Integration of high-solid digestion and gasification to dispose horticultural waste and chicken manure☆

Wangliang Li*,Changbo Lu ,Gaojun An ,Yuming Zhang ,Yen Wah Tong

1 The Key Laboratory of Green Process and Engineering,Institute of Process Engineering,Chinese Academy of Sciences,Beijing 100190,China

2 Beijing POL Research Institute,Beijing 102300,China

3 State Key Laboratory of Heavy Oil Processing,China University of Petroleum(Beijing),Beijing 102249,China

4 NUS Environment Research Institute,National University of Singapore,Singapore 117411,Singapore

1.Introduction

Anaerobic digestion(AD)is widely used to dispose municipal solid wastes(MSW)by converting organic fractions into biogas[1].Horticultural waste and animal manure are the main fractions of MSW,which are appropriate to be disposed of with AD process because of high organic and suitable moisture content.Compared with Liquid AD,highsolid AD has the advantages of high solid loading capacity,increased volumetric biogas productivity,and reduced energy needs as there is less water to heat[2].However,compared with wet AD process,highsolid AD is limited by low hydrolysis rates,low mass transfer efficiency,and inhibition of volatile fatty acids(VFAs)and ammonia[3].

Forthe solid wastes with high C/Nratio,accumulation ofVFAs leads to the sharp decrease of pH[4].When the pH value of the AD system is below 5,the methanogen activity would be seriously inhibited[5].Codigestion is one of the effective methods to remove the inhibition and to increase the digestion efficiency of lignocellulosic wastes.While,the digestion efficiency of animal manure has the problem of low biogas yield because of the inhibition of ammonia[6].The buffering effects of ammonia and rich nutrients such as balanced C:N:P ratio and trace elements are very critical to improve the stability and microbial growth[7].Codigestion of horticultural waste and animal manure has been studied to avoid inhibition of high concentrations of ammonia and VFAs[8,9].The buffering systems formed by ammonium and VFAs increased the concentrations of VFAs,therefore,a high tolerance to ammonium and VFAs was maintained[10].Although codigestion process can increase biogas yield,the volatile solid(VS)removal is about 50%,therefore,large amount of biomass,especially lignin fraction,remains unconverted[11].Gasification,as a technology for efficient utilization of biomass,has drawn more and more attentions due to the energy recovery and environmental concerns[12,13].Gasification is a thermochemical conversion process which converts biomass through partial oxidation into a gaseous mixture of syngas consisting mainly of H2,CO,CH4and CO2.To improve energy recovery efficiency from organic wastes and reduce the volume of wastes,integrated systems were developed to combine anaerobic digestion(AD)and gasification for energy recovery from organic wastes[14-16].The feasibility of integration of HSAD and gasification was tested experimentally and numerically in our previous research.The total energy recovery efficiency was 70.8%at the mixing ratio of20 wt%AD residue with 30 wt%moisture content[13].Although the codigestion performance of horticultural wastes and animal manure has been thoroughly studied,the effects of horticultural waste to animal manure on the overall energy recovery in the integrated process of digestion and gasification have never been reported.

The gasification performances of digestate were tested using thermogravimetric-differential thermal analysis(TG/DTA)and lab-scale gasifier.The enhancement of codigestion was tested in batch and semi-continuous systems with CM and grass as substrates.The effects of VS ratio of grass to CM on overall energy generation were studied.

2.Materials and Methods

2.1.Feedstock characteristics

Grass was collected from the campus of National University of Singapore.The grass was shredded and homogenized to small pieces(approximately 2 cm in length for grass).The CM was collected from Chew's Group Limited,Singapore.A scraping system was used for manure collection,and the manure was then stacked in an open field.The anaerobic sludge from PUB Ulu Pandan Water Reclamation Plant was used as the inoculum.It had a pH of 7.62,total solids(TS)of 29.3 g·L-1,and VS/TS of 73.12%.Wood chips were Kingsford wood chips from Clorox Company,USA,approximately 10-50 mm in length,5-25 mm in width and 1-5 mm in thickness.

