Analysis of Machinable Structures and Their Wettability of Rotary Ultrasonic Texturing Method

XU Shaolin, SHIMADA Keita, MIZUTANI Masayoshi, , and KURIYAGAWA Tsunemoto

?

Analysis of Machinable Structures and Their Wettability of Rotary Ultrasonic Texturing Method

XU Shaolin1, SHIMADA Keita2, MIZUTANI Masayoshi2,*, and KURIYAGAWA Tsunemoto1

1 Division of Biomechanical Engineering, Graduate School of Biomedical Engineering, Tohoku University, Sendai 980-8579, Japan;2 Department of Mechanical Systems Engineering, Graduate School of Engineering, Tohoku University, Sendai 980-8579, Japan

Tailored surface textures at the micro- or nanoscale dimensions are widely used to get required functional performances. Rotary ultrasonic texturing (RUT) technique has been proved to be capable of fabricating periodic micro- and nanostructures. In the present study, diamond tools with geometrically defined cutting edges were designed for fabricating different types of tailored surface textures using the RUT method. Surface generation mechanisms and machinable structures of the RUT process are analyzed and simulated with a 3D-CAD program. Textured surfaces generated by using a triangular pyramid cutting tip are constructed. Different textural patterns from several micrometers to several tens of micrometers with few burrs were successfully fabricated, which proved that tools with a proper two-rake-face design are capable of removing cutting chips efficiently along a sinusoidal cutting locus in the RUT process. Technical applications of the textured surfaces are also discussed. Wetting properties of textured aluminum surfaces were evaluated by combining the test of surface roughness features. The results show that the real surface area of the textured aluminum surfaces almost doubled by comparing with that of a flat surface, and anisotropic wetting properties were obtained due to the obvious directional textural features.

rotary ultrasonic texturing, geometrically defined cutting edges, surface generation mechanisms, machinable structures, wetting properties

1 Introduction

Surfaces can be designed with tailored micro- or nanotextures for functional performances, including physical, biological and technological properties, among which the wetting property plays a significant role in many application fields[1]. Superhydrophobic textured surfaces can be used to get self-cleaning engineering parts[2]; hydrophilic textured surfaces have the possibility to enhance the osseointegration of human body implants[3?4], or increase bonding strength between porcelain and metal for dental restorations[5], and bonding strength between metal and resin cements[6]that highly required in the automobile industry; directional wettable textured surfaces can be utilized to improve the dew condensation efficiency and drainage efficiency of fin stocks of dehumidifying heat exchangers[7]. To change roughness characteristics and adjust chemical compositions of surfaces are two major ways to control the surface wettability. The advance of microfabrication technologies has been accelerating the research of modulating wettability by controlling the micro- or nanometers surface textures[8].

The capability of a microfabrication method with regard to the machinable materials, structures and sizes is crucial for generating textual features to get required functional performances in specific application fields. When considering the surface wettability, increasing the surface area with different micro- or nanostructures, creating directional textural features[9], or generating hierarchical or hybrid structures[10]have been paid much attention recently. The development of texturing methods for fabricating these functional surfaces at low cost and high efficiency is highly preferred. Diamond machining remains a major technique to meet these requirements, especially when high precision structures are essential. However, the spectrum of machinable structures of diamond machining techniques is usually limited by the machine tool’s kinematics and tool’s geometry[11], and the machining efficiency is also limited when very fine structures are required. High-frequency tool-workpiece relative motions can be actively controlled to quickly fabricate fine textures by using a fast tool servo system[12]or the tool ultrasonic vibration. Texturing methods by applying ultrasonic vibration such as turning with an excited tool[13], elliptical vibration assisted texturing[14], and rotary ultrasonic texturing (RUT)[15]have been developed for fabrication of micro- and nanostructures recently. The cutting edge’s geometries have a significant influence on the machined textural features due to the mechanical material removal processes.

