Selection of organic Rankine cycle working fluids in the low-temperature waste heat utilization*

LI Dian-xun (李殿勛), ZHANG Shu-sheng (張樹(shù)生),2, WANG Gui-hua (王桂華)

1. School of Energy and Power Engineering, Shandong University, Jinan 250061, China, E-mail: 6277237@163.com

2. School of Reronautics, Shandong Jiaotong University, Jinan 250357, China

Selection of organic Rankine cycle working fluids in the low-temperature waste heat utilization*

LI Dian-xun (李殿勛)1, ZHANG Shu-sheng (張樹(shù)生)1,2, WANG Gui-hua (王桂華)1

1. School of Energy and Power Engineering, Shandong University, Jinan 250061, China, E-mail: 6277237@163.com

2. School of Reronautics, Shandong Jiaotong University, Jinan 250357, China

(Received January 21, 2014, Revised June 9, 2015)

In the current study, simulations based on the engineering equation solver (EES) software are performed to determine the suitable working fluid for the simple organic Rankine cycle system in different temperature ranges. Under the condition of various temperatures and a constant thermal power of the flue gas, the influence of different organic working fluids on the efficiency of the subcritical organic Rankine cycle power generation system is studied, and its efficiency and other parameters are compared with those of the regenerator system. It is shown that the efficiency of the subcritical organic Rankine cycle system is the best when the parameters of the working fluid in the expander inlet are in the saturation state. And for the organic Rankine cycle, the R245fa is better than other working fluids and the efficiency of the system reaches up to 10.2% when the flammability, the toxicity, the ozone depletion, the greenhouse effect and other factors of the working fluids are considered. The R601a working fluid can be used for the high-temperature heat source, however, because of its high flammability, new working fluid should be investigated. Under the same condition, the efficiency of the organic Rankine cycle power generation system with an internal heat exchanger is higher than that of the simple system without the internal heat exchanger, but the efficiency is related to the properties of the working fluid and the temperature of the heat source.

Rankine cycle, working fluid, waste heat, heat exchanger, low-temperature

Introduction

The energy is the material basis for the social development. Now, as the social problems brought by using the fossil energy is increasingly recognized, the renewable energy and the low-temperature waste heat is attracting much research attentions. It is shown that the industrial low-temperature heat which accounts for 50% of the total heat consumption is wasted in the manner of thermal pollution emissions[1]. In China, the temperature range of the exhaust gas produced by power station boilers and industrial boilers is from 393 K to 523 K. According to the data provided by China Energy Statistical Yearbook 2009, the calorific value of these waste heat is equivalent to 1.8×108t of standard coal, and the wasted heat resource accounts for about 20% of the total amount of industrial waste heat resources. For the low temperature heat source, the power generation efficiency of the organic Rankine cycle system is significantly higher than that of the ordinary steam power cycle[2,3]. Because the boiling point of the organic matter is low, a higher steam pressure is acquired under the condition of the low-temperature heat source and is used to drive the expander. Nguyen and Saitoh studied different forms of small generation system[4,5]. However, in recent years, theoretical studies of organic Rankine cycle power generation systems focus on the working fluid selection and the thermodynamic analysis[6,7]. The results of Tchanche et al. show that the organic working fluids such as R134a, R152a, R290, R600 and R600a are suitable for the organic Rankine power generation system with the heat source of 343 K[8]. Bertrand, Fankam, Tchanche et al studied the selection of working fluid for the organic Rankine cycle system with solar heat source of low-temperature (343 K) andfound that R134a has a good performance when the expander entrance is at a dry saturated state[8]. Cao[9]theoretically analyzed the performance of R245fa and R600 as the working fluid for an industrial waste heat regenerative system below 373 K, their study shows that the best expansion ratio is 4 or 3 when using screw expander. Zhu et al.[10]compared the net work and the energy efficiency of systems with six kinds of working fluid (R290, R134a, R600a, R600, R601a, and R601) under heat sources of different temperatures.

In this paper, the system thermal efficiency is taken as the main evaluation parameter. The flue gas in the temperature range from 373 K to 523 K is used as the heat source. Parameters of the working fluid such as the flammability, the toxicity, the destruction of the ozone layer and the greenhouse effect are also considered. The suitable working fluid for the simple organic Rankine cycle system in different temperature ranges is determined by using the engineering equation solver (EES) simulation software, at the same time, the parameters such as the flow rate of the working fluid, the flue gas flow rate of the heat source and the expansion ratio are also determined for the selection of the suitable working fluid for the organic Rankine cycle power generation system of different heat sources. Finally, we compare the efficiency of a simple organic Rankine cycle system using the preferred working fluid with that of an organic Rankine cycle power generation system with internal heat exchanger.

