Improving the process forming limit considering forming defects in the transitional region in local loading forming of Ti-alloy rib-web components

Pengfei GAO,Xiaodi LI,He YANG,Xiaoguang FAN,Zhenni LEI

State Key Laboratory of Solidification Processing,School of Materials Science and Engineering,Northwestern Polytechnical University,Xi’an 710072,China

Improving the process forming limit considering forming defects in the transitional region in local loading forming of Ti-alloy rib-web components

Pengfei GAO*,Xiaodi LI,He YANG*,Xiaoguang FAN,Zhenni LEI

State Key Laboratory of Solidification Processing,School of Materials Science and Engineering,Northwestern Polytechnical University,Xi’an 710072,China

Available online 21 December 2016

*Corresponding authors.

E-mail address:gaopengfei@nwpu.edu.cn(P.F.GAO).

Peer review under responsibility of Editorial Committee of CJA.

Production and hosting by Elsevier

http://dx.doi.org/10.1016/j.cja.2016.11.004

1000-9361?2016 Chinese Society of Aeronautics and Astronautics.Production and hosting by Elsevier Ltd.

This is an open access article under the CC BY-NC-ND license(http://creativecommons.org/licenses/by-nc-nd/4.0/).

The isothermal local loading forming technology provides a feasible way to form Ti-alloy large-scale rib-web components in aerospace and aviation fields.However,the local loading process forming limit is restricted by forming defects in the transitional region.In this work,the feasibility of controlling forming defects and improving the process forming limit by adjusting die parameters is explored through finite element(FE)simulation.It is found that the common cavum and folding defects in the transitional region are significantly influenced by the fillet radii of left rib and middle rib,respectively.The cavum and folding defects can be effectively controlled by increasing the fillet radii of left rib and middle rib,respectively.The process forming limits considering forming defects in the transitional region are determined by the stepwise searching method under various die parameters.Moreover,the relationship between the process forming limit and die parameters is developed through the response surface methodology(RSM).The developed RSM models suggest that increasing the fillet radii of left and middle ribs is effective to improve the process forming limit during local loading forming of rib-web components.The results will provide technical basis for the design of die parameters and the reduction amount,which is of great importance to control forming defects and improve the process forming limit in local loading forming of Ti-alloy large-scale rib-web components.

?2016 Chinese Society of Aeronautics and Astronautics.Production and hosting by Elsevier Ltd.This is an open access article under the CC BY-NC-ND license(http://creativecommons.org/licenses/by-nc-nd/4.0/).

Defect;

Large-scale

rib-web component;

Local loading forming;

Process forming limit;

Transitional region

1.Introduction

Ti-alloy large-scale complex components(such as bulkheads)are a kind of high-performance and lightweight structural component,which have been widely used in the aviation field.However,their complex shapes and the hard-to-deform property of titanium alloy makes it very difficult to form these components using the integral forging method.To overcome the challenge,Yang et al.1–5proposed an isothermal local loading forming technology,in which a component is formed by changing the loading region(Fig.1).It can reduce the forming load,enhance the formability of a material,and enlarge the size of a component,providing a highly attractive way of forming Ti-alloy large-scale complex components.However,during local loading forming,the transitional region undergoes large uneven deformation under the constraints of the loading and unloading regions,which may lead to some forming defects such as folding and cavum.A previous investigation6indicated that the amount of uneven deformation and forming defects can be suppressed by reducing the reduction amount.Nevertheless,this will increase the total required loading passes,and then prolong the production cycle and raise the cost.Moreover,too many isothermal loading passes may result in a bad microstructure and a poor performance,since the workpiece undergoes series of thermal cycles(heating,holding,deformation,and cooling).Therefore,it is very critical to maximize the reduction amount in each loading pass under the precondition of avoiding forming defects.Here,we call the allowablemaximum reduction amount without forming defects in the transitional region as process forming limit.

To date,many works have been conducted on the formation and avoidance of forming defects during integral forging.For instance,Chan et al.7studied the dependence of the folding defect on tooling geometrical parameters in forging of asymmetrical f l anged components by finite element(FE)simulation.Zhang et al.8investigated the formation mechanisms of folding and underfilling during isothermal forging of aluminum-alloy ring seats through a combination of FE simulation and experiments.Petrov et al.9revealed the variation law of the folding length with die geometrical parameters and friction in closed-die forging of an aluminum part with an irregular shape.Then they obtained the optimal die parameters and friction to avoid the folding defect.Chen et al.10found that flow-through is a common defect in press forging of AZ31 magnesium-alloy sheets,which can be suppressed by increasing the sheet thickness.In addition,they determined the minimum sheet thickness without flow-through using the stepwise searching method.The research methodologies and results of the above works enlighten the investigation of forming defects during local loading forming.