The RUT technology has been verified to be capable of fabricating hybrid micro/nanotextures by using electroplated one-point diamond tools[15]. To further develop the RUT process with better stability and capability of fabricating more technically applicable machinable structures is still required. In the present study, geometrically defined tools were designed and the surface generation mechanisms and machinable structures are analyzed. The RUT processes by using diamond tools with a square pyramid cutting tip and a triangular pyramid cutting tip were carried out successively. Textured patterns at different dimensions from several micrometers to several tens of micrometers were successfully fabricated. The wetting properties of textured surfaces were also preliminarily measured for analyzing the technical applications of the RUT technique.

2 Texturing Procedures and Machinable Structures

Fig. 1 schematically shows the RUT process and two applicable texturing procedures. An ultrasonic spindle that can generate longitudinal vibration is mounted on a 4-axis () precision machine as shown in Fig. 1(a). Specifically, the workpiece stage can rotate (-axis) and feed along the-axis and the spindle can feed along the-axis. Therefore, the RUT method by using this machine tool can be applied on both flat surfaces and inner cylindrical surfaces theoretically as shown in Fig. 1(b).

Fig. 1. Schematics of (a) the RUT process and (b) two applicable texturing procedures

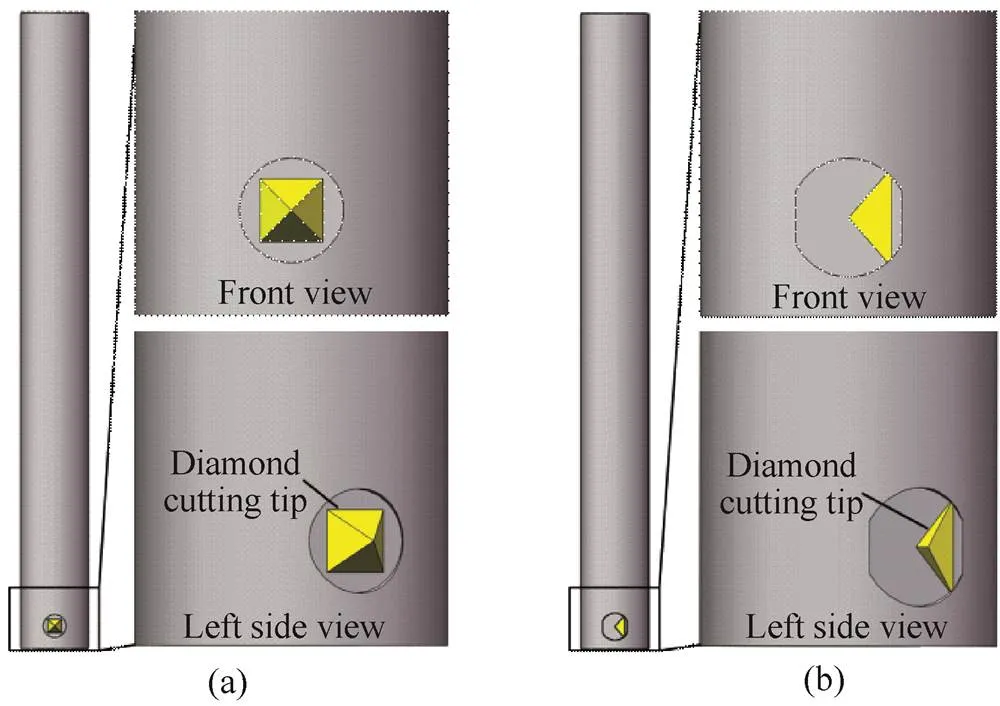

By combining the tool rotation, feed and ultrasonic vibration motions, the diamond cutting edge can remove materials along a sinusoidal cutting locus for fabricating periodical textural patterns. Because the ultrasonic-vibration frequency locates at several tens of kilohertz (usually no less than 20 kHz), it is possible to fabricate surface textures rapidly using the RUT technique. Two types of geometrically defined diamond tools with a square pyramid cutting tip and a triangular pyramid cutting tip as shown in Fig. 2 were designed successively to analyze and experimentally verify the surface generation mechanisms of the RUT process.