Properties of grass and CM were measured in terms of VS,elemental analysis and composition analysis,as shown in Table 1.For grass,organic fractions contributed to a major part of the biomass,representing a VS content of 77.87%.While for CM,the VS was relatively low,about 38.38%.Based on elemental analysis,the C/N ratio of grass and CM was 40.27 and 8.09,respectively.The C/N ratios of all the different samples were not in the range of 15 to 30,which was proposed to be most suitable for optimum operation of the AD[17,18].The contents of metal elements such as Ni and Mn were higher in CM than in grass.

Table 1 Physical properties of grass and CM

2.2.High-solid digestion of grass and CM

The mixtures of CM and grass were digested in 30.0 L digester containing a substrate of 2500 g of VS.The samples of codigestion with CM/grass VS ratio as 0:100,20:80,50:50,80:20 and 100:0 were marked as Grass,Co-1,Co-2,Co-3 and CM.After inoculation,all batch reactors were purged with nitrogen gas to create an anaerobic condition.The effect of using various CM/grass VS ratios on biogas and methane production of grass was evaluated using batch experiments.The flasks were sealed using rubber stoppers,and incubated at 35°C for up to 40 days.Biogas production was collected with Tedlar bags(Table 2).

Table 2 Process parameters of codigestion with different CM/grass ratios after 15 days

2.3.Semi-continuous high-solid codigestion of grass and CM

The high-solid semi-continuous codigestion was carried out with chicken manure and grass(VS ratio 20:80)in a 30 L bioreactor at 35°C.Total VS was keptas 2500 g.Tap water was added to digesters to maintain a TS content of 20.0%.After 20 days' start-up,anaerobic co-digestion was then initiated in a semi-continuous style.All reactors were gently mixed for approximately 1 min prior to sampling and feeding,with an organic loading rate(OLR)of 4.0 g VS·L-1·d-1and 8.0 g VS·L-1·d-1for the stage of OLR1 and OLR2,respectively.

2.4.Gasification of digestate and woodchips

A schematic diagram of the digester used for studying the AD performance is given in Fig.1(a).Feedstock was mixed externally before being fed into a HSAD reactor.In the reactor,temperature was kept at 35°C with a continuous mixing rate of 20 r·min-1.

A schematic diagram of the lab-scale gasifier used for studying the gasification performance is given in Fig.1(b).Air was used as gasifying medium,which passed through a preheating zone with the same temperature to that of the gasification zone,where it reacted with the digestate sample at a certain temperature.The sample was filled in a quartz holder.Gasification reaction started from the time of sample insertion into the reactorat the certain temperature.The produced syngas was condensed in ice followed by a water bath to remove tar.Moisture was removed using anhydrous calcium chloride.Gas chromatograph was used to determine components of syngas including H2,CO,CO2and CH4.

The AD digestate was dried to a certain moisture content,mixed with woodchips and then,fed into the gasifier for syngas production.To calculate energy efficiency of the integrated process,the total amount of feedstock input energy for both AD and gasification process,electricity input for both AD and gasification system,and extra energy input for drying process was the energy input.Energy output included both biogas generated from AD and syngas generated from cogasification.The energy efficiency was calculated in our previous study[13].

LHV of gaseous species was calculated according to the following equation:

where CO,H2,and CH4represent the volume percentage of CO,H2,and CH4in produced gas.

Fig.1.Schematic diagram of AD reactor(a)and gasifierreactor(b).1-motor;2-feed tank;3-screw feeder;4-nitrogen;5- flowmeter;6-reactor;7-furnace;8-liquid collection;9-condenser;10-gas flowmeter;11-gas washing;12- filter;13-gas analysis system.

LHV of feedstock was calculated based on HHV,which was calculated from empirical correlation[13].

whereMC,MH,MS,MO,MNandMArepresent carbon,hydrogen,sulfur,oxygen,nitrogen,and ash content of material,respectively,expressed in mass percentage on a dry basis.Mmis the moisture content of materials.

2.5.Analytical methods

The grass and CM samples were analyzed for total solid(TS)and volatile solid(VS)contents according to the standard methods of the American Public Health Association[19].

The biogas yield of grass was the total biogas yield deducted by the biogas yield of CM.Methane and carbon dioxide in the biogas were measured by gas chromatography(Perkin Elmer?,Model 4016)equipped with a 2000 mm×3 mm stainless steel column packed with TDX-01 and a thermal conductivity detector.Temperatures of the detector,injector,and oven were 150 °C,150 °C,and 120 °C,respectively.