Fig.1 Simple ORC system

1. Organic Rankine cycle systems

The schematic diagram of the organic Rankine cycle system (also called the double-cycle system) is shown in Fig.1. The working principle is as follows. The organic working fluid is heated in the heater E until its temperature reaches the preset value of the expander inlet, then the organic working fluid flows into the expander to do work, next the organic working fluid vapor is condensed into liquid in the condenser C. Finally the liquid organic fluid is boosted into the heater by the working fluid pump P and be heated again, to close the organic Rankine cycle. The heat source fluid flowing through the heater is discharged after heating the organic fluid. The whole circulation system is mainly composed of the following components: a heater, an expander, a condenser, a working fluid pump, a cooling water pump, a fluid reservoir and some pipes. The difference between the high temperature heat resource such as the boiler flue gas and the low temperature heat resource such as the solar and geothermal energy is the liquefaction phenomenon of the water vapor or other gases in the flue gas after the heat exchange between the flue gas and the organic working fluid, thus the latent heat of vaporization of the flue gas will be released in the heat exchanger, leading to the mixing of the hot and cold sources, which should be avoided in the simulation. When the percentage of the volume of water vapor in the flue gas reaches 18.57%, and the combustion occurs at the atmospheric pressure, the corresponding temperature of the flue gas dew point is 58.5oC. With the decrease of the water vapor content, the dew point temperature is decreased slightly[11].

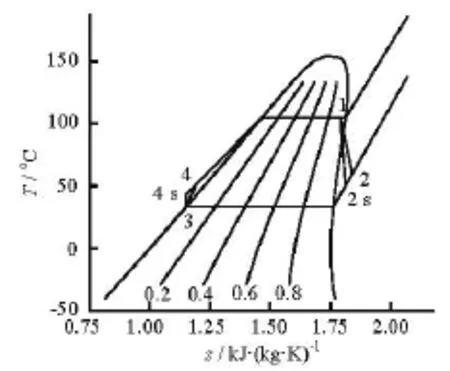

The pressure of the above circulation is below the critical pressure of the working fluid[12]. According to the state of the working fluid in the expander inlet, the organic Rankine cycle system is in three different forms, i.e., the subcritical saturated steam cycle, the subcritical superheated steam cycle and the gasliquid two-phase cycle. The T-S diagrams of the three forms are shown in Fig.2, Fig.3 and Fig.4.

Fig.2 T-S diagram of saturation ORC system

Fig.3 T-S diagram of vapor-liquid phase ORC system

Fig.4 T-S diagram of superheat ORC system

Figure 2 is a T-S diagram of the sub-critical Organic Rankine saturated steam cycle, in which, 4-1 is the process of heating, evaporating and the saturation of the working fluid in the heater. 1-2 is the working process of the working fluid in the expander. 1-2 s is the isentropic working process. 2-3 is a isobaric heat process in the condenser. 3-4 s is an isentropic compression process in the refrigerant pump. 3-4 is the actual compression process in the working fluid pump. The difference between Figure 3 and Fig.4 is that Fig.3 is the working cycle T-S diagram for the process of the refrigerant in a heater heating the gasliquid two phase fluid, which flows into the expander, while Figure 4 is the working T-S diagram for the process of the refrigerant heating the working fluid to the overheating state, which then flows into the expander.

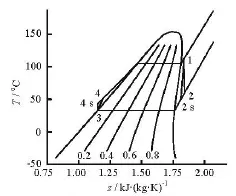

Fig.5 ORC system with internal heat exchanger

The overheating state of the organic fluid may appear after doing work in the expander. As shown in Fig.1, if the organic fluid reaches the overheating state at point 2, the heat exchanging will be carried out between the pump boosted working fluid and the organic fluid to reach the dry saturated state from the expander outlet state under the same pressure by the heat exchanger in order to reduce emissions of heat in the condenser, and improve the efficiency of the system. The organic Rankine cycle heat regenerative system is shown in Fig.5.

2. Thermodynamic analysis of organic Rankine cycle power generation system

In this paper, the efficiency of the organic Rankine cycle system is chosen as one of the criteria in the selection of the working fluid under the condition of constant heat source power. The system efficiencyηis defined as the output of the system net work over the heat taken away by the organic working fluid in the heater.

where Wnetis the net output power of the system, which is equal to the expander output power subtracting the working fluid pump power consumptionWpand the cooling water pump power consumption Wp1. The power consumed by the flue gas heat flow is ignored in this article.

