Method for Evaluating the Reliability of Compressor Impeller of Turbocharger for Vehicle Application in Plateau Area

WANG Zheng, WANG ZengquanWANG A-na, ZHUANG Liand WANG Jinwei

?

Method for Evaluating the Reliability of Compressor Impeller of Turbocharger for Vehicle Application in Plateau Area

WANG Zheng1,*, WANG Zengquan1, WANG A-na2, ZHUANG Li1, and WANG Jinwei1

1 Key Laboratory of Diesel Engine Turbocharging Technology, China North Engine Research Institute, Tianjin 300400, China;2 Center of Engine Test and Measurement, China North Engine Research Institute,Tianjin 300400, China

As turbocharging diesel engines for vehicle application are applied in plateau area, the environmental adaptability of engines has drawn more attention. For the environmental adaptability problem of turbocharging diesel engines for vehicle application, the present studies almost focus on the optimization of performance match between turbocharger and engine, and the reliability problem of turbocharger is almost ignored. The reliability problem of compressor impeller of turbocharger for vehicle application when diesel engines operate in plateau area is studied. Firstly, the rule that the rotational speed of turbocharger changes with the altitude height is presented, and the potential failure modes of compressor impeller are analyzed. Then, the failure behavior models of compressor impeller are built, and the reliability models of compressor impeller operating in plateau area are developed. Finally, the rule that the reliability of compressor impeller changes with the altitude height is studied, the measurements for improving the reliability of the compressor impellers of turbocharger operating in plateau area are given. The results indicate that when the operating speed of diesel engine is certain, the rotational speed of turbocharger increases with the increase of altitude height, and the failure risk of compressor impeller with the failure modes of hub fatigue and blade resonance increases. The reliability of compressor impeller decreases with the increase of altitude height, and it also decreases as the increase of number of the mission profile cycle of engine. The method proposed can not only be used to evaluating the reliability of compressor impeller when diesel engines operate in plateau area but also be applied to direct the structural optimization of compressor impeller.

turbocharger, plateau area, compressor impeller, failure behavior, reliability

1 Introduction

Turbocharger is one of the most important components for turbocharging diesel engines to improve their power density and their environmental adaptability in plateau area[1]. As one of key components of turbocharger, the compressor impeller plays an important role in the performance and reliability of turbocharger.

The environmental adaptability of turbocharging diesel engines which are applied in plateau area has drawn attention. When turbocharging diesel engines work in plateau area, their performance parameters such as input air, thermal loss, output power, fuel consumption rate, the rotational speed of turbocharger, will change at different levels because of the change of aerosphere environment[2]. Generally speaking, for turbocharging diesel engines, the rotational speed of turbocharger and the input air temperature of turbine are two of the most important factors which limit the normal output power of engines operating in plateau area. As for the compressor impeller of turbocharger, when turbocharging diesel engines work in plateau area, its reliability will be challenged because of the change of operating conditions.

For the reliability problem of compressor impeller, many researches have been done from different aspects[3–16]. PANKAJ, et al[4], studied the nonlinear stochastic dynamics, chaos, and reliability for a single degree of freedom model of a rotor blade with the modified numerical method. LIN, et al[5], studied the blade vibration strength problem of turbocharger of aero piston engine and analyzed the strength and vibration modes of turbine and compressor impeller applied by the centrifugal force in the structural improvement design. MA, et al[6], studied the blade resonance vibration frequency of compressor impeller and turbine against the problem of inlet noise of turbocharger, which is helpful for controlling the blade vibration and noise. STEPHAN, et al[7], studied the excitation characteristic of blade vibration of turbine in the pulse-charged mixed-flow turbocharger by the method of 3-D model calculation. NAKHODCHI, et al[8], studied the fatigue life prediction method of damaged and un-damaged compressor blades. HUANG, et al[9], studied the low cycle fatigue failure mode of compressor impeller of turbocharger, and the relationship between the stress of compressor impeller and the rotational speed of turbocharger was derived through the stress calculation and strength analysis. CHEN, et al[12], studied the static stress of compressor impeller of turbocharger with the finite element method and applied the secondary moment method to analyze the reliability of blade. In the existed literatures, the influence of environmental conditions on the reliability of compressor impeller can not been taken into accounted.

