冷卻潤滑介質(zhì)對鈦合金Ti6Al4V加工性能的影響

戚寶運 何 寧 李 亮

(南京航空航天大學機電學院,南京,210016,中國)

INTRODUCTION

Titanium alloys have been widely used in the aerospace,chemical and petroleum industry for good mechanical properties.However,titanium alloys are difficult to machine due to their high temperature strength,relatively low modulus of elasticity,low thermal conductivity,and high chemical reactivity[1]. High-speed machining technology offers many advantages over conventional machining such as higher material removal rate,increased machining accuracy and better surface finish,etc[2].All these advantages have led to the application of high-speed machining technology in titanium alloys[3].

But severe friction of tool-chip and high cutting temperature lead to rapid tool wear,thereby restricting the processing efficiency[4].So a suitable cooling/lubrication medium plays an important role in high-speed machining titanium alloys.Hong et al[5]injected the focused liquid nitrogen to the chip-tool interface at the point of the highest temperature and the flank at the cutting edge through specially designed micro-nozzles,thus effectively improving the toollife. Venugopal et al[6]utilized the uncoated carbide cutting tool to turn T i6Al4V alloy,and a substantial improvement in tool life was obtained under cryogenic cooling compared with dry and wet machining.Kovacevic et al[7]put forward the use of highpressure water jet cooling to improve surface quality and tool life in the milling of titanium alloy.Yamazaki et al[8]studied the application of cold air in turning T i6Al4V and it was proposed that the tool life using cold air was equal to that using minimal quantity lubrication(MQL).The influence of cold air with oil mist on the tool temperature was studied experimentally in the milling of Ti6Al4V alloy[9].Su et al[10]investigated the influence of compressed cold nitrogen gas on tool wear in high-speed end milling of T i6Al4V and evaluated the effectiveness of cooling/lubrication conditions in tool life.

Static cooling cutting technology is a dry cut-ting technology invented by Russian in the eighties of the 20th century,its principle is that the pressed air is ionized by high voltage electric field device,sent into cutting zone through the nozzle,and then a special atmosphere is formed so as to achieve the effects of cooling and lubrication.Rose T echnology Company of Russian has done a lot of tests about static cooling technology,and achieved more than thirty national patents.This technology may take the place of the coolant in most situations and succeed to pass the tests in America, Germany,Japan,Switzerland,and other countries[11].In China there are a few reports about it[11-12].

In this paper,uncoated cemented carbide tools are used in high-speed turning Ti6Al4V.Dry,cold air,MQL,cryogenic MQL(CMQL)and ionized air with ozone and oxygen ions as the cooling/lubrication conditions are studied,in order to better understand and know the roles of coolant/lubrication conditions in the cutting process and expand their applicability.

1 EXPERIMENTAL SET-UP

1.1 Workpiece and tool

An α+βphase Ti6Al4V alloy is used for the machining tests.T he main nominal compositio of Ti6Al4V is 90%Ti+6%Al+4%V,with a hardness of HV320—330.YG8,uncoated cemented carbide cutters are used,having rake angle(?)of-7°,clearance angle(α)of 7°,corner radius(R)of 0.5 mm,and side cutting edge angle(Kr)of 45°.

1.2 Machining tests

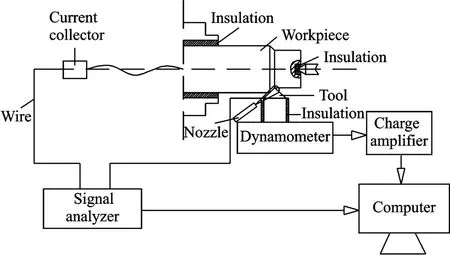

All the cutting tests are carried out on CA6140 lathe.T he cutting tool is clamped onto the dynamometer.T he cutting speed of120 m/min is chosen to study the effectiveness of various cooling/lubrication conditions in this paper,including dry,cold air(-20°C),MQL,CMQL and ionized air.Feed rate f=0.1 mm/r,and depth of cut ap=0.5 mm.The temperature of cold air used for CMQL also is-20°C.T he experimental set-up of turning as a schematic illustration is shown in Fig.1.

Fig.1 Schematic illustration of turning set-up

The appropriate lubricant is essential for MQL and CMQL machining.In order to reduce the impact on the environment and simultaneously maintain the performance of lubricant,it also needs to be taken into account that the characteristics of lubricating oil at low temperature,such as viscosity,pour point and so on.In this test,Vascomill MMS FA 1 produced by Blasser Company is used,which is a kind of vegetable oil without chlorine,sulfur or mineral oils,and with the polar molecular structure and fatty alcohol as base oil,and better atomization performance under low temperature.The small amount(30 ml/h)of cutting oil for the mist requirement is supplied at the pressure of 0.4 MPa by external MQL lubrication system VE1B produced by Vogel Company.A nozzle positioned 15 mm away from the cutting tool nose is applied to the rake face.

