Catalytic Cracking and PSO-RBF Neural Network Model of FCC Cycle Oil

Liu Yibin; Tu Yongshan; Li Chunyi; Yang Chaohe

(State Key Laboratory of Heaνy Oil Processing, China Uniνersity of Petroleum, Qingdao 266580, China)

Catalytic Cracking and PSO-RBF Neural Network Model of FCC Cycle Oil

Liu Yibin; Tu Yongshan; Li Chunyi; Yang Chaohe

(State Key Laboratory of Heaνy Oil Processing, China Uniνersity of Petroleum, Qingdao 266580, China)

Catalytic cracking experiments of FCC cycle oil were carried out in a fixed fluidized bed reactor. Effects of reaction conditions, such as temperature, catalyst to oil ratio and weight hourly space velocity, were investigated. Hydrocarbon composition of gasoline was analyzed by gas chromatograph. Experimental results showed that conversion of cycle oil was low on account of its poor crackability performance, and the effect of reaction conditions on gasoline yield was obvious. The paraffin content was very high in gasoline. Based on the experimental yields under different reaction conditions, a model for prediction of gasoline and diesel yields was established by radial basis function neural network (RBFNN). In the model, the product yield was viewed as function of reaction conditions. Particle swarm optimization (PSO) algorithm with global search capability was used to obtain optimal conditions for a highest yield of light oil. The results showed that the yield of gasoline and diesel predicted by RBF neural network agreed well with the experimental values. The optimized reaction conditions were obtained at a reaction temperature of around 520 ℃, a catalyst to oil ratio of 7.4 and a space velocity of 8 h-1. The predicted total yield of gasoline and diesel reached 42.2% under optimized conditions.

catalytic cracking; cycle oil; radical basis function neural network; particle swarm optimization

1 Introduction

Fluid catalytic cracking (FCC) is an important process in heavy oil processing which plays an irreplaceable role in increasing light oil, in particular the gasoline output. The total processing capacity of FCC units reaches more than 130 Mt/a in China. If the light oil yield of FCCU is increased by one percentage point, the product output will increase by 1.3 Mt/a. Therefore, optimizing FCC unit operation to maximize the light oil yield is of great significance for boosting light oil production and full use of petroleum resource.

In order to obtain high yield of light oil, recycle operations are used in most Chinese FCC units. The cycle oil is pumped back from the fractionation column into the riser to take part in cracking reaction again. However, the competition between the fresh feed and the cycle oil occurs due to strong adsorption and poor crackability of the cycle oil. The two-stage riser catalytic cracking technology can dampen this competition through section reaction, which means that the fresh feed reacts in the first-stage riser and the cycle oil reacts in the second-stage riser. Moreover, this measure can reduce overcracking reaction, improve light oil yield and increase the diesel/gasoline ratio by taking advantage of the section reaction, catalyst relay and short reaction time[1]. In the process scheme for maximizing diesel, the cycle oil is pumped into the secondstage riser separately. Therefore, it is worthwhile to study the mechanism for catalytic cracking of cycle oil in order to optimize the operating conditions and enhance the light oil yield.

Properties of feedstock, catalyst and operating conditions have important influence on the product distribution and property. Generally, studying the reaction performance under different operating conditions is meaningful since the feedstock diet and catalyst are already fixed by the production plan at a refinery. The product slate can be optimized by adjusting operating conditions. Prediction of product yield is the precondition for optimization of unit operation. Mechanism model research on catalytic cracking is very difficult owing to the complexity of re-action system and strong nonlinear relationship between various influencing factors. Artificial neural network is a black box mathematic model with good nonlinear mapping ability, and can respond to the complicated relationship between the target and influencing factors. So it has wide application in the area of product yield prediction and device simulation of refining process[2-6]. Radial basis function neural network (RBFNN) is an efficient feedforward artificial neural network which is characteristic of best approximation performance, global optimal property, simple structure and fast training speed. So it has been widely used in fields such as pattern recognition, nonlinear function approximation, etc. With the rapid development of computer technology, the intelligent optimization algorithms, such as genetic algorithm, particle swarm optimization, ant colony algorithm, are becoming the research hotspot. Combining the artificial neural network with intelligent algorithms for mathematical modeling and optimization of influencing factors is a new research method in the domain of chemical industry[7-9].

In this paper, catalytic cracking experiments of FCC cycle oil were carried out in a fixed fluidized bed reactor. The effect of reaction conditions, such as temperature, catalyst to oil ratio and WHSV, was investigated. Hydrocarbon group compositions of gasoline were determined by a gas chromatograph. A RBFNN model was developed based on the experimental data. The product distribution under different operating conditions was predicted by this model. On this basis, the reciprocal of gasoline and diesel yield was used as the objective function to optimize operating conditions by particle swarm optimization algorithm.

