Preparation of Cellulose Acetate Butyrate Porous Micro/Nanofibrous Membranes and Their Properties

ZHANG Xiaoxiao(張曉曉), SU Yazhou(蘇亞洲), SHI Lingxiang(石凌翔), WANG Yujie(王玉潔),HUANG Changfen(黃長芬), WANG Xinhou(王新厚), SUN Xiaoxia(孫曉霞)*

1 College of Textiles, Donghua University, Shanghai 201620, China 2 College of Mechanical Engineering, Donghua University, Shanghai 201620, China

Abstract:Cellulose acetate butyrate (CAB) is a cellulose ester that is commonly used in applications such as coatings and leather brighteners. However, its appearance in a fibrous form is rarely reported. CAB porous micro/nanofibrous membranes with a large number of nanopores on the fiber surface were successfully prepared by electrospinning with dichloromethane (DCM)/acetone (AC) as the mixed solvent. Apparent morphology, porosity, moisture permeability, air permeability, static water contact angles, and thermal conductivity of the fibrous membranes were investigated at different spinning voltages. The results showed that with the increase of the spinning voltage, the average fiber diameter of the CAB porous micro/nanofibrous membranes gradually decreased and the fiber diameter distribution was more uniform. When the spinning voltage reached 40 kV, the porosity reached 91.38%, the moisture permeability was up to 743 0 g/(m2·d), the air permeability was up to 36.289 mm/s, the static water contact angle was up to 145.0°, while the thermal conductivity of the fibrous membranes reached 0.030 W/(m·K). The material can be applied as thermal-insulation, waterproof and moisture-permeable membranes.

Key words:electrospinning; cellulose acetate butyrate(CAB); porous material; waterproof and permeable membrane; low thermal conductivity

0 Introduction

Electrospinning is an efficient technology which is used to fabricate fibers with diameters in the sub-micrometer to nanometer range from various materials. The emergence of electrospinning allows the material to obtain excellent moisture permeability and thermal insulation and maintain a high level of fabric protection[1-3]. In the process of electrospinning, fibers can be stacked by continuous deposition, thus producing a three-dimensional mesh structure. This three-dimensional mesh structure usually has the characteristics of small pore sizes and high porosity[4]. It makes the material store a large amount of static air so that the thermal conductivity of the material is much lower than that of nonwovens. Meanwhile, the heat loss of the electrospun membrane is reduced, and the static air in the countless ultra-fine fibers prevents the flow of air due to heat exchange[5-7]. Therefore, it has a very good effect on the thermal insulation. Moreover, the electrospinning process has the advantages of simple operation, low costs, controllable fiber structures, a wide range of raw materials, small equipment footprint and layered/mesh structures with micro/nano-scale roughness, and the thickness of the film can be adjusted by controlling the operating parameters[8-10].

Cellulose is a long-known renewable resource. However, the process of direct spinning of cellulose is more complicated because of the difficulty of cellulose dissolution[11]. Cellulose acetate butyrate (CAB) is a cellulose-mixed fatty acid ester obtained from cellulose with acetic anhydride and butyric anhydride in the presence of an acid catalyst[12]. Because of the acetyl and the butyl on the molecule, CAB has improved dimensional stability, and has higher chemical and moisture resistance than cellulose. CAB is considered as one of the appropriate materials for different applications because it is one of the toughest cellulosic plastics, and has good performance in colorability, weatherability, electrical properties, and resistance to inorganic chemicals. Also, it is considered as one of the appropriate membrane materials with good resistance to fouling, chlorine tolerance, and chemical stability[13-16].

In this study, CAB porous micro/nanofibers with a large number of nanopores on the fiber surface are prepared by electrospinning. The mixed solvent of dichloromethane (DCM) and acetone (AC) is adopted. The apparent morphology of the generated electrospun micro/nanofibrous membranes is evaluated through a scanning electron microscope (SEM). Porosity, moisture permeability, air permeability, water contact angles, and thermal conductivity of the fibrous membranes obtained at different spinning voltages are also investigated.

1 Experiments

1.1 Materials

CAB powder (65 000 g/mol) was purchased from Sigma Aldrich, USA. DCM (an analytical reagent) and AC (an analytical reagent) were purchased from Sinopharm Chemical Reagent Co., Ltd., Shanghai, China. None of the chemicals were treated any further.

1.2 Preparation of spinning solution

DCM and AC were mixed at a volume ratio of 1∶1, and the mixed solution was transferred to a glass bottle with a good seal. CAB was added into the mixed solution at a mass fraction of 10%. The solution was stirred on a magnetic stirrer at 25 ℃ for 24 h until the solution was clear. The speed of the magnetic stirrer was 500 r/min, and then the solution was placed in a fume hood for 12 h to eliminate air bubbles.

