A Task-oriented Modular and Agent-based Collaborative Design Mechanism for Distributed Product Development

LIU Jinfei, CHEN Ming, WANG Lei, and WU Qidi

1 School of Electronics and Information Engineering, Tongji University, Shanghai 201804, China

2 School of Mechanical Engineering, Tongji University, Shanghai 201804, China

1 Introduction

With the formation of global production network in the information-technology industry, new product research &development (R&D) is no longer confined to one city, region or country, and product development is involving multiple fields and disciplines. Product collaborative design (PCD)under the distributed heterogeneous environment has become the trend of product development[1–2]. Agent and multi-agent technology is one hotspot in research on distributed artificial intelligence. Multi-agent technology, with the abilities of distribution, coordination, self-organization, learning and reasoning, provides an integrated framework for parallel collaborative design of mechanical products[3]. Meanwhile,modularity is a prerequisite of distributed product development, and the performance of sub-modules directly affects the functions, efficiency and cost of the agent-based product R&D system[4].

So far, research has been carried out extensively on distributed product development with combined use of the modularity thought and Agent-based technology. A modularity method for PCD based on multi-objective oriented product lifecycle management (PLM) is proposed by using fuzzy mathematics to analyze the product construction, and thereby provides evidence for quantitative analysis of modularity[5]. The modularity requirements of the collaborative relationship between enterprises are studied by analyzing the restrictions of interface and the feasibility of modularity in four aspects as parts, modules, sub-systems and system[6]. In a modularity method of PCD based on clients, functions and structures, the design view model of product modularity constitutes product requirements,decomposition-based modularity, module combination and design evaluation[7]. A method for modular design of structural products is presented as an optimization to minimize the reduction of structural strength, while maximizing the manufacturability of the component sharing between two structures[8]. By expressing the correlation between product functions and structures with a similarity matrix, product modularity can be achieved by the filter conditions of the cohesion degree and the coupling degree and using an intelligent algorithm[9–10]. By applying multi-agent technology into collaborative design of mechanical products, the co-design unit construction was put forward, as well as the integrated method of heterogeneous design environment[11]. The structure of Agent has adopted a BDI (belief, desire, and intension) model based on linear temporal logic[12–13]. In the implementation, it is very complicated to map the concepts of BDI model to a specific Agent software tool. Therefore, it relatively lowers the modeling efficiency. A structure model of product data management for network collaborative was established on basis of a multi-agent system[14]. A product component agent model combining the Agent theoretical model and the product model was proposed on basis of multi-layer finite state machine for product design, which can effectively improve the PCD capability[15–16].

The above research provides many valuable thoughts and methodologies, but the following problems also need to be further discussed and improved.

(1) Obtaining the task-modules is a prerequisite for distributed product development, and previous research concentrates on the interaction and impact of the main components in the modules by quantifying the relationship between product functions or structures, but the executability of task-modules is rarely discussed.

(2) In the research field of distributed product collaborative development, multi-agent systems of PCD have to face the problem of product life cycle. The lack of a universally-agreed expandable system model for the top-down design of distributed product development does not facilitate knowledge sharing and mining, and has inhibited further development of PCD.

(3) Under distributed heterogeneous environment, the available resources, R&D capability, and software/ hardware configurations of collaborative agents are different. Therefore,constructing a reasonable mechanism of reasoning and decision of agent is still a vital problem to implement task-modules for distributed product development.

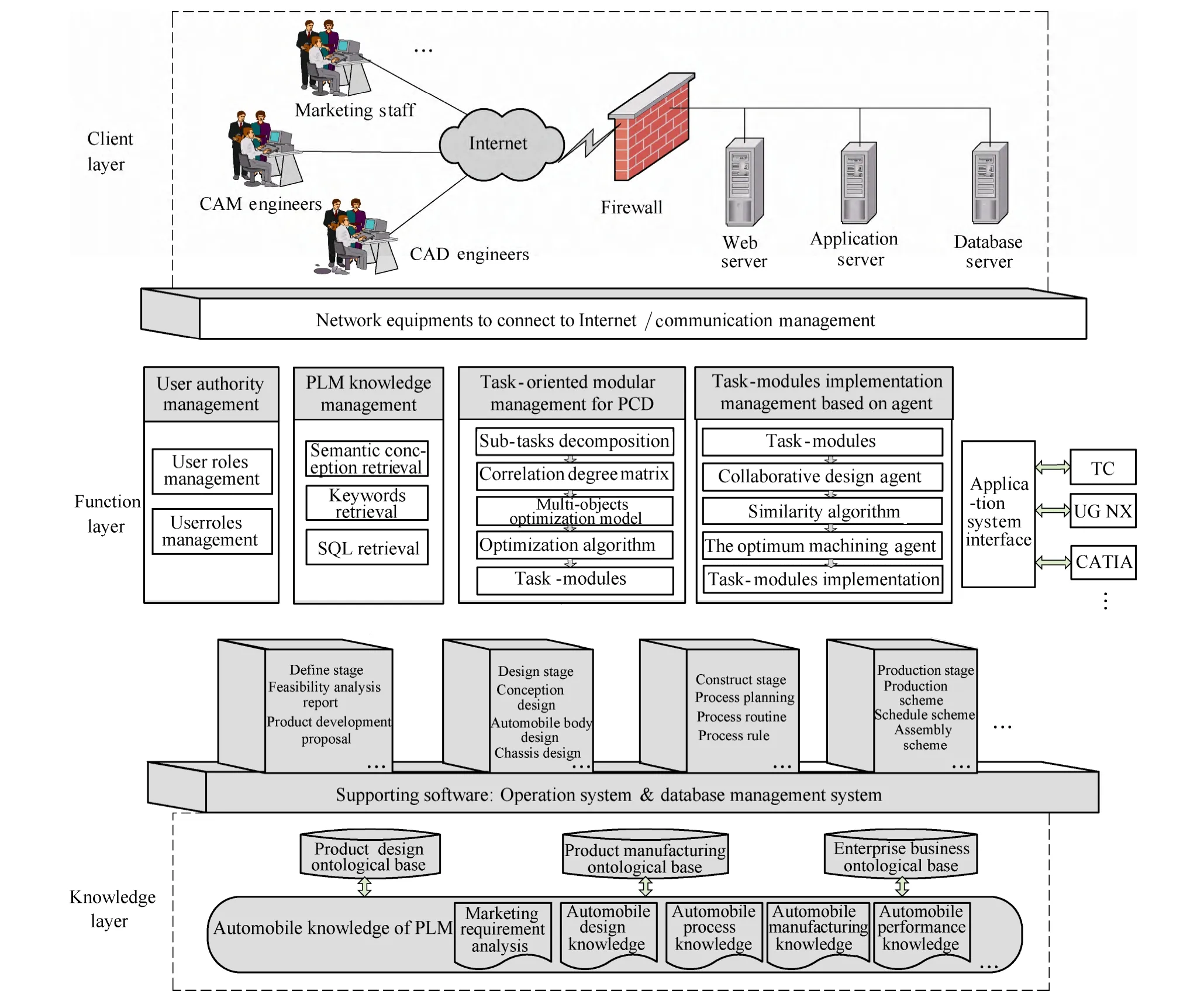

Given the above requirements, a collaborative design mechanism for PCD is presented based on the combination of modularity thoughts and Agent technologies. A mathematic model of product modularity is constructed through discussing the three aspects of module cohesion degree, module coupling degree, and module executable degree. To simplify the mathematic model to a continuity problem with a known number of variables, a modified PSO is used to optimize the mathematic model and partition modules. Moreover, the agent structure model for collaborative design is put forward, and the optimism matching agents are selected by using similarity algorithm to implement different task-modules by the integrated reasoning and decision-making mechanism with the behavioral model of collaborative design agents. On this basis, a B/S-based R&D platform for automobile collaborative design is developed.

2 Process Model based on Task-oriented Modular and Agent for PCD

The purpose of collaborative design is to meet customer requirements for product functions, and the requirements dictate the specific parts of structures and design tasks. The product functions and structures are the operation objects in the process of PCD with the implement ligament of the logical relationship between tasks and timing constrains. The process model based on task-oriented modular and agent for PCD should achieve the following mapping relations.

