Optimization on cooperative feed strategy for radial–axial ring rolling process of Inco718 alloy by RSM and FEM

Zhu Xinglin,Liu Dong,Yang Yanhui,Hu Yang,Zheng Yong

School of Materials Science and Engineering,Northwestern Polytechnical University,Xi'an 710072,China

Optimization on cooperative feed strategy for radial–axial ring rolling process of Inco718 alloy by RSM and FEM

Zhu Xinglin,Liu Dong*,Yang Yanhui,Hu Yang,Zheng Yong

School of Materials Science and Engineering,Northwestern Polytechnical University,Xi'an 710072,China

During radial–axial ring rolling process,cooperative strategy of the radial–axial feed is critical for dimensional accuracy and thermo mechanical parameters distribution of the formed ring.In order to improve the comprehensive quality of the ring parts,response surface method(RSM)is employed for the first time to optimize the cooperative feed strategy for radial–axial ring rolling process by combining it with an improved and verified 3D coupled thermo-mechanical finite element model.The feed trajectory is put forward to describe cooperative relationship of the radial–axial feed and three variables are designed based on the feed trajectory.In order to achieve multiobjective optimization,four responses including thermo mechanical parameters distribution and rolling force are proposed.Based on the FEM results,RSM is used to establish a response model to depict the function relationship between the objective response and design variables.Through this approximate model,effects of different variables on ring rolling process are analyzed connectedly and optimal feed strategy is obtained by resorting to the optimal chart specific to a constraint condition.

1.Introduction

Radial–axial combined ring rolling is a rotary forming technology characterized by continuous and incremental deformation,which is widely used in producing all kinds of rings inaerospace field.Rings produced by radial–axial ring rolling possess integrated flow lines,higher dimensional accuracy and lower machining allowance.Furthermore,more sufficient deformation can be obtained and extra spending can be saved by using radial–axial ring rolling.Especially for aerospace rings made of difficult-to-deformation materials,such as super alloys and titanium alloys,radial–axial combined ring rolling has become a subject extensively concerned.

Inco718 alloy possesses outstanding mechanical property at temperature range of 253–700 °C.Also,Inco718 alloy is good at anti-fatigue,corrosion resistance and resistance to deformation.Therefore,Inco718 alloy is widely used in aerospace engines.However,the forging temperature range of Inco718 alloy is close limit and microstructure of Inco718 alloy is sensitive to temperature and strain rate.Recently,aimed at the microstructure evolution and mechanical properties of Inco718,Liu et al.1and Yu et al.2have researched the effects of cold rolling and thermal exposure,respectively.Also,the influences of base metal and welding speed on fusion zone microstructure and heat affected zone hot-cracking of electron-beam welded Inco718 were researched systematically by Liu et al.3In addition,through isothermal compression tests over wide ranges of strain rate and deformation temperature,Lin et al.4established a new constitutive model.Therefore,for radial–axial combined ring rolling,homogeneous distribution of thermo mechanical parameters is also a major challenge at high-temperature deformation of Inco718 alloy.

Reduction of rolling force is another challenge for large scale ring rolling.Extra spending and energy consumption can be saved using low power ring rolling mills.Generally,fluctuation of rolling force results from deformation resistance,feed rate,friction,ring geometry and so on.All these factors might cause unstable rolling force,including higher maximum force and unstable processing force,which may affect the dimensional accuracy and microstructure stability in rings.

Targeting the two challenges presented above,many studies have been conducted through experiment,theoretical analysis or numerical simulation.

Giorleo et al.5,6established a 3D FE model of hot ring rolling which was tested versus experimental results,and the accuracy of the FE model was analyzed through adual comparison.Yang et al.7researched the effects of the blank sizes on the uniformity of strain and temperature distribution during flat ring rolling by 3D FEM.Anjami and Basti8analyzed the size effects of forming rolls on strain and temperature distributions by 3D coupled thermo-mechanical FE simulation.Lee et al.9verified the control method of centering rolls by both FE simulation and ring rolling experiment of 42CrMo4 ring.Aimed at accurate geometry and effective control during vertical hot ring rolling,Hua et al.10analyzed the interaction modes and change laws of the ring's geometry by experimental study.Zhou et al.11studied the effects of feed rates and lubrication conditions on strain and temperature distributions and found that forming defects would appear in cross-section corners due to large strain.Based on the slab method theory,Parvizi and Abrinia12,13investigated the influences of the process parameters such as friction factor,feed speed,main roll rotational speed on process outputs and obtained the rolling force.Also,they validated the present method with experimental results extracted from ring rolling mill and determined the rolling force when minimizing the upper bound power with respect to neutral point position.Yea et al.14predicted spread,pressure distribution and roll force during rolling process by a commercial rigid-plastic FEM.Effect of different factors on homogeneous distribution of thermo mechanical parameters or rolling force has been researched.However,these investigations often aim at single optimal object or variable.In actual ring rolling process,multi-objective optimization should be carried out to improve the combined production quality.

After trials and references to the previous studies,we found that feed strategy is significantly effective on both thermo mechanical distributions and rolling force.Kim et al.15reduced the maximum load by optimizing the feed rates of the rolls,but they ignored another important index,the homogeneous distribution of deformation.Xu et al.16determined a desirable feed strategy that could obtain a higher efficiency of power dissipation.This research focused on application of the processing map and paid less attention on variation of the feed strategy.Zhu et al.17explored the effects of the ratio of axial to radial feed amount on strain and temperature distribution by FE simulations.However,this investigation only focused on feed amounts along two directions but not considered the cooperative strategy of the radial and axial feed rate for each rolling case.

For an optimization process,the objective can be expressed as a function of design variables through rigorous mathematical derivation.So far,several optimization objective functions have been proposed for optimization problems during metal forming process,such as cavity filling and forging quality control.18–20Also,in order to obtain the sensitivity information and avoid repeated work,non-gradient algorithms were introduced into metal forming process.21–23Different with these approaches mentioned above,response surface method(RSM)is a comprehensive optimization method to describe the response characteristics of the objective function to the design variables by combining mathematical and statistical algorithms.24RSM employs an approximate model on the basis of function fitting concept to replace experimental and numerical models.Thanks to its high efficiency and practicality,RSM has been widely applied in all kinds of fields such as reliability analysis,dynamics research and engineering control.25–27

In the present study,RSM and FEM are employed conjunctively to achieve multi-objective optimization of the feed strategy.During the optimization process,a verified 3D coupled thermo-mechanical FEM is used to calculate the response for the approximate model.In order to analyze the feed strategy comprehensively,three design variables are denoted based on the description of feed trajectory which is divided into three parts.Also,the objective function including four responses is designed to cover the main problems for ring rolling technology.Based on experimental data,response model is established and corrected by significance analysis and analysis of variance(ANOVA).Finally,effects of different variables on optimization objective are explored comprehensively based on the response model.This developed approach can be suitably used in the optimization with multiple variables and objectives for ring rolling process or any other relevant metal forming processes.