1.3 Preparation of fibrous membranes

To control the experimental variables, the spinning process was carried out at a temperature of (22±3) ℃ and a relative humidity of 30%-50%. The configured CAB solution was transferred to a 10 mL syringe with a needle size of 20 gauge (0.6 mm inner diameter and 0.91 mm outer diameter), and electrospinning was performed using a flat-plate receiving device with good conductive tinfoil on the receiving surface. The receiving distance was 20 cm; the spinning flow rate was 1 mL/h; the spinning voltages were 25, 30, 35 and 40 kV, respectively. The spinning time of each film was 7 h, and the thickness of all electrospun membranes is (0.20±0.02) mm.

1.4 Characterization

The microstructure of fibrous membranes was observed by the SEM (SU4800, Hitachi Ltd., Tokyo, Japan) at 5 kV. To ensure complete evaporation of the solvent, CAB porous micro/nanofibrous membranes were dried by a vacuum oven at 40 ℃ for 2 h. Due to the poor electrical conductivity of the membrane, gold was sprayed on the membrane before observation. The diameters of 100 fibers were measured using the Image J software, the fiber diameter distribution was plotted, and the average fiber diameter was calculated. The SEM micrographs that highlighted the porous structure of fibers were selected to analyze the morphology and the size of the fiber porous structure.

The porosity of fibrous membraneφcould be calculated according to

whereρ1andρ2were the densities of fibrous membranes and the CAB feedstock, respectively (ρ2=1.250 g/cm3).

The water vapor transmission (WVT) rate of the fibrous membranes was tested by a fabric moisture penetrometer (YG601, Ningbo Textile Instrument Factory, China) to analyze the moisture permeability. The same sample was tested five times at different positions. The test was performed by adding about 20 g desiccant to the permeable cup, placing the sample face up on the permeable cup, and sealing it. Then the water vapor could pass through the sample surface. The samples were equilibrated in the silica gel desiccant and weighed, then placed in the fabric moisture penetrometer for testing, and weighed after 1 h. The moisture permeability of the membrane was obtained by

wherermwas the moisture permeability (g/(m2·d));m1(g) andm2(g) were the masses of the experimental assembly after and before hygroscopicity, respectively;Swas the effective experiment area, andS=2.83×10-3m2;twas the hygroscopic time, andt=1 h.

The air permeability of the fibrous membranes was tested by an automatic air permeability tester(YG461E, Wenzhou Fangyuan Instrument Co., Ltd., China) according to ASTM D 737-2018. The same sample was tested five times at different positions.

The contact angle of the fibrous membranes was observed by a contact angle analyzer (OCA15EC, Dataphysics, Germany). Water (5 μL) was dropped on the surface of the sample. The static contact angle was measured according to the shape image of the water droplet on the sample surface.

The thermal conductivity of the fibrous membranes was measured by a thermal conductivity tester(TCi, C-Therm, Canada). The temperature was (20±2) ℃, the relative humidity was (65±5) %, the output voltage was 0.15 V, and the equilibrium time was 20 s.

2 Results and Discussion

2.1 Morphology

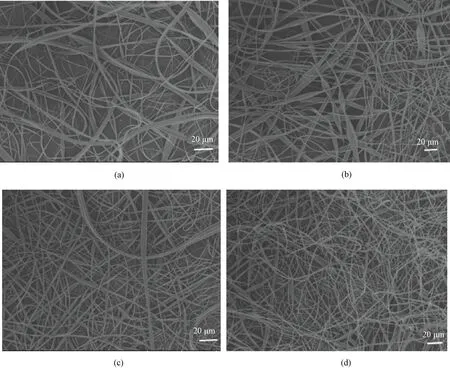

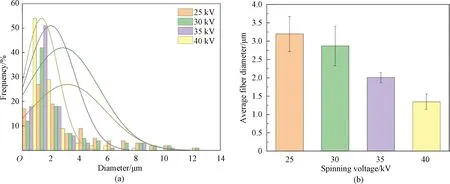

In the electrospinning process, the spinning voltage usually has an important effect on the fiber morphology. SEM images and the diameter distribution of CAB porous micro/nanofibers prepared by electrospinning at different spinning voltages are shown in Fig.1 and Fig.2. As the spinning voltage increases, the average diameter of the fibers becomes smaller and more uniform. The average fiber diameter reaches a minimum of 1.35 μm at 40 kV. The average fiber diameter is 3.20 μm at 25 kV, and the proportion of nanometer-sized fibers is low. As the spinning voltage increases, the proportion of larger fiber diameters increases, which is mainly due to the uneven drafting of the electrostatic field on the jet. With further increase in the spinning voltage, the jet is drafted more adequately, the proportion of small-diameter fibers increases and the proportion of uneven fibers decreases. Therefore, a spinning voltage of 40 kV is more suitable for the preparation of CAB porous micro/nanofibrous membranes.