Some primary works have also been carried out on forming characteristics during local loading forming.Zhang et al.11,12and Gao et al.13studied the behavior of material flow in the transitional region by FE simulation,and quantitatively uncovered the mechanisms of transverse material flow from the loading region into the unloading region.On these bases,the formation mechanisms of forming defects(folding and cavum)in the transitional region and their dependences on local loading processing parameters were revealed.6It was found that both decreasing the spacer block thickness and increasing friction can suppress folding and cavum,while the deformation temperature and loading speed have few effects on forming defects.The effects of structural parameters of the transitional region on folding and cavum have also been studied.14Furthermore,Gao et al.15developed the prediction models of forming defects in the transitional region for local loading forming of rib-web components with various structural parameters.Then,they determined the process forming limit considering forming defects in the transitional region through the stepwise searching method combined with the prediction models of forming defects.However,it was found that the process forming limit locates in the range of 7.1–8.1 mm at various structural parameters,which is still not a satisfactory result to reduce the loading pass.Therefore,it is still needed to find feasible ways to control the forming defects in the transitional region and then improve the process forming limit of local loading forming.

Up to now,there is no study on the method for improving the process forming limit of local loading forming.Zhang et al.16found that besides the processing condition and structural parameters,die parameters(fillet radius and draft angle)also play a great role in the material flow and deformation behavior during local loading forming of rib-web components.Therefore,it may be able to control forming defects and improve the process forming limit by adjusting die parameters.To this end,further investigations should be conducted on the effects of die parameters on forming defects in the transitional region and the process forming limit in isothermal local loading forming.

In this work,the dependences of forming defects in the transitional region and the process forming limit on die parameters in local loading forming were studied systematically.By carrying out orthogonal FE simulation analyses,the key influencing factors and laws of die parameters on forming defects and the process forming limit were revealed.Then,the relationships between the process forming limit and die parameters were developed.On these bases,design strategies of die parameters for improving the process forming limit were proposed.

The results will provide technological basis for optimizing die parameters in isothermal local loading forming of Ti-alloy large-scale rib-web components.

2.Research methodology

2.1.FE model of the transitional region

A previously developed FE model of the transitional region in local loading forming of rib-web components was employed in this work,as shown in Fig.2.13,14The FE model is developed based on DEFORM-2D software,in which the deformation in the transitional region is simplified as a plane strain problem.For the die structure,the lower die is kept integral,while the top die is divided into two symmetrical parts:Top die 1 and Top die 2.Fig.2(a)shows the structural dimensions of dies,where the unit is mm.In Fig.2,Lis the reduction amount,ris the fillet radius,and γ is the draft angle.The billet is TA15 alloy with a height(H)of 30 mm.A typical local loading process has two loading steps conducted by adjusting the relative position of the two top dies using a spacer block.In the first loading step(Fig.2(a)),Top die 1 is protuberant by implanting the spacer block between the top die bed and Top die 1.In the second loading step(Fig.2(b)),Top dies 1 and 2 are at the same level by removing the spacer block.

