The effects of surface morphology on the aerosol performance of spray-dried particles within HFA 134a based metered dose formulations

Feifei Yang,Xiaobin Liu,Wei Wang,Chunyu Liu,Lihui Quan, Yonghong Liao*

Institute of Medicinal Plant Development(IMPLAD),Chinese Academy of Medical Sciences&Peking Union Medical College,No.151 Malianwa North Road,Haidian District,Beijing 100193,China

The effects of surface morphology on the aerosol performance of spray-dried particles within HFA 134a based metered dose formulations

Feifei Yang,Xiaobin Liu,Wei Wang,Chunyu Liu,Lihui Quan, Yonghong Liao*

Institute of Medicinal Plant Development(IMPLAD),Chinese Academy of Medical Sciences&Peking Union Medical College,No.151 Malianwa North Road,Haidian District,Beijing 100193,China

ARTICLE INFO

Article history:

Received 10 April 2015

Received in revised form 13 July 2015

Accepted 14 July 2015

Available online 28 August 2015

Spray-drying

The aim of this study was to produce fi ne particles with different corrugated degree of surface by spray-drying and to investigate the effect of surface morphology on in vitro aerosol performance of the particles within HFA 134a based metered dose formulations.Compositions of rizatriptan and scutellarin were spray-dried using different spray-drying parameters,and particles were suspended within HFA 134a.The surface morphology were determined using scanning electron microscopy(SEM),while the aerodynamic performance of MDIs was evaluated using a next generation pharmaceutical impactor.The surface morphology of spraydried particles could vary from smooth to moderately corrugated,and to raisin-like depending upon spray-drying parameters and preparation compositions.In general,increasing inlet temperature,decreasing feed concentration and/or adding leucine to the feed solution tended to increase the corrugated degree of particle surface.Deposition results indicated that raisinlike particle based MDIs for all compositions of the two drugs produced signi fi cantly better aerodynamic performance in terms of fi ne particle fractions and mass median aerodynamic diameters relative to the formulations of the corresponding smooth or slightly corrugated particles when the particle compositions were the same.The present results demonstrated that wrinkled particles increased fi ne particle fractions within surfactant-free MDI formulations.

?2015 The Authors.Production and hosting by Elsevier B.V.on behalf of Shenyang Pharmaceutical University.This is an open access article under the CC BY-NC-ND license

(http://creativecommons.org/licenses/by-nc-nd/4.0/).

1. Introduction

Suspension metered dose inhalers(MDIs)are generally susceptible to physical instability such as phase separation, fl occulation and aggregation[1,2].As a result,surfactants have been often incorporated into propellants to increase physical stability of chloro fl uorocarbons(CFC)based MDIs[1].Due to the ozone-depletion effects,CFCs are to be totally banned for MDI until 2015[3]under the terms of the Montreal Protocol. Hence,HFA-134a and HFA-227 have been utilized as alternative propellants to CFCs[4].However,surfactants effective instabilizing drug suspensions in CFCs are no longer capable of stabilizing HFA based MDIs since those surfactants have limited solubility in the latter propellants.In order to minimize physical instability associated with dispersions in HFA,previous studies had added HFA-miscible cosolvents such as ethanol to increase the solubility of surfactants and/or utilized HFA-soluble surfactants,such as Brij[5], fl uorinated surfactants[6-8]; and polyoxyethylene glyceryl derivatives[9].However,HFA-soluble surfactants are yet to be available until their safety has been demonstrated.On the other hand,the inclusion of cosolvents presented certain disadvantages;for example,the low volatility of ethanol may decrease system vapor pressure and lower the fi ne particle fraction[10,11],and the change in solvency resulting from the addition of co-solvents may potentially solubilize drug substances and destabilize the suspension[12].

Breviscapine is the active component of Erigeron breviscopus (Van.)and has been used in the treatment of cerebral infarction,angina pectoris,and vertebrobasilar insuf fi ciency.However, its wider application was limited by its poor oral bioavailability, and repeated injection resulted in low compliance for injectable administration.Therefore,inhaled administration for systemic delivery was desirable as a non-invasive route to improve the bioavailability.Rizatriptan,which displays high agonist activity at mainly the serotonin 5-HT1B and 5-HT1D receptor subtypes,is extensively used in the treatment of migraine attack.Although several administrated routes had been developed,patients with migraine sought rapid relief;therefore,a more rapid onset of action was favorable.Thermally generated aerosols of rizatriptan exhibited excellent pharmacokinetic and pharmacological response;therefore,pulmonary delivery of rizatriptan is thought to provide a rapid pain relief of migraine.