(1) The mapping from the product abstract model of customer demands to multi-level design sub-tasks;

(2) The mapping from the design sub-tasks to the executable task-modules for PCD;

(3) The mapping from the task-modules to the Agents under the distributed heterogeneous environment.

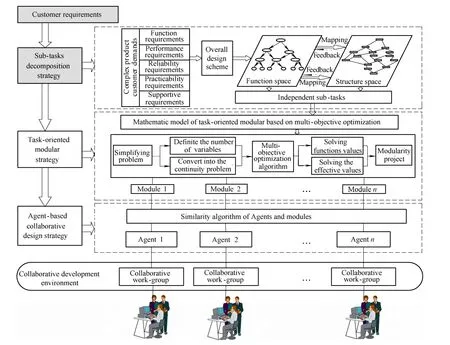

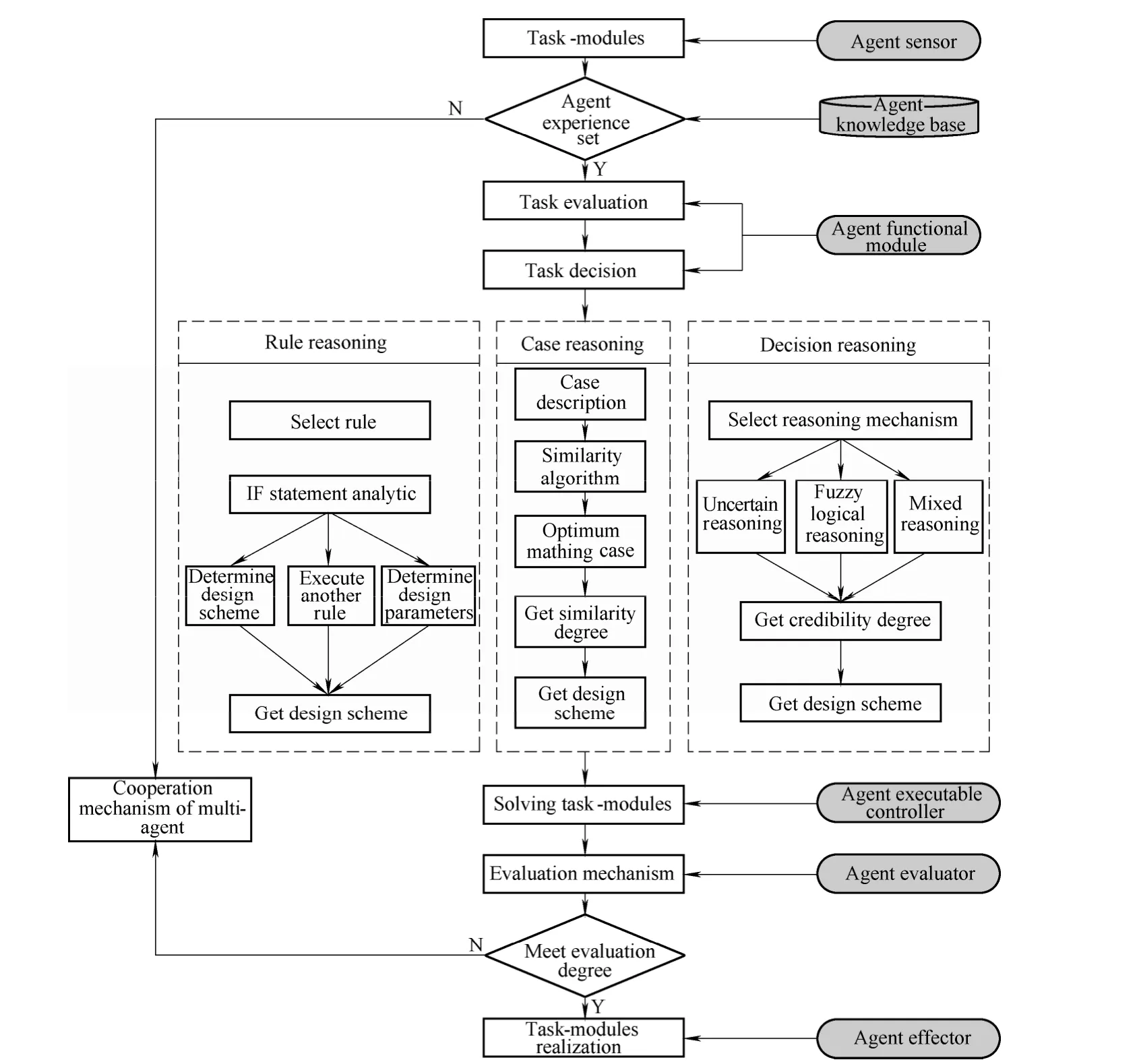

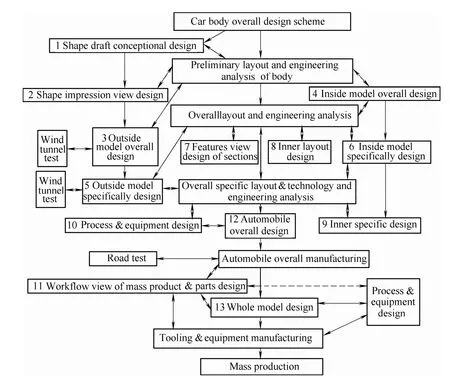

Based on the above analysis, the process model based on task-oriented modular and Agent for PCD is established(Fig. 1).

First, the overall design scheme is determined by analyzing customer requirements. With the function decomposition of the design plan and component decomposition of all levels of structures, the layer-by-layer analysis from the customer requirements to independent sub-task units is achieved by using the mapping relationships between functions and structures[17]. Then, the executable task-modules are obtained by adopting the modified PSO to solve the multi-objective optimization model. Finally, by using the similarity algorithm of task-modules and Agents,the most suitable Agent is matched to the modules. With the cooperation and collaboration of Agent to solve the task-modules, PCD is implemented.

3 Sub-task Decomposition Strategy for PCD

With the rapid development of economic globalization,incorporate annexation and purchasing becomes a pattern of distributed technology centers, which requires new product development achieved by R&D groups under distributed heterogeneous environment. The purpose of modularity is to simplify problem solving by decomposing design sub-tasks into executable task-modules, and thereby to achieve concurrent collaborative design of products.Modularity is the key of PCD.

However, it is not easy to map from the function to the structure if the products are decomposed by function, it is not convenient to extract the creative design elements if the products are decomposed by structure, and it is not easy to control the appropriate granularity of decomposition if the products are decomposed by work flow. Given these problems, a mixed method of product sub-task decomposition (Fig. 2) was proposed in this paper. With this method, the sub-task decomposition of the function, the structure and the task was carried out one after another to achieve the layer-by-layer modular analysis from the top-level products to the bottom-level task nodes.

Fig. 1. Process model based on task-oriented modular and agent for PCD

Fig. 2. Sub-task decomposition based on mixed structure for PCD

Firstly, by analyzing the general function for product development, the general function will be decomposed into many independent sub-functions. And to determine the workflows that be used to achieve sub-functions, the workflows will be decomposed into many sub-tasks. Then,the physical sub-structures of product can come from sub-tasks, and the functions can be obtained by performing one-to-one functional mapping. By repeating above steps from functions-structures-tasks, the complicated product will be decomposed into the independent and creative sub-tasks.

