Toughness Effect of Graphene Oxide-Nano Silica on Thermal-Mechanical Performance of Epoxy Resin

XU Mingtao(徐銘濤), ZHANG Suxin (張?zhí)K心), ZHOU Xia(周 霞), ZHANG Yan(張 巖), WANG Ping(王 萍) , GU Zhiqi (谷志旗), LI Yuanyuan(李媛媛), 3*

1 Key Laboratory of Jiangsu Province for Silk Engineering, College of Textiles &Clothing Engineering, Soochow University, Suzhou 215123, China

2 Nantong Hanvo New Material Technology Co., Ltd., Nantong 226400, China

3 Jiangsu Advance Textile Engineering Technology Center, Nantong 226400, China

Abstract:A graphene oxide/nano-silica (GOS) hybrid was rapidly and easily synthesized using graphene oxide (GO) and nano-silica (nano-SiO2) as raw materials, and the synthesized GOS was used to improve the mechanical properties of epoxy resin (EP). The modified EP with different mass fractions of GOS (0, 0.1%, 0.2%, 0.3% and 0.4%) were prepared and studied. The structure, thermal stability, mechanical properties, fracture toughness and failure morphology of the modified EP were analyzed. The results showed that the tensile strength of GOS modified EP increased from 40.6 MPa to 80.2 MPa compared with EP, the critical stress intensity factor of GOS modified EP increased by 65.9% from 0.82 MPa·m1/2 to 1.36 MPa·m1/2, indicating a significant enhancement in fracture toughness. In addition, failure morphology was observed by scanning electron microscopy (SEM) observation. The toughness mechanism of the modified EP was also discussed. Finally, the thermal stability of the modified EP was improved by the addition of GOS. Compared with neat EP, the initial thermal degradation temperature and glass transition temperature of GOS modified EP increased by 4.5 ℃ and 10.3 ℃, respectively.

Key words:toughness modification; epoxy resin(EP); graphene oxide (GO);nano-silica; mechanical property; failure mechanism; thermal behavior

0 Introduction

Epoxy resin (EP) is a thermosetting polymer material and is often used as a matrix of reinforced composites due to its excellent thermal, mechanical and chemical properties[1-3]. Composites based on EP have been widely used in aerospace, automobiles and machinery fields[4]. However, EP with a high crosslinking structure exhibits brittle damage and low fracture toughness resulting in limitations in engineering applications[5-7]. Many attempts have been made to improve the fracture toughness of EP. Most modification methods involved adding various toughening agents into the resin system, such as rubber elastomers[8-11], thermoplastic[12-15]and nanoparticles[16]. Generally, the introduction of rubber particles or thermoplastic into the resin system led to the degradation of thermal stability or mechanical properties. Jamshidietal.[17]investigated the effect of EP toughened with carboxyl-terminated butadiene acrylonitrile (CTBN). The results showed that the maximum fracture toughness of the modified EP was 45.8 kJ/m2, which was about 58% higher than that of neat EP. However, the modulus of the modified EP decreased from 2.9 GPa to 0.9 GPa with increasing CTBN content. Jungetal.[18]used CTBN to modify EP. The toughness of the modified EP was significantly improved by 86.6%, while the tensile strength and elastic modulus of it were reduced by 20.0% and 19.0%, respectively. This phenomenon was mainly because the modulus of rubber elastomers was lower than that of EP. With the increase of the content of rubber elastomers, the modulus of the modified EP decreased, and much rubber elastomers would aggregate and lead to stress concentration, which aggravated the decrease of modulus. Thermoplastic resins have excellent mechanical properties and thermal stability because their main chain contains rigid aromatic rings or aliphatic ring structures. Therefore, thermoplastic resins are gradually used as toughening agents for EP. Jonesetal.[13]mixed a thermoplastic resin of polybisphenol A-co-epichlorohydrin (PBAE) into EP to improve the toughness. The fracture toughness of the modified EP increased by 150.0% from 0.4 MPa·m1/2to 1.0 MPa·m1/2, while glass transition temperature and storage modulus of the modified EP slightly decreased due to the fact that thermoplastic resin reduced the crosslink density of EP[19]. Tangthana-umrungetal.[20]modified EP with polyethersulfone (PESU), the results showed that PESU not only improved the thermal stability of EP but also improved the tensile strength and fracture toughness by 35.0% and 40.0%, respectively. According to fracture analysis, crack deflection of PESU dispersed particles was the main toughening mechanism.