In the last two decades,studies have utilized engineered particles to prepare surfactant free MDIs[11-14].Unlike traditional micronized particles by milling,novel particles prepared by particle engineering techniques may be self-dispersible in the surfactant free propellants and produce excellent aerosol performance.Such particle engineering technology in the literature that includes spray-drying[15-17],spray freeze drying [18,19],supercritical fl uids[20],and controlled crystallization [16,21-23]classi fi ed the engineered particles into three types, namely,porous particles,particles with surface chemical modifi cation and with irregular surface,respectively,based upon mechanisms by which the particles conferred to the enhanced performance of dry powder inhalers(DPIs)and MDIs. For the fi rst two types of particles,numerous studies have demonstrated their applicability to MDIs.For example,several work reported that hollow porous particles from a pressurized metered dose inhaler produced excellent in vitro and in vivo deposition with fi ne particle fractions up to 70%[24,25].In addition,particles coated with HFA-insoluble surfactants[10,26,27] or modi fi ed with polymers such as albumin[28-30]also led to promising dispersion enhancing effects in HFA propellants.As for the third type of particles,although corrugated (also called raisin-like or wrinkled)surface has been shown to lower the interparticulate interactions and increase the FPF from DPIs[31-34],the feasibility in using wrinkled particles to improve aerosol performance of MDIs has not been validated experimentally.Therefore,the objective of the present study was to produce spray-dried particles with varying surface morphology from smooth to moderately corrugated,and to raisinlike,and to determine whether the raisin like surface positively affects the aerosol performance of MDI-formulated spraydried particles in the surfactant-free HFA propellants.

2. Materials and methods

2.1. Materials

The buffer phosphate salts,sucrose,trehalose,poly(vinyl alcohol)75 and 80(PVA75 and PVA80),poly(vinyl pyrrolidone) K15(PVP15)and leucine were purchased from Sigma Aldrich (China or UK).Scutellarin was obtained by purifying commercial breviscapine(pharmaceutical grade,Wangzilong Ltd. Yunnan,China)using Sephadex LH-20(Amersham Bioscience Ltd.Hong Kong,China)column chromatography,and its HPLC chromatography purity was determined to be more than 98%.Rizatriptan benzoate was of pharmaceutical grade,obtained from Beijing HvsF United Technology Co.Ltd.(Beijing, China),Powder bulk density meter(Matuhaku),sodium hyaluronate of injection grade obtained fromTonicrays(Zhenjiang, China)and all other reagents were of analytical grade or HPLC grade and commercially available.PG semi-automatic miniature propellant fi ller(Yangzhou Aishaer Aerosol Manufacture Co.,Ltd),HFA 134a was purchased from Xi’an Jinzhu Modern Chemical Co.Ltd.,China,and aluminium MDI canisters(~20 ml) fi tted with 50 μl metering valves actuators were kindly gifted by Bespak(UK)and 3M(UK).

2.2. Spray-dried drug particles

The drug particles(Table 1)were prepared by spray-drying using a Model 191 Büchi mini spray-dryer following the preparation of feed solution.The higher cyclone designs was used in our study.The processing parameters comprised a feed rate of 3 ml/min,an atomizing air- fl ow rate of 600 l/h and inlet temperatures of 70~140°C.Outlet temperatures were found to be47~98°C.Prior to spray-drying,scutellarin and rizatriptan was dissolved a phosphate buffer(0.1 M,pH 7.3)and puri fi ed water, respectively.Because of the differences in solubility of the two drugs,the solubility of scutellarin in puri fi ed water was smaller than 1 mg/ml,and therefore,it was dissolved in phosphate buffer while excipient solutions were prepared by hydrating polymers or dissolving excipients in puri fi ed water.Subsequently,the feed solutions were obtained by mixing the drug and excipient solutions to give a drug concentration of 4-20 mg/ ml(Table 1).Spray-dried particles were obtained in the collection jar of the spray-dryer.