4 Task-oriented Modular Strategy Based on Optimization Algorithm

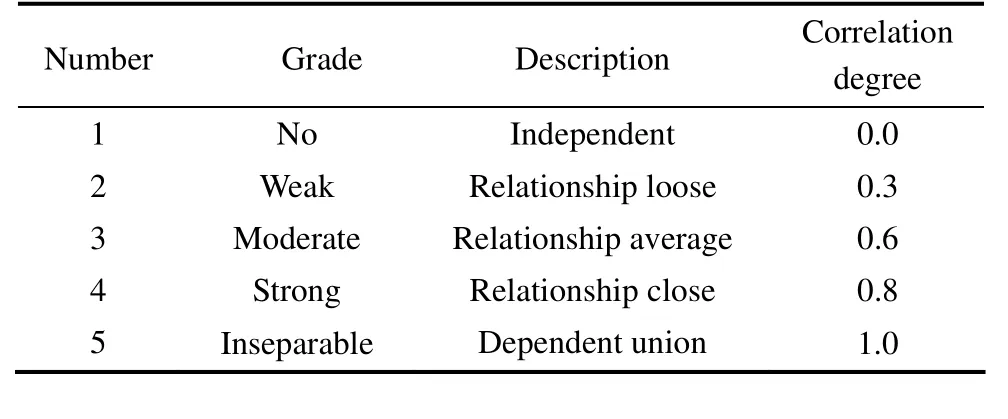

In the process of PCD, modules are composed of independent sub-tasks. In order to achieve the modularity,it is necessary to discuss the interactive relationship of sub-tasks. According to the correlation strength between design tasks, quantifying the correlation degree of their dependent relationship is a prerequisite for product modularity. The relationship of sub-tasks needs to be analyzed by considering the synthesized factors that affect various segments of task interaction. In this paper, the correlation degree of sub-tasks is divided into 5 levels: no,weak, average, strong and inseparable. The relationship of sub-tasks can be quantified by assigning a value to each correlation grade (Table 1).

Table 1. Definition of sub-tasks correlation degree

4.1 Mathematic model of task-oriented modular

Reasonable modularity can be used to lower the complexity and constraints of information exchange in solving sub-tasks, help collaborative product development,shorten product development cycle and reduce production cost. The evaluation indexes of modularity include module cohesion degree and module coupling degree. A higher cohesion degree means better aggregation of sub-tasks,which solves modules rapidly through information interaction. A lower coupling degree means more independence of modules that contribute to module modification and reuse. In the current mode of production,the product design is involved in multi-region, multi-field,and multi-department. Under distributed heterogeneous environment, the available resources, R&D capability, and design concepts of collaborative groups are different.Therefore, the module executable degree should be introduced in product modularity. The mathematic model of task-oriented modular is constructed to maximize module cohesion degree and minimize module coupling degree, while considering the module executable degree as a restriction.

4.1.1 Problem description of task-oriented modular

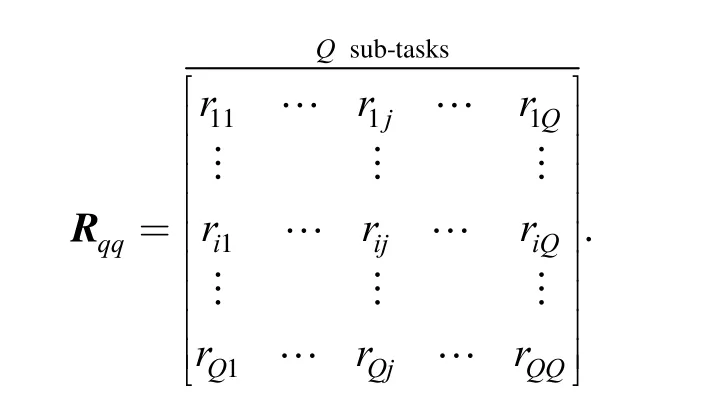

We assume that product P comprises of Q independent sub-tasks, and the function set is P={t1, t2,…, tQ}, namely,Meanwhile, product P comprises of K modules {M1, M2,…, MK}, namely∪…MK. And module k comprises of Dksub-tasks:

rijis the correlation degree between task i and task j.The correlation matrix of sub-tasks is

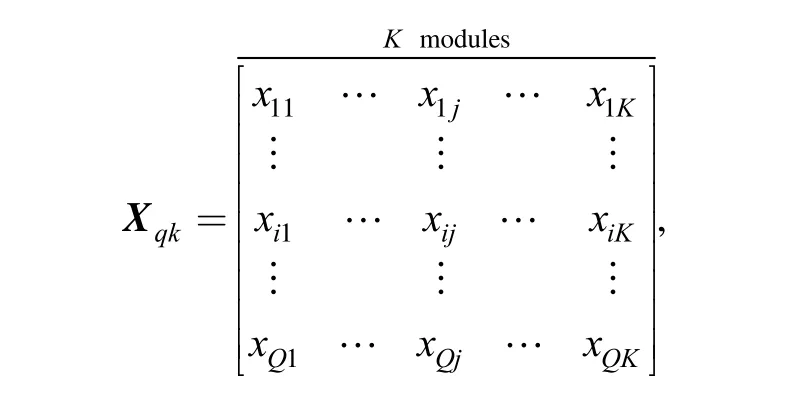

The solving variables matrix is

4.1.2 Definition of objective functions of task-oriented modular

The objective functions based on multi-objective optimized decomposition will evaluate a given decomposition as a weighted sum of the following criteria:(1) the close cohesion of sub-tasks is included in modules,and modules are well polymerized; (2) the strong independence of the individual module, and the coupling of modules is small; (3) a collaborative R&D group can easily achieve the design sub-task in modules, and the module executability is high.

Based on the above analysis, the objective functions of task-oriented modular are as follows: module cohesion degree, module coupling degree, and module executable degree.

(1) Module cohesion degree

Cohesion is a measure of the correlation among the constituents of a module. Module cohesion degree is expressed as the average of all correlation degrees of sub-tasks in modules. The cohesion degree of module k is defined as

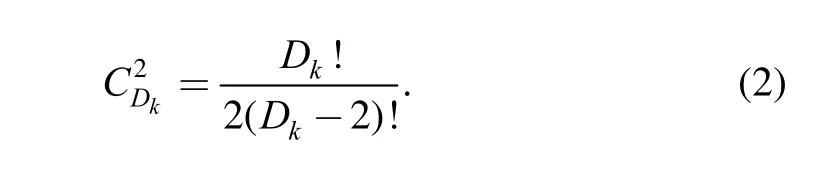

where rijis the cohesion degree between task i and task j;is the combination of two tasks in module k,

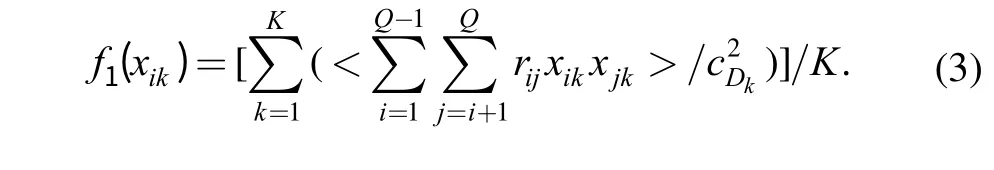

The cohesion degree of all modules can be written as

(2) Module coupling degree

Coupling is a measure of the correlation among constituents between different modules. Module coupling degree is expressed as the average of all correlation degrees of sub-tasks between modules. The coupling degree between module a and module b is defined as

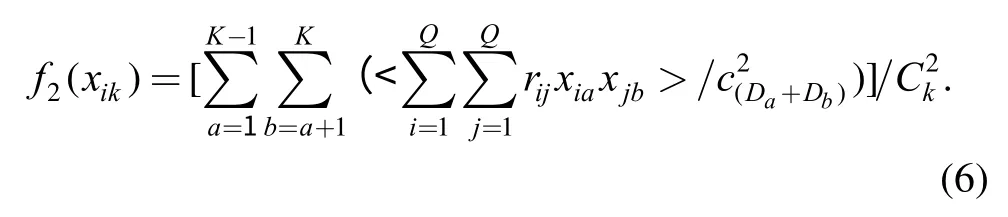

The coupling degree of all modules can be evaluated as

(3) Module executable degree

Under distributed heterogeneous environment, the software/hardware configurations of collaborative R&D workgroup, as well as the task solving abilities are different.The ability (actual and potential) of solving task-modules is the key of task modularity decomposition. In this paper, the concept of module executable degree is proposed to discuss the modular executability in modularity decomposition.

Definition 4.1. Module executable degree means the ability of collaborative groups to solve modules under distributed heterogeneous environment. We assume S R&D teams join in PCD.