In addition, for the environmental adaptability problem of turbocharging diesel engines, the present studies almost focus on the optimization of performance match between turbocharger and engine[3], and the reliability problem of turbocharger is always ignored.

In this paper, take the compressor impeller of turbocharger for vehicle application as an example, the rule that the rotational speed of turbocharger changes with the altitude height is studied, and the potential failure modes of compressor impeller and their failure mechanisms are analyzed. Then, the models for describing the failure behaviors of the compressor impeller of turbocharger working in plateau area are developed, and further the reliability models are derived. Finally, the reliability of compressor impeller working in plateau area is studied.

2 Rotational Speed of Turbocharger Operating in Plateau Area

As for the compressor impeller of turbocharger working in plateau area, the rotational speed of turbocharger is the parameter changing most obviously among all the state parameters of compressor impeller, and it is also the parameter affecting the reliability of compressor impeller most significantly. Here, taking a compressor impeller of turbocharger for vehicle application as an example, with the GT-power software developed by the Gamma Technologies Company, the performance simulation model of turbocharging diesel engine is built, and the rule that the rotational speed of turbocharger changes with the altitude height is studied for different operating modes of the turbocharging diesel engine. It should be pointed out that before it is applied to calculate the rule that the rotational speed of turbocharger changes with the altitude height, the performance simulation model of turbocharging diesel engine is calibrated with the test data of turbocharging diesel engine.

The rules that the rotational speed of turbocharger changes with the altitude height for different operating modes of engine working in plateau area, are shown in Fig. 1. From Fig. 1, it can be concluded that the rotational speed of turbocharger increases obviously as the altitude height increases when the operating speed of engine keeps constant, especially for the case that engines operate at the altitude height of 4500 m, the rotational speed of turbocharger is 17.6% up that in plain area.

Fig. 1. Rotational speed of turbocharger changes with the altitude height

3 Potential Failure Mode Analysis of Compressor Impeller of Turbocharger in Plateau Area

For determining the potential failure modes of compressor impeller of turbocharger in plateau area, the stress state and blade vibration characteristics of compressor impeller are analyzed. For the compressor impeller of turbocharger, among all the loads applied on the compressor impeller, the centrifugal load has the most important influence on the stress of compressor impeller[17]. Fig. 2 shows the stress distribution state of compressor impeller applied by the centrifugal load. In Fig. 2, it indicates that the maximal stress of compressor impeller appears at the hub back near the axle hole.

Fig. 2. Stress distribution state of compressor impeller applied by the centrifugal load