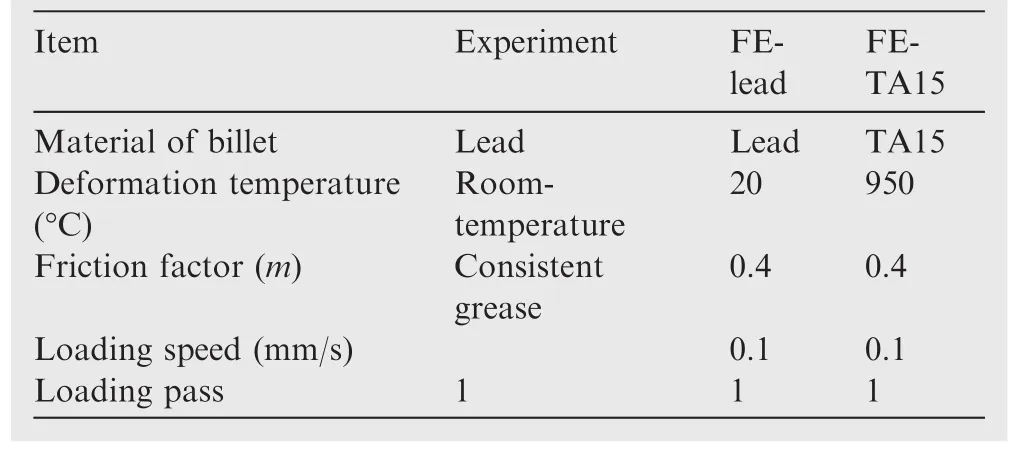

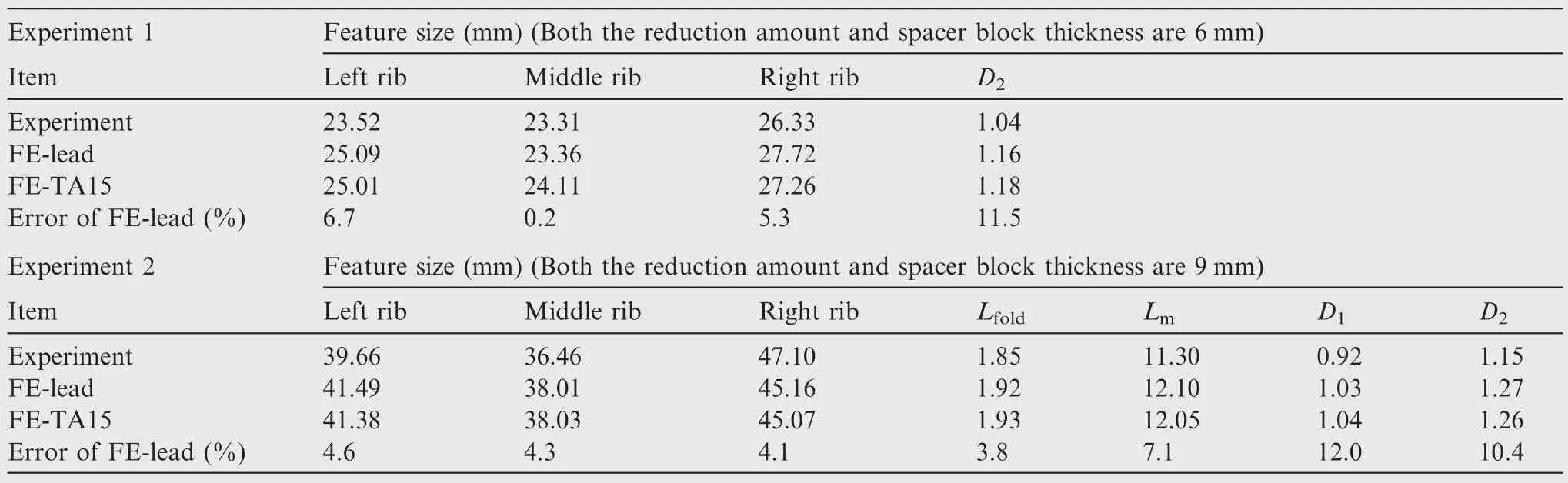

During FE modeling,the flow behavior of TA15 alloy is input into DEFORM software in the form of discrete points based on the experimental results in Fig.3.17(Trepresents the temperature).Meanwhile,the dies are modeled as rigid bodies.As isothermal local loading is performed under high temperature and low loading speed,the whole forming process is modeled in an isothermal condition without any thermal events.The shear friction model and von Mises yielding criteria are adopted.Besides,the automatic remeshing and local refined meshing techniques are applied to avoid the meshinginduced singularity.The FE model has been validated by physical experiments with a material of lead in previous works.13,14Table 1 lists the key parameters in the physical experiment and FE models.The good agreements on the flow line,shape,and feature sizes between the simulated and experimental samples(Fig.4 and Table 2)suggest that the FE model is reliable in studying forming defects in the transitional region during local loading forming.In Table 2,left rib,middle rib,and right rib represent the heights of three ribs respectively;Lfoldis the length of folding andLmis the distance between folding and middle rib;D1andD2represent the depths of cavum in left rib and middle rib,respectively.

