi’an,China

b Shijiazhuang Transportation Survey and Design Institute,Shijiazhuang,China

c Department of Civil and Environmental Engineering,University of Alberta,Edmonton,Canada

Keywords:Weathered phyllite fills Crushing behavior Compaction test Fractal dimension Relative fractal dimension

A B S T R A C T The objective of this paper is to investigate the effects of initial particle gradation and rock content on the crushing behavior(i.e.grain size before and after crushing)of weathered phyllite fills.Compaction tests were conducted on weathered phyllite fills with rock contents of 35% ,45% ,55% ,65% and 75% (by weight).First,the particle size distributions(PSDs)were observed before and after compaction,and then the particle breakage of weathered phyllite fills was analyzed by fractal dimension.Relative fractal dimension was proposed to evaluate the effects of initial rock content and initial gradation on the particle breakage.It was found that the fractal dimension method can well characterize the crushing behaviors of the weathered phyllite fills.The finer the fills were,the more they were compacted.That is,after the first compaction,the relative fractal dimension of the weathered phyllite fills increased as the rock content increased,reaching the values of 0.013,0.016,0.024,0.037 and 0.08,respectively.After the second compaction,these relative fractal dimension values,dominated by the initial particle gradation,became 0.059,0.072,0.052,0.095 and 0.118,respectively.In conclusion,the weathered phyllite fills with 55% rock content exhibited the least breakage and were most suitable for filling the subgrade.Findings in this paper will provide significant guidance for the construction of weathered phyllite filling subgrade in future projects.

1. Introduction

In road engineering,subgrade refers to the in situ material at natural ground level on which a road is constructed(Speight,2015).Subgrade is an essential part of the road.It bears the weight of the pavement and traffic load(Speight,2015).Accordingly,the working condition of the subgrade is of great significance.A good subgrade will improve the serviceability of the road,while a poor one may lead to pavement damage such as cracks and collapses,endangering safety.The subgrade fills play a key role, i.e. when poor-quality subgrade fill is used, roads fail frequently(Abd Karim et al.,2014).For example,due to the poor filling used for the subgrade of the Binjiang Road in Jiangmen City,Guangdong Province,China,uneven settlement was produced,inducing a great number of longitudinal cracks on the asphalt pavement(Sun et al.,2008).Subgrade fill is usually obtained locally based on its availability,that is,the source of subgrade fills varies depending on locations and geological conditions where the road is constructed.For example,after a tunnel excavation in Baihe County,Ankang City in Shaanxi Province,China,weathered phyllite waste slag became widely available.This phyllite is being used in the project of east Ankang section of Shiyan-Tianshui highway.It is an important section of Shiyan-Tianshui highway in the“2367”highway planning network in Shaanxi Province,China.The total length of the east Ankang section of the highway is 130 km(Mao,2012).Weathered phyllite is a low-grade metamorphic rock with “l(fā)eaf” structure and silky luster on a microscopically deformed wafer(Xu et al.,2018).Along the section is a large amount of weathered phyllite.From an industry perspective,using this weathered phyllite as subgrade fills saves construction costs and reduces environmental impacts.

However,more investigation is needed on using weathered phyllite as subgrade fills because particles of weathered phyllite are easily broken(Mao et al.,2011).Previous studies have shown that particle breakage is strongly associated with the mechanical behaviors of soil particles(Bolton,1986;Leung et al.,1996;Karube et al.,1999;Vilhar et al.,2013).In particular,particle breakage reduces the ratio between volumetric dilation and peak stress,and changes the plastic deformation mechanisms and shear failure modes(Kwok and Bolton,2011;Wang and Yan,2013;Yu and Towhata,2016).Particle breakage has also resulted in an increase in the mobilized basic friction angle,especially before failure(Yu and Su,2016).Research has shown that particle breakage plays a significant role in many engineering failures,such as landslides and deformation of subgrade(Nakamura et al.,2014).

Over the years,a great deal of research has examined the crushing behavior of granular soils(Ueng et al.,1988;AASHTO M145,1991;Lade et al.,1996).Generally,direct shear tests,uniaxial compression tests,and triaxial tests are the common laboratory approaches used to investigate particle crushing behavior(Nakata et al.,1999;Tarantino and Hyde,2005;Leleu and Valdes,2007;Xiao et al.,2014;Yu,2017).Some researchers(e.g.Zhao et al.,2015) adopted uniaxial compression tests with X-ray microtomography tests to investigate the particle crushing behavior,which has brought the study of particle breakage to a microscopic scale.

In recent years, researchers have proposed new ways to examine the particle crushing behaviors(i.e.grain sizes before and after crushing).Two of the most prominent methods are the discrete element method(Bolton et al.,2008;Liu et al.,2017;Manso et al., 2018) and the fractal dimension method (Tyler and Wheatcraft,1992).In particular,the fractal dimension method can directly reflect the soil particle size and has become an excellent tool to evaluate soil particle breakage.Despite many studies on normal granular soils(Luzzani and Coop,2002;Wang et al.,2013,2017a;Ghafghazi et al.,2014;Lee et al.,2018;Zhong et al.,2018),very little research has focused on the particle crushing behavior of weathered phyllite.Weathered phyllite has a flaky structure,and it presents layered microscopic morphologies(Garzón et al.,2010;Mao et al.,2016).This structure makes it different from other granular soils.Hence,the crushing behavior of weathered phyllite may be very different from that of normal granular soils.Weathered phyllite fills vary in particle gradations and rock contents.Herein,the“rock”is distinguished from the soil only in terms of the particle size,and it is defined as a block coarser than the soil matrix.This is the usual way to define soil and rock in the soil-rock mixture(e.g.subgrade fills)in transport engineering(Cen et al.,2017;Gao et al.,2018).In this way,“rock content”in this paper refers to a certain percentage(by weight)of coarser blocks(or coarse-grain content with grain size >5 mm)in the subgrade fills.Previous studies indicate that subgrade fills with a certain percentage of rock content(or coarse-grain content)are extremely inhomogeneous,and the rock content has greatly impact on the physical and mechanical properties of the fills(Vallejo and Mawby,2000;Coli et al.,2011;Xu et al.,2011;Wang et al.,2017b).Wang et al.(2009)studied the effect of coarse-grain(grain size >5 mm)contents on the crushing behavior of fills,concluding that the particle breakage first increases and then decreases with the increment of the coarsegrain content. Wang et al. (2012) pointed out that particle breakage is strongly associated with the coarse-grain contents by large-scale direct shear experiments.Likewise,the rock content may influence the crushing behaviors of fills.Altuhafi et al.(2011)and Huang et al.(2013)concluded that,in the well-graded samples, particle breakage is relatively harder than that in the uniformly-graded samples.Muir Wood(2006) made a similar conclusion indicating that when the particle size range is wider in a single sample,there is a lower probability of breakage.Hence,the rock contents and particle gradations are closely related to the crushing behaviors of fills,and further affect the physical and mechanical properties of fills(Hu et al.,2018).To this end,it is of great significance to investigate the crushing behavior of weathered phyllite fills-the effects of particle gradation and rock content on the changes of grain size(before and after crushing)-to examine the feasibility of using weathered phyllite as a potential subgrade fill.