Fig. 2. Schematics of two types of geometrically defined diamond tools with (a) a square pyramid cutting tip and(b) a triangular pyramid cutting tip

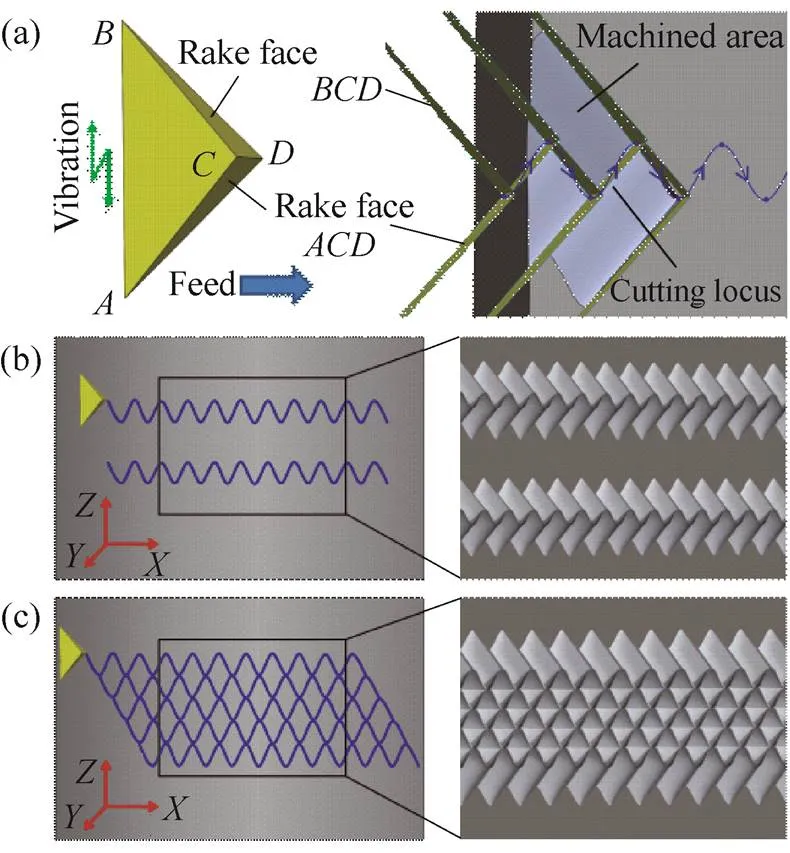

The materials removal process and the machinable structures by using the triangular pyramid cutting tip as shown in Fig. 3 are analyzed in this section.

Fig. 3. Schematics of (a) materials removal along a sinusoidal cutting locus and (b–c) two textured surfaces with different patterns by controlling cutting locus

A two-rake-face design was applied to help to remove materials efficiently along a sinusoidal cutting locus. For simplifying the surface generation process, the depth of cut is assumed to be constant along the sinusoidal loci without considering the radial motion in the RUT process. The facesandas shown in Fig. 3(a) are the two rake faces of the triangular pyramid cutting tip. When the cutting tip vibrates upward from a lower peak point to a next upper peak along the sinusoidal locus, the faceacts as the rake face; when the cutting tip vibrates downward, the faceacts as the rake face. The workpiece materials are removed periodically along the cyclical upward and downward locus, and the generated surface structures can be simulated by using a 3D-CAD program (Solidworks) as shown in Fig. 3(a) supposing the two rake faces can remove cutting chips completely from the machined surfaces. Therefore, all the geometrical features of textured patterns can be directly obtained from the constructed surfaces with a designed cutting locus. Using the texturing procedure as shown in Fig. 3(b), textured patterns composing of two parallel rows of grooves on the two sides of sinusoidal locus can be generated. The depth of the textured patterns achieves at the highest value along the sinusoidal locus. Finer structures can be fabricated by controlling the cutting loci with a smaller interval between two adjacent loci as shown in Fig. 3(c). The adjustment of the interval can be achieved by controlling the relationship between the tool rotational frequency and the feed speed in the RUT process. Continuous textural patterns of micrometers dimensions can be fabricated with sharp cutting edges. The overall surface textures not only depend on the geometry of the diamond cutting tip, but also depend on the shapes and combinations of the sinusoidal cutting loci.