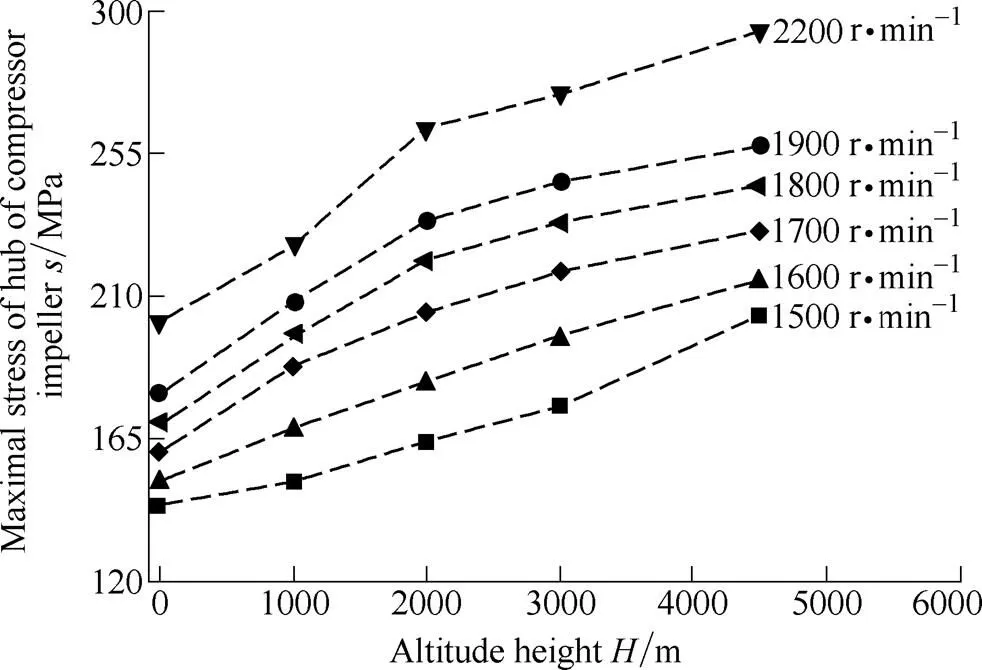

According to the rules that the rotational speed of turbocharger changes with the altitude height shown in Fig. 1, the rule that the maximal stress of hub of compressor impeller changes with the altitude height when engines operate at different speeds is shown as Fig. 3.

From Fig. 3 it can be concluded that as the altitude height increases the maximal stress of hub of compressor impeller increases, and correspondingly the risk that the hub fatigue failure mode of compressor impeller appears increases. A broken compressor impeller of turbocharger caused by the hub fatigue failure mode is shown as Fig. 4.

Fig. 3. Change of the maximal stress of compressor impeller hub with the altitude height

Fig. 4. Broken compressor impeller with hub fatigue failure mode

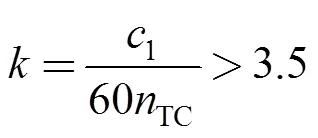

Additionally, according to the design criterion of compressor impeller of turbocharger for vehicle application, the ratio of the first-order natural vibration frequencyof big blade of compressor impeller and the rotational speed of turbochargershould be greater than 3.5, that is

Obviously, when the turbocharging diesel engine operates in plateau area, the rotational speed of turbocharger increases as shown in Fig. 1, and the ratio of the first-order natural vibration frequency of big blade of compressor impeller and the rotational speed of turbochargerdecreases, especially for some operating modes of engine, the ratio of the first-order natural vibration frequency of big blade of compressor impeller and the rotational speed of turbochargercan not meet the design criterion, as shown in Fig. 5. Because the decrease of the ratio of the first-order natural vibration frequency of big blade of compressor impeller and the rotational speed of turbocharger can cause the resonance vibration of blade of compressor impeller, the risk that the blade resonance vibration failure mode of compressor impeller appears increases when engines operate in plateau area. Fig. 6 shows a damaged compressor impeller caused by the blade resonance vibration failure mode.

Fig. 5. Ratio of first-order vibration frequency of big blade of compressor impeller and rotational speed of turbocharger

Fig. 6. Damaged compressor impeller with blade resonance vibration failure mode

From the above analysis, it can be concluded that when the turbocharging diesel engine operates in plateau area, the rotational speed of turbocharger will increase. And the increase of rotational speed of turbocharger can affect the reliability of compressor impeller in two aspects, namely, one is the increase of hub fatigue failure risk, and the other is the increase of blade resonance vibration failure risk.

4 Failure Behavior Description of Compressor Impeller of Turbocharger

For the potential failure modes of compressor impeller of turbocharger when turbocharging diesel engines operate in plateau area, the failure behavior models of compressor impeller with the hub fatigue failure mode and the blade resonance vibration failure mode will be developed respectively in this section.

4.1 With hub fatigue failure mode

The compressor impeller of turbocharger for vehicle application is generally made of 2A70-marked aluminum alloy, and according to the test data of 2A70-marked aluminum alloy, the relationship between fatigue lifeand stresscan be expressed as

Where—Strength parameter which can be derived from the fatigue test data,

—Strength parameter which can be derived from the fatigue test data.

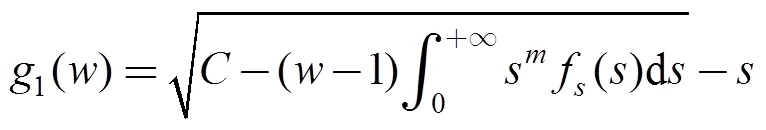

Generally, because the operating profile of vehicle engine is complex and variable, the maximal rotational speed of turbocharger is uncertain during one operating cycle of engine, and the fatigue stress of hub of compressor impeller is uncertain, too. Here, the random variable with the probability density function denoted byis applied to describe the fatigue stress of hub of compressor impeller. For one operating cycle of engine, the damage increment of compressor impeller with the hub fatigue failure mode can be expressed as[18]

