Yarn Quality Prediction and Diagnosis Based on Rough Set and Knowledge-Based Artificial Neural Network

YANG Jian-guo (楊建國), XU Lan(徐 蘭) , XIANG Qian(項 前), LIU Bin(劉 彬)

College of Mechanical Engineering, Donghua University, Shanghai 201620, China

Yarn Quality Prediction and Diagnosis Based on Rough Set and Knowledge-Based Artificial Neural Network

YANG Jian-guo (楊建國)*, XU Lan(徐 蘭) , XIANG Qian(項 前), LIU Bin(劉 彬)

CollegeofMechanicalEngineering,DonghuaUniversity,Shanghai201620,China

In the spinning process, some key process parameters (i.e., raw material index inputs) have very strong relationship with the quality of finished products. The abnormal changes of these process parameters could result in various categories of faulty products. In this paper, a hybrid learning-based model was developed for on-line intelligent monitoring and diagnosis of the spinning process. In the proposed model, a knowledge-based artificial neural network (KBANN) was developed for monitoring the spinning process and recognizing faulty quality categories of yarn. In addition, a rough set (RS)-based rule extraction approach named RSRule was developed to discover the causal relationship between textile parameters and yarn quality. These extracted rules were applied in diagnosis of the spinning process, provided guidelines on improving yarn quality, and were used to construct KBANN. Experiments show that the proposed model significantly improve the learning efficiency, and its prediction precision is improved by about 5.4% compared with the BP neural network model.

yarnqualityprediction;roughset(RS);knowledgediscovery;knowledge-basedartificialneuralnetwork(KBANN)

Introduction

Spinning process is a typically complex unstable industrial process, that can be easily disturbed by the surrounding environment, including not only the material displacement process, fluid dynamics process, but also heat exchange and chemical reactions. Traditional quality prediction was conducted frequently based on mathematical statistics, gray theory,etc. It has done a lot to simplify production conditions, with little consideration of the interaction between variables, which is a major factor in the actual production.

A great many experts and scholars have done a lot of researches on complex production process quality prediction and diagnosis. Compared with the traditional regression methods, artificial neural network and support vector machine technology has a great advantage in dealing with complex nonlinear problems[1-9]. The research of Refs.[1-4] showed that, the neural network had good prediction performance in textile field; Evander and Eng used the neural network to predict the existence of acute pulmonary embolism[5-6]; Gebraeeletal. and Tian established the prediction model of remaining life of electronics or equipment based neural network[7-8]; Ribeiro applied support vector machines in injection molding production process quality diagnosis[9]. But the artificial neural network (ANN) has two obvious defects: one is using the gradient descent method leads to the slow learning speed and local optimization, and the other is the “black box” defects of neural network. Many scholars optimized the structure parameters of ANN by using the GA algorithm, PSO algorithm, and other optimization algorithm, and experiments showed that improved ANN’s performance had been significantly enhanced[10-16]. Considering the ANN cannot explicitly pointed out the shortcomings of the nonlinear relationship between process parameters and production quality, some machine learning algorithms which based on knowledge discovery have been proposed[17-25]. Sette developed a classification system based on fuzzy logic and applied to the process rules’ generation of the fiber into yarn’s production process[17]. Lüetal. presented rough set to extract the spinning process rules and extraction rules providing support for product quality control[18-19]. Yu proposed a quality remote monitoring and diagnosis model based on GA and the knowledge-based artificial neural network, and applied this model in a coating production line, which effectively improved the quality of the product[21-22]. Akkalaetal. applied the neural network of knowledge in the areas of environmental engineering and machine processing,etc[23-25].

In this paper, considering the two major drawbacks of ANN, a hybrid intelligent forecasting model was established based on rough set (RS) and knowledge-based artificial neural network (KBANN), which reflected the complex nonlinear relationship between the parameters and the product quality in Spinning process. The results show that the model not only improves the prediction performance, but also solves the problem of diagnosis and adjustment of quality fluctuation through the extracted knowledge.