3 Experiments and Discussions

Two geometrically defined diamond tools with the designs as shown in Fig. 2 were manufactured. The cutting tips were welded to the tungsten carbide tool shank and their geometries were examined with a scanning electron microscope (SEM) (Hitachi, SU1510). As shown in Fig. 4(a), the square pyramid cutting tip was designed with 70-degree included angles of opposite faces, and the cutting tip is very sharp with a nose radius at submicrometer dimension. The triangular pyramid cutting tip was designed with a 90° included angle between two rake faces (and), and the facewas designed with a 30° inclined angle as shown in Fig 4(b). Square steel plates with electroless nickel-phosphorus (Ni-P) plating as an important mold material were selected as the samples for surface texturing. The capability of the RUT method was experimentally verified on the flat Ni-P plating surfaces. Two rotary ultrasonic spindles with different vibration frequencies produced by Taga Electric Co., Ltd. were tried in the texturing experiments. The detailed experimental conditions are listed in Table 1. All textured surfaces were examined with the SEM and a white light interferometer (Taylor Hobson, talysurf CCI - lite non-contact 3D profiler) for examining the textural features.

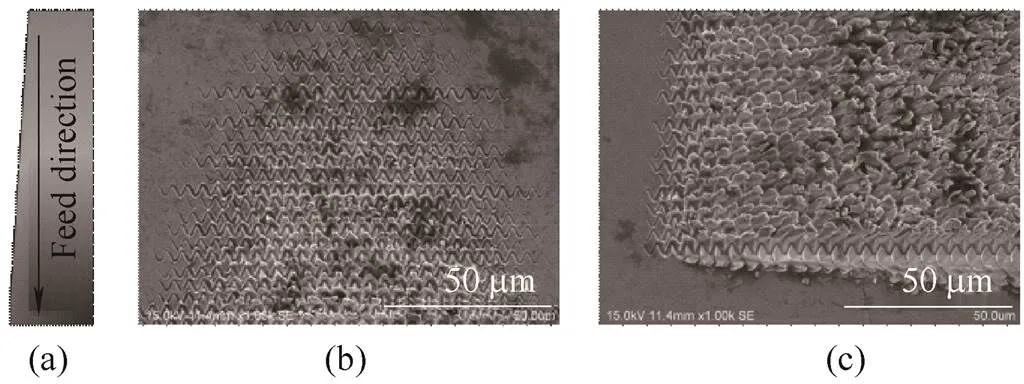

First, the RUT process was carried out by using the tool with the square pyramid cutting tip. As shown in Fig. 5(a), the depth of cut was increased gradually along the feed direction by using a tilted workpiece surface. Figs. 5(b) and 5(c) show the SEM images of textured areas with different depths of cut under the condition of=25 kHz,=3 μm,n=500 r/min,v=2 mm/min. Due to the radial motion of the cutting tip, the depth of cut actually increases from 0 to the maximum value and then decreases to 0 from the left to the right on the workpiece during every rotation cycle. The amount of the work material removed by the cutting tip increased with the growth of depth of cut. When the depth of cut remains at a very small value as shown in the top surface area of Fig. 5(b), cutting chips had been removed from the workpiece and the sinusoidal grooves were fabricated successfully. However, it is very difficult to control the depth of cut at such a small value in the practical texturing process. As the increase of the depth of cut, cutting chips occupy all the machined area, and no obvious surface patterns can be obtained as shown in Fig. 5(c). The periodic upward and downward vibration makes the material removal process to be discontinuous. The materials just pile up along the two sides of the sinusoidal locus with plastic deformation when using the square pyramid cutting tip. Therefore, to design geometrically defined tools that can remove discontinuous cutting chips efficiently along the sinusoidal locus is required. Furthermore, to control the amount of work material removed in every vibration period as small as possible is also beneficial for fabricating micro- or nanometer structures by using the RUT method.