Table 1-Spray-drying parameters and compositions for preparing drug particles with different surface morphology.Particles Compositions Spray-drying parameters

2.3. Particle morphology and size analysis

Particle size and morphology were investigated using scanning electron microscopy.Powder samples were mounted onto metal sample plates and coated with gold with a thickness of 3 nm.The samples were then examined under a Jeol JSM 6000F (Tokyo,Japan),operating at an electrical potential of 12 kV.

Particle size analysis was carried out using a Mastersizer 2000 laser diffraction analyzer(Malvern Instruments,UK). Several milligrams of the spray-dried powders were dispersed in 1 ml of 0.1%w/v lecithin cyclohexane solution.The particle suspension was sonicated in a water bath for 30 s to disperse any possible agglomerates before being added to the sample cell.Particle size distributions were expressed in terms of volume median diameter(VMD)and span.TheVMD was the diameter at the 50%point of the entire volume distribution while the span was de fi ned as[D(v,90)-D(v,10)]/D(v,50),where D(v,90),D(v,50),and D(v,10)were the respective diameters at 90,50 and 10%cumulative volumes.

2.4. Density measurements

A 5 cm3cylinder with an internal diameter of 7.6 mm was used in the bulk density determination of spray-dried particles.The container was fi lled with accurately weighed particles and the top was levelled.The density was calculated as the ratio of the mass to the volume of the sample.The tap density was determined similarly to the bulk density,but the volume taken for calculations was that after 500 strokes.

2.5. Preparation of pMDI formulationsSamples(approximately 50 mg)of spray-dried particles were accurately weighed into individual canisters.The canisters were stored open in a desiccator containing phosphorus pentoxide,thereby exposing the formulation to a relative humidity of 0%for 24 h,so as to reduce the moisture content to approximately 1.5%(w/w)(thermogravimetric analysis(TGA) results showed that the moisture content of scutellarin or rizatriptan particles was at approximately 1.5%(w/w)upon exposure in a desiccator containing phosphorus pentoxide for a period of 24 h or longer).Subsequently,the aluminum canisters were capped by crimping metering valves into place and fi lling through the valves with~10 g of HFA 134a.The integrity of the crimping of the canisters was tested by monitoring the weight change,when a weight change less than 10 mg over 3 days was regarded as meeting the integrity requirement.

2.6. Analysis of the samples by HPLC

The amount of scutellarin and rizatriptan in the samples collected in the cups of the NGI was determined using a Waters HPLC system,which included a Waters 717 plus autosampler, Waters 2487 Dual λ Absorbance Detector,Multi δ fl uorescence detector,Waters 600 Controller pump and an Empower software system.Each sample was injected onto a C18 Apollo column(150 mm×4.6 mm,5 μm,Alltech Associates Inc.) equipped with a Phenomenex guard column(Phenomenex Inc.) for better analyzing results.Each drug solution was analyzed with an aliquot of 10 μL being applied to the column maintained at 40°C,eluted at a fl ow rate 1 ml/min.For assaying scutellarin,an isocratic mobile phase system consisting of acetonitrile and 0.1%acetic acid aqueous solution(17:83)and a detection wavelength of 335 nm was employed,while for the analysis of rizatriptan, fl uorescence detection was performed at an excitation wavelength of 225 nm and an emission wavelength of 360 nm,and the mobile phase was composed of 0.05% (v/v)triethylamine in water(adjusting to pH 2.75 with 85% phosphoric acid)and acetonitrile(90:10,v/v).Before the measurements,both methods were validated in terms of speci fi city, linearity,precision,recovery,limit of detection(LOD)and limit of quanti fi cation(LOQ).

2.7. Determination of uniformity of delivered dose

The dose delivered through the actuation of a canister was determined using a dose collection apparatus(Copley Scienti fi c Ltd.,UK)according to the protocol detailed in the European Pharmacopoeia.Brie fl y,an inhaler was shaken for 5 s,discharged 1-3 times to waste with>5 s between each activation and the device washed using puri fi ed water;subsequently the inverted inhaler was fi red to the apparatus and the amount of active substance quantitatively collected for assaying.The dose uniformity of scutellarin and rizatriptan formulations were determined based on variations in each puff.Four puffs were assayed for the uniformity of delivered dose.Firstly,20 ml of deionized water was used to dissolve drugs,and then the actuator and valve stem were washed and dried after priming to waste and before the sampling to prevent drug being carried over.