2.3D coupled thermo-mechanical FE model

2.1.FEM

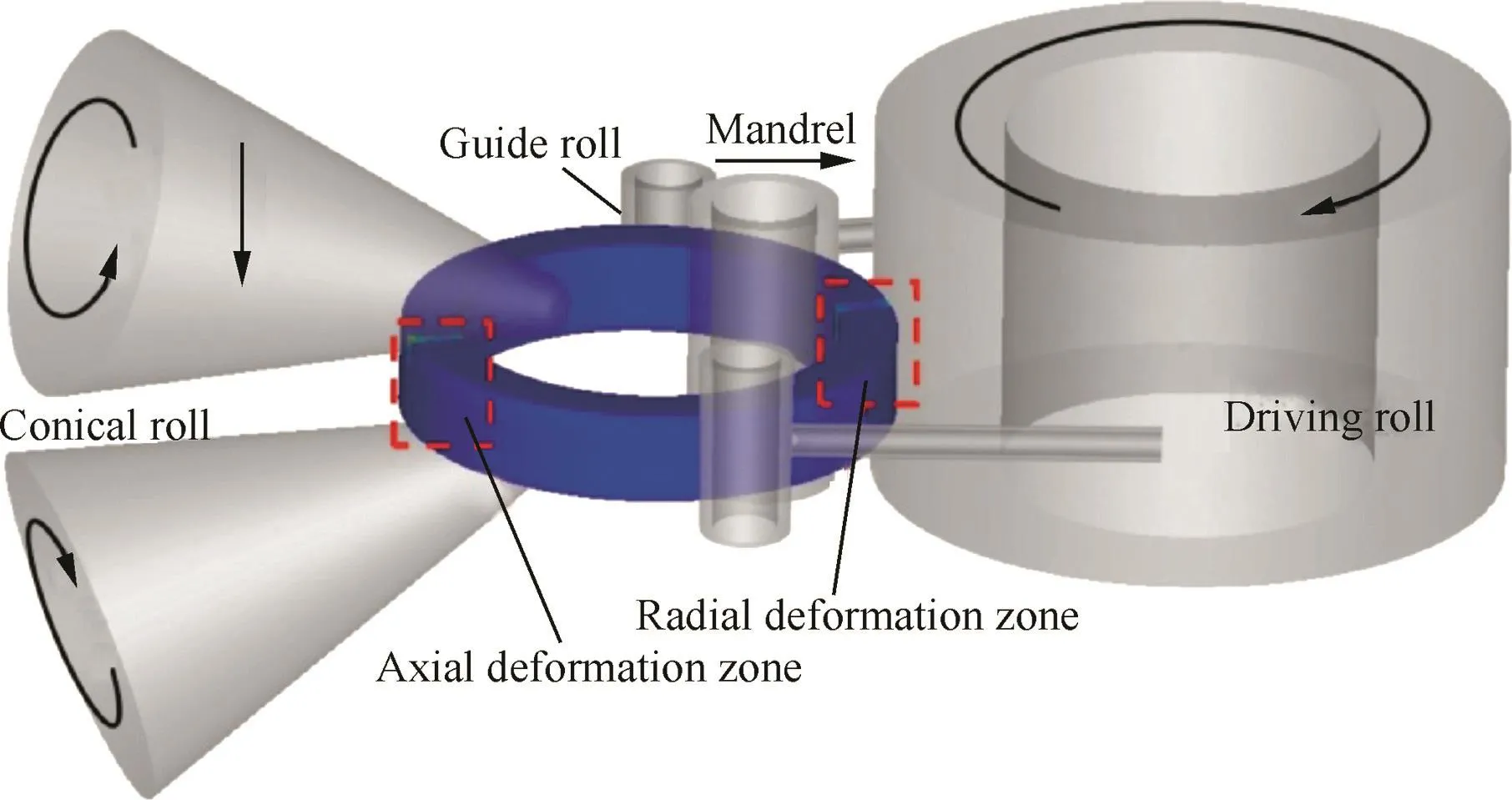

By referring to the FE model described in Refs.28,29,an improved 3D coupled thermo-mechanical FE model for radial–axial ring rolling of Inco718 alloy is established as shown in Fig.1 based on FORGE-3D.The rolls are established as rigid body and the material of the rolls is 5CrNiMo.The ring is set as deformable body whose material is Inco718.The motions of the rolls are controlled according to actual forming process,while the optimal value of the revolving speed of the main roll is 20 r/min and the feed speed of the mandrel is 0.875 mm/s.Revolving speed of conical rolls are settled by calculating the contact position and linear speed of the ring's medium diameter,which is equal to the linear speed of driving roll approximately.Penalty function method with penetration restriction and Coulombic friction coefficient are used for the contact conditions between ring and rolls.In order to improve the accuracy and efficiency of the simulation,three key improvements of the new FE model are proposed and described as follows:

Fig.1 3D coupled thermo-mechanical FE model.

Fig.2 Mixed finite element mesh of the ring.

(1)3D FE model uses a kind of mixed finite element mesh as shown in Fig.2.At locations of the two main deformation zones,the blank is meshed into fine finite elements to improve the calculation accuracy.At locations of the two idling zones,the blank is meshed into coarse finite elements to shorten the calculation time.The mesh system fixed in space and remains relatively static with the rolls.

(2)The pressure between the guide rolls and the ring is realized by controlling the force moment of the two guide rolls.The rotation axis is the fixed end of the guide roll arm on rolling equipment,while the length of the force arm is equal to the length of the guide roll arm.By dynamic controlling of the guide rolls,the new model maintains better consistency with actual forming process,which can predict all kinds of defects such as ovality and decentration.

(3)In this model,two remeshing methods can be selected.One is remesh by limiting interval period,and the other one is remesh by limiting deformation.In this study,the prior method is selected.By setting reasonable remeshing interval period,calculation time for remeshing judgment can be saved to improve computational efficiency.