Rapid simultaneous determination of the carbon,hydrogen,nitrogen and sulfur(CHNS)contents in grass and CM was carried out in Elemental Analysis Laboratory,National University of Singapore with the instrument Elementar Vario Micro Cube.The contents of cellulose,hemicellulose,and lignin were analyzed according to the procedure of Van Soest[20].

The total carbon(TC)and total nitrogen(TN)were analyzed with an elemental analyzer(Vario El III).For the high solid content of the sample,20.0 ml deionized water was added into 5.0 g sample.The sample then was centrifuged at 10,000 r·min-1for 10 min.The liquid was analyzed by a pH meter(Mettler Toledo FE20).Then,COD,ammonium and total nitrogen in the liquid were analyzed with Dr.Lange cuvette tests(Dr.Bruno Lange,GmbH&CO.KG,Dusseldorf,Germany)and measured spectrophotometrically with a HACH XION 500 spectrophotometer[11].

The digestate from batch experiments was tested using TG/DTA(Shimadzu,DTG-60A).Dried digested digestate sample was loaded in a platinum crucible and it was first heated and held at 105°C for 15 min in N2to remove its moisture.Then the sample was heated to 950 °C at 20 °C·min-1.When the temperature was steady,air was introduced at 950°C for another 10 min to make sure the reaction was completed.

3.Results and Discussion

3.1.Codigestion of CM and grass in batch systems

The mass ratio of horticultural waste to CM has significant influences on the biogas yield and process stability.Fig.2 shows the effects of ratio of grass to CM on cumulative biogas yield and methane concentration.When using grass as the sole substrate,the daily biogas yield decreased in the startup period because of the accumulation of VFA.To avoid the failure of anaerobic digestion and to keep the process stable,solid CaO powder was used to adjust pH value.After 10 days,the methane concentration increased to above 60%.The biogas yield of grass was relatively low because of the lack of nitrogen in the substrate and the rapid consumption of nitrogen by methanogens to meet their protein requirements[21].Thus,no longer consuming the left over carbon content of the material leads to a lower gas production.While the accumulative biogas yield of CM was very low,because the ammonia toxicity inhibited microorganism growth and the digestion of CM.Therefore,it is essential to balance the C/N in the feed for sustainable anaerobic processes and biogas production.An optimum C/N ratio between 15:1 and 30:1 has been suggested[17].Biogas yield and digestion performances were enhanced by codigestion.After 40 days of digestion,the biogas yield of Co-2(VS ratio of grass to CM as 80:20)was the highest,237 ml·(g VS)-1.Besides the C/N ratio,the rich metal contents in CM can also improve the growth of microbials and are favorable for HSAD.Ammonia ensured sufficient buffer capacity of AD and kept a neutral pH thus increasing the stability of AD,a possible main reason for the high performance and methane yields in AD process.For the archaeal community,the stable AD and pH increases the relative abundance ofMethanosarcinain the total archaeal population,which is a multifunctional methanogen that can produce methaneviathree different metabolic pathways using H2/CO2,acetate and methylated one-carbon compounds[22,23].

Fig.2.Effects of CM/grass ratio on cumulative biogas yield and methane concentration.

As shown in Table 1,the contents of metal elements in the CM were considerably higher than those in the grass.For example,the metal concentrations such as Fe,Ni and Mo in the CM were 20-30 times higher than those in the grass.Considering the roles of the trace elements on maintaining enzyme activities and improving bacterial growth,the trace elements in the grass might be insufficient for stable AD[24,25].Lack of trace elements might be one of the reasons for the poor HSAD performance of grass.

For all the digested samples,the pH value was in the range of 7.26 to 7.58 after 15 days of digestion,which was suitable for methanogenesis.Soluble COD(SCOD)in the codigested samples was higher than that of grass.Co-2 had the highest biogas yield,but its SCOD was the lowest.Table 3 shows the composition variation after digestion.Compared with the fresh grass,after digestion the contents of NDS,lignin and ash increased,the contents of cellulose and hemicelluloses decreased,which were due to the hydrolysis of cellulose and hemicellulose.The increase of ash was due to the addition of CM and anaerobic sludge which have more ash content.