2.8. In vitro deposition tests

An in vitro aerodynamic assessment of fi ne particles of scutellarin and rizatriptan MDI was performed using a next generation pharmaceutical impactor(NGI)(MSP Corporation, Minneapolis,USA).Each canister was mounted onto the end of the throat via a rubber mouthpiece adapter and an actuator.The vacuum pump was adjusted so that an air fl ow of 30 l/ min was established through the NGI setup and the MDI was discharged 3 times to waste prior to each test.The vacuum pump was switched on and the MDI actuated once only for each formulation.After actuation,the pump was left on for a further 5 s,air fl ow was then stopped and the setup dismantled.20 mL of deionized water was used to dissolve the drug deposits on the NGI parts for assay.The actuator and stem were washed after priming and before the sampling to prevent drug being carried over.

Following the recovery of the drug solution from each collection cup,the amount of the active ingredient in the cups was determined using the above mentioned assays.The fi ne particle dose was calculated as the recovered dose of active ingredient from stage 3 to micro-ori fi ce collector(MOC)of the NGI.The FPF was de fi ned as the fi ne particle dose divided by the whole dose of the drug found in the impactor(including the throat).The recovery of drug found in the impactor relative to the emitted dose varied from 89.7%to 101.6%.The mass median aerodynamic diameter(MMAD)was the diameter at the 50%cumulative percentage while the geometric standard deviation(GSD)was de fi ned as the ratio of the diameter at the 84.1%cumulative percentage to the 50%.

3. Results and discussion

3.1. Physical characteristics of spray-dried particles

Spray-drying has been utilized for the preparation of microparticles with controlled particle morphology and suitable for pulmonary drug delivery[15,17].Previous studies showed that varying the feed solvent[35,36]and adjusting the outlet drying temperature[37]affected particle morphology, and concomitantly manipulating feed concentration and atomization rate might produce particles with different degrees of surface corrugation[1,38].In the present study,a preliminary study had tested the effect of spray-drying parameters such as inlet temperature,feed concentration,feed rate and atomizing pressure on particle surface morphology and the results(data not shown)indicated that inlet temperature,feed concentration and feed rate markedly affected the surface morphology,with the feed rate also dramatically in fl uencing the particle size.As a result,in order to produce particles with similar particle size but different surface morphology,only the parameters of inlet temperature and feed concentration were manipulated in the further study,while feed rate and atomizing pressure were maitained constant.

Apart from spray-drying parameters,including excipients such as lactose,Tween 20[32,37,39]and leucine[40]to the feed solution might favor to yield particles with rougher surfaces. As such,a pilot study was carried out to test the effect of various excipients on the surface morphology of rizatriptan particles using an inlet temperature of 90°C and results showed that leucine,PVA75,PVA 80,PVP15,albumin and lecithin increased the degree of corrugation while HA,sucrcose,lactose, trehalose and dextran negatively affect the formation of corrugated particles(data not shown).Based upon the above fi ndings,two compositions of the model drugs(Table 1) were spray-dried,and SEM results(Fig.1 and Table 2)showed that the surface morphology of spray-dried particles could vary from smooth to moderately raisin-like,and to raisin-like depending upon spray-drying parameters and preparation compositions.In particular,leucine appeared to be an excellent promoter for the production of wrinkled particles and it could overcome the negative effect of HA on the formation of corrugated surface.

The mechanism by which spray-drying parameters and feed compositions affect the particle surface morhology is not entirely clear.A previous study suggested it might be related to Peclet numbers which represent the ratio between convection and diffusion,and compositions with higher Peclet numbers tended to form particles with irregular surface[17]. The Peclet number is in fl uenced by the evaporation rate andthe latter is dictated by the combination of feed composition and spray-drying parameters[17].Therefore,it is conceivable that an increase in inlet temperature favors the formation of wrinkled particles since the Peclet number may increase with an increase in evaporation rate of sprayed droplets as a result of high inlet temperature.In addition,the feed concentration and solubility were also reported to affect the particle morphology.Previously,it was suggested that a high feed concentration and/or low solubility favored the formation of a very early shell on the droplet surface[12,41,42],and the raisinlike particles may be produced when the shell was shriveled. In the present study,rizatriptan had a higher solubility than scutellarin,and hence it was more dif fi cult to be spray-dried to produce particles with raisin-like surface.The solubility of rizatriptan is 42 mg/mL,whereas it was smaller than 1 mg/ ml for scutellarin.Therefore,the aqueous phases used for dissolving the two drugs were different;scutellarin was fi rstly dissolved in phosphate buffer,and then diluted to certain concentrations.Our results from rizatriptan demonstrated that phosphate buffer had no effects on the inhalable activity.