1 Frame of a Hybrid Intelligent Learning Model

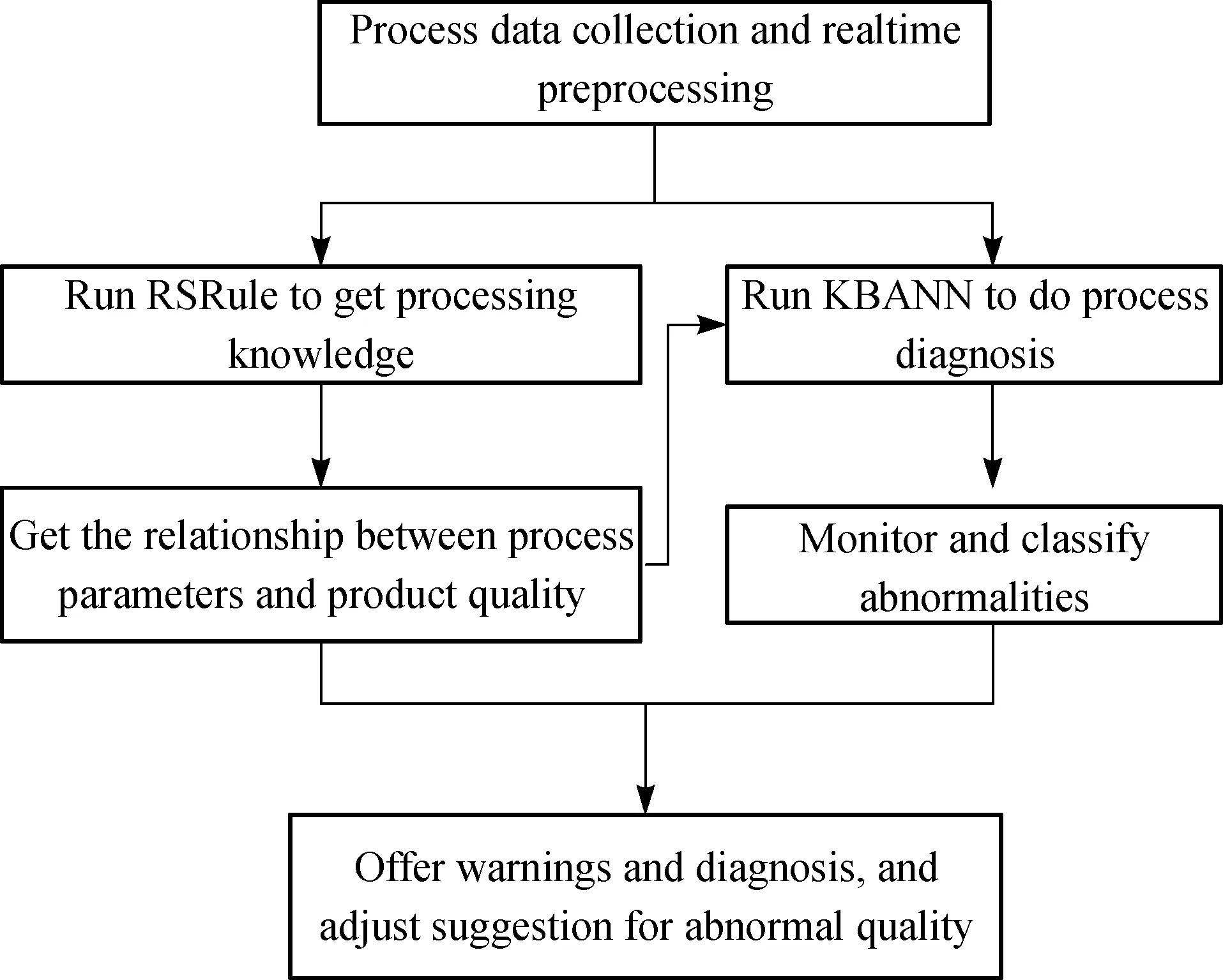

Fig.1 Frame of a hybrid intelligent learning model

Figure 1 illustrates the framework of a hybrid intelligent learning model presented in this paper. In order to realize intelligent monitoring, KBANN uses the training set to study the complex relationship between process parameters and product quality, then outputs neuron value to monitor the process status. To achieve intelligent diagnosis, explicit rules are extracted to explain the relationship between the process parameters and product quality based on RSRule. Meanwhile rules extracted by RSRule (i.e., domain knowledge) can be applied to the initialization of KBANN model. Therefore, the integration of KBANN and RSRule can not only monitor process anomalies, but also explain why there will be quality fluctuations and how to adjust the parameters to achieve stability control of product quality.

2 Spinning Process Decision Rules Extraction Based on RS

RS theory is a new mathematical tool proposed by Pawlak professor, it was based on set theory to deal with vagueness and uncertainty problem[26]. Pawlaketal. argued that knowledge could be understood as the ability to divide things within a certain category, and the research object of knowledge was described by decision table[26-29].

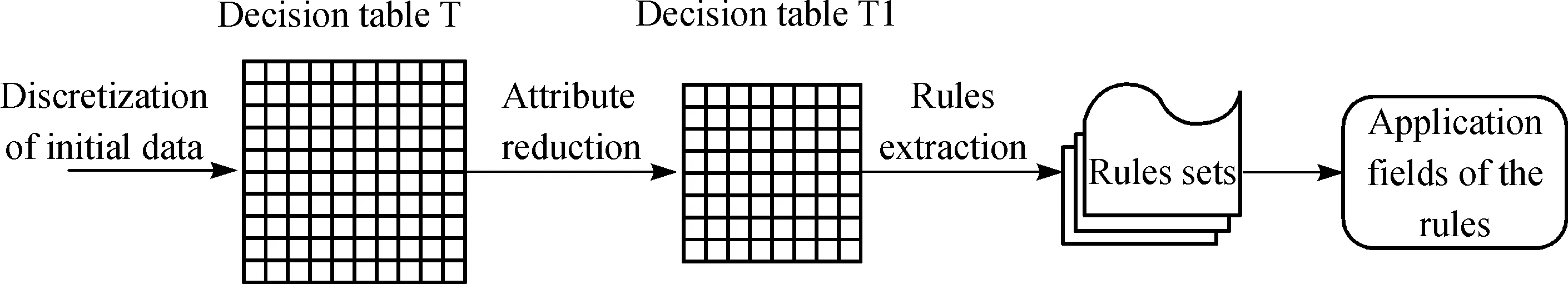

Figure 2 shows the algorithm flow of knowledge extraction algorithm based on rough set theory. It consists of data preprocessing, data attribute reduction, decision algorithm, and other parts. Firstly, the data are discretized with the ordination and cluster analysis method, and then use genetic algorithm for attribute reduction of decision table, and further a minimal set of decision rules to get the final classification rules.

Fig.2 Algorithm flow of rough set knowledge extraction

2.1 Discrete data of textile process

In the textile process, values of decision tables must be represented by discrete data when using rough set theory to deal with decision tables, which require the discrete processing prior the data processing if range of condition attributes and decision attributes are continuous value. For continuous textile processing attribute data, its discretion methods often need to consider the technical characteristics of the classification criteria, data distribution, data sample size, and other information. This paper deals with discrete problems by sorting and cluster analysis methods.

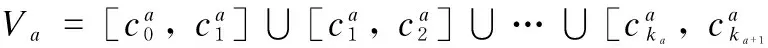

Step 1 Sort the value of the attributea, get ordered domainVa.

Step 2 The relative change rateδi -1=ai-ai -1of the property pointai(i=2, 3, …,n) into the previous property pointai -1is calculated, there may be a breakpoint where the rateδhas a step change, thereby obtaining an ordered domainVaand classification quantityka.

(1)

(2)

(3)

2.2 Decision table reduction based on the genetic algorithm

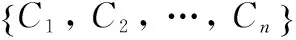

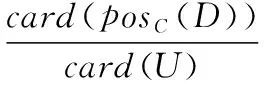

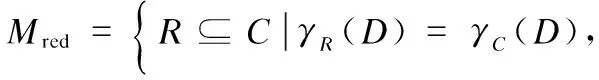

Reduction process is removing unnecessary condition attributes from the condition attributes of decision table system to analyze the decision rules for condition property relative to decision property from the formerly obtained reduction. In this paper, the minimum attribute reduction problem is solved by transforming it into a multi-objective optimization problem, and the redundant condition is reduced based on the genetic algorithm to get the simplified decision table.

(4)

Set of reduction is:

(5)

wherecard(·) indicates the base of a set;Ris an attributes set to which minimal attribute reduction,card(R) denotes the number of elements of the attributes set,i.e., the attribute length;γR(D) is the dependence of condition attribute setRrelative to the decision attributeDfor the sense of rough set.