The objective of this study is to investigate the effect of rock content and initial particle gradation on the crushing behaviors of weathered phyllite fills from the eastern Ankang section of the Shiyan-Tianshui highway,China.This study has highlighted the use of the fractal dimension method to evaluate the crushing behavior.Also,it has provided the optimum particle composition of weathered phyllite fills,at which particles are less likely to be crushed.The results obtained in this study can be further used in other pavement projects that are rich in weathered phyllite.

2. Experimental details

2.1. Physical characteristics of weathered phyllite fill

The weathered phyllite fills in this study were chosen randomly from the eastern Ankang section of the Shiyan-Tianshui highway in China(see Fig.1).According to the International Society for Rock Mechanics and Rock Engineering (ISRM) classification (Brown,1981),this weathered phyllite is considered as a highly weathered rock(W4).

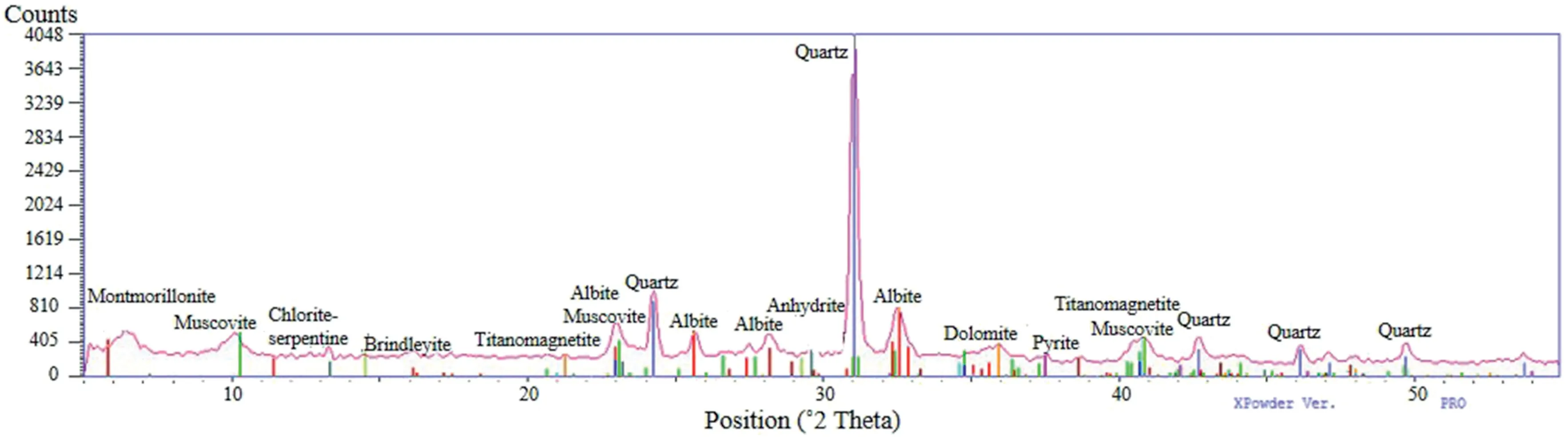

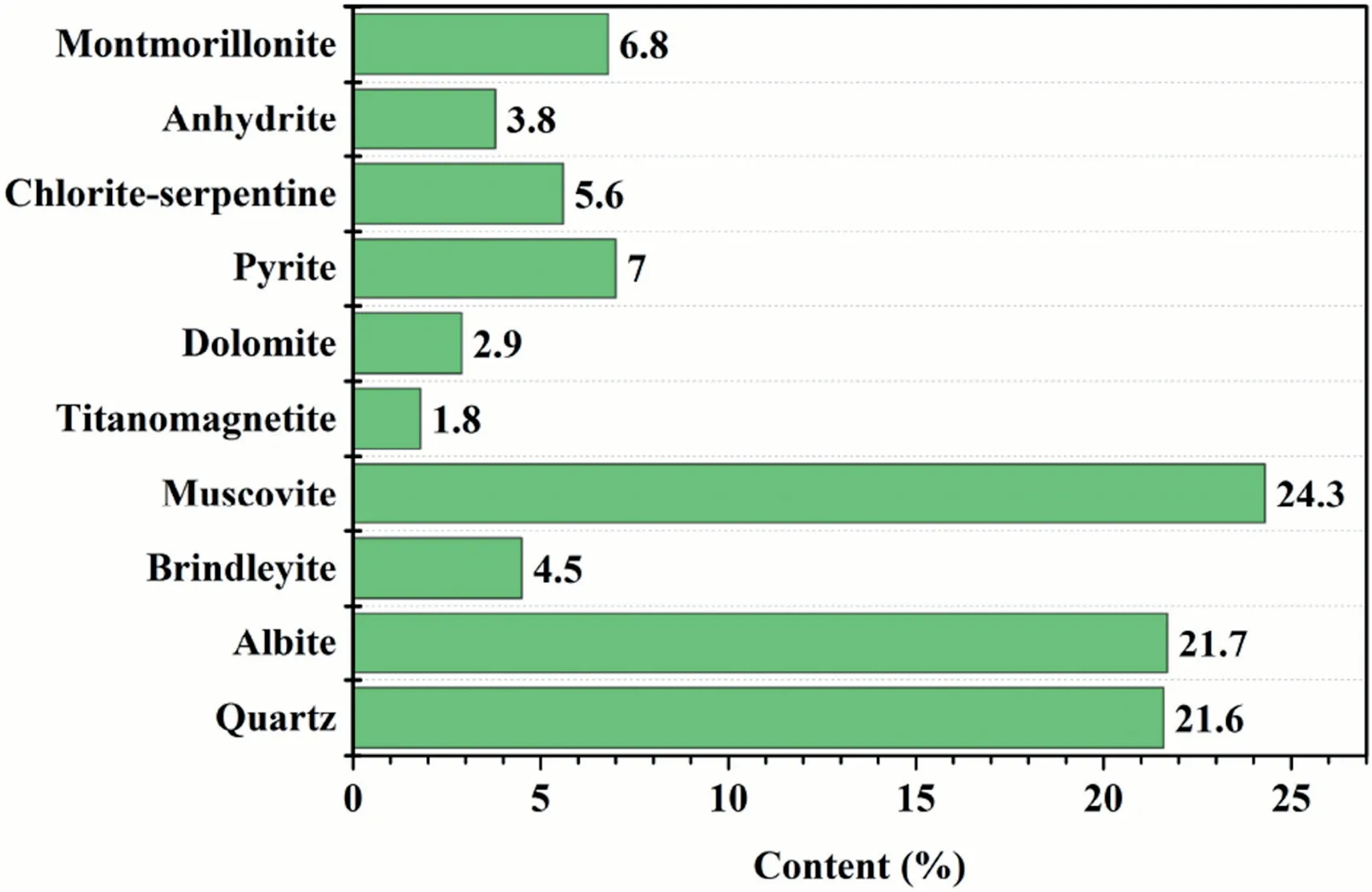

An X-ray powder diffraction(XRD)test was carried out to obtain the mineralogy of the weathered phyllite fills.As per Garzón et al.(2010),a sample was crushed and passed through a 63 μm sieve.The powdered sample was oven-dried at 110°C for 24 h.Then,the powered sample was sprinkled on a fiber lens(25 mm×25 mm×1 mm)for the XRD test.The results are shown in Fig.2.The quantitative results of the XRD analysis(Fig.3)indicate that the main mineralogy compositions are quartz(21.6% ),albite(21.7% ),and muscovite(24.3% ).The results obtained by Garzón et al.(2010)and Kemp et al.(2010)also showed that the main mineralogy composition of phyllite contained quartz and muscovite,although in different quantities.