Thus,this FE model is applicable to study forming defects in the transitional region and the process forming limit in this work.To study the effects of die parameters,the fillet radii and draft angles of the three ribs are set changing from 3 to 9 mm and 1 to 3°,respectively.It should be noted that the fillet radii and draft angles are symmetrical for the three ribs.As far as the processing parameters are concerned,the deformation temperature,loading speed,and friction factor are set as 950°C,0.1 mm/s,and 0.5,respectively.Both the spacer block thickness and reduction amount are 13 mm.These processing parameters are all set as favorable values for suppressing forming defects in the transitional region according to the results of previous studies.6,14

Quantities simulations show that the cavum at left rib and folding defects are still prone to emerge,while the cavum at middle rib would not occur in the above ranges of die parameters,as shown in Fig.5.In this work,the cavum defect at left rib is evaluated by its depth,noted asD,and the folding defect is evaluated by its length,noted asLfold(Fig.5).If no folding is generated,we defineLfoldas 0.According to the requirements of machining allowance and forming quality in precision forging15,18,the standards for qualif i ed workpiece are set as follows:no folding emerges and the cavum depth is less than 3 mm.

2.2.Orthogonal experiment design and response surface methodology

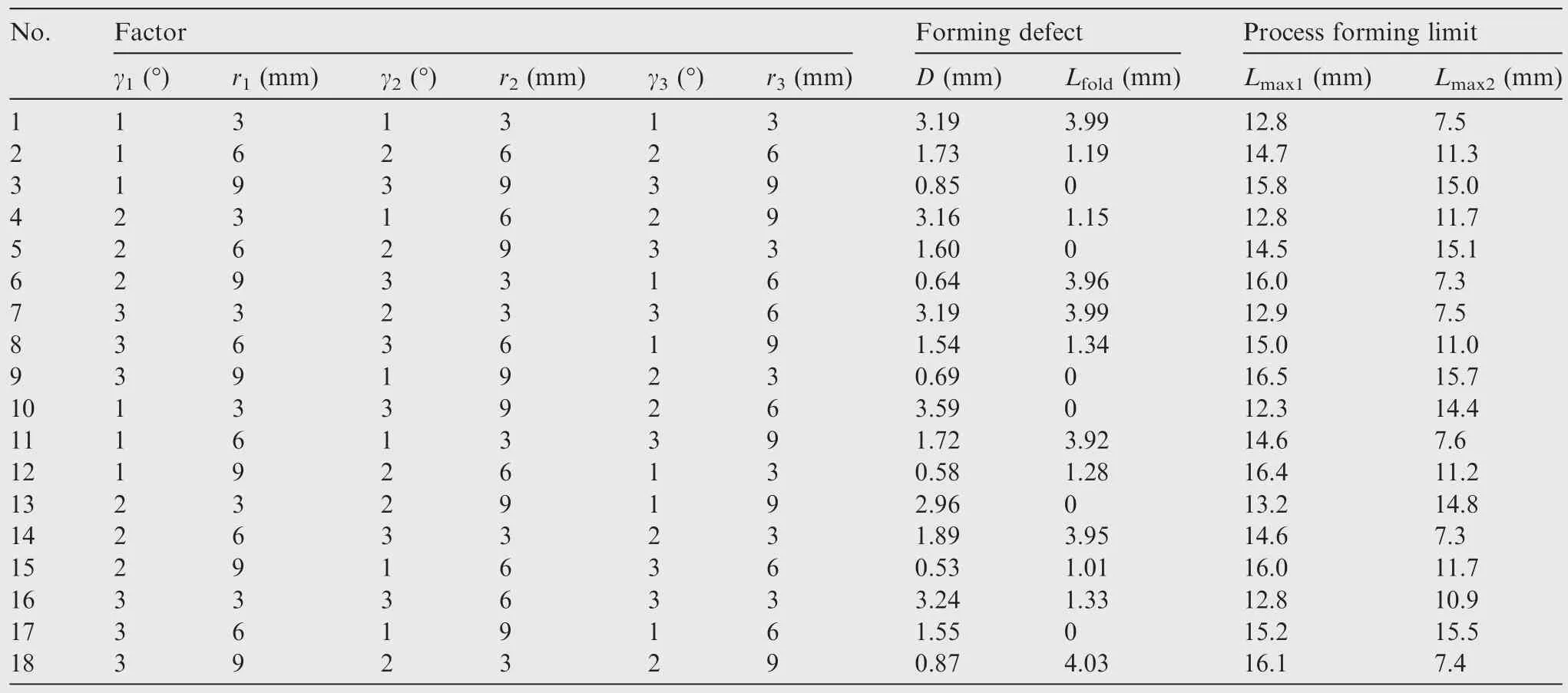

The orthogonal experiment design is a widely used sampling strategy,which can study the effects of many factors simultaneously in a single set of experiments with much fewer experiments.19,20Thematrix,an orthogonal array of seven factors and three levels,was used to study the effects of die parameters on forming defects and the process forming limit.The considered die parameters and their levels are given in Table 3,and the designed experiment schemes are shown in Table 4.FE simulations were conducted according to the experiment schemes,and then the simulated cavum depth and folding length were measured(Table 4).

In this work,the range analysis was used to study the orthogonal experiment results.During range analysis,two key parameters,i.e.,KjiandRj,need to be calculated,whose detailed calculation processes can be found in Ref.19.is the average value of the indexes of all levels(i,i=1,2,3)in each factorjat the same leveli.The range between the maximum and minimum values ofis de fi ned as range value,Rj,which can be used to evaluate the significance of a factor,i.e.,the greaterRjis,the more significant a factor is.

Table 1 Key parameters in the physical experiment and FE models.14

Response surface methodology(RSM)is one of the most popular modeling techniques,which has been widely used to approximate the time-consuming FE simulation in various fi elds.21,22Thus,the RSM modeling method was employed to correlate the process forming limit and die parameters in this work.During RSM modeling,the quadratic polynomial without a quadratic term was used with the following formulation:

whereyis the response(process forming limit),kis the number of input variables,xiandxjare the sets of model input variables(γ1,r1,γ2,r2,γ3,r3),and β0,βj,βijrepresent the regression coefficients.

Table 2 Comparisons of feature sizes between the simulated and experimental results.14

3.Results and discussion

3.1.Effects of die parameters on forming defects

Fig.6 shows the range analysis results on the cavum depth based on the data in Table 4.From the range values of different factors,it can be concluded thatr1is the only significant factor for the cavum depth.The cavum depth decreases monotonically with an increases ofr1,as shown in Fig.6(b).It has been reported that the cavum at left rib is produced in the second loading step due to a shift of the rib root,which is essentially caused by the leftward transverse flow of the web material.6Fig.7 compares the formation of the cavum defect between samples with differentr1.It can be found that the sample with a greaterr1(Fig.7(d))presents a smoother transition at the rib root,rather than a V-shaped cavum in the sample with a smallerr1(Fig.7(b)).This indicates that a smoother transition at the rib root could suppress the cavum greatly.As a result,with an increase ofr1,the cavum depth decreases gradually.

The range analysis results on the folding defect are given in Fig.8.From Fig.8(a),we can find that there is only one significant factor,i.e.,r2,for folding,which is similar to the case of cavum.It can be found from Fig.8(b)that the folding length decreases with an increase ofr2,and folding disappears whenr2increases to 9 mm.Fig.9(a)shows a typical formation process of the folding defect in the second loading step.It includes three main steps:(1)a step is created under the effect of transverse material flow;(2)the step evolves to a V-shaped cavum;(3)the V-shaped cavum gets close gradually and becomes folding.It can be concluded that the creations of a step and a V-shaped cavum play a critical role in the formation of folding.From the comparison of samples with differentr2(Fig.9(b–e)),it can be found that a greaterr2can reduce the slope of the step(Fig.9(d))and suppress the generation of a V-shaped cavum(Fig.9(e)),then controlling the formation of folding.Thus,the folding length decreases with an increase ofr2.

3.2.Dependence of process forming limit on die parameters

The results in Section 3.1 suggest that die parameters,especiallyr1andr2,present great influences on forming defects in the transitional region.Increasingr1andr2can significantly suppress cavum and folding,respectively.Thus,it can be deduced that increasingr1andr2can improve the process forming limit constrained by forming defects in the transitional region.In this section,the dependence rule of the process forming limit on die parameters will be investigated in detail.