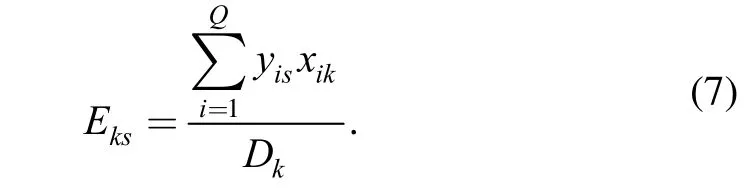

The executable degree for work-team s to solve module k is defined as

The executable degree for solving module k can be written as

Module executable degree can be expressed as

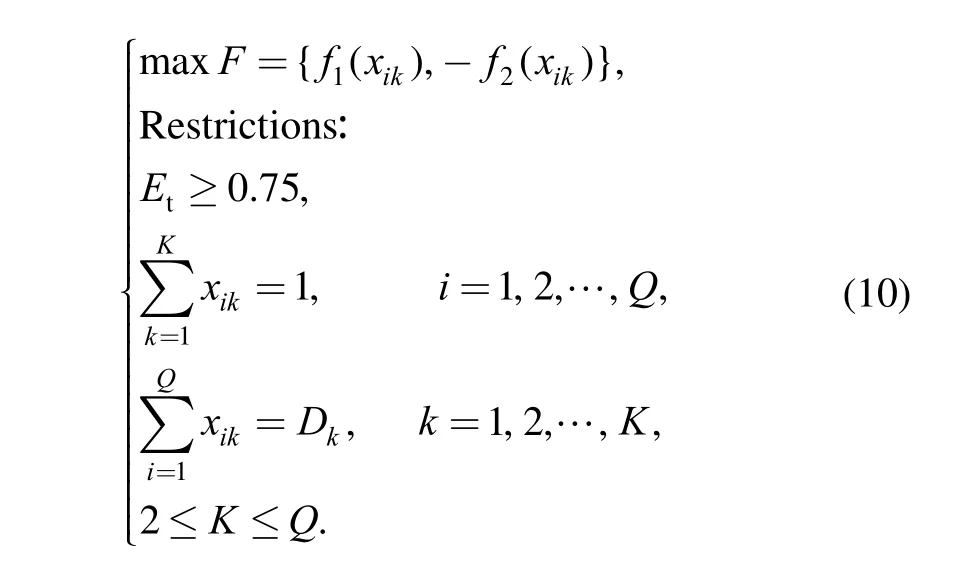

4.1.3 Mathematic model of task-oriented modular

With maximizing module cohesion degree and minimizing module coupling degree as the main objectives of module decomposition, and with the module executable degree as the evaluation index, the mathematic model of decomposition-based modularity is constituted below. The optimized objects are the module cohesion degree and the module coupling degree, the solving variables are K and xik,and the restriction qualification is the module executable degree. The threshold value of the module executable degree as the evaluation index is set to direct 0.75, namely,Et≥0.75. The optimization problem of product modularity can be abstracted to the following mathematical model:

On basis of satisfying restrictions, all sub-tasks are organized to become the optimized modules with a high cohesion degree and a low coupling degree, and meanwhile,the executable degree is up to the threshold.

4.2 Optimization algorithm of task-oriented modular

4.2.1 Simplifying mathematic model

Model (10) is the 0-1 discrete problem belonging to a classical NP problem. Two problems make it difficult to solve the model: (1) the number of variables changes with the number of modules; (2) the model to be solved belongs to a 0-1 discrete problem. In order to solve this problem,the mathematic model should be simplified as follows.

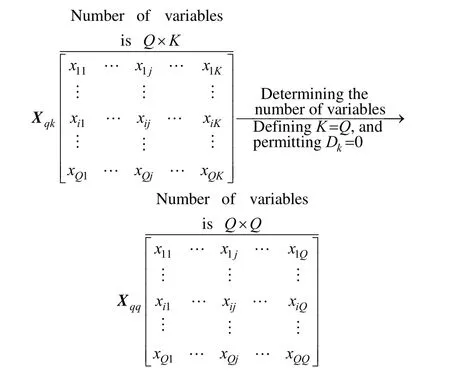

(1) If the number of modules K is equal to Q, and Dkcan be 0, then module k contains no sub-tasks and will be deleted. Therefore, the correlation matrix between modules and sub-tasks becomes a Q×Q square matrix, and the number of variables is Q×Q. As a result, the number of solving variables becomes definite (Fig. 3).

Fig. 3. Determining the number of variables

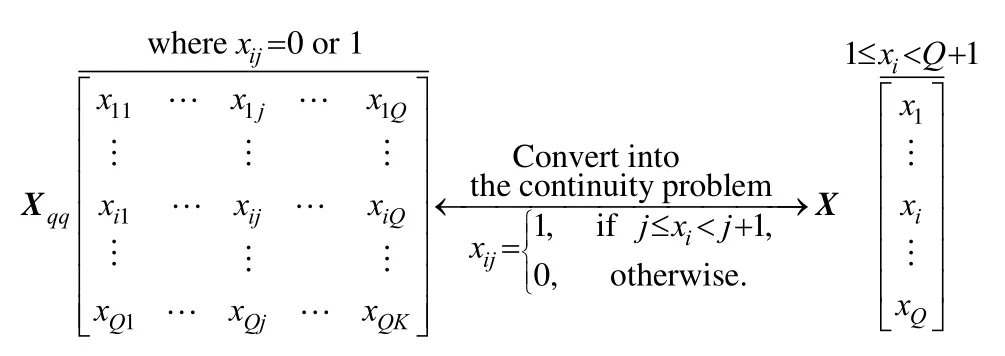

(2) The number of variables is simplified from Q×Qtoand value i can be obtained as follows:

By defining the variable xi–values range from 1 to Q+1,the value of xican be set a serial discrete value of 0-1 based on Eq. (11). As a result, the discrete 0-1 matrix is transformed into the vector with continuity value (Fig. 4).

Fig. 4. Converting into the continuity vector

4.2.2 Optimization algorithm

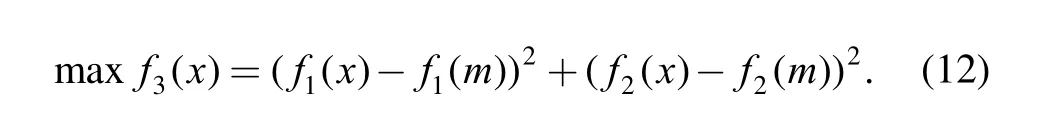

According to the simplification of the mathematic model, the problem to be solved is transformed into a continuity problem with a known number of variables based on the multi-objective optimization. PSO is adopted to solve the mathematic model. The use of evolutionary algorithms to solve multi-objective optimization problem will generally obtain an efficient solution set, but in the problem of product modularity, an effective and optimal solution is needed. Generally two steps are needed to find the optimal solution: first, solve the optimal value of the object, and second, solve the effective value. The traditional method makes optimization problem complex and low executable efficiency. The modified PSO based on Refs. [18–20] is adopted to optimize the mathematic model by calculating the values of the object functions and the optimal solutions at the same time. The algorithm flow is shown in Fig. 5.

Fig. 5. Flow of the modified PSO

The specific steps of optimization algorithm are as follows.

Step 1: Initialize particle population: the population size N, location xiand speed viof particle i, the correlation matrix of sub-tasks and modules obtained by Eq. (9) to deal with xi.

Step 2: Optimize fj( m) by calculatingN).

Step 3: Construct the function:

Step 4: Calculate the overall optimal points gBest[j] of each function fj(x ) j=1, 2, 3, and theas the gBest.

Then find the local optimal point of pBest[ i] by randomly selecting one value in the four points:pBest[ i , j](i=l, 2,…, N) and

Step 6: Update locations and speeds of all particles by the basic formula of PSO[19], solve xijand find the correlation matrix of sub-tasks and modules by Eq. (11) to deal with the xi.

Step 7: If it has been satisfied with termination condition,calculate the functions values as follows:

Else, return to step 3.