Based on the definition of the minimum attribute reduction, the problem can be solved by transforming it into a multi-objective optimization problem, and the problem is described as:

(6)

The reduction step of condition attributeCof decision table is as follows.

Step 1 Use the binary string {0, 1} of the lengthl(lrepresents the number of condition attributes) to represent the code of each, each bit corresponds to one conditional attribute.

Step 3 If the best individual in the population is small enough, or after multi-generational cycle of continuous operation, individualf(R) hasn’t been significantly improved, go to Step 6, otherwise, population genetic manipulation goes on.

Step 4 Select the operator to filter the individuals from the contemporary populations that meet the conditions.

Step 5 Do crossover and mutation operations for individuals that meet the conditions, and return to Step 2.

Step 6 Get the minimum attribute reduction, and form decision table after reduction.

722 Research progress of mesenchymal stem cell-derived exosomes in kidney diseases

2.3 Reduction of decision rules

The results of attribute reduction, for the classification decision, still contain redundant information. Reduction of decision rule is to eliminate the unnecessary conditions of each decision rule of decision rule set by the means of decision logic,i.e., to remove redundant attribute values of each decision rule to make a further minimization of set of decision rules.

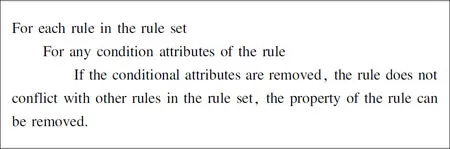

For a decision table after attribute reduction obtained, we can form a decision rule for each sample. Therefore, samples of the decision table can be represented by the rules.Reduced decision table is actually a set of rules. For this set of rules, we can use the following reduction algorithm (Fig.3)[29].

Fig.3 Flow chart of reduced algorithm

All the rules in the processed rule set do not contain redundant attributes, that is, the number of conditions attributes of a rule is minimized.

3 Intelligent Monitoring Model Based on KBANN

The relationship between input and output can be modeled by KBANN algorithm, which is a method of constructing the network structure and giving the network connection weights based on the obtained expert knowledge in the field[30]. As shown in Fig.4, KBANN algorithm is consisted of two key steps: analysis step (neighborhood knowledge is transformed into equivalent neural network (steps 1-3)), and inductive step (neighborhood knowledge is then summed and refined with the back-propagation algorithm (step 4))[31].

Fig.4 KBANN algorithm

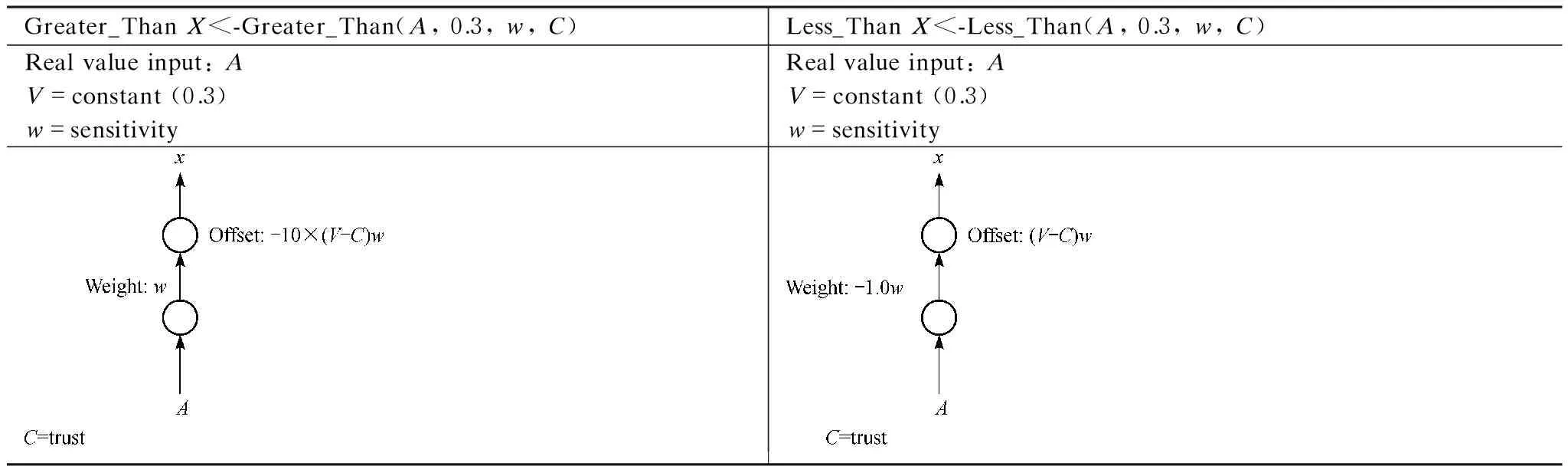

The basic KBANN algorithm supports rules based on binary (Bianry) and the discrete input feature. Fernando and Bernard presented a KBANN based INSS system[31]. INSS expands the types of rules that can be used by KBANN so that KBANN can use the rules of input feature of real type. The real rule type can be performed as follows:

IF Greate_Than (Sensor_S1, 1.0) and Less_Than (Sensor_S2, 0.5) Then Conclusion_C1 where Sensor_S1 and Sensor_S2 are input features of the dataset, and Conclusion_C1 is corresponding conclusion class label. Such a rule set can be mapped into ANN by KBANN which is similar to multilayer perceptron. Figure 5 shows a simple rule mapping process.