Fig. 4. Two types of diamond tools with (a) the square pyramid cutting tip and (b) the triangular pyramid cutting tip

Table 1. Experimental conditions

Fig. 6 shows textured surfaces fabricated by using the tool with the triangular pyramid cutting tip by changing the feed speed under the condition of=62 kHz,=2 μm,n=1000 r/min. It can be observed that cutting chips have been efficiently removed from the workpiece, and textured surfaces with periodic patterns were fabricated successfully with few burrs in all the machined area. The textural features coincide well with the predictions as shown in Fig. 3. Two parallel rows of grooves along the two sides of every sinusoidal groove were generated by the two tool rake faces respectively, and the sinusoidal grooves have the highest depth as shown in Fig. 6(a). Finer structures were fabricated by controlling the cutting loci with a smaller interval as shown in Fig. 6(b). The adjustment of the interval was achieved by controlling the feed speed along the axial direction. Fig. 7 shows three other textured surfaces by increasing the rotation speed for different wavelength of sinusoidal grooves using the spindle with the lower frequency. It can be found that much finer structures with periodic features of several micrometers dimensions can be generated.

Fig. 5. (a) Schematic of texturing procedure and (b–c) textured patterns fabricated by the tool with the square pyramid cutting tip under different depths of cut

Fig. 6. Textured surfaces fabricated by the tool with the triangular pyramid cutting tip by decreasing the feed speed from (a)v=6mm/min to (b) 2 mm/min

Cutting burrs have bad effects and should be controlled at a negligible level. Burrs occurs in most machining operations is a result of the cutting edge exiting the workpiece[16]. The sinusoidal cutting locus in the RUT process makes the cutting edge exit the workpiece at each peak point of the sinusoidal locus, which results in the formation of burrs around the peak points on the textured surfaces. The radial motion of the diamond cutting tip makes the instantaneous depth of cut change periodically from 0 to the maximum value and then to 0 as mentioned above, which means the amount of material removed in every rotational period keeps changing in the same manner. The rake facecan always remove most of materials along the feed direction and make the instantaneous depth of cut around the cutting tip at a very small value as shown in Fig. 6(b), namely controlling the amount of the work material removed in every period of vibration at a very small value, thus making the texturing process possible and stable. The large amounts of material removed in every period of vibration by using the square pyramid cutting tip results in the gathering of the large amounts of cutting chips on the machined surface. The higher vibration frequency can give a higher machining efficiency.

Fig. 7. Three other textured surfaces fabricated by the tool with the triangular pyramid cutting tip under the conditions of (a)n=250 r/min,v=1 mm/min, (b)n=500 r/min,v=2 mm/min, and (c)n=1000 r/min,v=4 mm/mim

4 Technical Applications of Textured Surfaces

By controlling the cutting locus, different types of textured patterns can be fabricated with geometrically defined diamond tools as experimentally shown in section 3. Comparing with other conventional mechanical machining methods, the RUT technique provides advantages on quickly fabricating very fine textured patterns. The potential technical applications of these textured surfaces including good-osseointegration surface, high adhesive surface, directional wettable surface, and so on. Factors such as surface morphology, real surface area and surface wettability have a major influence on these properties. As for the applications of the RUT method, structures can be fabricated on mold inserts (Ni-P plating) for replicating structures on polymer or glass materials, in which some technical problems have not yet been well resolved, or directly fabricated on metal engineering components. In the present research, directly textured aluminum surfaces were firstly used to investigate the influence of textural features on surface wettability. Aluminum and aluminum alloy are widely used materials in automotive industry, where increasing bonding strength or creating direct bonding (adhesive-free) between metal and polymer components are required[17]. A larger surface area and better surface wettability are beneficial to increase the bonding strength.