With the linear cumulative fatigue damage rule, the total damage of compressor impeller with the hub fatigue failure mode corresponding to themission profile cycles of engine, can be derived as

. (4)

For theoperating cycles of engine, the residual and allowable fatigue damage of compressor impeller with the hub fatigue failure mode can be expressed as

With Eq. (2) and Eq. (5), the residual strength of compressor impeller with the hub fatigue failure mode after themission profile cycles of engine can be developed as

. (6)

Therefore, the limit state function of compressor impeller with hub fatigue failure mode for theth mission profile cycle of engine can be expressed as

According to the data of compressor impeller hub stresses for different rotational speeds of turbocharger, the relationship between the stress of compressor impeller hub and the rotational speed of turbocharger can approximately be expressed as

. (8)

Further, the limit state function of compressor impeller with hub fatigue failure mode for theth operating cycle of engine can be expressed as

Obviously, the serviceable state of compressor impeller with hub fatigue failure mode for theth mission profile cycle of engine can be denoted by, and the failure state can be denoted by.

4.2 With blade resonance vibration failure mode

During the working process of turbocharger for vehicle application, the blades of compressor impeller are applied by the variably periodical aerodynamic force, which is caused by the unsteady inlet air flow. Generally, based on the Fourier transform, the variable force acting on the blades of compressor impeller can be expressed as a function of rotational speed of turbocharger, and the relationship between the natural vibration frequency of blade of compressor impeller and its rotational speed can be presented with Campbell graph[17].