Ionized air generating device with the dimension of 140 mm×100 mm×110 mm and the mass of 3.5 kg needs input power 45 W(AC110/220 V,50/60 Hz),and output voltage is 4.6 kV.It mainly includes high-voltage power supply cell,ion nozzle,wire,and wind-pipe,the diameter of which is 8 mm.After the air is ionized by the ion nozzle,a certain concentration of negative oxygen ions and ozone generated are transported into the cutting zone.

1.3 Measure tools

T he cutting forces are measured by Kistler piezoelectric dynamometer 9265B,and the average temperature of the cutting zone is measured using the natural thermocouple method.Surface roughness of Ti6Al4V is measured using three-dimensional profilometer MicroXAM.Tool rake and flank wears are measured using 10×optical microscope.The worn rake and flank regions on the tools are examined using Joel JSM 5610LV scanning electron microscope.

2 RESULTS AND ANALYSIS

2.1 Cutting force and cutting temperature

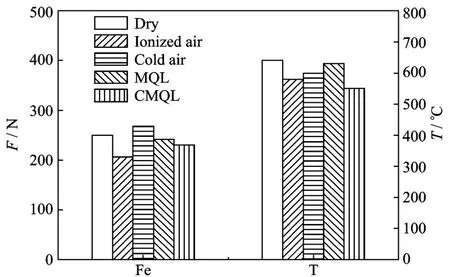

Fig.2 shows the main cutting force F and cutting temperature T under different coolant/lubrication conditions.It is found that under dry condition,the cutting temperature is highest under all conditions,and the cutting force is larger than those under other coolant/lubricants conditions except cold air.MQL has some lubrication action,but little effect at high cutting temperatures for decomposition of the oil film.Cold air cutting has highest main cutting force,but has a better cooling effect,effectively lowering the cutting temperature.CMQL can maintain the stability of lubricating oil film and still play good lubrication action under high-speed cutting conditions,so CMQL has better cooling and lubrication effect for its lowest cutting temperature and smaller cutting force.Compared with that under dry,the cutting temperature under CMQL condition decreases by 14.1%.Ionized air has obvious advantages in reducing main cutting force,which is smallest under all conditions,and decreases by 17.6%than dry cutting.

Fig.2 Cutting force and cutting temperature(v=120 m/min,f=0.1 mm/r,ap=0.5 mm,V B=0.1 mm)

2.2 Tool wear

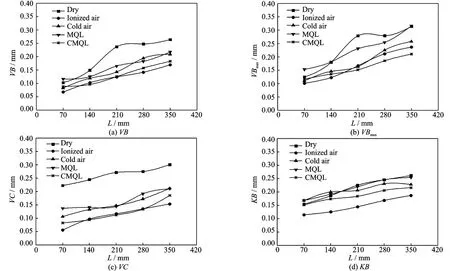

The results obtained from the cutting experiments show that tool wear is significantly affected by the cooling/lubrication conditions. Fig.3 shows the curve of tool wear with cutting length L,including average flank wear VB,maximum flank wear VBmax,nose wear V C and rake crater wear K B.When cemented carbide turns titanium alloys,tool wears mainly occur in rake face and flank face.T he crater wear in rake face,which seriously weakens the cutting edge,will lead to accelerate the flank wear and the final damage of tool,but intense friction of tool-chip is the main reason of crater wear.

As seen in Fig.3(a),the flank average wear V B rapidly increases with the cutting length under dry cutting condition,except at a lower rate under other cooling/lubrication conditions,especially when using CMQL and ionized air.CMQL plays an important role in inhibiting the tool wear.In contrast,the effect of ionized air is a little better than CMQL.It is attributed to its antifriction properties,thus effectively reducing the friction of tool-chip.T he evidence is that crater wear is the smallest under ionized air condition,as shown in Fig.3(d).Meanwhile it is found that the maximum flank wear VBmaxunder dry and MQL conditions are larger than those under other conditions in Fig.3(b).