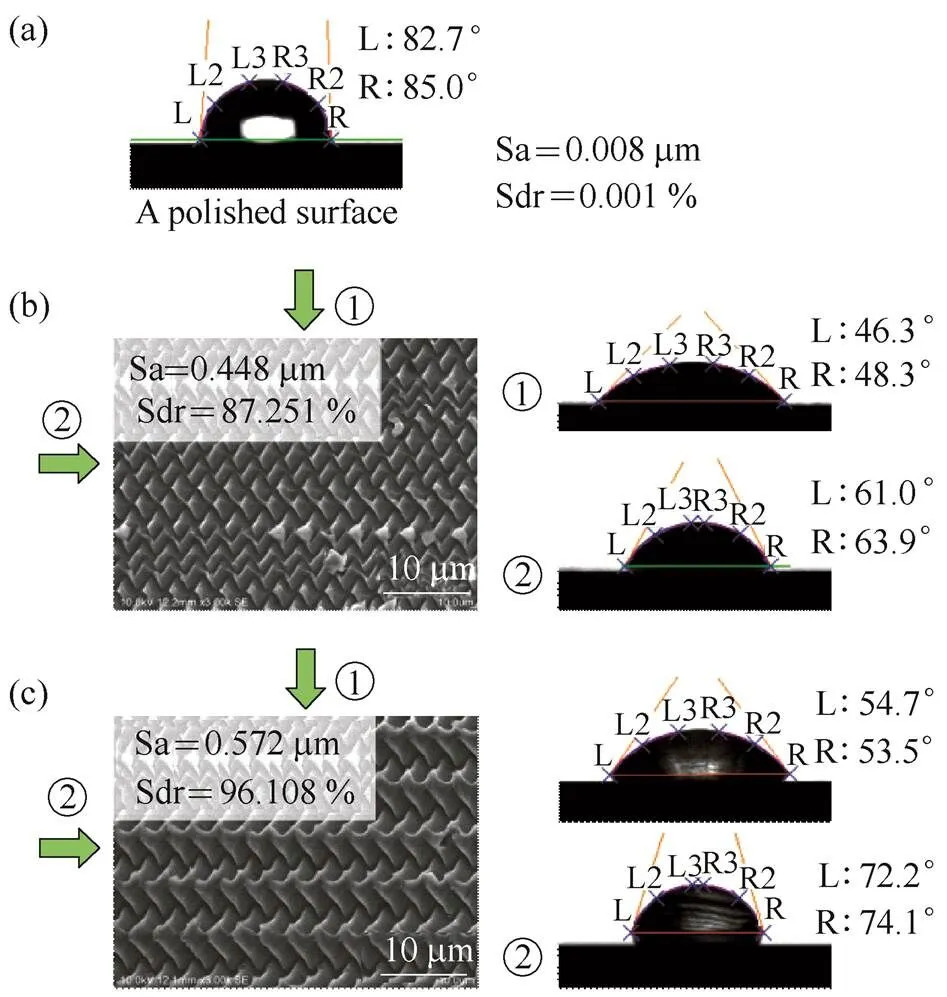

The wetting property of textured pule aluminum (99.9 wt.%) surfaces using the RUT method was evaluated by comparing with that of a polished aluminum surface. The textured surfaces were fabricated by repeating the machining processes along the axial direction (axis) with an interval distance of 400 μm along the horizontal direction (axis). The machined specimens were cleaned in an ultrasonic bath with ethanol (99.5 vol.%) for 60 min, and then with deionized water for 30 min twice after diamond machining procedures. After that, the samples were dried in the air environment for 60 min. The wettability of the finished surfaces was evaluated by testing their contact angles with deionized water. The sessile drop technique was employed by using an automatic contact angle meter (Kyowa, DM-501). The volumes of water droplets were all kept at 2 μL, and the spreading time was set at 1000 ms. The roughness parameters of the machined surfaces were measured at a surface area of 0.15′0.15 mm2using the white light interferometer with a software (Talymap Gold 6.2) at 110′objective magnification: Sa is the average surface roughness; Sdr is the developed interfacial area ratio, which is expressed as the percentage of additional surface area contributed by the textures as compared to the area of an ideal complete plane surface. Fig. 8 shows the representative images of water contact angles of a polished aluminum surface and two textured aluminum surfaces.