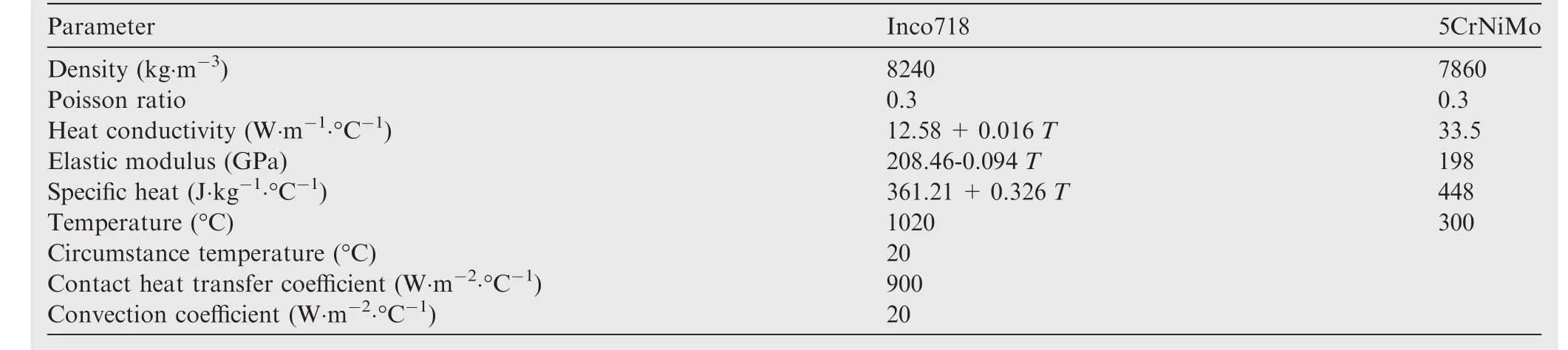

Contact conditions and thermos-physical parameters of Inco718 alloy and 5CrNiMo are listed in Table 1,in which the thermal conductivity,Elastic modulus and specific heat are temperature dependent functions.The main process parameters of the FE model and ring size are presented in Table 2.

2.2.Verification experiment

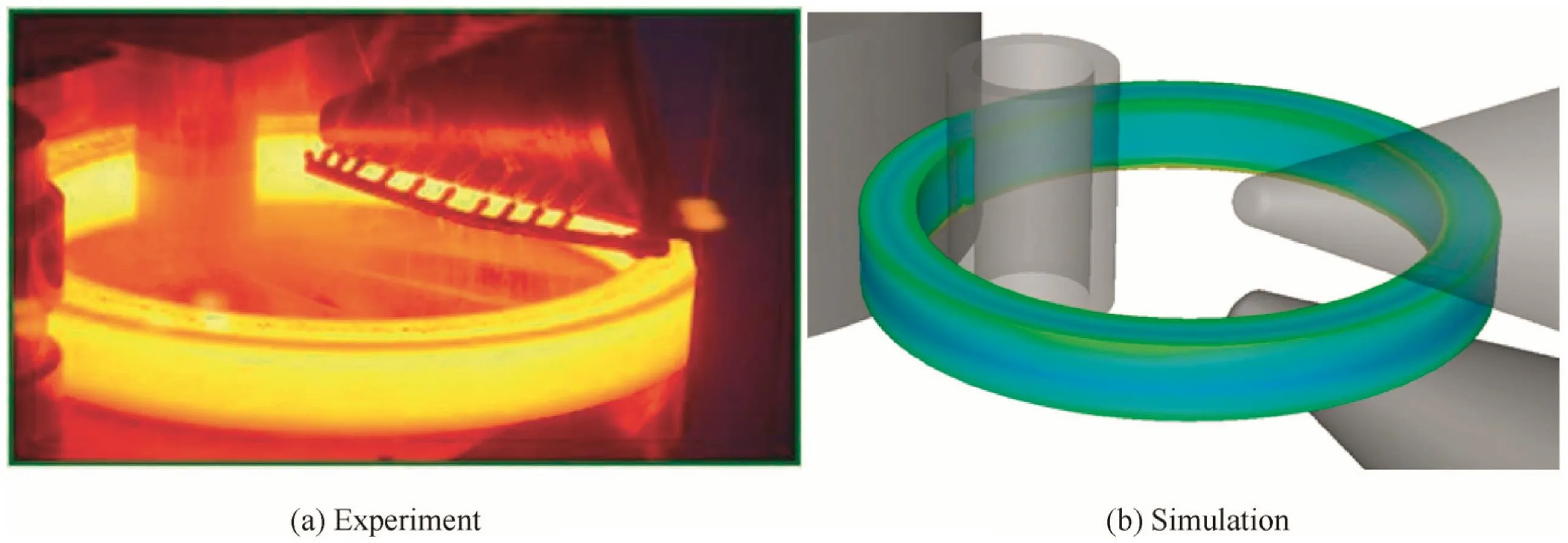

Reliable FEM is necessary to achieve the aim of optimization.In order to verify the simulation,experiment of radial–axial ring rolling was carried out on numerical control ring rollingmill produced by Wagner Banning as shown in Fig.3.Ring material is Inco718 whose initial grain size is 50 μm.The main process parameters of the experiment are the same as the FE model as shown in Table 2.

Table 1 Contact conditions and thermo-physical parameters.

Table 2 Main rolling parameters and ring size requirement.

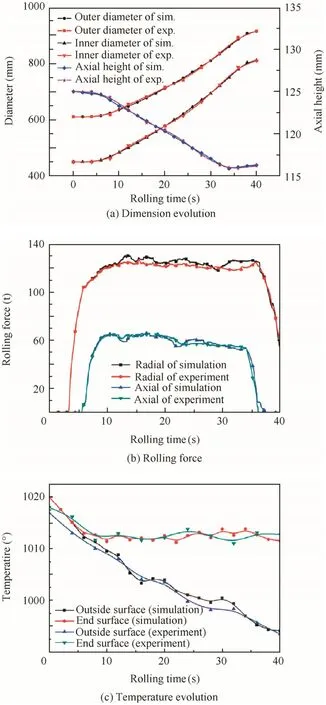

Fig.4 illustrates the evaluation comparison of ring dimension,rolling force and surface temperature.The temperatures of outside and end surfaces of the ring were measured by infrared thermometer and the rolling forces along two feed directions were obtained by force sensor equipped on the rolling mill.It can be found from these comparisons that evolution of each parameter predicted by simulation is coincident with the experiment.The maximum relative error among these parameters is 5%.All above analysis verifies the reliability of the 3D-coupled thermo-mechanical FEM established in this paper.Therefore,this developed FEM can be adequately used in researching the ring rolling process of Inco718 alloy.

3.Characterization of feed strategy

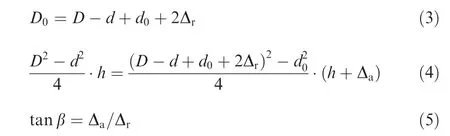

In radial–axial ring rolling process,mandrel and conical roll feed in their own speed to generate radial and axial deformation,respectively.As shown in Fig.5(a),with feed process going on,the cross section of blank shapes into cross section of ring.However,the cooperative strategy of the two feed rolls is critical for thermo mechanical parameters' distribution and dimensional accuracy.As shown in Fig.5(b),the shaded area is the cross section of the formed ring.Δa,Δrand β are axial feed amount,radial feed amount and rolling angle,respectively.With the rolls feeding,the initial section profile evolves to the final section profile.In this paper,the feed trajectory from point A to point B is used in describing the cooperative strategy of the radial and axial feeds.