Greater_ThanX<-Greater_Than(A,0.3,w,C)Less_ThanX<-Less_Than(A,0.3,w,C)Realvalueinput:AV=constant(0.3)w=sensitivityRealvalueinput:AV=constant(0.3)w=sensitivity

Fig.5 Greater_Than with Less_Than rule mapping process in INSS system

4 Yarn Quality Monitoring and Diagnosis Based on Hybrid Intelligent Learning Model

4.1 Spinning decision rules: RSrule

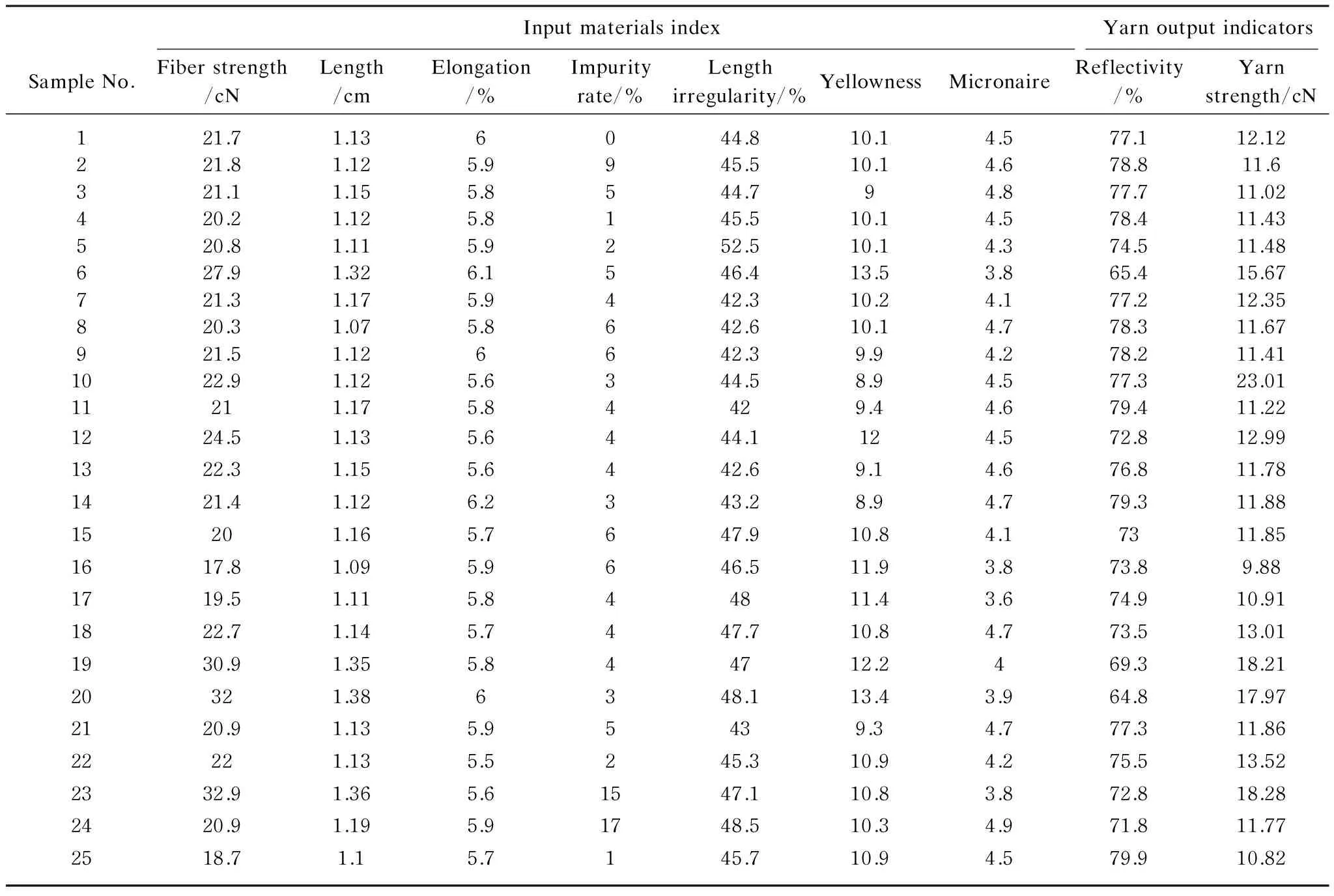

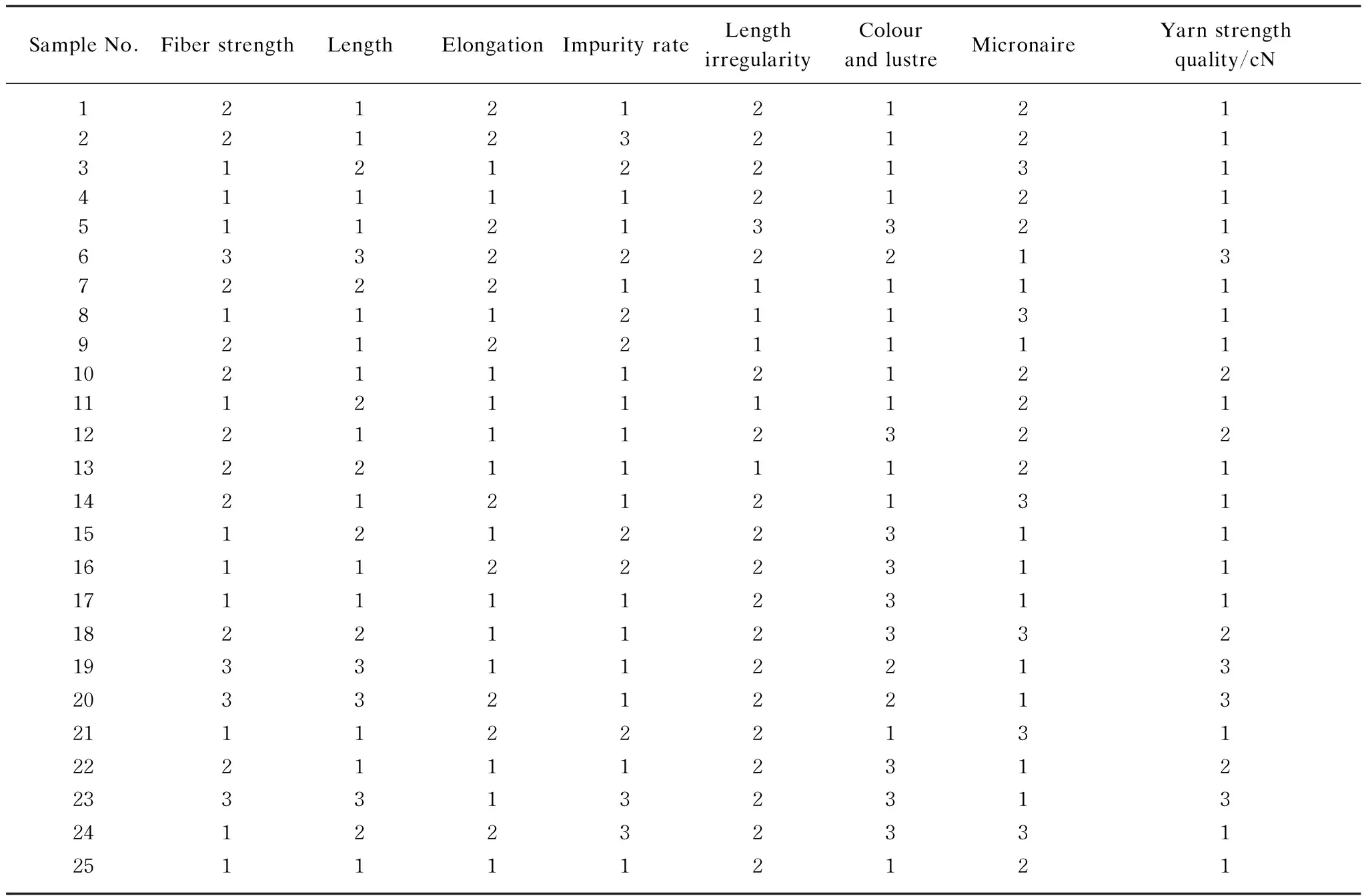

Twenty five different sets of cotton samples are collected from the production, whose fiber qualities are measured by the fast large-capacity instruments. All the samples are spun by SDL MDTD/Quick spin system to total of 10 yarns and stored at conditions of relative humidity of (62±2)% and temperature of 20±2 and measuring the quality of its yarn 24 h later. Data are shown in Table 1.

Table 1 Crude materials and yarn quality index sample

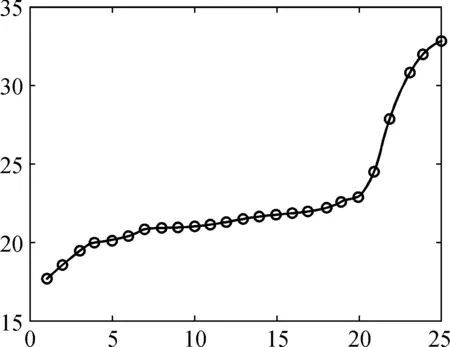

(2) Discrete data

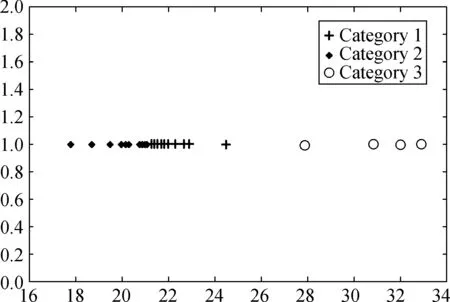

Take fiber strength for example, it can be sorted from small to large by its value. We can observe the slope of the data changes by using the order as the horizontal axis and the fiber strength as the vertical axis (Fig.6). Classifying the data into three categories, and then using theK-mean clustering method to determine the split point (Fig.7); ultimately results are shown in Tables 2 and 3.

Fig.6 Fiber strength values in ascending order

Fig.7 Fiber strength property values cluster