Table 3 Components of substrates after anaerobic digestion

3.2.High-solid digestion of grass and CM in semi-continuous systems

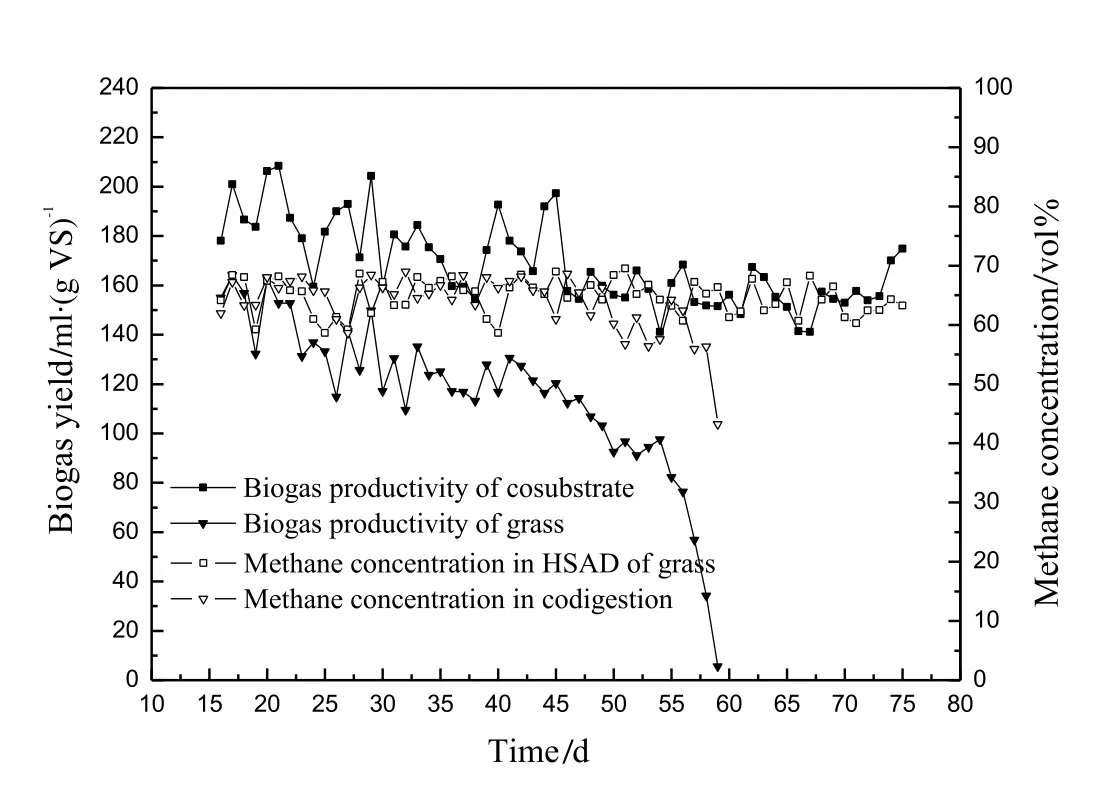

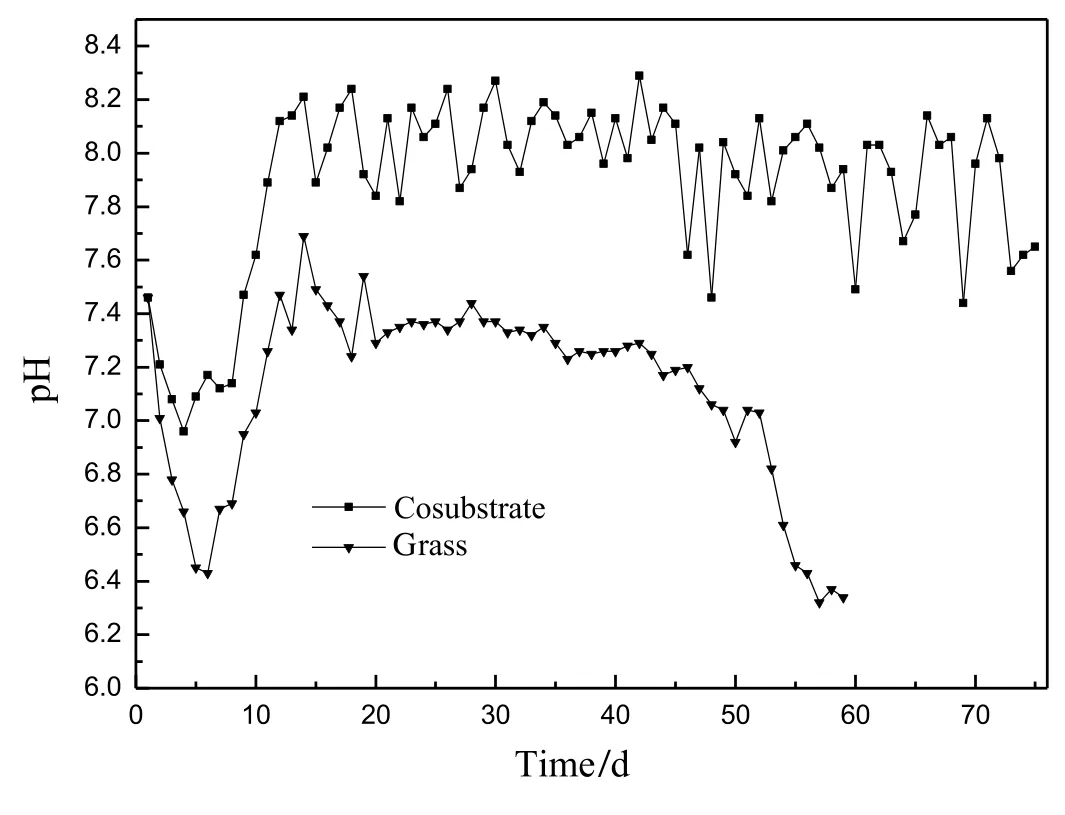

To verify the effects of codigestion,semi-continuous experiments were carried out with the organic loading rates(OLR)of 4.0 g VS·L-1·d-1and 8.0 g VS·L-1·d-1,respectively.The semicontinuous process was divided into three stages:start-up period,OLR1 and OLR2.As shown in Fig.3,the biogas yield of codigestion was higher than that of the digestion process with grass as sole substrate,and the stability of the former was much better than that of the latter.In the two OLR stages,the average methane yield of the codigestion process was 115.7 ml·(g VS)-1and 107.9 ml·(g VS)-1and the average methane concentration was 67.70 vol%and 67.21 vol%,respectively.For the digestion of grass,the average methane yield was 104.9 ml·(g VS)-1and 93.6 ml·(g VS)-1and the average methane concentration for the two stages was 61.93 vol%and 61.22 vol%.When the OLR was 4.0 g VS·L-1·d-1and 8.0 g VS·L-1·d-1,the codigestion system would produce 10.68%and 15.28%more methane than that of grass,respectively.When the OLR increased from 4.0 g VS·L-1·d-1to 8.0 g VS·L-1·d-1,the methane yield and methane concentration decreased which indicated that the OLR 8.0 g VS·L-1·d-1was too high for both processes.As shown in Fig.4,during the semi-continuous experiment,the pH value oscillated between 7.12 and 8.24.For the codigestion process,in the first 15 days,the pH values decreased from 7.46 to 6.85 and increased to 7.52,which indicated that the production of VFAs was much faster than that