Actual ring rolling process can be divided into three stages.I.Pre-rolling stage.At the beginning of the rolling process,the work piece is rotated by rolls' motivation.In order to ensure a stable rolling process,the pre-rolling stage continues for several seconds to eliminate the ovality and decentration of the preformed blank.II.Main rolling stage.During this main deformation stage,the height and wall thickness decrease,while the diameter increases gradually.III.Finishing stage.In order to avoid resilient deformation and ovality,at the end of the rolling process,the ring is renovated by slight radial feed.According to the actual process,the feed trajectory is divided into three parts in this paper(see Fig.5(b)),and diff ident parts has their own linear features.In order to obtain homogeneous deformation,temperature and smaller rolling force,the feed trajectory will be optimized by RSM and FEM.

4.RSM design

In general,the procedure of RSM consists the following steps:(1)design of variables and objective function;(2)design of experiment(DOE)and implementation;(3)establishment of the response model;(4)analysis of the direct and interactive effects and optimization of the response model.

4.1.Design variables

As the description of the feed trajectory,there are three main variables present as follows:

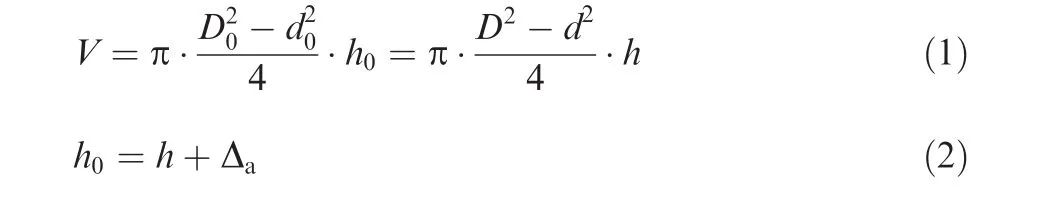

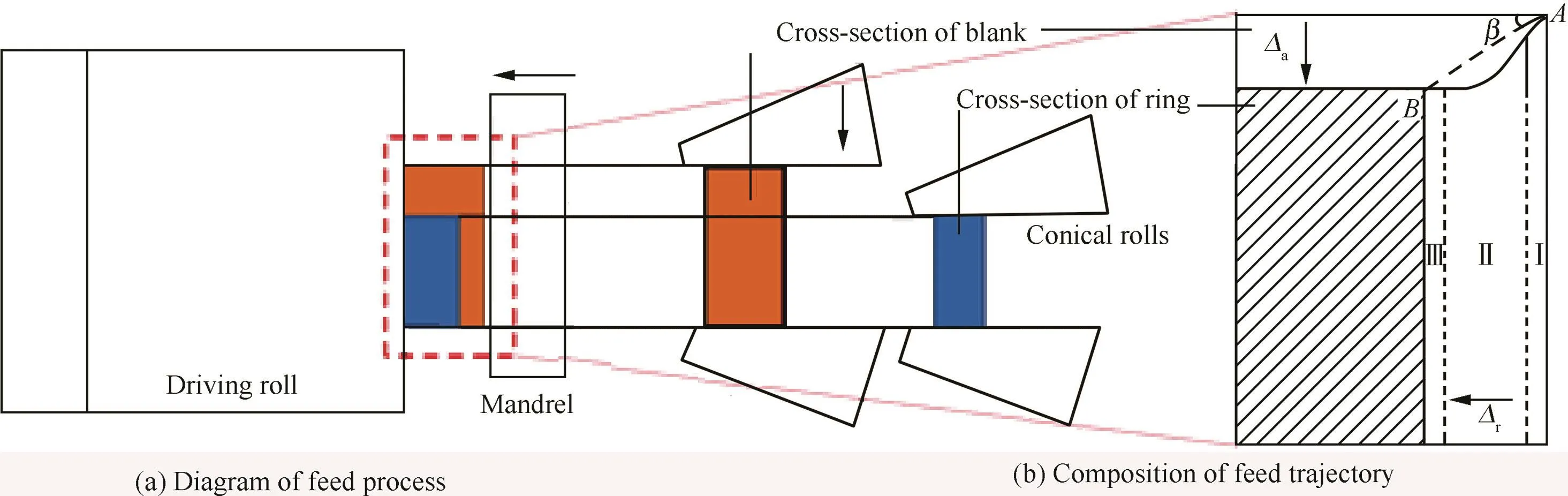

(1)Following constant volume principle,the relationships of axial feed Δaand radial feed Δrcan be denoted by Eqs.(1)–(4)and the rolling angle β can be settled by Eq.(5).

Fig.3 Ring rolling process.

Fig.4 Data comparison between experiment and simulation.

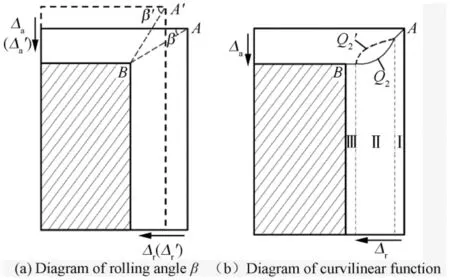

where D0,d0and h0are the outer diameter,inner diameter and height of the blank,respectively.D,d and h are the outer diameter,inner diameter and height of the formed ring,respectively.In blank design process,inner diameter of the blank d0is assumed as a fixed value.Therefore,Δaand Δr are the only two associated variables in Eq.(4).When Δais assumed,Δrand β are determined accordingly.As shown in Fig.6(a),when Δachanges toand β change toand β′,respectively.Therefore,axial feed Δais regarded as the first variable to describe the radio of axial to radial feed amount.

(2)The feed trajectory decides the cooperative strategy of the radial and axial feeds.Therefore,curvilinear function of the feed trajectory during main rolling stage denoted by Eq.(6)is regarded as the second variable.

As shown in Fig.6(b),feed trajectory Q2appears as concave slope when mgt;1,while feed trajectoryappears as convex slope when mlt;1.With feed trajectory Q2,axial feed takes place mainly at earlier stage,and radial feed is predominant feed mode at the following stage.Oppositely,axial feed takes place mainly at later stage with feed trajectoryThe starting and finishing points of trajectory Q2can be settled by assumed rolling angle;also with assumed m,n is well-determined.

(3)At the finishing stage,there is only radial feed without constraint of conical rolls.However,the length of this stage is frequently indeterminacy that may influence distribution of the thermo mechanical parameters.Therefore,the radial feed L during finishing stage is regarded as the last variable.

For convenience,three design variables a,b and c are determined as follows to represent the corresponding variables described above.For each variable,equal interval distribution of values is required for encoding in experiment design.Therefore,for the second variable,exponent m is changed to b by logarithmic transformation.Feed trajectory Q2appears as concave slope when bgt;0,while feed trajectoryappears as convex slope when blt;0.

Fig.5 Feed principle of radial–axial ring rolling process.

Fig.6 Variables of feed trajectory.

4.2.Objective function

In order to achieve multi-objective optimization towards the main problems of ring rolling process,both thermo mechanical parameters' distribution and rolling force should be taken into account.