2 Experimental

2.1 Feedstock and catalyst

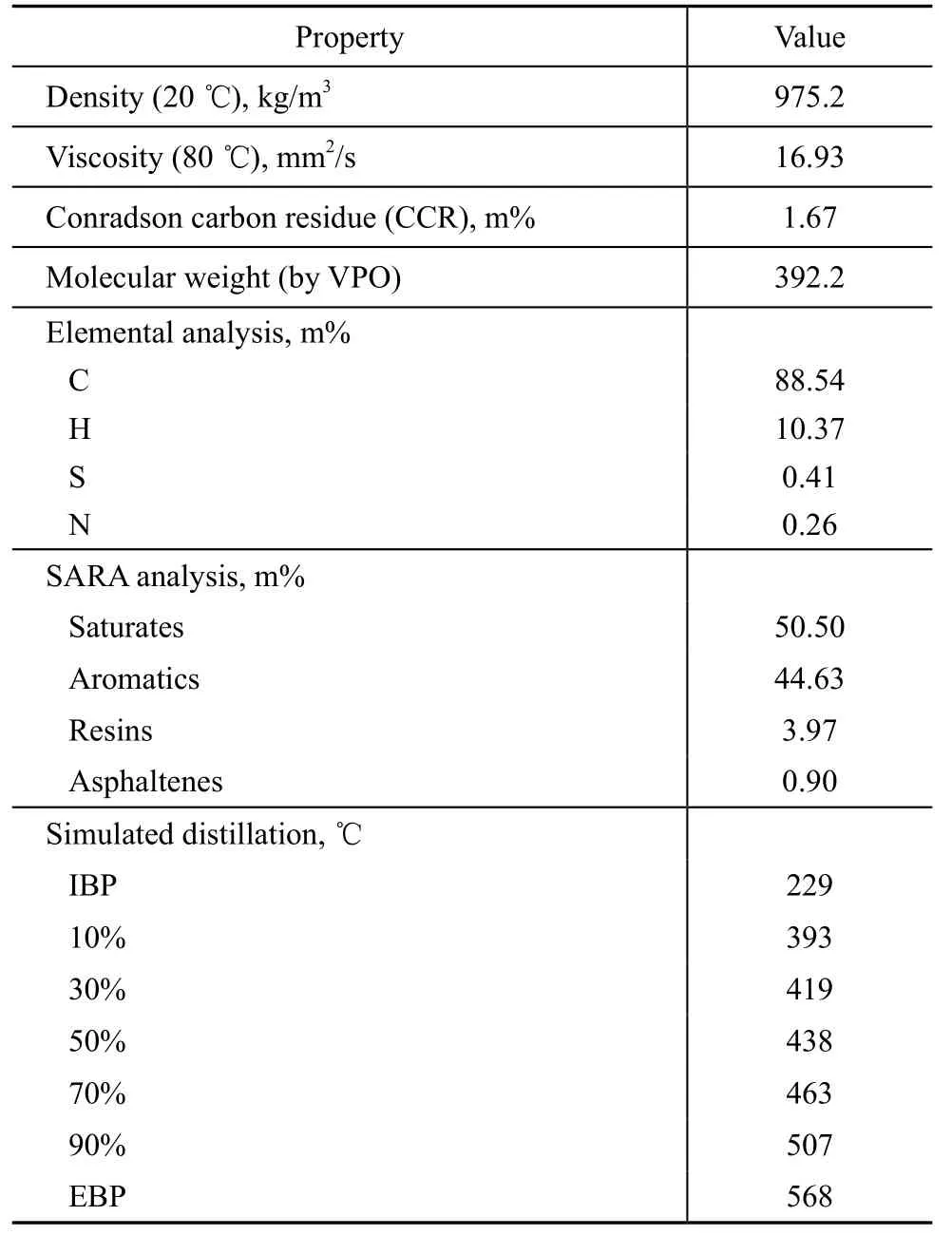

The cycle oil was obtained from RFCC unit at the Changqing Petrochemical Company of China National Petroleum Corporation and used as the feedstock. The detailed properties of the feedstock are shown in Table 1.