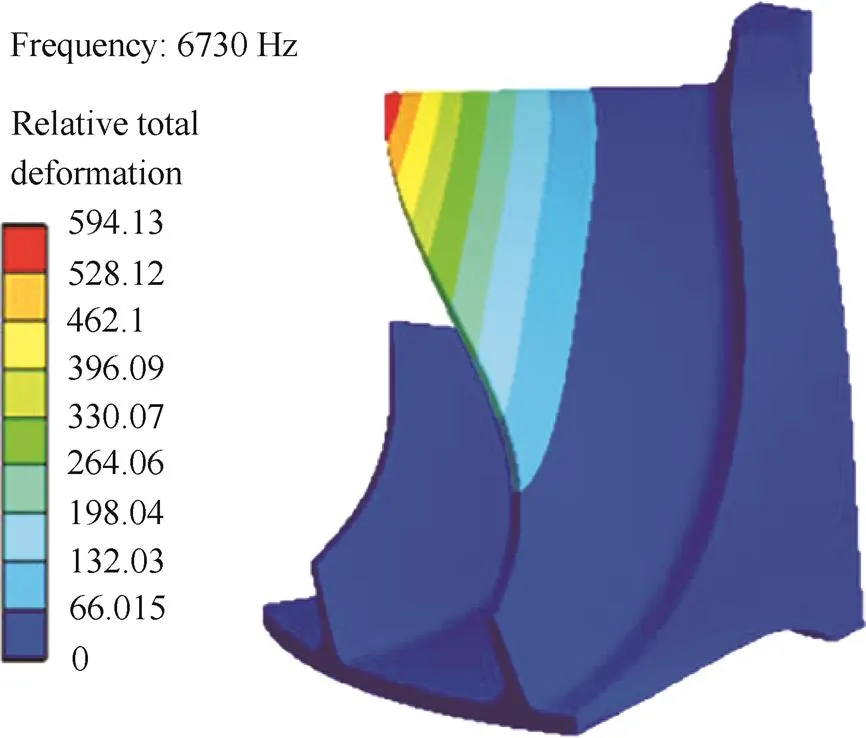

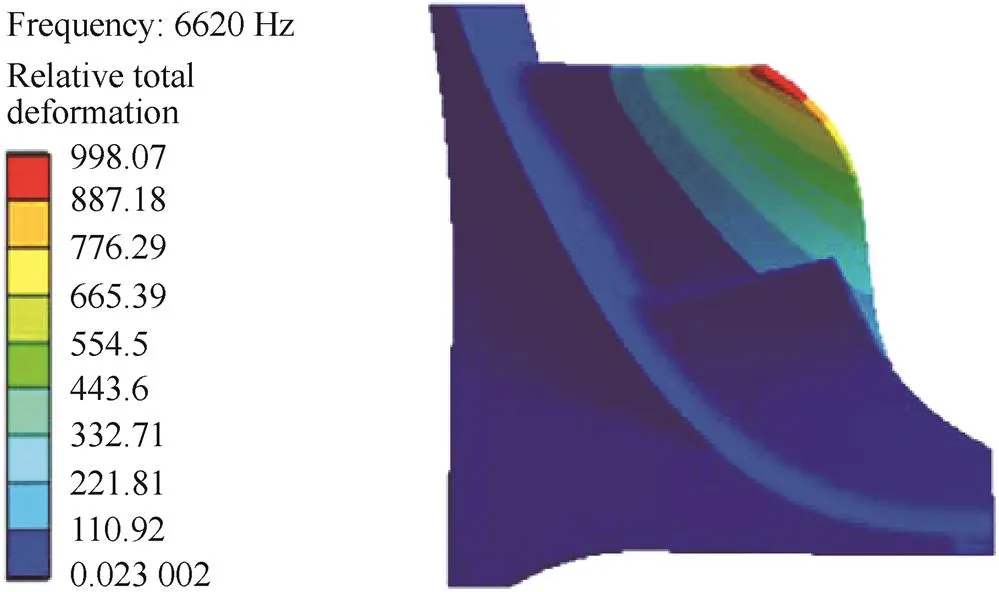

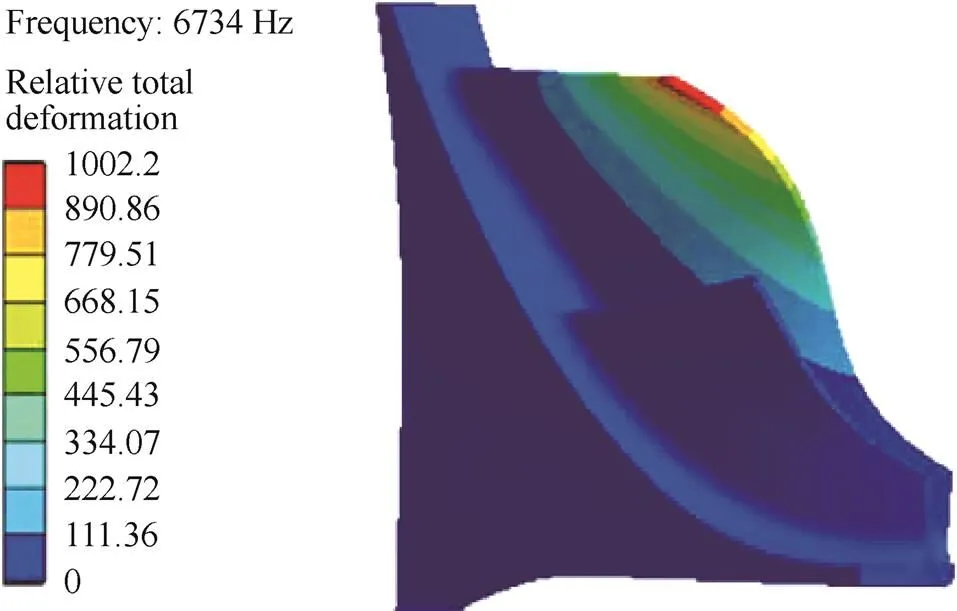

When working, the compressor impeller is simultaneously applied by centrifugal load, thermal load and aerodynamic load, and the first-order natural vibration frequency of blade in active state will change with the operating conditions of engine. Fig. 7 shows the first-order natural vibration modes of big blade of compressor impeller in static state calculated by the finite element method. The first-order natural vibration modes of big blade of compressor impeller under the centrifugal load, thermal load and aerodynamic load are shown as Fig. 8 to Fig. 10, respectively. It can be concluded that there is obvious difference between the dynamic first-order natural vibration frequency of big blade of compressor impeller and the static first-order natural vibration frequency, and the effects of different loads on the dynamic first-order natural vibration frequency of big blade of compressor impeller are different. The effect of centrifugal load caused by the rotational speed is obvious, but the effect of thermal load and aerodynamic load is obscure and can be ignored[19].