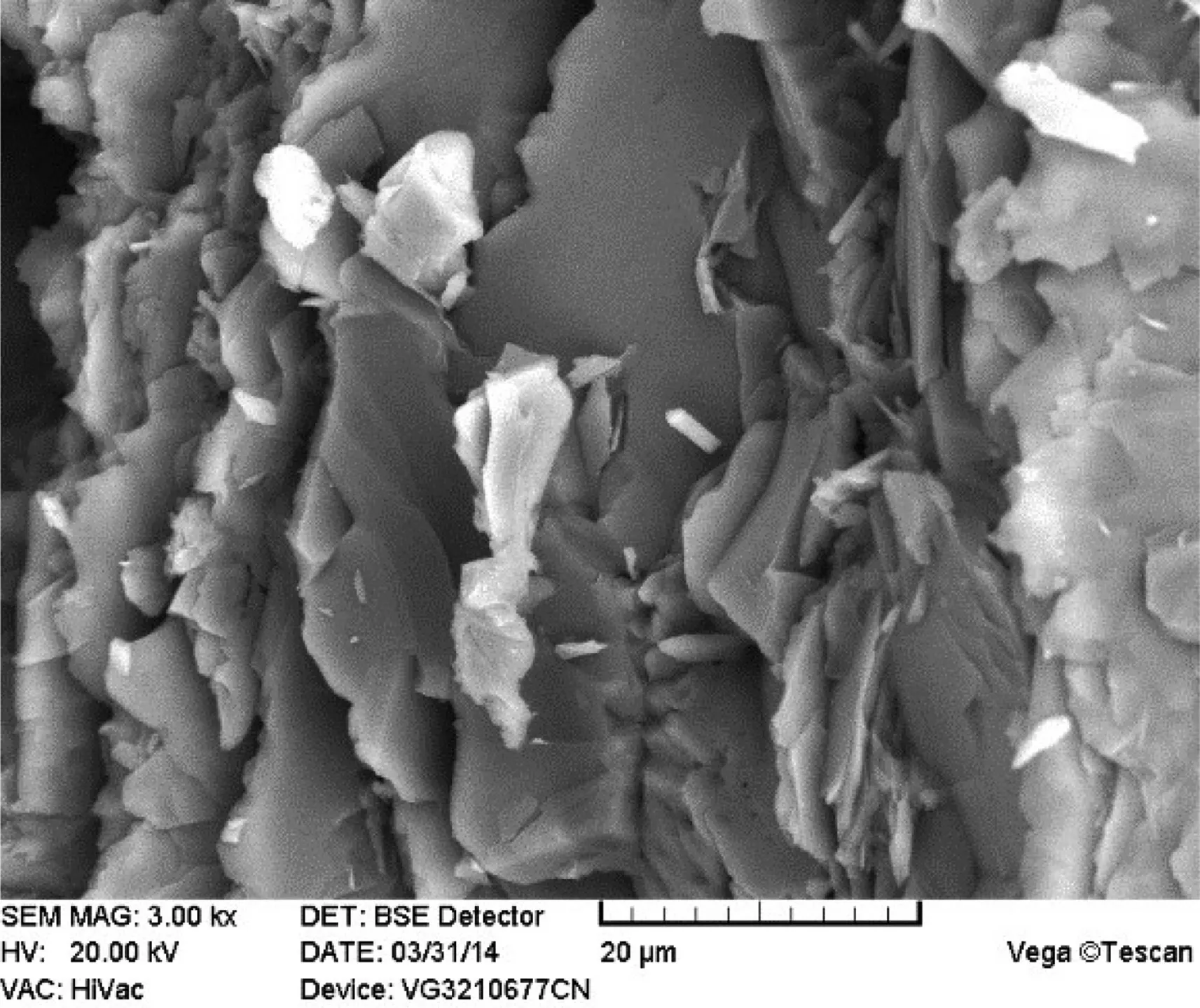

Micrographs of weathered phyllite sample(see Fig.4)were obtained in the early work(Mao et al.,2016).It can be seen from Fig.4 that the weathered phyllite presents layered morphologies due to the presence of muscovite.Besides,the grain characteristic of quartz can be also revealed in Fig.4.

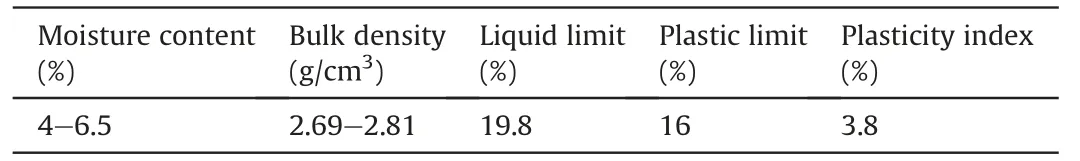

Physical properties of weathered phyllite fills such as moisture content,bulk density,and Atterberg limits were measured according to ASTM D2216-10(2010),ASTM D7263-09(2018)e2(2018)and ASTM D4318-17e1(2017),respectively.The results are shown in Table 1.

2.2. Preparation of samples

Different rock contents of weathered phyllite fills were chosen for this study.According to Medley and Lindquist(1995),the soilrock threshold(dthr)is 0.05 times the engineering dimensions.Herein,the engineering dimensions refer to as a characteristic dimension of an engineering structure,e.g.the diameter of a tunnel,the width of a foundation or the dimension of a laboratory sample.In this paper,the diameter of the compaction cylinder is 152.4 mm.Therefore,the calculated value of the soil-rock threshold(dthr)is 7.64 mm.Since a particle with the diameter of 7.64 mm will pass a 9.5 mm sieve and be retained on a 4.75 mm sieve,weathered phyllite particles with a diameter larger than 4.75 mm were defined as“rock”in this paper.

Fig.1.Location of weathered phyllite fills being studied.

Since the rock content of the weathered phyllite fills on-site ranged from 32% to 77% (by weight),five groups of weathered phyllite fills were prepared with 35% ,45% ,55% ,65% and 75% rock contents.According to ASTM D1557-12e1(2012),the tested soils(materials)should have 30% or less by mass of their particles retained on the 0.75 inch(19 mm)sieve.It was necessary to equivalently replace the oversized particles of the fill so that the maximum particle size was 37.5 mm after replacement.