One purpose of this paper is optimizing the distribution of strain and temperature.Therefore,an objective function was needed to evaluate the optimized design.The strain and temperature homogeneity of cross section calculated with Eqs.(10)and(11)are assumed to be the first two responses θ1and θ2.

where εiand Tiare respectively the effective strain value and temperature value of the trace point,ˉε andˉT are respectively the average effective strain and average temperature of all trace points.The less the Sεand ST,the more uniform the strain and temperature distribution,while the microstructure becomes more uniform.

Furthermore,big grains may appear in the area with excessive strain and temperature,which may have an effect on the macro-performance of the formed ring.Therefore,the volume of this area,another important factor to evaluate the processing feasibility of rings and their quality,is regarded as another response θ3,denoted by Eq.(12).

where Vεand VTare the zone volumes due to excessive strain and temperature,respectively.By referencing the recrystallization analysis in Ref.30and continuous rolling research in Ref.31,grain size increases as temperature increases,and recrystallization volume fraction is low when there are insuff icient deformation and low temperature.In order to obtain fine and uniform grains,enough deformation and reasonable temperature range are essential.Therefore,in this paper,the excessive ranges of strain and temperature are defined by Eq.(13).

Another major challenge of this research is the reduction of roll loads.The load ratio of maximum force between the designed simulation case and verification experiment above is defined as the last response θ4,denoted by Eq.(14).

where Max(Fr,i)and Max(Fa,i)are maximum radial load and maximum axial load of simulation case i,respectively,while Max(Fr,e)and Max(Fa,e)are maximum radial load and maximum axial load of experiment,respectively.

In order to eliminate the influence of different dimensions of the four responses,data normalization must be carried out before the four responses are taken into account.In this paper,Min-Max normalization is employed to map each sample value to the range of[0,1].The four responses θ1,θ2, θ3, θ4are converted into φ1, φ2, φ3, φ4by Eq.(15),respectively.

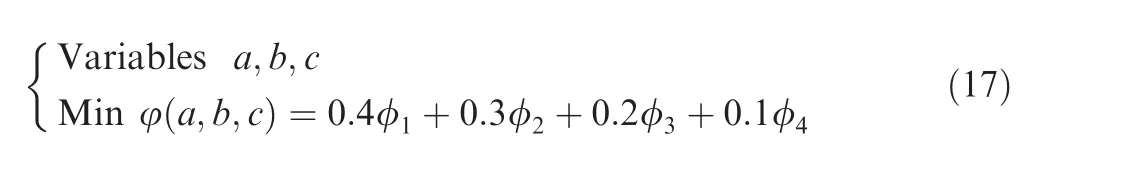

where θi,maxand θi,minare the maximum and minimum sample of response i,respectively.With the converted responses,the objective function is then formulated as follows:

According to the previous works and earlier studies,fine microstructure can be acquired through optimization in pursuit of the best thermo mechanical parameters' distribution or the minimum volume of big grain area alone.However,they are frequently inconsistent and have different effects on ring quality.According to the difficulty of optimization and importance to microstructure,ρ1,ρ2,ρ3and ρ4are determined as 0.4,0.3,0.2,0.1.

Then,the optimization of the feed strategy can be defined as

4.3.Experiment design and simulation schedule

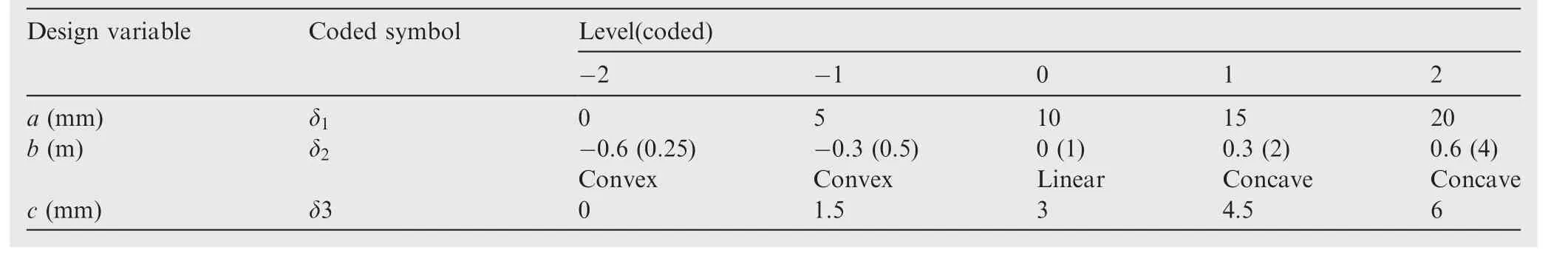

A center composite design(CCD)matrix32with three factors and five levels was adopted in the experiment.This design includes one central point,six axial points and eight vertices.Table 3 presents the levels of factors and the design variables are replaced by coded symbols.Eq.(18)is used in conversion between design variables and coded symbols.

Table 3 CCD factor levels.

Table 4 Design matrix and experimental results.

where δiis the coded value of the corresponding design value.δ, δmaxand δminare the design values of the corresponding factor,respectively.

Twenty sets of coded conditions determined by CCD and respective experimental results are presented in Table 4.The design matrix includes five repeated coded conditions.

4.4.Response model

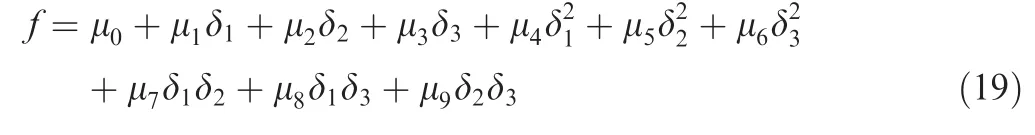

In order to improve the accuracy of the mathematical model,second-order model is used to express the objective function φ.For the case with three factors in this paper,the quadratic polynomial is presented as follows:

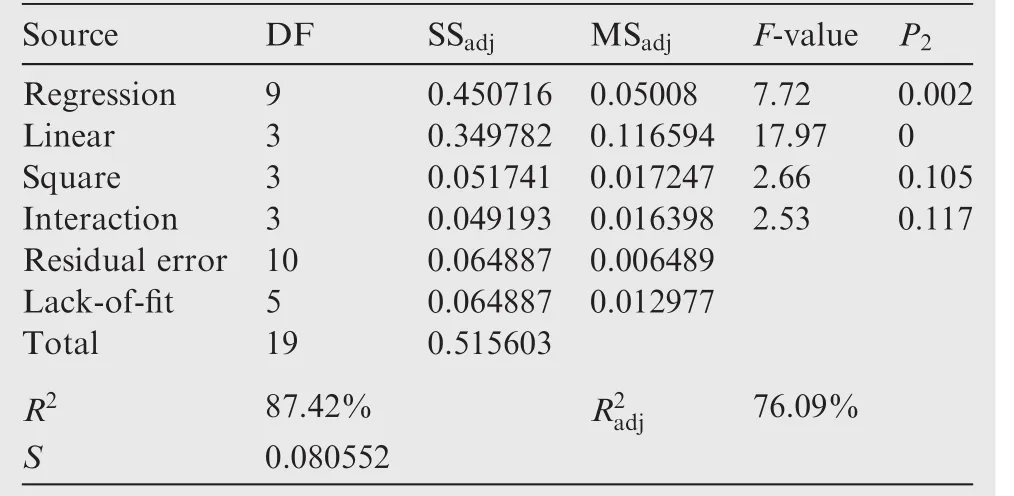

All coefficients in Eq.(19)can be settled by regression analysis with the data presented in Table 4.In order to examine the fitness of the response model,significance analysis was carried out for each term of the model and the analysis of variance(ANOVA)was also applied.Significance results of various terms and ANOVA results of the response model are presented in Tables 5 and 6,respectively.Meanings of some statistic data presented in these two tables are illustrated in Table 7.