Here,we define the process forming limit constrained by the cavum defect asLmax1,the process forming limit constrained by the folding defect asLmax2,and the limit considering both of the two defects asLmax.Naturally,for a certain group of die parameters,Lmax=min{Lmax1,Lmax2}.According to the requirements of a qualif i ed workpiece mentioned in Section 2.1,Lmax1andLmax2of samples in Table 4 are determined by thestepwise searching method based on FE simulation.Based on these results(Table 4),the range analysis is also conducted onLmax1(Fig.10)andLmax2(Fig.11).From Fig.10,it can be found thatr1plays a great role inLmax1.Whenr1increases from 3 to 9 mm,the averageLmax1increases from 12.8 to 16.1 mm.On the other hand,r2plays a great role inLmax2,as shown in Fig.11.Whenr2increases from 3 to 9 mm,the averageLmax2increases from 7.4 to 15.1 mm.This verifies that increasingr1andr2is an effective method to improve the process forming limit constrained by forming defects in the transitional region.

Table 3 Factors and levels of orthogonal experiment design.

Table 4 Orthogonal experiment schemes and simulated forming results.

To develop the design criteria of die parameters and the reduction amount in local loading forming,it is still needed to establish the relationship between the process forming limit and die parameters.To this end,the RSM modeling method described in Section 2.2 is used.Using the stepwise regression method,the final regression models forLmax1andLmax2are obtained as follows:

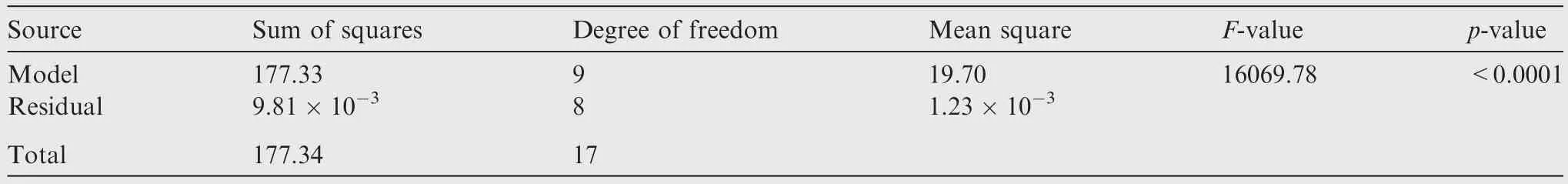

The ANOVA analysis for the two regression models are shown in Tables 5 and 6,respectively.It can be found that thep-values of the two models are both less than 0.01,suggesting that the regression models are both significant.Moreover,the adequacy measures ofR2and adjustedR2are in a reasonable agreement and are both close to 1 for the two models.These indicate that the regression models are both adequate and meaningful.

To verify the accuracy of the developed RSM models,we design 6 additional random samples within the whole die parameters space(Section 2.1)by the general Latin Hypercube design.Table 7 gives the detailed scheme of random samples and the comparisons between the process forming limits(Lmax1andLmax2)obtained by RSM and FE simulation.It can be found that the predicted errors of the two models are both very small,which suggests that the developed RSM models are reliable to predictLmax1andLmax2at various die parameters.

After getting both the process forming limit considering the cavum defect(Lmax1)and the process forming limit considering the folding defect(Lmax2),the final process forming limit considering both defects(Lmax)can be represented by:

3.3.Coupling effects of die parameters

In this section,the coupling effects of two key factors(r1andr2)on the process forming limits and the restriction laws ofLmax1andLmax2onLmaxare analyzed.Here,bothr1andr2range from 3 to 9 mm,while γ1,γ2,γ3,andr3are fixed as 2°,2°,2°,and 6 mm,respectively.Using Eqs.(2)and(3),Lmax1andLmax2are calculated at 32×32 uniform distributed points in the space ofr1×r2.Then,the variations ofLmax1andLmax2withr1andr2are shown in Fig.12(a)through a threedimensional diagram.It can be found that the surfaces ofLmax1andLmax2are both close to planes.Moreover,theLmax1andLmax2planes are roughly parallel tor2-axis andr1-axis,respectively,suggesting that the coupling effects ofr1andr2onLmax1andLmax2are small.This is to say,Lmax1andLmax2are mainly determined byr1andr2,respectively.On the other hand,it can be observed from Fig.12(a)that the surfaces ofLmax1andLmax2intersect in the space.Ther1-r2plane can be divided into Region A and Region B(Fig.12(a))by projecting the intersecting line of the two surfaces.In Region A,Lmax2is smaller thanLmax1,so the final process forming limitLmaxequals toLmax2.This means that the final process forming limitLmaxis essentially constrained by folding in Region A.Conversely,Lmax1is smaller thanLmax2in Region B,and thus the final process forming limitLmaxis essentially constrained by cavum and equals toLmax1in Region B.Fig.12(b)gives the process forming limit considering both defects(Lmax)at various die parameters.It can be found that the process forming limit(Lmax)can be improved from 7.6 mm to 15.4 mm,whenr1andr2both increase from 3 mm to 9 mm.