With the finite element method, the dynamic first-order natural vibration frequency of big blade of compressor impeller for different rotational speed of turbocharger are studied, and according to the simulation results, the dynamic first-order natural vibration frequency of compressor impellercan be expressed as a function of its static natural frequencyand the rotational speed of turbocharger, that is

Fig. 7. First order natural vibration mode (1=6730Hz) of big blade of compressor impeller in static state

Fig. 8. First-order vibration mode of big blade of compressor impeller applied by centrifugal load (1=7078Hz)

Fig. 9. First-order vibration frequency mode of big blade of compressor impeller applied by thermal load (1=6620Hz)

Fig. 10. First-order vibration mode of big blade of compressor impeller applied by aerodynamic load (1=6734Hz)

Further, according to the design criterion of compressor impeller with blade resonance vibration failure mode shown as Eq. (1), the limit state function of compressor impeller with blade resonance vibration failure mode can be expressed as

Obviously, the event that the blade resonance vibration failure mode of compressor impeller appears can be denoted by, and the event that the blade resonance vibration failure mode of compressor impeller does not happen can be denoted by.

5 Reliability Modeling of Compressor Impeller of Turbocharger

In this section, taking account of the blade resonance vibration failure mode and hub fatigue failure mode of compressor impeller which are the main potential failure modes of compressor impeller of turbocharger operating in plateau area, the reliability models of compressor impeller are developed with the number of operating cycle of engine as the life parameter.

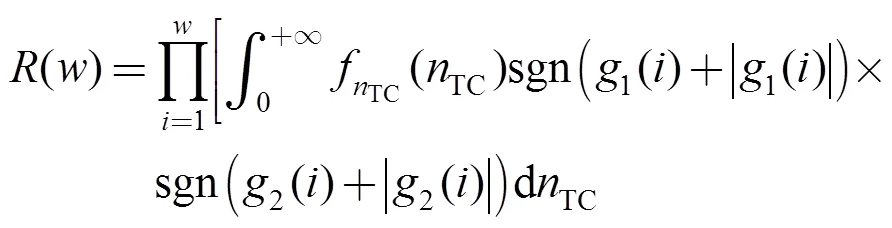

In reality, the maximal rotational speed of turbocharger is always uncertain during one operating cycle of engine because of the complexity and variation of operating profile of engine for vehicle application. Here, the maximal rotational speed of turbocharger is described by the random variable with the probability density functionand the cumulative distribution function. The probability that the compressor impeller is serviceable for theth operating cycle of engine can be expressed as

The reliability of compressor impeller of turbocharger experiencingmission profile cycles of enginecan be expressed as

(13)

Eq.(13) can also be expressed as

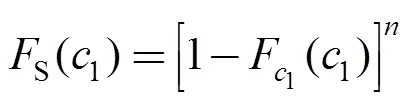

Affected by all kinds of uncertain factors such as material performance, size parameters, and so on, the strength indexes of compressor impeller are always uncertain. For the hub fatigue failure mode of compressor impeller, the strength parameteris described with the random variable with the probability density functionand the cumulative distribution function. For the blade resonance vibration failure mode of compressor impeller, the compressor impeller can be regarded as a series system composed by the blade units of compressor impeller. If the first-order natural vibration frequency of big blade is described with the random variable with probability density functionand cumulative distribution function, according to the equivalent strength probability distribution model of series system[20], the probability density functionand cumulative distribution functionof first-order natural vibration frequency of big blade of compressor impeller withbig blades can be derived respectively as

, (15)

Further, with the total probability formula, the reliability of compressor impellerexperiencingmission profile cycles of enginecan be expressed as

(17)

According to the failure rate model with the discrete variable as life parameter[20], the failure rate of compressor impeller experiencingmission profile cycles of enginebe can expressed as

The life probability density function of compressor impellercan be developed as

(19)

and the life cumulative distribution function of compressor impellercan be developed as

6 Reliability of Compressor Impeller in Plateau Area

Taking a compressor impeller with 7 big blades as an example, when the engine operates at the altitude height of 0, 3000 m, and 4500 m, respectively, the probability distribution characteristics of maximal rotational speed of turbocharger in one mission profile cycle of vehicle, are shown as Table 1.