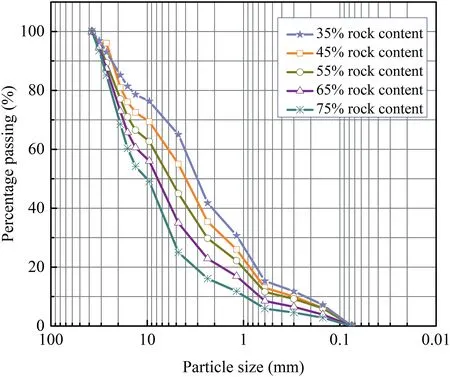

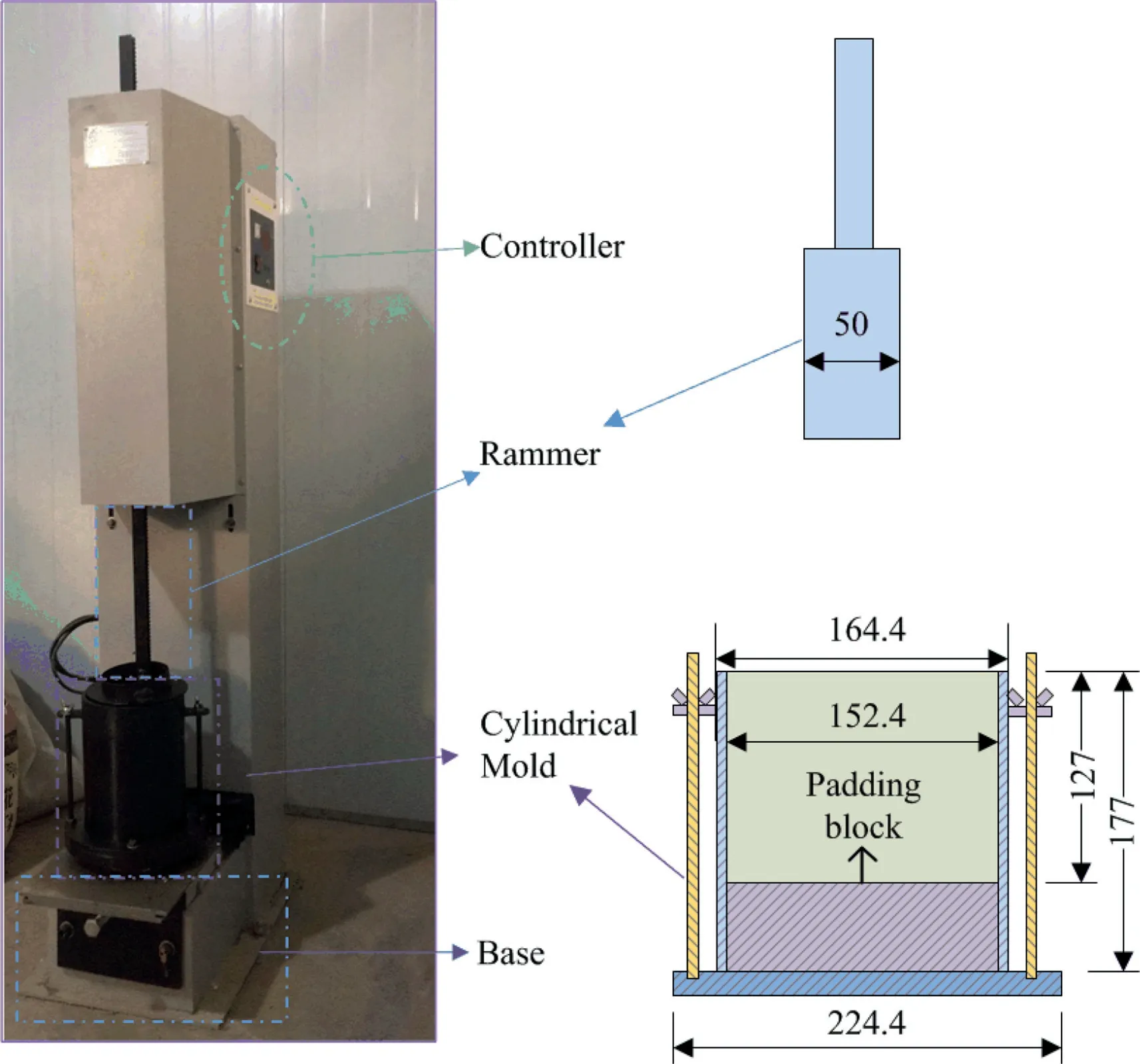

Particle size distribution(PSD)analyses of the weathered phyllite fills were carried out according to ASTM C136/C136M-14(2014).The PSDs for the five groups of weathered phyllite fills are shown in Fig.5.

Fig.2.XRD powder diagram of the weathered phyllite sample.

Fig.3.Summary of mineralogy composition of the weathered phyllite sample using XRD.

Fig.4.Scanning electron microscope(SEM)micrograph of a phyllite sample(Mao et al.,2016).

As illustrated in Fig.5,the gradation curve of weathered phyllite fills with 75% rock content is at the bottom,while that of weathered phyllite fills with 35% rock content is at the top.Fig.5 shows that the larger the rock content,the coarser the particle in the weathered phyllite fills.In addition,the coefficients of uniformity(CU)of the five groups are all larger than 10,while the coefficients of curvature(CC)range from 1 to 2(see Table 2),indicating that the five groups of fills are well-graded.Furthermore,it should be noted that the coefficient of uniformity(CU)of weathered phyllite fills with 55% rock content is the largest in the five groups,suggesting that the weathered phyllite fills with 55% rock content have a wider particle distribution than the other four groups.

Table 1 Physical properties of weathered phyllite sample.

Fig.5.Particle size distributions for weathered phyllite fills.

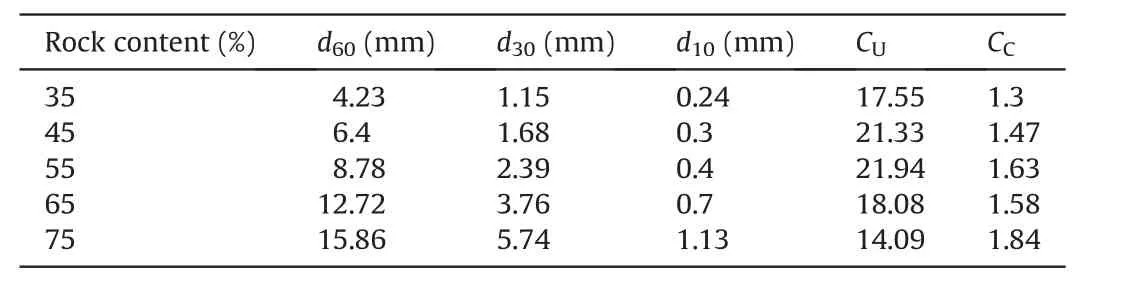

The maximum dry bulk density and optimum moisture content of the five groups of weathered phyllite fills were obtained according to the compaction standard ASTM D1557-12e1(2012),as shown in Table 3.

According to ASTM D1557-12e1(2012),the weathered phyllite fills(with 35% ,45% ,55% ,65% and 75% rock contents)were first oven-dried at 105°C.Then,the fills were mixed with distilled water to achieve their optimum moisture contents of 8.72% ,8.04% ,7.31% ,6.74% and 6.38% ,respectively(see Table 3)until the optimum compaction effect was obtained.The prepared fills were then placed in sealed containers for 24 h to ensure that the moisture content was uniformly distributed.