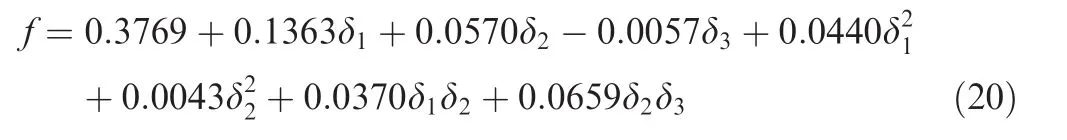

For significance analysis,P1is used in judging the significance of various terms.When P1of each term is lower thanconfidence level α,the response model can be retained as an ideal candidate.For ANOVA,in general,the higher theand the lower the S are,the higher the accuracy of the response model is.Therefore,according to the analytical data presented in Tables 5 and 6,the response model can provide an adequate approximation.However,the values of P1of square termand interaction term δ1δ3are relatively high result in exceed value of corresponding P2when confidence level is defined as α=0.05,that means these terms are less significance for the response value.Therefore,these terms are neglected in the following analysis and the response model is rebuilt as follows:

Table 5 Significance levels of different terms.

Table 6 ANOVA for response model.

The ANOVA for the new response model was carried out and the results are presented in Table 8.The values of P2for square and interaction are 0.035 and 0.047(α=0.05),respectively,which indicates the prominent significance with the remaining terms.Compared with the corresponding data inTable 6,in Table 8 is higher and S is lower,that means,the reduced model possesses higher accuracy to predict the response for the design variables.

Table 7 Meanings of statistic data presented in Tables 5 and 6.

Table 8 ANOVA for the new response model(Eq.(20)).

5.Results and discussion

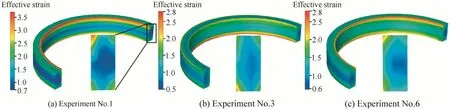

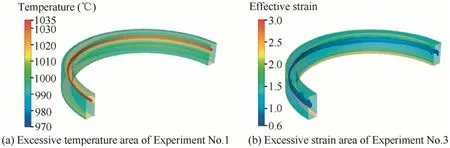

According to the experimental results presented in Table 4,the results of different responses are frequently inconsistent.Three representative experiments No.1,No.3 and No.6 are chosen for illustration.The distribution of effective stain and temperature of these three experiments are presented in Figs.7 and 8,respectively.It is observed that the temperature distribution of experiment No.1 is most uniform,but the strain distribution is non uniform.Conversely,experiment No.3 possesses uniform strain distribution but non uniform temperature distribution.The formed ring of experiment No.1 has larger strain at two end regions due to larger axial feed amount and less strain at central region due to less radial feed amount.Also,ring No.1 has less temperature drop at two end regions due to deformation heat.In experiment No.6,at prior part of the main rolling stage,there is mainly radial deformation and it is more prone to generate deformation at central region.Axial deformation mainly occurs at the later part of the main rolling stage,so there is less temperature drop at two end regions than experiment No.6.

According to design response θ3,two volumetric areas of experiment No.1 and No.3 are presented in Fig.9.The temperature of red area in Fig.9(a)is larger than 1033°C,while strain of blue area in Fig.9(b)is smaller than 0.8.High temperature area of experiment No.1 locates at the center area close to the upper conical roll due to larger axial deformation.For ring rolling process,deformation transfers from outside to inside and the small deformation are locate at the central area of the formed ring.Radial deformation is more beneficial for forging penetration efficiency due to less width along radial direction.Therefore,experiment No.3 possesses more uniform strain distribution from outside to inside.

Fig.7 Effective stain distribution of formed rings with different experiments.

Fig.8 Temperature distribution of formed rings with different experiments.

Fig.9 Volumetric areas within excessive ranges.

Fig.10 Rolling forces of three different experiments.

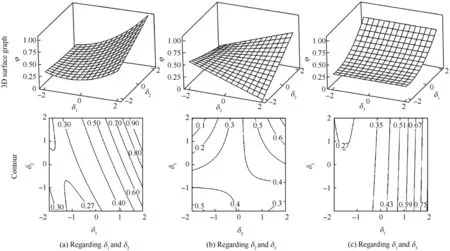

Fig.11 3D surface graph and contour for objective response.

Fig.12 Optimizing chart with constraint condition of δ1=-1.

Table 9 Optimal combination of three variables.

Fig.13 Optimal feed strategy.