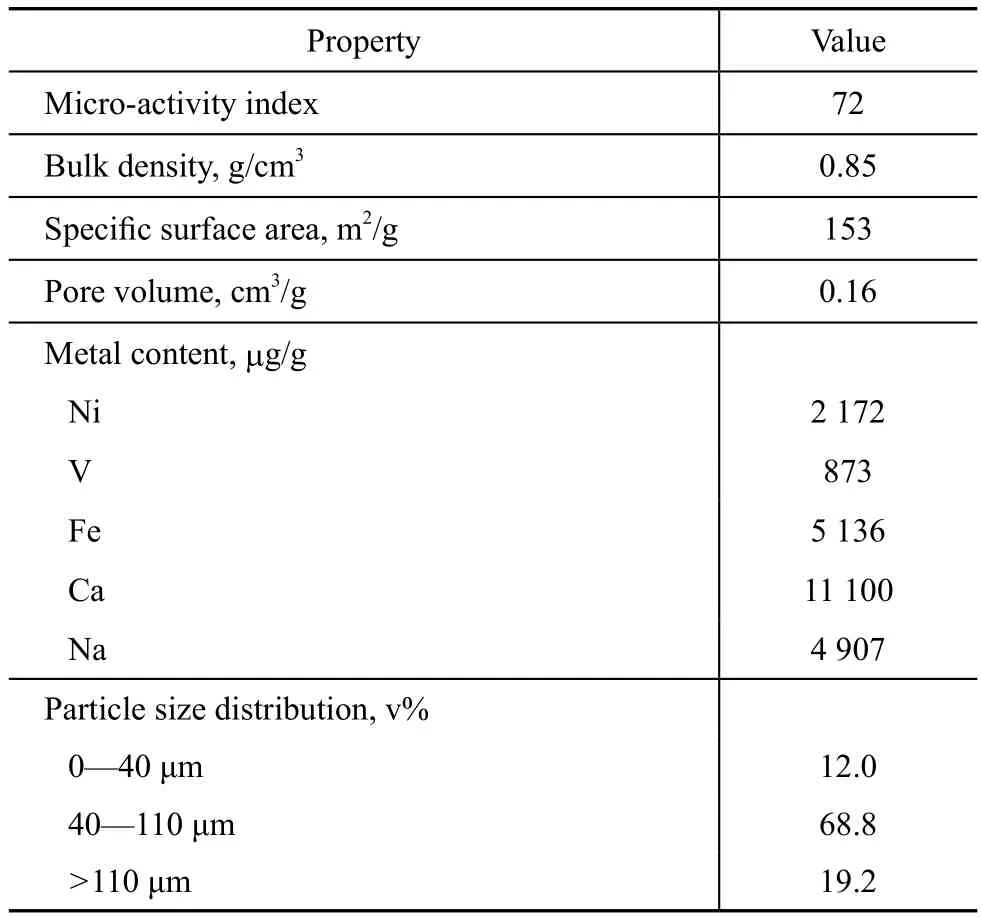

A catalytic cracking equilibrium catalyst with USY zeolite functioning as the active component, which was also obtained from RFCC unit at the Changqing Petrochemical Company, was used as the catalyst in the experiments. Main properties of the equilibrium catalyst are presented in Table 2.

Table 1 Properties of the cycle oil

Table 2 Properties of the equilibrium catalyst

2.2 Experimental apparatus

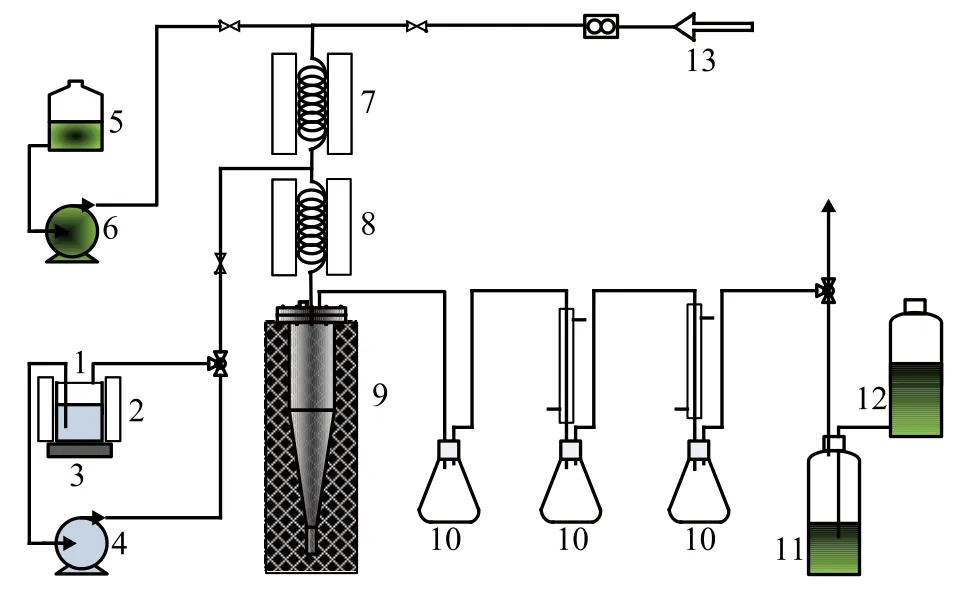

A fixed fluidized bed reactor system, as shown in Figure 1, was used to carry out the experiments. It was a batch system operating according to a fluidized reaction mode.New equilibrium catalyst was put into the reactor before each run. The feedstock was pumped into the furnace firstly to be preheated to 350 ℃, and was then routed to the reactor together with the steam. The feedstock was cracked to gas, gasoline, light cycle oil, and heavy cycle oil along with formation of coke. The liquid products were collected in three liquid product collecting bottles, which were kept at 0 ℃ by a mixture of ice and water. The gaseous products were collected via water displacement. The coked catalyst was stripped with steam for 20 minutes to recover entrapped hydrocarbons after reaction. Then the coked catalyst was taken out by a vacuum pump for determining the coke content.

Figure1 Schematic diagram for experimental apparatus

2.3 Product analysis

The gaseous products were analyzed by a Varian 3800C gas chromatograph to measure the volume percentage of H2and mass percentage of C1to C6hydrocarbons. The collected liquid products were analyzed by the simulated distillation carried out on an Agilent 6890N gas chromatograph according to the ASTM D2887 method. Based on the data of products analysis, the yield of gas (H2, C1, C2, C3and C4), gasoline (C5—204 ℃), light cycle oil (LCO, 205—350 ℃) and heavy cycle oil (HCO, >350 ℃) was determined respectively. Gasoline was obtained by true boiling point distillation, with the hydrocarbon group composition analyzed by a HP5890 gas chromatograph. The coke content of coked catalyst was measured via combustion and chromatography.