The particle size and size distribution of the spray-dried particles are shown in Table 2.The volume median diameters (VMD)of all spray-dried batches were found to be between 2.39 and 3.61 μm.In addition,the particle size span for these batches laid between 1.37 and 1.60,which indicates that all the powders exhibited a moderate degree of monodispersity.The majority of particles in these batches were≤10.0 μm.The bulk and tap density(Table 2)were found to relate to the surface morphology in general,with the raisin-like particles always having the highest bulk and tap density when the compositions were the same.The relatively high density of raisin-like particles indicated that such particles were nonporous[43].

Table 2-Particle properties of spray-dried rizatriptan and scutellarin particles.

3.2. Deposition of MDI-formulated particles

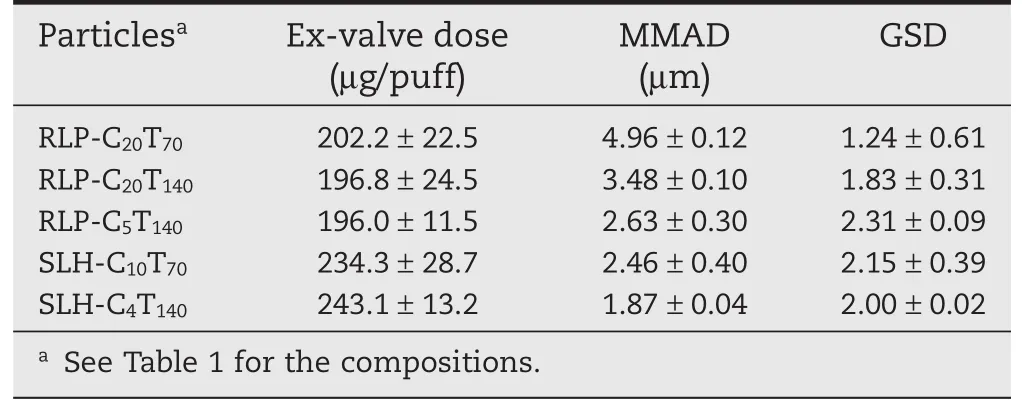

After fi lling HFA 134a,RLP-C20T70 particles were visually found to dramatically fl occulate and other particles with slightly corrugated surface moderately fl occulated,while apparent fl occulation were not observed for those raisin-like particles (data not shown).In the present study,the amount of drug that remained in the actuator device varied from 14%to 23%of the total amount of ex-valve dose.In addition,the coef fi cients of variation of delivered dose(collected drug amount in the dose collection apparatus)appeared to be related to the particle morphology.Raisin-like particle based formulations always had a better dose uniformity while smooth or less corrugated particle containing formulations resulted in variations of over 10% (Table 3),The physical stability of the MDI suspensions after shaking partly depended on the surface morphology;therefore,deposition experiment was performed immediately after shaking to avoid the variation in different formulations.For example,the mean delivered doses of rizatriptan from three formulations,RLP-C20T70,RLP-C20T140 and RLP-C5T140(each of which comprised three independent samples),were found to be 202.2±22.5 μg,196.8±24.5 μg,196.0±11.5 μg per actuation,respectively.Due to the relatively large variations in the delivered dose,the total recovered fractions from NGI were normalized to 100%for each individual deposition test.

The in vitro deposition results of rizatriptan MDI formulations are shown in Table 3 and Fig.2.The aerosol performance of MDIs with the same compositions but different spraydrying parameters was found to be markedly different.The drug fractions recovered from stage 3 to MOC of the NGI( fi ne particle fraction,FPF)for RLP-C20T70,RLP-C20T140 and RLPC5T140 MDI formulations were found to be about 9.2,20.2 and 30.8%,respectively,and FPF was inversely related to the corresponding MMAD.In general,raisin-like particles conferred the highest FPF and the lowest MMAD,while spherical particles with broadly smooth surface had the lowest FPF and the highest MMAD.The apparent higher MMAD could be due to the presence of agglomerates in the aerosol of smooth particles.It has been shown that the inter-particular forces between smooth particles are higher for DPI formulations.Another possible reason is that smooth particles have a higher particle density.