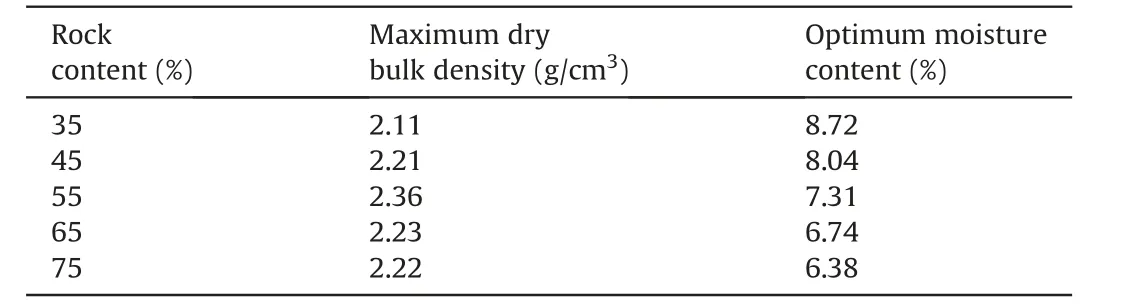

2.3. Testing apparatus and procedure

The ASTM(American Society of Testing Materials)laboratory compaction test was conducted in this study to explore the crushing behavior of weathered phyllite fills during the subgrade compaction process.The main apparatus used was the multifunctional electric hammer(see Fig.6),which consisted of a 44.48-N rammer,a controller,and a cylindrical mold with an internal diameter of 152.4 mm and a height of 177 mm.The controller was used to set the number of blows so that the hammer would work according to the predefined blows.

The prepared weathered phyllite fills were placed in five layers in the mold according to the requirements of the ASTM compaction test(ASTM D1557-12e1,2012).Each layer was compacted by 25 blows of the 10-lbf(44.48-N)rammer dropped from a distance of 18 inch(457.2 mm),i.e.the weathered phyllite fills were each subjected to a total compaction effort of about 56,000 ft-lbf/ft3(2700 kN m/m3).After the ASTM compaction test,the weatheredphyllite fills were placed in an oven at 110°C for at least 24 h,and then they were screened to determine their PSD.Later,the samples were re-compacted for a second time,according to ASTM C136/C136M-14 (2014), using the same compaction process and equipment.

Table 2 Coefficients of uniformity and curvature of weathered phyllite fills.

Table 3 Maximum dry bulk density and optimum moisture content for the weathered phyllite fills.

Fig.6.Testing apparatus for ASTM compaction test(unit:mm).

2.4. Fractal dimension method

The fractal dimension method(Tyler and Wheatcraft,1992)was used to characterize the crushing amount(the increase in fine particles)in this study.According to the fractal model,the fractal dimension can reflect the particle sizes of the fills.That is,the higher the content of the coarse grain,the smaller the fractal dimension(Tyler and Wheatcraft,1992;Jia et al.,2009).Based on this theory,the increase in fine particles can be determined by calculating the difference between the fractal dimensions before and after the compaction test.In this way,the amount of crushed weathered phyllite fills can be obtained.In this paper,the fractal dimension of the soil was calculated by

where D is the fractal dimension;diis the sieve size(mm);dmaxis the maximum grain size of the soil particles(mm),M1(di)is the mass of particles(g)with a grain size smaller than di;M2(di)is the mass of particles(g)with a grain size larger than di;Mtis the total mass of soil particles(g),and Mt=M1(di)+M2(di).Taking the logarithm on both sides of Eq.(1),we have

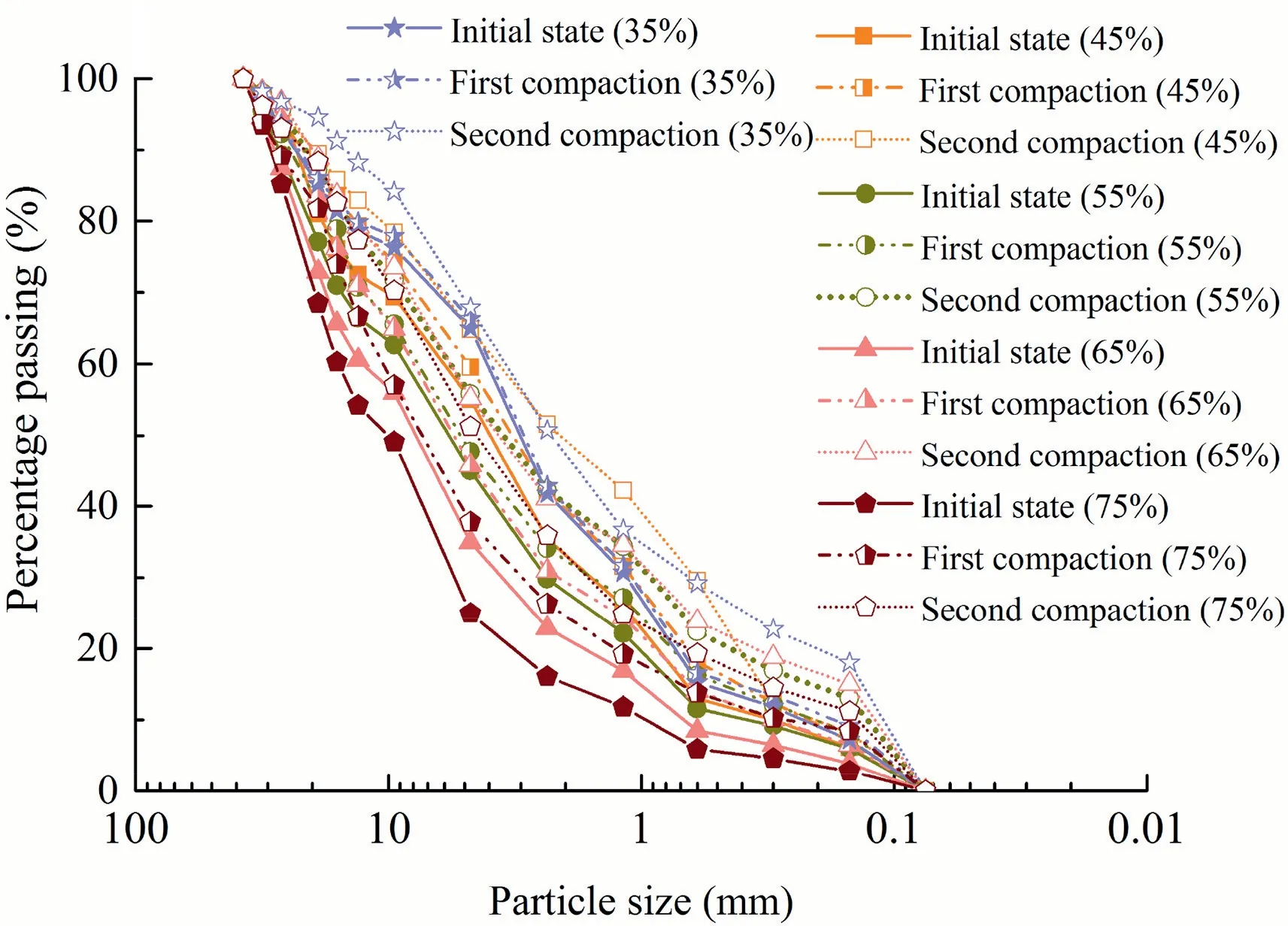

Fig.7.Particle size distributions for the weathered phyllite fills before and after compaction.

As shown in Eq.(2),according to the fractal dimension theory(Tyler and Wheatcraft,1992),if log10[M1(di)/Mt]is linearly correlated with log10(di/dmax)then the soil possesses fractal characteristics.

3. Results and discussion

3.1. Grain sizes before and after compaction

Particle size distributions for the weathered phyllite fills before and after compaction are shown in Fig.7.The gradation curves of the weathered phyllite fills after compaction were above those before compaction,indicating that compaction had broken the particles.In addition,the gradation curves of the fills after the second compaction tests were above those after the first tests,indicating that the fills had been further broken down during the second compaction as compared with the first compaction.In other words,the phyllite fills became finer after each test.