Compared to rubber elastomers and thermoplastics, nanoparticles are high-performance fillers that do not compromise the mechanical and thermal properties for EP reinforcement and toughening, such as nano-silica (nano-SiO2)[21-22], carbon nanofibers (CNFs)[23-24], graphene oxide (GO)[25-27], carbon nanotubes (CNTs)[28-29]. Particularly, GO is a valuable material for polymer reinforcement due to its high thermal conductivity, mechanical properties, excellent flexibility and low density[30-31]. However, GO is highly susceptible to aggregation and stress concentrations due to van der Waals forces[32]. Chemical modification of GO is an effective measure to improve the GO dispersion in the EP system. A large number of polar functional groups in GO provide conditions for surface modification, such as hydroxyl, carboxyl and epoxy groups. The modification allows GO to form a firm interface between GO and EP. Wanetal.[33]used diglycidyl ether of bisphenol A (DGEBA) functionalized GO to modify EP. The results showed that the tensile modulus, tensile strength and fracture toughness of the modified EP increased by 13.0%, 75.0% and 41.0%, respectively. Glass transition temperature of the modified EP slightly increased and the decomposition temperature increased by 16-30 ℃ compared to those of neat EP and GO/EP. In addition, the introduction of nano-SiO2on the GO surface is also a very effective method to toughen EP. Nano-SiO2has high surface area, high surface energy, low toxicity, and ease of manufacture[34-35]. The covalent reaction between Nano-SiO2and GO not only prevents the self-aggregation of GO, but also interlocks with EP, which gives full play to their respective advantages and produces the synergistic effect. Jiangetal.[36]investigated the effects of functionalized nano-SiO2attached GO in EP, the results showed that the tensile strength, tensile modulus and fracture toughness of the modified EP were 29.2%, 22.0% and 57.0% higher than those of neat EP. Wangetal.[37]grafted nano-SiO2onto GO via thiol-ene click chemistry, compared with neat EP, the tensile strength and elastic modulus of the graphene oxide/nano-silica modified EP(GOS/EP) increased by 32.2% and 22.9%, respectively. The main failure modes of the modified EP in the toughness test are local plastic deformation, crack deflection, crack tip anchor, particle-matrix interface and pulling out. Grafting nano-SiO2onto the GO surface could contribute to absorbing more fracture energy and promote stress transfer. However, the above hybrid modes of GOS are complex, time-consuming and polluting.

In this work, one rapid and easy method of hybrid preparation of GOS was developed, and the prepared GOS was used to improve the mechanical performance of EP. The tensile properties and toughness of the modified EP were investigated. In addition, the toughness effects of GO and GOS in EP were compared and analyzed. Based on the discussion about the failure morphologies of the modified EP, the toughness mechanism of EP modified by GO and GOS was analyzed. Furthermore, the thermal properties of the modified EP were investigated. This work provides fundamental knowledge and suggestions for the design and application of composite materials.

1 Experiments

1.1 Materials

JC-02A EP and JC-02B curing agents were provided by Changshu Jiafa Chemical Co., Ltd., China. Nano-SiO2was purchased from Shanghai Mackin Biochemical Co., Ltd., China. Ethanol and formic acid were supplied by Chinasun Specialty Products Co., Ltd., China. GO was provided by Suzhou Hengqiu Technology Co., Ltd., China.

1.2 Preparation of GOS/EP and GO/EP

The preparation process of GOS/EP is presented in Fig.1. Firstly, nano-SiO2(0.2 g) and GO (0.2 g) were added into 200 mL deionized water with 2% HCOOH, ultrasonic dispersion for 0.5 h. Then, the mixture was stirred at 100 ℃ for 5 h and heated to 120 ℃, stirred for 0.5 h. When GO and nano-SiO2were heated at 120 ℃ under acidic conditions, —OH and —COOH on the surface of GO underwent esterification and etherification reactions with —Si—OH on the surface of nano-SiO2to generate graphene—COO—Si and Si—O—graphene. Finally, GOS was obtained by centrifuge, cleaned and dried. GOS with different mass fractions (0.1%, 0.2%, 0.3% and 0.4% respectively) was added into the required amount of EP with JC-02A EP and JC-02B curing agent at the ratio of 100:80. GOS/EP was dispersed by ultrasonic dispersion instrument for 0.5 h and then removed air bubbles by heating in a vacuum oven. GOS/EP was then poured into stainless steel molds and heated continuously for 2 h at 90 ℃, 1 h at 110 ℃ and 4 h at 130 ℃ in the vacuum drying oven. The obtained samples with GOS mass fraction of 0.1%, 0.2%, 0.3% and 0.4% are named 0.1%-GOS/EP, 0.2%-GOS/EP, 0.3%-GOS/EP and 0.4%-GOS/EP. The preparation process of GO/EP is the same as that of GOS/EP. The obtained samples with GO mass fraction of 0.1%, 0.2%, 0.3% and 0.4% are named 0.1%-GO/EP, 0.2%-GO/EP, 0.3%-GO/EP and 0.4%-GO/EP.