Table 5 ANOVA analysis for the RSM model of Lmax1.

Table 6 ANOVA analysis for the RSM model of Lmax2.

Table 7 Comparisons between the predicted process forming limits obtained by RSM and FE simulation.

3.4.Discussion

The above analyses suggest that increasingr1andr2is an effective way to suppress cavum and folding defects in the transitional region,and then improve the process forming limit during local loading forming of rib-web components.Moreover,r1andr2are the only significant factors for the cavum and folding defects,respectively.There is little coupling effect ofr1andr2on forming defects and the process forming limit.These results are essentially determined by the formation mechanisms of defects and their dependences on die parameters.As described in Section 3.1,local geometrical parameters at the rib root greatly influence the material flow and determine forming defects.A greater fillet radius is more beneficial to avoid a V-shaped cavum at the rib root,which usually results in the cavum and folding defects.In addition,formations of cavum and folding defects both mainly depend on the local deformation behavior at the rib root.Thus,increasingr1andr2could control the cavum and folding defects,respectively,and little coupling effect exists.

Using Eqs.(2–4),the process forming limit,i.e.,the allowable maximum reduction amount,at different die parameters can be determined,as shown in Fig.12(b).This will provide technical basis for the design of die parameters and the reduction amount,which is of great importance to control forming defects and improve the process forming limit in local loading forming of Ti-alloy large-scale rib-web components.Although the process forming limit models(Eq.(2–4))are developed for a specific component,the effect laws of die parameters on forming defects and the process forming limit in this work are still propagable for local loading forming of rib-web components.

4.Conclusions

In this paper,we have explored the effects of die parameters on forming defects in the transitional region and the process forming limit during local loading forming of rib-web components.The following conclusions can be drawn:

(1)The common cavum and folding defects in the transitional region mainly depend on the fillet radii of left rib and middle rib,respectively.Increasing the fillet radii of left rib and middle rib can suppress the cavum and folding defects,respectively.

(2)The process forming limit constrained by forming defects in the transitional region is determined by the stepwise searching method based on FE simulation,and correlated with die parameters by the response surface methodology.

(3)Increasing the fillet radii of left and middle ribs is an effective way to improve the process forming limit during local loading forming of rib-web components.The process forming limit can be improved from 7.6 mm to 15.4 mm when the fillet radii of left and middle ribs both increase from 3 mm to 9 mm for the component in this work.

Acknowledgements

The authors would like to gratefully acknowledge the support of the National Natural Science Foundation of China(Nos.51605388,51675433),111 Project(B08040),the Research Fund of the State Key Laboratory of Solidification Processing(NWPU)in China(Grant No.131-QP-2015),the Fundamental Research Funds for the Central Universities,and the Open Research Fund of State Key Laboratory of Materials Processing and Dieamp;Mold Technology at Huazhong University of Science and Technology.

1.Yang H,Fan XG,Sun ZC,Guo LG,Zhan M.Recent developments in plastic forming technology of titanium alloys.Sci China Technol Sci2011;54(2):490–501.

2.Fan XG,Yang H,Gao PF.Through-process macro-micro finite element modeling of local loading forming of large-scale complex titanium alloy component for microstructure prediction.J Mater Process Technol2014;214(2):253–66.

3.Fan XG,Yang H,Sun ZC,Zhang DW.Effect of deformation inhomogeneity on the microstructure and mechanical properties of large-scale rib-web component of titanium alloy under local loading forming.Mater Sci Eng A2010;527(21–22):5391–9.

4.Zhang DW,Yang H,Sun ZC.Analysis of local loading forming for titanium-alloy T-shaped components using slab method.J Mater Process Technol2010;210(2):258–66.

5.Zhang DW,Yang H,Sun ZC,Fan XG.Deformation behavior of variable-thickness region of billet in rib-web component isothermal local loading process.Int J Adv Manuf Technol2012;63(1–4):1–12.