Fig.1 SEM images of CAB porous micro/nanofibrous membranes at different spinning voltages: (a) 25 kV; (b) 30 kV; (c) 35 kV; (d) 40 kV

Fig.2 Fiber diameters of CAB porous micro/nanofibrous membranes at different spinning voltages: (a) fiber diameter distribution; (b) average fiber diameter

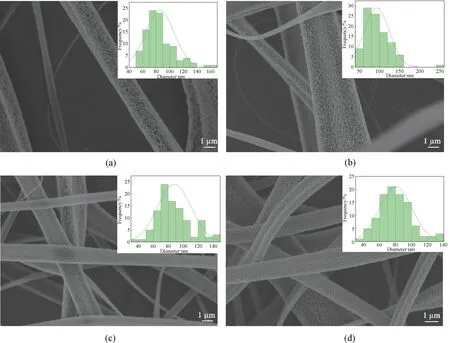

Figure 3 shows the morphology of pores on CAB fibers and the distribution of pore sizes. Nanopores are formed on the fibers, and the average pore size is 80-92 nm. The morphology of the pores varies, but the distribution is relatively dense, and the morphology of the fibrous membranes obtained at different spinning voltages is almost the same. Thus, in this voltage range, the spinning voltage has little effect on the morphology and the diameter of the porous structure.

In the process of electrospinning, the rapid evaporation of the solvent may lead to the extremely rapid decrease of the fiber surface temperature in a short time. This rapid evaporation absorbed a lot of heat, making the water vapor in the humid environment condense into water droplets on the fiber surface. It causes localized microphase separation on the fiber surface. After the fiber is dried, porous structure is formed on the fiber surface[17-19].

Fig.3 Porous structure and pore size distribution of CAB porous micro/nanofibrous membranes at different spinning voltages: (a) 25 kV; (b) 30 kV; (c) 35 kV; (d) 40 kV

2.2 Density and porosity

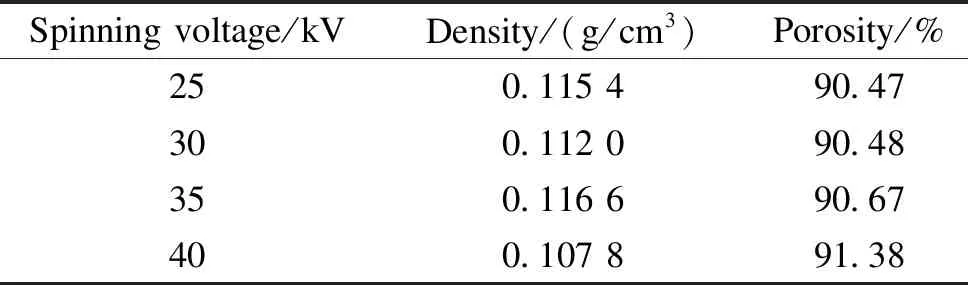

The density and the porosity of the CAB porous micro/nanofibrous membranes are shown in Table 1. It is seen from Table 1 that the density of CAB porous micro/nanofibrous membranes at different spinning voltages ranges from 0.107 8 g/cm3to 0.116 6 g/cm3and the porosity ranges from 90.47% to 91.38%. The variation of spinning voltages has little effect on the density and the porosity of the membrane. The low density and the high porosity of CAB porous micro/nanofibrous membranes make the material promising in the field of ultra-thin and ultra-warm materials.

Table 1 Density and porosity of CAB porous micro/nanofibrous membranes at different spinning voltages

2.3 Moisture permeability and air permeability

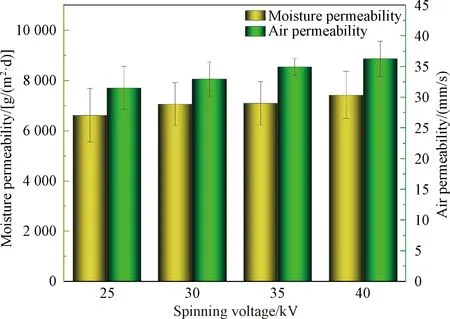

Moisture permeability and air permeability of CAB porous micro/nanofibrous membranes are shown in Fig.4. At the spinning voltage of 25, 30, 35 and 40 kV, the moisture permeability of the membranes is 6 628, 7 075, 7 094 and 7 430 g/(m2·d), respectively, while the air permeability of membranes is 31.524, 33.008, 34.987, and 36.289 mm/s, respectively. Under the condition of the constant spinning velocity and the constant spinning time, the thickness difference of the membrane is small. With the increase of the spinning voltage, the average diameter of the fiber is lower, and the porosity of the membrane is higher, so the moisture permeability and the air permeability of the membrane show a slightly increasing trend.