Fig.1 Diagram of preparation process of GOS/EP

1.3 Testing and characterization

The experimental setup and the sizes of tensile specimens and three-point bending (SENB) specimens are shown in Fig.2. SENB specimens are 44 mm×10 mm×5 mm and the length range of the notch is 4-6 mm. Tensile tests were conducted on an Instron model 5967 (Instron Ltd., USA) according to the standard of ASTM D638[38], with a rate of 2 mm/min. The fracture toughness was measured by the single-edge notched SENB tests through the Instron model 5967 according to the standard of ASTM D5045[39], which was performed at a rate of 10 mm/min. The fracture toughness was evaluated by the critical stress intensity factorKIC,

(1)

Fig.2 Experimental setup: (a) tensile specimen; (b) SENB specimen; (c) size of tensile specimen; (d) size of SENB specimen

(2)

wherePQis the fracture load;Bis the specimen thickness;Wis the specimen width;ais the crack length,x=a/W.

Fourier transform infrared spectrum (FTIR) was used to analyze the functional groups on the GOS surface, which was recorded in the wavelength range of 4 000-500 cm-1. Thermogravimetric analysis (TGA) was carried out to investigate the thermal stability of neat EP and modified EP, which was measured at a rate of 20 ℃/min from room temperature to 800 ℃ in nitrogen atmosphere. Thermal mechanical properties of neat EP and modified EP were investigated through dynamic mechanical analysis (DMA). It was operated in the three-point bend mode at a frequency of 1 Hz, heating from room temperature to 200 ℃ at a rate of 3 ℃/min. Scanning electron microscope (SEM) was used to observe the fracture morphology of neat EP and modified EP.