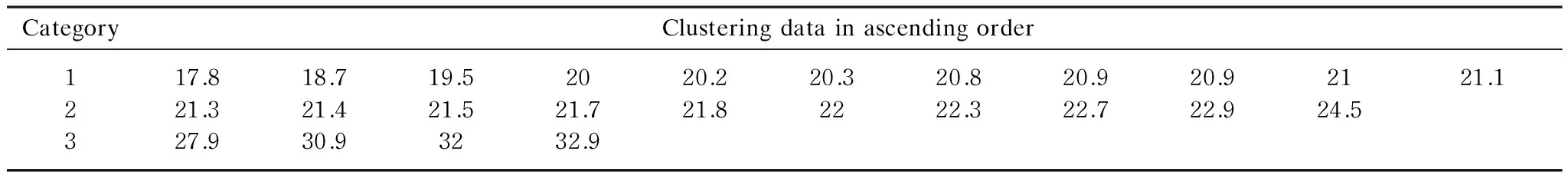

CategoryClusteringdatainascendingorder117.818.719.52020.220.320.820.920.92121.1221.321.421.521.721.82222.322.722.924.5327.930.93232.9

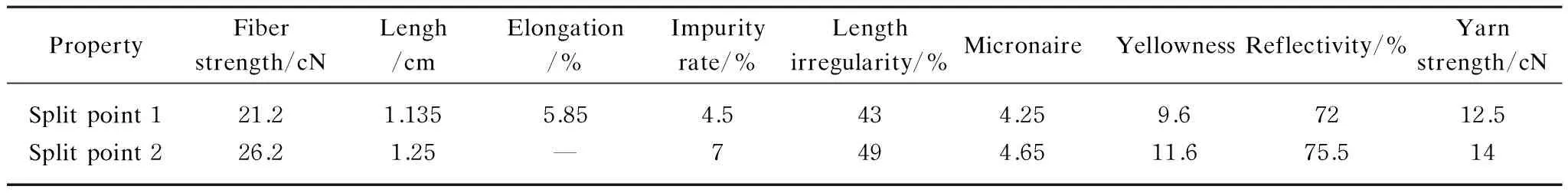

Table 3 Cut point value of each attribute

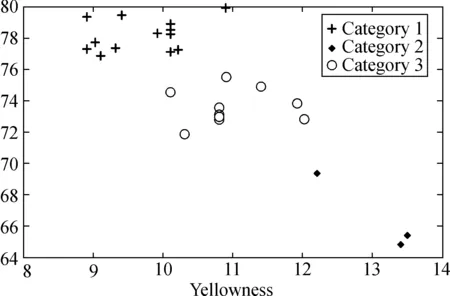

For discretion of combination attributes, the yellowness and the reflectance, for example, can be composed to color properties, using the samek-mean clustering method as well, shown in Fig.8, to classify the color property value into three categories. Synthesize discrete split point set of all the properties, the condition attributes C and decision attributes D are summarized in Table 4.

Fig.8 The yellow color combination with reflectance properties of clusters

Redundant condition attributes can be removed by attribute reduction, and the obtained attribute set after attribute reduction is: {fiber strength, elongation, length irregularity}.

(4) Decision rules reduction

After consolidating with reduction, redundant condition attribute items and attribute values are removed. As shown in Table 5,xrepresents a sample record, such asx3means the third sample. Each row represents a decision rule. Uncertainty factor of 1 indicates that the rules generated do not conflict with each other. The support of a decision rule means the ratio of the number of record data of the decision rule to the total number of records, reflecting the degree of confidence of the rule.