5 Collaborative Design Strategy Based on Multi-agent

Agent technology originates from research in distributed artificial intelligence, where the activities of the system are distributed among multiple nodes for cooperative problem solving. Various researches have been conducted into applying intelligent agent-based technology toward real-world problems[21]. There has been considerable growth of interest in the design of a distributed, intelligent society of agents capable of dealing with complex problems and vast amounts of information collaboratively.Furthermore, there has been a rapid growth in developing and deploying intelligent agent-based systems to deal with real-world problems by taking advantage of the intelligent,autonomous, and active nature of this technology[22]. Since agent technology provides flexible, distributed, and intelligent solutions for collaborative work, researchers have proposed to design and develop numerous intelligent agent-based systems to support PCD. The main benefits of an agent-based approach come from its flexibility,adaptability, and decentralization.

5.1 Structure model of agent for collaborative design

Despite the lack of unified definitions and structural patterns, Agents have to meet the same requirements in autonomy, independence, communication, self-learning,and other aspects[23–24]. PCD requires that the design links of different modules and different design aspects can be carried out in parallel and in coordination with each other so as to detect and solve the design problems[25]. The modules as the design units in collaborative design are independent and connected by standard interface. Therefore,a series of Agents can be constructed by the partial design tasks of each product’s functional module, and parallel collaborative patterns are used to complete product design.

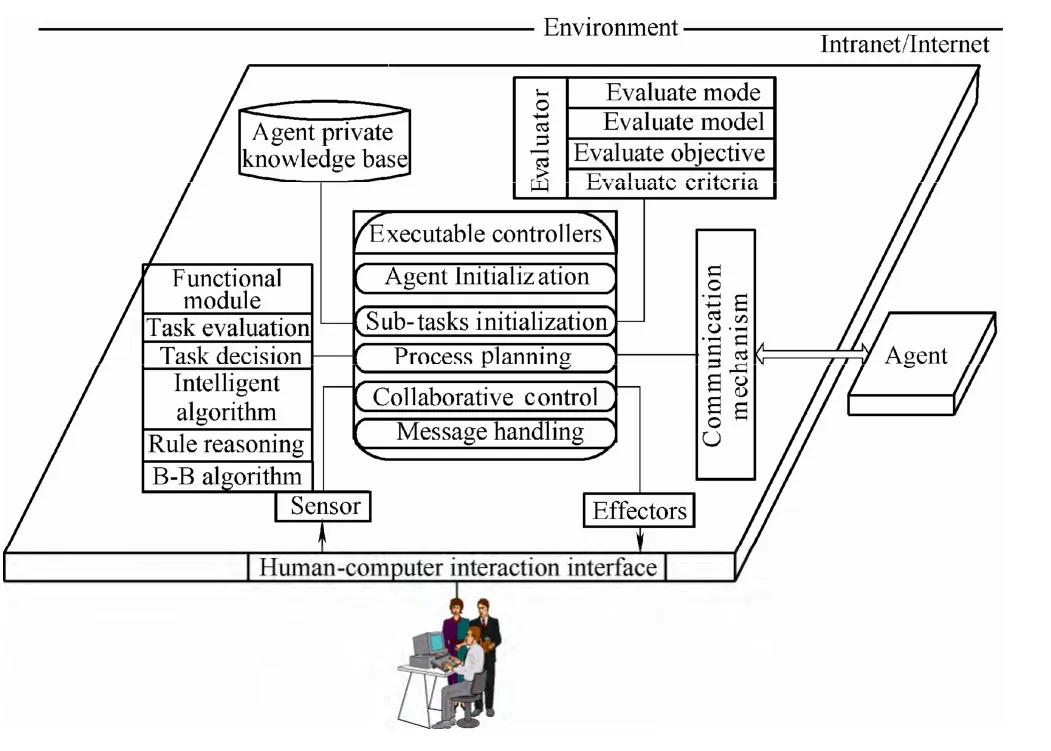

Agent for collaborative design will plan and solve the local problem of modular design by using design-related knowledge. Each Agent is a knowledge system that solves the modular design problem by using its knowledge base.But the complexity of the solving problems and the size of knowledge base are less than the requirements of centralized design. Fig. 6 shows the Agent structure model for collaborative design.

Fig. 6. Agent structure model for collaborative design

The main components comprise of a human-computer interface, a sensor, effectors, executable controllers, a functional module, evaluators, a communication mechanism, and a private Agent knowledge base. Their functions are as follows.

(1) Sensor: Accepts information from the external environment, converts it into identifiable information in Agent, and activates the executable controller.

(2) Effectors: Accept the information of implementation machine, and pass it into the environments as required by the export constraint set.

(3) Executable controller: completes the design sub-tasks by support of Agent functional modules and the knowledge base according to the design constraints submitted by sensors. Main tasks: initialization of agent and design task,module design planning, collaborative design control,message processing, etc.

(4) Functional module: Agent carries out product and project design based on knowledge. Various functional modules are the tools for performance of knowledge- based design, and have the specific design algorithms to achieve the design features. It mainly comprises of design task assessment, design task decision-making, collaborative rule algorithm, and collaborative reasoning algorithm.

(5) Evaluator: Provides the opinion of solving scheme and compares the object parameters and design requirements or standards to support the designer with the optimal design project. It comprises of an evaluation mode,an evaluation model, an evaluation objective, and evaluation criteria.

(6) Communication mechanism: Deals with the information exchange between Agent and the environment,and achieves multi-agent collaboration and consultation. It includes message processors and s network interface, then receives and sends thread and other components.

(7) Private knowledge base of Agent: Stores Agent’s own basic knowledge, including name, design tasks,task-related data and design knowledge, URL address, and communications ports.

5.2 Similarity algorithm between agents and modules

In the majority of cases, it is hard to find the optimal similar Agent that matches with the module in a multiagent system. This problem can be effectively solved by quantifying the agent-module matching degree with the similarity degree. The modules as the task set, and the Agents knowledge base are defined as a historical experience set, so that the agent-module matching degree can be converted into the similarity degree between the historical experience set and the task set.

Definition 5.1. A module task set is the aggregate of all tasks to be solved in modules M={t1, t2,…, tn}, and element t as the attribution of module task set is the requirement of the software/hardware of design tasks.

Definition 5.2. A historical experience set is the aggregate of all abilities to achieve tasks of agent private knowledge base N={e1, e2,…, em}, and element e as the attribution of experience set is the ability restriction of solving design tasks.

Let the module task set and the experience set of Agent as random variables, and the elements of each dimension as the properties of the random variables, then their similarity degree will be the matching problem of their properties.

Each element of Agents and modules is matched. If the design requirements of a module are consistent with the capacity constraint of an Agent, the similarity is 1, otherwise it is 0. By assigning a specific weight to each design requirement by weighting each similarity degree of all design requirements,the integrated similarity will be calculated as follows:

where siis the similarity degree of task i in module, and ωIis the corresponding weight.

Then the similarity degrees of the task set of all modules and the experience set of all Agents knowledge-base are calculated, and the optimal matching Agent will be selected by ordering S from large to small to solve the module.

5.3 Behavioral model of collaborative design agents to implement task-modules

Collaborative design agent adopts integrated reasoning and decision-making mechanism to solve task-modules. First,agent obtains task demand information via the sensor. If agent has the solution set including knowledge and experience to solve the task, the task will be solved by an executable controller by using the reasoning mechanisms of functional module, otherwise through cooperation with other agent. After the task is solved, agent evaluator makes an appraisal. If the solution is not up to the evaluation index, the task needs to be resolved through agents’ cooperation for the new solving solution. The behavioral model of collaborative design Agents to implement task-modules is shown in Fig. 7.

Fig. 7. Behavioral model of collaborative design agents to implement task-modules

Rule reasoning: The functional module of Agent assesses the design task to obtain the necessary conditions of solving task, and form the complete solution rules. The executable controller of agent implements task-modules by searching the private knowledge base to find each corresponding design parameter.

Case-based reasoning: Sub-tasks need to be described as Agent-knowing formats as the first step of CBR to solve task-modules. A sub-task is composed of task ID, task description, and solved solution. In this paper, Euclidean distance of the nearest neighbor law is adopted to scale the case similarity[26]. Let X be a new case, and Y be an old one.Then their similarity is calculated as follows:

where xiis the ith attribution of the new case, and yiis that of the old case.