2 Results and Discussion

2.1 Structural characterization of GOS

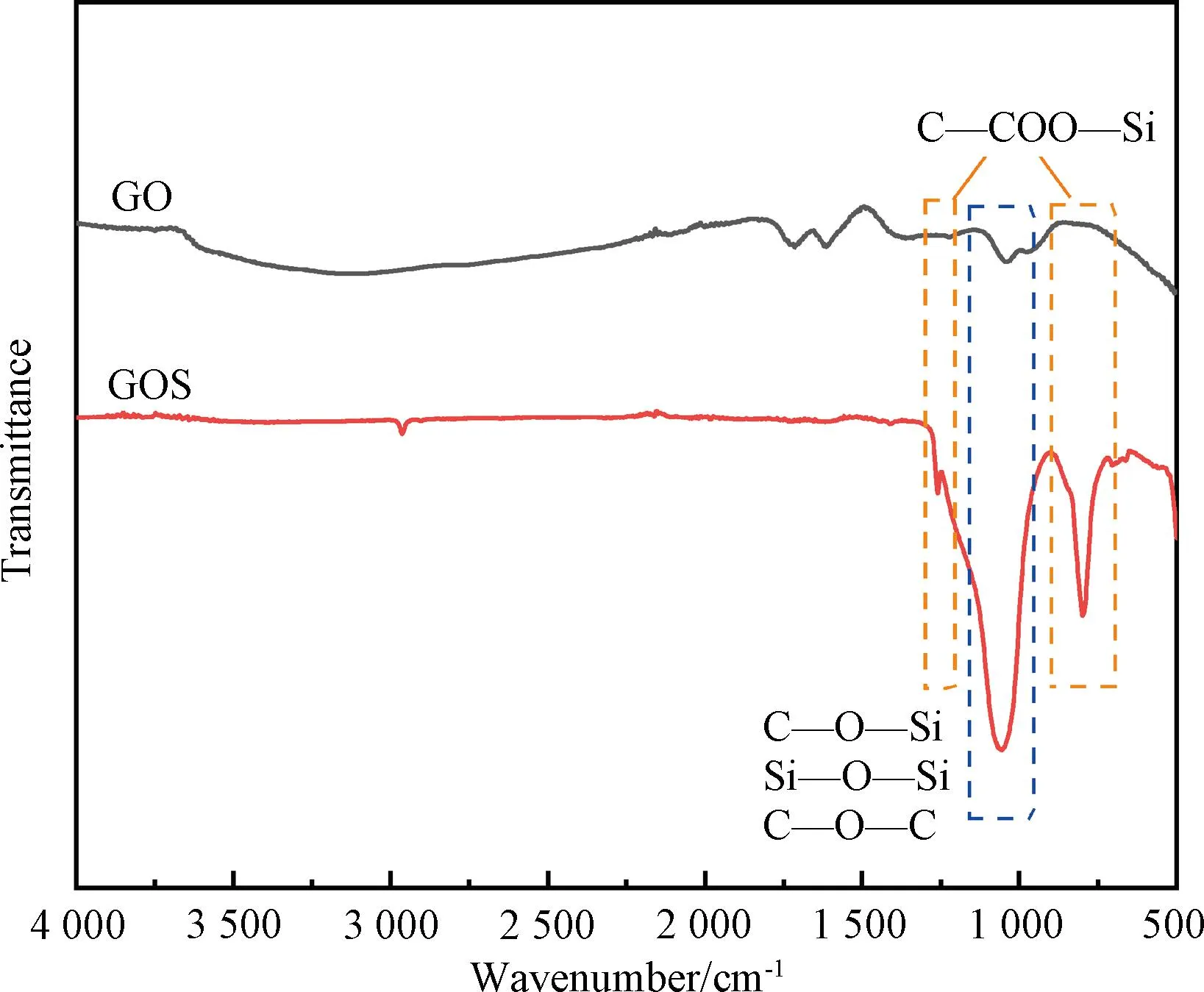

FTIR spectra of GO and GOS are shown in Fig.3. The peaks at 800 and 1 412 cm-1correspond to C—COO—Si resulted from the esterification reaction of GO and nano-SiO2, indicating the successful hybridization of GO and nano-SiO2. The peak around 1 261 cm-1corresponds to Si—O—C, Si—O—Si and C—O—C, which indicates that etherification reactions occur between GO and nano-SiO2, between GO and GO, and between nano-SiO2and nano-SiO2[40].

Fig.3 FTIR spectra of GO and GOS

Figure 4 presents SEM images of GOS surface morphology. As shown in Fig.4(a), the surface of GOS exhibits a lasagna-like structure pattern where GO slices are superimposed layer by layer. A locally enlarged image of GOS surface is shown in Fig.4(b). A large number of nano-SiO2particles adhere to the GO layer to form the silica layer. The GO layer and the nano-SiO2layer are connected layer by layer, forming a stable GOS lasagna-like structure.