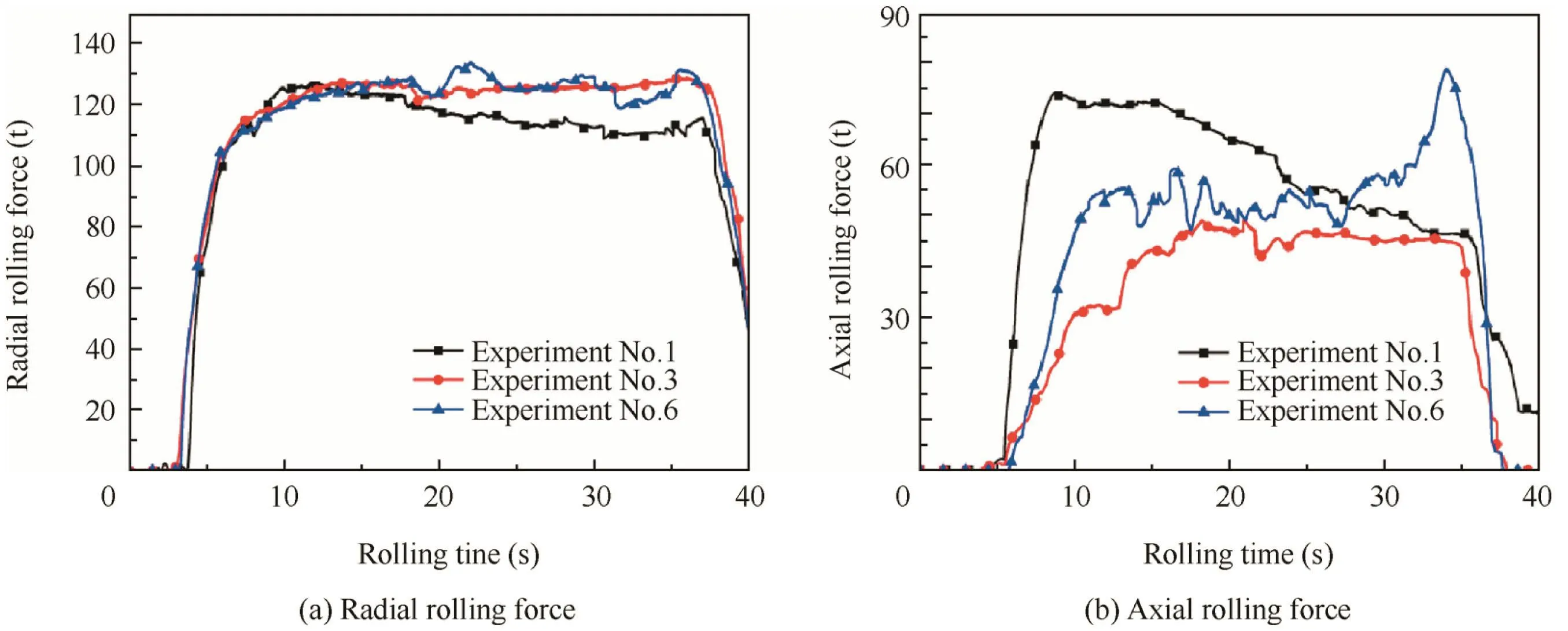

Rolling forces along two directions of the three experiments are presented in Fig.10.From Fig.10(a),radial force of No.1 is smaller at the second half of the rolling process because of its lower feed rate along radial direction.Fig.10(b)shows axial force carves,in which axial force of No.3 is the lowest and most stable because there is no axial feed.Peak values of the other two carves appear at different stages of rolling process because of different curvilinear functions of the feed trajectory during main rolling stage.

Fig.11(a)shows the 3D surface graphs and the 2D contours of the objective response φ against δ1and δ2when δ3=0.From Eq.(20)and Fig.11(a),it is observed that the objective response decreases with decrease in variable δ1and δ2.When δ1lt;0, δ2has less effect on the objective response and φ declines to smaller than 0.4.

Fig.11(b)shows the 3D surface graphs and the 2D contours of the objective response φ against δ2and δ3when δ1=0.As shown in Fig.11(b),the objective response firstly decreases and then increases with increasing δ2and δ3.Furthermore,the objective response firstly increases and then decreaseswith decreasing δ2and increasing δ3.When δ2lt;-0.8 and δ3gt;0.5,the objective response declines to a value smaller than 0.3.

From Fig.11(c),it is observed that the objective response decreases with decrease in variable δ1and there is less effect of δ3when δ2=0.

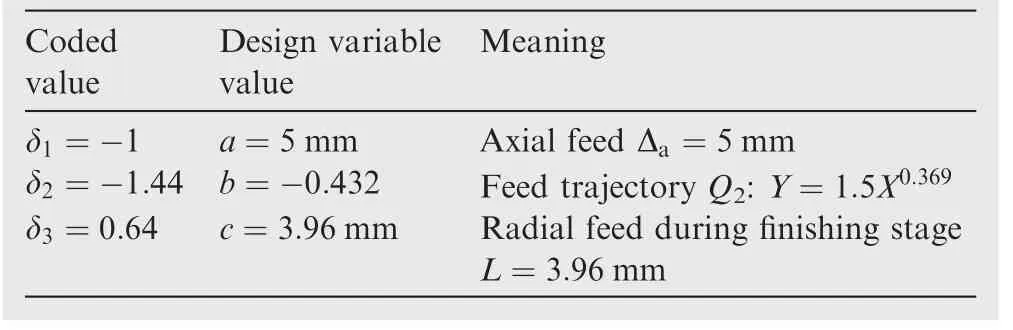

According to the response model,aimed at different target responses,there are corresponding response curves of the three variables within assumed optimal range.The response model established in this study is the smaller,the better.However,being constrained of actual production condition,the most ideal combination of the variables by the theoretical model is often not the most appropriate.During response optimization of RSM,all kinds of constraint conditions of variables and target response can be presupposed according to the actual condition.For example,assuming 0.2 as the desired value of the response objective,Fig.12 shows the optimizing chart with the constraint condition of δ1=-1.

Fig.14 Strain and temperature distributions of optimized case.

In this optimizing chart,the dash line represents the desired objective response 0.2 and the abscissa values of the intersection points between dash line and each response curve are the optimal combination of the three variables.According to the optimal variable combination listed in Table 9,with the constraint condition of Δa=5 mm,using the feed trajectory with convex slope and a certain amount of radial feed during finishing stage is beneficial to ring quality.Corresponding to b=-0.432,exponent m of feed trajectoryQ2equals 0.369.

With this optimal feed strategy(see Fig.13),the ring rolling process has been simulated by FEM,and the distributions of the strain and temperature in the formed ring are presented in Fig.14.By analyzing the extracted results from the simulation,the four responses φ1,φ2,φ3,φ4are equal to 0.0501,0.4502,0.1429,0.1861 and objective response φ is 0.2023.

6.Conclusions

(1)According to the proposed feed trajectory,three variables were designed to describe the radial–axial cooperative feed strategy.Also,four responses were designed to evaluate comprehensive forming quality of Inco718 alloy rings.

(2)Based on the verified FEM,a response model(Eq.(20))was established by RSM and the response model can depict the function relationship between ring quality and design variables with a high accuracy.According to this response model,effects of different variables on the response have been analyzed connectedly.

(3)The optimal ranges of design variables and their optimal combination can be obtained by resorting to the optimal chart specific to different constraint conditions.For rings with ratio of height to thickness about 2.3,the feed strategy with Δa/Δr≈ 0.153 and convex feed trajectory is beneficial to comprehensive forming quality.

Acknowledgments

The authors would like to thank Specialized Research Fund for the Doctoral Program of Higher Education (No.20126102120022)of China and Northwestern Polytechnical University(NPU)Foundation for Fundamental Research(NPU-FFR-JC200822)of China for the support given to the research.

1.Mei YP,Liu YC,Liu CX,Li C,Yu LM,Guo QY,et al.Effects of cold rolling on the precipitation kinetics and the morphology evolution of intermediate phases in Inconel718 alloy.J Alloy Compd 2015;649:949–60.

2.Yu ZS,Zhang JX,Yuan Y,Zhou RC,Zhang HJ,Wang HZ.Microstructural evolution and mechanical properties of Inconel718 after thermal exposure.Mater Sci Eng A-Struct 2015;634:55–63.

3.Mei YP,Liu YC,Liu CX,Li C,Yu LM,Guo QY.Effect of base metal and welding speed on fusion zone microstructure and HAZ hot-cracking of electron-beam welded Inconel718.Mater Des 2015;89:964–77.