of ammonia in the initial stage.Besides methane production,process stability is another key parameter for HSAD.Methanogenic bacteria are slow-growing and may be discharged from the reactor when solid waste was overloaded.The imbalance between acidogens and methanogens can then lead to accumulation of VFA at the inhibitory levels.For both of the two OLR stages,the ammonia content in codigestion was higher which was due to the high nitrogen content in CM and higher efficiency of codigestion.When the OLR increased from 4.0 g VS·L-1·d-1to 8.0 g VS·L-1·d-1,the average ammonia decreased from 7.19 mg·(g VS)-1to 6.08 mg·(g VS)-1,which also indicated that AD efficiency decreased and the OLR 8.0 g VS·L-1·d-1was overloaded.The analysis of VFAs revealed that the concentrations of acetic and propionic acid were not high,which indicated that most of the acetic and propionic acids were consumed by microbials.While,for both codigestion and the digestion of grass,when OLR increased from 4.0 g VS·L-1·d-1to 8.0 g VS·L-1·d-1,the ratio of acetic acid to propionic acid decreased.The slight accumulation of propionic acid also indicated the inhibition of methanogenesis[1].From the aspects of energetic recovery,VS removal and process stability,codigestion process is much better than the digestion of grass.The HSAD systems described in this work,fed with identical OLRs,codigestion gave higher energy recovery than the process with grass as sole substrate.An accumulation of undegraded intermediate metabolites observed in the digestion of grass was the cause of its lower efficiency,the possible reason of which was that the growth of microbials was inhibited in this process.