Fig.4 SEM images of GOS: (a) overall image; (b) local amplification

2.2 Dispersion of GOS in EP

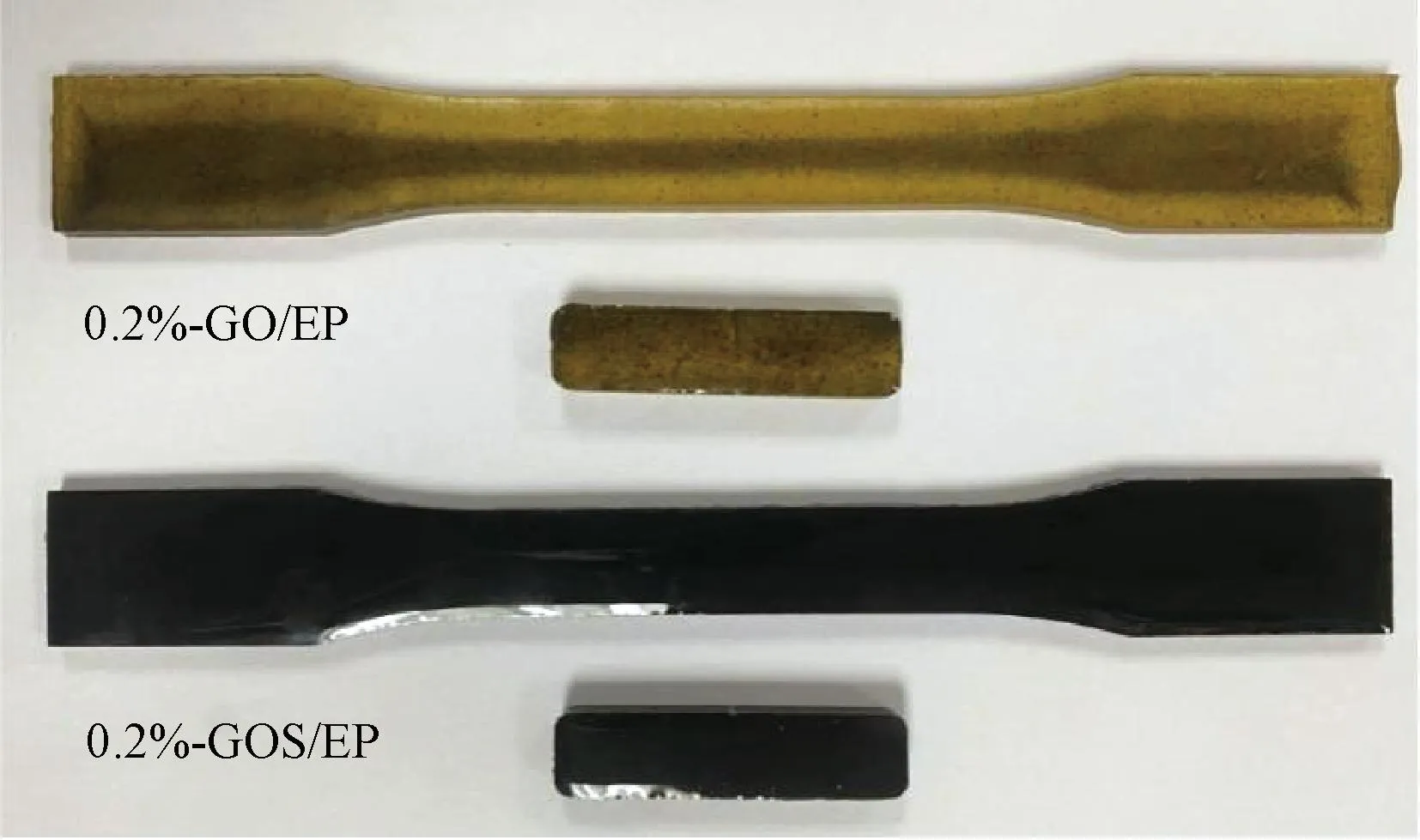

Morphology of 0.2%-GO/EP and 0.2%-GOS/EP were extracted as examples to investigate the dispersion condition, as shown in Fig.5. It can be found from Fig.5 that a large amount of GO concentrates in the middle region of the GO/EP. Compared with 0.2%-GO/EP, 0.2%-GOS/EP exhibits a well-distributed black color indicating good dispersion of GOS in EP. To further understand the dispersion of GO and GOS in EP, optical microscope (OM) views of the modified and unmodified EP are observed by OM. As shown in Figs. 6(b) and 6(c), GOS with the mass fraction of 0.1% is in good dispersion, but 0.1% is too low to improve tensile properties. When the mass fraction of GOS increases to 0.2%, it can be seen that GOS achieves the optimum state of dispersion in EP. Furthermore, an agglomeration phenomenon is observed in the modified EP with GOS mass fraction of 0.3%, as shown in Fig.6(d).When the mass fraction of GOS increases to 0.4%, GOS agglomeration increases in EP, as shown in Fig.6(e). Figure 6(f) shows the OM view of 0.2%-GO/EP.Compared with Fig.6(c), it can be seen that GO appears in a large number of agglomerations in EP and the dispersion of GOS in EP is better than that of GO in EP with the same mass fraction. This is mainly because the combination of nano-SiO2with GO can form GOS with a lasagna-like structure. GOS interacts with EP and has better dispersion.

Fig.5 Images of 0.2%-GO/EP and 0.2%-GOS/EP

Fig.6 OM images of GOS/EP: (a) neat EP; (b) 0.1%-GOS/EP; (c) 0.2%-GOS/EP; (d) 0.3%-GOS/EP; (e) 0.4%-GOS/EP; (f) 0.2%-GO/EP