Decision reasoning: If the largest case similarity degree is below the pre-set value, the task-modules will be solved by decision reasoning. First, the functional module of agents searches a method from the reasoning machine including uncertainty reasoning, fuzzy reasoning and mixed reasoning, and then selects the decision rules to create a logical expression of rules. To assign values to design parameters by engineers in collaborative environment, the solution solving task-modules will be obtained. Finally, the executable controller of agents implements the corresponding command to solve task-modules.

6 Experimental Analysis

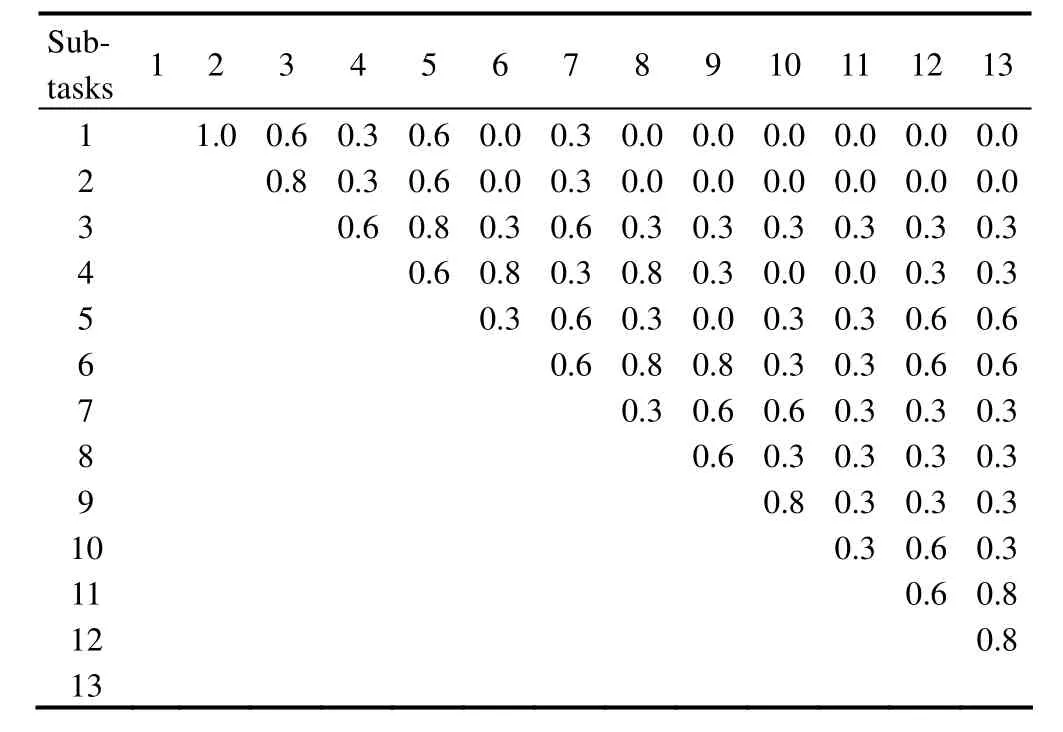

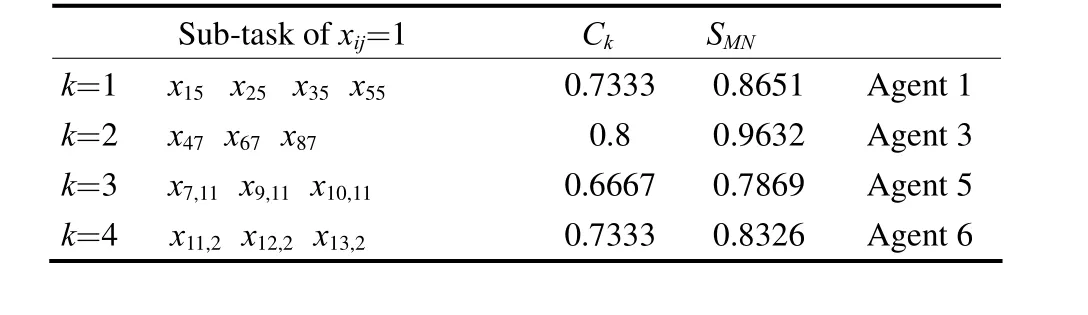

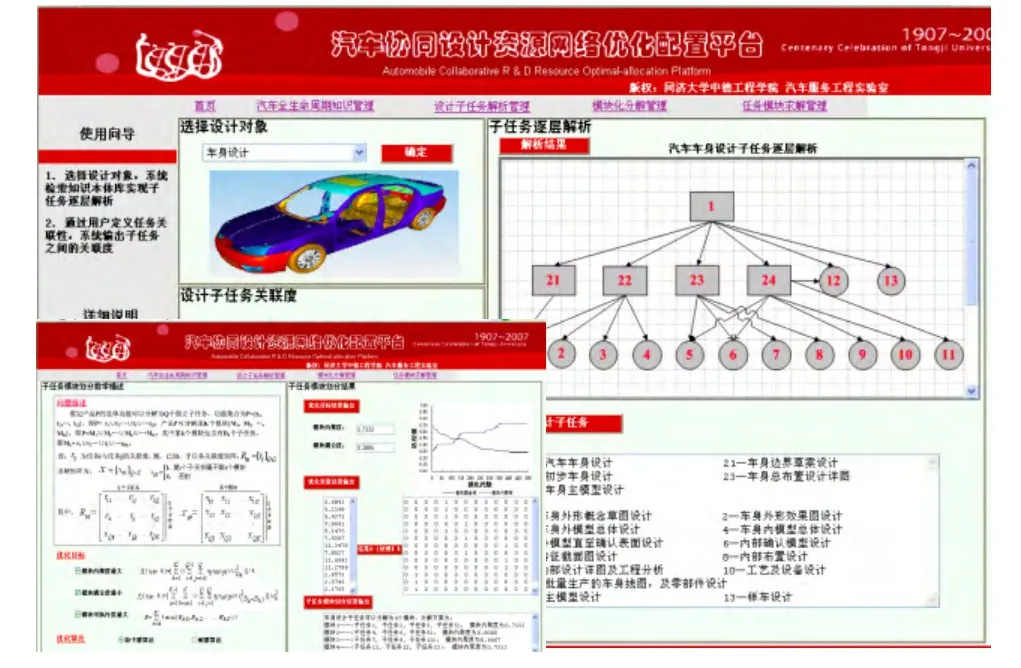

In this section, a case study on design task modularity in collaborative design of automobile bodies is described.According to the R&D situation of an automobile manufacturer, the entire design process of the automobile bodies is divided into 13 independent sub-tasks (Fig. 8).According to the situation of information exchange between sub-tasks with the quantification method, the correlation degree is obtained (Table 2). On basis of the decomposition-based modularity of automobile design, the most suitable agents are selected to solve design sub-tasks of modules so as to achieve collaborative design of automobile bodies.

In accordance with section 4.1 constructing mathematic model of modularity decomposition for the above problem,the modified PSO described in section 4.2 is used to optimize the model. Instruction: the swarm populations are 200, the optimal generations are number 500, the inertial coefficient is 0.4, the acceleration is 1.494 and sub-tasks are 13. VC++ used to compile the program, while the mathematic model is optimized and simulated by Dell PRECISION T3400 workstation. Fig. 9 shows the variable matrix of sub-task modularity during PSO optimization. Rqqis the correlation matrix of sub-tasks, X is the matrix of optimization variables,and Xqkis the correlation matrix of sub-tasks and modules after dealing with matrix X by Eq. (11). The optimized module cohesion degree is 0.733 3, and the module coupling degree is 0.288 5. The historic values of optimization functions in running of the modified PSO are showed in Fig. 10.Therefore, the optimized modules are {1, 2, 3, 5}, {4, 6, 8},{7, 9, 10}, and {11, 12, 13}.