6.Gao PF,Yang H,Fan XG,Lei PH.Forming defects control in transitional region during isothermal local loading of Ti-alloy ribweb component.Int J Adv Manuf Technol2014;76(5–8):857–68.

7.Chan WL,Fu MW,Lu J,Chan LC.Simulation-enabled study of folding defect formation and avoidance in axisymmetrical f l anged components.J Mater Process Technol2009;209(11):5077–86.

8.Zhang YQ,Jiang SY,Zhao YA,Shan DB.Isothermal precision forging of aluminum alloy ring seats with different preforms using FEM and experimental investigation.Int J Adv Manuf Technol2014;72(9):1693–703.

9.Petrov P,Perf i lov V,Stebunov S.Prevention of lap formation in near net shape isothermal forging technology of part of irregular shape made of aluminum alloy A92618.J Mater Process Technol2006;177(1–3):218–23.

10.Chen FK,Huang TB,Wang SJ.A study of flow-through phenomenon in the press forging of magnesium-alloy sheets.J Mater Process Technol2007;187–188:770–4.

11.Zhang DW,Yang H,Sun ZC,Fan XG.Deformation behavior under die partitioning boundary during titanium alloy large-scale rib-web component forming by isothermal local loading.Proceedings of the 12th World Conference on Titanium.Beijing:Science Press;2011.p.328.

12.Zhang DW,Yang H.Distribution of metal flowing into unloaded area in the local loading process of titanium alloy rib-web component.Rare Metal Mater Eng2014;43(2):296–300.

13.Gao PF,Yang H,Fan XG.Quantitative analysis of the material flow in transitional region during isothermal local loading forming of Ti-alloy rib-web component.Int J Adv Manuf Technol2014;75(9–12):1339–47.

14.Gao PF,Yang H,Fan XG,Lei PH.Quick prediction of the folding defect in transitional region during isothermal local loading forming of titanium alloy large-scale rib-web component based on folding index.J Mater Process Technol2015;219:101–11.

15.Gao PF,Yang H,Fan XG,Lei PH.Forming limit of local loading forming of Ti-alloy large-scale rib-web components considering defects in the transitional region.Int J Adv Manuf Technol2015;80(5):1015–26.

16.Zhang DW,Yang H,Sun ZC,Fan XG.Influences of fillet radius and draft angle on local loading process of titanium alloy T-shaped components.Trans Nonferrous Met Soc China2011;21(12):2693–704.

17.Shen CW.Research on material constitution models of TA15 and TC11 titanium alloys in hot deformation process[Dissertation].Xi’an Northwestern Polytechnical University;2007.

18.Shipley RJ.Precision forging,forging process,ASM Handbook.ASM International;1988.

19.Shen Q,Zheng Y,Li S,Ding H,Xu Y,Zheng C,et al.Optimize process parameters of microwave-assisted EDTA method using orthogonal experiment for novel BaCoO3-δ perovskite.J Alloy Comp2016;658:125–31.

20.Meng Y,Chen Y,Li S,Chen C,Xu K,Ma F,et al.Research on the orthogonal experiment of numeric simulation of macromolecule-cleaning element for sugarcane harvester.Mater Des2009;30(6):2250–8.

21.Yang YH,Liu D,He ZY,Luo ZJ.Optimization of preform shapes by RSM and FEM to improve deformation homogeneity in aerospace forgings.Chin.J Aeronaut2010;23(2):260–7.

22.Wang H,Li GY,Zhong ZH.Optimization of sheet metal forming processes by adaptive response surface based on intelligent sampling method.J Mater Process Technol2008;197(1–3):77–88.

25 June 2016;revised 21 September 2016;accepted 18 October 2016

CHINESE JOURNAL OF AERONAUTICS2017年3期

CHINESE JOURNAL OF AERONAUTICS2017年3期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- Residual stress determination in friction stir butt welded joints using a digital image correlation-aided slitting technique

- A cost driven predictive maintenance policy for structural airframe maintenance

- Analysis of the current density characteristics in through-mask electrochemical micromachining(TMEMM)for fabrication of micro-hole arrays on invar alloy film

- Beam-pointing error compensation method of phased array radar seeker with phantom-bit technology

- Estimation of ballistic coefficients of space debris using the ratios between different objects

- A rapid compensation method for launch data of long-range rockets under influence of the Earth’s disturbing gravity field