3 Results and Discussion

3.1 Reaction performance of feedstock

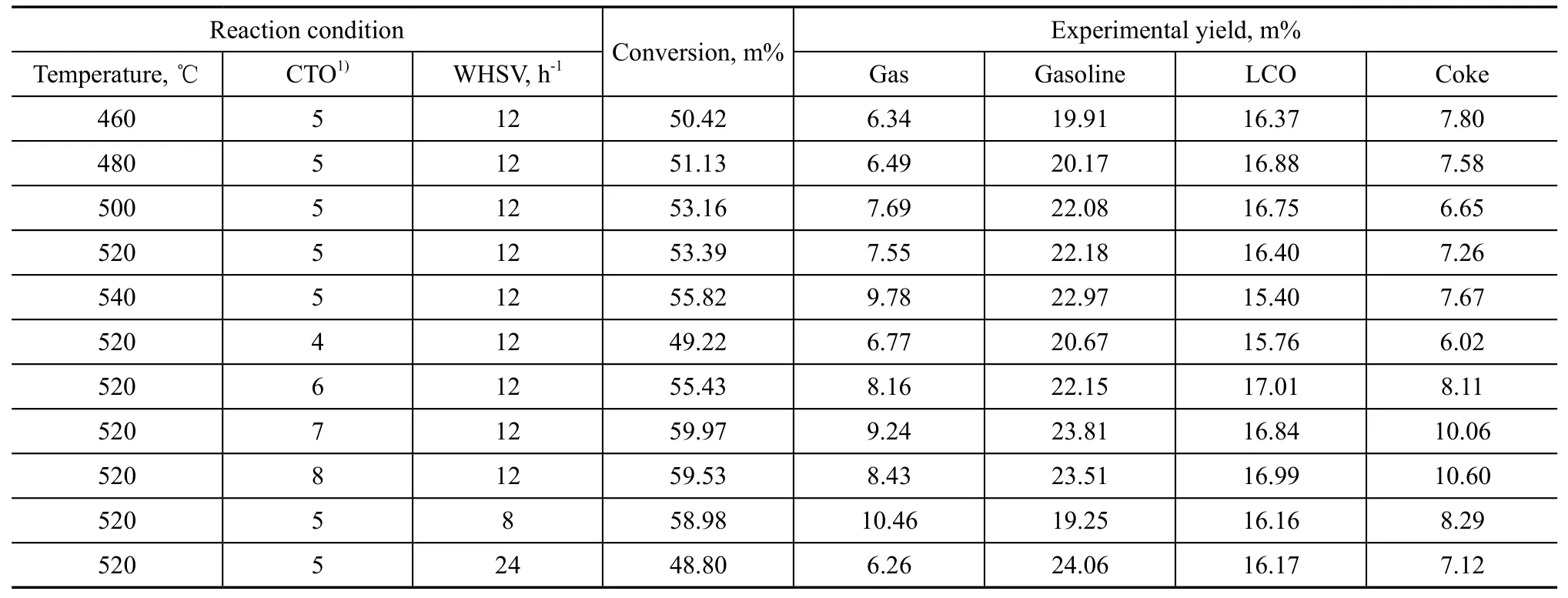

The conversion of cycle oil and product distribution at different operating conditions are shown in Table 3.

There was almost no difference between the distillation range of cycle oil and VGO. However, the cycle oil was a kind of heavy circulating oil formed during catalytic cracking of fresh catalytic feed. Generally, the heavy cycle oil (HCO) contained a large amount of aromatics, especially polycyclic aromatics, featuring poor crackability performance with its conversion rate not exceeding 60%. Despite all these facts, the coke yield originated from cycle oil catalytic cracking was even greater than that of VGO. Temperature is an overriding factor for catalytic cracking reaction. Since the catalytic cracking is an endothermicreaction, improving reaction temperature is beneficial to the cracking process. The temperature coefficient of catalytic cracking is 1.1—1.2. That is to say, with the reaction temperature increasing by 10 ℃, the conversion can increase by 10%—20%[10]. With regard to the cycle oil, its conversion increased gradually with the rise of the reaction temperature, while the effect of the temperature was not obvious. The conversion only increased by 0.7% with the reaction temperature increasing by 10 ℃. Yields of gasoline and gas increased with an increasing reaction temperature, but the change was insignificant due to the low conversion rate of cycle oil. LCO yield declined slightly. This phenomenon indicated that the diesel formation rate was lower than its consumption rate identified during the increase in reaction temperature.

Table 3 Conversion of cycle oil and product distribution at different operating conditions

Increasing CTO provides more active sites, and can improve the opportunities of contact between the feedstock and active sites, meanwhile can reduce the coke content in catalyst which is benefitial to maintaining catalyst activity. In addition, the increase of CTO also weakens the competitive adsorption on the catalyst surface between the readily crackable components and the refractory components including polycyclic aromatics and heterocyclic aromatics. Higher CTO enhances the adsorption driving force of hydrocarbons[11]. Therefore, with the increase of CTO, the cycle oil conversion rate also increased. However, it had less influence on LCO yield. The gasoline yield increased only about 3%. But the influence on coke yield was obvious. When CTO increased from 4 to 8, the coke yield increased from 6.02% to 10.60%. Increasing CTO provided more active sites for cracking and condensation reaction simultaneously. Meanwhile, stripping effect became worse because of increasing amount of catalyst load, resulting in increased strippable coke on the catalyst Increasing WHSV decreases the time for contact of the feed with the catalyst, which reduces the contact probability between the feed and active sites on the catalyst. When the WHSV was increaed from 8 h-1to 24 h-1, the conversion of the feedstock decreased by 10%, while the gasoline yield and the gas yield decreasd by 4.2% and 3.6%, respectively. But the LCO and coke yields changed little. Reducing WHSV could improve the cracking depth. However, FCC is a complicated parallel and sequential reaction process. Reducing WHSV would increase the occurrence of secondary reactions.