The organic working fluid from the evaporator enters into the expander to do work. Assuming that the working fluid internal energy and the kinetic energy are negligible, the expander output power in the steady state is

The working fluid pump consumption and the power consumption of the cooling water pump can be expressed as

The working fluid flow mwfis

mcw,mwfin the above formula are the mass flow rates of the cooling water and the organic working fluid,cbis the average specific heat of the heat source fluid,mgis the volume flow of the flue gas,taand tbare the temperatures of the heat source fluid through the heat exchanger inlet and outlet, respecti-vely,h1,h4and h5are the enthalpies at points in Fig.1.ηp1are the efficiencies of the working fluid pump and the cooling water pump, respectively.p1, p2and v3are the working fluid pressures and the mass volume of the corresponding points in Fig.2.h1is the cooling pump lift.

The organic working fluid boosted by the pump is heated in the heater to the selected expander inlet temperature t1, and then enters into the expander to do work. There is a minimum heat transfer temperature difference between the flue gas and the organic fluid in the heat exchanger, which is described as the narrow point temperature difference?tpp. In the simulation, it is often taken as 3oC-7oC[13]. In this paper, we take the value of 10oC in the experiment preparation. The working process of the organic working fluid in the heat exchanger and the pipes is taken as an isobaric process, the efficiency of the working fluid pump and the cooling water pump are both taken as 75%, the efficiency of the expander is taken as 75%[14,15]. The specific heat of the flue gas is taken as 1.375 kJ/m3·oC. The cooling water temperature is taken as 20oC. During the calculation, the temperature rise is taken as 5oC, and the cooling pump lift is taken as 15 m.

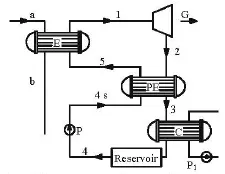

Fig.6(a) Efficiency of working fluids for different degrees of dryness when the expander inlet temperature is 100oC

Fig.6(b) Efficiency of working fluids for different degrees of superheat when the expander inlet temperature is 100oC

3. Working fluid selection

As is known, many refrigerant working fluids in use might destroy the ozone layer and cause the greenhouse effect, therefore, they should be gradually avoided in use. Now there are mainly three kinds of refrigerant alternatives. Firstly, the pure substances of a halogenated hydrocarbon containing chlorine ions, such as HFC-134a. Secondly, the natural refrigerants such as the long-term use of NH3(R717) and hydrocarbons such as propane butane and isobutane (R600a). Thirdly, a mixture consisting of HFC or HCFC substances[16]. Therefore, the working fluid should be selected among the environmental friendly HFC (incomplete halohydrocarbon containing carbon, fluorine and hydrogen), the HCS (hydrocarbon) and the new working fluid. In addition, the following factors should be taken into consideration in the selection of the working fluid: the flammability, the toxicity, the chemical and thermal stability, the thermal conductivity, the liquidity and the price[17]. Through investigation of the practical applications of working fluids in references, and the consideration of the properties of the working medium[18], the organic working fluids shown in Table 1 are provided for the related calculations and the working fluid selection, wherein R152a, R134a are wet fluids, R236fa, and R245fa, R600a, R600, R601a and R601 are dry flui

ds[8,9,10].

Fig.7(a) Efficiency of working fluids for different degrees of dryness when the expander inlet temperature is 150oC

Fig.7(b) Efficiency of working fluids for different degrees of superheat when the expander inlet temperature is 150oC

Table1 Properties of the selected working fluids

4. Analyses of results

4.1 Calculation and analysis of simple system without heat regeneration

The subcritical Rankine cycle shown in Fig.1 is calculated under the conditions of the same heat source power and different temperatures. The simulation results for three different conditions of the superheated state, the saturation and the gas-liquid two-phase are shown in Fig.6 and Fig.7 when the temperatures in the expander inlet of the organic fluid are taken as 373 K and 523 K, respectively.

In Fig.6 and Fig.7,Es is the system efficiency, Deis the dryness of the working fluids at the expander inlet,Hsis the superheat of the working fluids at the expander inlet.