Table 5 can be interpreted as decision rules as follows:

Rule 1: if fiber strength is smaller than 21.2, then yarn strength is smaller than 12.5.

Rule 2: if yarn strength lies in 21.2-26.2 and elongation is smaller than 5.85% and the length of the uneven rate is smaller than 43%, then yarn strength is smaller than 12.5.

Rule 3: if fiber strength is between 21.2 and 26.2 and elongation is smaller than 5.85% and the length of unevenness between 43% and 49%, then yarn strength is between 12.5 and 14.

Rule 4: if fiber strength is between 21.2 and 26.2 and elongation of is bigger than 5.85%, then yarn strength is smaller than 12.5.

Rule 5:if fiber strength is bigger than 26.2, then yarn strength is bigger than 14.

Table 4 Discrete data samples

Table 5 Material properties and yarn strength decision rule table

4.2 Monitoring model: KBANN

4.2.1 The construction of KBANN

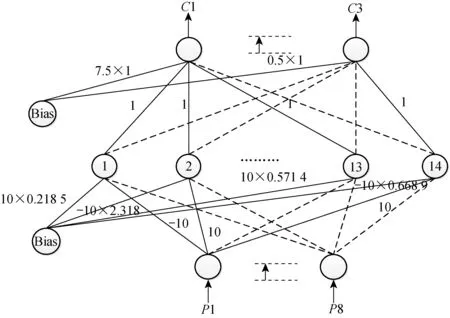

Take the raw material index as the model input, and take the type of yarn strength quality as the output. The nonlinear relationship between them can be constructed based on KBANN. The network architecture can be built based on the spinning process rules, in which rule-to-network algorithm maps the rules to be the input layer hidden layer of KBANN structure, and the Topwell and Shavlik method[29]constructed the connection between the hidden layer and the output layer. Figure 9 shows the topology of the final structure of KBANN. The rule set contains a total of 14 conditions, and produces a total of 14 connections between the input layer and the hidden layer. Meanwhile, the weight and bias values are initiated to satisfy all rule conditions. Thus, a network topology is composed of 8 input neurons (corresponding to eight input indicators), 14 hidden nodes, and 3 output neurons (corresponding to the three types of output quality quality).

Fig.9 KBANN mapping rules

The output layer contains three neurons, corresponding to the three types of output quality, and the output can be represented by the following form:C1: (1, 0, 0),C2: (0, 1, 0), andC3: (0, 0, 1), which were used to identify three quality types. Output range of KBANN is [0, 1], where 1 represents an output completely corresponding to an output quality type. Meanwhile, deviation thresholds can be set. IfC1,C2, andC3 are greater than the predetermined deviation threshold, the quality fluctuations occurrence can be determined.

4.2.2 Analysis

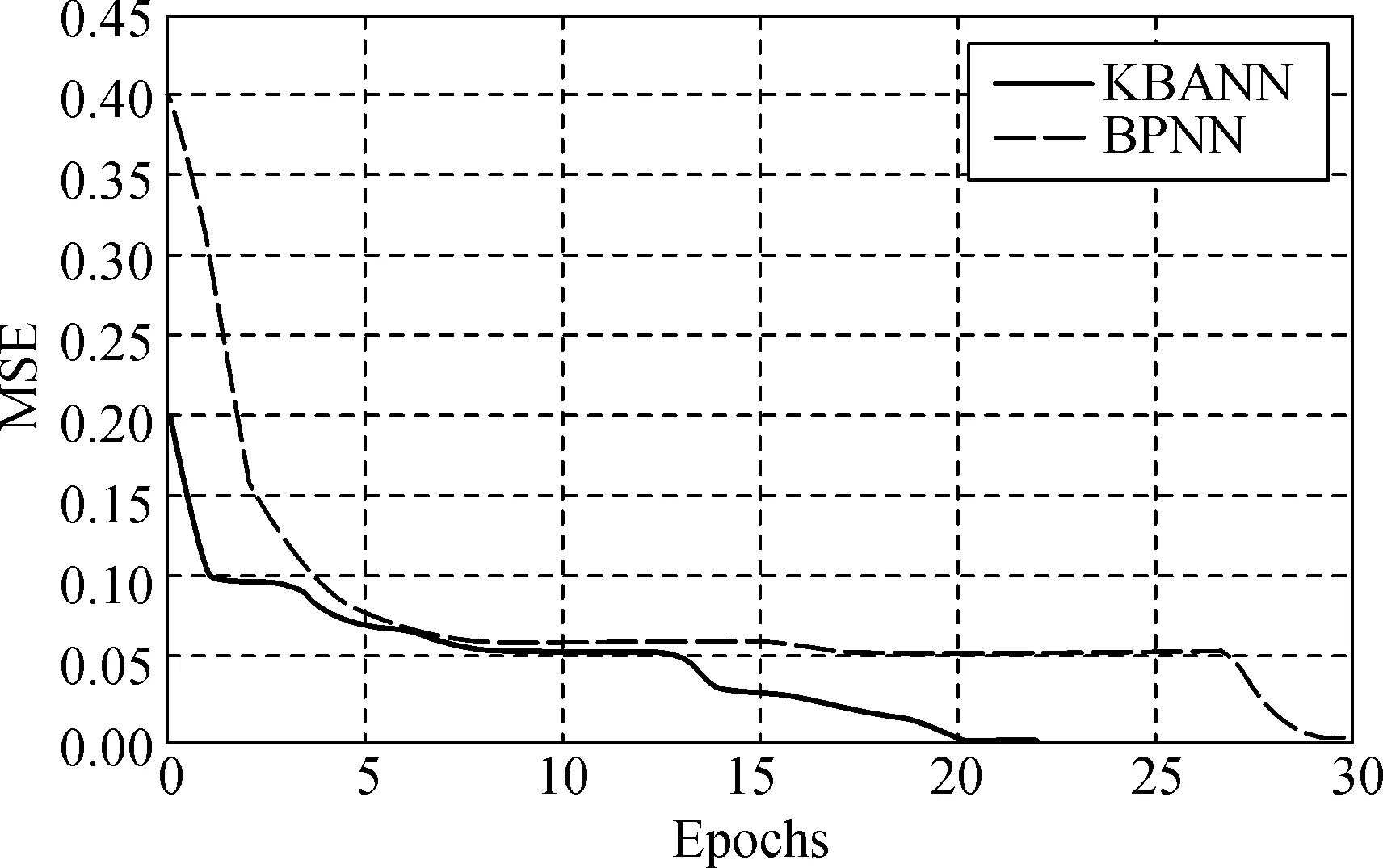

After the construction of the network topology of KBANN is completed, KBANN will further learn the knowledge of the training set, using back-propagation algorithm. In order to compare the performance of learning between KBANN and BP neural network (BPNN), BPNN using KBANN topology and related parameters while the initial weights and thresholds are randomly obtained in the range [-0.05, 0.05]. Shown in Fig.10, both the learning process curves show: compared with standard BPN, KBANN has a faster fitting speed and better training result.