3.2 Hydrocarbon composition of gasoline

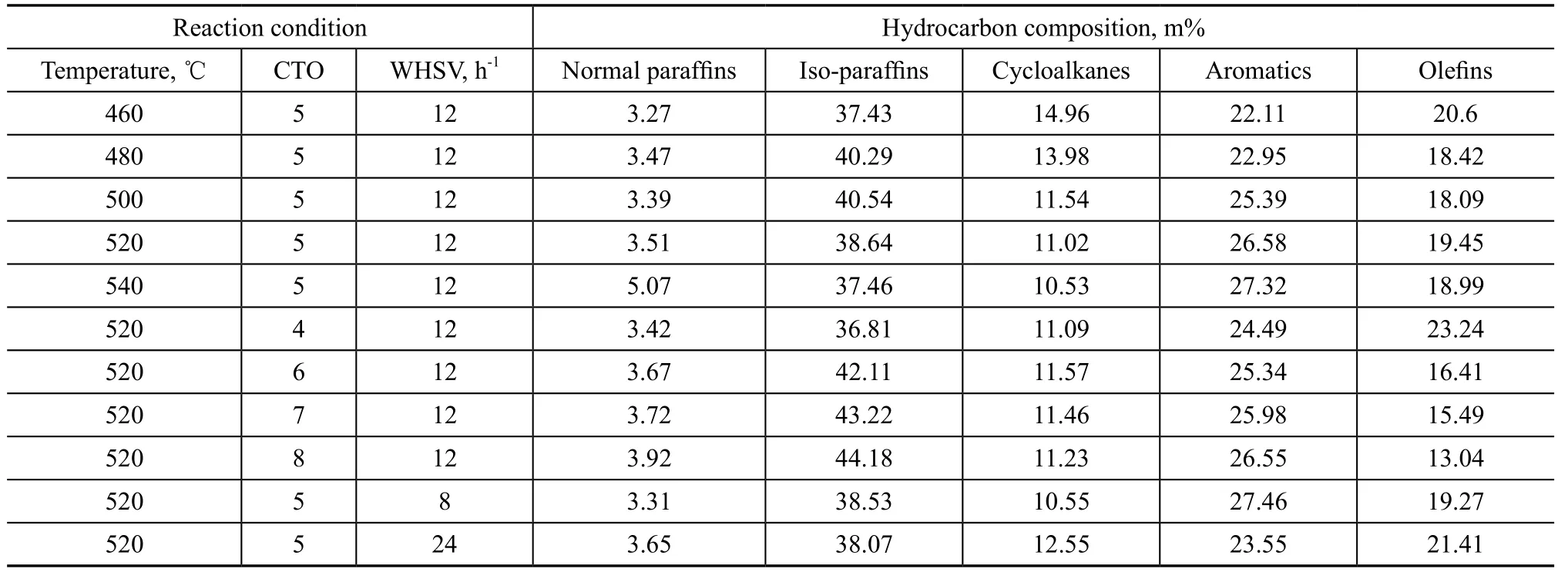

Gasoline is the intermediate product of FCC process. Operating conditions can affect the hydrocarbon composition of gasoline. The hydrocarbon composition of gasoline formed at different conditions is shown in Table 4.

Generally, FCC gasoline is rich in olefins. But the olefin content of gasoline obtained from Changqing cycle oil was lower than the aromatic content. The cycle oil contained much more aromatics. The aromatics with bridgechain structure were readily cracked to small molecular aromatics in gasoline.

With an increasing reaction temperature, the aromatic content increased with decrease in the content of olefins and cycloalkanes, but the content of paraffinic hydrocarbons almost did not change. However, with an increasing CTO, the paraffin content increased and olefin contentdecreased, but the content of aromatics and cycloalkanes was almost not changed. Since different hydrocarbons have different reaction rate, the operating condition also has different influences on catalytic cracking reactions.

Table 4 Hydrocarbon composition of gasoline formed at different operating conditions

4 PSO-RBF Neural Network

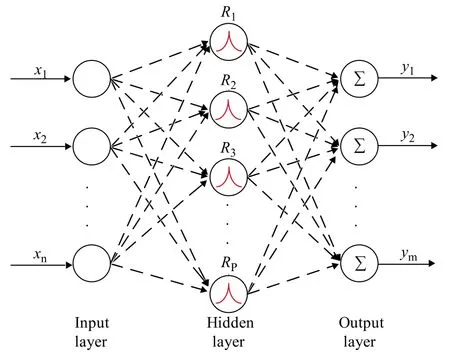

4.1 Radial basis function neural network (RBFNN)RBFNN originates from the radial basis function (RBF) used in multivariate interpolation in numerical analysis[12]. It is a typical three layer forward neural network composed of the input layer, the hidden layer and the output layer. Its structure is shown in Figure 2.