Fig. 8. Representative water contact angles of (a) a polished surface and (b-c) two textured aluminum surface (=25 kHz,=3 μm,n=1000 r/min,v=2 mm/min; 6 mm/min) measured from two perpendicular directions

From Fig. 8, it can be found the percentage of additional surface area contributed by the textures nearly achieves 100 percent improvement, which means the textures almost doubled the real surface area of the textured surfaces compared with that of a flat surface. The textured surfaces are more wettable than the polished surface. The directionality of textural features also makes the textured surface show an anisotropic wetting property. As described in the Wenzel model, the increase of the real surface area generally improves the wettability of the chemically hydrophilic surfaces[8]. Therefore, the increase of surface area contributes to the enhancement of surface wettability of the aluminum-water system. The directionality of the textured surfaces induces the anisotropic wetting property[8]. In the present case, the capillary action along the sinusoidal microgrooves can enhance the wettability along the grooves, and the pinning effect of the edges of the grooves prevents the extent of water along the direction perpendicular to the grooves.

5 Conclusions

In the present research, the surface generation mechanisms, machinable structures and related technical applications of the RUT technique were studied by using geometrically defined diamond tools. Different types of textural patterns with few burrs were successfully fabricated on flat surfaces with the triangular pyramid cutting tip. The following conclusions can be drawn.

(1) The longitudinal vibration makes the cutting tip feed upward and downward periodically at a very high frequency, therefore the workpiece materials are also removed at the same manner. The two-rake-face design can help to remove cutting debris efficiently along the sinusoidal cutting locus in the RUT process and thus textured patterns with few burrs can be quickly fabricated.

(2) By controlling the cutting locus, textured patterns on dimensions from several micrometers to several tens of micrometers can be fabricated. The textured surfaces by using geometrically defined cutting edges can be simply constructed by using a 3D-CAD software like Solidworks, and therefore the textural features can be predicted. The experimental results coincide well with the results of the predictions.

(3) The RUT technique provides a new way to quickly fabricate very fine surface textures by mechanical material removal processes. The textured patterns can increase the real surface area significantly and thus enhance the wettability of chemical hydrophilic surfaces; the directional surface textures can induce directional wettability.

[1] Bruzzone A A G, Costa H L, Lonardo P M, et al. Advances in engineered surfaces for functional performance[J]., 2008, 57(2): 750–769.

[2] Fürstner R, Barthlott W, Neinhuis C, et al. Wetting and self-cleaning properties of artificial superhydrophobic surfaces[J]., 2005, 21(3): 956–961.

[3] Guéhennec L Le, Soueidan A, Layrolle P, et al. Surface treatments of titanium dental implants for rapid osseointegration[J]., 2007, 23(7): 844–854.

[4] TANG T, WAN Z, LU L, TANG Y. Characteristics and formation mechanism for stainless steel fiber with periodic micro-fins[J]. 2016, 29(3): 564–570.

[5] ZHANG S, LI Y, HAO L, XU T, WEI Q, SHI Y. Metal-ceramic bond mechanism of the Co-Cr alloy denture with original rough surface produced by selective laser melting [J]. 2014, 27 (1): 69–78.

[6] Rotella G, Alfano M, Candamano S. Surface modification of Ti6Al4V alloy by pulsed Yb-laser irradiation for enhanced adhesive bonding[J]., 2015, 64(1): 527–530.

[7] Liu L, Jacobi A M, Chvedov D. A surface embossing technique to create micro-grooves on an aluminum fin stock for drainage enhancement[J]., 2009, 19(3): 035026.

[8] Quéré D. Wetting and roughness[J]., 2008, 38: 71–99.