2.3 Tensile properties

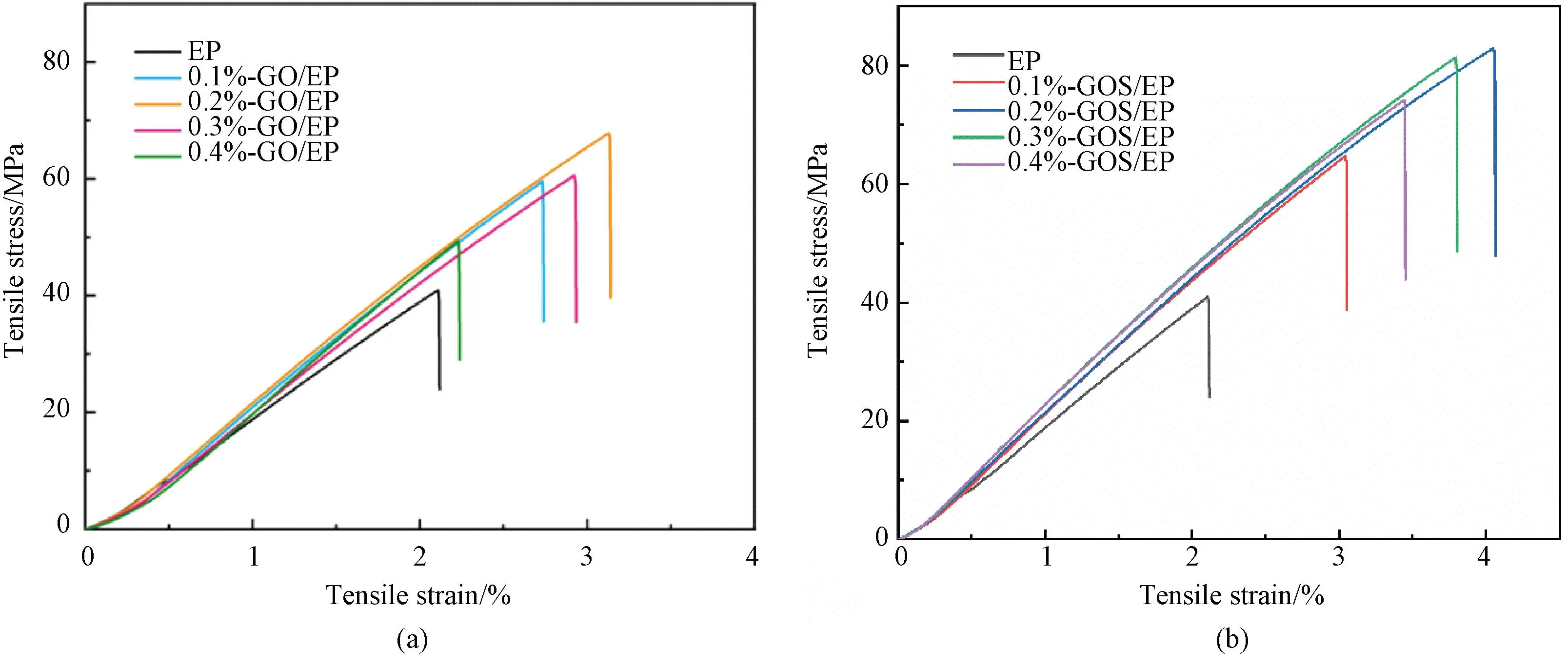

The tensile stress-strain curves, tensile strength and tensile modulus of GO/EP and GOS/EP are shown in Fig.7. It can be seen from Fig.7(a) that the tensile stress of GO/EP is higher than that of neat EP. With the increase of GO mass fraction, the peak stress first increases and then decreases. As shown in Figs. 7(a) and 7(b), the tensile strength of 0.2%-GO/EP reaches the maximum value of 67.9 MPa, increasing by about 67.2%. Tensile modulus shows a similar trend to tensile strength. The maximum tensile modulus of 0.2%-GO/EP reaches 1.99 GPa, which is about 17.8% higher than that of neat EP, as shown in Fig.7(d). For GOS/EP, the peak stress of GOS/EP is higher than that of GO/EP from Fig.7(b). With the increase of GOS mass fraction, peak stress increases first and then decreases. Tensile strength of 0.2%-GOS/EP increases from 40.6 MPa to 80.2 MPa, increasing by about 97.5%, as shown in Fig.7(c). In addition, tensile strength is 18.0% higher than that of 0.2%-GO/EP. At the same time, the tensile modulus of GOS/EP increases first and then decreases slightly with the increase of GOS mass fraction, as shown in Fig.7(d). For 0.2%-GOS/EP, the maximum tensile modulus reaches 2.01 GPa. Compared with neat EP and GO/EP, the tensile modulus of 0.2% GOS/EP increases by 18.9% and 6.9%, respectively. Particularly, the tensile modulus of GOS/EP is constant while that of GO/EP significantly decreases when the mass fraction of GOS or GO exceeds 0.2%. It is ascribed to the fact that the agglomeration of GO in EP greatly increases with the increase of GO mass fraction. On the contrary, GOS can disperse in EP better and form strong interaction with EP as a lasagna-like structure.

Fig.7 Tensile properties of different modified EP: (a) tensile stress-strain curves of GO/EP; (b) tensile stress-strain curves of GOS/EP; (c) comparison of tensile strength of GO/EP and GOS/EP with various mass fractions of filler; (d) comparison of tensile modulus of GO/EP and GOS/EP with various mass fractions of filler

2.4 Toughness properties

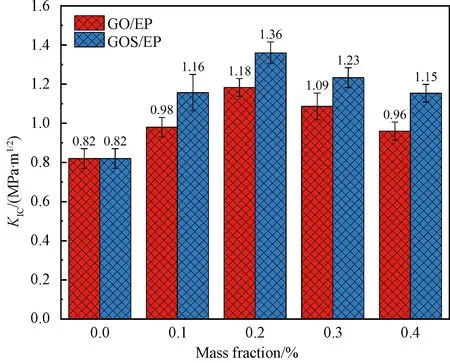

The fracture toughness of the EP system can be expressed byKIC. TheKCIvalues of GO/EP and GOS/EP are shown in Fig.8.