Figure 2 Structure diagram of RBFNN

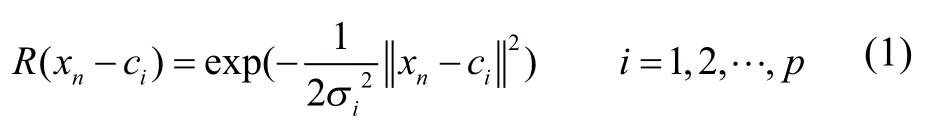

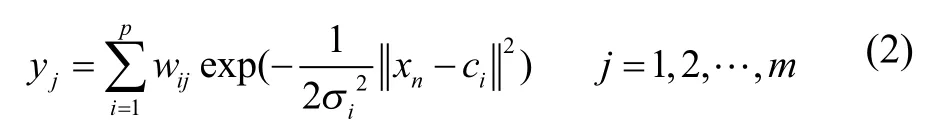

RBFNN has multiple neurons in each layer. Neurons have a one-way connection between adjacent layers. Nodes in the hidden layer are formed by radial basis function (RBF), and are responsible for the nonlinear transformation of input variables. The Gaussian function, as shown in equation (1), is normally used as the radial basis function.

wherexndenotes the multidimensional input vector;cidenotes the center of basis function that has the same dimension ofxn, which is obtained by the K-means clustering method;σidenotes the width of the basis function around a central point, which is equal to the variance[13]; andpdenotes the node number of hidden layer.

The input data are transformed from one space to another space by Gaussian transformation. The network output acquired by linear weighted data in new space of hidden layer is expressed by equation (2).

wherewijdenotes the connection weight from the hidden layer to the output layer, which is calculated by the least square method; andmdenotes the number of output variables.

4.2 Particle swarm optimization (PSO)

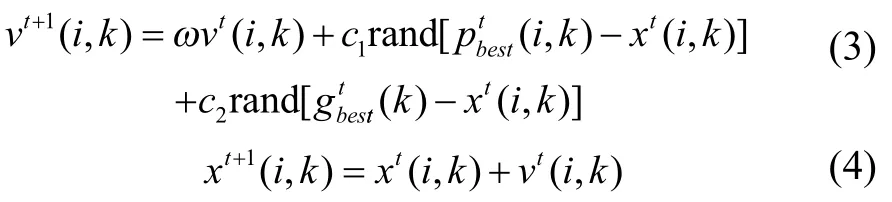

Particle swarm optimization (PSO) put forward by Kennedy and Eberhart in 1995 is a random optimization algorithm based on swarm intelligence. Swarm intelligence, which is produced through cooperation and competition among the particles in the group, is used to optimize the search. In the searching process, each particle is a point in the multi-dimensional solution space and has its own speed. Different particle has an individual fitness corresponding to the objective function. Each particle adjusts its flight path to the optimization point based on its flight experience and group flight experience[14]. The particles update their speed and position according to equation (3) and equation (4).

whereidenotes the number of particles;kis the number of coordinate components;tdenotes the iterations;ωdenotes the inertia weight;c1andc2denote the acceleration factor and is equal to 2 generally; and ‘rand’ is a random number between 0 and 1.

The selection ofωis very important in PSO. Whenωis larger, the global search ability of PSO will be better; whenωis smaller, the local search ability of PSO will be better[15]. Soωis larger at beginning of the iteration to make PSO converge globally. With the increase of iterations,ωdiminishes. In this paper,ωdiminishes linearly from 0.9 to 0.4 with the increase of iterations.

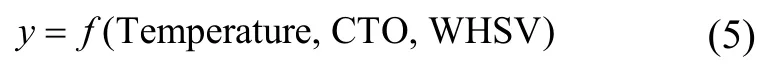

4.3 Yield model of gasoline and LCO

As regards a specific feedstock, the yield of objective product is a function of operating conditions. It is implemented by RBF neural network. It is expressed by equation (5)

MATLAB was used to establish the RBF neural network. Gasoline yield and LCO yield under different conditionswere used as the learning samples. The main parameters of the model were determined by the numerical experiments for many times as follows: the basis function center width is 100 and the sum of squared residuals index is 0.08. The comparison between the experimental yields and the model-predicted yields is shown in Figure 3. It indicates that the model can fit the experimental data well.