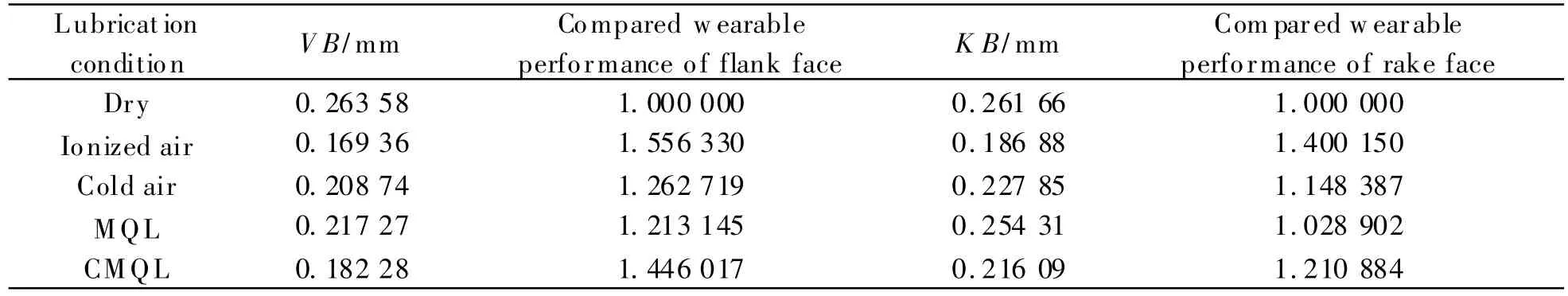

T ool wear using cold air is equal to that using MQL.When high-speed turning T i6Al4V,high cutting temperature makes the oil film break up and the lubrication action lose,so the effect of MQL to improve tool life is not obvious.Cold air can reduce the cutting temperature,expressing a certain advantages at high-speed machining.In Fig.3(c),the nose wear is most serious under dry cutting condition,which may be the main reason leading to rapid wear of tool.Table 1 shows the wear relative value compared with the tool wear under dry condition,where v=120 m/min,f=0.1 mm/r,ap=0.5 mm,cutting time t=8.5 min.It can be concluded from the results that the wearable performance from worst to best is dry cutting,MQL,cold air,CMQL,and ionized air.

Fig.3 T ool wears against cutting length

Table1 Effect of coolant/lubrications on wearable performance

Fig.4 shows the scanning electron microscope(SEM)images of worn tools under all the coolant/lubrication conditions.Wear mechanisms remain almost the same for all the tools regardless of different conditions.Main modes of tool wear are adhesion wear and chippings.

As seen from Fig.4,under dry condition,both on the rake and flank,adhesion phenomena are very serious.Meanwhile the cutting edge occurres more chippings under the action of thermal stress.Compared with that under the dry condition,the adhesive materials are less under the CMQL condition.T he reason mainly is that cryogenic oil mist reduces the friction between tool and workpiece for its lubrication action,and decreases the temperature for its cooling action,thus reducing the adhesion ability of titanium alloy.

Under the ionized air condition,there are enough high concentrations of ozone and oxygen ions to form oxide films between tool and chip,which put into effect of effective lubrication and anti-friction.T he oxide film can prevent the occurrence of adhesion wear.As shown in Fig.4,crater wear is present in rake face under all the conditions,but smallest in ionized air,which may be the reason of the longest tool life.

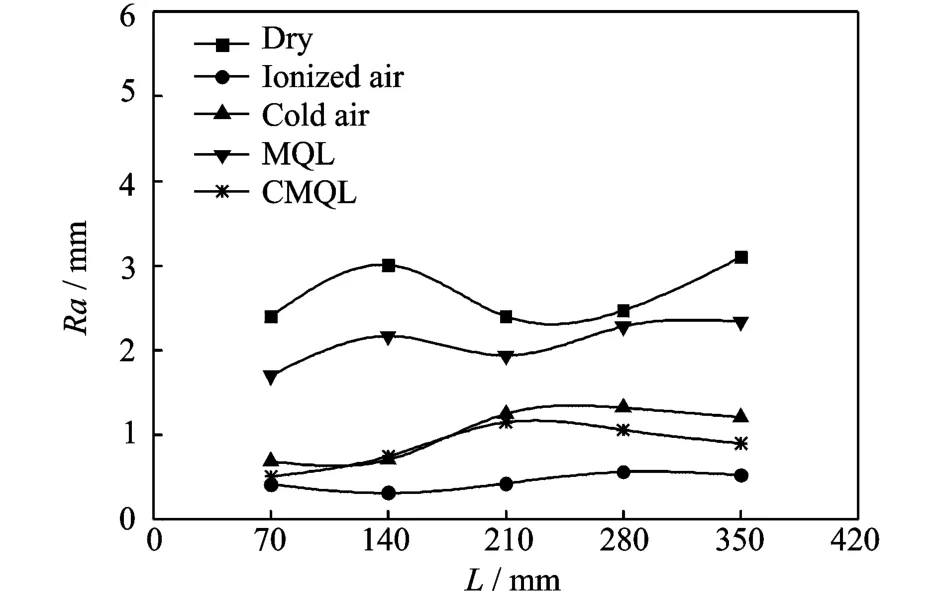

2.3 Surface roughness

Fig.5 illustratesthe variation of surface roughness values Ra with the cutting length under different coolant/lubricant conditions.With the increase of cutting length the surface roughness increases slowly but not obviously.And the value of surface roughness under ionized air cooling condition is least under all the conditions.The reason is that under ionized air the Rehbinder effect occurrs on the surface of titanium alloy,which is that the surface hardness and strength decrease under the physical and chemical actions as absorbing gas phase particles,surface charging and so on.T he internal stress of machined surface is reduced,so the worn surface qualities are improved more effectively.