Deposition results(Table 3)of scutellarin MDI formulations also indicated that raisin-like particle based MDI produced signi fi cantly better aerodynamic performance in terms of FPF (P<0.01,Mann-Whitney test)and MMAD(P<0.05,Mann-Whitney test)relative to the formulation of moderately corrugated particles.

The above results showed that raisin-like particle based MDIs always exhibited better aerosol performances in terms of doseuniformity, fi ne particle fractions and MMAD relative to the formulations of the corresponding smooth or slightly corrugated particles.The dispersions of raisin-like particles in HFA propellants gave MMAD less than 3 μm and therefore such aerosols may deposit in the deep lung,suitable for pulmonary delivery of rizatriptan and scutellarin intended to elicit systemic effects[44,45].In addition,a previous study[45]showed hyaluronic acid(HA)may enhance pulmonary absorption of scutellarin due to its mucoadhesive properties.Although spraydried scutellarin-HA particles appeared not to be well dispersed in an HFA propellant(data not shown),the wrinkled particles spray-dried in the presence of leucine could enhance the dispersibility,leading to high FPF.

Table 3-Deposition results of spray-dried rizatriptan and scutellarin formulated MDIs(mean±SD,n=4).

The better performances conferred by wrinkled particles could not be explained by the coating effect of excipients.For example,leucine is an excellent coating excipient in enhancing the particle dispersibility in DPIs[38].However,leucine containing particles with smooth surface in the present study produced a poor aerosol performance in MDIs.Particulate aggregation/ fl occulation is common in MDI suspension formulations,and the dispersibility of particles is essentially dependent upon the physicochemical properties of the material interface with the propellant.The incompatibility of coating ingredients on the particle surface with the dispersion medium may alter interparticulate cohesive forces, resulting in different aerosol performances between DPI and MDI formulations.The enhanced aerosol performance of raisinlike particles over the smooth or slightly corrugated particles may be explained by the reduction in the contact area of between particles,which would in turn increase the average distance between particles.Such a rationale has been proposed by Chew and colleagues[31,38]to account for the reduction in the interparticulate interactions and the increase in the FPF of corrugated particles from DPIs.Indeed, increasing the average distance between particles would dramatically decrease van der Waal’s and electrostatic attraction forces for particles suspended in propellant medium.

4. Conclusion

In this study,the effects of spray-drying parameters and feed compositions on the formation of raisin-like particles were investigated,and the results indicated that the parameters of inlet temperature,feed concentration and inclusion of certain excipients to the feed solution could affect the surface morphology of spray-dried particles.In particular,the presence of leucine in the feed solution favored to produce raisin-like particles when spray-drying was carried out at a high inlet temperature.In addition,the present results suggested that MDIs formulated with raisin-like particles afforded a better aerosol performance over those counterparts with smooth or slightly corrugated particles.

Acknowledgements

The authors thank the National Natural Science Foundation of China(grant no.81172997)and the Ministry of Science and Technology of the People’s Republic of China(grant no. 2012ZX09301-002-030)for the fi nancial supports.

REFERENCES

[1]Saleem IY,Smyth HD.Tuning aerosol particle size distribution of metered dose inhalers using cosolvents and surfactants.Biomed Res Int 2013;2013:574310.

[2]Smyth HDC.The in fl uence of formulation variables on the performance of alternative propellant-driven metered dose inhalers.Adv Drug Deliv Rev 2003;55:807-828.

[3]Redberg RF.Not breathing easier with the US FDA’s ban on chloro fl uorocarbons in inhalers.JAMA Intern Med 2015;175(7):1086.

[4]McDonald KJ,Martin GP.Transition to CFC-free metered dose inhalers-into the new millennium.Int J Pharm 2000;201:89-107.

[5]Vervaet C,Byron PR.Drug-surfactant-propellant interactions in HFA-formulations.Int J Pharm 1999;186:13-30.

[6]Somani A,Steele G,Lim JG.Propellant compositions.WIPO Patent WO 9111173,1991;08 Aug.

[7]Quessy SN,Schultz RK.The use of soluble fl uorosurfactants for the preparation of metered dose aerosol formulations. WIPO Patent WO 9114422,1991;03 Oct.