Figure 3 Comparison between predicted yields and experimental yields

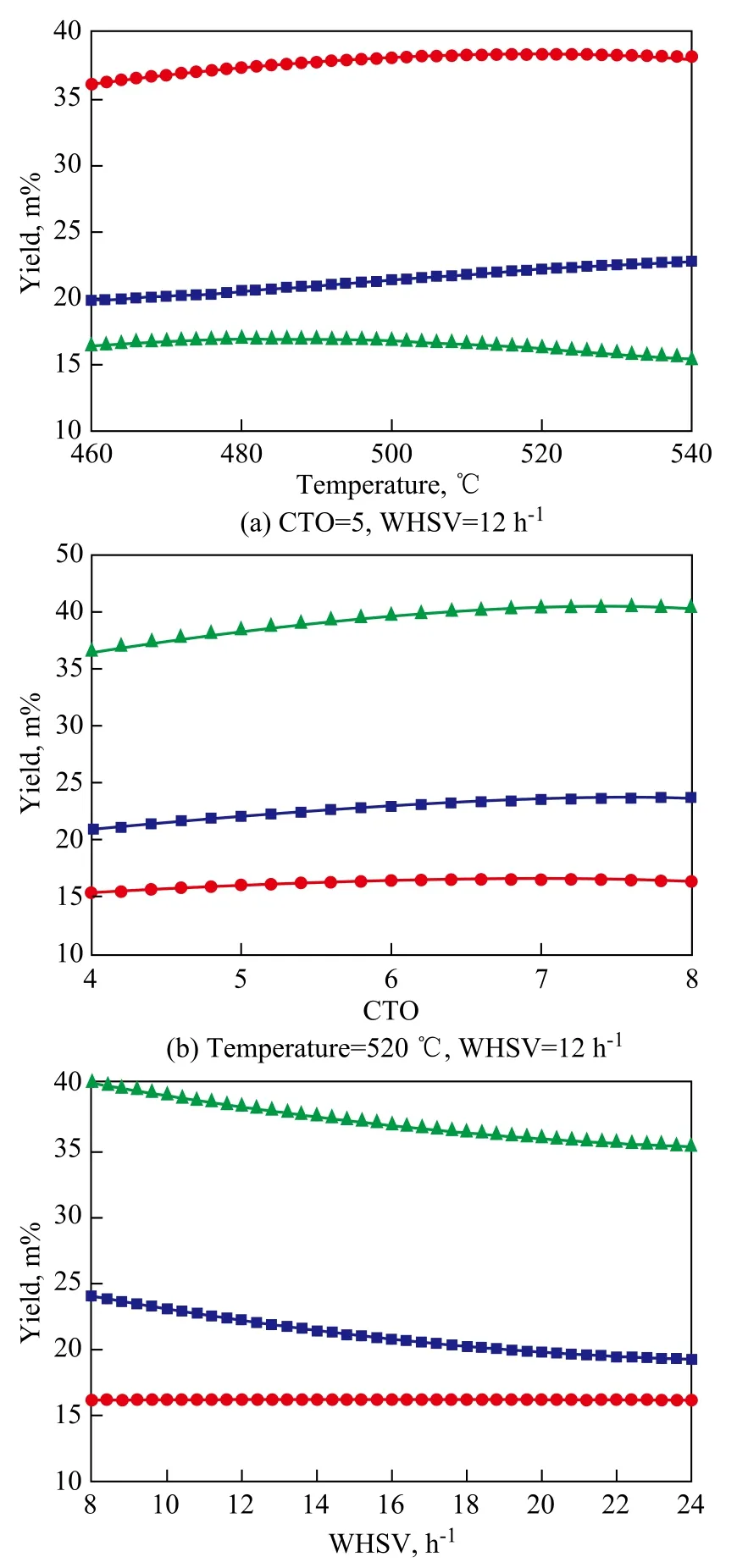

According to the established model, the calculated yields of gasoline, LCO and light oil at different reaction temperatures, catalyst to oil ratios and WHSV are shown in Figure 4.

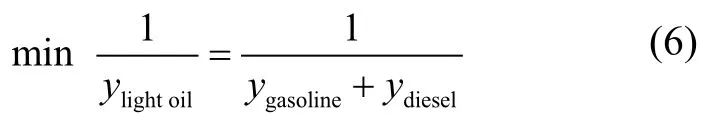

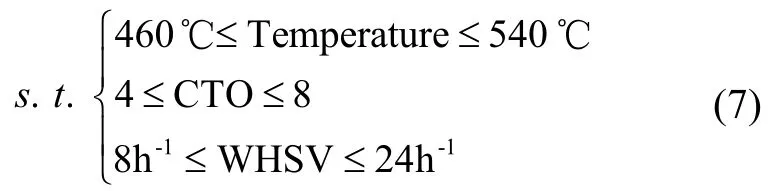

4.4 Optimization of reaction conditions

In order to obtain the maximum light oil yield, the reciprocal of gasoline and LCO yields was used as the objective function.

PSO was used to find the optimal reaction conditions. The fitness function of the PSO is:

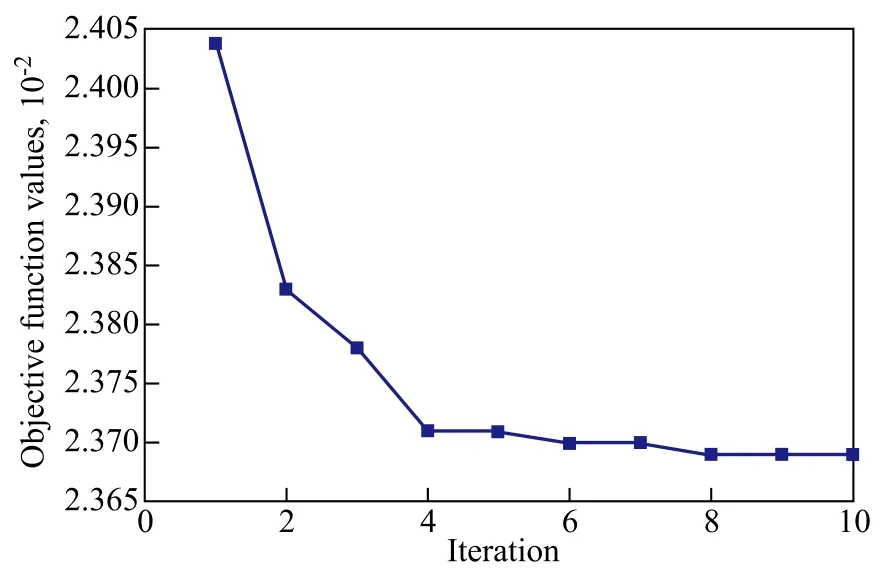

The group number was set at 20 in the PSO. The iteration result of optimization of objective function is shown in Figure 5.