Fig.3.Biogas production in semi-continuous systems.

Fig.4.Variation of pH in semi-continuous systems.

3.3.Thermogravimetric analysis of digestates

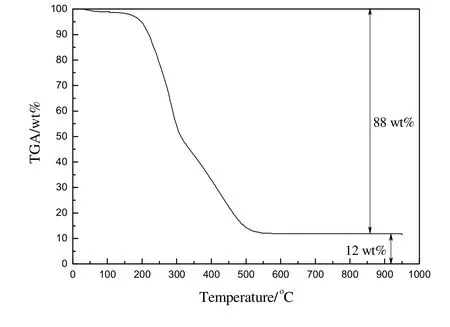

Thermogravimetric(TG)analysis was often used to analyze the composition of volatile matters and ashes in biomass,both of which have significant influences on gasification performances of digestates[11,13].Fig.5 showed one representative TG curve of the digestates.The small slope occurring before 200°C represents the moisture release because of the increasing temperature.In the range of200°Cand 900 °C,a sharp slope meant that the thermal decomposition of biomass led to a huge mass loss,in which the mass loss occurring at the temperature of 200 to 600°C was due to the decomposition of hemicelluloses,cellulose and lignin[11].In the range of600 °C to 900 °C,the mass loss was due to the char oxidation.Table 4 is the integral results of TG curves.For all the digestates,more than 80 wt%of the fractions are volatile matters,and the content of ash is higher than 10 wt%.The amount of fixed carbon is very limited for digestate,while the fixed carbon of woodchips is slightly higher.With the increase of CM content,the amount of ashes increased.With the increase of grass contents,the volatile matters in digestates increased and the contents of ashes and fixed carbons decreased.Compared to the fresh grass,the ash content of digestates increased significantly because the anaerobic sludge brought inorganic non- flammable salts or sands.Compared with the digestate of horse manure,the volatile matters in the digestate of CM are lower because of the higher content of inorganic salts in CM[11].

Fig.5.TG curves of the digested grass.

Table 4 Proximate analyses of digestate samples(wt%,on a dry basis)

3.4.Gasification of digestates

The effects of the composition of digestate on gasification performance were studied at the temperature of 700 °C,900 °C and 1000°C.Fig.6 shows the effect of gasification temperature of digestate(grass:CM,80:20)on the total syngas yield.As it can be seen,the gasification temperature had a positive effect on the syngas yield because the increase of temperature improved the conversion of biomass into syngas.With the increase of gasification temperature,the peaks of the gas production shifted towards lower residence time because higher temperature enhanced the kinetics of decomposition.Fig.7 shows the syngas composition produced at 900°C.During the first 8 min-10 min,CO2was the dominant component of syngas,the concentrations of H2and CO were relatively low.This was because the decarboxylation of amino acids,acetic acid and other carboxylic groups generated during thermal decomposition.During the process of gasification,the combustion of biomass produced water,which reacted with hydrocarbons through reforming of apart from thermal cracking and led to the increase of H2and CO production(Table 5).

Fig.6.Effect of gasification temperature of digestate on the total syngas yield.

Fig.7.The syngas composition produced at 900°C.

Table 5 Feedstocks for gasification

The digestates were harvested from the batch experiments with different VS ratios of grass to CM.Fig.8 shows the components of digestates on gasification performance at 900°C.It can be seen that the composition of the digestates had significant influences on the syngas yield and the syngas composition.When the grass contentincreased from 0 to 100%,the total syngas yield increased because of the increase of volatile matters,which was in accordance with the results of the proximate analysis.While,from the syngas composition analysis,the percentage of H2and CO2increased with the increase of grass content.CO production increased with the increase of CM content,because the higher alkali or alkaline metal contents in CM have positive catalytic effects on the gasification of char.Table 6 shows the energy generation through HSAD and gasification.The LHV of biogas and syngas was calculated through Eq.(1).It can be seen that the ratio of grass to CM had a significant influence on the LHV of biogas and syngas.The overall energy output was the highest,12.70 MJ·kg-1,when the VS ratio ofgrass to CM was 80:20.