[8]Johnson KA.Aerosol drug formulation.UK Patent GB 2263064,1993;14 Jul.

[9]Hettche H,Engel J,Muckenschnabel R.Compressed-gas packages using polyoxyethylene glyceryl fatty-acid esters as suspension stabilizers and valve lubricants.US patent US 5536444,1996;16 Jul.

[10]Steckel H,Muller BW.Metered-dose inhaler formulation of fl uticasone-17-propionate micronized with supercritical carbon dioxide using the alternative propellant HFA-227. Int J Pharm 1998;173:25-33.

[11]Myrdal PB,Sheth P,Stein SW.Advances in metered dose inhaler technology:formulation development.AAPS PharmSciTech 2014;15:434-455.

[12]Vehring R,Lechuga-Ballesteros D,Joshi V,et al. Cosuspensions of microcrystals and engineered microparticles for uniform and ef fi cient delivery of respiratory therapeutics from pressurized metered dose inhalers.Langmuir 2012;28:15015-15023.

[13]Gupta A,Stein SW,Myrdal PB.Balancing ethanol cosolvent concentration with product performance in 134a-based pressurized metered dose inhalers.J Aerosol Med 2003;16:167-174.

[14]Rubin BK,Williams RW.Emerging aerosol drug delivery strategies:from bench to clinic.Adv Drug Deliv Rev 2014;75:141-148.

[15]Seville PC,Li HY,Learoyd TP.Spray-dried powders for pulmonary drug delivery.Crit Rev Ther Drug Carrier Syst 2007;24:307-360.

[16]Chow AHL,Tong HHY,Chattopadhyay P,et al.Particle engineering for pulmonary drug delivery.Pharm Res 2007;24:411-437.

[17]Vehring R.Pharmaceutical particle engineering via spray drying.Pharm Res 2008;25:999-1022.

[18]Maa YF,Nguyen PA,Sweeney T,et al.Protein inhalation powders:spray drying vs spray freeze drying.Pharm Res 1999;16:249-254.

[19]D’Addio SM,Chan JG,Kwok PC.Aerosol delivery of nanoparticles in uniform mannitol carriers formulated by ultrasonic spray freeze drying.Pharm Res 2013;30:2891-2901.

[20]Palakodaty S,York P.Phase behavioral effects on particle formation processes using supercritical fl uids.Pharm Res 1999;16:976-985.

[21]Rasenack N,Steckel H,Muller BW.Micronization of antiin fl ammatory drugs for pulmonary delivery by a controlled crystallization process.J Pharm Sci 2003;92:35-44.

[22]Kaerger JS,Price R.Processing of spherical crystalline particles via a novel solution atomization and crystallization by sonication(SAXS)technique.Pharm Res 2004;21:372-381. [23]Ragab D,Rohani S,Samaha MW,et al.Crystallization of progesterone for pulmonary drug delivery.J Pharm Sci 2010;99:1123-1137.

[24]Dellamary LA,Tarara TE,Smith DJ,et al.Hollow porous particles in metered dose inhalers.Pharm Res 2000;17:168-174.

[25]Hirst PH,Pitcairn GR,Weers JG,et al.In vivo lung deposition of hollow porous particles from a pressurized metered dose inhaler.Pharm Res 2002;19:258-264.

[26]Williams RO,Repka MA,Barron MK.Application of cogrinding to formulate a model pMDI suspension.Eur J Pharm Biopharm 1999;48:131-140.

[27]Tarara TE,Hartman MS,Gill H,et al.Characterization of suspension-based metered dose inhaler formulations composed of spray-dried budesonide microcrystals dispersed in HFA-134a.Pharm Res 2004;21:1607-1614.

[28]Huang HP,Mehta SC.Procaterol microspheres controlledrelease aerosol.Canada Patent CA 2036844,1991;23 Aug.

[29]Liao YH,Brown MB,Jones SA,et al.The effects of polyvinyl alcohol on the in vitro stability and delivery of spray-dried protein particles from surfactant-free HFA 134a-based pressurised metered dose inhalers.Int J Pharm 2005;304:29-39.

[30]Jones SA,Martin GP,Brown MB.Manipulation of beclomethasone hydro fl uoroalkane interactions using biocompatible macromolecules.J Pharm Sci 2006;95:1060-1074.