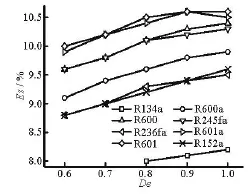

Figures 6(a) and 6(b) show the simulation results of the system efficiency for different degrees of dryness and superheat when the heat source power is constant (in this paper, this heat source power is taken as 100kW, the temperature of the heat source is taken as 100oC-160oC), the temperature of the organic working fluid in the expander inlet is 100oC and the temperature of the heat source is 120oC. It can be seen from the Figures that the system efficiency is related to the working fluid. Except for the organic mediums of R601a and R134a, the maximum efficiency of the system is 10.5% when the organic working fluid in the inlet of the expander is the dry saturated vapor and R601 is employed as the organic working fluid. When the working substances are R601a, R601 and R245fa, the system efficiencies take intermediate values. When the overheat degree is 5oC, the system efficiency reaches the maximum value of 8.6%. When the working substance is R134a, the maximum system efficiency is 10.2%, which is only 0.3% lower than the system efficiency when the working fluid is R601. However, in consideration of the safety, especially, the flammability of the organic working fluid, when the heat source temperature is below 150oC, R245fa is often selected as the working fluid.

Figures 7(a) and 7(b) show the variations of the system efficiency when the heat source power is constant (in this paper, this heat source power is taken as 100 kW, the temperature of the heat source is taken as 160oC-250oC), with different values of dryness and superheat degrees while the temperature of the organic working fluid in the expander inlet is 160oC and the temperature of the heat source is 190oC. Since the calculated efficiency of the sub-critical system is related to the type and the parameters of the working fluid, only R601 and R601a in Table 1 are selected to be the working fluid in the system efficiency simulation for different values of dryness.

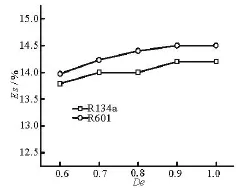

4.2 Calculation and analysis of heat regenerative system

After doing work in the expander, the organic working fluid is in the overheated state. A heat regenerator should be used to recycle the heat released by the working fluid when it is transformed into the saturated vapor under the same pressure in the outlet of the expander to improve the system efficiency. Figure 5 is a system diagram of the heat regenerative system. The difference between this system and the system shown in Fig.1 is that for the former system, the organic working fluid exchanges heat with the pump boosted liquid organic fluid in the heat exchanger first, then enters into the condenser. R245fa and R601a are selected to be the organic working fluids to simulate the parameters of the regenerative organic Rankine cycle system under different temperatures at the inlet of the expander and the simulation results are compared with those of the system without the heat regeneration. When R245fa works as the organic working fluid, the temperature of the heat source is taken as 120oC, the temperature of the working fluid in the expander inlet of the saturated steam is 100oC, The parameters of the organic Rankine Cycle system are calculated, other parameters are as above mentioned. Thecalculation results in Table 2 shows the parameters of the organic Rankine cycle system with heat regenerative system when the heat source temperature is 190oC, the organic working fluid temperature in the expander inlet is 160oC and the organic fluid is dry saturated steam of R601a.

Table2 Comparison of different parameters for two systems

As shown in Table 2, if a heat regenerator is adopted in the system, the efficiency of the system with the working fluid of R245fa is 1.2% higher than that of the system without the heat regenerator. This is mainly due to the reduction of the heat content of the working fluid from the expander to become the saturated steam under the same pressure. Meanwhile, both the power output of the system and the system efficiency are improved. The volume flow rate of the flue gas and the mass flow rate of the organic working fluid are increased slightly. The final temperature of the flue gas is increased by 2oC as a consequence of the adoption of the heat exchanger. When R601a is taken as the refrigerant, the heat regenerative system can improve the system efficiency by 2.5%, and the temperature of the flue gas emissions is increased by 10oC. From the above analysis, the system efficiency can be improved through adding a heat regenerator into the system, the increase of efficiency is related to the characteristics of the working fluid and the temperatures of the heat source and the working fluid.

5. Conclusions

In selecting the working fluid for the organic Rankine cycle power generation system, not only the characteristics of the working fluid, such as the flammability, the toxicity and the thermal stability, but also the impact of different working fluids on the system efficiency under different heat source temperatures should be taken into consideration. Some conclusions are as follows.

For the subcritical organic Rankine cycle system with certain heat source parameters, when the temperature of the organic working fluid at the inlet of the expander is constant, the maximum system efficiency can be obtained when the organic fluid is in the dry saturated vapor state.

For the organic Rankine cycle power generation system with a low temperature waste heat source, when considering the system efficiency and the working fluid flammability, R245fa is more suitable as the working fluid. For a high-temperature waste heat source, though R601a can be taken as the working fluid, its high flammability may be a problem, so it is recommended that a new working fluid applicable to the high-temperature waste heat source should be studied.

For the recuperative organic Rankine cycle power generation system under the same conditions of the waste heat source, the working fluid, and the system equipment parameters, the system efficiency can be improved by the use of a heat regenerator. However, the increased of system efficiency is associated with the properties of the working fluid, the heat source temperature, and other factors.