Fig.10 Mean square error (MSE) curves of KBANN and BPNN training process

The reason that KBANN is better than BPN on training performance is: KBANN learns from the rules before training the initial implicit knowledge in the data, obtains the optimized initialized network weights, and speeds up network fitting process. When using back-propagation algorithm to learn knowledge further, it will fine-tune the initial network weights and thresholds, and learn knowledge of those missing. This process avoids complex process where the traditional ANN needs to constantly try to get a proper network structure, which further improves the learning performance.

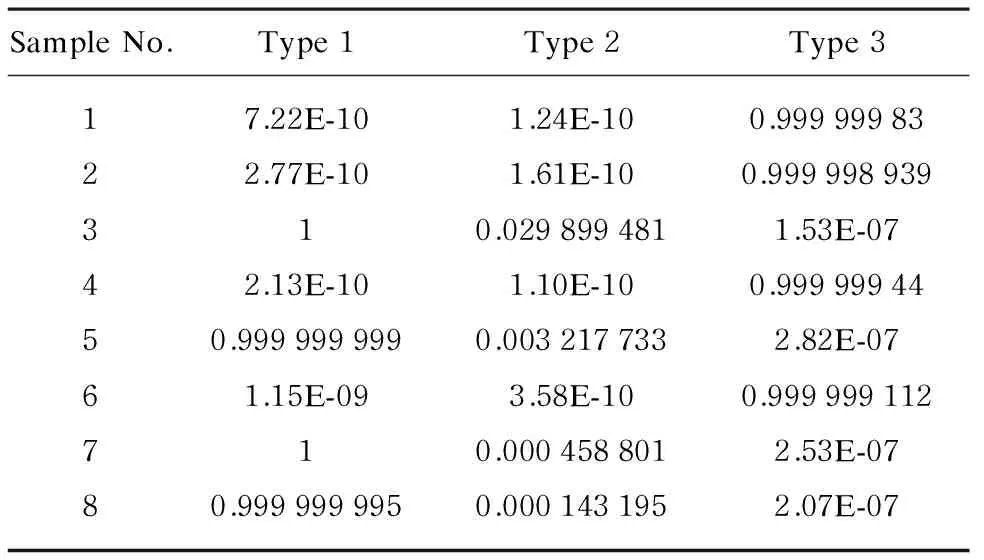

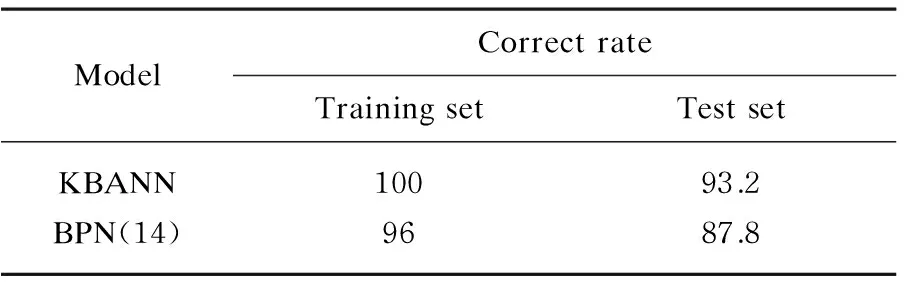

Table 6 shows the KBANN model predictions for some sample results and the effectiveness of KBANN to identify the type of yarn product quality, while Table 7 shows correct identification rate of yarn quality type of both method. KBANN identification results are better than the standard BPN. Experiments show that using KBANN for yarn manufacturing process quality classification and forecasting process status is valid.

Table 6 Predictions of the test set KBANN

Table 7 Recognition accuracy of KBANN and BPN/%

5 Conclusions

This study proposed a hybrid learning-based system for online monitoring and diagnosis of spinning process, where some key process parameters (i.e., system inputs) have very strong relationship with the quality of finished products(i.e., system outputs). In order to provide effective and accurate monitoring and diagnosis, a hybrid learning-based model by seamless integration of KBANN and RSRule is developed. RSRule can extract accurate and comprehensible rules to help operators accurately diagnosis abnormal processes and optimally set spinning process parameters. KBANN correctly learns knowledge from a training data set collected from spinning process. KBANN shows better performance than those of the standard BPNs when it is used for predicting the faulty quality category of the product on-line.

[1] üreyen M E, Gürkan P. Comparison of Artificial Neural Network and Linear Regression Models for Prediction of Ring Spun Yarn Properties: I. Prediction of Yarn Tensile Properties [J].FibersandPolymers, 2008, 9(1):87-91.

[2] Yin X G, Xiang Q, Lü Z J,etal. The Whole Virtual Manufacturing System for the Worsted Based on the Intelligent Technology [J].JournalofXi’anPolytechnicUniversity, 2008, 22(4): 407-411. (in Chinese)

[3] üreyen M E, Gürkan P. Comparison of Artificial Neural Network and Linear Regression Models for Prediction of Ring Spun Yarn Properties. II. Prediction of Yarn tlairiness and Uneveness [J].FibersandPolymers, 2008, 9(1): 92-96.

[4] Li X, Peng Z Q, Jin F Y,etal. Comparing Prediction Models for Worsted Yarn Performances Based on Neutral Networks [J].JournalofTextileResearch, 2011, 32(3): 51-56. (in Chinese)

[5] Evander E, Holst H, Jarund A,etal. Role of Ventilation Scintigraphy in Diagnosis of Acute Pulmonary Embolism: an Evaluation Using Artificial Neural Networks [J].EuropeanJournalofNuclearandMolecularImaging, 2003, 30(7): 961-965.