Table 1. Maximal rotational speed of turbocharger operating at different altitude height

According to the blade vibration test of 50 compressor impellers selected randomly, the natural vibration frequency of big blade of compressor impeller is submitted to the normal distribution with mean 6798 Hz and standard deviation 87 Hz. Through the fatigue test of specimens sampled from the compressor impeller hub, the relationship between the fatigue lifeand the stresscan be described with Eq. (2), in which the material parameteris submitted to the normal distribution with mean 5.930 9′1033and standard deviation 5.768 6′1032, and the material parameteris 12.457 4.

Further, the reliability and failure rate of compressor impeller of turbocharger working in plateau area can be calculated with Eq. (17) and Eq. (18), respectively. And with Eq. (19) and Eq. (20), the life probability distribution functions of compressor impeller can be calculated. Fig. 11 shows the rules that the reliability of compressor impeller changes as the mission profile cycles of engine at different altitude height. It can be concluded that the reliability of compressor impeller decreases as the altitude height increases, and it also decreases as the number of mission profile cycle of vehicle increases.

Fig. 11. Reliability of compressor impeller operating at different altitude height

Based on the above analysis results, for the compressor impellers of turbocharger operating in plateau area, the following two measurements can be adopted to improve the reliability in the design stage, that is, the one measurement is decreasing the rotational speed of turbocharger through optimizing the matching scheme of turbocharger and diesel engine, and the other one is increasing the hub strength and the first order natural vibration frequency of blade through the structural optimization of compressor impeller.

7 Conclusions

(1) For the reliability problem of compressor impeller of turbocharger operating in plateau area, the rule that the rotational speed of turbocharger changes with the altitude height is studied, and the potential failure modes of compressor impeller are analyzed. It is pointed that the risk of hub fatigue failure and blade resonance vibration failure of compressor impeller increases when turbocharging engines operate in plateau area.

(2) With the number of mission profile cycles of engine as life parameter, the reliability models of compressor impeller are developed, and the rule that the reliability of compressor impeller changes with altitude height is studied. The results show that when the engine operates in plateau area, the reliability of compressor impeller decreases as the altitude height increases, and it also decreases as the number of mission profile cycle of engine increases.

(3) In order to improve the reliability of the compressor impellers of turbocharger operating in plateau area, the following two measurements can be adopted in the design stage, that is, one is decreasing the rotational speed of turbocharger through optimizing the matching scheme of turbocharger and diesel engine, and the other one is increasing the hub strength and the first order natural vibration frequency of blade through the structural optimization of compressor impeller.

[1] Jiang D M.[M]. Beijing: China Machine Press, 1986. (in Chinese)

[2] Zhu D X.[M]. Beijing: China Machine Press, 1992. (in Chinese)

[3] Liu R L.[M]. Beijing: Beijing Institute of Technology Press, 2013. (in Chinese)

[4] Pankaj K, Narayanan S. Nonlinear stochastic dynamics, chaos, and reliability analysis for a single degree of freedom model of a rotor blade [J]., 2009,131, 0125061–0125067.

[5] LIN H Y, CHEN M. Analysis of stress and vibration of blade for aero turbocharger[J]., 2009, 6: 44–49. (in Chinese)

[6] MA Y X, LI H B, WANG Y D, et al. Blade vibration analysis of turbocharger turbine[J]., 2005, 25(2): 131–133. (in Chinese)

[7] Stephan M S, Martin S, Ottmar S. Blade excitation in pulse-charged mixed-flow turbocharger turbines[J]., 2011, 133, 0210121–0210126.

[8] NAKHODCHI S, MAMAN E S. Fatigue life prediction in the damaged and un-damaged compressor blades[J]., 2014, 2(1): 43–50.

[9] HUANG R, MENG L G, ZHANG H. LCF strength calculating and analyzing of turbocharger compressor wheel[J]., 2006, 27(4): 55–57. (in Chinese)

[10] Zhang H, Ma C C. Structure computation and analysis of vehicle turbocharger compressor impeller[J]., 2007, 28(1): 62–66. (in Chinese)

[11] Pierre B, Regis L. Nonintrusive turbomachine blade vibration measurement system[J].g, 2007, 21: 1717–1738.