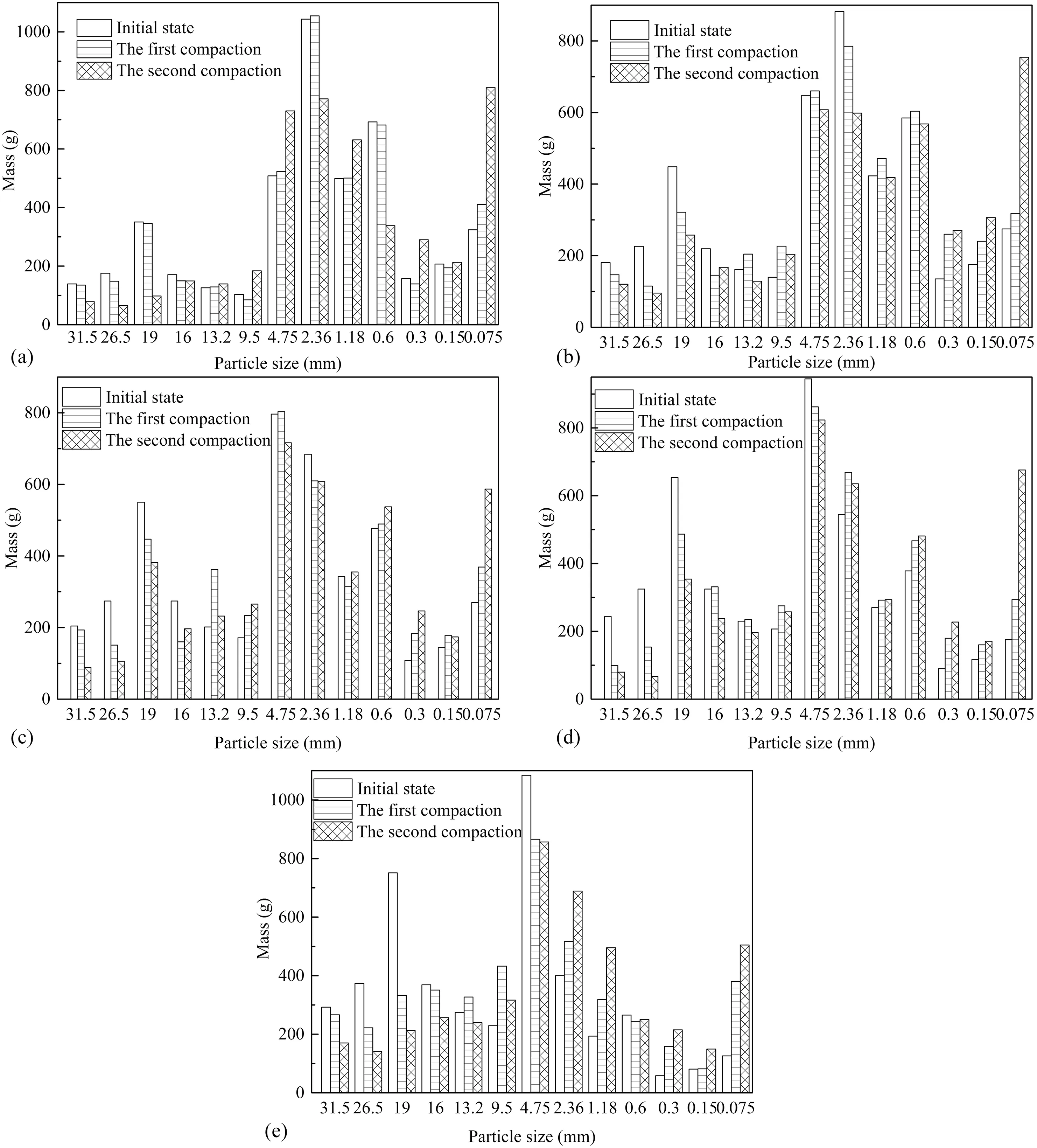

Regarding the crushing characteristics of the weathered phyllite fills,the particle mass changes were monitored for the weathered phyllite fills with different rock contents(see Fig.8).For weathered phyllite fills with 35% rock content,the mass of particles retained on the 16-31.5 mm,2.36 mm and 0.6 mm sieves showed a decreasing trend,while the mass of other particle groups increased.For weathered phyllite fills with 45% and 55% rock contents,there was an observable decrease in the mass of particles retained on the 16-31.5 mm and 2.36 mm sieves,with a remarkable increase in the mass of particles retained on the 9.5-13.2 mm and 0.15-0.075 mm sieves.For weathered phyllite fills with 65% and 75% rock contents,the mass of the particles retained on the 19-31.5 mm and 4.75 mm sieves was significantly reduced,while the mass of the particle groups retained on the 9.5 mm and 2.36-0.075 mm sieves was dramatically increased.It was interesting to note that the mass of larger particles decreased,while the mass of smaller particles increased,indicating that the larger particles were broken into smaller ones under compaction.This is because the smaller particles exhibit higher strength than the larger ones(Nakata et al.,2001;McDowell,2002).

Fig.8.Mass of weathered phyllite fills retained on various sieves before and after compaction:(a)35% rock content;(b)45% rock content;(c)55% rock content;(d)65% rock content;and(e)75% rock content.

Fig.8 shows that the mass of small grains after compaction varied with compaction efforts and initial rock contents. For weathered phyllite fills with 35% rock content,the mass of the particles retained on the 0.075 mm sieve after the first and second compactions increased by 26.81% and 150% ,respectively,when compared with the initial state samples.For the fills with 45% rock content,the mass of the particles retained on the 0.075 mm sieve after the first and second compactions increased by 38.83% and 174.75% ,respectively,compared with the initial state samples.For the fills with 55% rock content,the mass of particles retained on the 0.075 mm sieve after the first and second compactions increased by 36.7% and 117.44% ,respectively,when compared with the initial state samples.For the fills with 65% rock content,the mass of particles retained on the 0.075 mm sieve after the first and second compactions increased by 67.29% and 285.24% , respectively,compared with the initial state samples.While for the fills with 75% rock content,the mass of particles retained on the 0.075 mm sieve increased by 202.14% and 300.71% ,respectively,compared with the initial state samples.In other words,the mass of particles retained on the 0.075 mm sieve increased with the compaction effort.The compaction effort is the external work or the total energy input applied to the particles.Xiao et al.(2014)showed that particle crushing was well correlated with the external work,or the total energy input to the soil element.Other researchers also found that the mass of small grains increased with greater rock content,similar to the findings of Sammis and Steacy(1995)and Zhang and Baudet(2013).Weathered phyllite fills with different initial rock contents present different initial PSDs.According to Sazzad and Suzuki(2013),PSD is a key factor that affects particle crushing.This suggested that it was not only the compaction effort but alsothe initial rock content of the weathered phyllite fills affected the amount of crushed particle.