Fig.5 Surface roughness Ra against cutting time

It is also found that surface roughness Ra under cold air and CMQL conditions are less than that under MQL condition.So in high-speed machining titanium alloy,the cooling effect is better to improve the surface roughness than lubricant effect.

3 CONCLUSIONS

T ests on high-speed turning T i6Al4V are performed under various cooling/lubrication conditions.Based on the results of test investigation,the following conclusions can be summarized:

(1)Ionized air has obvious advantages in lowering cutting force and can improve tool life and surface roughness when high-speed turning T i6Al4V.Compared with dry cutting,the cutting force and the tool wear V B under ionized air condition are reduced by 17.6%and 35.7%,respectively.

(2)Cryogenic MQL has good cooling and lubrication actions,and can decrease the cutting temperature by 17.6%and the tool wear VB by 30.8%respectively than dry cutting.

(3)The wearable performance from worst to best is dry,MQL,cold air,CMQL,and ionized air.

(4)Flank wear and crater wear are the dominantfailure modeswhen high-speed turning T i6Al4V.Ionized airand CMQL can reduce crater wear,thereby inhibiting tool wear rapidly.

[1] Machado A R,Wallbank J.Machining of titanium and its alloys:a review[J].Proc Inst M ech Eng,1990,204:53-60.

[2] Schulz H,M oriwaki T.High-speed machining[J].Annals CIRP,1992,41(2):637-645.

[3] Ashley S.High-speed machining goes main stream[J].Mech Eng,1995,117(5):56-61.

[4] Ezugwu E O,Wang Z M.Titanium alloys and their machininability—A review[J].J MaterProcess T echnol,1997,68(3):262-274.

[5] Hong S Y,M arkus I,Jeong W C.New cooling approach and tool life improvement in cryogenic machining of titanium alloy Ti-6Al-4V[J].Int J Machine Tools Manufacture,2001,41(15):2245-2260.

[6] Venugopal K A,Paul S,Chattopadhyay A B.T ool wear in cryogenic turning of Ti-6Al-4V alloy[J].Cryogenics,2007,47:12-18.

[7] Kovacevic R,Cherukuthota C,M azurkiewiez M.High pressure waterjet cooling/lubrication toimprove machining efficiency in milling[J].Int J Machine Tools Manufacture,1995,35(10):1459-1473.

[8] Yamazaki T,Miki K,Sato U.Cooling air cutting of T i-6Al-4V alloy[J].J Jpn Inst Light M etals,2003,53(10):416-420.

[9] Jiang F,Li J F,Rong Y M,et al.Study of cutting temperature in cold-air milling of Ti6Al4V alloy[C]∥The 41st CIRP Conference on Manufacturing Systems.Tokyo:Publications by Kanji Ueda,2008:371-376.

[10]Su Yu,He Ning,Li Liang,et al.An experimental investigation of effects of cooling/lubrication conditions on tool wear in high-speed end milling of T i-6Al-4V[J].Wear,2006,261:760-766.

[11]Yao Bingtang,Yan Jiakui.Metal cutting with static cooling[J].Metal Working,2003(10):9-12.(in Chinese)

[12]Gao Ji,Cao Guoqiang,Kang Yaqin.Experimental study on the technology of dry cutting titanium alloy BT20with static cooling[J].Machinery Design&Manufacture,2007(4):90-91.(in Chinese)

Transactions of Nanjing University of Aeronautics and Astronautics2011年3期

Transactions of Nanjing University of Aeronautics and Astronautics2011年3期

- Transactions of Nanjing University of Aeronautics and Astronautics的其它文章

- 《南京航空航天大學學報(英文版)》征 稿 簡 則

- 基于多GPU的大型線性和非線性方程組的求解

- 基于GIS的機場凈空障礙物評定研究

- 基于遺傳EM 算法的航班延誤狀態(tài)空間模型

- 基于OPNET的低軌衛(wèi)星的點波束確定算法

- 基于因果圖的微小型渦噴發(fā)動機安全性分析