Figure 5 shows that PSO had good convergence property. It converged to close to a minimum in the fourth iteration. Within the scope of the experimental conditions, the minimum value of objective function is 0.023 7. The optimized reaction temperature is 520 ℃, the catalyst to oil ratio is 7.4 and WHSV is 8 h-1. The optimized gasoline and LCO yield reached 25.6% and 16.6%, respectively.

Figure 4 Predicted gasoline and LCO yields at different conditions

Figure 5 Iterative result of particle swarm optimization.

5 Conclusions

The crackability performance of Changqing cycle oil was poor and the conversion was only about 50%. The influence of operating conditions on gasoline yield was remarkable. Gasoline contained much more aromatics than olefins. RBFNN based on experimental results predicted the gasoline and LCO yield well. PSO was used to optimize the operating conditions. Under the optimized conditions, the yield of gasoline and LCO was 25.6% and 16.6%, respectively.

Acknowledgements:We are grateful for the financial support of the Chinese National Program for Fundamental Research and Development (973 program) (2012CB215006). The authors would also like to thank Li Wei and Sun Zhongchao for their hard work.

[1] Yang C H, Shan H H, Zhang J F, et al. Shortcoming of conventional RFCC reactor and advantage of TSRFCC technology [J]. Journal of China University of Petroleum (The Natural Science Edition), 2007, 31 (1): 127-131, 138 (in Chinese)

[2] Mehdi S, Kamyar K. Modeling of thermal cracking of heavy liquid hydrocarbon: Application of kinetic modeling, artificial neural network, and neuro-fuzzy models [J]. Industrial & Engineering Chemistry Research. 2011, 50 (3): 1536-1547

[3] Nabavi R, Niaei A, Salari D, et al. Modeling of thermal cracking of LPG: Application of artificial neural network in prediction of the main product yields [J]. Journal of Analytical and Applied Pyrolysis, 2007, 80 (1): 175-181

[4] Ma F S, Li Z C, Weng H X. A model of deep catalytic cracking product yields using artificial neural networks [J]. Petroleum Refinery Engineering, 2001, 31 (2): 35-38 (in Chinese)

[5] Zahedi G, Mohammadzadeh S, Moradi G. Enhancing gasoline production in an industrial catalytic-reforming unit using artificial neural networks [J]. Energy & Fuels, 2008, 22 (4): 2671-2677

[6] Deng Y, Jiang Q Y, Cao Z K, et al. ANN modeling of industrial FCC unit [J]. Computers and Applied Chemistry, 2011, 28 (9): 1163-1166 (in Chinese)

[7] Xia J, Mei L H, Huang J, et al. Optimization of γ-aminobutyric acid fermentation medium based on artificial neural network and particle swarm optimization [J]. Journal of Chemical Engineering of Chinese Universities, 2007, 21 (6): 997-1001 (in Chinese)

[8] Suo H B, Jiang X, Hu Y, et al. Optimization of the reaction conditions of ethanol dehydration to ethylene based on RBF neural network simulation [J]. Petroleum Processing and Petrochemicals, 2010, 41 (3): 69-73 (in Chinese)

[9] Zhou X W, Yang B L, Yi C H, et al. Prediction model for increasing propylene from FCC gasoline secondary reactions based on Levenberg-Marquart algorithm coupled with support vector machines [J]. Journal of Chemometrics, 2010, 24 (9): 574-583

[10] Xu C M, Yang C H. Petroleum Refining Engineering [M]. 4thEdition. Beijing: Petroleum Industry Press, 2009: 309 (in Chinese)

[11] Wang J G. The effect of catalyst-oil ratio on fluid catalytic cracking process [J]. Petroleum Processing and Petrochemicals, 1995, 26 (5): 22-25 (in Chinese)

[12] Zou G, Yao Z J, Li C, et al. An application of RBF neural network to mechanical properties of wheat straw-reinforced composite prediction [J]. Computers and Applied Chemistry, 2007, 24 (10): 1397-1400 (in Chinese)

[13] Zhang D X, Liu X Z, Guan Z H. Radial basis function neural network algorithm and its application [J]. Journal of Petrochemical University, 2007, 20 (3): 86-88 (in Chinese)

[14] Xiong W L, Xu B G. Study on optimization of SVR parameters selection based on PSO [J]. Journal of System Simulation, 2006, 18 (9): 2442-2445 (in Chinese)

[15] Li W, Shi L S, Liang C L. Forecasting model of research octane number based on PSO-LSSVM [J]. Control and Instruments in Chemical Industry, 2008, 35 (2): 25-27 (in Chinese)

Recieved date: 2013-06-27; Accepted date: 2013-08-19.

Professor Yang Chaohe, Telephone: +86-0532-86981718; E-mail: statelab@upc.edu.cn.

- 中國煉油與石油化工的其它文章

- Study on Preparation of Waterproofing Agent for Mineral Wool Board from Modified C9Petroleum Resin

- Catalytic Dehydration of 4-Hydroxy-3-hexanone to 4-Hexen-3-one over HZSM-5 Zeolite

- Diffusion and Reaction Model of Catalyst Pellets for Fischer-Tropsch Synthesis

- Simulation of Low-Temperature Coal Tar Hydrocracking in Supercritical Gasoline

- Effect of Impregnation Sequence on Propane Dehydrogenation Performance of PtSnNa/ZSM-5 Catalyst

- Influence of Synthesis Parameters with Low Seed Addition on the Crystallinity of ZSM-5