[6] Eng J. Predicting the Presence of Acute Pulmonary Embolism: a Comparative Analysis of the Artificial Neural Network, Logistic Regression, and Threshold Models [J].AmericanJournalofRoentgenology, 2002, 179(4): 869-874.

[7] Gebraeel N Z, Lawley M A. A Neural Network Degradation Model for Computing and Updating Residual Life Distributions[J].IEEETransactionsonAutomationScienceandEngineering, 2008, 5(1): 154-163.

[8] Tian Z G. An Articial Neural Network Method for Remaining Useful Life Prediction of Equipment Subject to Condition Monitoring [J].JournalofIntelligentManufacturing, 2012, 23(2): 227-237.

[9] Ribeiro B. Support Vector Machines for Quality Monitoring in a Plastic Injection Molding Process [J].IEEETransactionsonSystems,ManandCybernetics,PartC:ApplicationsandReviews, 2005, 35(3): 401-410.

[10] Lü Z J, Xiang Q, Li B Z,etal. Support Vector Machine with Real Code Genetic Algorithm for Yarn Quality Prediction [J].AdvancedScienceLetters, 2013, 19(8): 2468-2472.

[11] Li S, Liu L J, Xie Y L. Chaotic Prediction for Short-Term Traffic Flow of Optimized BP Neural Network Based on Genetic Algorithm [J].ControlandDecision, 2011, 26(10): 1581-1585. (in Chinese)

[12] Das S, Ghosh S, Majumdar A,etal. Yarn Engineering Using Hybrid Artificial Neural Network-Genetic Algorithm Model [J].FibersandPolymers, 2013, 14(7): 1220-1226.

[13] Josphat M I, Huang X B, Wang X H. The Use of Hybrid Algorithms to Improve the Performance of Yarn Parameters Prediction Models [J].FibersandPolymers, 2012, 13(9): 1201-1208.

[14] Kuo C F J, Chang C D, Su T L,etal. Optimization of the Dyeing Process and Prediction of Quality Characteristics on Elastic Fiber Blending Fabrics [J].Polymer-PlasticsTechnologyandEngineering, 2010, 47(7): 678-687.

[15] Ji R Y. Particle Swarm Optimization Neural Network in the Application of Traffic Flow Prediction [D]. Hangzhou: Zhejiang University of Technology, 2013. (in Chinese)

[16] Liu B, Xiang Q, Yang J G,etal. Combining the Genetic Algorithm with Artificial Neural Networks for Yarn Quality Forecasting [J].JournalofDonghuaUniversity:NaturalEdition, 2013, 39(4): 504-508.(in Chinese)

[17] Sette S, Langenhove L V. An Overview of Soft Computing in Textile [J].TextileInstitute, 2003, 94(1/2): 103-109.

[18] Lü Z J, Xiang Q, Yang J G. A Novel Date Mining Method on Quality Control within Spinning Process [J].AppliedMechanicsandMaterials, 2012, 224: 87-92.

[19] Xiang Q, Lü Z J, Yang J G,etal. Mining Rule of Quality Control for Spinning Process with Rough Set Theory[J].AppliedMechanicsandMaterials, 2011, 80/81: 1021-1026.

[20] Zhang X W, Wu Z W. Rough Set Theory and Method [M]. Beijing: People’s Posts and Telecommunications Press, 2007. (in Chinese)

[21] Yu J B. Studying of Manufacturing Process Quality Control Theory and Methodology Based on Intelligent Learning Model [D]. Shanghai: Shanghai Jiaotong University, 2009. (in Chinese)

[22] Yu J B, Xi L F, Zhou X J. Intelligent Monitoring and Diagnosis of Manufacturing Processes Using an Integrated Approach of KBANN and GA [J].ComputersinIndustry, 2008, 59(5): 489-501.

[23] Akkala A, Bhatt D, Devabhaktuni V,etal. Knowledge-Based Neural Network Approaches for Modeling and Estimating Radon Concentrations [J].EnvironmentalProgress&SustainableEnergy, 2013, 32(2): 355-364.

[24] Chandra R, Knight R, Omlin C W. Renosterveld Conservation in South Africa: a Case Study for Handling Uncertainty in Knowledge-Based Neural Networks for Environmental Management [J].JournalofEnvironmentalInformatics, 2009, 13(1): 56-65.

[25] Jha M N, Pratihar D K, Bapat A V,etal. Knowledge-Based Systems Using Neural Networks for Electron Beam Welding Process of Reactive Material (Zircaloy-4) [J].JournalofIntelligentManufacturing, 2014, 25(6): 1315-1333.

[26] Pawlak Z. Rough Sets [J].InternationalJournalofComputerandInformationSciences, 1982(5): 341-356.

[27] Wang G Y, Yao Y Y, Yu H. A Survey on Rough Set Theory and Applications [J].ChineseJournalofComputers, 2009, 32(7): 1229-1246.(in Chinese)

[28] An L P. Multi-attribute Decision Analysis Based on Rough Set Theory [M]. Beijing: Science Press, 2008. (in Chinese)

[29] Towell G G, Shavlik J W. Knowledge-Based Artificial Neural Networks [J].ArtificialIntelligence, 1994, 70(1/2): 119-165.

[30] Mitchell T. Machine Learning [M]. Beijing: China Machine Press, 2003.(in Chinese)

[31] Fernando S O, Bernard A. INSS: a Hybrid System for Constructive Machine Learning [J].Neurocomputing, 1999, 28(1/2/3): 191-205.

Foundation item: National Natural Science Foundation of China (No.51175077)

1672-5220(2014)06-0817-07

Received date: 2014-08-08

* Correspondence should be addressed to YANG Jian-guo, E-mail: jgyangm@dhu.edu.cn

CLC number: TS103.2 Document code: A

Journal of Donghua University(English Edition)2014年6期

Journal of Donghua University(English Edition)2014年6期

- Journal of Donghua University(English Edition)的其它文章

- Stress-Strength Structural Reliability Model with a Stochastic Strength Aging Deterioration Process

- Settlement Prediction of Dredger Fill with the Optimal Combination Model

- Condition-Based Maintenance Decision-Making for Equipment

- Identification of the Credit Guarantee Network of Steel Trade Enterprises in China

- Methods for Reliability Assessment under Irregular Time-Varying-Stress Degradation Testing

- Efficient Method for Accelerated Reliability Qualification Testing