Fig. 8. Design of automobile bodies

Table 2. Quantifying sub-tasks correlation degree of automobile bodies design

Fig. 9. Variables matrixes of modularity in the process of PSO

Fig. 10. Historic values of optimization functions in the run of the modified PSO

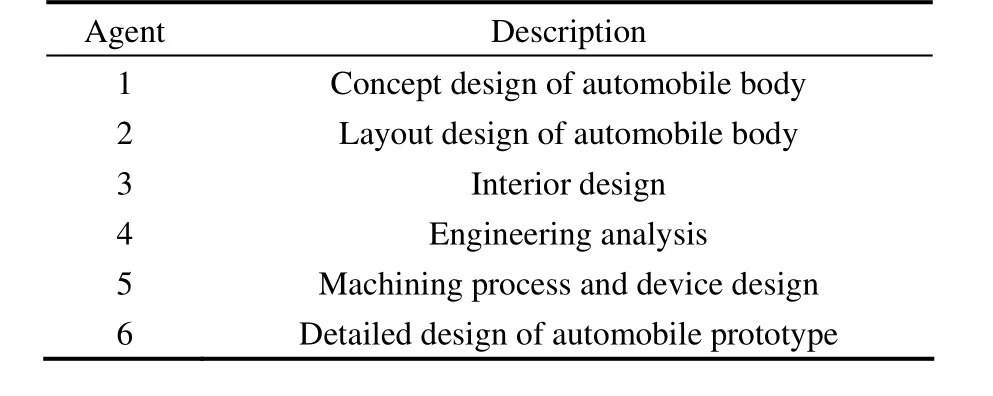

The automobile manufacturer has three branches in Shanghai, Nanjing and the United Kingdom respectively,and there are a couple of collaborative groups in each branch. If each collaborative group is defined as an Agent,the number of agents is 6. Table 3 shows the descriptions of the Agent private knowledge base. The similarity degree of modules and Agents is calculated by Eq. (15) described in section 5.2, and Table 4 shows the best similarity of Agents with modules. Therefore, based on the modularity decomposition, the design of automobile bodies can be decomposed to 4 modules, which are solved by cooperation and collaboration of agents at global scale.

Table 3. Description of agent experience set

Table 4. Optimum agent for solving task-modules

7 System Design and Implementation

Based on the above related key technologies, a practical prototype system (B/S-based R&D platform for automobile collaborative design) is developed. The logic architecture of prototype system is shown in Fig. 11. This system adopts three-tier framework: a client layer, a functional layer, and a knowledge layer.

(1) The client layer mainly consists of a cooperative module supported by Web browser and enterprise other application system, and provides the system operation interface for all participants during collaborative development. The Web browser explains hypertext mark language to UI which can be understood by users, and supports Plug-in and Active X. The client layer is made up of all users who are involved in R&D,including CAD designers, CAE analysts, and CAM manufacturing personnel.

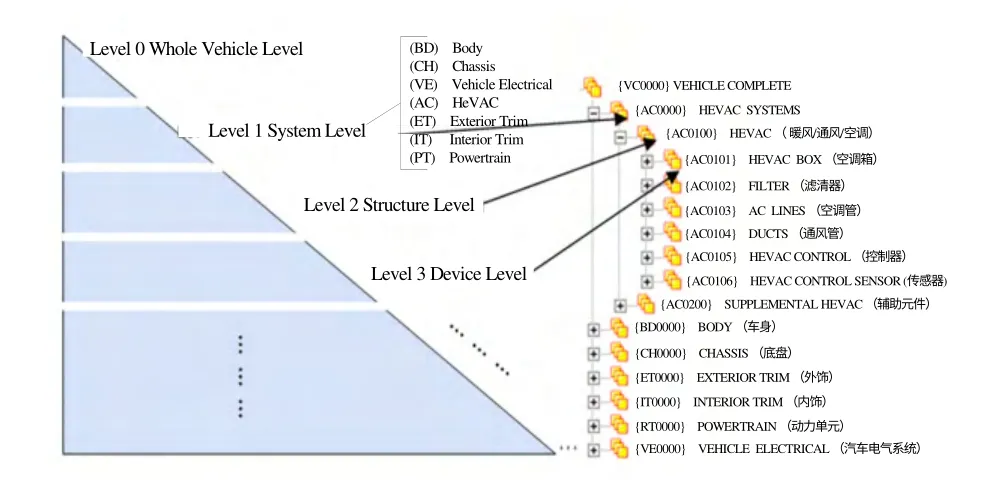

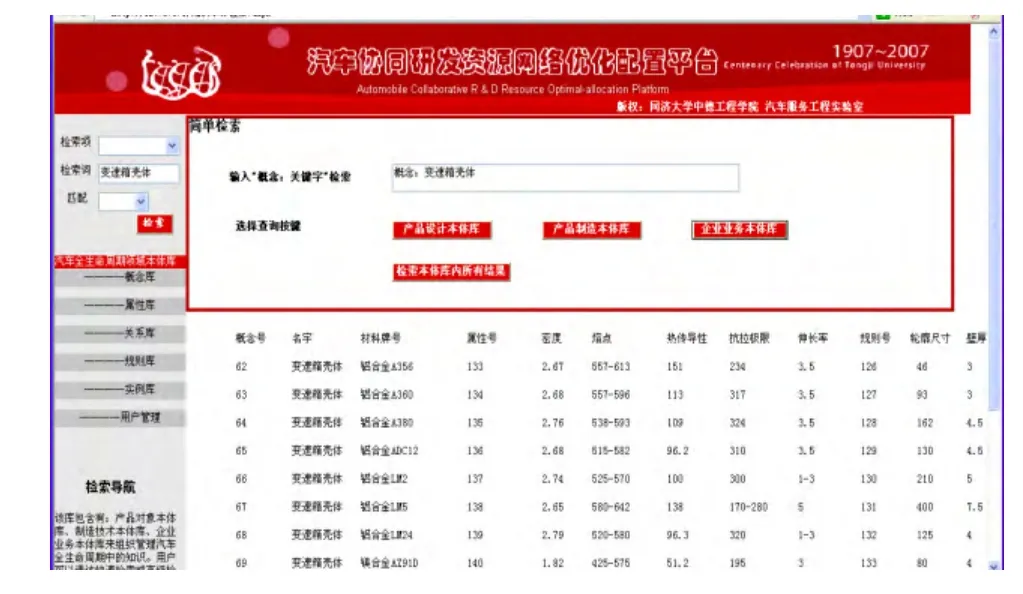

(2) The knowledge layer covers all the relative knowledge of the automobile lifecycle including product requirement,design, manufacturing, product assembly, resource organization scheduling, sales and services. Information inside and outside the enterprise can be effectively integrated through the ontology organization expression based on semantics. As a data management network, it consists of a product design ontology base, a product manufacturing ontology base, and an enterprise business ontology base. It provides access to different types of databases and electronic warehouses. The concept hierarchy generation for automobile knowledge is shown in Fig. 12. The knowledge management module of this system is shown in Fig. 13.

Fig. 11. Architecture of B/S-based R & D platform for automobile collaborative design

Fig. 12. Concept hierarchy generation for automobile knowledge

Fig. 13. Knowledge management of the prototype system

(3) The functional layer is the core of the R&D platform for automobile collaborative design, and it almost integrates all the system’s business logic functions. This layer is divided into four modules: user authority management, PLM knowledge management, task-oriented modular management for PCD, and Agent-based task- module implementation management.

When a user loads the system for the first time, he needs to input basic information to the register. Then the administrator verifies the user’s information, sets the user a role, and gives certain privileges. Different privileges can use different system resources and functions. The user authority management UI is shown in Fig. 14.

The user fills in the user name and password for logging in this system, and can retrieve knowledge and information in PLM knowledge management UI. For example, if the user inputs the keyword “gear-housing” and clicks the button of product design ontology base, the relevant knowledge of gear-housing will be outputted as shown in Fig. 15.

The main works of the functional module of taskoriented modular management for PCD are to complete product task decomposition and task-oriented modularization. To choose a design object, the taskoriented decomposition structure with the sub-task- related information will be outputted. Meanwhile, the system will output a sub-task correlation matrix. Moreover, on basis of sub-task decomposition for PCD based on a mixed method,the decomposed modules are obtained by solving the mathematic model of task-oriented modular based on multi-objective optimization and thereby maximizing the module cohesion degree and minimizing the module coupling degree. The task-oriented modular management UI is shown in Fig. 16.