[12] Chen X W, Zhu M L, Xu K, et al. A new approach to calculate safety index of the ICE components[J]., 1999, 27(11): 51–52, 55. (in Chinese)

[13] Nick B, Karl D W, Antonis D. The analysis of heat transfer in automotive turbochargers[J]., 2010, 132: 042301.

[14] Roethlisberger R P and Favrat D. Comparison between direct and indirect(prechamber) spark ignition in the case of a cogeneration natural gas engine, part II: engine operating parameters and turbocharger characteristics[J]., 2002, 22: 1231–1243.

[15] JU Y P, LIU H, YAO Z Y, XING P, et al. Fluid-structure interaction analysis and lifetime estimation of a natural gas pipeline centrifugal compressor under near-choke and near-surge conditions[J]., 2015, 28(6): 1261–1268.

[16] EJAZ N, SALAM I, TAUQIR A. Fatigue failure of a centrifugal compressor[J]., 2007, 14(7): 1313– 1321.

[17] WANG Z Q, WANG Z.[M]. Beijing:Science Press, 2013. (in Chinese)

[18] WANG Z, WANG Z Q, HE H, et al. Predicting model for fatigue life of mechanical structures under random cyclic loads[J].2012, 23(1): 98–101. (in Chinese)

[19] WANG Z, WANG Z Q, ZHUANG L, et al. Time-dependent vibration frequency reliability analysis of blade vibration of compressor wheel of turbocharger for vehicle application[J]., 2014, 27(1): 205–210.

[20] WANG Z,XIE L Y.[M]. Beijing: Science Press, 2012.(in Chinese)

Biographical notes

WANG Zheng, born in 1981, is currently a research fellow at. He received his bachelor degree from, and his PhD degree from, in 2003, and 2008, respectively. His research interests include mechanical system reliability, turbocharging technology, and diesel engine reliability technology.

Tel: +86-22-58707272; E-mail: wzneu@126.com

WANG Zengquan, born in 1962, is currently a researcher at

and the chief expert of,. He received his bachelor degree and master degree from, in 1982, and 2001, respectively. His research nterests include special vehicle engine design, diesel engine eliability and engine turbocharging technology.

Tel: +86-22-58707042; E-mail: zenquanwang2005@163.com

WANG A-na, born in 1986, is currently a research assistant at. She received her bachelor degree and master degree from, in 2008, and 2011, respectively. Her research interests include engine test and reliability analysis.

Tel: +86-22-58707536; E-mail: xx5nx@163.com

ZHUANG Li, born in 1982, is currently an engineer at. She received her bachelor degree from, in 2006. Her research interests include engine turbocharging technology and innovative design.

Tel: +86-22-58707892; E-mail: lzhuang@nlett.com

WANG Jinwei, born in 1964, is currently an associate research fellow at at. His research interests include engine turbocharging and turbocharger manufacture.

Tel: +86-22-58707893; E-mail: jwwang@nlett.com

Received December 22, 2015; revised August 9, 2016; accepted August 25, 2016

Supported by National Natural Science Foundation of Chin (Grant No. 51375465)

? Chinese Mechanical Engineering Society and Springer-Verlag Berlin Heidelberg 2016

10.3901/CJME.2016.0825.099, available online at www.springerlink.com; www.cjmenet.com

E-mail: wzneu@126.com

Chinese Journal of Mechanical Engineering2016年6期

Chinese Journal of Mechanical Engineering2016年6期

- Chinese Journal of Mechanical Engineering的其它文章

- Surface Topography and Roughness of High-speed Milled AlMn1Cu

- Digital Evaluation of Sitting Posture Comfort in Human-vehicle System under Industry 4.0 Framework

- Thermo-physical Characteristics of Nickel-coated Aluminum Powder as a Function of Particle Size and Oxidant

- Effect of Magnetic Field on Forced Convection between Two Nanofluid Laminar Flows in a Channel

- Gas Film Disturbance Characteristics Analysis of High-Speedand High-Pressure Dry Gas Seal

- Influence of Blade Thickness on Transient Flow Characteristics of Centrifugal Slurry Pump with Semi-open Impeller