Fig.8.Components of digestates on gasification performance at 900°C.

Fig.9 shows the gasification performance of the mixture of the digestate(grass:CM,80:20)and woodchips.Compared with the gasification of the woodchips,the addition of digestate decreased the syngas yield,due to the increase of ashes and decrease of lignin.When the content of digestate was in the range of 0 to 10%,the addition of digestate had little effects on the syngas yield.While,when the content of digestate was in the range of 10%to 30%,the concentrations of CO decreased slightly,while the concentration of H2and CH4kept almost constant.The decrease of CO concentration and syngas yield led to the lower LHV of syngas.Syngas is affected by the content of the cellulose,hemicellulose,lignin and the inorganic matters in the feedstock[13,26].It is feasible to realize the co-gasification of digestate and woodchips with the mass ratio 10 wt%to 90 wt%.

Fig.9.Cogasification of woodchips and digestate.

4.Conclusions

In terms of biogas yield,the codigestion of grass and CM(237 ml biogas·(g VS)-1)showed better performance than the digestion of grass and CM.When the VS ratio of CM to grass was 20:80,that is C/N ratio 21.70,the biogas yield was the highest.With the increase of TS,the performance of codigestion decreased,especially for TS higher than 25%.When the loading rate was 4.0 g VS·L-1·d-1,the average biogas yield was 168.73 ml·(g VS)-1.The composition analysis revealed that cellulose and hemicellulose contributed the biogas production.More than 80 wt%of the fractions of the digestate are volatile matters.VS ratio of grass to CM had a signification influence on overall energy generation through HSAD and gasification.This study suggested that anaerobic digestion followed by gasification could be a viable option for energy recovery from horticultural waste and animal manure.

Table 6 Evaluation of energy generation of the integrated system

Nomenclature

AD anaerobic digestion

CM chicken manure

HRT hydraulic retention time

HSAD high-solid anaerobic digestion

LHV low heat value

OFMSW organic fraction municipal solid waste

OLR organic loading rate

TG/DTA thermogravimetric-differential thermal analysis

TS total solids

VFAs volatile fatty acids

VS volatile solids

[1]Q.Zhang,J.Hu,D.J.Lee,Biogas from anaerobic digestion processes:research updates,Renew.Energy98(2016)108-119.

[2]F.Xu,Y.Li,Z.-W.Wang,Mathematical modeling of solid-state anaerobic digestion,Prog.Energy Combust.Sci.51(2015)49-66.

[3]R.Chandra,H.Takeuchi,T.Hasegawa,Methane production from lignocellulosic agricultural crop wastes:a review in context to second generation of biofuel production,Renew.Sust.Energ.Rev.16(2012)1462-1476.

[4]K.Xiao,C.Guo,Y.Zhou,Y.Maspolim,J.Wang,W.J.Ng,Acetic acid inhibition on methanogens in a two-phase anaerobic process,Biochem.Eng.J.75(2013)1-7.

[5]I.S.Kim,M.H.Hwang,N.J.Jang,S.H.Hyun,S.Lee,Effect of low pH on the activity of hydrogen utilizing methanogen in bio-hydrogen process,Int.J.Hydrog.Energy29(2004)1133-1140.

[6]I.Angelidaki,D.Karakashev,D.J.Batstone,et al.,Biomethanation and its potential,Methods Enzymol.494(2011)327-351.

[7]J.Fierro,E.J.Martínez,A.Morán,X.Gómez,Valorisation of used cooking oil sludge by codigestion with swine manure,Waste Manag.34(2014)1537-1545.

[8]Y.Li,S.Y.Park,J.Zhu,Solid-state anaerobic digestion for methane production from organic waste,Renew.Sust.Energ.Rev.15(2011)821-826.

[9]W.Li,K.-C.Loh,J.Zhang,Y.W.Tong,Y.Dai,Two-stage anaerobic digestion of food waste and horticultural waste in high-solid system,Appl.Energy209(1)(2018)400-408.

[10]Q.Wang,L.Peng,H.Su,The effect of a buffer function on the semi-continuous anaerobic digestion,Bioresour.Technol.139(2013)43-49.