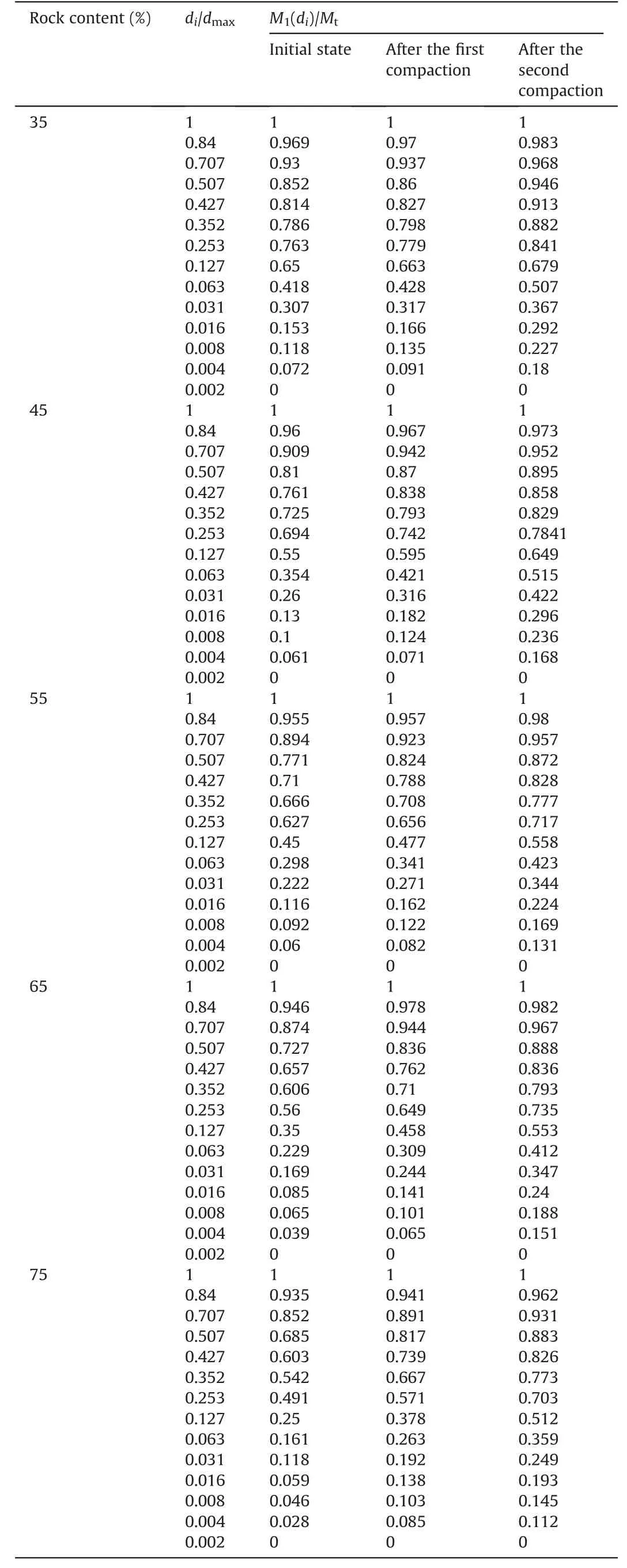

Table 4 M1(di)/Mt vs.di/dmax.

3.2. Fractal dimensions of weathered phyllite fills

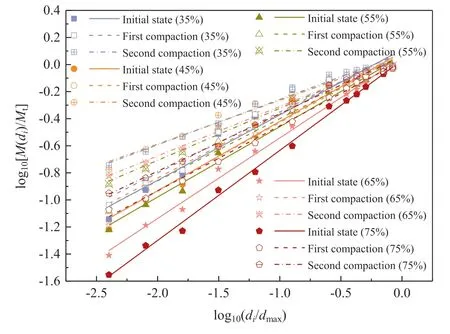

According to Eq.(1),dmaxof the weathered phyllite fills was 37.5 mm.Mtand M1(di)of the weathered phyllite fills before and after compaction were calculated according to Eqs.(1)and(2),as shown in Table 4 and Fig.9.It can be observed that log10[M1(di)/Mt]and log10(di/dmax)have a good linear correlation,and the coefficients of correlation are greater than 0.96.

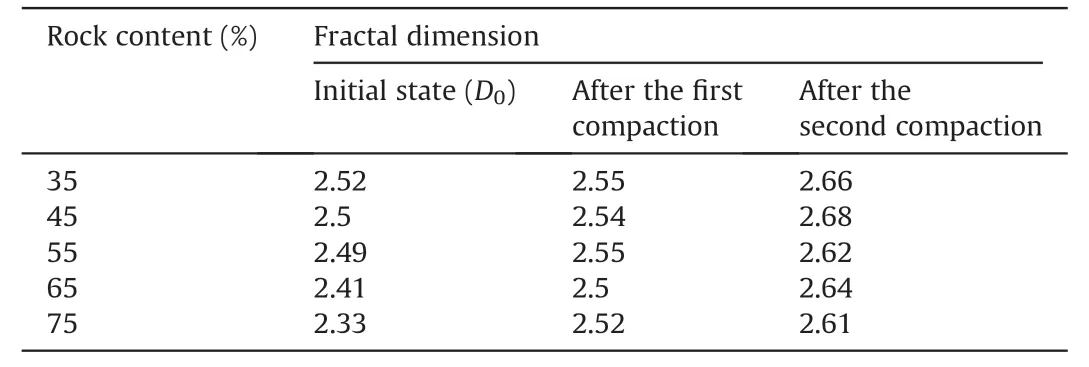

According to Tyler and Wheatcraft(1992),if log10[M1(di)/Mt]is linearly correlated with log10(di/dmax), then the soil possesses fractal characteristics.Based on this,the studied weathered phyllite fills before and after compaction had fractal characteristics.The fractal dimensions of the weathered phyllite fills are shown in Table 5.

As shown in Table 5,in the initial state,the fractal dimension(D0)of the weathered phyllite fills with 35% rock content was the largest(D0=2.52)in these five groups.In contrast,the fractal dimension of the weathered phyllite fills with 75% rock content was the smallest(D0=2.33).This agrees with the theory of fractal dimension,i.e.the coarser the fills,the smaller the fractal dimension(Tyler and Wheatcraft,1992).The weathered phyllite fills with 75% rock content were coarser than other groups,hence,their fractal dimension was the smallest.After compaction,the fractal dimensions of all the weathered phyllite fills increased.This means that the weathered phyllite fills have been crushed into finer particles after compaction.This is similar to the results of Kikumoto et al. (2010), who found that particle breakage increases the number of fine particles.

The fractal dimensions of the weathered phyllite fills after the second compaction were larger than those after the first compaction,indicating that weathered phyllite fills were further broken.This is because particle breakage increases when external work on the particles increases (Xiao et al., 2016a, b). This finding is consistent with the results in the analysis from the particle mass changes of the weathered phyllite fills(Section 3.1).This suggests that the fractal dimension can well characterize the fragmentation characteristics of weathered phyllite fills.

Table 5 shows that fractal dimensions of weathered phyllite fills after the second compaction all exceeded 2.6.For many granular soils,such as sand and gravel,the maximum fractal dimension during compression is around 2.5-2.6(McDowell et al.,1996;McDowell and Bolton,1998).This indicates that it is easier to break up weathered phyllite than other granular soils.Particle shape affects the way in which the particle breaks(Sazzad and Suzuki,2013).With their flaky structure,weathered phyllite particles are relatively fragile and much easier to break than other granular soils(e.g.sand,silt and gravel).