Fig.8 Fracture toughness of GO/EP and GOS/EP at different filler mass fractions

The fracture toughness of GO/EP increases first and then decreases slightly with the increase of GO mass fraction, but is still higher than that of neat EP. With the increase of GO mass fraction, theKCIincreases from 0.82 MPa·m1/2to 1.18 MPa·m1/2and then decreases to 0.96 MPa·m1/2. The maximumKCIof 0.2%-GO/EP is about 43.9% higher than that of neat EP. With a further increase of GO, the fracture toughness begins to decrease due to GO aggregation in EP, resulting in local stress concentration. For GOS/EP, with the increase of GOS mass fraction, the fracture toughness increases firstly and then decreases slightly. With the GOS mass fractions of 0.1%, 0.2%, 0.3% and 0.4%, the fracture toughness of GOS/EP increases by 41.4%, 65.9%, 50.0% and 40.2%, respectively, compared with neat EP. More importantly, the fracture toughness of GOS/EP is higher than that of GO/EP at the same mass fraction. The lasagna-like structure of GOS helps form a strong interaction effect between GOS and EP.

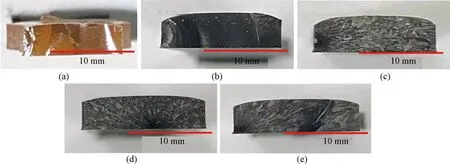

2.5 Failure morphology

For a better understanding of the enhancement mechanism, the failure morphology of different modified EP samples was further analyzed. Figure 9 shows the tensile macro fracture cross-sections of 0.1%-GOS/EP, 0.2%-GOS/EP, 0.3%-GOS/EP and 0.4%-GOS/EP, respectively. The fracture surface of neat EP is relatively smooth in a brittle fracture mode. The fracture surface becomes rougher with the increase of GOS mass fraction. As shown in Fig.9(c), the roughest but uniform failure cross-section is observed at 0.2%-GOS/EP, resulting in the best tensile performance of the modified EP. As shown in Figs. 9(d) and 9(e), fracture transforms from rough into brittle mode with a further increase of GOS mass fraction. It is due to the agglomeration caused by the excessive amount of GOS.

Fig.9 Tensile fracture cross-sections of GOS/EP: (a) neat EP; (b) 0.1%-GOS/EP; (c) 0.2%-GOS/EP; (d) 0.3%-GOS/EP; (e) 0.4%-GOS/EP

Figure 10 presents SEM images of fracture surfaces of GOS/EP samples with different GOS mass fractions. As shown in Fig.10(a), many parallel cracks are observed at the fracture surface of neat EP. This characteristic of brittle fracture indicates faster crack propagation. After adding 0.1% GOS, the fracture section becomes rough and the cracks no longer spread in a straight line but deflect the path. Obvious dimples and tear morphology are observed near the crack line. It is demonstrated that GOS is difficult to deform as a rigid particle, generates cavities that can impede crack propagation and closure, deflecting the cracks and generating many microcracks and silver lines, thus absorbing more energy and improving the fracture toughness. For 0.2%-GOS/EP, the fracture section becomes rougher. Faults and gullies appear but cracks are evenly distributed and there is no large area gully. This indicates that a strong interaction has developed between GOS and EP. It helps EP absorb more energy and transform from brittle fracture to plastic fracture. As shown in Figs. 10(d) and 10(e), although the fracture section is rough with the increase of GOS content, large area gullies appear on the failure surface. This is because with the increase of GOS content, agglomeration occurs, and the agglomerated GOS produces stress concentration and uneven energy absorption in the process of hindering crack extension and closure, which leads to a decrease in the toughening effect.

Fig.10 SEM images of fracture morphology of GOS/EP: (a) neat EP; (b) 0.1%-GOS/EP; (c) 0.2%-GOS/EP; (d) 0.3%-GOS/EP; (e)0.4%-GOS/EP

2.6 Dynamic mechanical properties

Figure 11 shows the storage modulus and loss factor tanδof neat EP and GOS/EP samples. Compared with neat EP, the storage modulus of GOS/EP is increased obviously. It is because the GOS lamellar structure prevents the molecular chain segments of EP from moving during the heating process, thus increasing the rigidity of the molecular chains. The peak value of the tanδcurve is used as a function of temperature to determine the glass transition temperature. As shown in Fig.11, the GOS/EP samples possess higherTgthan neat EP. It is due to GOS containing a lot of rigid structure, which acts as cross-linking points in the matrix and makes EP more stable. The tanδvalues of neat EP and GOS/EP samples are shown in Fig.11. Only one peak is observed in each curve, indicating that GOS and EP have good dispersion and strong interfacial bonding[18].