[1] HUNG T. C., SHAI T. Y. and WANG S. K. A review of organic rankine cycles (ORCs) for the recovery of low grade waste heat[J]. Energy, 1997, 22(7): 661-667.

[2] SALEH B., KOGLBAUE G. and WENDLAND M. et al. Working fluids for low-temperature organic Rankine cycles[J]. Energy, 2007, 32(7): 1210-1221.

[3] GAO Dong-ming, SHI Xiao-jun. Analysis of reclaiming residual heat of the flue gas of gas-fired boiler with a condensing air heat exchanger[J]. Industrial Boiler, 2005, (6): 1-6(in Chinese).

[4] NGUYEN V. M., DOHERTY P. S. and RIFFAT S. B. Development of a prototype low temperature Rankine cycle electricity generation system[J]. Applied Thermal Engineering, 2001, 21(2): 169-181.

[5] SAITOH T., YAMADA N. and WAKASHIMA S. Solar rankine cycle system using scrollexpander[J]. Journal of Energy and Engineering, 2007, 2(4): 708-718.

[6] HUSBAND W. W., BEYENE A. Low-grade heat-driven Rankine cycle, a feasibility study[J]. International Journal of Energy Research, 2008, 32(15):1373-1382.

[7] CHEN H., YOGI GOSWAMI D. and MUHAMMAD M. A supercritical Rankine cycle using zeotropic mixture working fluids for the conversion of low-grade heat into power[J]. Energy, 2010, 36(1): 549-555.

[8] TCHANCHE B. F., PAPADAKIS G. and LAMBRINOS G. et al. Fluid selection for a low-temperature solar organic rankine cycle[J]. Applied Thermal Engineering,

[9] CAO Bin-bin. Analysis of screw expander surplus heat recovery system[D]. Doctoral Thesis, Tianjin, China: Tianjin university, 2007(in Chinese). 2009, 29(11-12): 2468-2476.

[10] ZHU Jiang, LU Yuan-wei and MA Chong-fang et al. Working fluid selection for organic rankine cycle (ORC) in low temperature geothermal power generation system[J]. Renewable Energy Resources, 2009, 27(2): 76-79(in Chinese).

[11] SUN J., LI W. Operation optimization of an organic rankine cycle (ORC) heat recovery power plant[J]. Applied Thermal Engineering, 2011, 31(11-12): 2032-2041.

[12] SHI Shuo, LIU Zheng-gang and DU Guang-sheng et al. Study of errors in ultrasonic heat meter measurements caused by impurities of water based on ultrasonic attenuation[J]. Journal of Hydrodynamics, 2015, 27(1): 141-149.

[13] GU Wei, WENG Yi-wu and CAO Guang-yi. The latest research findings concerning low-temperature heat energy-based power generation and its development trend[J]. Journal of Engineering for Thermal Energy and Power, 2007, 22(2): 115-119(in Chinese).

[14] YAN Jia-lu. Thermodynamic principles and formulas for choosing working fluids and parameters in designing power plant of low temperature heat[J]. Journal of Engineering Thermophysics, 1982, 3(1): 1-7(in Chinese).

[15] ANGELINO G., COLONNA DI PALIANO P. Multicomponent working fluids for organic Rankine cycles (ORCs)[J]. Energy, 1998, 23(6): 449-463.

[16] ANGELINO G., COLONNA DI PALIANO P. Organic Rankine cycles (ORCs) for energy recovery of molten carbonate fuel cells[C]. 35th Intersociety Energy Conversion Engineering. Las Vegas, USA, 2000.

[17] CAO Deng-sheng, SHI Lin. Refrigerant using manual[M]. Beijing, China: Metallurgical Industry Press, 2007(in Chinese).

[18] ISSN 1041-2336. Designation and safety classification of refrigerants[S]. ANSI/ASHRAE Standard 34, 2007.

* Biography: LI Dian-xun (1974-), Male, Ph. D. Candidate

ZHANG Shu-sheng,

E-mail: shshzhang@sdu.edu.cn

水動(dòng)力學(xué)研究與進(jìn)展 B輯2015年3期

水動(dòng)力學(xué)研究與進(jìn)展 B輯2015年3期

- 水動(dòng)力學(xué)研究與進(jìn)展 B輯的其它文章

- United friction resistance in open channel flows*

- Ski jump trajectory with consideration of air resistance*

- Stability of a tumblehome hull under the dead ship condition*

- Multi-scale Runge-Kutta_Galerkin method for solving one-dimensional KdV and Burgers equations*

- Numerical study of the performance of multistage Scaba 6SRGT impellers for the agitation of yield stress fluids in cylindrical tanks*

- The impact of macroalgae on mean and turbulent flow fields*