3.3. Effects of initial rock content and initial gradation on the degree of crushing

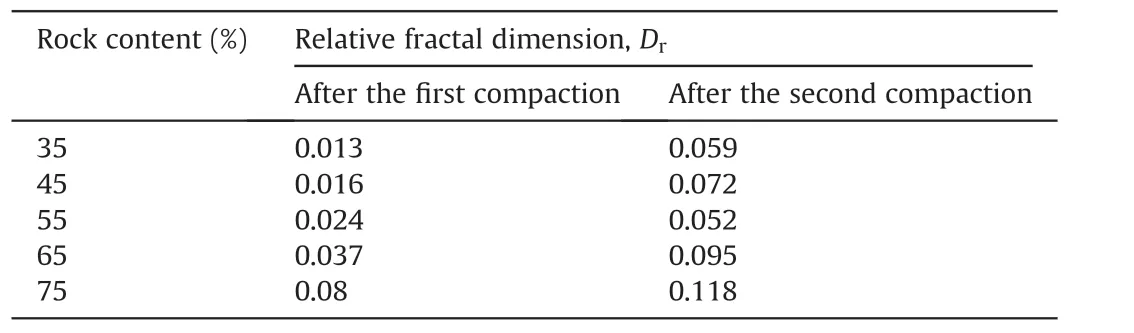

This study puts forward the method of relative fractal dimension(as shown in Eq.(3))to directly compare the degree of crushing for weathered phyllite fills with different rock contents.According to the definition of relative fractal dimension,a larger relative fractal dimension reflects a greater degree of crushing.

Fig.9.Fitting curves of log10(di/dmax)vs.log10[M(di)/Mt]for weathered phyllite fills before and after compaction.

where Dris the relative fractal dimension of weathered phyllite fills,and Dais the fractal dimension of weathered phyllite fills after compactions.Note that the values of Daare different,and they change after the first and second compactions.For example,as listed in Table 5,for 35% rock content,Daequals 2.55 after the first compaction,while it increases to 2.66 after the second compaction.

The relative fractal dimensions of weathered phyllite fills calculated according to Eq.(3)are shown in Table 6.

As shown in Table 6,after the first compaction,the relative fractal dimensions of the weathered phyllite fills with 35% ,45% ,55% ,65% and 75% rock contents were 0.013,0.016,0.024,0.037 and 0.08,respectively.That is,after the first compaction,the relative fractal dimensions of weathered phyllite fills increase with the rock content.In other words,the degree of crushing increases with the rock content after the first compaction.This is because a larger rock content is related to a higher percentage of large particles.However,large particles are more prone to being broken than small ones because smaller particles tend to exhibit greater strength than larger ones.For example,McDowell(2002)also observed that smaller particles present larger strength. He conducted onedimensional compression tests on dry silica Leighton Buzzard sand of various initial gradings,and found that the yield strength increases with the reduction of particle size. To sum up, the breakage of weathered phyllite fills seems to increase with the larger particle content under the first compaction.The data in Table 6 also show that,after the second compaction,the relative fractal dimensions of weathered phyllite fills all increase compared with those obtained after the first compaction,indicating that the fills have been further broken.

I read the list on her pad: starting school, confirmation10, turning 16, first date, graduation. While I worried how to help her deal with death, she was planning for her children s future.

The relative fractal dimension of fills with 55% rock content after the second compaction was smaller than that with 35% and 45% rock contents.In other words,the degree of crushing for fills with55% rock content was lower than that of fills with 35% and 45% rock contents.This observation did not agree with the findings by McDowell(2002).It may be caused by the initial particle gradation,which is of significance for defining the degree of crushing of soil samples.According to Muir Wood(2006)particle gradation of fills will certainly define the void ratio and particle breakage of the sample.He obtained this conclusion by investigating soils with various PSDs through the discrete element method.He also noticed that when the particle size range is wider in a single sample,most of the particles might rearrange and reverse under the external load,thereby reducing the crushing caused by mutual extrusion and thus lowering the probability of breakage.In addition,Altuhafi et al.(2011)pointed out that well-graded soil samples exhibit less breakage than those with uniform gradation;when the gradation is good enough,the gradation of particles will not change,even when subjected to high stress or strain.Table 2 shows that the coefficients of uniformity(CU)of weathered phyllite fills with 55% rock content were larger than those of the fills with other rock contents,meaning that the fills with 55% rock content had a wider particle distribution than the other four groups.Accordingly,the fills with 55% rock content experienced the least breakage in comparison with the other four groups after the second compaction.

Table 5 Fractal dimensions of weathered phyllite fills before and after compaction.

Table 6 Relative fractal dimensions of weathered phyllite fills.

For fills with 55% rock content,the coarse grains formed skeletons,while the fine grains were filled properly between the skeletons formed by the coarse grains.Thus,the coarse and fine grains synergistically resisted external load and accordingly,reduced the amount of stress on the large particles;for fills with 65% and 75% rock contents,more than 60% coarse grains in the fills were large particles.Due to lack of small particles to fill the skeleton formed by large particles,the large particles would bear higher stress,which made them more vulnerable to breakage (Vallejo and Lobo-Guerrero,2012;Zhang and Baudet,2013).For fills with 35% and 45% rock contents,there were more than 50% fine grains,in which coarse grains were absent to form the skeleton to resist the external load,leading the particles to break more easily.

To sum up,with the increase of compaction time(from one to two),the effect of rock content on the degree of crushing was weakened.On the other hand,the effect of the initial gradation of the fills on the degree of crushing increased.

4. Conclusions

This study investigated the effects of the initial particle gradation and rock content on the crushing behavior(i.e.grain size before and after crushing)of weathered phyllite fills from eastern Ankang section of Shiyan-Tianshui highway.The relative fractal dimension was used to evaluate the degree of crushing. The following conclusions were drawn:

(1)The relative fractal dimension can be used to compare the degree of crushing among different groups of subgrade fills with weathered phyllite,i.e.a larger relative fractal dimension represents a greater degree of crushing.

(2)External work has a great influence on the crushing of weathered phyllite fills.Particle breakage increases at larger external work on the particles.

(4)Weathered phyllite fills with 55% rock content had the optimum initial particle gradation and exhibited the least breakage. Hence, weathered phyllite fills with 55% rock content are recommended to fill the subgrade.

Declaration of Competing Interest

The authors wish to confirm that there are no known conflicts of interest associated with this publication,and there has been no significant financial support for this work that could have influenced its outcome.

Acknowledgments

This work was supported by the National Natural Science Foundation of China(Grant Nos.51378072 and 51878064)and the Special Fund for Basic Scientific Research of the Central College of Chang’an University (Grant No. 300102218408). The authors gratefully acknowledge their financial support.Finally,the first author would like to thank the financial support provided by the China Association of Science and Technology (Grant No.2017CASTQNJL048)for visiting the University of Alberta.

Journal of Rock Mechanics and Geotechnical Engineering2020年2期

Journal of Rock Mechanics and Geotechnical Engineering2020年2期

- Journal of Rock Mechanics and Geotechnical Engineering的其它文章

- Mountain tunnel under earthquake force:A review of possible causes of damages and restoration methods

- Determination of full-scale pore size distribution of Gaomiaozi bentonite and its permeability prediction

- Sugarcane press mud modification of expansive soil stabilized at optimum lime content:Strength,mineralogy and microstructural investigation

- Centrifuge model test and numerical interpretation of seismic responses of a partially submerged deposit slope

- Reliability analysis of earth dams using direct coupling

- Dynamic compression characteristics of layered rock mass of significant strength changes in adjacent layers