[31]Chew NYK,Chan HK.Use of solid corrugated particles to enhance powder aerosol performance.Pharm Res 2001;18:1570-1577.

[32]Chew NYK,Shekunov BY,Tong HHY,et al.Effect of amino acids on the dispersion of disodium cromoglycate powders. J Pharm Sci 2005;94:2289-2301.

[33]Adi H,Traini D,Chan HK.The in fl uence of drug morphology on aerosolisation ef fi ciency of dry powder inhaler formulations.J Pharm Sci 2008;97:2780-2788.

[34]Yang JJ,Liu CY,Quan LH.Preparation and in vitro aerosol performance of spray-dried Shuang-Huang-Lian corrugated particles in carrier-based dry powder inhalers.AAPS PharmSciTech 2012;13:816-825.

[35]Gilani K,Najafabadi AR,Barghi M,et al.The effect of water to ethanol feed ratio on physical properties and aerosolization behaviour of spray dried cromolyn sodium particles.J Pharm Sci 2005;94:1048-1059.

[36]Dürrigl M,Kregar ML,Hafner A,et al.Mupirocin calcium microencapsulation via spray drying:feed solvent in fl uence on microparticle properties,stability and antimicrobial activity.Drug Dev Ind Pharm 2011;37:1402-1414.

[37]Maa YF,Costantino HR,Nguyen PA,et al.The effect of operating and formulation variables on the morphology of spray-dried protein particles.Pharm Dev Technol 1997;2:213-223.

[38]Chew NYK,Tan P,Chan HK,et al.How much particle surface corrugation is suf fi cient to improve aerosol performance of powders?Pharm Res 2005;22:148-152.

[39]Conte U,Giunchedi P,Maggi L,et al.Spray dried albumin microspheres containing nicardipine.Eur J Pharm Biopharm 1994;40:203-208.

[40]Morton D,Kamlag Y.Methods for preparing pharmaceutical compositions,WIPO Patent WO/2005/025535,2005;24 Mar.

[41]Langrish TAG,Marquez N,Kota K.An investigation and quantitative assessment of particle shape in milk powders from a laboratory-scale spray dryer.Dry Technol 2006;24:1619-1630.

[42]Elversson JE,Millqvist-Fureby A.Particle size and density in spray drying-effects of carbohydrate properties.J Pharm Sci 2005;94:2049-2060.

[43]Heng D,Tang P,Cairney JM,et al.Focused-ion-beam milling: a novel approach to probing the interior of particles used for inhalation aerosols.Pharm Res 2007;24:1608-1617.

[44]Wang C,Quan LH,Guo Y,et al.Uptake and biodistribution of rizatriptan to blood and brain following different routes of administration in rats.Int J Pharm 2007;337:155-160.

[45]Liu XB,Ye JX,Quan LH,et al.Pulmonary delivery of scutellarin solution and mucoadhesive particles in rats.Eur J Pharm Biopharm 2008;70:845-852.

*Corresponding author.Institute of Medicinal Plant Development(IMPLAD),Chinese Academy of Medical Sciences&Peking Union Medical College,No.151 Malianwa North Road,Beijing 100193,China.Tel.:+86 10 57833268;fax:+86 10 57833268.

E-mail address:yhliao@implad.ac.cn(Y.Liao).

Peer review under responsibility of Shenyang Pharmaceutical University.

http://dx.doi.org/10.1016/j.ajps.2015.07.006

1818-0876/?2015 The Authors.Production and hosting by Elsevier B.V.on behalf of Shenyang Pharmaceutical University.This is an open access article under the CC BY-NC-ND license(http://creativecommons.org/licenses/by-nc-nd/4.0/).

Raisin-like/wrinkled particles Metered dose inhaler

Rizatriptan

Scutellarin

Asian Journal of Pharmacentical Sciences2015年6期

Asian Journal of Pharmacentical Sciences2015年6期

- Asian Journal of Pharmacentical Sciences的其它文章

- GUIDE FOR AUTHORS

- Preface

- Novel potential for optimization of antitubercular therapy:Pulmonary delivery of rifampicin lipospheres

- The in fl uence of amino acids on aztreonam spray-dried powders for inhalation

- Optimizing aerosolization of a high-dose L-arginine powder for pulmonary delivery

- Delivery of theophylline as dry powder for inhalation