4.Lin YC,Li KK,Li HB,Chen J,Chen XM,Wen DX.New constitutive model for high-temperature deformation behavior of inconel718 superalloy.Mater Des 2015;74:108–18.

5.Ceretti E,Giardini C,Giorleo L.3D simulation of a hot ring rolling industrial process.Int J Mater Form 2010;3(Suppl.1):323–6.

6.Giorleo L,Giardini C,Ceretti E.Validation of hot ring rolling industrial process 3D simulation.Int J Mater Form 2013;6(1):145–52.

7.Yang H,Wang M,Guo LG,Sun ZC.3D coupled thermomechanical FE modeling of blank size effects on the uniformity of strain and temperature distribution during hot rolling of titanium alloy large rings.Comput Mater Sci 2008;44(2):611–21.

8.Anjami N,Basti A.Investigation of rolls size effects on hot ring rolling process by coupled thermo-mechanical 3D-FEA.J Mater Process Tech 2010;210(10):1364–77.

9.Lee KH,Ko DC,Kim DH,Lee SB,Sung NM,Kim BM.Control method for centering rolls in radial-axial ring rolling process.Int J Precis Eng Manuf 2014;15(3):535–44.

10.Wang XK,Hua L,Han XH,Wang XX,Wang DH,Liu YL.Numerical simulation and experimental study on geometry variations and process control method of vertical hot ring rolling.Int J Adv Manuf Tech 2014;73(1–4):389–98.

11.Zhou J,Wang FL,Wang MH,Xu WJ.Study on forming defects in the rolling process of large aluminum alloy ring via adaptive controlled simulation.Int J Adv Manuf Tech 2011;55(1–4):95–106.

12.Parvizi A,Abrinia K,Salimi M.Slab analysis of ring rolling assuming constant shear friction.J Mater Eng Perform 2011;20(9):1505–11.

13.Parvizi A,Abrinia K.A two dimensional upper bound analysis of the ring rolling process with experimental and FEM verifications.Int J Mech Sci 2014;79(1):176–81.

14.Yea YS,Ko YS,Kim NS,Lee JC.Pressure distribution and roll force in ring rolling process using rigid-plastic finite element method.J Mater Process Tech 2003;140(1–3):478–86.

15.Kim N,Kim H,Jin K.Optimal design to reduce the maximum load in ring rolling process.Int J Precis Eng Manuf 2012;13(10):1821–8.

16.Xu WJ,Yang XB,Jiang ZY,Wang QL.Feeding strategy design for steel 42CrMo in radial-axial ring rolling using processing map.Int J Mater Form 2014;7(4):405–12.

17.Zhu S,Yang H,Guo LG,Hu LL.Research on the effects of coordinate deformation on radial-axial ring rolling process by FE simulation based on in-process control.Int J Adv Manuf Tech 2014;72(1):57–68.

18.Fourment L,Chenot JL.Optimal design for non-steady-state metal forming processes-I shape optimization method.Int J Numer Meth Eng 1996;39(1):33–65.

19.Badrinarayanan S,Zabaras N.Sensitivity analysis for the optimal design of metal-forming processes.Comput Method Appl M 1996;129(4):319–48.

20.Zhao G,Ma X,Zhao X,Grandhi R.Studies on optimization of metal forming processes using sensitivity analysis methods.J Mater Process Tech 2004;147(2):217–28.

21.Kusiak J.A technique of tool-shape optimization in large scale problems of metal forming.J Mater Process Tech 1996;57(1-2):79–84.

22.Roy S,Ghosh S,Shivpuri R.A new approach to optimal design of multi-stage metal forming processes with micro genetic algorithms.Int J Mach Tool Manuf 1997;37(1):29–44.

23.Chung JS,Hwang SM.Application of a genetic algorithm to process optimal design in non-isothermal metal forming.J Mater Process Tech 1998;80–81(3):136–43.

24.Montgomery DC.Design and analysis of experiments.New York:John Wiley;1984.p.509–42.

25.Yang YH,Liu D,He ZY,Luo ZJ.Optimization of preform shapes by RSM and FEM to improve deformation homogeneity in aerospace forgings.Chin J Aeronaut 2010;23(2):260–7.

26.Myers RH.Response surface methodology-current status and future directions.J Qual Technol 1999;31(1):30–74.

27.Bucher CG,Bourgund U.A fast and efficient response surface approach for structural reliability problems.Struct Saf 1990;7(1):57–66.

28.Ma YW,Wang ZH,Liu D,Zhu XL,Yang ZS.Optimization of rotational speed of main roll in pro file ring rolling of GH4169 alloy.Acta Aeronaut Astronaut Sin 2011;32(8):1555–62 Chinese.

29.Zhu XL,Liu D,Yang YH,Hu Y,Liu GW,Wang YN.Effects of blank dimension on forming characteristics during conical-section ring rolling of Inco718 alloy.Int J Adv Manuf Tech 2015.http://dx.doi.org/10.1007/s00170-015-7839-y.

30.Zhou LX,Baker TN.Effects on dynamic and meta dynamic recrystallization on microstructures of wrought IN-718 due to hot deformation.Mater Sci Eng A-Struct 1995;196(1–2):89–95.

31.Sui FL,Zuo Y,Liu XH,Chen LQ.Microstructure analysis on IN 718 alloy round rod by FEM in the hot continuous rolling process.Appl Math Model 2013;37(20–21):8776–84.

32.Myers RH,Montgomery DC.Response surface methodology:process and product optimization using designed experiments.Technometrics 1996;38(3):284–6.

Liu Dongis a professor and doctoral supervisor at School of Materials Science and Engineering,Northwestern Polytechnical University,and he received the Ph.D.degree from the same university.His main research interest is material processing technology.

4 September 2015;revised 10 November 2015;accepted 20 January 2016

Available online 7 May 2016

Cooperative feed strategy;

Finite element method;

Inconel 718;

Multi-objective optimization;

Response surface method;

Ring rolling

?2016 Chinese Society of Aeronautics and Astronautics.Production and hosting by Elsevier Ltd.This is an open access article under the CCBY-NC-ND license(http://creativecommons.org/licenses/by-nc-nd/4.0/).

*Corresponding author.Tel.:+86 29 88460545.

E-mail address:liudong@nwpu.edu.cn(D.Liu).

Peer review under responsibility of Editorial Committee of CJA.

CHINESE JOURNAL OF AERONAUTICS2016年3期

CHINESE JOURNAL OF AERONAUTICS2016年3期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- Prediction of cutting forces in ball-end milling of 2.5D C/C composites

- Performance optimization of grooved slippers for aero hydraulic pumps

- Modeling of reliability and performance assessment of a dissimilar redundancy actuation system with failure monitoring

- Motion synchronization in a dual redundant HA/EHA system by using a hybrid integrated intelligent control design

- Remaining useful life prediction based on the Wiener process for an aviation axial piston pump

- High-precision RCS measurement of aircraft's weak scattering source