Fig.11 Storage modulus and tan δ of neat EP and GOS/EP

Fig.12 TGA curves of neat EP and GOS/EP

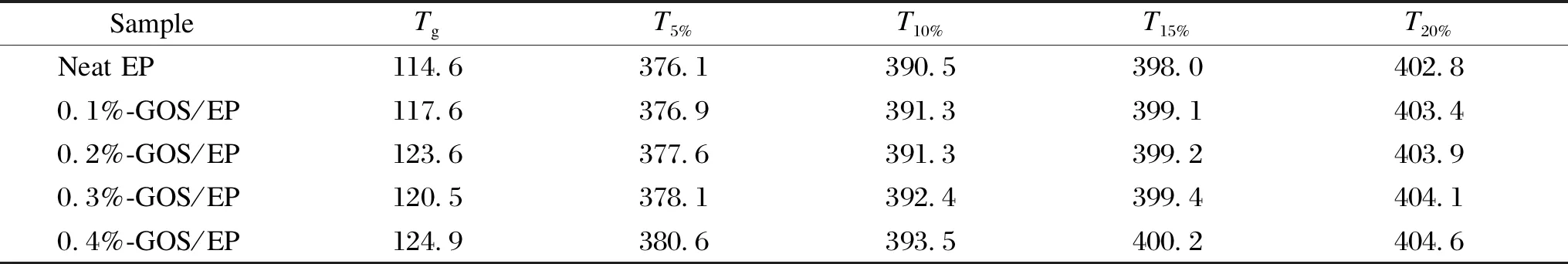

2.7 Thermal properties

Figure 12 illustrates the TGA curves of neat EP and GOS/EP samples. The TGA data,Tg,T5%(the temperature where 5% mass loss occurs, the initial thermal degradation temperature),T10%(the temperature where 10% mass loss occurs),T15%(the temperature where 15% mass loss occurs) andT20%(the temperature where 20% mass loss occurs) of neat EP and GOS/EP samples are shown in Table 1. It can be found that there are two stages in the TGA curve. The first stage, is mainly due to the decomposition of the less thermally stable substances in EP. After the second stage, the mass of EP and GOS/EP samples tends to be stabilized, this is mainly because the high thermal stability substances in EP and GOS no longer decompose. Thus, the more GOS mass fraction, the more the residual mass. Compared with neat EP, the thermal decomposition temperature of GOS/EP increases, as shown in Table 1. TheTgof 0.4%-GOS/EP is up to 124.9 ℃, increased by 10.3 ℃ compared with neat EP. In addition,T10%,T15%andT20%of 0.4%-GOS/EP are 393.5, 400.2 and 404.6 ℃,respectively, which are 3.0, 2.2 and 1.8 ℃ higher than those of neat EP. This is mainly because the thermal stability of GOS is relatively more stable than neat EP. With the increase of the GOS mass fraction, the thermal stability of the modified EP would be improved more significantly.

Table 1 TGA data of neat EP and GOS/EP Unit: ℃

3 Conclusions

A rapid and easy method of hybrid preparation of GOS was developed, and the prepared GOS was used to modify EP to enhance its mechanical properties. A lasagna-like structure of GOS improved the dispersion condition and helped to form a strong interaction effect between GOS and EP. The tensile properties and fracture toughness of the modified EP with different mass fractions of GO and GOS were compared and analyzed. Both GO and GOS could improve the mechanical properties of EP. For GOS/EP, tensile strength increased first and then decreased with a further increase of GOS mass fraction. When the mass fraction of GOS was 0.2%, the tensile strength reached the maximum value of 80.2 MPa, which increased by 97.5%. The critical stress intensity factor increased from 0.82 MPa·m1/2to 1.36 MPa·m1/2, increasing by 65.9%. Furthermore, the enhancement mechanism was revealed through macro fracture morphology and SEM observation. Higher tensile properties and toughness corresponded to the evenly rougher fracture mode. On the contrary, the fracture surface of neat EP or GO modified EP exhibited a brittle fracture mode. The thermal performance of the modified EP was investigated through DMA and TGA. DMA results showed that theTgof GOS/EP was increased due to the rigid structure of GOS. TGA results showed that GOS/EP had good thermal stability.

Journal of Donghua University(English Edition)2023年6期

Journal of Donghua University(English Edition)2023年6期

- Journal of Donghua University(English Edition)的其它文章

- Recent Progress on Fabrication of Thermal Conductive Aluminum Nitride Fibers

- Cleaning of Multi-Source Uncertain Time Series Data Based on PageRank

- Deep Multi-Module Based Language Priors Mitigation Model for Visual Question Answering

- Detection of Residual Yarn in Bobbin Based on Odd Partial Gabor Filter and Multi-Color Space Hierarchical Clustering

- Electromagnetic and Thermal Characteristics of Molybdenite Concentrate in Microwave Field

- Path Planning of UAV by Combing Improved Ant Colony System and Dynamic Window Algorithm