Fig. 14. User authority management of the prototype system

Fig. 15. Knowledge management of the prototype system

Fig. 16. Task-oriented modular management UI of the prototype system

The functional module of task-module implementation management based on agent has two major functions:(1) select the optimal matching agents by using similarity algorithm; (2) implement different task-modules by the integrated reasoning and decision-making mechanism with the behavioral model of collaborative design Agents. The task-module implementation management UI is shown in Fig. 17.

Fig. 17. Task-modules implementation management UI of the prototype system

8 Conclusions

Under distributed heterogeneous environment, products should be collaboratively developed by the researchers from multiple fields and disciplines. The available software/hardware resources, R&D capability, design concepts of the collaborative work-group are different under this environment. According to the new requirements, the collaborative design mechanism for distributed product development based on task-oriented modularity and multi-agent collaboration is discussed, and the integrated theories system for product collaborative design (PCD)under distributed heterogeneous environment is formed. The main works and contributions are as follows:

(1) The process model of task-oriented modular and Agent technology for PCD was constructed by analyzing the mapping relationships between requirements and functions in the collaborative design. The layer-by-layer task analysis from top-level products to bottom-level task nodes was achieved by adopting a task decomposition strategy.

(2) By quantifying the correlation of sub-tasks and defining the concept of product executable degree, the mathematic model is constructed to maximize the module cohesion degree and minimize the module coupling degree,while considering the module executable degree as a restriction. This model belongs to a 0-1 discrete problem,and the number of variables to be solved is indefinite. By simplifying the mathematic model, this problem was changed to a multi-objective optimization problem that can be solved easily by the modified PSO. This task-oriented modular strategy based on optimization algorithm is the theoretical foundation of product modularity for collaborative design under heterogeneous environment.

(3) The Agent model for collaborative design is constructed. By defining the task set of modules and the experience set of Agents as the random variables, the best matching Agent was selected to solve the module by calculating the integrated similarity degree between modules and Agents. The task-modules are solved by using the cooperation and collaboration of Agents. As a result, PCD is achieved to improve the efficiency of product development under distributed heterogeneous environment.

(4) Based on the above key technologies, a practical prototype system (B/S-based R&D platform for automobile collaborative design) is developed. The logic architecture of the prototype system is given, and the key function modules are introduced. This system provides an effective platform for automobile manufacturing enterprises to achieve PCD, and helps to promote product numeralization collaborative R&D and management development.

[1] LI Yuliang, SHAO Xinyu, LI Peigen, et al. Design and implementation-of a process oriented intelligent collaborative product design system[J]. Computers in Industry, 2004, 53(2):204–229.

[2] RUI Yannian, LIU Wenjie, GUO Xuhong. Collaborative design[M]. Beijing: Mechanical Industry Press, 2003. (in Chinese)

[3] ZHANG Jie, GAO Liang, LI Peigen. Multi-agent application in the advanced manufacturing[M]. Beijing: Science Press, 2004.

[4] HOU Liang, TANG Renzhong, XU Yanshen. Review of theory,key technologies and its application of modular product design[J].Chinese Journal of Mechanical Engineering, 2004, 40(1): 56–61.(in Chinese)

[5] GU P, SOSALE S. Product modularization for life cycle engineering[J]. Robotics and Computer Integrated Manufacturing,1999, 15(5): 387–401.

[6] JULIANA H. Impacts of supplier-buyer relationships on modularization in new product development[J]. European Journal of Purchasing & Supply Management, 1999(5): 197–209.

[7] ASAN U, POLAT S, SERDAR S. An integrated method for designing modular products[J]. Journal of Manufacturing Technology Management, 2004, 581(3): 29–49.

[8] CETIN O, SAITOU K. Decomposition-based assembly synthesis for structural modularity[J]. Journal of Mechanical Design,2004(3): 244–253.

[9] GAO Weiguo, XU Yanshen, CHEN Yonliang, et al. Theory and methodology of generalized modular design[J]. Chinese Journal of Mechanical Engineering, 2007, 43(6): 48–54. (in Chinese)

[10] MAIONE G, NASO D. A soft computing approach for task contracting in multi-agent manufacturing control[J]. Computers in Industry, 2003, 52(3): 199–219.

[11] OSTROSI E, FOUGèRES, ALAIN J, et al. Fuzzy agents for product configuration in collaborative and distributed design process[J]. Applied Soft Computing, 2012, 12(8): 2091–2105.

[12] CHEN Xiaoan, ZHENG Xiaoguang, CHEN Bingkui. Multi agent collaborative design system model based on the Internet and experiments[J]. Chinese Journal of Mechanical Engineering, 2001,37(4): 357–361. (in Chinese)

[13] YI Lin, KW Tien, CH Chu. Multi-agent hierarchical negotiation based on augmented price schedules decomposition for distributed design[J]. Computers in Industry, 2012, 63(6): 597–609.

[14] QIU Fusheng, LIU Wenjian. Research on Web collaborative product data management based on multi-agent[J]. Computer Integrated Manufacturing Systems, 2006(5): 702–708. (in Chinese)

[15] BOLONI L, MARINESCU D C. A component agent model from theory to implementation[C]//International Symposium “From Agent Theory to Agent Implementation”, West Lafayette, USA, 1999: 1–13.

[16] KORNIENKO S, KORNIENKO O, PRIESE J. Application of multi-agent planning to the assignment problem[J]. Computers in Industry, 2004, 54(3): 273–290.

[17] GAO Fei, XIAO Gang, PAN Shuangxia, et al. Method of product function module partition[J]. Chinese Journal of Mechanical Engineering, 2007, 43(5): 29–35. (in Chinese)

[18] HU X, EBERHART R C. Multi-objective optimization using dynamic neighborhood particle swarm optimization[C]//IEEE Congress on Evolutionary Computation, Honolulu, Hawaii, USA,2002: 1667–1681.

[19] CARLOS A, GREGORIO T, MAXIMINO S. Handing multiple objectives with particle swarm optimization[J]. IEEE Transactions on Evolutionary Computation, 2004: 256–279.

[20] MO Yuanbin, CHEN Dezhao, HU Shangxu. Particle swarm optimization for multi-objective process system optimization problems[J]. Journal of Chemical Engineering of Chinese Universities, 2008(2): 94–99. (in Chinese)

[21] NACHET B, ADLA A. An agent-based distributed collaborative decision support system source[J]. Intelligent Decision Technologies,2014, 8(1): 15–34.

[22] LI Yingzi, ZHANG Shuo, ZHANG Xiaodong, et al. Agent model for mass collaborative product development process and its simulation application[J]. Computer Integrated Manufacturing Systems, 2013,8(19): 1948–1956. (in Chinese)

[23] PAN Shuangxia, JIANG Shaofei, FENG Peien. Research on multi-agent based model for cost reduction in product design process[J]. Chinese Journal of Mechanical Engineering, 2004, 40(1):99–103. (in Chinese)

[24] CHAO K M, NORMAN P, ANANE R, et al. An agent-based approach to engineering design[J]. Computers in Industry, 2002, 48:17–27.

[25] ROSENMAN M, WANG Fujun. CADOM: A component agent-based design-oriented model for collaborative design[J]. Research in Engineering Design, 1999, 11(4): 193–205.

[26] BURKHARDH D. Similarity and distance in case-based reasoning[J].Foudamenta Informaticae, 2010, 47(3): 201–215.

Chinese Journal of Mechanical Engineering2014年3期

Chinese Journal of Mechanical Engineering2014年3期

- Chinese Journal of Mechanical Engineering的其它文章

- Analysis of the Flow Rate Characteristics of Valveless Piezoelectric Pump with Fractal-like Y-shape Branching Tubes

- Experimental Study of the Influence of Flow Passage Subtle Variation on Mixed-flow Pump Performance

- Numerical and Experimental Study on Flow-induced Noise at Blade-passing Frequency in Centrifugal Pumps

- Overall Life Cycle Comprehensive Assessment of Pneumatic and Electric Actuator

- Unsteady Flow Simulations in a Three-lobe Positive Displacement Blower

- Surface Roughness and Roundness of Bearing Raceway Machined by Floating Abrasive Polishing and Their Effects on Bearing’s Running Noise