Fig.4 Moisture permeability and air permeability of CAB porous micro/nanofibrous membranes at different spinning voltages

2.4 Hydrophobicity

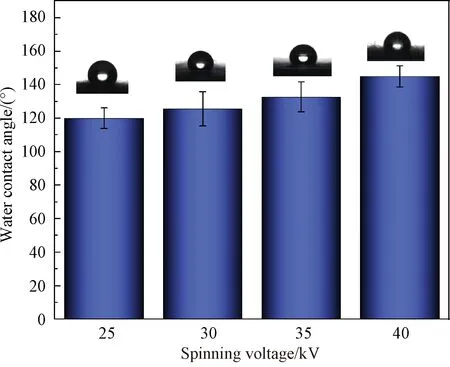

Figure 5 shows the wettability of CAB porous micro/nanofibrous membranes. Water contact angles of the membranes obtained at the spinning voltages of 25, 30, 35 and 40 kV are 120.0°, 125.7°, 132.7° and 145.0°, respectively, indicating that the CAB porous micro/nanofibrous membrane has good hydrophobicity. With the increase of the spinning voltage, the water contact angles of the membranes gradually increase. On the one hand, with the increase of the spinning voltage, the evenness of the fiber diameter is improved. At the same time, the average size of pores formed by the fiber accumulation is reduced, and the nano-pores appearing on the fibers increase the surface roughness of the material. When the droplets drip on the membrane surface, it is difficult for the droplets to wet the surface of the membrane. On the other hand, the CAB itself possesses good hydrophobicity.

Fig.5 Water contact angle of CAB porous micro/nanofibrous membranes at different spinning voltages

2.5 Thermal conductivity

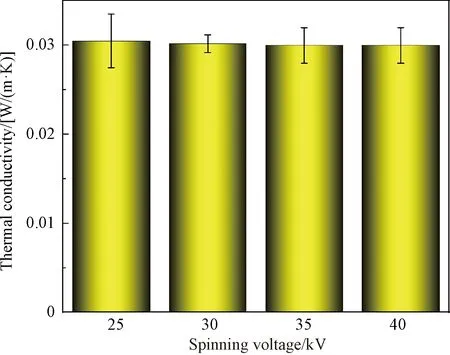

The thermal conductivity of CAB porous micro/nanofibrous membranes is shown in Fig.6. The thermal conductivity of the membranes is about 0.030 W/(m·K), indicating the excellent thermal insulation property of CAB porous micro/nanofibrous membranes. Because of the porous structure, more static air is retained, which can effectively reduce the heat dissipation due to gas heat convection and heat conduction, resulting in a lower thermal conductivity of the material. At the same time, as the spinning voltage increases, the porosity of the membrane increases, which facilitates the membrane to store more static air. Thus the heat dissipated by the gas is reduced, resulting in low thermal conductivity.

Fig.6 Thermal conductivity of CAB porous micro/nanofibrous membranes at different spinning voltages

3 Conclusions

Waterproof, moisture-permeable, and breathable CAB porous micro/nanofibrous membranes were successfully prepared by electrospinning. With the increase of the spinning voltage, the average fiber diameter of CAB porous micro/nanofibrous membranes gradually decreased and the fiber diameter distribution was more uniform. When the spinning voltage reached 40 kV, the porosity reached 91.38%, the moisture permeability was up to 7 430 g/(m2·d), the air permeability was up to 36.289 mm/s, the static water contact angle was up to 145.0°, while the thermal conductivity of the membrane reached 0.030 W/(m·K).

Journal of Donghua University(English Edition)2023年5期

Journal of Donghua University(English Edition)2023年5期

- Journal of Donghua University(English Edition)的其它文章

- Oscillation Reduction of Breast for Cup-Pad Choice

- Effect of Weft Binding Structure on Compression Properties of Three-Dimensional Woven Spacer Fabrics and Composites

- Optimization for Microbial Degumming of Ramie with Bacillus subtilis DZ5 in Submerged Fermentation by Orthogonal Array Design and Response Surface Methodology

- pth-Moment Stabilization of Hybrid Stochastic Differential Equations by Discrete-Time Feedback Control

- Semantic Path Attention Network Based on Heterogeneous Graphs for Natural Language to SQL Task

- Device Anomaly Detection Algorithm Based on Enhanced Long Short-Term Memory Network