[11]W.Li,High-solid anaerobic codigestion of horse manure and grass in batch and semi-continuous system,Energy Fuel30(8)(2016)6419-6424.

[12]H.Li,E.Larsson,E.Thorin,et al.,Feasibility study on combining anaerobic digestion and biomass gasification to increase the production of biomethane,Energy Convers.Manag.100(2015)212-219.

[13]Z.Yao,W.Li,X.Kan,Y.Dai,Y.W.Tong,C.-H.Wang,Anaerobic digestion and gasification hybrid system for potential energy recovery from yard waste and woody biomass,Energy124(2017)133-145.

[14]S.Kataki,S.Hazarika,D.C.Baruah,Assessment of by-products of bioenergy systems(anaerobic digestion and gasification)as potential crop nutrient,Waste Manag.59(2017)102-117.

[15]G.Allesina,S.Pedrazzi,L.Guidetti,P.Tartarini,Modeling of coupling gasification and anaerobic digestion processes for maize bioenergy conversion,Biomass Bioenergy81(2015)444-451.

[16]L.A.Hadidi,M.M.Omer,A financial feasibility model of gasification and anaerobic digestion waste-to-energy(WTE)plants in Saudi Arabia,Waste Manag.59(2017)90-101.

[17]J.Mata-Alvarez,J.Dosta,S.Macé,S.Astals,Codigestion of solid wastes:a review of its uses and perspectives including modeling,Crit.Rev.Biotechnol.31(2)(2011)99-111.

[18]Z.Yong,Y.Dong,X.Dong,T.Tan,Anaerobic co-digestion of food waste and straw for biogas production,Renew.Energy78(2015)527-530.

[19]APHA,Standard Methods for the Examination of Water and Wastewater,American Public Health Association,Washington,DC,2005.

[20]P.J.Van Soest,J.B.Robertson,B.A.Lewis,Methods for dietary fiber,neutral detergent fiber,and nonstarch polysaccharides in relation to animal nutrition,J.Dairy Sci.74(1991)3583-3597.

[21]P.Sensai,A.Thangamani,C.Visvanathan,Thermophilic co-digestion feasibility of distillers grains and swine manure:effect of C/N ratio and organic loading rate during high solid anaerobic digestion(HSAD),Environ.Technol.35(20)(2014)2569-2574.

[22]L.Zhang,Y.W.Lee,D.Jahng,Anaerobic co-digestion of food waste and piggery wastewater:focusing on the role of trace elements,Bioresour.Technol.102(2011)5048-5059.

[23]J.Zhang,K.-C.Loh,W.Li,J.W.Lim,Y.Dai,Y.W.Tong,Three-stage anaerobic digester for food waste,Appl.Energy194(2017)287-295.

[24]J.Zhang,W.Li,J.Lee,K.-C.Loh,Y.Dai,Y.W.Tong,Enhancement of biogas production in anaerobic co-digestion of food waste and waste activated sludge by biological copretreatment,Energy137(2017)479-486.

[25]W.Zhang,L.Zhang,A.Li,Enhanced anaerobic digestion of food waste by trace metal elements supplementation and reduced metals dosage by green chelating agent[S,S]-EDDS via improving metals bioavailability,Water Res.84(2015)266-277.

[26]F.Pinto,R.N.André,C.Carolino,et al.,Effects of experimental conditions and of addition of natural minerals on syngas production from lignin by oxy-gasification:comparison of bench-and pilot scale gasification,Fuel140(2015)62-72.

Chinese Journal of Chemical Engineering2018年5期

Chinese Journal of Chemical Engineering2018年5期

- Chinese Journal of Chemical Engineering的其它文章

- Controlling dispersion and morphology of MoS2 nanospheres by hydrothermal method using SiO2 as template☆

- Morphological,mechanical and thermal properties of cyanate ester/benzoxazine resin composites reinforced by silane treated natural hemp fibers☆

- Thermal conductivity of PVDF/PANI-nanofiber composite membrane aligned in an electric field☆

- A simple strategy to synthesize and characterization of zirconium modified PCs/γ-Al2O3☆

- Antioxidant activity of phytosynthesized biomatrix-loaded noble metallic nanoparticles

- Cr(III)removal from simulated solution using hydrous magnesium oxide coated fly ash:Optimization by response surface methodology(RSM)☆