[9] Xia D, Johnson L M, López G P. Anisotropic wetting surfaces with one-dimensional and directional structures: fabrication approaches, wetting properties and potential applications[J]., 2012, 24(10): 1287–1302.

[10] Bhushan B, Jung Y C, Koch K. Micro-, nano-and hierarchical structures for superhydrophobicity, self-cleaning and low adhesion[J]., 2009, 367: 1631–1672.

[11] Brinksmeier E, Gl?be R, Sch?nemann L. Review on diamond-machining processes for the generation of functional surface structures[J]., 2012, 5(1): 1–7.

[12] Gao W, Araki T, Kiyono S, et al. Precision nano-fabrication and evaluation of a large area sinusoidal grid surface for a surface encoder[J]., 2003, 27(3): 289–298.

[13] Denkena B, Ostermann J, Becker C, et al. Mechanical information storage by use of an excited turning tool[J]., 2007, 1(1): 25–30.

[14] Guo P, Ehmann KF. An analysis of the surface generation mechanics of the elliptical vibration texturing process[J]., 2013, 64: 85–95.

[15] Xu S, Shimada K, Mizutani M, et al. Fabrication of hybrid micro/nano-textured surfaces using rotary ultrasonic machining with one-point diamond tool[J]., 2014, 86: 12–17.

[16] Boothroyd G, Knight WA.[M]. Taylor and Francis, 2006.

[17] Grujicic M, Sellappan V, Omar MA, et al. An overview of the polymer-to-metal direct-adhesion hybrid technologies for load-bearing automotive components[J]., 2008, 197(1–3): 363–373.

Biographical notes

XU Shaolin, born in 1985, is currently an assistant professor atHe received his PhD degree from, in 2015. His research interests include ultrasonic assisted machining, laser assisted machining, nanofabrication and its biomedical applications.

Tel: +81-22-795-6949; E-mail: shaolin@pm.mech.thohou.ac.jp

SHIMADA Keita, born in 1985, is currently an assistant professor at.He received his PhD degree from Tohoku University, in 2012. His research interests include grinding, ultrasonic machining and laser machining.

Tel: +81-22-795-6949; E-mail: shimada@m.tohoku.ac.jp

MIZUTANI Masayoshi, born in 1979, is currently an associate professor at. He received his PhD degree from, in 2006. His research interests include laser process, biomaterials, biomimetic surfaces and their biomedical applications.

Tel: +81-22-795-6946; E-mail: mizutani@m.tohoku.ac.jp

KURIYAGAWA Tsunemoto, born in 1957, is currently a professor at. His research interests include nano-precision mechanical manufacturing, micro/meso mechanical manufacturing (M4 Processes), powder jet processing and creation of functional interface.

Tel: +81-22-795-6948; E-mail: tkuri@m.tohoku.ac.jp

Received February 17, 2016; revised August 31, 2016; accepted September 10, 2016

Supported by Japan Society for the Promotion of Science (Grant Nos. 14J04115, 16K17990)

? Chinese Mechanical Engineering Society and Springer-Verlag Berlin Heidelberg 2016

10.3901/CJME.2016.0910.112, available online at www.springerlink.com; www.cjmenet.com

E-mail: mizutani@m.tohoku.ac.jp

Chinese Journal of Mechanical Engineering2016年6期

Chinese Journal of Mechanical Engineering2016年6期

- Chinese Journal of Mechanical Engineering的其它文章

- Surface Topography and Roughness of High-speed Milled AlMn1Cu

- Digital Evaluation of Sitting Posture Comfort in Human-vehicle System under Industry 4.0 Framework

- Thermo-physical Characteristics of Nickel-coated Aluminum Powder as a Function of Particle Size and Oxidant

- Effect of Magnetic Field on Forced Convection between Two Nanofluid Laminar Flows in a Channel

- Gas Film Disturbance Characteristics Analysis of High-Speedand High-Pressure Dry Gas Seal

- Method for Evaluating the Reliability of Compressor Impeller of Turbocharger for Vehicle Application in Plateau Area